Use of Unmanned Aerial Vehicle for Pesticide Application in Soybean Crop

Abstract

1. Introduction

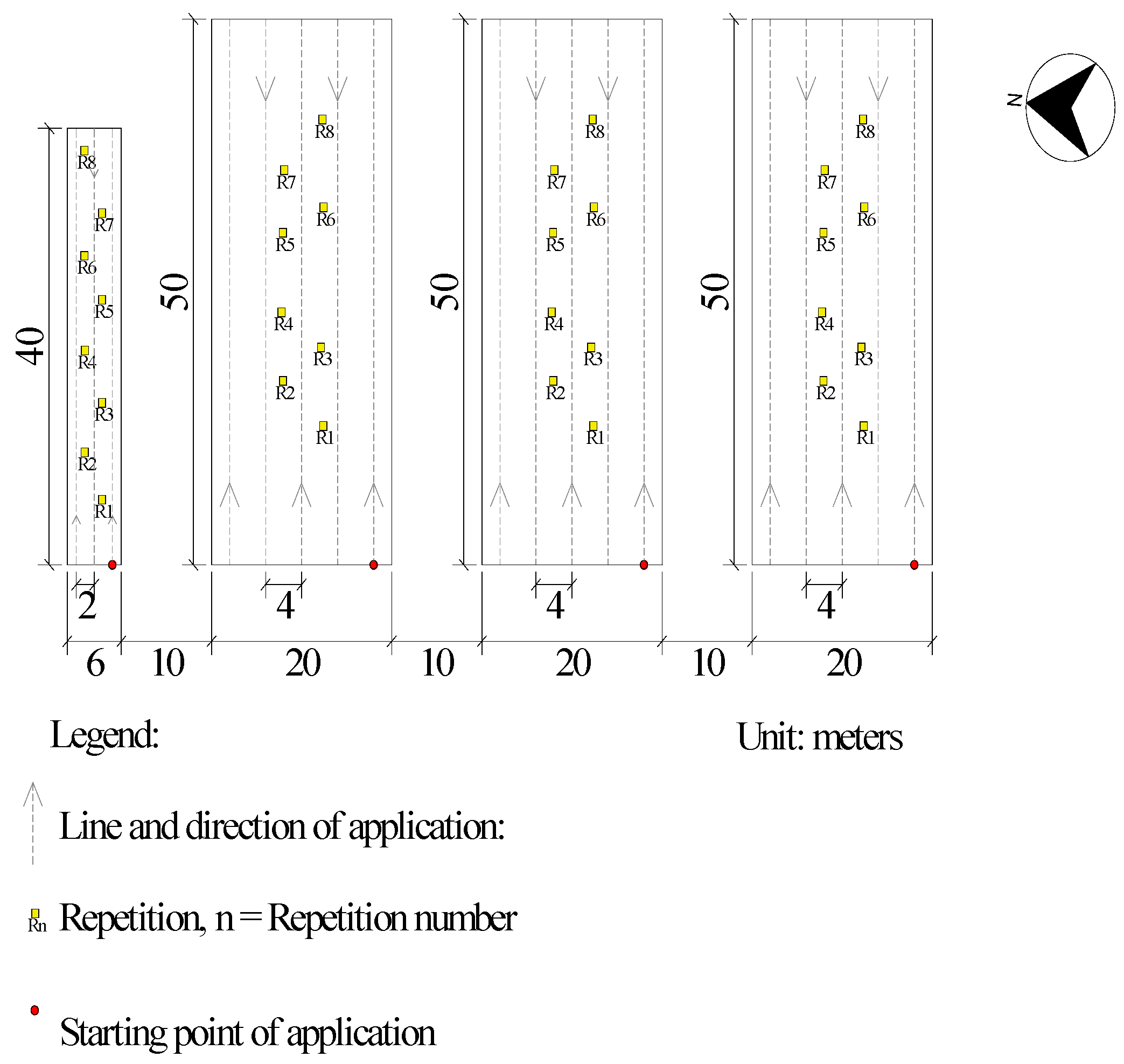

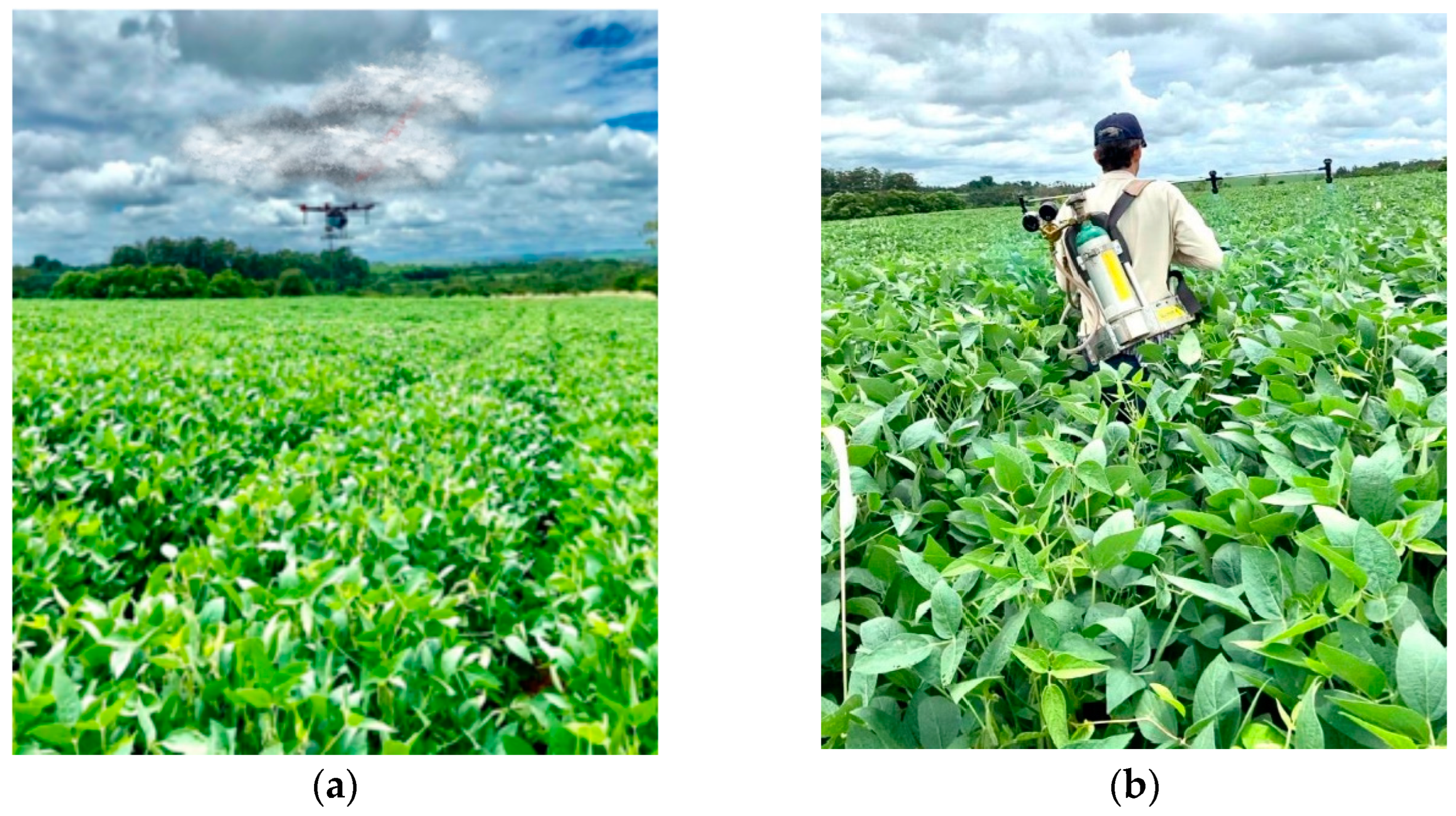

2. Materials and Methods

2.1. Experimental Site

2.2. Cultivar

2.3. Experimental Unit, Equipment, and Treatments

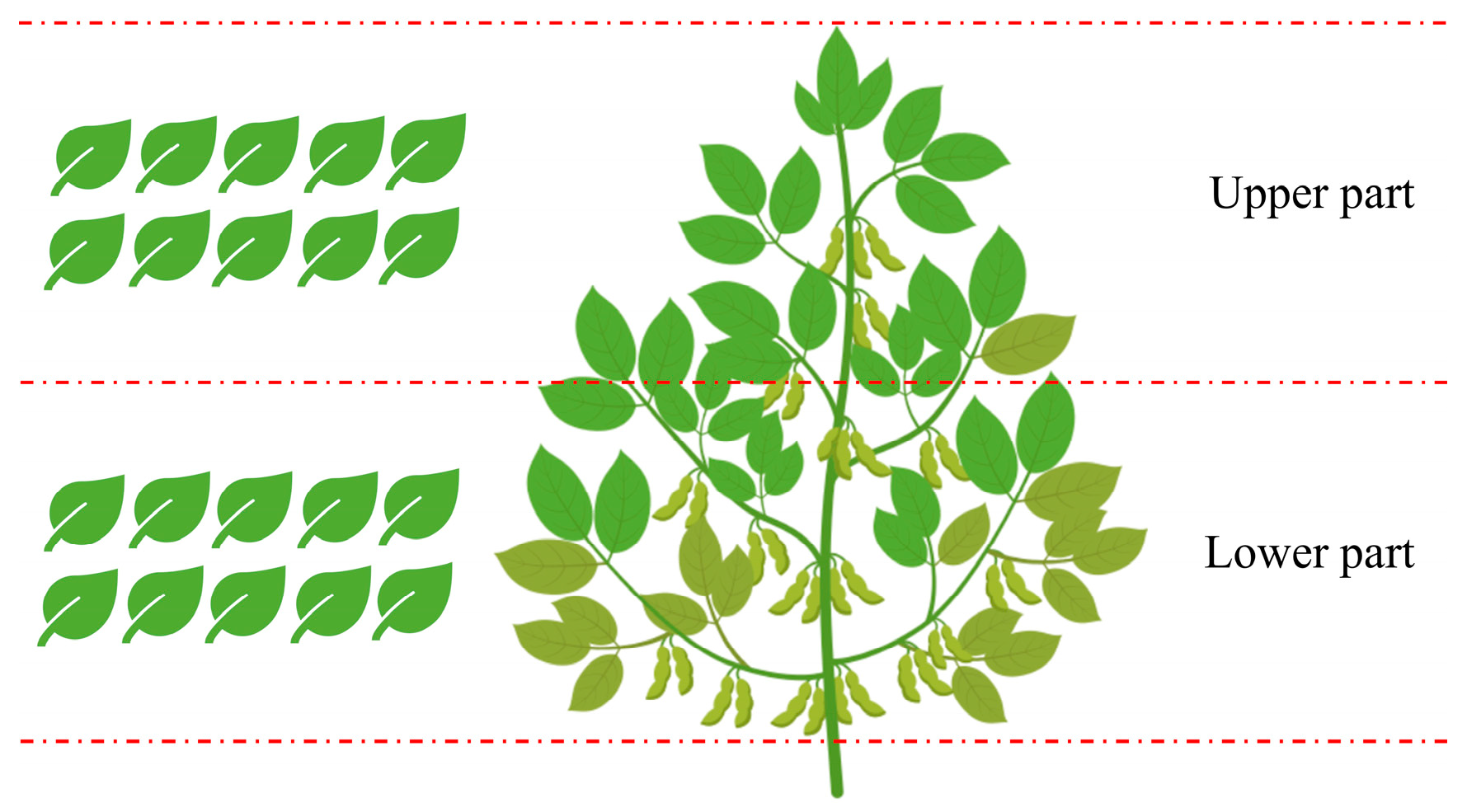

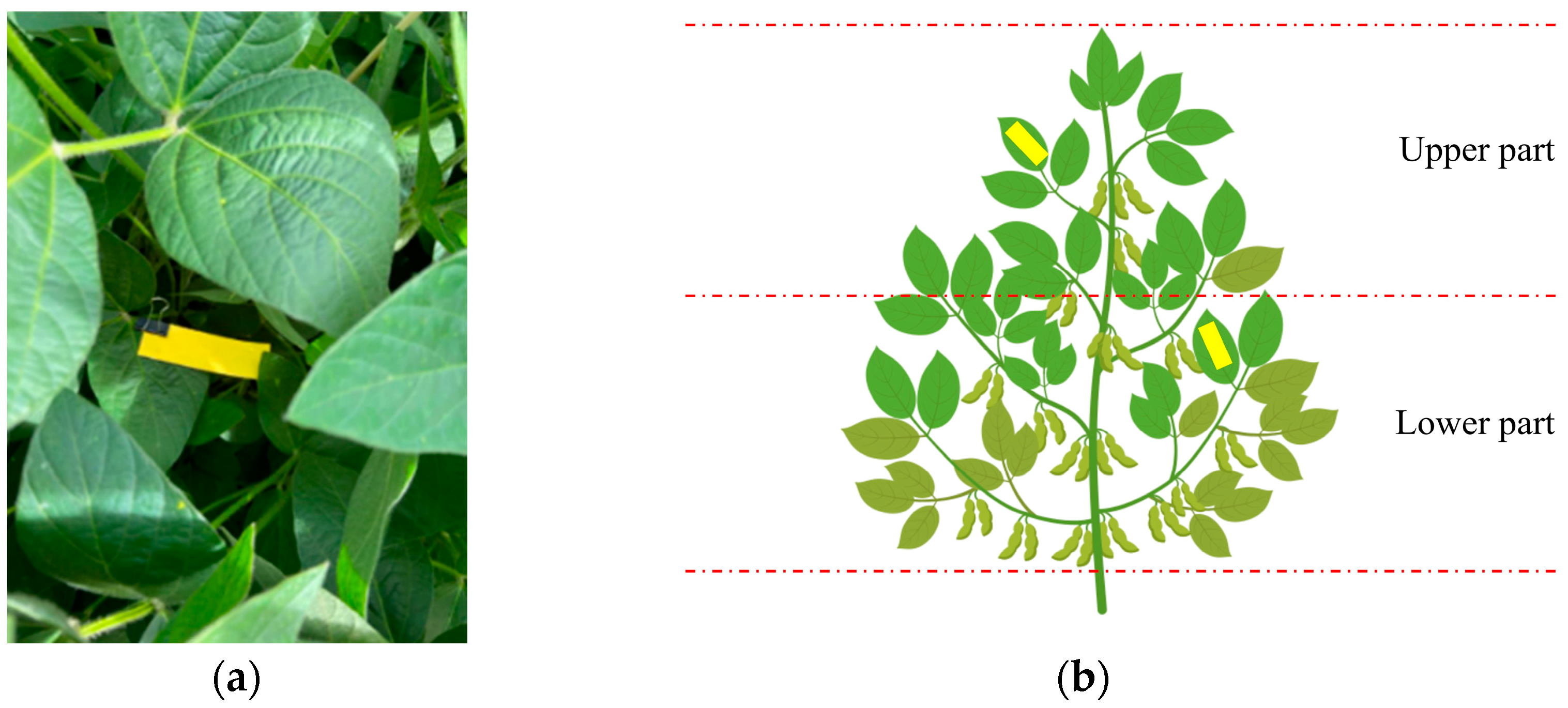

2.4. Evaluations

2.4.1. Deposition

2.4.2. Droplet Spectrum

2.5. Statistical Analysis

3. Results and Discussion

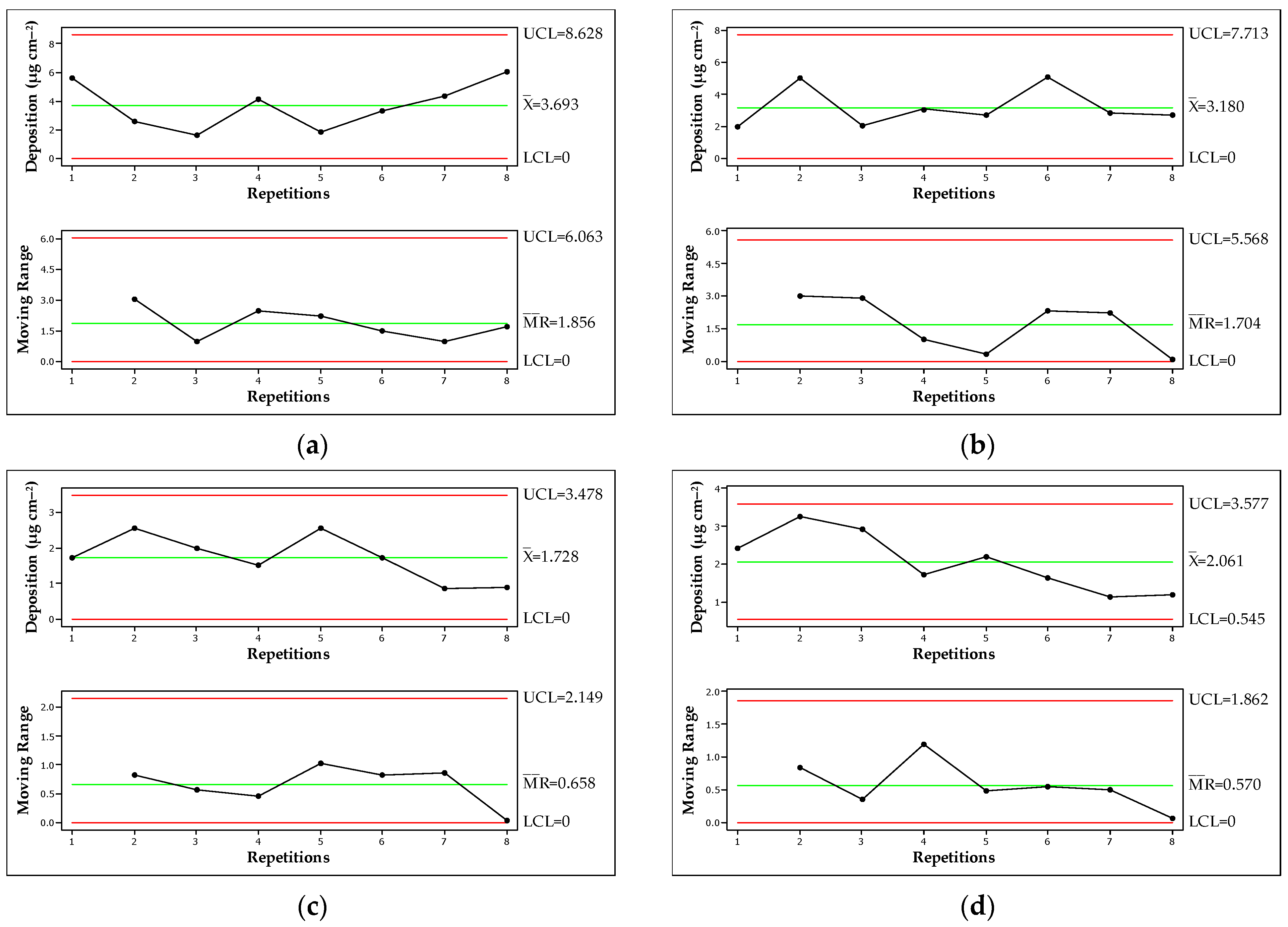

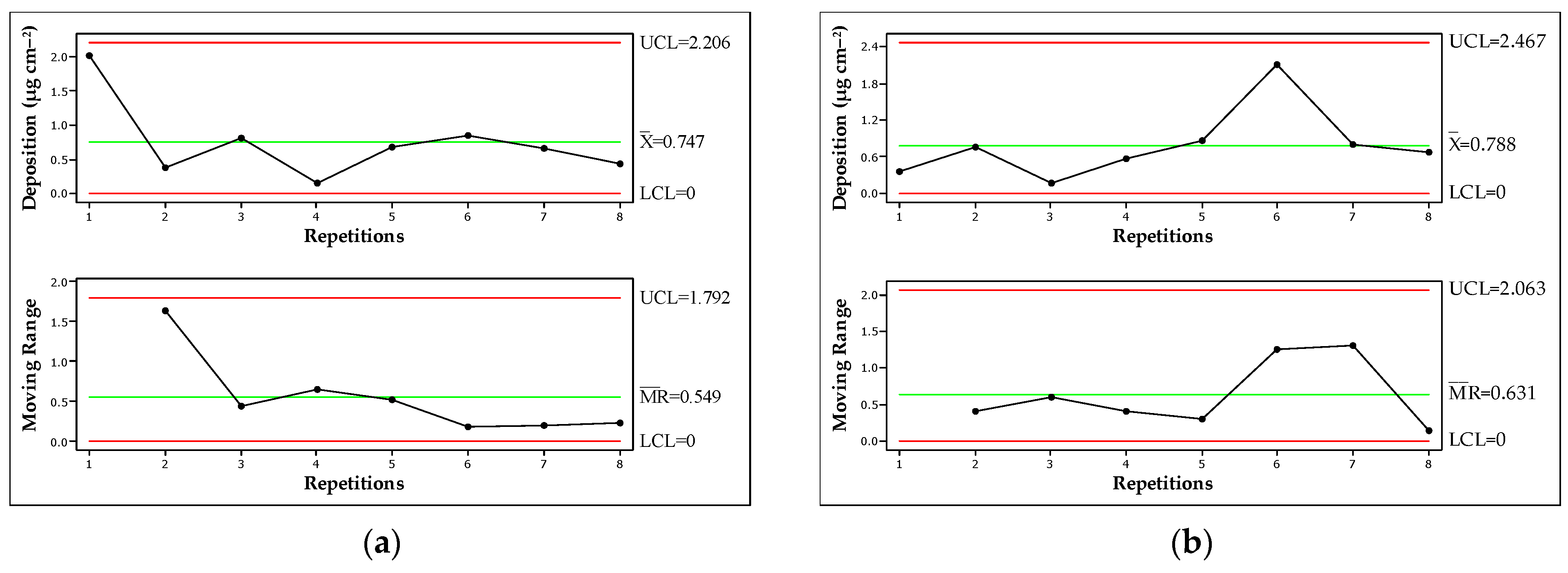

3.1. Spray Deposition

3.2. Droplet Spectrum

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fang, C.; Kong, F. Soybean. Curr. Biol. 2022, 32, R902–R904. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, L.L.; Boller, W.; Forcelini, C.A. Fungicide Spraying Programs Reducing Asian Soybean Rust Impact on Soybean Yield Components. J. Agric. Sci. 2022, 14, 40. [Google Scholar] [CrossRef]

- Zhang, H.; Chandio, A.A.; Yang, F.; Tang, Y.; Ankrah Twumasi, M.; Sargani, G.R. Modeling the Impact of Climatological Factors and Technological Revolution on Soybean Yield: Evidence from 13-Major Provinces of China. Int. J. Environ. Res. Public Health 2022, 19, 5708. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.L.; Baptista, F.; Cruz, V.F.; Silva, J.R.M. da Aumentar as competências dos agricultores para a prática de uma agricultura sustentável. Rev. Ciênc. Agron. 2020, 43, 240–252. [Google Scholar] [CrossRef]

- Gugan, G.; Haque, A. Path Planning for Autonomous Drones: Challenges and Future Directions. Drones 2023, 7, 169. [Google Scholar] [CrossRef]

- Martin, D.E.; Rodriguez, R.; Woller, D.A.; Reuter, K.C.; Black, L.R.; Latheef, M.A.; Taylor, M.; López Colón, K.M. Insecticidal Management of Rangeland Grasshoppers Using a Remotely Piloted Aerial Application System. Drones 2022, 6, 239. [Google Scholar] [CrossRef]

- Wang, Z.; Hussain, M.; Yin, J.; Yuan, M.; Mo, Y.; Quan, M.; Duan, L.; Tan, W. Analysis of Droplet Deposition and Maize (Zea mays L.) Growth Control: Application of Ethephon by Small Unmanned Aerial Vehicle and Electric Knapsack Sprayer. Field Crops Res. 2023, 292, 108822. [Google Scholar] [CrossRef]

- Da Cunha, J.P.A.R.; Marques, R.S.; Alves, G.S. Deposição da calda na cultura da soja em função de diferentes pressões de trabalho e pontas de pulverização. Rev. Ceres 2016, 63, 761–768. [Google Scholar] [CrossRef][Green Version]

- Negrisoli, M.M.; de Souza, D.M.; Rodrigues, D.M.; de Jesus, P.J.; Raetano, C.G. Effect of Angled Spray Nozzle Designs on Spray Distribution and Droplet Spectrum. Rev. Ciênc. Agron. 2021, 52, e20197043. [Google Scholar] [CrossRef]

- Sayinci, B.; Demir, B.; Acik, N. Comparison of Spray Nozzles in Terms of Spray Coverage and Drop Distributionuniformity at Low Volume. Turk. J. Agric. For. 2020, 44, 262–270. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Papa, R.; Longo, D. Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Appl. Sci. 2021, 11, 9283. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Yu, S.; Choi, Y.; Lee, J. Effect of Geometrical Parameters of Air-Induction Nozzles on Droplet Characteristics and Behaviour. Biosyst. Eng. 2021, 209, 14–29. [Google Scholar] [CrossRef]

- Vallet, A.; Tinet, C. Characteristics of Droplets from Single and Twin Jet Air Induction Nozzles: A Preliminary Investigation. Crop Prot. 2013, 48, 63–68. [Google Scholar] [CrossRef]

- Makhnenko, I.; Alonzi, E.R.; Fredericks, S.A.; Colby, C.M.; Dutcher, C.S. A Review of Liquid Sheet Breakup: Perspectives from Agricultural Sprays. J. Aerosol Sci. 2021, 157, 105805. [Google Scholar] [CrossRef]

- Singh, A.K. System of Mathematical Equations to Predict Wear Rate on Circular-Cone Orifice of Pesticide Spray Nozzles. Int. J. Precis. Agric. Aviat. 2019, 2, 76–80. [Google Scholar]

- Martin, D.; Singh, V.; Latheef, M.A.; Bagavathiannan, M. Spray Deposition on Weeds (Palmer Amaranth and Morningglory) from a Remotely Piloted Aerial Application System and Backpack Sprayer. Drones 2020, 4, 59. [Google Scholar] [CrossRef]

- De Azevedo Silva Rodrigues, E.; do Carmo Lima, S. Associação entre a incidência do levantamento de índice rápido de Aedes Aegypti (Liraa) e as condições climáticas em uberlândia, Minas Gerais, Brasil, entre 2014 A 2016. Caminhos Geogr. 2019, 20, 251–263. [Google Scholar] [CrossRef]

- Da Cunha, J.P.A.R.; da Silva, M.R.A. Spray Deposition from a Remotely Piloted Aircraft on the Corn Crop. Rev. Ciênc. Agron. 2023, 54, e20217862. [Google Scholar] [CrossRef]

- Chen, P.; Ouyang, F.; Wang, G.; Qi, H.; Xu, W.; Yang, W.; Zhang, Y.; Lan, Y. Droplet Distributions in Cotton Harvest Aid Applications Vary with the Interactions among the Unmanned Aerial Vehicle Spraying Parameters. Ind. Crops Prod. 2021, 163, 113324. [Google Scholar] [CrossRef]

- Meng, Y.; Lan, Y.; Mei, G.; Guo, Y.; Song, J.; Wang, Z. Effect of Aerial Spray Adjuvant Applying on the Efficiency of Small Unmanned Aerial Vehicle for Wheat Aphids Control. Int. J. Agric. Biol. Eng. 2018, 11, 46–53. [Google Scholar] [CrossRef]

- Wang, G.; Lan, Y.; Qi, H.; Chen, P.; Hewitt, A.; Han, Y. Field Evaluation of an Unmanned Aerial Vehicle (UAV) Sprayer: Effect of Spray Volume on Deposition and the Control of Pests and Disease in Wheat. Pest Manag. Sci. 2019, 75, 1546–1555. [Google Scholar] [CrossRef]

- Biglia, A.; Grella, M.; Bloise, N.; Comba, L.; Mozzanini, E.; Sopegno, A.; Pittarello, M.; Dicembrini, E.; Alcatrão, L.E.; Guglieri, G.; et al. UAV-Spray Application in Vineyards: Flight Modes and Spray System Adjustment Effects on Canopy Deposit, Coverage, and off-Target Losses. Sci. Total Environ. 2022, 845, 157292. [Google Scholar] [CrossRef] [PubMed]

- DJI. AGRAS MG-1 User Manual. V. 1.2 2016; DJI: Shenzhen, China, 2016; Available online: https://dl.djicdn.com/downloads/mg-1/en/MG-1_User_Manual_en_v1.2.pdf (accessed on 18 August 2023).

- De Morais, A.R. Estatística Experimental: Uma Introdução Aos Delineamentos e Análise de Experimentos; UFLA: Lavras, Brazil, 2001; p. 197. [Google Scholar]

- Montgomery, D.C. Introdução Ao Controle Estatístico Da Qualidade, 7th ed.; LTC: Rio de Janeiro, Brazil, 2017; p. 528. [Google Scholar]

- R Core Team. The R Foundation for Statistical Computing Platform 2020; R Foundation for Statistical Computing: Vienna, Austria, 2020; Available online: https://www.r-project.org (accessed on 3 October 2023).

- Minitab 16, Statistical Software; Minitab, Inc.: State College, PA, USA, 2010.

- Pergher, G.; Zucchiatti, N. Influence of Canopy Development in the Vineyard on Spray Deposition from a Tunnel Sprayer. J. Agric. Eng. 2018, 49, 164–173. [Google Scholar] [CrossRef]

- Alheidary, M.H.R. Influence of nozzle type, working pressure, and their interaction on droplets quality using knapsack sprayer. Iraqi J. Agric. Sci. 2019, 50, 857–866. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Li, X.; Nuyttens, D.; Zhang, L.; Liu, Y.; Li, X. Evaluationof Compact Air-Induction Flat Fan Nozzles for Herbicide Applications: Spray Drift and Biological Efficacy. Front. Plant Sci. 2023, 14, 1018626. [Google Scholar] [CrossRef]

- Yang, S.; Zheng, Y.; Liu, X. Research Status and Trends of Downwash Airflow of Spray UAVs in Agriculture. Int. J. Precis. Agric. Aviat. 2019, 2, 1–8. [Google Scholar] [CrossRef][Green Version]

- Lan, Y.; Qian, S.; Chen, S.; Zhao, Y.; Deng, X.; Wang, G.; Zang, Y.; Wang, J.; Qiu, X. Influence of the Downwash Wind Field of Plant Protection UAV on Droplet Deposition Distribution Characteristics at Different Flight Heights. Agronomy 2021, 11, 2399. [Google Scholar] [CrossRef]

- Xiao, Q.; Du, R.; Yang, L.; Han, X.; Zhao, S.; Zhang, G.; Fu, W.; Wang, G.; Lan, Y. Comparison of Droplet Deposition Control Efficacy on Phytophthora Capsica and Aphids in the Processing Pepper Field of the Unmanned Aerial Vehicle and Knapsack Sprayer. Agronomy 2020, 10, 215. [Google Scholar] [CrossRef]

- Machado, W.A.; Silva, S.M.; Carvalho, S.M.; da Cunha, J.P.A.R. Effect of Nozzles, Application Rates, and Adjuvants on Spray Deposition in Wheat Crops. Eng. Agríc. 2019, 39, 83–88. [Google Scholar] [CrossRef]

- Sun, W. Labor-Saving Control Technology Using Multicopters in Mountainous Areas. NARO Tech. Rep. 2020, 5, 30–33. [Google Scholar]

- Mammadova, U.; Özkale, M.R. Profile Monitoring for Count Data Using Poisson and Conway–Maxwell–Poisson Regression-Based Control Charts under Multicollinearity Problem. J. Comput. Appl. Math. 2021, 388, 113275. [Google Scholar] [CrossRef]

- Rakitzis, A.C.; Chakraborti, S.; Shongwe, S.C.; Graham, M.A.; Khoo, M.B.C. An Overview of Synthetic-Type Control Charts: Techniques and Methodology. Qual. Reliab. Eng. Int. 2019, 35, 2081–2096. [Google Scholar] [CrossRef]

- Özdemir, A. Development of Fuzzy X-S Control Charts with Unbalanced Fuzzy Data. Soft Comput. 2021, 25, 4015–4025. [Google Scholar] [CrossRef]

- Nascimento, R.S.M.; Ferreira, L.R.; Zambolim, L.; Parreira, D.F.; Oliveira, P.L.D.S.; Moraes, R.G.S. Influence of Spraying Tips on the Efficiency of Chemical Control of Soybean Rust. Crop Prot. 2022, 160, 106031. [Google Scholar] [CrossRef]

- Da Silva, J.E.R.; da Cunha, J.P.A.R.; Nomelini, Q.S.S. Controle estatístico de processo em pulverização hidropneumática na cultura do café. Coffee Sci. 2016, 43, 11–21. [Google Scholar]

- Soela, D.M.; da Vitória, E.L.; de Oliveira, R.F.; Crause, D.H.; de Jesu s Freitas, I.L.; Locatelli, T. Controle estatístico de processo em pulverização usando veículo aéreo não tripulado na cultura do café conilon. Braz. J. Prod. Eng. 2020, 6, 52–63. [Google Scholar]

- Ribeiro, L.F.O.; da Vitória, E.L.; Soprani Júnior, G.G.; Chen, P.; Lan, Y. Impact of Operational Parameters on Droplet Distribution Using an Unmanned Aerial Vehicle in a Papaya Orchard. Agronomy 2023, 13, 1138. [Google Scholar] [CrossRef]

- Qi, P.; Zhang, L.; Wang, Z.; Han, H.; Müller, J.; Li, T.; Wang, C.; Huang, Z.; He, M.; Liu, Y.; et al. Effect of Operational Parameters of Unmanned Aerial Vehicle (UAV) on Droplet Deposition in Trellised Pear Orchard. Drones 2023, 7, 57. [Google Scholar] [CrossRef]

- Da Cunha, J.P.A.R.; de Alvarenga, C.B.; Rinaldi, P.C.N.; Marques, M.G.; Zampiroli, R. Use of remotely piloted aircrafts for the application of plant protection products. Eng. Agríc. 2021, 41, 245–254. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, S.; Xue, X.; Jiao, Y. Comparison of Droplet Distribution and Control Effect of Wheat Aphids under Different Operation Parameters of the Crop Protection UAV in the Wheat Flowering Stage. Agronomy 2022, 12, 3175. [Google Scholar] [CrossRef]

- ASABE S572.1; Droplet Size Classification. ASABE: St. Joseph, MI, USA, 2009.

- Guo, H.; Zhou, J.; Liu, F.; He, Y.; Huang, H.; Wang, H. Application of Machine Learning Method to Quantitatively Evaluate the Droplet Size and Deposition Distribution of the UAV Spray Nozzle. Appl. Sci. 2020, 10, 1759. [Google Scholar] [CrossRef]

- Dengeru, Y.; Ramasamy, K.; Allimuthu, S.; Balakrishnan, S.; Kumar, A.P.M.; Kannan, B.; Karuppasami, K.M. Study on Spray Deposition and Drift Characteristics of UAV Agricultural Sprayer for Application of Insecticide in Redgram Crop (Cajanus cajan L. Millsp.). Agronomy 2022, 12, 3196. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Bradley, K.F.; Li, J.; Liu, A.; Mao, Y. Effect of Wind Field below Rotor on Distribution of Aerial Spraying Droplet Deposition by Using Multi-rotor UAV. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 105–113. [Google Scholar]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of Droplet Size Parameters on Droplet Deposition and Drift of Aerial Spraying by Using Plant Protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the Deposition and Canopy Penetration of Nozzles with Different Spray Qualities in an Oat (Avena sativa L.) Canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef]

- Fritz, B.K.; Hoffmann, W.C.; Lan, Y.B. Evaluation of the EPA Drift Reduction Technology (DRT) Low-Speed Wind Tunnel Protocol. J. ASTM Int. 2009, 6, 183–191. [Google Scholar] [CrossRef]

- Wang, G.; Han, Y.; Li, X.; Andaloro, J.; Chen, P.; Hoffmann, W.C.; Han, X.; Chen, S.; Lan, Y. Field Evaluation of Spray Drift and Environmental Impact Using an Agricultural Unmanned Aerial Vehicle (UAV) Sprayer. Sci. Total Environ. 2020, 737, 139793. [Google Scholar] [CrossRef]

- Ahmad, F.; Qiu, B.; Dong, X.; Ma, J.; Huang, X.; Ahmed, S.; Ali Chandio, F. Effect of Operational Parameters of UAV Sprayer on Spray Deposition Pattern in Target and Off-Target Zones during Outer Field Weed Control Application. Comput. Electron. Agric. 2020, 172, 105350. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, S.; Wang, G.; Lan, Y. Drift Evaluation of a Quadrotor Unmanned Aerial Vehicle (UAV) Sprayer: Effect of Liquid Pressure and Wind Speed on Drift Potential Based on Wind Tunnel Test. Appl. Sci. 2021, 11, 7258. [Google Scholar] [CrossRef]

- Hunter, J.E.; Gannon, T.W.; Richardson, R.J.; Yelverton, F.H.; Leon, R.G. Coverage and drift potential associated with nozzle and speed selection for herbicide applications using an unmanned aerial sprayer. Weed Technol. 2020, 34, 235–240. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Method of operation | Remote control |

| Dimensions (mm) | 1471 × 1471 × 482 (measures with arms open) |

| Work capacity (ha h−1) | 2.80–4.05 |

| Spraying system | Atomized spraying |

| Tank capacity (L) | 10 |

| Number of nozzles | 4 |

| Application range (m) | 4–6 (with application 1.5–3.0 m from the crop) |

| Altitude detection accuracy (m) | 0.1 |

| Maximum operating speed (m s−1) | 8 |

| Positioning mode | GPS 1 or manual |

| Hovering accuracy (Strong GPS signal) | Horizontal ±0.6 m, vertical ±0.3 m (±0.1 m, radar module enabled) |

| Hovering time | 9–20 min |

| Max operating speed | 7 m s−1 |

| Max wind resistance | 8 m s−1 |

| Treatment | Nozzle | Sprayer | Application Rate (L hm−2) |

|---|---|---|---|

| 1 | XR 11001 flat fan | UAV 1 | 10 |

| 2 | AirMix 11001 air-induction flat fan | UAV | 10 |

| 3 | COAP 9001 hollow cone spray | UAV | 10 |

| 4 | XR 110015 flat fan | Ground | 100 |

| Treatments | Deposition on the Upper Part 1,2 | Deposition on the Lower Part 1,3 |

|---|---|---|

| UAV-COAP 9001 | 3.693 a | 0.747 a |

| UAV-AirMix 11001 | 3.180 ab | 0.788 a |

| UAV-XR 11001 | 1.728 c | 0.394 ab |

| GROUND-XR 110015 | 2.061 bc | 0.264 b |

| Assumptions | W= 0.97; L = 1.36; DW = 1.84 | W= 0.96; L = 0.21; DW = 2.18 |

| Treatments | Upper | ||||

|---|---|---|---|---|---|

| Coverage 1,3 (%) | Density 1,4 (Droplets cm−2) | VMD 1,4 (μm) | RA 1 | % < 100 μm 1,3 | |

| UAV-COAP 9001 | 0.22 b | 8.18 b | 166.35 c | 0.90 ab | 18.28 a |

| UAV-AirMix 11001 | 0.39 b | 4.90 b | 270.97 ab | 0.64 b | 3.04 b |

| UAV-XR 11001 | 0.48 b | 12.20 b | 178.18 bc | 1.04 ab | 8.58 a |

| GROUND-XR 110015 | 5.00 a | 47.48 a | 301.40 a | 1.09 a | 1.77 b |

| Assumptions | W = 0.94; L = 0.48; DW = 2.55 | W = 0.98; L = 2.77; DW = 2.51 | W = 0.97; L = 1.03; DW = 2.48 | W = 0.95; L = 1.84; DW = 2.35 | W = 0.98; L = 2.58; DW = 2.61 |

| Treatments | Lower | ||||

| Coverage 2 (%) | Density 1,4 (droplets cm−2) | VMD 1 (μm) | RA 1 | % < 100 μm2 | |

| UAV-COAP 9001 | 0.07 b | 2.62 ab | 232.57 a | 0.58 a | 8.30 ab |

| UAV-AirMix 11001 | 0.09 b | 1.15 b | 271.99 a | 0.37 a | 2.76 bc |

| UAV-XR 11001 | 0.09 b | 4.06 ab | 210.81 a | 0.68 a | 10.88 a |

| GROUND-XR 110015 | 0.40 a | 5.35 a | 354.62 a | 0.77 a | 1.28 c |

| Assumptions | W = 0.48; L = 1.21; DW = 2.39 | W = 0.99; L = 0.84; DW = 2.53 | W = 0.94; L = 2.31; DW = 2.12 | W = 0.97; L = 1.03; DW = 2.48 | W = 0.54; L = 0.37; DW = 2.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, L.d.L.; Cunha, J.P.A.R.d.; Nomelini, Q.S.S. Use of Unmanned Aerial Vehicle for Pesticide Application in Soybean Crop. AgriEngineering 2023, 5, 2049-2063. https://doi.org/10.3390/agriengineering5040126

Lopes LdL, Cunha JPARd, Nomelini QSS. Use of Unmanned Aerial Vehicle for Pesticide Application in Soybean Crop. AgriEngineering. 2023; 5(4):2049-2063. https://doi.org/10.3390/agriengineering5040126

Chicago/Turabian StyleLopes, Luana de Lima, João Paulo Arantes Rodrigues da Cunha, and Quintiliano Siqueira Schroden Nomelini. 2023. "Use of Unmanned Aerial Vehicle for Pesticide Application in Soybean Crop" AgriEngineering 5, no. 4: 2049-2063. https://doi.org/10.3390/agriengineering5040126

APA StyleLopes, L. d. L., Cunha, J. P. A. R. d., & Nomelini, Q. S. S. (2023). Use of Unmanned Aerial Vehicle for Pesticide Application in Soybean Crop. AgriEngineering, 5(4), 2049-2063. https://doi.org/10.3390/agriengineering5040126