Abstract

US cotton producers are motivated to optimize planter performance to ensure timely and uniform stand establishment early in the season, especially when planting in sub-optimal field conditions. Field studies were conducted in 2017, 2018 and 2019 to evaluate the effect of seeding depth and planter downforce on crop emergence and yield in cotton planted in different soil moisture conditions. Field conditions representative of dry, normal and wet soil moisture conditions were attained by applying 0, 1.27 and 2.54 cm of irrigation within the same field. Two cotton cultivars (representing a small-seeded and a large-seeded cultivar, 9259–10,582 and 11,244–14,330 seeds kg−1, respectively), were planted at seeding depths of 1.3, 2.5 and 3.8 cm with each seeding depth paired with three different planter downforces of 0, 445 and 890 N in each block. Cotton was planted in plots that measured 3.66 m (four-rows) wide by 10.67 m long. Results indicated that crop emergence was affected by the seeding depth across most field conditions and higher crop emergence was observed in the large-seeded cultivar at 1.3 and 3.8 cm seeding depths in dry and wet field conditions, respectively. Lint yield was also higher for the large-seeded cultivar at the 3.8 cm seeding depth across all field conditions in 2017, and in dry field conditions in 2018. Planter downforce effect on crop emergence varied among the cultivars where the large-seeded cultivar exhibited higher crop emergence than the small-seeded cultivar at 445 and 890 N downforce. Planter downforce of 445 N yielded greater than the 0 and 890 N treatment in dry field conditions in 2017. The study results suggest that matching planter depth and downforce settings for prevalent soil moisture conditions at planting along with appropriate cultivar selection can help in achieving optimal emergence and yield in cotton.

1. Introduction

The US cotton producers face many challenges including adverse weather conditions, equipment issues during field operations, appropriate variety selection, equipment or technology upgrades, timing and rate of crop-protection chemicals, and many more similar issues during each growing season [1]. Among these challenges, growers need to make some important and timely decisions to warrant a high yielding crop at harvest. Alike other farming operations, planting is a critical operation that requires well-informed and timely decision making to ensure successful stand establishment. Due to unexpected weather events (excessive rain or prolonged dry periods) every year, planting in sub-optimal field conditions is usual for cotton growers. Research suggests that optimal in-field planter performance is important for timely and uniform crop emergence [2,3,4], and planting in unfavorable field conditions can affect planter performance resulting in poor seed placement and reduced crop emergence [5,6]. Therefore, an understanding of prevalent field conditions at planting and ways to optimize planter settings can help in achieving maximized planting equipment performance under varying field conditions.

Soil moisture has been identified as a key component of the soil’s physical environment that can influence planter performance [2] and must be considered to attain a satisfactory crop emergence in prevailing field conditions. During planting, crop-seeding depth is carefully considered to place seeds at the soil depth where sufficient moisture for germination and emergence is present. Cotton plants emerge rapidly, usually within 7–10 days after planting, when soil moisture conditions remain favorable for 5–7 days after planting [2]. Soil conditions are considered favorable for optimum seed germination and seedling emergence when soil moisture is near field capacity [7,8]. However, soil moisture conditions at planting can vary considerably within the same field as well as throughout the planting season, which necessitates planter adjustments specific for each condition during the growing season. Past researchers have suggested that an accurate depiction of field soil moisture conditions through measurement and sensing is required to make desired planter adjustments [9,10,11,12]. Soil moisture below or above adequate levels can create problems during planting by producing excessively dry or wet field conditions, both of which can hinder seed germination and emergence. While excessively dry field conditions can cause seed depth variations across the field, wet soil conditions can lead to soil compaction around the seedbed [3,13].

Variability in field conditions, especially soil moisture, at planting can influence the selection of planter depth and downforce settings, which are used for achieving the desired seed depth. Chen et al. (2004) [14] evaluated crop performance in no-till conditions for different drill configurations in corn, wheat and soybeans, and reported that crop emergence and yield was reduced in normal and dry field conditions (but not in wet field conditions) when the planter gauge wheel and/or press wheel were not used during planting. Hanna et al. (2010) [3] reported that plant emergence was affected by variations in existing soil moisture conditions in a study aimed at evaluating different planter downforces in corn. The authors reported that emergence was rapid and uniform in moist and wet soil conditions with a low planter downforce, and in dry soil conditions with a high planter downforce. The observed differences in crop emergence were primarily attributed to variations in seed depth due to varying soil conditions in the field. The study results indicated that downforce requirement on planters can vary with prevalent soil moisture conditions in the field at planting and need to be adjusted accordingly to attain timely and uniform crop emergence across the field. Poncet et al. (2018) [15] reported similar results where seeding depth variations were observed in corn due to heterogeneous soil conditions present within and among the fields. The authors suggested the need for detailed investigation into soil and field properties that affect in-field planter performance and identify parameters that can explain variations in seeding depth during planting. Other recent studies have also indicated that accurate measurement and quantification of field soil properties are needed to effectively utilize advanced planter systems in realizing on-the-go depth or downforce adjustments for varying soil conditions [13,16,17].

Technological advancements in agriculture during recent years have provided newer and better control systems on planting machinery for precise seed depth management during planting. For example, active downforce systems available on modern planters can provide real-time monitoring and control capabilities for better seed depth control during planting. While several research studies have been conducted recently to understand the importance of maintaining adequate planter downforce and maintaining uniform seeding depth to maximize crop emergence potential across the whole field [13,15,16], the research has been primarily limited to corn with very little to no research existent in cotton. A recent study conducted by Virk et al. [17] in cotton suggested that planter downforce should be managed (either manually or by utilizing active downforce systems) based on prevalent soil texture variability within a field as inadequate downforce resulted in large emergence variations within fields with high soil textural variability in their study. As stated earlier, besides soil texture, soil moisture is also an important parameter at planting that influences planter setup and operation especially the selection of depth and downforce settings. For cotton, seeding depth recommendations in the southeastern US ranges anywhere from 1.3 to 3.8 cm (0.5 to 1.5 inch) depending on soil type, soil moisture conditions, and the weather expected during the planting season [18,19,20]. Currently, no specific recommendations for adjustments to planter depth and/or downforce based on prevalent soil moisture conditions exist for planting cotton, which also implies a knowledge gap with regard to the influence of planter depth and downforce settings on crop emergence and/or yield in cotton. Furthermore, cultivar selection is an important consideration in cotton production and research conducted by Snider et al. [21] and Virk et al. [22] indicated that cotton seed size (used to differentiate cotton cultivars) is highly correlated to early-seeding vigor which can influence emergence time and uniformity. For that reason, some growers prefer to plant large-seeded cultivars to attain rapid and more vigorous growth early in the season. The combined effect of planter setup (depth and downforce) and cultivar has also not been fully evaluated yet to better understand how cultivar selection can influence planter settings and can potentially affect cotton emergence and/or yield especially in sub-optimal field conditions. Therefore, the main objective of this study is to investigate the effect of seeding depth and planter downforce on crop emergence and lint yield in two cotton cultivars (differing in seed size) planted in different at-plant soil moisture conditions, in an effort to determine how growers can effectively manage planter depth and downforce in conjunction with cultivar selection for existing field conditions to maximize cotton emergence and yield.

2. Materials and Methods

2.1. Test Site and Planting Equipment

Research studies were conducted at the University of Georgia’s Gibbs Research Farm located in Tifton, GA in 2017 and 2018, and at the University of Georgia’s Stripling Irrigation Research Park located in Camilla, GA in 2019. The field selected for this study in 2017 and 2018 had a lateral irrigation system whereas the field used for the 2019 study had a center-pivot irrigation system. Table 1 provides information on the soil properties in the two fields used for planting cotton in 2017, 2018 and 2019. The predominant soil type in both fields was loamy sand with slopes of up to 5 percent.

Table 1.

Information on soil properties for the fields planted in cotton in 2017, 2018 and 2019.

In all studies, cotton was planted using a four-row Monosem NGPlus vacuum precision planter (Monosem Inc., Edwardsville, KS, USA) shown in Figure 1a. The planter was equipped with a mechanically driven seed meter and a mechanical downforce control system equipped with heavy-duty springs for applying additional force on each individual row-unit. The seed depth setting on each row-unit was controlled by turning the knob, which positioned the gauge wheel stop to attain the predetermined seeding depth (Figure 1b). A depth positioning guide and label, adjacent to the knob, were also provided on each row-unit to attain different seeding depths. Seeding depths up to 8.9 cm can be attained on this planter by adjusting the gauge wheel stop position. Downforce adjustments were made by positioning and securing the lateral arm (attached to the heavy springs) in four different positions (Figure 1c), which changed the spring tension, thus varying the amount of load applied on the gauge wheels. The four positions of the spring-loaded arm corresponded to approximately 445, 890, 1335 and 1780 N of applied force on each row-unit, whereas disengaging the arm resulted in no additional load on the row-unit other than the row-unit weight plus the weight of any seed and product in the hopper. Cotton was planted at a seeding rate of 105,020 seeds ha−1 during all three years.

Figure 1.

(a) Four-row Monosem NGPlus vacuum precision planter, (b) depth control mechanism, and (c) mechanical downforce assembly used for attaining different downforce adjustments in this study.

2.2. Study Treatments and Planting Layout

During each year, the selected field was split into three distinct blocks of equal area. These blocks were utilized to attain different soil moisture conditions at planting by applying different amounts of irrigation 24 h prior to any planting. The irrigation treatments consisted of 0, 1.27 and 2.54 cm of irrigation applied to each block separately to establish soil moisture conditions that were representative of dry, normal, and wet field conditions for planting cotton. The reason behind selecting these irrigation amounts was to simulate similar field conditions as a result of either no rainfall (dry) or after receiving 1.27 cm (normal) and 2.54 cm (wet) of rainfall in this soil type prior to planting. These field conditions attained in this soil type were also based on the visual soil moisture observations during the planting season in the previous years. During planting, soil samples were collected to determine the soil moisture content (gravimetric soil water content) within each block. Soil samples were weighed, oven-dried at 105 °C for 24 h and re-weighed to calculate soil moisture content. The mean soil moisture content measured within each block during each year is presented in Table 2. As expected, the soil moisture content range increased with an increase in the amount of irrigation applied within the field during each year. Mean soil moisture content values achieved within each block during all three years were significantly different (p < 0.05) from each other (Table 2), and provided a distinct separation between the soil moisture conditions characterized as dry, normal and wet field conditions. The observed soil moisture variability among the fields and between the growing seasons was somewhat expected due to the difference in the local weather and soil conditions that existed during the planting season (months of May and June) each year.

Table 2.

Mean soil moisture content and standard deviation values for the dry, normal and wet field conditions in 2017, 2018 and 2019.

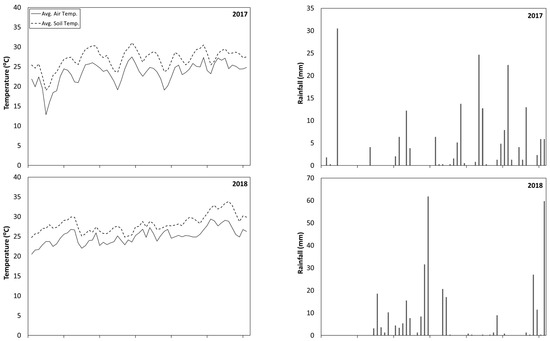

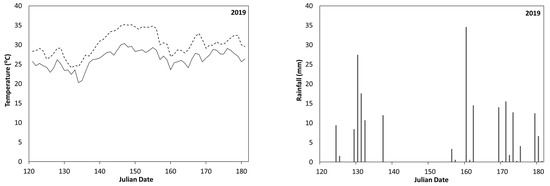

Cotton was planted between mid-May to early-June during each year. Table 3 provides information on the different weather and soil parameters averaged over the first 5 days after planting for each year. High air and soil temperatures during the 2019 planting season created extremely hot and dry conditions, which are generally considered unsuitable for planting cotton, especially at shallower seeding depths. The 5-day soil temperature was highest in 2019 followed by 2018 and 2017. The research site in 2017 and 2018 also received 2.03 and 1.02 mm, respectively, of total rainfall during the first 5 days after planting compared to no rainfall in 2019 leading to extremely dry topsoil conditions. Graphs with mean air temperature, soil temperature, and total rainfall during the month of May and June in 2017, 2018 and 2019 are presented in Figure A1 in Appendix A.

Table 3.

Mean air temperature, relative humidity, 5-cm soil temperature, soil moisture averaged across 5 days after planting and total rainfall during the 5 days after planting in 2017, 2018 and 2019.

Each year, planter treatments consisted of three different seeding depths of 1.3, 2.5 and 3.8 cm with each seed depth paired with three downforces of 0, 445, and 890 N applied on each row-unit on the planter. The selected values for seeding depths and downforces represented the nominal planting depth and downforce settings utilized by growers across the state of Georgia for planting cotton. Each seeding depth and downforce combination was replicated four times in dry, normal and wet field conditions. In each study, two cotton cultivars differing in seed size were planted across all three field conditions. Cotton cultivars DP1553, DP1555 and DP1553 (Deltapine®, Bayer Corporation, Pittsburgh, P.A.) were selected to represent small-seeded (SS) cultivars in 2017, 2018 and 2019, respectively, whereas cotton cultivar PHY312 (PhytoGen, Corteva Inc., Wilmington, D.E.) was chosen to represent a large-seeded (LS) cultivar during all three years of study. Table 4 provides information on the seed size classification for the selected cultivars. During each year, study treatments were organized in a factorial arrangement of seeding depth × planter downforce × cultivar within each field condition and planted in plots that measured 3.66 m (four-rows) wide by 10.67 m long. The experimental layout was a strip-split plot design [23] where field condition and cultivar served as whole plots, and seed depth and downforce were treated as sub-plots. Cultivar treatments were arranged such that both cultivars were planted adjacent to each other, where the left four rows were planted in the SS cultivar and right four rows were planted in the LS cultivar. All cotton was planted following conventional tillage and the crop was maintained as per recommendations in the University of Georgia’s cotton production guide [18].

Table 4.

Cotton cultivars (and their seed size) planted in the studies conducted in 2017, 2018 and 2019.

2.3. Data Collection and Analysis

For data collection, the center two rows within each four-row plot were treated as data rows and the outside two rows as buffer rows. During all three years, stand counts were performed at 7, 14 and 21 days after planting (DAP) in a randomly-selected 3.05 m section towards the center of each plot (in the data rows and marked using flags). In 2019, stand counts were also collected in the data rows at 5, 11, 17, and 19 DAP to record emergence data at more frequent intervals. Stand count data was converted to percent crop emergence by dividing the number of plants counted for each within-row area (0.81 × 3.05 m2) and computing a mean percent crop emergence for each plot. Cotton was harvested using a custom two-row cotton picker modified to collect cotton samples in the picker basket. Cotton was harvested on October 26th in 2017, November 1st in 2018, and October 11th in 2019. Yields were collected by harvesting the center two data rows and collecting seed cotton samples in bags. Afterwards, seed cotton samples were ginned at the University of Georgia’s microgin located in Tifton, GA, and lint yield was determined by dividing the lint weight by the harvested area (1.83 × 10.67 m2) for each plot. Similar data collection and harvest procedures were followed during all three years. For year 2019, large errors in yield data were noticed during data analysis. The exact reason behind the erroneous data could not be determined, and therefore, the yield data for 2019 could not be used for analysis and are not reported here. The results and discussion for the study conducted in 2019 are limited to emergence data only.

Due to differences in soil moisture contents for the dry, normal and wet field conditions among the study years, data were analyzed separately for each year. Results from statistical analysis [using SAS 9.4 (SAS Institute Inc., Cary, NC, USA)] suggested that crop emergence data collected at 7, 14 and 21 DAP were not significantly different (p > 0.05) from each other, indicating that crop emergence was rapid and mostly attained before or at 7 DAP in each year, and no significant increase in crop emergence occurred after that period. Thus, the crop emergence data were not separately presented and discussed for each data collection period. The crop emergence recorded at 21 DAP was used for statistical analysis and results reported in the subsequent sections.

Data were analyzed as a strip-split plot design using the PROC GLM procedure in SAS 9.4 (SAS Institute Inc., Cary, N.C.) with corrected error terms for fixed and random effects. For analysis of variance, the main effects of depth, downforce and cultivar, and the interactions among them were used as fixed effects in the model, while rep, rep x cultivar, rep × depth, and rep x depth x cultivar were considered as random effects. An alpha value (α) of 0.05 was used for evaluating the significance of main and interaction effects on crop emergence and lint yield. Fisher’s least significant difference (LSD) method [24] was used for pairwise comparisons among the treatment means at p ≤ 0.05 using MEANS LSD option in PROC GLM procedure.

3. Results

3.1. Crop Emergence

The mean crop emergence averaged across all seeding depths, downforces, and cultivars attained in dry, normal and wet field conditions at planting during each year is presented in Table 5. During 2017 and 2018, the mean emergence observed in dry and normal field conditions was considerably similar to each other, whereas a decreased emergence was observed in wet field conditions during both years. In 2019, the highest emergence (67%) was attained in wet field conditions followed by normal (59%) and dry (40%) field conditions. The observed variation in crop emergence across three years was largely attributed to the differences in local weather conditions during planting season each year, which also represented typical weather conditions observed in the southeastern US during the cotton-planting season from mid-May to early-July.

Table 5.

Mean crop emergence obtained in different at-plant field conditions in 2017, 2018 and 2019.

In 2017, a significant depth × cultivar interaction existed for crop emergence in dry and normal field conditions (Table 6). In dry field conditions, the SS cultivar exhibited reduced emergence across all three seeding depths with the lowest emergence (49%) observed at the 3.8 cm seeding depth. In normal field conditions, a similar trend was noticed at the seeding depths of 2.5 and 3.8 cm with the lowest emergence again observed at the 3.8 cm seeding depth for the SS cultivar. In wet field conditions, crop emergence was affected by both seeding depth and cultivar; however, no significant interaction existed between these two effects (Table 6). As observed in both dry and normal field conditions, crop emergence was reduced (30%–33%) at the 3.8 cm seeding depth, and the LS cultivar (64%) exhibited higher crop emergence than the SS cultivar (48%) in wet field conditions. In normal field conditions, a significant downforce x cultivar interaction also occurred for crop emergence, where the LS cultivar (70%–72%) exhibited higher emergence than the SS cultivar (55%–56%) when cotton was planted using 445 and 890 N of downforce. No difference in crop emergence among the cultivars were noticed when no additional downforce was applied in normal field conditions.

Table 6.

Influence of seeding depth, cultivar, depth × cultivar, and downforce × cultivar on crop emergence in different at-plant field conditions in 2017.

In 2018, a significant depth x downforce interaction occurred for crop emergence in normal field conditions (Table 7) where cotton planted at the 3.8 cm seeding depth using 445 and 890 N of downforce had lower emergence (36% and 44%, respectively) than the emergence attained (52%) when no additional downforce was applied at the same seeding depth. Additionally, a significant interaction also existed between seeding depth and cultivar in all three field conditions (Table 7). Both the SS and LS cultivar performed well at the seeding depth of 2.5 cm whereas the LS cultivar outperformed the SS cultivar at the 1.3 and 3.8 cm seeding depths. For both cultivars, crop emergence initially increased with an increase in the seeding depth from 1.3 cm to 2.5 cm, and then decreased with an increase in the seeding depth from 2.5 cm to 3.8 cm, irrespective of the field conditions. Planter downforce did not have a significant effect on crop emergence in all field conditions and both cultivars; however, a significant downforce x cultivar interaction existed in wet field conditions (Table 7). In these field conditions, the LS cultivar exhibited higher crop emergence (47–67%) than the emergence (31–33%) attained for the SS cultivar across all three downforces.

Table 7.

Influence of seeding depth, cultivar, depth × downforce, depth × cultivar, and downforce × cultivar on crop emergence in different at-plant field conditions in 2018.

In 2019, both seeding depth and cultivar had a significant effect on crop emergence in normal field conditions and a significant depth x cultivar interaction existed in dry and wet field conditions (Table 8). In dry field conditions, the LS cultivar performed better, exhibiting a higher crop emergence across all three seeding depths. This trend was only noticed for the SS cultivar in wet field conditions at seeding depths of 1.3 and 2.5 cm. In addition, a significantly reduced crop emergence was observed for both cultivars (6% and 18% for SS and LS, respectively) in dry field conditions. For both cultivars, the crop emergence increased with an increase in seeding depth from 1.3 cm to 2.5 cm in dry and wet field conditions. In normal field conditions, crop emergence increased from 30% to 76% with an increase in seeding depth from 1.3 cm to 3.8 cm, and the LS cultivar (64%) had higher mean emergence than the SS cultivar (54%). A significant downforce x cultivar interaction also occurred in dry field conditions where crop emergence was reduced with no downforce compared to when cotton was planted using 445 and 890 N of downforce for the LS cultivar.

Table 8.

Influence of seeding depth, downforce, cultivar, depth × cultivar, and downforce × cultivar on crop emergence in different at-plant field conditions in 2019.

3.2. Lint Yield

The mean lint yield averaged across all depths, downforces, and cultivars in dry, normal and wet field conditions at planting for 2017 and 2018 is presented in Table 9. The mean lint yield for dry and normal field conditions in 2017 and 2018 was not statistically different from each other while decreased lint yield (more than 100 kg ha−1) was recorded in wet field conditions during both years. The effect of seeding depth, planter downforce, and cultivar on lint yield in different field conditions is discussed separately for each year in the next section.

Table 9.

Mean lint yield averaged across seeding depths, downforces and cultivars in different at-plant field conditions in 2017 and 2018.

In 2017, a significant depth × cultivar interaction existed for lint yield in all three field conditions (Table 10). Lint yield was considerably reduced for the SS cultivar planted at the 3.8 cm seeding depth with yield reductions as large as 424 kg ha−1 observed in wet field conditions. No difference in lint yield existed between the cultivars at 1.3 and 2.5 cm seeding depths. For the SS cultivar, yield reductions were noted with an increase in seeding depth from 2.5 cm to 3.8 cm in all three field conditions, while similar lint yields were recorded for the LS cultivars across all seeding depths. Planter downforce had a significant effect on lint yield in dry field conditions, where cotton planted using 445 N of downforce exhibited higher lint yield (1050 kg ha−1) than the lint yield attained when no downforce and 445 N (871 and 746 kg ha−1, respectively) of planter downforce was used.

Table 10.

Influence of seeding depth, downforce, cultivar, and depth × cultivar on lint yield in different at-plant field conditions in 2017.

In 2018, lint yield was influenced by seeding depth in normal field conditions and a significant depth × cultivar interaction existed for lint yield in dry and wet field conditions (Table 11). In normal field conditions, decreased lint yield (637 kg ha−1) was observed at the 2.5 cm seeding depth compared to the lint yield recorded at the 1.3 and 3.8 cm seeding depths (764 and 819 kg ha−1, respectively). In dry field conditions, the SS cultivar (602 kg ha−1) yielded lower than the LS cultivar (859 kg ha−1) at the 3.8 cm seeding depth. No significant effect of downforce on lint yield was noticed across all field conditions; however, a significant depth × downforce interaction occurred in wet field conditions (Table 11). Cotton planted using no downforce at the 2.5 cm seeding depth showed reduced yield (453 kg ha−1) compared to the lint yield when planter downforce of 445 and 890 N (637 and 650 kg ha−1, respectively) were utilized at the same seeding depth. Similarly, lint yield was reduced for the planter downforce of 890 N (486 kg ha−1) compared to the lint yield at zero and 445 N of planter downforce (610 and 742 kg ha−1, respectively) at the 3.8 cm seeding depth.

Table 11.

Influence of seeding depth, cultivar, depth × downforce, and depth × cultivar on lint yield in different at-plant field conditions in 2018.

4. Discussion

While the dry, normal and wet field conditions differed each year, some common trends in crop emergence and lint yield still existed among the study years. The overall results indicated that seeding depth had a more profound effect on crop emergence and lint yield than planter downforce. In dry field conditions, it is usually expected that seeds placed at shallower depths (1.3 cm or less) would exhibit decreased emergence due to lack of adequate soil moisture at the planted depth. This trend was observed in 2018 and 2019 where emergence was considerably reduced at the 1.3 cm seeding depth in dry field conditions. Crop emergence was reduced considerably (mean emergence = 12%; averaged across cultivars) in 2019 due to extremely dry weather and high soil temperatures experienced during planting in the month of May. The excessive heat possibly depleted the topsoil moisture driving the soil moisture front down into the soil profile. This emergence trend was not noticed in 2017 due to the presence of sufficient soil moisture in topsoil with enough timely rainfall during the planting season. As noted earlier, the field conditions that existed due to weather conditions during all three study years were representative of the nominal field conditions that generally exist during the cotton planting season in the southeastern US.

Though a similar trend in crop emergence was observed in normal and wet field conditions at the 1.3 seeding depth in 2018 and 2019, the emergence reductions were not quite as large as in dry field conditions, mainly due to presence of sufficient soil moisture (1.27 and 2.58 cm pre-plant irrigation amounts) in these field conditions. In normal field conditions, the 2.5 cm seeding depth exhibited higher crop emergence than the other two seeding depths in both 2017 and 2018. These findings suggest that a seeding depth of 2.5 cm can be utilized as an optimal seeding depth when sufficient soil moisture is present at or below the topsoil. There was an exception to this in 2019, where the seed placed deeper at 3.8 cm exhibited better emergence due to lack of moisture at the 2.5 cm seeding depth because of extremely dry weather conditions. However, it can be noted that crop emergence was reduced at the 3.8 cm seeding depth in both 2017 and 2018 all field conditions, which suggested that emergence penalties can occur at seeding depths greater than 2.5 cm in fields when adequate soil moisture is present in the topsoil. Reduced emergence at deeper seeding depths is generally attributed to increased soil compaction around the seedbed during planting [25] and depletion of energy for deep planted seeds before they emerge [2], leading to poor emergence. Thus, growers should be careful about planting cotton seed deeper than 2.5 cm especially in field conditions where sufficient soil moisture is present at shallower depths.

For the cultivar effect, the general trend observed among the field conditions was that the LS cultivar performed better than the SS cultivar, exhibiting higher overall crop emergence. While the planter downforce effect was non-significant for crop emergence in most cases, a significant cultivar x downforce interaction existed in some field conditions. In general, the LS cultivar exhibited increased crop emergence, especially at higher downforces of 445 and 890 N (emergence differences greater than 16%) than the SS cultivar. Irrespective of the cultivar, a higher downforce typically helps in pushing the seed deeper and closer to the soil moisture front especially in dry field conditions as noticed in 2019. However, in certain field conditions, an excessively heavy downforce can also create soil compaction around the seedbed, hindering the seed germination process and resulting in delayed or poor emergence [3,13]. In our studies, this delayed or reduced emergence effect under heavy downforce conditions was only observed in the SS cultivar as cultivar response under such conditions is directly related to its seed size. Therefore, growers who prefer to plant small-seeded cultivars every year should be mindful of the influence of excessive downforce on crop emergence in these situations. The overall results for the cultivar effect suggested that the large-seeded cultivars can compensate better for lack of adequate planter settings under adverse field conditions. These results were in agreement with the findings of other research studies [21,22,26,27] where the authors stated that a more vigorous cultivar tends to perform better for available resources and outperformed a less vigorous cultivar in sub-optimal field conditions.

Though cotton is known to compensate well for early season stresses due to an indeterminate growth habit, the effect of seeding depth and cultivar interaction was noticed on the lint yield as well. This effect was more pronounced at the 3.8 cm seeding depth in all three field conditions in 2017, and in dry field conditions in 2018, where a significant yield penalty was observed in the SS cultivar. A similar but contrasting effect was observed at the 1.3 cm seeding depth in wet field conditions with decreased lint yield for the LS cultivar. Although the effect of depth, downforce and cultivar on lint yield for 2019 could not be evaluated, the authors anticipate a similar trend of reduced lint yield at the 1.3 cm seeding depth in dry field conditions where extremely low crop emergence (6%–18%) was recorded in both cultivars. The influence of planter downforce on lint yield was only observed in dry field conditions in 2017, where 0 and 890 N of downforce resulted in decreased lint yield. These findings imply that while some of the emergence reductions observed earlier in the season may not translate to the yield, both planter settings and cultivar can influence lint yield in cases where emergence penalties are significant.

5. Conclusions and Research Implications

The results from this study suggest that the selection of seeding depth, downforce, and cotton cultivar are important considerations that should be carefully evaluated based on the prevailing field conditions at planting. In this study, seeding depth had the most pronounced effect on crop emergence and yield followed by downforce, which were further influenced by the cultivar. The study results suggest that without appropriate seeding depth adjustments, planting in sub-optimal field conditions—too dry or excessively wet soil conditions—can result in large emergence penalties and/or reduced yield in some cases. Growers should be cautious about planting cotton seed at shallower seeding depths of 1.3 cm or less in dry field conditions, and may consider utilizing an additional downforce of 450 N or higher to attain seed placement as close to the soil moisture front as possible. Similarly, when planting in wet field conditions, growers can benefit by utilizing a shallower seeding depth (2.5 cm or less) and low planter downforce (between none and 445 N) to avoid any compaction issues in the seedbed during planting. The recommended depth and downforce settings are more critical for growers who prefer to plant small-seeded cultivars as these cultivars are more prone to reduced emergence and/or yield due to improper planter depth and downforce settings. While growers with active depth and downforce systems on their planting equipment can capitalize on advanced technology benefits by making real-time depth or downforce adjustments during planting, those with traditional planting systems should be more mindful of depth and downforce during planting as these settings remain constant throughout a field and sometimes across multiple fields during the whole planting season.

Author Contributions

Conceptualization, W.P. and S.V.; methodology, W.P. and S.V.; investigation, S.V., W.P. and J.S.; writing—original draft preparation, S.V. and W.P.; writing—review and editing, J.S., G.R., C.L. and Y.L.; visualization, S.V. and W.P.; supervision, W.P.; funding acquisition, W.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Georgia Cotton Commission, and Cotton Incorporated.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would also like to thank the staff of the University of Georgia Gibbs, Plant Sciences, and Stripling Irrigation Research Park research farms for their assistance with planting, and Seth Newell, Seth Williams, and Cole Patterson for help with planting, data collection, and harvest.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Mean air temperature, soil temperature and rainfall for the months of May and June in 2017, 2018 and 2019.

References

- Mollaee, M.; Mobli, A.; Kaur, N. Challenges and opportunities in cotton production. Cotton Prod. 2019, 217–247. [Google Scholar] [CrossRef]

- Bowen, H.D. Measurement of edaphic factors for determining planter specifications. Trans. ASAE 1966, 9, 725–735. [Google Scholar] [CrossRef]

- Hanna, H.M.; Steward, B.L.; Aldinger, L. Soil loading effects of planter depth-gauge wheels on early corn growth. Appl. Eng. Agric. 2010, 26, 551–556. [Google Scholar] [CrossRef]

- Nielson, R.L. Planting speed effects on stand establishment and grain yield of corn. J. Prod. Agric. 1994, 8, 391–393. [Google Scholar] [CrossRef][Green Version]

- Carter, P.R.; Nafzinger, E.D.; Lauer, J.G. Uneven Emergence in Corn. 1989. Available online: http://corn.agronomy.wisc.edu/Pubs/UWEX/NCR344.pdf (accessed on 19 August 2019).

- Ford, J.H.; Hicks, D.R. Corn growth and yield in even emerging stands. J. Prod. Agric. 1992, 5, 185–188. [Google Scholar] [CrossRef]

- Gupta, S.; Swan, J.; Schneider, E. Planting depth and tillage interactions on corn emergence. Soil Sci. Soc. Am. J. 1988, 52, 1122–1127. [Google Scholar] [CrossRef]

- Elmore, R. Corn Planting FAQs. In Integrated Crop Management News; Iowa State University: Ames, IA, USA, 2013; Available online: https://crops.extension.iastate.edu/cropnews/2013/04/corn-planting-faqs (accessed on 19 August 2019).

- Bowers, C.; Bowen, H. Drying front sensing and signal evaluation for planters. Trans. ASAE 1975, 18, 1051–1056. [Google Scholar] [CrossRef]

- Weatherly, E.; Bowers, C. Automatic depth control of a seed planter based on soil drying front sensing. Trans. ASAE 1997, 40, 295–305. [Google Scholar] [CrossRef]

- Bowers, C.; Collins, C.; Harris, E. Low soil moisture planting of cotton for optimum emergence. Appl. Eng. Agric. 2006, 22, 801–808. [Google Scholar] [CrossRef]

- Rene-Laforest, F.; Adamchuck, V.; Mastorakos, M.; Dhawale, N.; Su, Y. Variable Depth Planting of Corn. In Proceedings of the 2014 ASABE Annual International Meeting, Montreal, QC, Canada, 13–16 July 2014. [Google Scholar]

- Sharda, A.; Fulton, J.; Badua, S.; Griffin, T.; Ciampitti, I.; Haag, L. Planter Downforce Technology for Uniform Seeding Depth; MF3331; Kansas State University Extension Publication: Manhattan, KS, USA, 2017. [Google Scholar]

- Chen, Y.; Tessier, S.; Irvine, B. Drill and crop performances as affected by different drill configurations for no-till seeding. Soil Tillage Res. 2004, 77, 147–155. [Google Scholar] [CrossRef]

- Poncet, A.M.; Fulton, J.P.; McDonald, T.P.; Knappenberger, T.; Shaw, J.N.; Bridges, R.W. Effect of heterogeneous field conditions on corn seeding depth accuracy and uniformity. Appl. Eng. Agric. 2018, 34, 819–830. [Google Scholar] [CrossRef]

- Virk, S.S.; Fulton, J.P.; Porter, W.M.; Pate, G.L. Row-crop planter requirements to support variable-rate seeding of maize. Prec. Agric. 2020, 21, 603–619. [Google Scholar] [CrossRef]

- Virk, S.S.; Porter, W.M.; Li, C.; Rains, G.C.; Snider, J.L.; Whitaker, J.L. On-farm evaluation of planter downforce in varying soil textures within grower fields. Precis. Agric. 2020, 21, 603–619. [Google Scholar] [CrossRef]

- Hand, L.; Culpepper, S.; Harris, G.; Kemerait, B.; Liu, Y.; Perry, C.; Porter, W.; Roberts, P.; Smith, A.; Virk, S.; et al. University of Georgia Cotton Production Guide; University of Georgia: Athens, GA, USA, 2021; p. 75. Available online: http://www.ugacotton.com/production-guide/ (accessed on 15 January 2021).

- Jones, M.; Farmaha, B.; Greene, J.; Marshall, M.; Mueller, J.; Smith, N. South Carolina Cotton Growers Guide. 2020. Available online: https://www.clemson.edu/extension/agronomy/cotton1/cotton-growers-guide.pdf (accessed on 15 January 2021).

- Edmisten, K.; Collins, G. Cotton Information: Planting Decisions. 2020. Available online: https://content.ces.ncsu.edu/cotton-information/planting-decisions (accessed on 15 January 2021).

- Snider, J.L.; Collins, G.D.; Whitaker, J.R.; Chapman, K.D.; Horn, P. The impact of seed size and chemical composition on seedling vigor, yield, and fiber quality of cotton in five production environments. Field Crops Res. 2016, 193, 186–195. [Google Scholar] [CrossRef]

- Virk, G.; Snider, J.L.; Pilon, C. Physiological contributors to early season whole-crop vigor in cotton. Crop Sci. 2019, 59, 2774–2783. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; Wiley: New York, NY, USA, 2017; pp. 645–649. [Google Scholar]

- Williams, L.J.; Abdi, H. Fisher’s least significant difference (LSD) test. Encycl. Res. Des. 2010, 218, 840–853. [Google Scholar]

- Montemayor, M.B. The effect of soil compaction during planting on cotton emergence. J. Agric. Eng. 1995, 61, 129–136. [Google Scholar] [CrossRef]

- Coomes, D.A.; Grubb, P.J. Colonization, tolerance, competition and seed-size variation within functional groups. Trends Ecol. Evol. 2003, 18, 283–291. [Google Scholar] [CrossRef]

- Muller-Landau, H.C. The tolerance-fecundity trade off and the maintenance of diversity in seed size. Proc. Natl. Acad. Sci. USA 2012, 107, 4242–4247. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).