Abstract

Bruise damage is one of the mechanical injuries that fresh produce can sustain during the postharvest supply chain. The study investigated the effect of drop impact levels, storage temperatures, and the storage period on the quality changes of cucumbers. A known mass ball was used to damage cucumbers once from three different drop heights (30, 60, and 90 cm) before they were stored for 24 days at 5 °C, 10 °C, and 22 °C. The data showed that the bruise area (BA), bruise susceptibility (BS), yellowness, and chroma* increased with the increase in the drop height and storage temperature. The study found that the bruise area (BA) and bruise susceptibility (BS) of the damaged cucumbers increased substantially (p < 0.05) with the increase in storage temperature and drop height. Due to the increment in drop height, storage temperature, and the storage period, the weight loss (Wl)% significantly increased after 24 days of storage. The storage period affects the firmness of damaged cucumbers stored in all storage conditions. The highest value of lightness (L*) was observed for the cucumbers bruised from the 60 cm drop height and stored at 22 °C with a value of 43.08 on day 24 of storage. Hue*, redness (a*), and total soluble solids (TSS) were all unaffected by the drop height. This study can serve as a resource for horticultural researchers and experts involved in the fresh fruit and vegetable supply chain. The study pays attention to the importance of postharvest supply chain activities, such as handling and storage to maintain the quality and prolong the shelf life of perishable produce, such as cucumbers.

1. Introduction

The cucumber (Cucumis sativus L.) is a popular vegetable that is produced in high quantities. In 2021, the total harvested area and production of cucumbers reached more than 2 million hectares and more than 93 million tons, respectively [1]. Cucumbers are used in salads and to make pickles. The cucumber is a high water content vegetable that is high in potassium, calcium, vitamin A, and vitamin. Reference [2] stated that cucumbers are one of the most versatile vegetables, since they may be utilized topically and they help to control stress. Additionally, cucumbers assist in relaxation and aid in digestion, and they reinforce cells by keeping them hydrated so they can perform efficiently. Cucumbers are also known to aid in slowing age-related cellular degradation. Fresh cucumber has several health benefits and has antioxidant, anti-inflammatory, and anti-cancer properties. Furthermore, cucumbers contain many vitamins that are beneficial for diabetes patients, since they contain little sugar and help the body in burning excess fat.

According to Al-Dairi et al. [3], visual appearance plays an important role in consumer decisions (up to 83 %) which are extremely influenced by the presence of flaws and damage. Bruising is determined to be one of the most common obstacles to purchasing produce, more so than the price [4], and because bruising is widespread, it is recognized to be one of the leading causes of fresh produce deterioration and quality loss [5]. According to Celik [6], bruising is a subcutaneous mechanical injury without skin rupture that is induced by an impact, quasi-static compression, or vibration. It consists of the local deterioration of external tissue, intracellular water extravasation, and the browning (oxidation) of phenolic chemicals from the released intracellular water. The bruising is characterized as damage to the plant tissue caused by external forces, resulting in chemical, physical, textural, and flavor changes [7].

Bruising can greatly affect the economic value of horticultural produce and cause its decline in marketability. In one study on apples, a “Galaxy” apple had minor bruising damage, and this resulted in browning and a loss of firmness [8]. In another study, bruised kiwifruit stored for 10 days had less hardness and greater weight loss [9]. Fruit weight loss influences not only customer preferences, but also the marketing of fresh fruit as weight is one of the most essential quality factors in fruit production [7].

The term “storage” refers to the storing of fresh produce under regulated conditions [10]. Eboibi and Uguru [11] mentioned that storage duration affects the physical properties of cucumbers. Weight loss in fresh fruit and vegetables is primarily due to water loss induced by transpiration and respiration processes that occur during storage. According to Ndukvu and Manuwa [12], fresh fruits and vegetables tend to spoil more quickly compared to other produce. This is because they undergo increased respiration during storage, which is caused by their high moisture content and exposure to hot tropical temperatures. These conditions can result in various physical and physiological changes that may affect the produce’s overall quality, viability, and market value. Meanwhile, storage throughout the value chain is essential to guarantee that processors have access to raw materials consistently. Storage helps to extend the processing season and ensure product supply consistency throughout the year. Fresh produce can be stored at room temperature for a short time (up to a week) if there is enough ventilation to prevent heat accumulation from respiration. Yellowing, moisture loss resulting in shriveling, and physiological harm caused by low temperatures are the most common deteriorative changes in cucumbers during storage and distribution.

The cucumber is a very temperature-sensitive produce. When the temperature is lower than 10 °C, symptoms of chilling injuries (CIs), such as surface pitting, water spots, scale depressions, tissue collapse, and decay are frequently observed in cucumbers [13]. Cucumbers are prone to cold harm due to their thermal properties. No previous study has evaluated the effect of mechanical damage on cucumbers. Therefore, this study was aimed at evaluating the effect of mechanical damage caused by three impact levels and different storage temperatures on the bruising parameters and quality attributes of cucumbers after 24 days of storage in two storage conditions.

2. Materials and Methods

2.1. Cucumber Sample Preparation

Fresh cucumbers were purchased from the market and directly transported to the Postharvest Technology Laboratory at Sultan Qaboos University. A total of 215 cucumbers with a uniform shape, color, and surface condition were selected. The mean weight of the fresh cucumbers was 117.69 ± 25.51 g.

2.2. Bruising Measurements and Storage

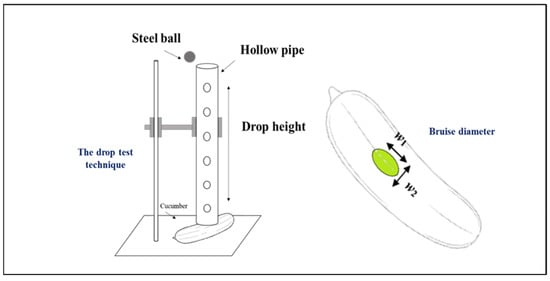

The drop impact technique described by Pathare and Al-Dairi [7] (Figure 1) was used to bruise/damage the cucumbers used in this experiment. This method comprises the free fall of a steel ball (66.81 g) through a PVC hollow pipe into each cucumber from a height of 30 cm, 60 cm, and 90 cm that represent the low, medium, and high drop impacts, respectively. Upon applying the impact damage, the bruised region on the cucumbers was marked to facilitate the bruise recognition for further measurements. The impact energy (Ei) resulting from the impact test was calculated using Equation (1), as described by Pathare and Al-Dairi [14].

where mb is the ball mass (66.81 g), g is the gravitational constant (9.81 m s−2), and h represents the drop height (cm). The impact energies produced from the three drop heights were 0.197 J (low), 0.39 J (medium), and 0.59 J (high).

Figure 1.

Schematic diagram of the experimental setup (the drop impact test). w1 and w2 are the major and minor widths (bruise diameter).

A digital caliper (model: Mitutoyo, Mitutoyo Corp., Japan) was utilized to determine the bruise diameter (d) for the major (w1) and minor widths (w2) (Figure 1). Bruise measurements were shown as the bruise area (BA) (Equation (2)) [15] and the bruise susceptibility (BS) (Equation (3)) [7]. The bruise diameter (w1 and w2) was used to calculate the bruise area of the cucumber.

The cucumber samples were stored at 5 °C, 10 °C, and 22 °C (63 cucumbers per storage condition) for 24 days. Each storage condition contained three groups of cucumbers bruised from the different drop heights. To study the bruise development and quality changes in the cucumbers, measurements for weight loss %, color attributes (L*, a*, b*, hue*, and chroma*), firmness, and total soluble solids (TSS) were taken at intervals of 2, 4, 8, 12, 16, 20, and 24 days. Visual and daily observations were recorded to measure the occurrence of quality changes and bruising in cucumbers. For the analysis on day 0, the weight, firmness, color, and total soluble solids (TSS) of the cucumber samples were analyzed prior to the impact test and storage.

2.3. Quality Analysis

2.3.1. Weight Loss % (Wl%)

An electric weight balance (model: GX-4000, Japan) with an accuracy of 0.01 g was used to weigh the cucumbers. The percentage of weight loss in the cucumbers was calculated using Equation (4).

2.3.2. Color

The surface color of the cucumbers was measured using a colorimeter (model: NR110, Shenzhen ThreeNH Tech, Shenzhen, China) that was calibrated using a white plate. Color measurements were performed 6 times for each sample (162 readings per day) for 24 days of analysis to find the alternations in L* (lightness-darkness), a* (redness-greenness), b* (yellowness-blueness), chroma*, and hue* on the bruised cucumbers stored at 5 °C, 10 °C, and 22 °C. Furthermore, the total color difference (ΔE*) was calculated using Equation (5), as described by Pathare et al. [16].

2.3.3. Firmness

The firmness test was conducted by penetrating the upper, middle, and lower regions of the cucumber by applying a hand penetrometer (model: FHP-803, LLC., Franklin, ME, USA) after 2, 4, 8, 12, 16, 20, and 24 days and expressed in N.

2.3.4. Total Soluble Solids (TSS)

The TSS (Brix) of the cucumber was measured using a hand-held refractometer (model: PR-32 α, ATAGO Co., Ltd., Tokyo, Japan) and was calibrated at 20 °C. For each cucumber sample, three readings were taken (upper, middle, and lower regions). Each region was squeezed longitudinally to obtain a mixture of juice from all regions. From each group, 9 readings of TSS were taken (63 readings per day).

2.4. Statistical Analysis

To carry out all statistical analyses, SPSS 20.0 (International Business Machine Corp., New York, NY, USA) software was applied. The analysis of variance (ANOVA) was performed to assess the influence of three studied factors, including drop height, storage temperature, and storage duration on the bruise size measurements (bruise area (BA) and bruise susceptibility (BS)) as well as on the quality attributes (weight loss % (Wl%), color, firmness, and total soluble solids (TSS)) of the cucumbers at a 95% significance level. The values of all resulted data were shown as the mean ± standard deviation (SD). A Pearson correlation analysis was also conducted to study the correlation between the studied parameters.

3. Results and Discussions

3.1. Bruise Area (BA) and Bruise Susceptibility (BS) of Cucumbers

Table 1 shows the results of the bruise area (BA) of cucumbers damaged from three different drop heights (30, 60, and 90 cm) after 24 days of storage at 5, 10, and 22 °C. In this study, the BA and BS of damaged cucumbers significantly increased (p < 0.05) with the increase in storage temperature and drop height. The study obtained no relationship between BA and BS with storage duration (p > 0.05). The highest drop height (90 cm, 0.590 J) and storage at 5 °C increased the BA average value of cucumbers from 109.47 mm2 on day 2 to 151.88 mm2 on day 8. Later, the BA increased on day 12 (204.88 mm2) and then decreased to reach 161.64 mm2 on day 24. The BA value was the highest for the 90 cm bruised cucumbers stored at 10 °C, where the BA showed an increment from 190.32 mm2 to 209.57 mm2 on days 2 and 24, respectively (Table 1). At 22 °C storage conditions, the BA was reduced by 13.14% from days 2 to 24 in the high impact (90 cm) bruised cucumbers.

Table 1.

Bruise area of cucumbers impacted by three drop height levels (30, 60, and 90 cm) stored at 5 °C, 10 °C, and 22 °C during 24 days of storage. The values were represented as the mean ± standard deviation of three readings per three replicates.

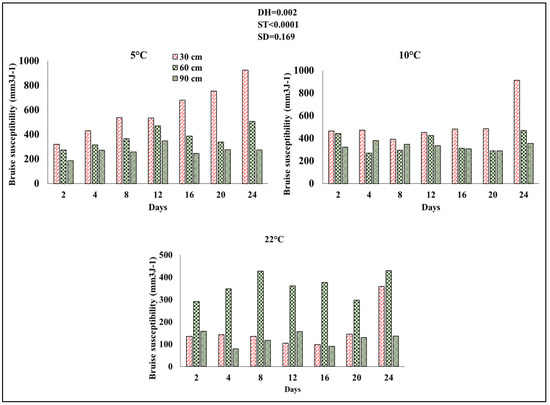

The results showed that the BS was influenced by the drop height and storage temperature (p < 0.05), but not by the storage duration (p > 0.05) (Figure 2). With storage days, an increasing trend in BS was observed as the drop height was reduced (Figure 2). The BS of 60 and 30 cm bruised cucumbers stored at 10 °C was 469.64 and 505.92 mm2 J−1 on day 24, respectively. The BS of cucumbers stored at 22 °C reached the maximum values of 274.02, 355.28, and 136.47 mm3 J−1 for 30, 60, and 90 cm drop heights, respectively. On the last day of storage, less BS was recorded on bruised cucumbers stored at 22 °C, which was 274.02, 355.28, and 136.47 mm3 J−1 for low (30 cm), medium (60 cm), and high (60 cm) drop heights, respectively (Figure 2). In the current study, cucumbers stored at 22 °C and impacted by the 30 cm height had the lowest BS value (358.01 mm2 J−1) compared to those stored at 5 °C and 10 °C at the same height (924.75 and 912.79 mm2 J−1). For the impact level heights (30 and 60 cm), cucumbers stored at 5 °C had the highest values of BS with values of 924.75 mm2 J−1 and 505.92 mm2 J−1, respectively. However, cucumbers kept at 22 °C storage and damaged by the 90 cm drop height showed the highest BS with the value of 355.28 mm2 J−1.

Figure 2.

BS values of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. Each bar represents the standard deviation of three replicates. DH; drop height, ST; storage temperature, SD; storage duration.

Generally, the study showed that reducing the storage temperature increased the BS of cucumbers to damage. Regarding impact damage, a drop height of 30 cm (low impact level) showed the greatest BA and BS than the drop heights of 60 cm and 90 cm at 5 and 10 °C. At 20 °C, the drop height of 60 cm revealed the greatest bruising size than for the other drop heights (30 and 90 cm). Thus, the BS values obtained for the study may not be an appropriate parameter to compare the sensitivity and incidence of cucumbers to impact bruising. Similarly, Hussein et al. [17] reported that the BS was higher in the order of 20 cm > 40 cm > 60 drop heights for the first 2 months of storage at a cold temperature (5 °C) for pomegranate fruit. The overall increase in BA and BS of cucumbers with increasing storage duration is due to the reduction in turgor pressure in terms of cold storage. Fresh fruit and vegetables, such as cucumbers, contain a huge percentage of water that is responsible for the tissue turgidity of the produce, and this is reduced because of the continuous loss in the moisture content during storage at cold temperatures; therefore, increasing the produce sensitivity to bruise damage [17]. The reduction observed in BA on the last day of storage could be the result of the drying effect of the cucumber peel because of excessive moisture loss in fruit stored for more than 20 days, thus leading to the hardening of the fruit peel [18].

In contrast, Pathare et al. [19] revealed that the bruise area and susceptibility of pomegranate fruit were greatly influenced by the impact level, storage temperature, and storage duration, particularly at 22 °C. Furthermore, Cui et al. [20] revealed that as storage temperatures decreased, the incidence of tomato bruising decreased. In the study conducted by Tabatabaekoloor [21], he found that raising the drop height from 5 to 15 cm increased the BA by 15% due to an increase in potential energy, which enhances the contact intensity. Pathare and Al-Dairi [14] found a correlation between the drop height and the presence of BA in bananas, and the association between the bruise size/area and impact energy emphasizes the importance of the impact level or drop height (i.e., impact energy increases with height) in increasing pomegranate bruising.

3.2. Cucumber Quality

3.2.1. Weight Loss (Wl%)

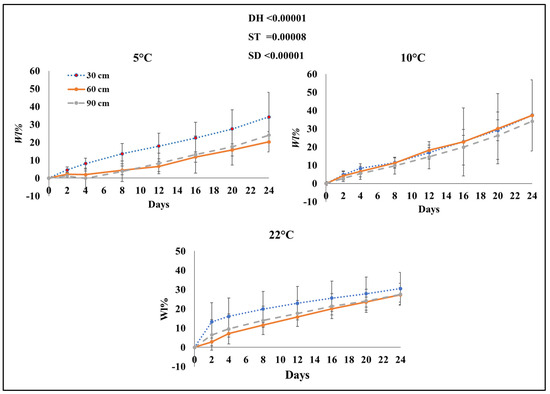

A statistical difference (p < 0.05) was found between Wl% for all studied factors, including drop height, storage temperature, and storage duration (Figure 3). The weight loss % in cucumbers increased during the entire period of storage (24 days). Following 24 days of storage, the highest Wl% value of cucumbers stored at 5 °C was 34.21% impacted by the 30 cm height. However, the Wl% at 10 °C and 22 °C were 37.418% (30 cm drop height) and 30.53% (30 cm drop height), respectively (Figure 3).

Figure 3.

Wl% values of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. Each bar represents the standard deviation of three replicates. DH; drop height, ST; storage temperature, SD; storage duration.

Hussein et al. [17] found that bruised fruit had a higher Wl% due to tissue injury and probable changes in the cell wall tissue permeability, resulting in a higher rate of transpiration during storage. Similarly, Al-Dairi and Pathare [22] recorded a significant decline in Wl% in tomato fruit stored at ambient temperature due to respiration and water dehydration processes after 12 days of storage, when compared to storage at a cold temperature. On day 16, cucumbers stored at 5 °C had white spots/ rots and tended to shrink more. The reduction in weight in shrunken cucumbers could be attributed to the reduction of water stress production surrounding each part of the cucumber, which reduces the rate of respiration [23]. Fresh cucumber weight loss is mostly due to water loss produced by transpiration and respiration processes [11]. Pathare et al. [24] showed that weight loss % was strongly impacted by the storage temperature, impact heights, and storage duration, particularly at ambient temperature.

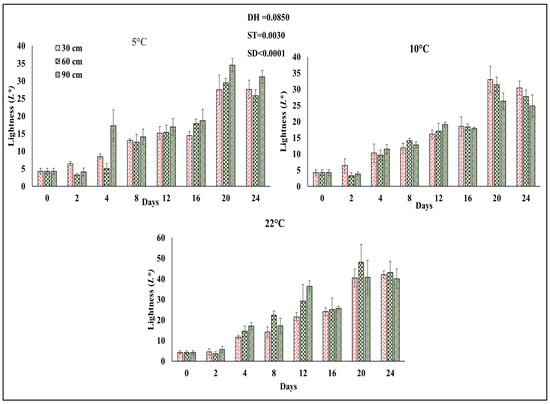

3.2.2. Color

In terms of storage days, all color values for all treated cucumbers followed a similar pattern. Alterations in the L* value (lightness) was significantly affected (p < 0.05) by storage temperature and storage duration, however, no significant (p > 0.05) relationship was observed between the L* value and drop height (Figure 4). The highest L* value was recorded in 60 cm bruised cucumbers stored at 22 °C with a value of 43.08. However, the lowest value of L* was observed for the 90 cm drop height bruised cucumbers stored at 10 °C with a value of 24.81 after 24 days of storage. The values for the L* color parameter for cucumbers stored at 5 °C on day 24 were 27.61, 27.74, and 31.14 for 30 cm, 60 cm, and 90 cm drop height, respectively.

Figure 4.

Lightness (L*) values of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. Each bar represents the standard deviation of 18 readings of three replicates. DH; drop height, ST; storage temperature, SD; storage duration.

Table 2 shows a decrease in the values of a* (redness) of bruised cucumbers during 24 days of storage at 5 °C, 10 °C, and 22 °C. The a* value significantly differed (p < 0.05) with storage duration, with no significant differences (p > 0.05) with respect to drop height and storage temperature. The average a* value on day 0 was −1.28. On the last day of storage, the highest reduction in a* value was observed on 90 cm bruised cucumbers (−6.56) stored at 5 °C. At this storage condition (5 °C), the a* values of 30 cm and 60 cm bruised cucumbers were −4.44 and −5.30, respectively, on the last day of storage. The smallest reduction in a* value was recorded in cucumbers damaged from the 60 cm drop height with a value of −3.80, followed by those impacted by the 90 cm drop height (−3.90) and stored at 22 °C. At 10 °C storage temperature conditions, the a* values were −6.84 on day 20 and −0.94 on day 24.

Table 2.

The values of redness (a*), hue*, chroma*, and total color changes (ΔE*) of cucumbers impacted by three drop height levels (30, 60, and 90 cm) in three storage conditions during 24 days of storage. The values were represented as the mean ± standard deviation of 18 readings per three replicates. ST; storage temperature; DH; drop height.

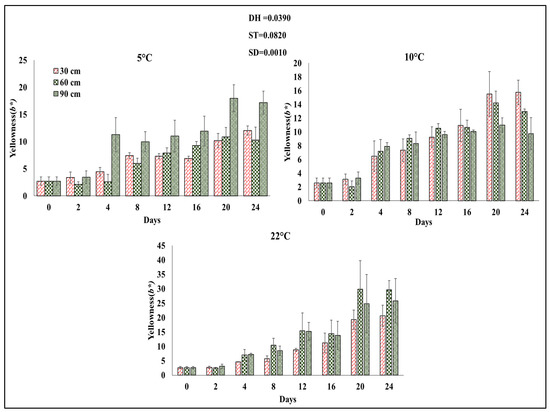

With storage duration, an increasing trend in the color attribute of b* was observed. The b* (yellowness) was statistically influenced (p < 0.05) by the storage duration and impact level (drop height). However, the effect of the storage temperature on the b* value of bruised cucumbers was not significant (p > 0.05). The b* value was increased gradually at all three temperatures during storage (Figure 5). The results showed that the medium impacted (60 cm, 0.393 J) bruised cucumbers provided the highest value of b* (29.60) stored at 22 °C. This was followed by bruised cucumbers subjected to a low impact (30 cm, 0.197 J) with a value of 20.65 at 22 °C. However, the smallest b* value was 9.75 for cucumbers stored at 10 °C and impacted by a 90 cm drop height.

Figure 5.

Yellowness (b*) values of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. Each bar represents the standard deviation of 18 readings of three replicates. DH; drop height, ST; storage temperature, SD; storage duration.

Regarding the hue* value (color purity), there was a significant (p < 0.05) influence of both storage duration and temperature on the color parameter, while the effect of the drop height was not significant (p > value) (Table 2). This study reported that the hue* value increased slowly at 5 °C, 10 °C, and 22 °C storage temperature on day 2 and then decreased rapidly on day 8. However, at the low-temperature condition (5 °C), the hue* value of 60 cm bruised cucumbers was 102.92, 134.28, and 113.61 on days 0, 4, and 24, respectively. Additionally, the chroma* value was significantly affected (p < 0.05) by the storage duration and drop height with no relationship with (p > 0.05) storage temperature (Table 2). The results show that there was an increase in chroma* values between the first day and the last day (day 24) of storage. The highest value (29.95) was on day 24 for cucumbers stored at 22 °C and impacted by the 60 cm height. However, the lowest value was recorded (2.17) on day 0 for the 60 cm bruised cucumbers stored at 10 °C.

The total color change (ΔE*) values significantly differed (p < 0.05) with all three factors (storage temperature, storage duration, and drop height). The highest value of ΔE* was (51.72) in cucumbers impacted by a drop height of 60 cm and stored at 22 °C (Table 2), while the lowest value (0.24) was recorded in cucumbers impacted by a drop height of 30 cm and stored at 22 °C (Table 2). The results show that the total color change during the experimental period increased until day 20. Korese et al. [25] observed similar findings where the color properties and ΔE* were affected by the storage period and were higher in week 12 than in week 1. Pathare and Al-Dairi [7] found that the total color change of bruised tomatoes was highly influenced by the storage temperature, storage duration, and impact level (drop height). Furthermore, Al-Dairi et al. [26] recorded that tomatoes stored at room temperature showed a high variation in total color differences, particularly at an ambient temperature. The changes observed in this study are attributed to the conversion of the cucumber surface from a green to a more yellowish color. According to Bodner and Scampicchio [27],bruising is one of the factors that causes fruit discoloration. The observed changes in color characteristics could be attributed to the rapid chlorophyll breakdown during the storage of bruise-damaged cucumbers [24].

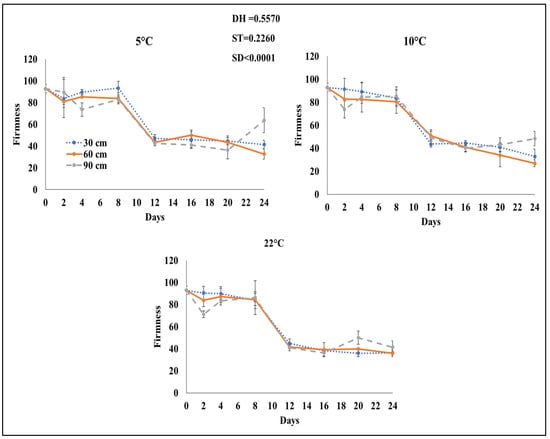

3.2.3. Firmness

The firmness of damaged cucumbers was statistically affected (p < 0.05) by the storage duration. Storage temperatures and drop heights showed no significant effect on the firmness of bruise-damaged cucumbers (p > 0.05). In this study, as the drop height increased, the firmness of cucumbers tended to decrease. The initial firmness value of the cucumber was 92.77 N. The smallest firmness value for medium impact (60 cm) bruised cucumbers stored at 10 °C was 26.87 N after 24 days of storage. As presented in Figure 6, the firmness value of the cucumbers showed a fluctuating trend until day 8 of storage. The firmness values decreased rapidly until day 12 of storage. Further results showed that the quality of cucumbers can be maintained up to day 8.

Figure 6.

Firmness value of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. The error bars represent the standard deviation of nine readings per three samples. DH; drop height, ST; storage temperature, SD; storage duration.

According to Azadbakht et al. [28], the firmness of the pear was reduced as the bruise and impact levels increased over the storage duration. Furthermore, Li et al. [29] confirmed that bruising was one of the main factors that contributed to the reduction in firmness due to increased polygalacturonase activity on fresh produce. The main cause of loss of firmness in fruits and vegetables is pectin depolymerization. The loss of integrity in the cell walls of cucumbers, as well as an increase in evaporation, transpiration, and metabolic activity of fruits stored in room settings, may lead to a drop in fresh produce firmness with an increased storage duration [11]. Furthermore, Al-Dairi et al. [30] discovered that the firmness values of damaged banana fruits were affected by storage temperature and duration, with the maximum value reported at 22 °C.

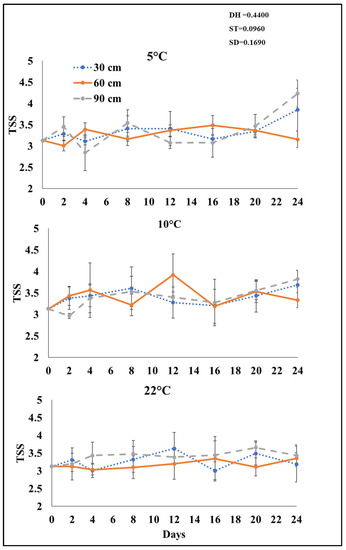

3.2.4. Total Soluble Solids (TSS)

The study found no statistical difference (p > 0.05) between TSS and the studied factors (drop height, storage temperature, and storage duration). The TSS value ranged between 2.84 and 4.23 °Brix for cucumbers stored at 5 °C, whereas the TSS values of cucumbers stored at 10 °C and 22 °C ranged between 2.97 and 3.82 °Brix and 3.00 and 3.66 °Brix, respectively (Figure 7). The highest content of TSS was recorded on the last day of storage on 90 cm bruised cucumbers at 5 °C with a value of 4.23 °Brix. The cucumber stored at 5 °C (90 cm drop height) on day 4 had the lowest TSS value (2.84 °Brix). The results of the study agreed with the findings obtained by Montero et al. [31], where the TSS content of grapefruits was significantly reduced by impact bruising. However, Maia et al. [32] found that high bruising incidence increased the TSS content of banana fruit. According to Pathare and Al-Dairi [7], storage temperature and storage duration had a high influence on the TSS value of pear fruit. In their study, they found that storage at 22 °C recorded the highest TSS levels in pears. In another study by Pathare et al. [19], they revealed that storage at 5 °C showed the smallest reduction in TSS.

Figure 7.

TSS values of cucumbers impacted by 30, 60, and 90 cm drop heights and stored at 5 °C, 10 °C, and 22 °C for 24 days. Each bar represents the standard deviation of nine readings of three replicates. DH; drop height, ST; storage temperature, SD; storage duration.

3.3. Pearson Correlation

To study the relationship between the quality attributes and bruising size parameters, the Pearson correlation test was performed (Table 3). A significant correlation (*, p < 0.05; **, p < 0.001) was found between the quality attributes of cucumbers. The BA of cucumbers impacted by the 30 cm drop height and stored at 5 °C recorded a high positive correlation with Wl% (r = 0.988 **), b* (r = 0.953 **), and ∆E* (r = 0.918 **), and a strong negative correlation with a* (r = 0.909 **). For quality attributes, Wl% was greatly correlated with Wl% across all treatments with r > 0.840. In all bruised cucumbers stored at 5 °C, the firmness exhibited a good relationship with color attributes, such as a* (r ≥ −0.747) and b* (r ≥ 0.734). Additionally, the a* values showed a strong correlation with b* in the majority of bruised cucumbers stored at different conditions. A weak correlation was observed between the firmness values and total soluble solids (TSS) of all tested conditions after 24 days of storage. The highest correlation found between total soluble solids and ∆E* (r = 0.804) was recorded for cucumbers bruised by the 90 cm height and stored at 10 °C.

Table 3.

Pearson correlation coefficients (r) between the bruise area (BA), bruise volume (BV), bruise susceptibility (BS), weight loss % (Wl%), firmness, lightness (L*), redness (a*), yellowness (b*), chroma*, hue*, the total color difference (∆E*), and total soluble solids (TSS) of cucumbers impacted by three drop height levels (30, 60, and 90 cm) in three storage conditions (5 °C, 10 °C, 22 °C) during 24 days of storage. Significant correlations of two-tailed tests are indicated: *, p < 0.05; **, p < 0.001.

4. Conclusions

This study investigated the effect of the drop height, storage temperature, and storage period on the quality and properties of cucumbers. The bruising damage measurements were influenced by the storage temperature and drop height. Cucumbers impacted by the maximum drop height (90 cm–0.590 J) increased BA and BS during storage. Once the cucumbers were subjected to an impact from a 90 cm drop height for a 24-day storage period, a rapid increase (L*, a*, b*, and hue*) was recorded in cucumbers stored at 22 °C, where more color deterioration and ripening were observed. The drop height did not affect the hue* value, but the temperature and duration of storage did. There was a significant influence of both storage duration and drop height on the chroma* value. The firmness is significantly affected by storage duration and does not affect the drop height and temperature. The total color change (ΔE*) values significantly differed with all studied factors. Fresh produce that has been bruised can be stored at 10 °C to preserve its qualitative features. This means that storage management is considered an important strategy to maintain the quality of fresh produce, such as cucumber, and to overcome mechanical damage issues during the supply chain.

Author Contributions

A.A.-H.: Data collection, formal analysis, investigation, and writing the original draft. P.B.P.: conceptualization, resources, writing—review and editing, funding acquisition, project administration, and supervision. M.A.-D.: data curation, formal analysis, and writing—original draft. A.A.-M.: formal analysis, and resources. All authors have read and agreed to the published version of the manuscript.

Funding

This work is based on the research supported in part by Sultan Qaboos University under the project code: IG/AGR/SWAE/19/03.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAOSTAT. Food and Agriculture Organization Corporate Statistical Database; FAO: Rome, Italy, 2023. [Google Scholar]

- Murad, H.; Nyc, M. Evaluating the potential benefits of cucumbers for improved health and skin care. J. Aging Res. Clin. Pract. 2016, 5, 139–141. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Opara, U.L. Mechanical damage of fresh produce in postharvest transportation: Current status and future prospects. Trends Food Sci. Technol. 2022, 124, 195–207. [Google Scholar] [CrossRef]

- Shao, Y.; Xuan, G.; Hu, Z.; Gao, Z.; Liu, L. Determination of the bruise degree for cherry using Vis-NIR reflection spectroscopy coupled with multivariate analysis. PLoS ONE 2019, 14, e0222633. [Google Scholar] [CrossRef] [PubMed]

- Nturambirwe, J.F.I.; Perold, W.J.; Opara, U.L. Classification learning of latent bruise damage to apples using shortwave infrared hyperspectral imaging. Sensors 2021, 21, 4990. [Google Scholar] [CrossRef] [PubMed]

- Celik, H.K. Determination of bruise susceptibility of pears (Ankara variety) to impact load by means of FEM-based explicit dynamics simulation. Postharvest Biol. Technol. 2017, 128, 83–97. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M. Bruise damage and quality changes in impact-bruised, stored tomatoes. Horticulturae 2021, 7, 113. [Google Scholar] [CrossRef]

- Ergun, M. Physical, physiochemical and electrochemical responses of ‘Galaxy’apples to mild bruising. Eur. J. Hortic. Sci. 2017, 82, 244–250. [Google Scholar] [CrossRef]

- Xia, M.; Zhao, X.; Wei, X.; Guan, W.; Wei, X.; Xu, C.; Mao, L. Impact of packaging materials on bruise damage in kiwifruit during free drop test. Acta Physiol. Plant. 2020, 42, 1–11. [Google Scholar] [CrossRef]

- Tadesse, B.; Bakala, F.; Mariam, L.W. Assessment of postharvest loss along potato value chain: The case of Sheka Zone, southwest Ethiopia. Agric. Food Secur. 2018, 7, 1–14. [Google Scholar] [CrossRef]

- Eboibi, O.; Uguru, H. Storage conditions effect on physic-mechanical properties of Nandini cucumber. Int. J. Eng. Tech. Res. 2017, 7, 264925. [Google Scholar]

- Ndukvu, M.; Manuwa, S. Impact of evaporative cooling preservation on the shelf life of fruits and vegetable in South Western Nigeria. Res. Agric. Eng. 2015, 61, 122–128. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Ma, Z.; Zheng, Y.; Jin, P. Hydrogen sulfide treatment alleviates chilling injury in cucumber fruit by regulating antioxidant capacity, energy metabolism and proline metabolism. Foods 2022, 11, 2749. [Google Scholar] [CrossRef] [PubMed]

- Pathare, P.B.; Al-Dairi, M. Effect of mechanical damage on the quality characteristics of banana fruits during short-term storage. Discov. Food 2022, 2, 4. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Bruise damage of pomegranate during long-term cold storage: Susceptibility to bruising and changes in textural properties of fruit. Int. J. Fruit Sci. 2020, 20, S211–S230. [Google Scholar] [CrossRef]

- Polat, R.; Aktas, T.; Ikinci, A. Selected mechanical properties and bruise susceptibility of nectarine fruit. Int. J. Food Prop. 2012, 15, 1369–1380. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M.; Al-Yahyai, R.; Al-Mahdouri, A. Simulated Handling to Investigate the Effect of Mechanical Damage on Stored Pomegranate Fruit. Processes 2022, 10, 2695. [Google Scholar] [CrossRef]

- Cui, J.; Yang, M.; Son, D.; Park, S.; Cho, S.-I. Estimation of tomato bruising by mechanical impact force using multivariate analysis. HortScience 2018, 53, 1352–1359. [Google Scholar] [CrossRef]

- Tabatabaekoloor, R. Engineering properties and bruise susceptibility of peach fruits (Prunus persica). Agric. Eng. Int. CIGR J. 2013, 15, 244–252. [Google Scholar]

- Al-Dairi, M.; Pathare, P.B. Kinetic modeling of quality changes of tomato during storage. Agric. Eng. Int. CIGR J. 2021, 23, 183–193. [Google Scholar]

- Dhall, R.K.; Sharma, S.R.; Mahajan, B. Effect of shrink wrap packaging for maintaining quality of cucumber during storage. J. Food Sci. Technol. 2012, 49, 495–499. [Google Scholar] [CrossRef] [PubMed]

- Pathare, P.B.; Al-Dairi, M.; Al-Yahyai, R.; Al-Mahdouri, A. Physiological Response of Stored Pomegranate Fruit Affected by Simulated Impact. Foods 2023, 12, 1122. [Google Scholar] [CrossRef] [PubMed]

- Korese, J.K.; Achaglinkame, M.A.; Adzitey, F. Effect of different packaging materials on storage stability of Gardenia erubescens Stapf. & Hutch. dried fruits and powder. Appl. Food Res. 2022, 2, 100143. [Google Scholar]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Effect of postharvest transport and storage on color and firmness quality of tomato. Horticulturae 2021, 7, 163. [Google Scholar] [CrossRef]

- Bodner, M.; Scampicchio, M. Does bruising influence the volatile profile of pears? Nutr. Food Sci. 2021, 51, 643–652. [Google Scholar] [CrossRef]

- Azadbakht, M.; Mahmoodi, M.J.; Vahedi Torshizi, M. Effects of different loading forces and storage periods on the percentage of bruising and its relation with the qualitative properties of pear fruit. Int. J. Hortic. Sci. Technol. 2019, 6, 177–188. [Google Scholar]

- Li, J.; Yan, J.; Cao, J.; Zhao, Y.; Jiang, W. Preventing the wound-induced deterioration of Yali pears by chitosan coating treatments. Food Sci. Technol. Int. 2012, 18, 123–128. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Mahdouri, A. The Contribution of Impact Damage to the Quality Changes of Stored Banana Fruit. Biol. Life Sci. Forum 2022, 16, 31. [Google Scholar]

- Montero, C.R.; Schwarz, L.L.; Santos, L.C.; Andreazza, C.S.; Kechinski, C.P.; Bender, R.J. Postharvest mechanical damage affects fruit quality of ‘Montenegrina’ and ‘Rainha’ tangerines. Pesqui. Agropecuária Bras. 2009, 44, 1636–1640. [Google Scholar] [CrossRef]

- Maia, V.M.; Salomão, L.C.C.; Siqueira, D.L.; Puschman, R.; Mota Filho, V.J.G.; Cecon, P.R. Physical and metabolic alterations in “Prata Anã” banana induced by mechanical damage at room temperature. Sci. Agric. 2011, 68, 31–36. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).