Development of Floor Structures with Crumb Rubber for Efficient Floor Impact Noise Reduction

Abstract

1. Introduction

2. Floor Structure with Crumb Rubber as Resilient Material

2.1. Crumb Rubber as Resilient Material

2.1.1. Residual Deformation Measurement

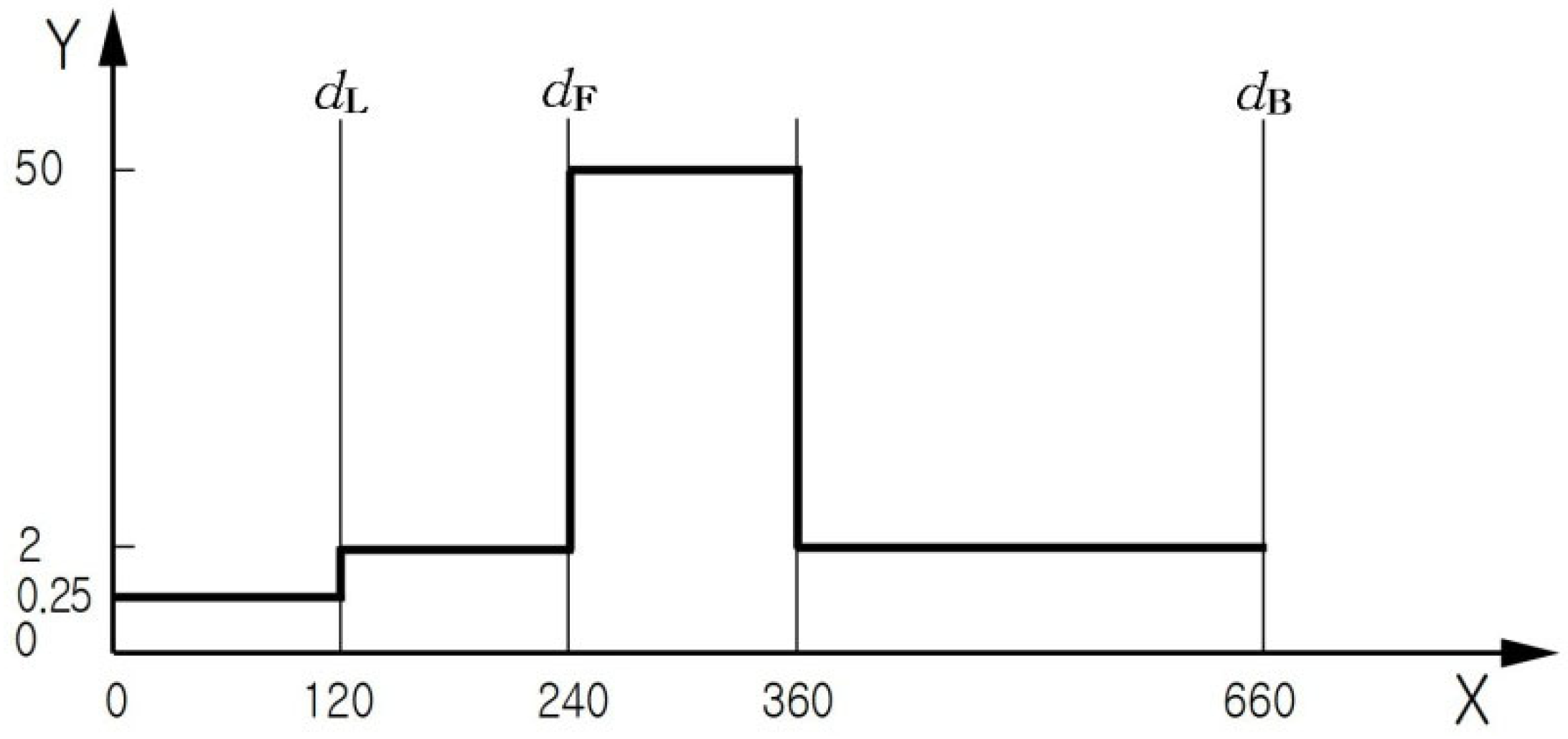

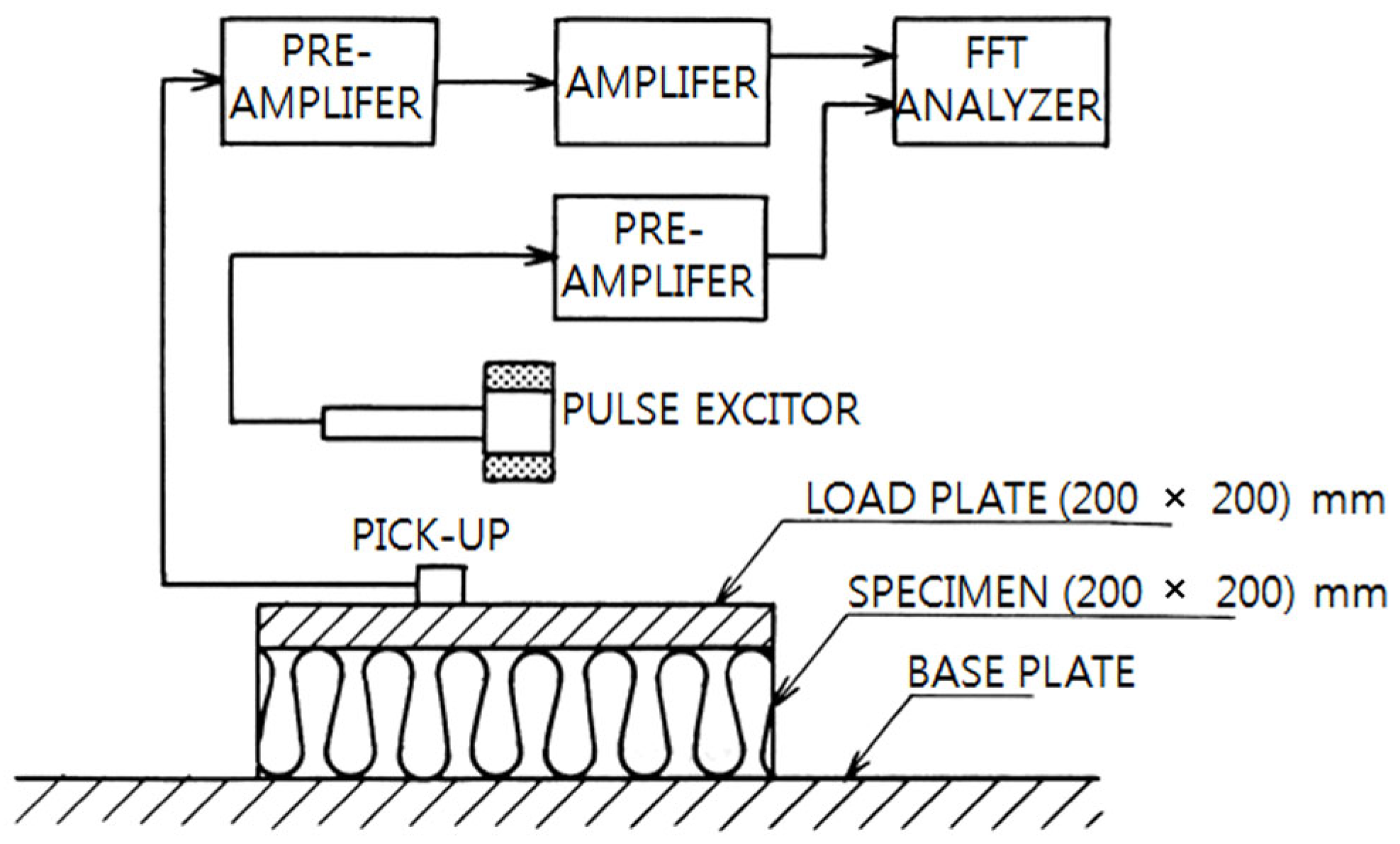

2.1.2. Dynamic Stiffness Measurement

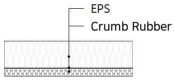

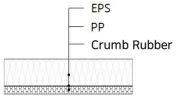

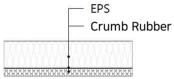

2.2. Floor Structures

3. Experiment

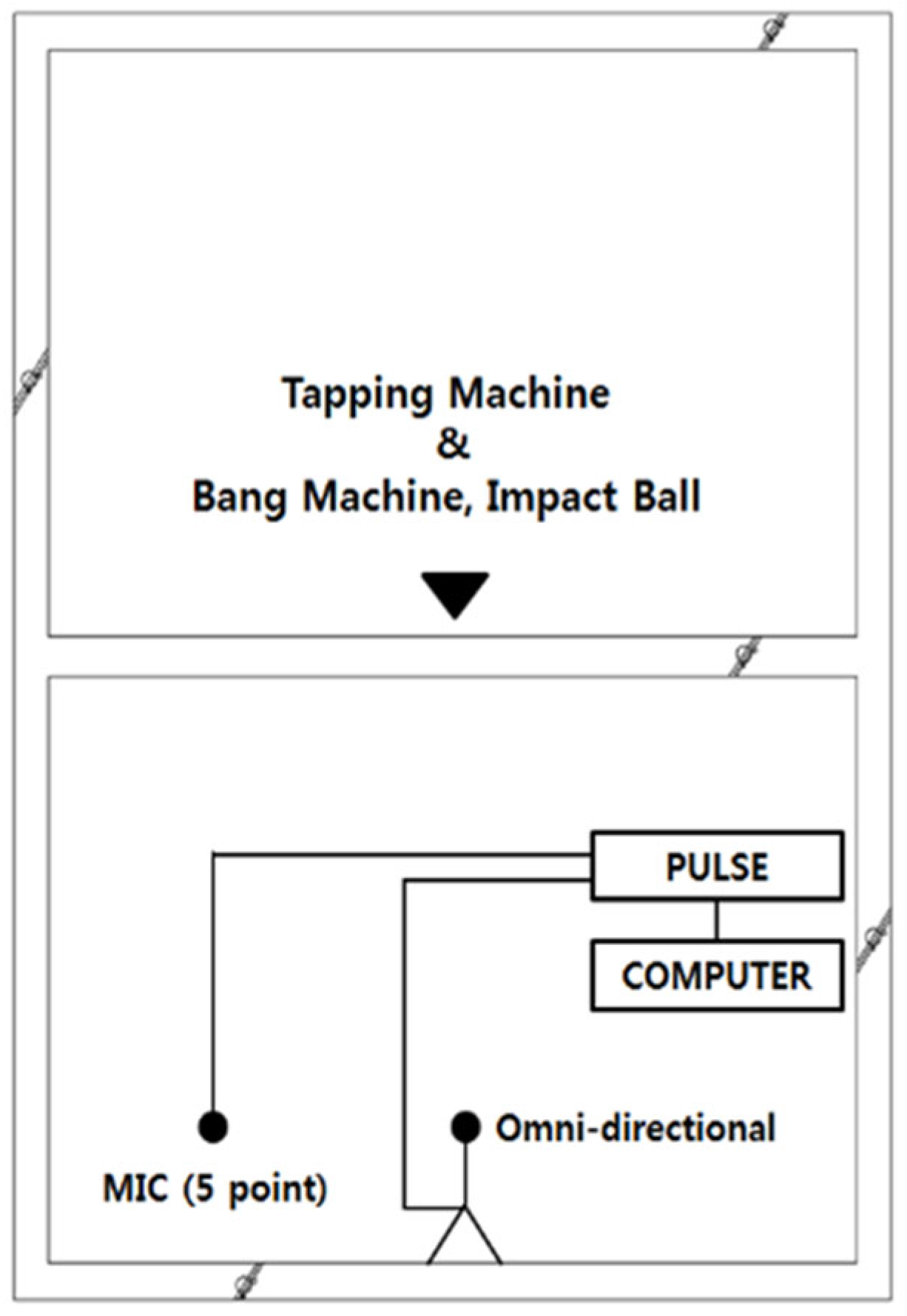

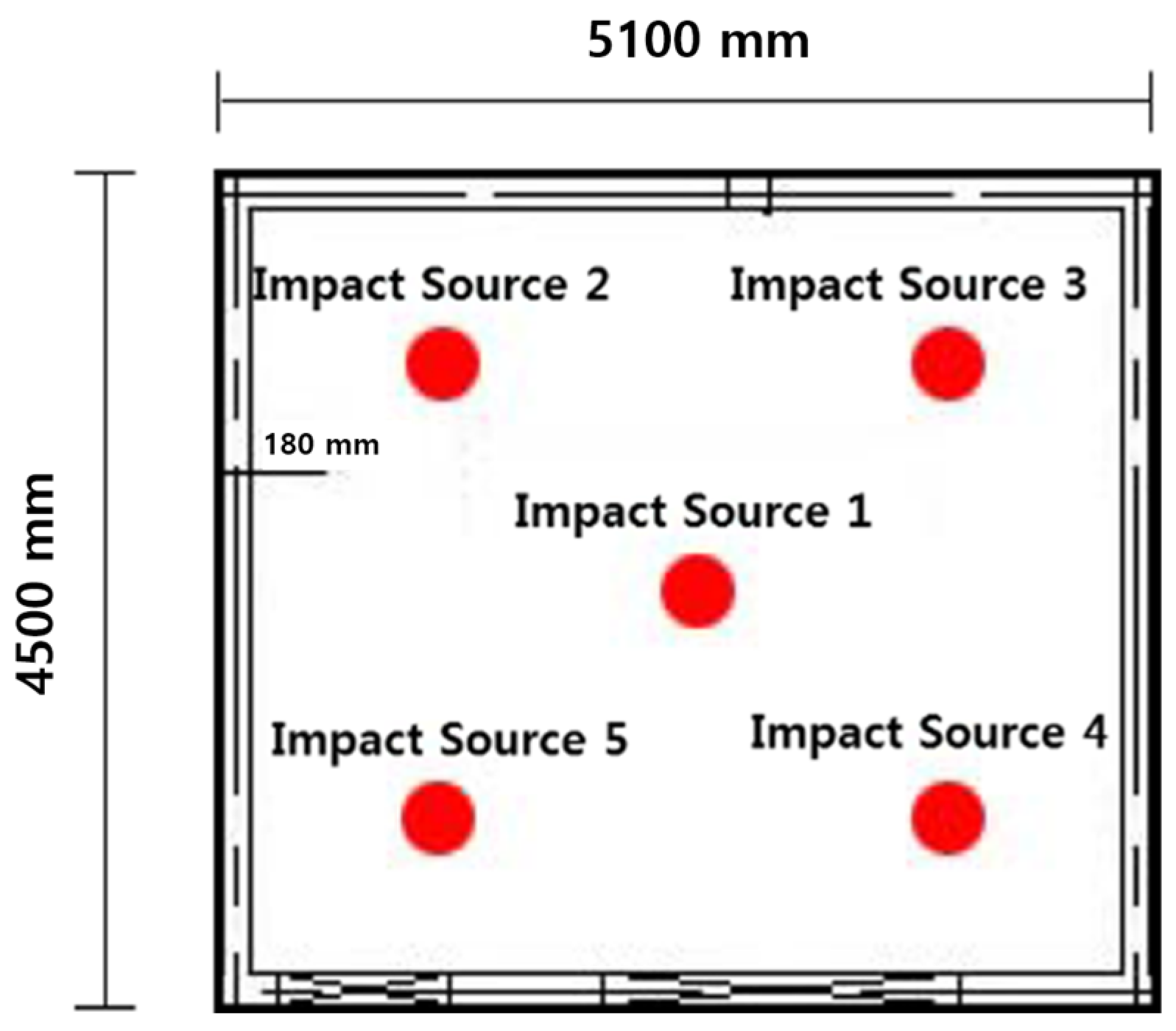

3.1. Classification of Standard Test Room

3.2. Methods of Experiment

3.3. Floor Impact Noise Standards of Korea

4. Results and Discussions

4.1. Floor Impact Noise Levels by Standard Light-Weight Impact Source (Tapping Machine)

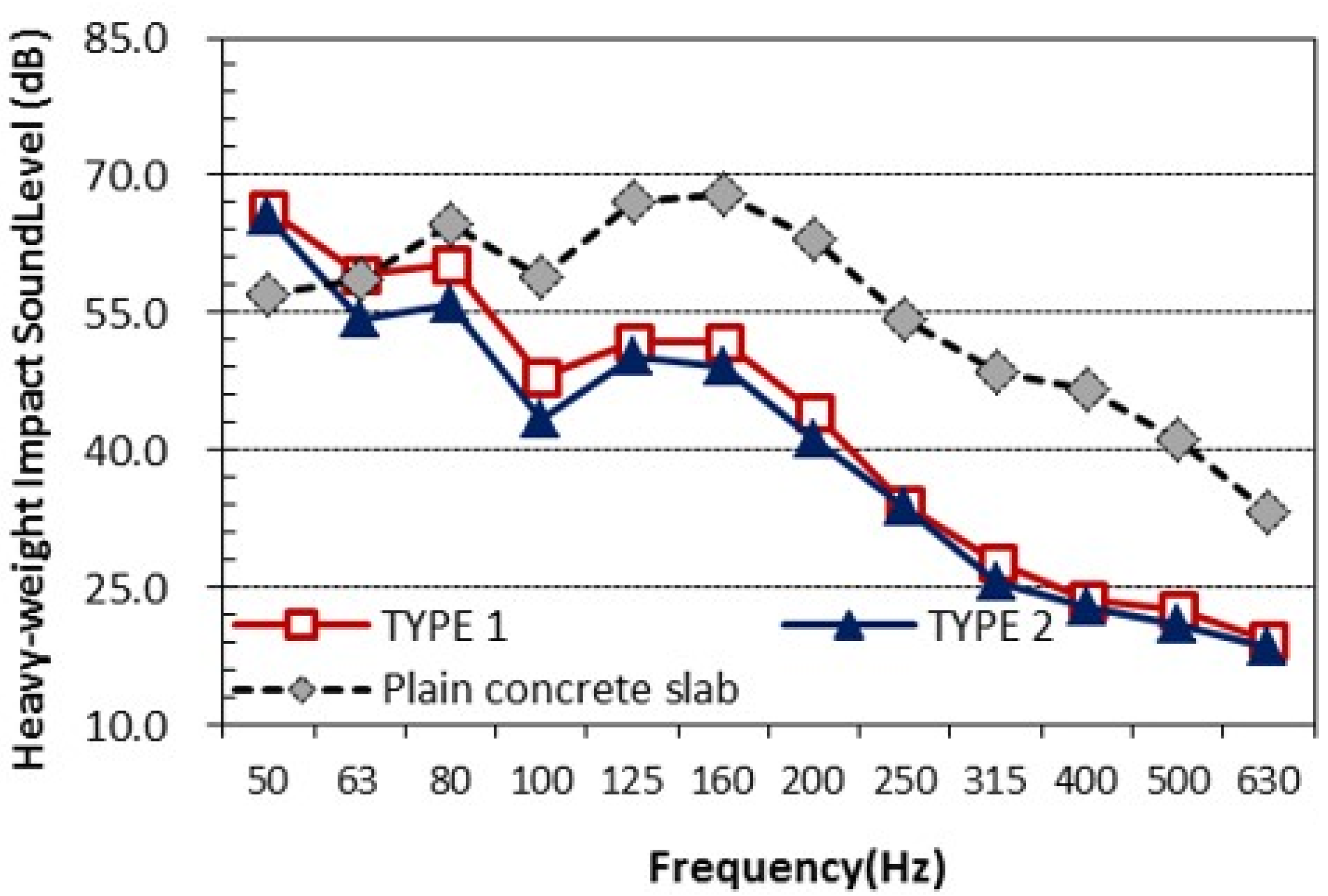

4.2. Floor Impact Noise Levels by Standard Heavy-Weight Impact Sources

4.2.1. Bang Machine

4.2.2. Impact Ball

4.3. Performance Grade of Floor Impact Noise of Resilient Material Utilizing Crumb Rubber

5. Conclusions

- (1)

- When the standard impact source was excited, the reduction performance of the resilient material of Type 2 floors exhibited the lowest measured levels for both the light and heavy impact noise, indicating superior sound insulation performance.

- (2)

- Although the floor impact noise insulation of Type 1 floors, which has a lower dynamic stiffness, was initially expected to be superior to that of Type 2 floors, onsite measurement results showed that Type 2 floors exhibited better performance.

- (3)

- In both Type 1 and 2 floors, a resonance was generated at 50 Hz so that the heavy impact noise was not reduced but rather increased.

- (4)

- For Type 1 floors, the sound insulation in the light impact noise satisfied the first-grade standard; among the heavy impact noises, the third-grade standard was achieved when excited by the Bang Machine, and the second-grade standard was achieved when excited by the Impact Ball. For Type 2 floors, the sound insulation satisfied the first grade in the light impact noise, and the sound insulation in the heavy impact noise satisfied the second-grade standard when excited by both the Bang Machine and the Impact Ball.

- (5)

- Regardless of the different characteristics of impact sources that the Bang Machine and the Impact Ball have as the standard heavy impact source, Type 2 floors showed a reduction in floor impact noise when examining two impact sources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, S.S.; Lee, S.M.; Haan, C.H. Floor structure for the reduction of floor impact noise of apartment with concrete slab less than 210 mm. J. Acoust. Soc. Korea 2024, 43, 724–736. [Google Scholar]

- Chung, J.Y. Minor repair technology using floor covering to reduce floor impact sound. Archit. Sci. Rev. 2023, 67, 41–44. [Google Scholar]

- Lee, J.W.; Jeong, G.C.; Kwon, Y.P. Correlation between Dynamic Characteristics of Isolation Material and Impact Noise Reduction of Light-weight Impact Source. In Proceedings of the KSNVE Annual Spring Conference; 2003; pp. 191–195. [Google Scholar]

- Kim, K.W.; Jeong, G.C.; Sohn, J.Y. Evaluation of the Dynamic stiffness and Heavy-weight Floor Impact Sound Reduction by Composition of Resilient Materials. Trans. Korean Soc. Noise Vib. Eng. 2008, 18, 247–254. [Google Scholar] [CrossRef]

- Ryu, J.K. Relationship between property of isolator for standardized floor structure and floor impact sound level. In Proceedings of the KSNVE Annual Spring Conference; 2002; pp. 278–279. [Google Scholar]

- Kim, J.H.; Mun, D.H.; Jeong, G.C.; Park, H.G. Influence of Floor Dimension and Resilient Material on Heavy Impact Noise of Floating Floor System. Trans. Korean Soc. Noise Vib. Eng. 2017, 27, 434–443. [Google Scholar] [CrossRef]

- Lee, K.J. A Study on the Floor Impact Sound Insulation Characteristics Due to Resilient Layer Compositions. Master’s Thesis, Dong Shin University, Naju, Republic of Korea, 2013. [Google Scholar]

- Lee, B.K.; Bae, S.H.; Hong, C.H. A evaluation study on reduction method of floor impact noise through field test and the effective method for heavy impact noise. In Proceedings of the KSNVE Annual Autumn Conference; 2004; pp. 451–456. [Google Scholar]

- Ryu, J.K.; Jeong, G.; Lee, J.; Kim, H. Effect of thickness and composition of isolator for standardized floor structure on floor impact sound level. In Proceedings of the KSNVE Annual Autumn Conference; 2013; pp. 382–383. [Google Scholar]

- Lee, J.; Lee, S.M.; Haan, C.H. Investigation of the level difference of floor impact noises through the shape variation of EVA resilient materials with composite floor structure. J. Acoust. Soc. Korea 2024, 43, 60–71. [Google Scholar]

- Koo, B.S.; Lee, B.K.; Hong, S.S. Developed plaster type of floor insulation material for remodel apartment. In Proceedings of the KSNVE Annual Spring Conference; 2018; p. 267. [Google Scholar]

- Koo, B.S.; Lee, B.K.; Hong, S.S. Analysis of reduction method of floor impact noise in remodeling apartment. In Proceedings of the KSNVE Annual Autumn Conference; 2020; p. 176. [Google Scholar]

- World Business Council for Sustainable Development. End-of-Life Tire Management Toolkit; WBCSD: Geneva, Switzerland, 2021. [Google Scholar]

- Lee, W.H.; Byeon, H.S.; Bae, H.M. Studies on physical properties of wood-based composite panel with recycled tire chip-Change of properties on composite panel by mixing ratio of combined materials. J. Korean Wood Sci. Technol. 1998, 26, 70–75. [Google Scholar]

- Yang, K.S.; Lee, S.H.; Kim, H.Y.; Kim, S.M. The Experimental Study on the Impact Sound insulation Floors due to Waste Tire Chip. Trans. Korean Soc. Noise Vib. Eng. 1999, 9, 477–484. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar]

- Bala, A.; Gupta, S. Thermal resistivity, sound absorption and vibration damping of concrete composite doped with waste tire Rubber: A review. Constr. Build. Mater. 2021, 299, 123939. [Google Scholar] [CrossRef]

- Atef, M.; Bassioni, G.; Azab, N.; Abdellatif, M.H. On the acoustical performance of eco-friendly cementitious composite with recycled fine rubber particles. Constr. Build. Mater. 2022, 325, 126830. [Google Scholar] [CrossRef]

- Wang, J.; Du, B. Experimental studies of thermal and acoustic properties of recycled aggregate crumb rubber concrete. J. Build. Eng. 2020, 32, 101836. [Google Scholar] [CrossRef]

- Thai, Q.B.; Chong, R.O.; Nguyen, P.T.T.; Le, D.K.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Recycling of waste tire fibers into advanced aerogels for thermal insulation and sound absorption applications. J. Environ. Chem. Eng. 2020, 8, 104279. [Google Scholar] [CrossRef]

- Wijesinghe, K.A.P.; Lanarolle, G.; Gunasekara, C.; Law, D.W.; Hidallana-Gamage, H.D.; Wang, L. Thermal and acoustic performance of solid waste incorporated cement-based composites: An analytical review. Arch. Civ. Mech. Eng. 2025, 25, 106. [Google Scholar] [CrossRef]

- Kim, I.H.; Choi, Y.; Jeong, D.H.; Park, D.H. A Study of Compressive Strength estimation of Rubberized Concrete using Ultrasonic Pulse Velocity Method. In Proceedings of the Architectural Institute of Korea Annual Autumn Conference, Seoul, Republic of Korea, 29–30 October 2015; pp. 519–520. [Google Scholar]

- KS F 2873:2011; Measuring Method of Compressibility of Resilient Materials for Floor Impact Sound. Korean Standards Association: Seoul, Republic of Korea, 2011.

- Sambucci, M.; Valente, M. Influence of waste tire rubber particles size on the microstructural, mechanical, and acoustic insulation properties of 3D-printable cement mortars. Civ. Eng. J. 2021, 7, 937–952. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Syamsir, A.; Baharom, S.; Alrshoudi, F.; Qaid, A.; Al-Fakih, A.M.; Mhaya, A.M.; Salah, H.A. Assessment of acoustic and mechanical properties in modified rubberized concrete. Case Stud. Constr. Mater. 2024, 20, e03063. [Google Scholar] [CrossRef]

- KS F 2868:2003; Determination of Dynamic Stiffness of Materials Used Under Floating Floors in Dwellings. Korean Standards Association: Seoul, Republic of Korea, 2003.

- KS F 2810-1:2015; Acoustics—Field Measurement of Impact Sound Insulation of Floors—Part 1: Method Using Standard Light Impact Source. Korean Standards Association: Seoul, Republic of Korea, 2015.

- KS F 2810-2:2012; Acoustics—Field Measurement of Impact Sound Insulation of Buildings—Part 1: Method Using Standard Heavy Impact Sources. Korean Standards Association: Seoul, Republic of Korea, 2012.

- KS F 2863-1:2017; Rating of Floor Impact Sound Insulation for Impact Source in Buildings and of Building Elements—Part 1: Floor Impact Sound Insulation Against Standard Light Impact Source. Korean Standards Association: Seoul, Republic of Korea, 2017.

- KS F 2863-2:2017; Rating of Floor Impact Sound Insulation for Impact Source in Buildings and of Building Elements—Part 2: Floor Impact Sound Insulation Against Standard Heavy Impact Source. Korean Standards Association: Seoul, Republic of Korea, 2017.

- Ministry of Land Infrastructure and Transport. Standards of Approval and Inspection for the Floor Impact Sound Insulation Structure of Apartment; Ministry of Environment of Korea: Sejong, Republic of Korea, 2023. [Google Scholar]

- Lee, W.H. Analysis of the Influence Factors on the Floor Impact Sound of Apartments through Field Experiments. Master’s Thesis, Chungbuk National University, Cheongju, Repubilc of Korea, 2020. [Google Scholar]

| Category | Type 1 | Type 2 | Type 3 | |

|---|---|---|---|---|

| Composition |  |  | ||

| EPS | Thickness (mm) | 25 | 25 | 25 |

| PP Sheet | - | - | 0.4 | |

| Crumb Rubber | Particle Size (mm) | 5~7 | 5~7 | 5~7 |

| Application Rate (g/m2) | 1600 | 850 | 850 | |

| Test Results | Exceeds Standard | Meets Standard | ||

| Category | Type 1 | Type 2 | |

|---|---|---|---|

| Composition |  | ||

| EPS | Thickness (mm) | 25 | 28 |

| PP Sheet | 0.4 | 0.4 | |

| Crumb Rubber | Particle Size (mm) | 5~7 | 2~3 |

| Application Rate (g/m2) | 1600 | 850 | |

| Dynamic Stiffness (MN/m3) | 3.54 | 4.78 | |

| Fabricated Specimens |  |  | |

| Classification | Architectural Dimension of Standard Test Room |

|---|---|

| Length (L) | 5.1 m |

| Width (W) | 4.5 m |

| Height (H) | 2.5 m |

| Volume (V) | 58.6 m3 |

| Floor area (F) | 22.9 m2 |

| Thickness of concrete slab | 180 mm |

| Category | Equipment | Specification/Description |

|---|---|---|

| Impact Sources | Tapping Machine | Light-weight impact source (KS F 2810-1) |

| Bang Machine | Heavy-weight impact source (KS F 2810-2) | |

| Impact Ball | Heavy-weight impact source (KS F 2810-2) | |

| Microphones | 0.5-inch Condenser Microphone | Ref. sensitivity: 54.23 mV/Pa Frequency range: 3.15 Hz–30 kHz |

| Calibrator | Acoustic Calibrator | 94 dB at 1 kHz |

| Analyzer | Real-Time Sound and Vibration Analyzer | Frequency range: 20 Hz–20 kHz Up to 12-channel simultaneous acquisition |

| Loudspeaker | Omnidirectional Loudspeaker | Max output: 125 dB |

| Amplifier | Power Amplifier | Output range: 220–700 W |

| Classification | Light-Weight Impact Noise (L’nT,w) | Heavy-Weight Impact Noise (L’I,Fmax) |

|---|---|---|

| 1st grade | L’nT,w ≤ 37 | L’I,Fmax ≤ 37 |

| 2nd grade | 37 < L’nT,w ≤ 41 | 37 < L’I,Fmax ≤ 41 |

| 3rd grade | 41 < L’nT,w ≤ 45 | 41 < L’I,Fmax ≤ 45 |

| 4th grade | 45 < L’nT,w ≤ 49 | 45 < L’I,Fmax ≤ 49 |

| Impact Source | Type 1 | Type 2 | ||

|---|---|---|---|---|

| Impact Noise Level (dB) | Class | Impact Noise Level (dB) | Class | |

| Tapping machine | 39 | 1 | 35 | 1 |

| Bang machine | 46 | 3 | 42 | 2 |

| Impact ball | 40 | 2 | 38 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-H.; Haan, C.-H. Development of Floor Structures with Crumb Rubber for Efficient Floor Impact Noise Reduction. Acoustics 2025, 7, 47. https://doi.org/10.3390/acoustics7030047

Park J-H, Haan C-H. Development of Floor Structures with Crumb Rubber for Efficient Floor Impact Noise Reduction. Acoustics. 2025; 7(3):47. https://doi.org/10.3390/acoustics7030047

Chicago/Turabian StylePark, Ji-Hoon, and Chan-Hoon Haan. 2025. "Development of Floor Structures with Crumb Rubber for Efficient Floor Impact Noise Reduction" Acoustics 7, no. 3: 47. https://doi.org/10.3390/acoustics7030047

APA StylePark, J.-H., & Haan, C.-H. (2025). Development of Floor Structures with Crumb Rubber for Efficient Floor Impact Noise Reduction. Acoustics, 7(3), 47. https://doi.org/10.3390/acoustics7030047