Maintenance 4.0 for HVAC Systems: Addressing Implementation Challenges and Research Gaps

Abstract

Highlights

- There is a lack of research on integrating Industry 4.0 into ventilation system maintenance planning.

- Existing reviews cover sensors, AI/ML, and big data in HVAC, but not integrated Maintenance 4.0.

- Effective ventilation is crucial for indoor air quality, health, and energy efficiency.

- AI-driven analytics enable proactive, data-driven maintenance for optimized schedules, failure prediction, and improved performance.

Abstract

1. Introduction

| Ref. | No. of Review Articles | Covered Period | Main Objective |

|---|---|---|---|

| [5] | 150 | 1999–2022 | Review of the development and application of IoT-based IAQ monitoring platforms. |

| [13] | 34 | 2013–2023 | Comprehensive evaluation of low-cost air pollution sensing technologies compared to high-quality instruments for IAQ monitoring. The review finds that while low-cost sensors show moderate correlations with reference instruments and are adequate for qualitative analysis, high-quality instruments are still crucial for accurate measurements. |

| [14] | 68 | 1999–2022 | Review outlining the relationship between hospital IAQ (IAQ) and factors such as building design, operation, and occupant behavior. |

| [6] | 211 | 1996–2023 | The paper provides a comprehensive review of current computing-based fault detection and diagnosis (FDD) methods for HVAC systems, classifying them into knowledge-based and data-driven approaches. It identifies key topics such as data availability, quality, approach generality, capability, interpretability, and modeling efforts. The review discusses the current state of FDD, highlights challenges like dealing with complex fault situations, improving model fidelity, and handling multiple faults, and suggests future research directions to enhance FDD methods’ applicability and effectiveness in real buildings. |

| [7] | 279 | 2002–2022 | Review of AI-based FDD methods for HVAC systems. |

| [8] | 400 | 2005–2021 | Review of the use of AI big data analytics in building automation and management systems (bamss). |

| [9] | 161 | 1993–2024 | Review of predictive maintenance from a data mining perspective. It highlights the importance of optimizing maintenance timing and type to maximize system availability and minimize resource usage. |

| [10] | 189 | 1999–2021 | Review and practical guidance on applying machine learning for air quality mapping. |

| [11] | 55 | 2002–2021 | Review of the existing algorithms used for predictive maintenance in HVAC systems. |

| [12] | 112 | 2007–2022 | It highlights how deep learning can optimize building performance, reduce energy consumption, improve predictive maintenance, and monitor equipment. The paper also discusses challenges, such as the need for public datasets, and emphasizes the importance of deep learning for predictive maintenance of thermal storage air-conditioning (TS-AC) systems to enhance sustainability and cost-efficiency. |

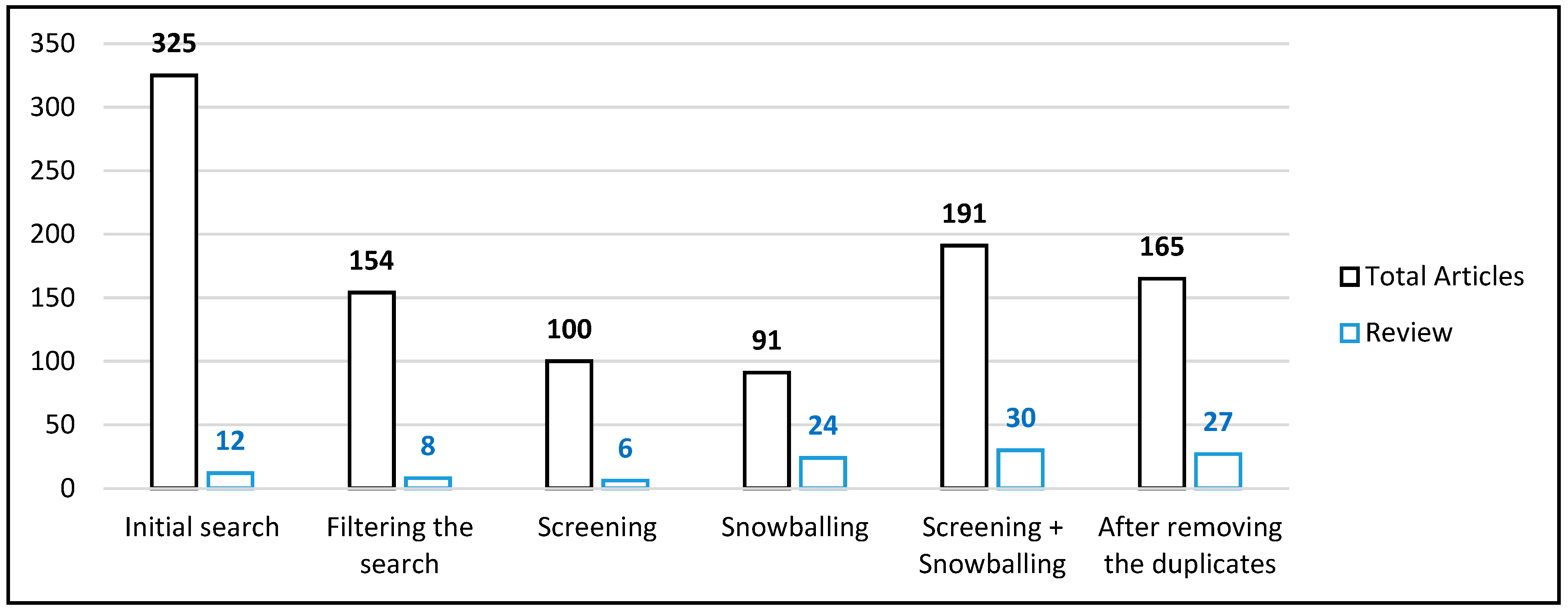

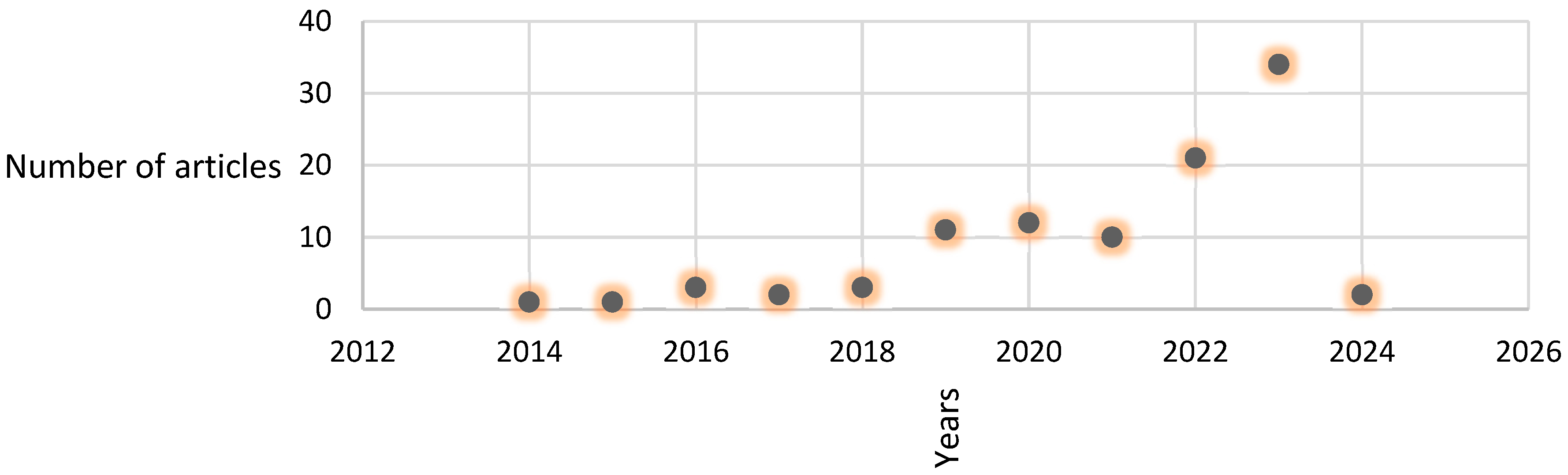

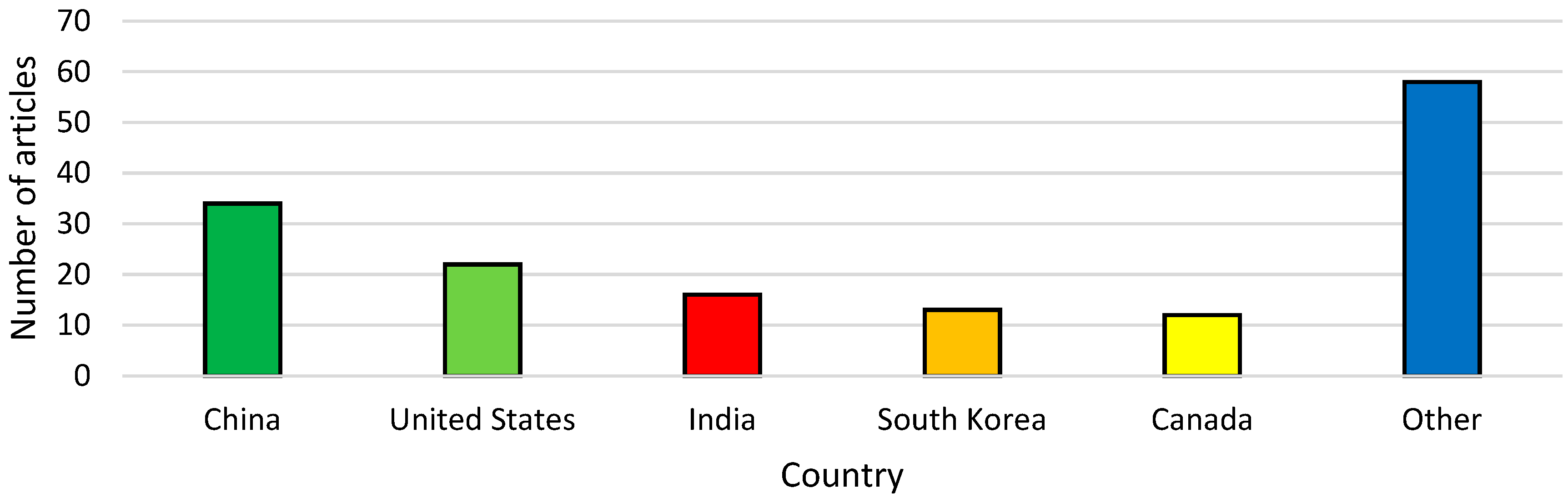

2. Research Methodology

2.1. Current Research Trajectory

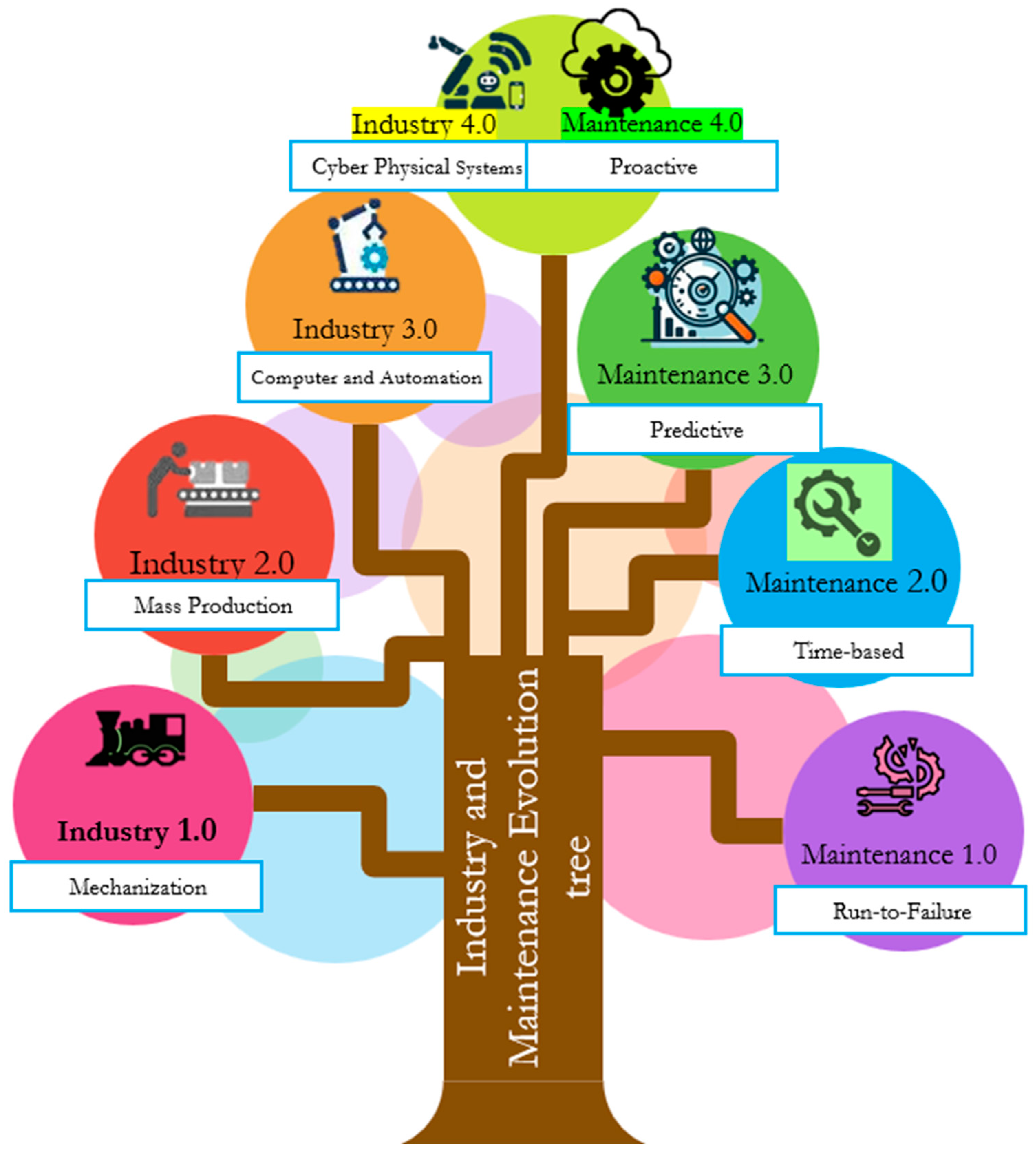

2.2. Maintenance vs. Industry Revolutions

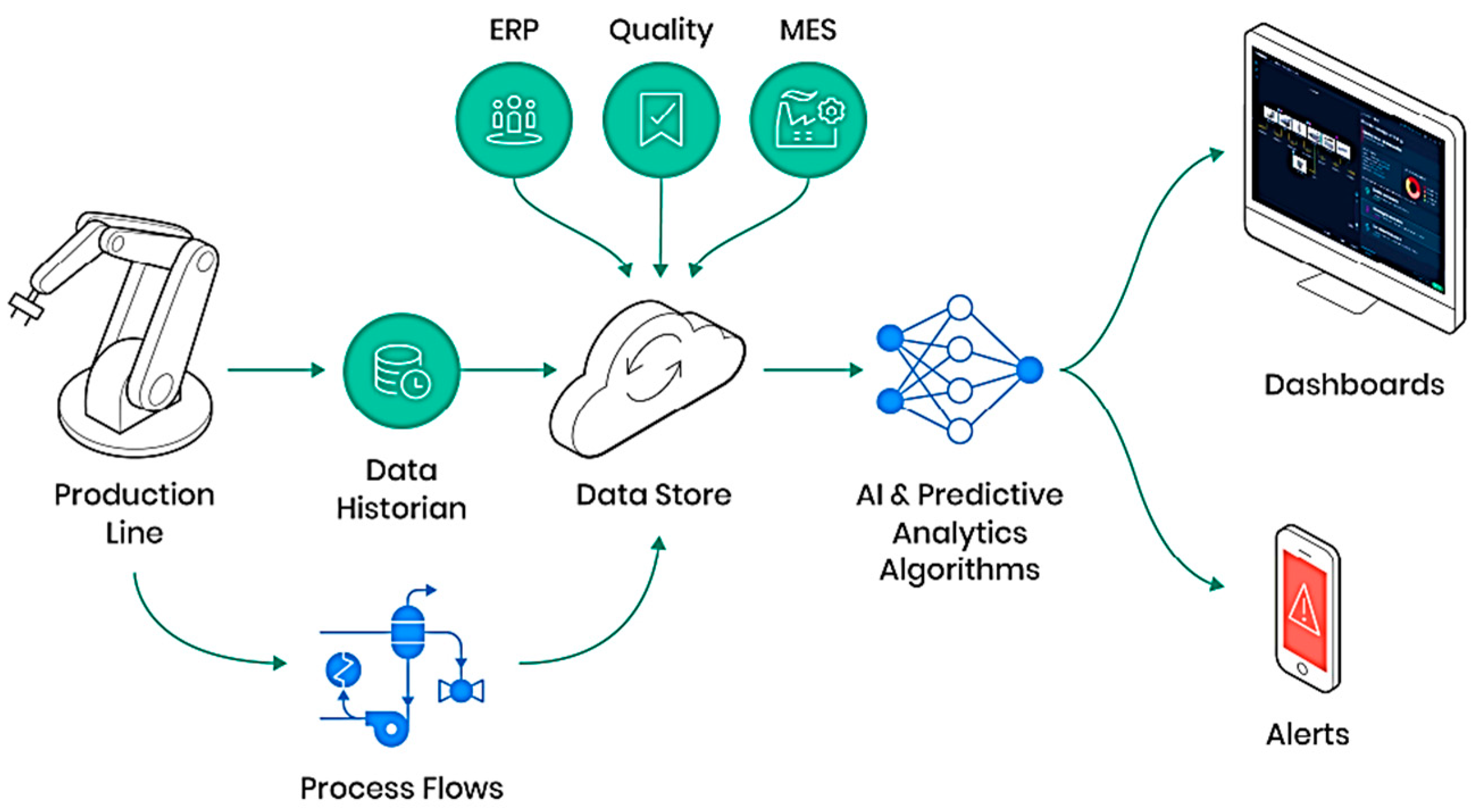

2.3. Maintenance 4.0 Structure

3. Maintenance 3.0: Predictive Maintenance

4. Fault Diagnosis Systems

- Environmental parameters: air temperature, humidity, CO2, and particulate matter (PM2.5, PM10) [28];

- Energy consumption metrics: real-time power usage, efficiency loss trends, and operational cycles [29];

- Equipment performance data: vibration levels, pressure differentials, airflow rates, and historical maintenance logs [30].

5. Sensing Elements and IoT Devices

5.1. Types of Sensors

5.2. IoT Sensors for Different Pollutant Categories

| Environmental Parameters | Sample of References |

|---|---|

| Temperature | [11,21,23,25,38,52,53,56,57,58,59,60,61,62,63,64,65,66,67,68] |

| Humidity | [21,38,69] |

| CO | [6,13,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83] |

| O3 | [84,85,86,87,88,89,90,91,92,93] |

| NO2 | [51,81,88,89,94,95] |

| PM | [96,97,98,99,100,101,102,103,104,105,106,107,108] |

| O2 | [38,71] |

| CH4 | [13,75,76,109] |

| CO2 | [110,111,112] |

| SO2 | [84,93,106] |

6. Data Management, Collection, and Analysis Techniques

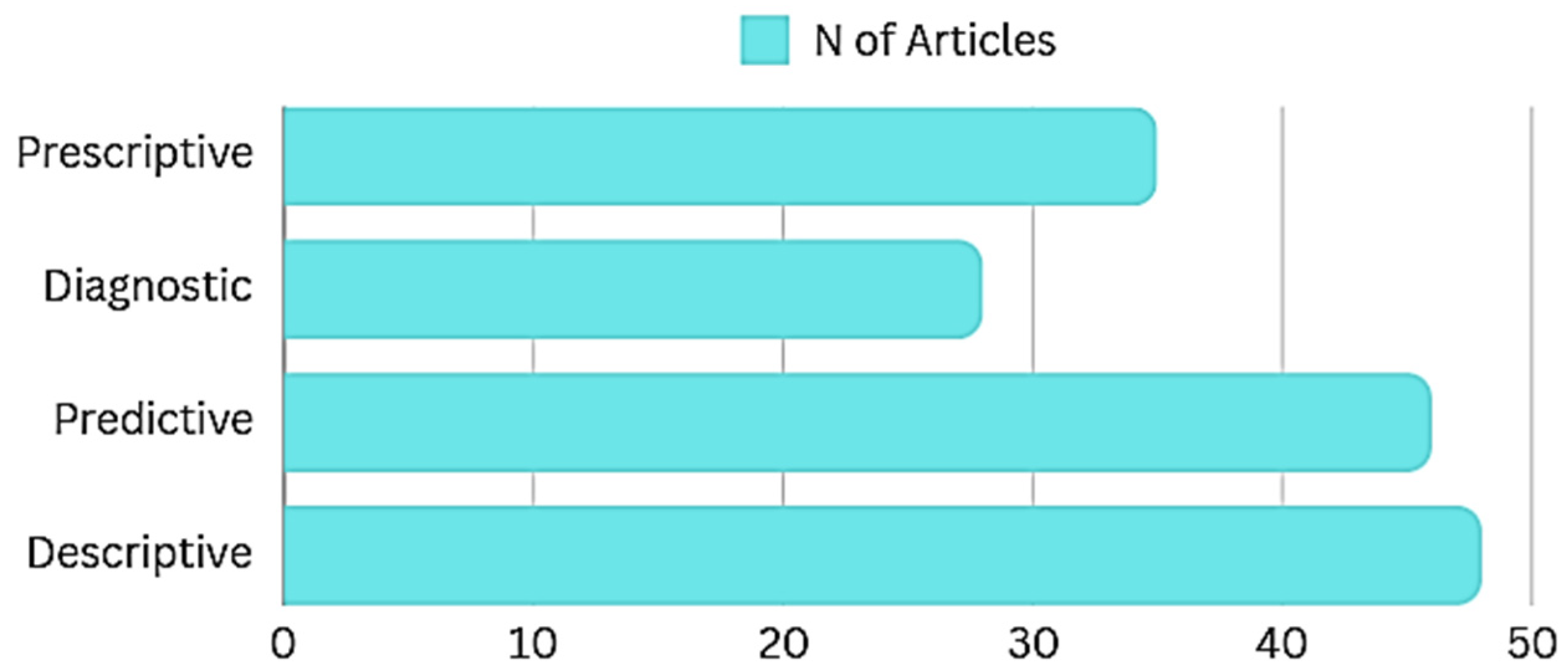

Classifying Articles Based on Common Analysis Techniques

7. Artificial Intelligence Techniques (AI)

Comparison of AI Techniques for Air Quality Prediction

8. Boosting the Implementation of Maintenance 4.0 in HVAC Systems

8.1. Existing Gaps and Challenges

8.2. Proposed Solutions for the Future

8.3. Advantages of Maintenance 4.0 in HVAC Systems

- Energy efficiency: Reduces energy consumption by optimizing HVAC operation.

- Cost savings: Minimizes unplanned downtime and maintenance costs through predictive analytics.

- Improved IAQ: Enhances IAQ by ensuring timely maintenance and performance optimization.

- Scalability: IoT-driven solutions can be integrated into smart building systems for enhanced automation.

- Addressing the existing gaps while leveraging these advantages will accelerate the adoption of Maintenance 4.0, leading to more sustainable and intelligent HVAC management.

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AI | artificial intelligence |

| ML | machine learning |

| IoT | Internet of Things |

| HVAC | heating, ventilation, and air conditioning |

| FDD | fault detection and diagnosis |

| bamss | building automation and management systems |

| TS-AC | thermal storage air-conditioning |

| IAQ | indoor air quality |

| M4.0 | Maintenance 4.0 |

| DT | digital twin |

| AHUs | air handling units |

| CHCP | central heating and cooling plant |

| AI-FADD | AI-driven fault detection and diagnosis |

| PAN | personal area networks |

| LANs | local area networks |

| WANs | wide area networks |

| BIM | building information management |

| ANN | artificial neural network |

| RNNs | recurrent neural network |

| FMM | facilities maintenance management |

| MAV | micro aerial vehicles |

References

- UNICEF. Air Pollution What is Air Pollution and How to Protect Your Family from It. Available online: https://www.unicef.org/parenting/emergencies/air-pollution (accessed on 27 November 2024).

- CDC. Mold. Available online: https://www.cdc.gov/mold-health/about/index.html (accessed on 27 November 2024).

- Resources for the Future. Investigating Air Quality in New York City Schools. Available online: https://www.rff.org/foundersday/foundersday-2023/investigating-air-quality-in-new-york-city-schools/ (accessed on 27 November 2024).

- Di Nardo, M.; Murino, T.; Cammardella, A.; Wu, J.; Song, M. Catalyzing industrial evolution: A dynamic maintenance framework for maintenance 4.0 optimization. Comput. Ind. Eng. 2024, 196, 110469. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P.; Suman, R.; Khan, S. Management 4.0: Concept, applications and advancements. Sustain. Oper. Comput. 2023, 4, 10–21. [Google Scholar] [CrossRef]

- Ibrahim, F.; Samsudin, E.Z.; Ishak, A.R.; Sathasivam, J. Hospital indoor air quality and its relationships with building design, building operation, and occupant-related factors: A mini-review. Front. Public Health 2022, 10, 1067764. [Google Scholar] [CrossRef]

- Bi, J.; Wang, H.; Yan, E.; Wang, C.; Yan, K.; Jiang, L.; Yang, B. AI in HVAC fault detection and diagnosis: A systematic review. Energy Rev. 2024, 3, 100071. [Google Scholar] [CrossRef]

- Himeur, Y.; Elnour, M.; Fadli, F.; Meskin, N.; Petri, I.; Rezgui, Y.; Bensaali, F.; Amira, A. AI-big data analytics for building automation and management systems: A survey, actual challenges and future perspectives. Artif. Intell. Rev. 2023, 56, 4929–5021. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Li, Y.; Shi, Y.; Gao, X.; Hu, Y. A review of computing-based automated fault detection and diagnosis of heating, ventilation and air conditioning systems. Renew. Sustain. Energy Rev. 2022, 161, 112395. [Google Scholar] [CrossRef]

- Tang, D.; Zhan, Y.; Yang, F. A review of machine learning for modeling air quality: Overlooked but important issues. Atmos. Res. 2024, 300, 107261. [Google Scholar] [CrossRef]

- Es-sakali, N.; Cherkaoui, M.; Mghazli, M.O.; Naimi, Z. Review of predictive maintenance algorithms applied to HVAC systems. Energy Rep. 2022, 8, 1003–1012. [Google Scholar] [CrossRef]

- Esteban, A.; Zafra, A.; Ventura, S. Data mining in predictive maintenance systems: A taxonomy and systematic review. WIREs Data Min. Knowl. Discov. 2022, 12, e1471. [Google Scholar] [CrossRef]

- Dai, X.; Shang, W.; Liu, J.; Xue, M.; Wang, C. Achieving better indoor air quality with IoT systems for future buildings: Opportunities and challenges. Sci. Total Environ. 2023, 895, 164858. [Google Scholar] [CrossRef]

- Sá, J.P.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. Application of the low-cost sensing technology for indoor air quality monitoring: A review. Environ. Technol. Innov. 2022, 28, 102551. [Google Scholar] [CrossRef]

- Nagpal, G.; Dawar, K.; Choudhury, S.R.; Singh, T. Disruption and Innovation Trends in the QSR Industry; IGI Global: Hershey, PA, USA, 2021; pp. 172–195. [Google Scholar] [CrossRef]

- Abdullah, Y.; Salem, H.; Al Ameri, H.M.A.Q.; Alnahdi, M.M.; Okasha, M.; Shaban, I.A. A Proposed Maintenance 4.0 Model for Laboratory Ventilation Systems: An Industry 4.0 Approach to Air Quality Management. In Proceedings of the 2024 IEEE Global Conference on Artificial Intelligence and Internet of Things (GCAIoT), Dubai, United Arab Emirates, 19–21 November 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Hector, I.; Panjanathan, R. Predictive maintenance in Industry 4.0: A survey of planning models and machine learning techniques. PeerJ. Comput. Sci. 2024, 10, e2016. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Wang, X.; Tan, K.; Cai, Y. Digital twin-enhanced predictive maintenance for indoor climate: A parallel LSTM-autoencoder failure prediction approach. Energy Build. 2023, 301, 113738. [Google Scholar] [CrossRef]

- Patel, M.; Vasa, J.; Patel, B. Predictive Maintenance: A Comprehensive Analysis and Future Outlook. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Belagavi, India, 24–26 November 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Zeghmar, F.; Benmansour, L.; Leila, Z.-G. Maintenance 4.0 Systems Architecture. In Journée Scientifique du département Génie Indstriel et Maintenance de l’Ecole Nationale Supérieure des Technologies Avancées; Département Génie Indstriel et Maintenance de l’Ecole Nationale Supérieure des Technologies Avancées: Alger, Algeria, 2022. [Google Scholar]

- Sanzana, M.R.; Maul, T.; Wong, J.Y.; Abdulrazic, M.O.M.; Yi, C.-C. Application of deep learning in facility management and maintenance for heating, ventilation, and air conditioning. Autom. Constr. 2022, 141, 104445. [Google Scholar] [CrossRef]

- Tian, R.; Gomez-Rosero, S.; Capretz, M.A.M. Health Prognostics Classification with Autoencoders for Predictive Maintenance of HVAC Systems. Energies 2023, 16, 7094. [Google Scholar] [CrossRef]

- Bouabdallaoui, Y.; Lafhaj, Z.; Yim, P.; Ducoulombier, L.; Bennadji, B. Predictive Maintenance in Building Facilities: A Machine Learning-Based Approach. Sensors 2021, 21, 1044. [Google Scholar] [CrossRef] [PubMed]

- Sanzana, M.R.; Abdulrazic, M.O.M.; Wong, J.Y.; Maul, T.; Yi, C.-C. Effects of external weather on the water consumption of Thermal-Energy-Storage Air-Conditioning system. Energy Nexus 2023, 10, 100187. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Svennevig, R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Nielsen, H.K.; Kraniotis, D.; Svennevig, R.; Svidt, K. Improving building occupant comfort through a digital twin approach: A Bayesian network model and predictive maintenance method. Energy Build. 2023, 288, 112992. [Google Scholar] [CrossRef]

- Zhao, X.; Yin, Y.; Zhang, S.; Xu, G. Data-driven prediction of energy consumption of district cooling systems (DCS) based on the weather forecast data. Sustain. Cities Soc. 2023, 90, 104382. [Google Scholar] [CrossRef]

- Song, Y.; Qin, S.; Qu, J.; Liu, F. The forecasting research of early warning systems for atmospheric pollutants: A case in Yangtze River Delta region. Atmos. Environ. 2015, 118, 58–69. [Google Scholar] [CrossRef]

- Ferreira, M.; Ruano, A.E.; Silva, S.; Conceição, E.Z.E. Neural networks based predictive control for thermal comfort and energy savings in public buildings. Energy Build. 2012, 55, 238–251. [Google Scholar] [CrossRef]

- Bam, R.V.P.; Gaonkar, R.S.P.; George, C.P. A machine learning framework for detection and severity estimation of faults for chillers and air handling units in HVAC systems. Energy Build. 2024, 313, 114235. [Google Scholar] [CrossRef]

- Wu, R.; Ren, Y.; Tan, M.; Nie, L. Fault diagnosis of HVAC system with imbalanced data using multi-scale convolution composite neural network. Build. Simul. 2024, 17, 371–386. [Google Scholar] [CrossRef]

- Yun, W.-S.; Hong, W.-H.; Seo, H. A data-driven fault detection and diagnosis scheme for air handling units in building HVAC systems considering undefined states. J. Build. Eng. 2021, 35, 102111. [Google Scholar] [CrossRef]

- Movahed, P.; Taheri, S.; Razban, A. A bi-level data-driven framework for fault-detection and diagnosis of HVAC systems. Appl. Energy 2023, 339, 120948. [Google Scholar] [CrossRef]

- Khan, U.; Aslam, N.; AlShedayed, R.; AlFrayan, D.; AlEssa, R.; AlShuail, N.A.; Al Safwan, A. A Proactive Attack Detection for Heating, Ventilation, and Air Conditioning (HVAC) System Using Explainable Extreme Gradient Boosting Model (XGBoost). Sensors 2022, 22, 9235. [Google Scholar] [CrossRef] [PubMed]

- Elnour, M.; Meskin, N. Novel Actuator Fault Diagnosis Framework for Multizone HVAC Systems Using 2-D Convolutional Neural Networks. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1985–1996. [Google Scholar] [CrossRef]

- Yang, C.; Gunay, B.; Shi, Z.; Shen, W. Machine Learning-Based Prognostics for Central Heating and Cooling Plant Equipment Health Monitoring. IEEE Trans. Autom. Sci. Eng. 2021, 18, 346–355. [Google Scholar] [CrossRef]

- Chen, K.; Chen, S.; Zhu, X.; Jin, X.; Du, Z. Interpretable mechanism mining enhanced deep learning for fault diagnosis of heating, ventilation and air conditioning systems. Build. Environ. 2023, 237, 110328. [Google Scholar] [CrossRef]

- Albayati, M.G.; Faraj, J.; Thompson, A.; Patil, P.; Gorthala, R.; Rajasekaran, S. Semi-Supervised Machine Learning for Fault Detection and Diagnosis of a Rooftop Unit. Big Data Min. Anal. 2023, 6, 170–184. [Google Scholar] [CrossRef]

- Martinez-Viol, V.; Urbano, E.M.; Rangel, J.E.T.; Delgado-Prieto, M.; Romeral, L. Semi-Supervised Transfer Learning Methodology for Fault Detection and Diagnosis in Air-Handling Units. Appl. Sci. 2022, 12, 8837. [Google Scholar] [CrossRef]

- Lee, D.; Lai, C.-W.; Liao, K.-K.; Chang, J.-W. Artificial intelligence assisted false alarm detection and diagnosis system development for reducing maintenance cost of chillers at the data centre. J. Build. Eng. 2021, 36, 102110. [Google Scholar] [CrossRef]

- Dixit, S.; Verma, N.K.; Ghosh, A.K. Intelligent Fault Diagnosis of Rotary Machines: Conditional Auxiliary Classifier GAN Coupled with Meta Learning Using Limited Data. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Albayati, M.G.; De Oliveira, J.; Patil, P.; Gorthala, R.; Thompson, A.E. A market study of early adopters of fault detection and diagnosis tools for rooftop HVAC systems. Energy Rep. 2022, 8, 14915–14933. [Google Scholar] [CrossRef]

- Deng, Z.; Chen, Q. Development and validation of a smart HVAC control system for multi-occupant offices by using occupants’ physiological signals from wristband. Energy Build. 2020, 214, 109872. [Google Scholar] [CrossRef]

- Peng, C.; Qian, K. Development and Application of a ZigBee-Based Building Energy Monitoring and Control System. Sci. World J. 2014, 2014, 528410. [Google Scholar] [CrossRef]

- Ala’raj, M.; Radi, M.; Abbod, M.F.; Majdalawieh, M.; Parodi, M. Data-driven based HVAC optimisation approaches: A Systematic Literature Review. J. Build. Eng. 2022, 46, 103678. [Google Scholar] [CrossRef]

- Longares, M.; Mselle, B.D.; Galindo, J.I.G.; Ballestin, V. Dynamic Indoor Environmental Quality Assessment in Residential Buildings: Real-Time Monitoring of Comfort Parameters Using LoRaWAN. Energies 2024, 17, 5534. [Google Scholar] [CrossRef]

- Lo, Y.W.; Tsoi, M.H.; Chow, C.; Mung, S.W.Y. A NB-IoT Monitoring System for Digital Mobile Radio with Industrial IoT Performance and Reliability Evaluation. IEEE Sens. J. 2024, 25, 5337–5348. [Google Scholar] [CrossRef]

- Minoli, D.; Occhiogrosso, B. Practical Aspects for the Integration of 5G Networks and IoT Applications in Smart Cities Environments. Wirel. Commun. Mob. Comput. 2019, 2019, 5710834. [Google Scholar] [CrossRef]

- Espejel-Blanco, D.F.; Hoyo-Montano, J.A.; Arau, J.; Valencia-Palomo, G.; Garcia-Barrientos, A.; Hernandez-De-Leon, H.R.; Camas-Anzueto, J.L. HVAC Control System Using Predicted Mean Vote Index for Energy Savings in Buildings. Buildings 2022, 12, 38. [Google Scholar] [CrossRef]

- Jones, C.B.; Carter, C. Trusted Interconnections Between a Centralized Controller and Commercial Building HVAC Systems for Reliable Demand Response. IEEE Access 2017, 5, 11063–11073. [Google Scholar] [CrossRef]

- Bainomugisha, E.; Ssematimba, J.; Okure, D. Design Considerations for a Distributed Low-Cost Air Quality Sensing System for Urban Environments in Low-Resource Settings. Atmosphere 2023, 14, 354. [Google Scholar] [CrossRef]

- Basmaji, T.; Yaghi, M.; Alhalabi, M.; Rashed, A.; Zia, H.; Mahmoud, M.; Palavar, P.; Alkhadhar, S.; Alhmoudi, H.; Ghazal, M. AI-powered health monitoring of anode baking furnace pits in aluminum production using autonomous drones. Eng. Appl. Artif. Intell. 2023, 122, 106143. [Google Scholar] [CrossRef]

- Saravanan, D.; Kumar, K.S. Improving air pollution detection accuracy and quality monitoring based on bidirectional RNN and the Internet of Things. Mater. Today Proc. 2023, 81, 791–796. [Google Scholar] [CrossRef]

- Tancev, G. Relevance of Drift Components and Unit-to-Unit Variability in the Predictive Maintenance of Low-Cost Electrochemical Sensor Systems in Air Quality Monitoring. Sensors 2021, 21, 3298. [Google Scholar] [CrossRef]

- Villa, V.; Bruno, G.; Aliev, K.; Piantanida, P.; Corneli, A.; Antonelli, D. Machine Learning Framework for the Sustainable Maintenance of Building Facilities. Sustainability 2022, 14, 681. [Google Scholar] [CrossRef]

- Dutta, S.M.; Marques, G. A comprehensive review on indoor air quality monitoring systems for enhanced public health. Sustain. Environ. Res. 2020, 30, 6. [Google Scholar] [CrossRef]

- Vajs, I.; Drajic, D.; Cica, Z. Data-Driven Machine Learning Calibration Propagation in A Hybrid Sensor Network for Air Quality Monitoring. Sensors 2023, 23, 2815. [Google Scholar] [CrossRef]

- Marques, G.; Saini, J.; Dutta, M.; Singh, K.; Hong, W.-C. Indoor Air Quality Monitoring Systems for Enhanced Living Environments: A Review toward Sustainable Smart Cities. Sustainability 2020, 12, 4024. [Google Scholar] [CrossRef]

- Dey, M.; Rana, S.P.; Dudley, S. Smart building creation in large scale HVAC environments through automated fault detection and diagnosis. Future Gener. Comput. Syst. 2020, 108, 950–966. [Google Scholar] [CrossRef]

- Von Clarmann, T.; Degenstein, D.A.; Livesey, N.J.; Bender, S.; Braverman, A.; Butz, A.; Compernolle, S.; Damadeo, R.; Dueck, S.; Zawada, D.; et al. Overview: Estimating and reporting uncertainties in remotely sensed atmospheric composition and temperature. Atmos. Meas. Tech. 2020, 13, 4393–4436. [Google Scholar] [CrossRef]

- Dutta, S.M.; Marques, G. Indoor Air Quality Monitoring Systems Based on Internet of Things: A Systematic Review. Int. J. Environ. Res. Public Health 2020, 17, 4942. [Google Scholar] [CrossRef]

- Vajs, I.; Drajic, D.; Gligoric, N.; Radovanovic, I.; Popovic, I. Developing Relative Humidity and Temperature Corrections for Low-Cost Sensors Using Machine Learning. Sensors 2021, 21, 3338. [Google Scholar] [CrossRef]

- Tancev, G.; Toro, F.G. Variational Bayesian calibration of low-cost gas sensor systems in air quality monitoring. Meas. Sens. 2022, 19, 100365. [Google Scholar] [CrossRef]

- Dutta, S.M.; Marques, G. Modeling indoor PM2.5 using Adaptive Dynamic Fuzzy Inference System Tree (ADFIST) on Internet of Things-based sensor network data. Internet Things 2022, 20, 100628. [Google Scholar] [CrossRef]

- Cavaliere, A.; Carotenuto, F.; Di Gennaro, F.; Gioli, B.; Gualtieri, G.; Martelli, F.; Matese, A.; Toscano, P.; Vagnoli, C.; Zaldei, A.; et al. Development of Low-Cost Air Quality Stations for Next Generation Monitoring Networks: Calibration and Validation of PM2.5 and PM10 Sensors. Sensors 2018, 18, 2843. [Google Scholar] [CrossRef]

- Wu, K.; Tsang, K.F.; Liu, Y.; Wang, H.; Zhu, H.; Koo, C.H.; Wan, W.H.; Wei, Y. An IoT Tree Health Indexing Method Using Heterogeneous Neural Network. IEEE Access 2019, 7, 66176–66184. [Google Scholar] [CrossRef]

- Topalović, B.; Davidović, M.D.; Jovanović, M.; Bartonova, A.; Ristovski, Z.; Jovašević-Stojanović, M. In search of an optimal in-field calibration method of low-cost gas sensors for ambient air pollutants: Comparison of linear, multilinear and artificial neural network approaches. Atmos. Environ. 2019, 213, 640–658. [Google Scholar] [CrossRef]

- Marques, G.; Pires, I.M.; Miranda, N.; Pitarma, R. Air Quality Monitoring Using Assistive Robots for Ambient Assisted Living and Enhanced Living Environments through Internet of Things. Electronics 2019, 8, 1375. [Google Scholar] [CrossRef]

- Muñiz, R.; Nuño, F.; Díaz, J.; González, M.; Prieto, M.J.; Menéndez, Ó. Real-time monitoring solution with vibration analysis for industry 4.0 ventilation systems. J. Supercomput. 2023, 79, 6203–6227. [Google Scholar] [CrossRef]

- Sharma, S.; Tanwar, P.; Yadav, A.; Sairam, B.K.; Jaswal, S. Critical Review of Air Quality Prediction using Machine Learning Techniques. In Proceedings of the 2022 Sixth International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Dharan, Nepal, 10–12 November 2022; pp. 1–7. [Google Scholar] [CrossRef]

- Palanisamy, S.K.A.; Rajangam, S.; Saminathan, J. Experimental investigation to identify the effect of nanoparticles based diesel fuel in VCR engine. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 9709–9723. [Google Scholar] [CrossRef]

- Gatti, R.C.; Velichevskaya, A.; Tateo, A.; Amoroso, N.; Monaco, A. Machine learning reveals that prolonged exposure to air pollution is associated with SARS-CoV-2 mortality and infectivity in Italy. Environ. Pollut. 2020, 267, 115471. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, R.; Jayaratne, R.; Morawska, L. A study on extending the use of air quality monitor data via deep learning techniques. J. Clean Prod. 2020, 274, 122956. [Google Scholar] [CrossRef]

- Wen, S.; Zou, H.; Liu, J.; Evrendilek, D.E.; Yan, Y.; Liang, G. Multi-response optimization toward efficient and clean (co-) combustions of textile dyeing sludge and second-generation feedstock. J. Hazard. Mater. 2021, 408, 124824. [Google Scholar] [CrossRef]

- Han, S.; Kundhikanjana, W.; Towashiraporn, P.; Stratoulias, D. Interpolation-Based Fusion of Sentinel-5P, SRTM, and Regulatory-Grade Ground Stations Data for Producing Spatially Continuous Maps of PM2.5 Concentrations Nationwide over Thailand. Atmosphere 2022, 13, 161. [Google Scholar] [CrossRef]

- Singh, D.; Dahiya, M.; Kumar, R.; Nanda, C. Sensors and systems for air quality assessment monitoring and management: A review. J. Environ. Manag. 2021, 289, 112510. [Google Scholar] [CrossRef]

- Xia, Y.; Jiang, L.; Wang, L.; Chen, X.; Ye, J.; Hou, T.; Wang, L.; Zhang, Y.; Li, M.; Yu, S. Rapid assessments of light-duty gasoline vehicle emissions using on-road remote sensing and machine learning. Sci. Total Environ. 2022, 815, 152771. [Google Scholar] [CrossRef]

- Saravanan, D.; Kumar, K.S. IoT based improved air quality index prediction using hybrid FA-ANN-ARMA model. Mater. Today Proc. 2022, 56, 1809–1819. [Google Scholar] [CrossRef]

- Laughner, L.; Roche, S.; Kiel, M.; Toon, G.C.; Wunch, D.; Baier, B.C.; Biraud, S.; Chen, H.; Kivi, R.; Wennberg, P.O.; et al. A new algorithm to generate a priori trace gas profiles for the GGG2020 retrieval algorithm. Atmos. Meas. Tech. 2023, 16, 1121–1146. [Google Scholar] [CrossRef]

- Seo, J.; Lim, Y.; Han, J.; Park, S. Machine learning-based estimation of gaseous and particulate emissions using internally observable vehicle operating parameters. Urban Clim. 2023, 52, 101734. [Google Scholar] [CrossRef]

- Lu, Y.; Li, K. Multistation collaborative prediction of air pollutants based on the CNN-BiLSTM model. Environ. Sci. Pollut. Res. 2023, 30, 92417–92435. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, K.; He, Y.; Fu, Q.; Luo, W.; Li, W.; Liu, X.; Wang, P.; Xiao, S. Research on Missing Value Imputation to Improve the Validity of Air Quality Data Evaluation on the Qinghai-Tibetan Plateau. Atmosphere 2023, 14, 1821. [Google Scholar] [CrossRef]

- Dimitroulopoulou, S.; Dudzińska, M.R.; Gunnarsen, L.; Hägerhed, L.; Maula, H.; Singh, R.; Toyinbo, O.; Haverinen-Shaughnessy, U. Indoor air quality guidelines from across the world: An appraisal considering energy saving, health, productivity, and comfort. Environ. Int. 2023, 178, 108127. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Noman, H. Predicting CO2 Emission Footprint Using AI through Machine Learning. Atmosphere 2022, 13, 1871. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E.; Mohamed, A.G. Indoor air quality for sustainable building renovation: A decision-support assessment system using structural equation modelling. Build. Environ. 2022, 214, 108933. [Google Scholar] [CrossRef]

- D’Elia, G.; Ferro, M.; Sommella, P.; De Vito, S.; Ferlito, S.; D’Auria, P.; Di Francia, G. Influence of Concept Drift on Metrological Performance of Low-Cost NO 2 Sensors. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Tao, S.; Sun, Z.; Lin, X.; Zhang, Z.; Wu, C.; Zhang, Z.; Zhou, B.; Zhao, Z.; Cao, C.; Xu, Y.; et al. Negative Air Ion (NAI) Dynamics over Zhejiang Province, China, Based on Multivariate Remote Sensing Products. Remote Sens. 2023, 15, 738. [Google Scholar] [CrossRef]

- Zheng, Q.; Tian, X.; Yu, Z.; Jin, B.; Jiang, N.; Ding, Y.; Yang, M.; Elhanashi, A.; Saponara, S.; Kpalma, K. Application of complete ensemble empirical mode decomposition based multi-stream informer (CEEMD-MsI) in PM2.5 concentration long-term prediction. Expert. Syst. Appl. 2024, 245, 123008. [Google Scholar] [CrossRef]

- Alhasa, M.; Nadzir, M.S.M.; Olalekan, P.; Latif, M.T.; Yusup, Y.; Faruque, M.R.I.; Ahamad, F.; Hamid, H.H.A.; Aiyub, K.; Ali, S.H.M.; et al. Calibration Model of a Low-Cost Air Quality Sensor Using an Adaptive Neuro-Fuzzy Inference System. Sensors 2018, 18, 4380. [Google Scholar] [CrossRef] [PubMed]

- Karagulian, F.; Attouch, M.; Mastefaoui, Z.; Laksaci, A. Review of the Performance of Low-Cost Sensors for Air Quality Monitoring. Atmosphere 2019, 10, 506. [Google Scholar] [CrossRef]

- Kaid, Z. Prediction of maximum ozone concentration using big data models. Appl. Ecol. Environ. Res. 2019, 17, 14231–14239. [Google Scholar] [CrossRef]

- Bekesiene, S.; Meidute-Kavaliauskiene, I. Artificial Neural Networks for Modelling and Predicting Urban Air Pollutants: Case of Lithuania. Sustainability 2022, 14, 2470. [Google Scholar] [CrossRef]

- Gryech, C.; Asaad, M.; Ghogho, M.; Kobbane, A. Applications of machine learning & Internet of Things for outdoor air pollution monitoring and prediction: A systematic literature review. Eng. Appl. Artif. Intell. 2024, 137, 109182. [Google Scholar] [CrossRef]

- Samad, A.; Garuda, S.; Vogt, U.; Yang, B. Air pollution prediction using machine learning techniques—An approach to replace existing monitoring stations with virtual monitoring stations. Atmos. Environ. 2023, 310, 119987. [Google Scholar] [CrossRef]

- Li, J.; Dong, J.; Chen, Z.; Li, X.; Yi, X.; Niu, G.; Lu, S.; Ke, Y.; Huang, M. Free nitrous acid prediction in ANAMMOX process using hybrid deep neural network model. J. Environ. Manag. 2023, 345, 118566. [Google Scholar] [CrossRef]

- Marques, G.; Pitarma, R. Particulate Matter Monitoring and Assessment through Internet of Things: A Health Information System for Enhanced Living Environments. J. Med. Syst. 2020, 44, 207. [Google Scholar] [CrossRef] [PubMed]

- Yen, Y.; Chang, J.-W.; Liao, J.-Y.; Yong, Y.-M. Analysis of interpolation algorithms for the missing values in IoT time series: A case of air quality in Taiwan. J. Supercomput. 2020, 76, 6475–6500. [Google Scholar] [CrossRef]

- Nam, K.; Heo, S.; Li, Q.; Loy-Benitez, J.; Kim, M.; Park, D.; Yoo, C. A proactive energy-efficient optimal ventilation system using artificial intelligent techniques under outdoor air quality conditions. Appl. Energy 2020, 266, 114893. [Google Scholar] [CrossRef]

- Chang, E.; Zhang, K.; Paczkowski, M.; Kohler, S.; Ribeiro, M. Association of temporary Environmental Protection Agency regulation suspension with industrial economic viability and local air quality in California, United States. Environ. Sci. Eur. 2021, 33, 52. [Google Scholar] [CrossRef]

- Giordano, R.; Malings, C.; Pandis, S.N.; Presto, A.A.; McNeill, V.; Westervelt, D.M.; Beekmann, M.; Subramanian, R. From low-cost sensors to high-quality data: A summary of challenges and best practices for effectively calibrating low-cost particulate matter mass sensors. J. Aerosol. Sci. 2021, 158, 105833. [Google Scholar] [CrossRef]

- Banach, R.; Długosz, T.; Talaśka, T.; Pedrycz, W. Air Pollution Monitoring System with Prediction Abilities Based on Smart Autonomous Sensors Equipped with ANNs with Novel Training Scheme. Remote Sens. 2022, 14, 413. [Google Scholar] [CrossRef]

- Adong, P.; Bainomugisha, E.; Okure, D.; Sserunjogi, R. Applying machine learning for large scale field calibration of low-cost PM 2.5 and PM 10 air pollution sensors. Appl. AI Lett. 2022, 3, e76. [Google Scholar] [CrossRef]

- Scowen, M.; Athanasiadis, I.N.; Bullock, J.M.; Eigenbrod, F.; Willcock, S. The current and future uses of machine learning in ecosystem service research. Sci. Total Environ. 2021, 799, 149263. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Gao, F.; Liao, S.; Li, S. Unraveling the association between the built environment and air pollution from a geospatial perspective. J. Clean Prod. 2023, 386, 135768. [Google Scholar] [CrossRef]

- Ren, C.; Zhu, H.-C.; Wang, J.; Feng, Z.; Chen, G.; Haghighat, F.; Cao, S.-J. Intelligent operation, maintenance, and control system for public building: Towards infection risk mitigation and energy efficiency. Sustain. Cities Soc. 2023, 93, 104533. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Y.; Liu, L.; Liu, Z.; Wu, H. Monitoring global cement plants from space. Remote Sens. Environ. 2024, 302, 113954. [Google Scholar] [CrossRef]

- Mohammadi, F.; Teiri, H.; Hajizadeh, Y.; Abdolahnejad, A.; Ebrahimi, A. Prediction of atmospheric PM2.5 level by machine learning techniques in Isfahan, Iran. Sci. Rep. 2024, 14, 2109. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, H.; Ma, Y.; Wang, Y.; Abokifa, A.A.; Lu, C.; Biswas, P. Spatiotemporal distribution of indoor particulate matter concentration with a low-cost sensor network. Build. Environ. 2018, 127, 138–147. [Google Scholar] [CrossRef]

- Schneising, O.; Buchwitz, M.; Reuter, M.; Bovensmann, H.; Burrows, J.P.; Borsdorff, T.; Deutscher, N.M.; Feist, D.G.; Griffith, D.W.T.; Wunch, D.; et al. A scientific algorithm to simultaneously retrieve carbon monoxide and methane from TROPOMI onboard Sentinel-5 Precursor. Atmos. Meas. Tech. 2019, 12, 6771–6802. [Google Scholar] [CrossRef]

- Taheri, S.; Ahmadi, A.; Mohammadi-Ivatloo, B.; Asadi, S. Fault detection diagnostic for HVAC systems via deep learning algorithms. Energy Build. 2021, 250, 111275. [Google Scholar] [CrossRef]

- Ulpiani, G.; Nazarian, N.; Zhang, F.; Pettit, C.J. Towards a Living Lab for Enhanced Thermal Comfort and Air Quality: Analyses of Standard Occupancy, Weather Extremes, and COVID-19 Pandemic. Front. Environ. Sci. 2021, 9, 725974. [Google Scholar] [CrossRef]

- Cui, C.; Liu, Y. A hierarchical HVAC optimal control method for reducing energy consumption and improving indoor air quality incorporating soft Actor-Critic and hybrid search optimization. Energy Convers. Manag. 2024, 302, 118118. [Google Scholar] [CrossRef]

- Basavaraju, A.; Du, J.; Zhou, F.; Ji, J. A Machine Learning Approach to Road Surface Anomaly Assessment Using Smartphone Sensors. IEEE Sens. J. 2020, 20, 2635–2647. [Google Scholar] [CrossRef]

- Ortiz, A.; Bonnin-Pascual, F.; Garcia-Fidalgo, E.; Company-Corcoles, J. Vision-Based Corrosion Detection Assisted by a Micro-Aerial Vehicle in a Vessel Inspection Application. Sensors 2016, 16, 2118. [Google Scholar] [CrossRef]

- Neo, E.X.; Hasikin, K.; Lai, K.W.; Mokhtar, M.I.; Azizan, M.M.; Hizaddin, H.F.; Razak, S.A. Artificial intelligence-assisted air quality monitoring for smart city management. PeerJ. Comput. Sci. 2023, 9, e1306. [Google Scholar] [CrossRef]

- Czabanski, R.; Jezewski, M.; Leski, J. Introduction to Fuzzy Systems; Springer: Cham, Stitzerland, 2017; pp. 23–43. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, F.; Hsieh, H.-P. U-Air. In Proceedings of the 19th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 11–14 August 2013; ACM: New York, NY, USA, 2013; pp. 1436–1444. [Google Scholar] [CrossRef]

| Research | Focus on IAQ and Monitoring | Focus on Building Automation, Maintenance, and Optimization |

|---|---|---|

| [18] | ✔ | |

| [51] | ✔ | |

| [52] | ✔ | |

| [53] | ✔ | |

| [54] | ✔ | |

| [26] | ✔ | |

| [22] | ✔ | |

| [25] | ✔ | |

| [34] | ✔ | |

| [55] | ✔ | |

| [23] | ✔ |

| Article | Citations | Research Focus | Gaps |

|---|---|---|---|

| [29] | 359 | Development and application of a model-based predictive control methodology for HVAC systems in buildings to optimize thermal comfort and minimize energy consumption. |

|

| [113] | 133 | Utilizing ML techniques for classifying road anomalies based on smartphone sensor data. |

|

| [25] | 115 | Optimize predictive maintenance and dynamic maintenance strategies in FMM processes. |

|

| [108] | 102 | Evaluating the effectiveness of a sensor network platform for real-time monitoring of indoor aerosol concentrations. |

|

| [109] | 94 | Developing a scientific algorithm to simultaneously retrieve XCO and XCH4 from shortwave infrared spectra recorded by the TROPOMI instrument onboard the Sentinel-5 Precursor satellite. |

|

| [40] | 88 | Developing a generic framework for predictive maintenance in buildings, incorporating literature review, interviews with FM experts, and case study demonstration. |

|

| [18] | 75 | Proposing a data-driven FDD scheme for AHU, specifically addressing undefined states to enhance maintenance reliability. |

|

| [59] | 72 | Development of a feature extraction technique for temperature and power data in TU systems, enabling automatic fault prediction and diagnosis. |

|

| [114] | 71 | Development of a semi-autonomous micro aerial vehicle (MAV) system equipped with image capture capabilities and neural network-based CBC detection for vessel structures. |

|

| [67] | 65 | Evaluating calibration methods for air pollution low-cost multi-sensor platforms, comparing LR, MLR, and ANN techniques. |

|

| AI Technique | Description | Strengths | Limitations | Example Applications |

|---|---|---|---|---|

| Traditional machine learning | Includes models like ANN, linear, and logistic regression. | Relatively simple to implement; suitable for initial exploration of relationships. | Limited capacity to capture complex, non-linear environmental relationships; often requires extensive feature engineering for optimal performance. | Predicting air quality index and pollutant concentrations [48]; air quality forecasting using decision tree [111]. |

| Advanced machine learning | Includes models like Ada Boost, SVR, RF, KNN, and MLP regressor. | More sophisticated; can capture complex relationships with less feature engineering; adaptable to dynamic environmental conditions. | May require larger datasets for training; interpretability of complex models can be challenging. | Air quality prediction in smart cities using LSTM model [110]. |

| Hybrid deep learning | Combines multiple deep learning architectures, such as CNN-BiLSTM, for enhanced accuracy and predictive capabilities. | Can achieve high accuracy for a wide range of pollutants; effective for multi-step-ahead forecasting. | Limitations in predicting specific pollutants (e.g., primary pollutants like NO2, SO2, and CO) may require further model refinement. | Pollutant concentration prediction using CNN-BiLSTM in Tianjin, China [74]. |

| Decentralized AI networks | Employs a network of smart sensors, each equipped with an ANN, for localized prediction and adaptable forecasting. | Captures local microclimates and urban environments effectively; adaptable to changing conditions; enhances responsiveness to local variations. | Requires coordination and management of multiple sensors; data synchronization and communication between sensors can be challenging. | Real-time air quality monitoring and prediction in urban environments [94]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaban, I.A.; Salem, H.; Abdullah, A.Y.; Ameri, H.M.A.Q.A.; Alnahdi, M.M. Maintenance 4.0 for HVAC Systems: Addressing Implementation Challenges and Research Gaps. Smart Cities 2025, 8, 66. https://doi.org/10.3390/smartcities8020066

Shaban IA, Salem H, Abdullah AY, Ameri HMAQA, Alnahdi MM. Maintenance 4.0 for HVAC Systems: Addressing Implementation Challenges and Research Gaps. Smart Cities. 2025; 8(2):66. https://doi.org/10.3390/smartcities8020066

Chicago/Turabian StyleShaban, Ibrahim Abdelfadeel, HossamEldin Salem, Ammar Yaser Abdullah, Hazza Muhsen Abdoul Qader Al Ameri, and Mansoor Mohammed Alnahdi. 2025. "Maintenance 4.0 for HVAC Systems: Addressing Implementation Challenges and Research Gaps" Smart Cities 8, no. 2: 66. https://doi.org/10.3390/smartcities8020066

APA StyleShaban, I. A., Salem, H., Abdullah, A. Y., Ameri, H. M. A. Q. A., & Alnahdi, M. M. (2025). Maintenance 4.0 for HVAC Systems: Addressing Implementation Challenges and Research Gaps. Smart Cities, 8(2), 66. https://doi.org/10.3390/smartcities8020066