Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes

Abstract

1. Introduction

2. Materials and Methods

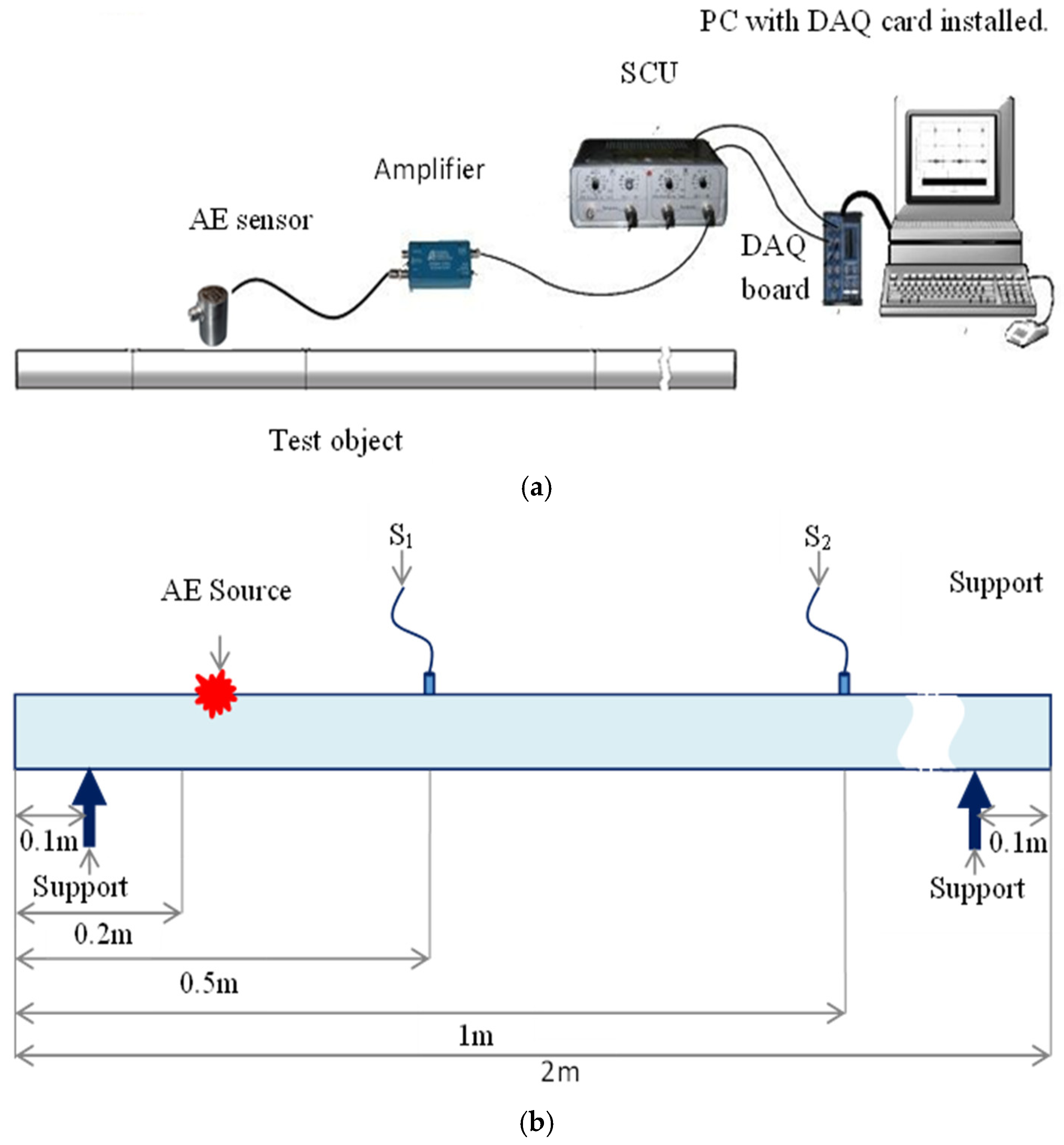

2.1. Experimental Setup

2.2. Finite Element Model

- is elastic coefficient;

- is a vector with six independent components;

- τ is shear stress and a component of the vector.

3. Results and Discussion

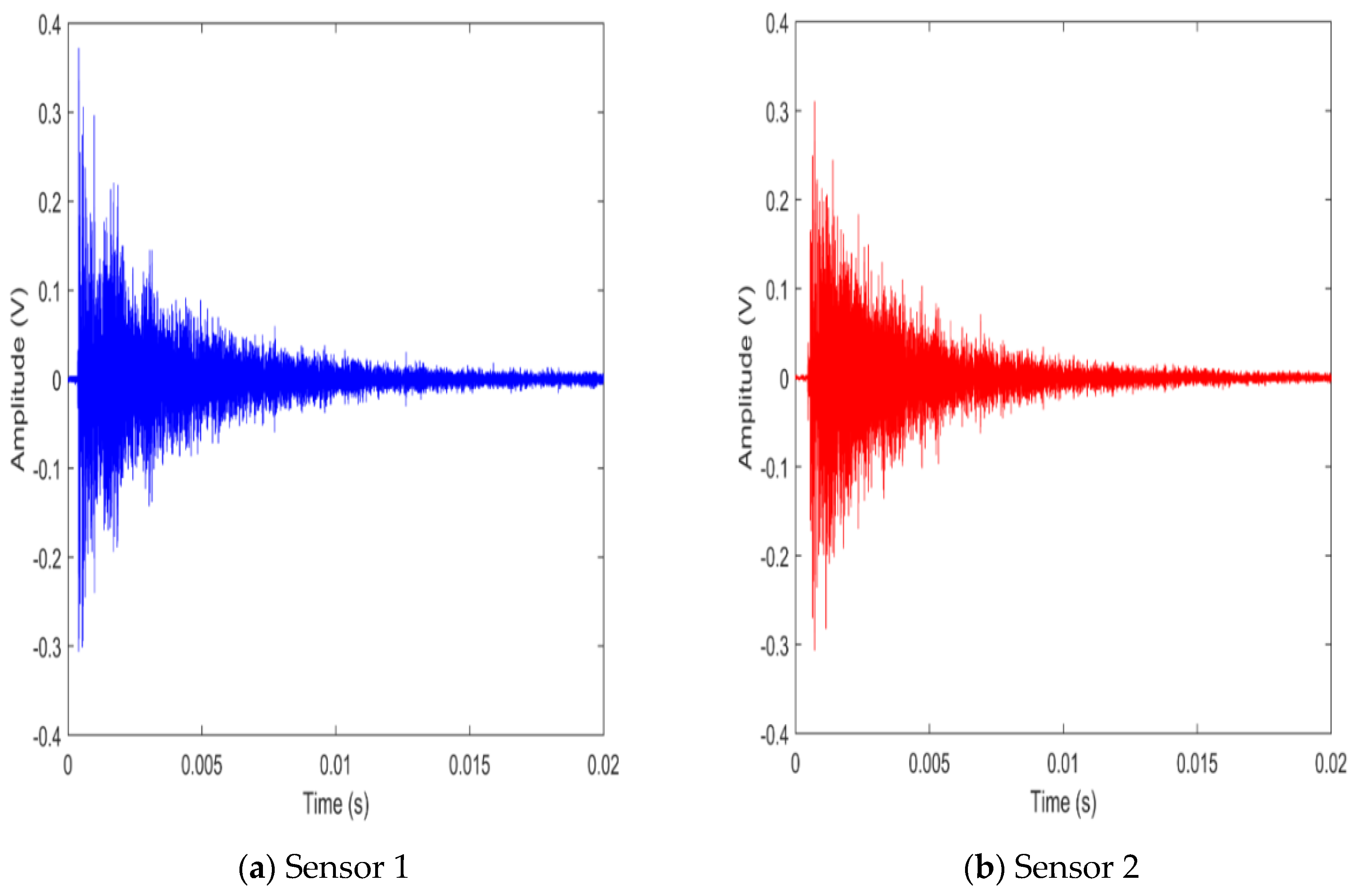

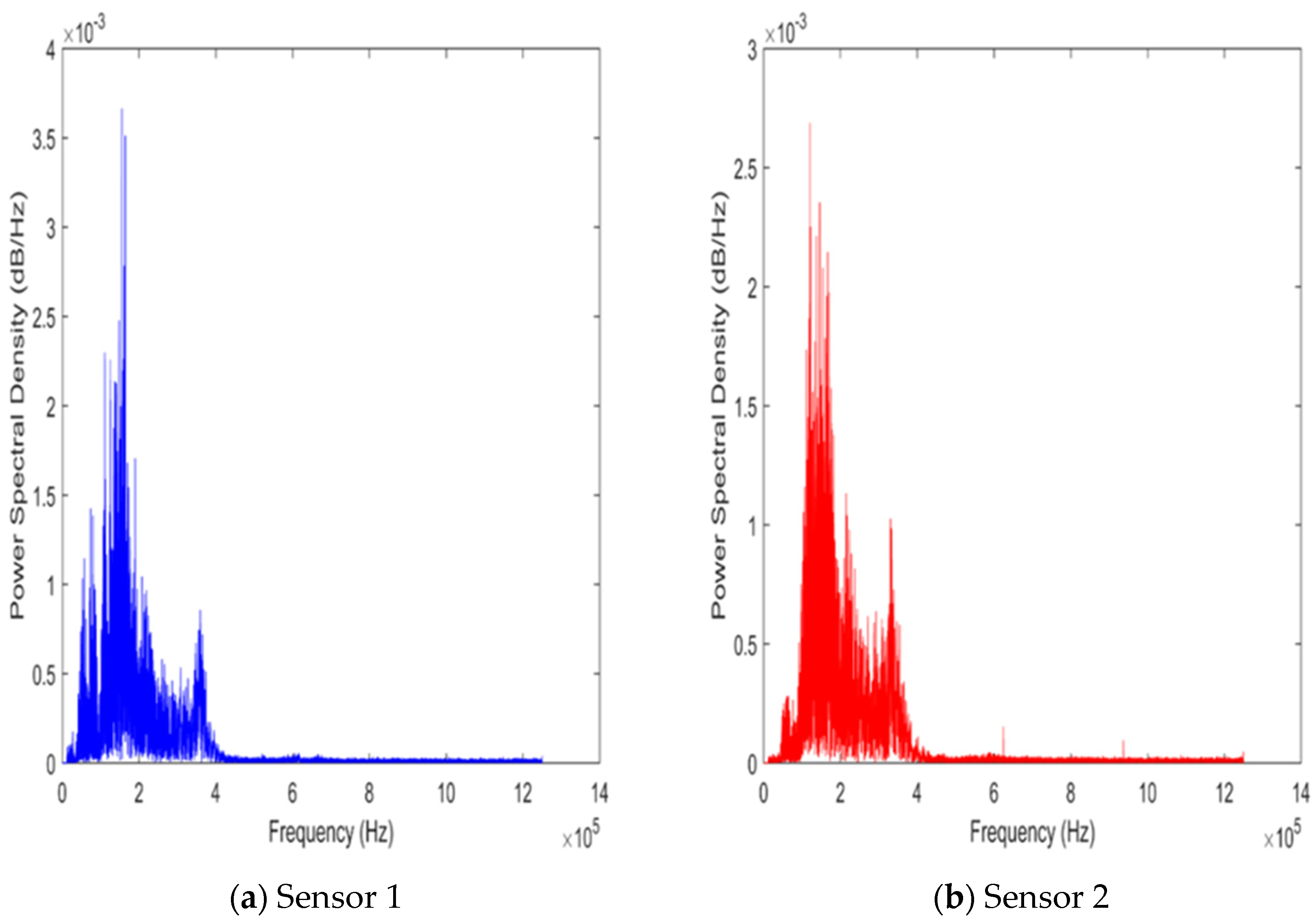

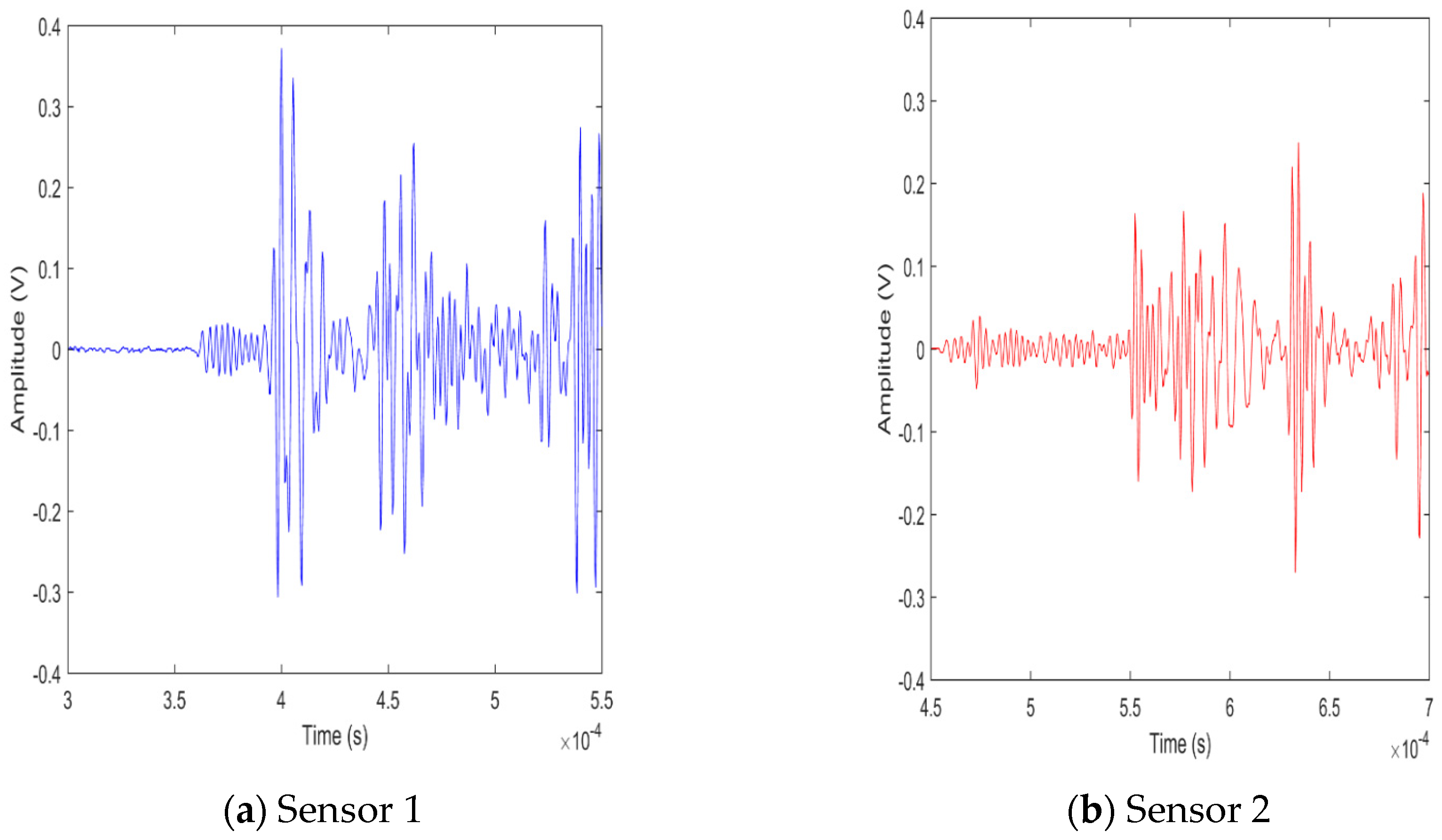

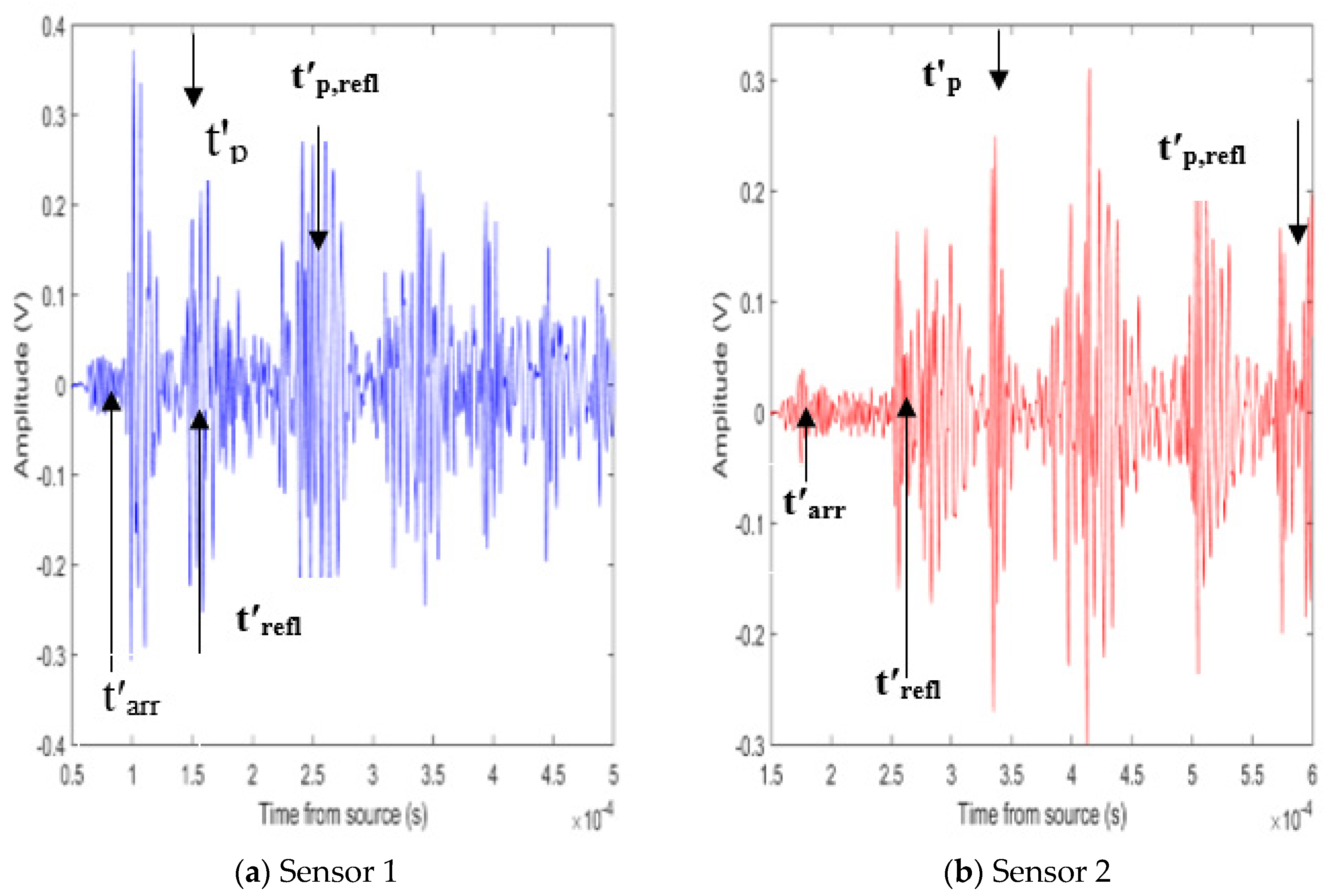

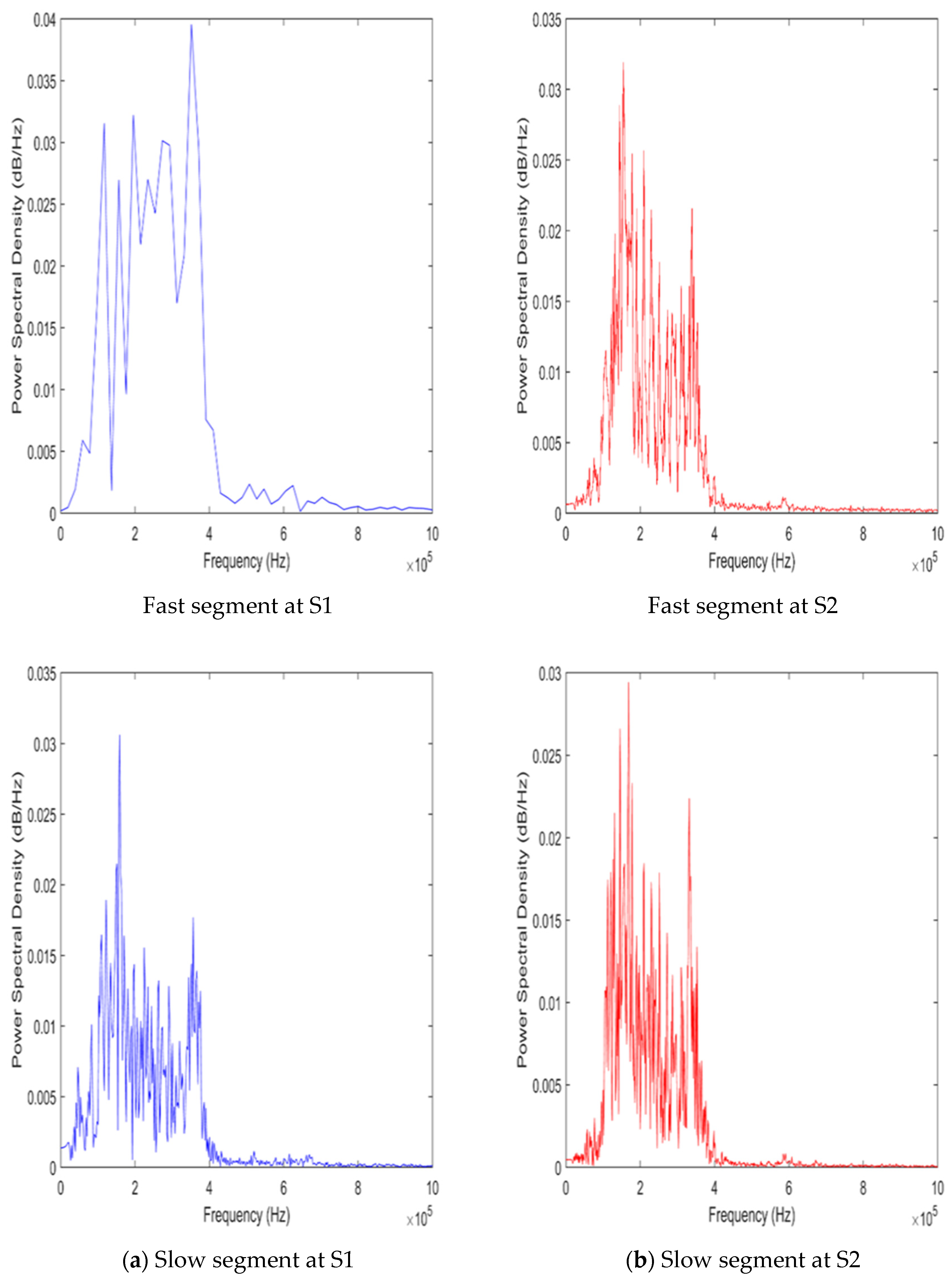

3.1. Experimental Pipe Model

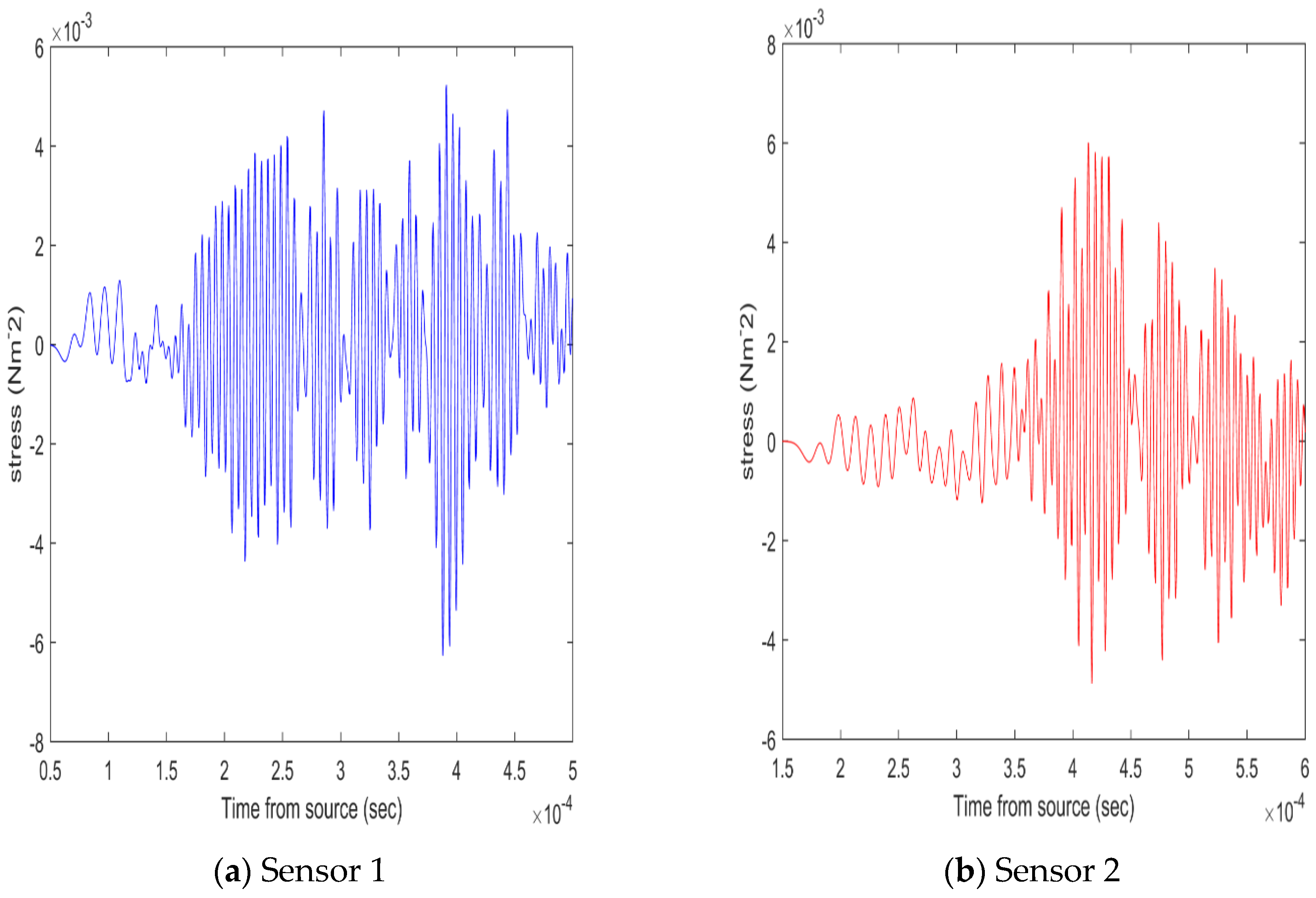

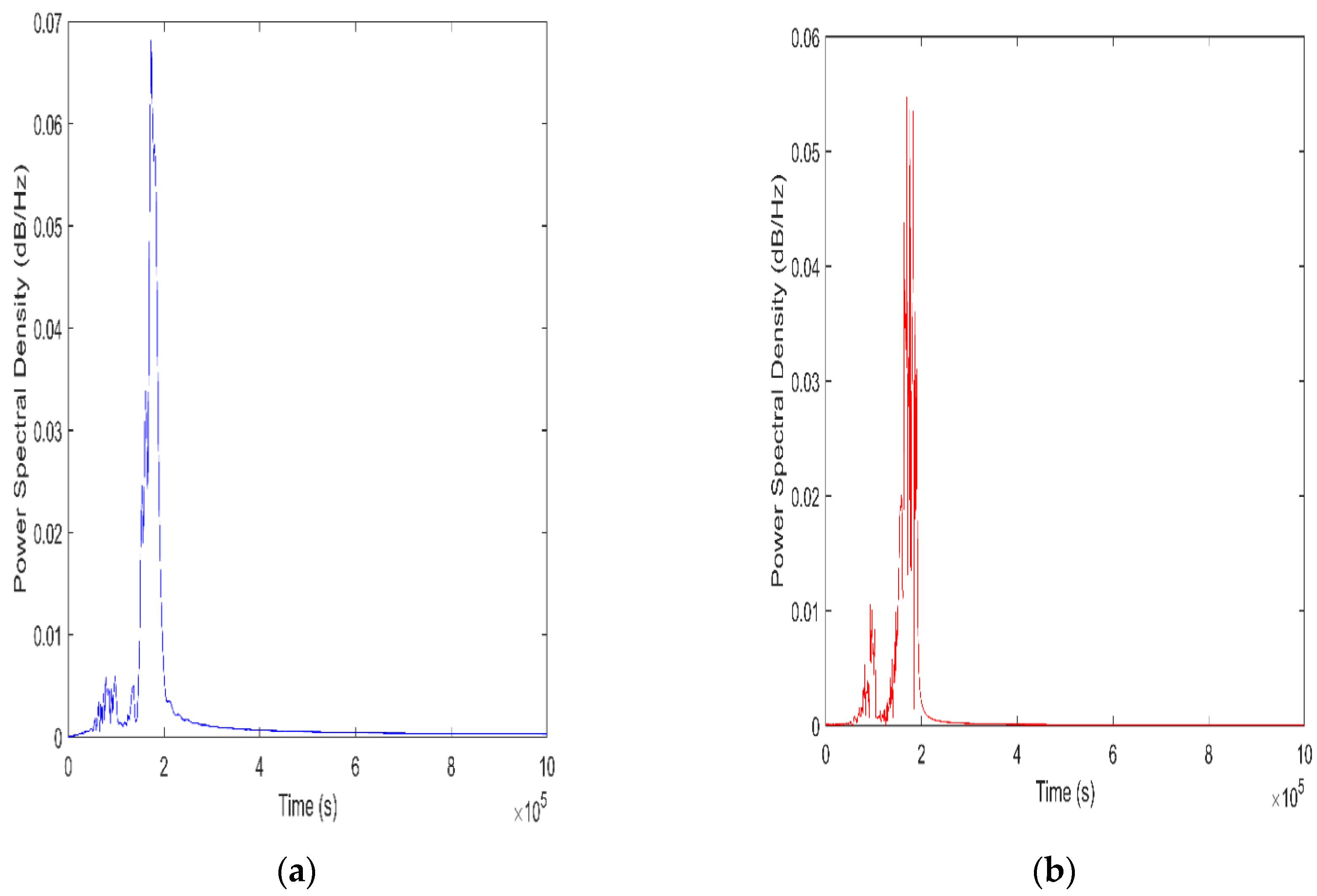

3.2. Pipe Simulation Model

3.3. Comparison of Experiments to Simulation

4. Conclusions

- Experiments on near full-scale pipes over longer lengths (tens of meters): These experiments would help understand attenuation at practical scales and could include variations in the internal and external environment of the pipe.

- Incorporating realistic attenuation mechanisms in simulations: Currently, the simulations only account for geometrical attenuation, which is minimal in pipes. Comparing simulations with experiments, as suggested above, would enable the development of a more accurate attenuation model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, H.; Guo, L.; Azimi, M.; Huang, K. Oil and Gas 4.0 era: A systematic review and outlook. Comput. Ind. 2019, 111, 68–90. [Google Scholar] [CrossRef]

- Wang, H.; Tong, Z.; Zhou, G.; Zhang, C.; Zhou, H.; Wang, Y.; Zheng, W. Research and demonstration on hydrogen compatibility of pipelines: A review of current status and challenges. Int. J. Hydrogen Energy 2022, 47, 28585–28604. [Google Scholar] [CrossRef]

- Biezma, M.V.; Andrés, M.A.; Agudo, D.; Briz, E. Most fatal oil & gas pipeline accidents through history: A lesson learned approach. Eng. Fail. Anal. 2020, 110, 104446. [Google Scholar]

- Kraidi, L.; Shah, R.; Matipa, W.; Borthwick, F. An investigation of mitigating the safety and security risks allied with oil and gas pipeline projects. J. Pipeline Sci. Eng. 2021, 1, 349–359. [Google Scholar] [CrossRef]

- Verstrynge, E.; Lacidogna, G.; Accornero, F.; Tomor, A. A review on acoustic emission monitoring for damage detection in masonry structures. Constr. Build. Mater. 2021, 268, 121089. [Google Scholar] [CrossRef]

- Rong, X.; Xie, A.; Zhao, P.; Wang, S.; Wei, X. Damage Detection and Evaluation of Stud Connectors for Composite Girder Bridge Using Acoustic Emission. J. Bridge Eng. 2024, 29, 4024001. [Google Scholar] [CrossRef]

- Tonelli, D.; Luchetta, M.; Rossi, F.; Migliorino, P.; Zonta, D. Structural health monitoring based on acoustic emissions: Validation on a prestressed concrete bridge tested to failure. Sensors 2020, 20, 7272. [Google Scholar] [CrossRef]

- Brunner, A.J. Structural health and condition monitoring with acoustic emission and guided ultrasonic waves: What about long-term durability of sensors, sensor coupling and measurement chain. Appl. Sci. 2021, 11, 11648. [Google Scholar] [CrossRef]

- Grazion, S.V.; Mukomela, M.V.; Erofeev, M.N.; Spiryagin, V.V.; Amelin, S.S. Experimental estimation of the waveguide effect on the acoustic emission signal parameters in monitoring facilities with a long surface radius of curvature. J. Mach. Manuf. Reliab. 2020, 49, 971–979. [Google Scholar] [CrossRef]

- Prajna, K.; Mukhopadhyay, C.K. Fractional Fourier transform based adaptive filtering techniques for acoustic emission signal enhancement. J. Nondestruct. Eval. 2020, 39, 1–15. [Google Scholar] [CrossRef]

- Wang, J.; Huo, L.; Liu, C.; Song, G. A new acoustic emission damage localization method using synchro squeezed wavelet transforms picker and time-order method. Struct. Health Monit. 2021, 20, 2917–2935. [Google Scholar] [CrossRef]

- Madarshahian, R.; Ziehl, P.; Caicedo, J.M. Acoustic emission Bayesian source location: Onset time challenge. Mech. Syst. Signal Process. 2019, 123, 483–495. [Google Scholar] [CrossRef]

- Sause, M.G.R. Investigation of pencil-lead breaks as acoustic emission sources. J. Acoust. Emiss. 2011, 29, 184–196. [Google Scholar]

- Šofer, M.; Cienciala, J.; Fusek, M.; PavlíCek, P.; Moravec, R. Damage analysis of composite CFRP tubes using acoustic emission monitoring and pattern recognition approach. Materials 2021, 14, 786. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Lipiec, S.; Adamczak, J.; Vičan, J.; Bahleda, F. Identification of Destruction Processes and Assessment of Deformations in Compressed Concrete Modified with Polypropylene Fibers Exposed to Fire Temperatures Using Acoustic Emission Signal Analysis, Numerical Analysis, and Digital Image Correlation. Materials 2023, 16, 6786. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Lipiec, S.; Vavruš, M.; Koteš, P. Non-destructive methods and numerical analysis used for monitoring and analysis of fibre concrete deformations. Materials 2022, 15, 7268. [Google Scholar] [CrossRef]

- Komijani, M.; Gracie, R.; Yuan, Y. Simulation of fracture propagation induced acoustic emission in porous media. Eng. Fract. Mech. 2020, 229, 106950. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, J.; Xu, C.; Du, F. Locating of acoustic emission source for stiffened plates based on stepwise time-reversal processing with time-domain spectral finite element simulation. Struct. Health Monit. 2023, 22, 927–947. [Google Scholar] [CrossRef]

- Oz, F.E.; Calik, E.; Ersoy, N. Finite element analysis and acoustic emission monitoring of progressive failure of corrugated core composite structures. Compos. Struct. 2020, 253, 112775. [Google Scholar] [CrossRef]

- Mu, W.; Gao, Y.; Wang, Y.; Liu, G.; Hu, H. Modeling and analysis of acoustic emission generated by fatigue cracking. Sensors 2022, 22, 1208. [Google Scholar] [CrossRef]

- Sause, M.G.R.; Richler, S. Finite element modelling of cracks as acoustic emission sources. J. Nondestruct. Eval. 2015, 34, 4. [Google Scholar] [CrossRef]

- Sause, M.G.R.; Hamstad, M.A. Numerical modeling of existing acoustic emission sensor absolute calibration approaches. Sens. Actuators A Phys. 2018, 269, 294–307. [Google Scholar] [CrossRef]

- Angulo, Á.; Yang, H.; Tang, J.; Khadimallah, A.; Soua, S. Structural Health Monitoring of Crack Initiation and Growth in Mooring Chains using FEA Methods for Acoustic Emission Characterisation. J. Acoust. Emiss. 2019, 36, S107. [Google Scholar]

- Banjara, N.K.; Sasmal, S.; Voggu, S. Machine learning supported acoustic emission technique for leakage detection in pipelines. Int. J. Press. Vessel. Pip. 2020, 188, 104243. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.-M. Crack detection and localization in a fluid pipeline based on acoustic emission signals. Mech. Syst. Signal Process. 2021, 150, 107254. [Google Scholar] [CrossRef]

- Abolle-Okoyeagu, C.J. Acoustic Emission Monitoring of Pipes; Combining Finite Element Simulation and Experiment for Advanced Source Location and Identification. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2019. [Google Scholar]

- Bolander, J.E.; Eliáš, J.; Cusatis, G.; Nagai, K. Discrete mechanical models of concrete fracture. Eng. Fract. Mech. 2021, 257, 108030. [Google Scholar] [CrossRef]

- Al-Azzawi, A.S.M.; Kawashita, L.F.; Featherston, C.A. Buckling and postbuckling behaviour of Glare laminates containing splices and doublers. Part 2: Numerical modelling. Compos. Struct. 2017, 176, 1170–1187. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, M.; Harrison, N.M. Resolution, energy and time dependency on layer scaling in finite element modelling of laser beam powder bed fusion additive manufacturing. Addit. Manuf. 2019, 28, 610–620. [Google Scholar] [CrossRef]

- Motamarri, P.; Das, S.; Rudraraju, S. DFT-FE-A massively parallel adaptive finite-element code for large-scale density functional theory calculations. Comput. Phys. Commun. 2019, 246, 106853. [Google Scholar] [CrossRef]

- Pled, F.; Desceliers, C. Review and recent developments on the perfectly matched layer (PML) method for the numerical modeling and simulation of elastic wave propagation in unbounded domains. Arch. Comput. Methods Eng. 2022, 29, 471–518. [Google Scholar] [CrossRef]

- Crawford, A.; Droubi, M.G.; Faisal, N.H. Analysis of acoustic emission propagation in metal-to-metal adhesively bonded joints. J. Nondestruct. Eval. 2018, 37, 33. [Google Scholar] [CrossRef]

- Kaphle, M.; Tan, A.C.C.; Thambiratnam, D.P.; Chan, T.H.T. Identification of acoustic emission wave modes for accurate source location in plate-like structures. Struct. Control Health Monit. 2012, 19, 187–198. [Google Scholar] [CrossRef]

- Shehadeh, M.F.; Elbatran, A.H.; Mehanna, A.; Steel, J.A.; Reuben, R.L. Evaluation of acoustic emission source location in long steel pipes for continuous and semi-continuous sources. J. Nondestruct. Eval. 2019, 38, 40. [Google Scholar] [CrossRef]

- Asamene, K.; Hudson, L.; Sundaresan, M. Influence of attenuation on acoustic emission signals in carbon fiber reinforced polymer panels. Ultrasonics 2015, 59, 86–93. [Google Scholar] [CrossRef]

- Tayfur, S.; Zhang, T.; Mahdi, M.; Issa, M.; Ozevin, D. Cluster-based sensor selection framework for acoustic emission source localization in concrete. Measurement 2023, 219, 113293. [Google Scholar] [CrossRef]

- Karakozova, A.; Kuznetsov, S. Oscillating Nonlinear Acoustic Waves in a Mooney–Rivlin Rod. Appl. Sci. 2023, 13, 10037. [Google Scholar] [CrossRef]

- Das, A.K.; Leung, C.K.Y. A new power-based method to determine the first arrival information of an acoustic emission wave. Struct. Health Monit. 2019, 18, 1620–1632. [Google Scholar] [CrossRef]

- Haider, M.F.; Giurgiutiu, V. Theoretical and numerical analysis of acoustic emission guided waves released during crack propagation. J. Intell. Mater. Syst. Struct. 2019, 30, 1318–1338. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, limitations and prospects of nondestructive testing and evaluation of thick composites and sandwich structures: A state-of-the-art review. Compos. Struct. 2021, 256, 112951. [Google Scholar] [CrossRef]

- Fu, J.; Xu, M.; Zhang, Z.; Kang, W.; He, Y. Muffler structure improvement based on acoustic finite element analysis. J. Low Freq. Noise Vib. Act. Control 2019, 38, 415–426. [Google Scholar] [CrossRef]

- van Gemmeren, V.; Graf, T.; Dual, J. Modeling the acoustic emissions generated during dynamic fracture under bending. Int. J. Solids Struct. 2020, 203, 84–91. [Google Scholar] [CrossRef]

- Han, C.; Yang, G.; Wang, J.; Guo, X. The research on propagation characteristics of acoustic emission signals in stiffened plates based on the multipath propagation model. Ultrasonics 2020, 108, 106177. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimkhanlou, A.; Dubuc, B.; Salamone, S. A generalizable deep learning framework for localizing and characterizing acoustic emission sources in riveted metallic panels. Mech. Syst. Signal Process. 2019, 130, 248–272. [Google Scholar] [CrossRef]

- Khon, H.; Bashkov, O.V. The study of acoustic emission waves generated from different types of sources. Mater. Today Proc. 2019, 19, 2243–2247. [Google Scholar] [CrossRef]

- Thiyagarajan, J.S. Non-destructive testing mechanism for pre-stressed steel wire using acoustic emission monitoring. Materials 2020, 13, 5029. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, Y.; Li, K. Differences in the acoustic emission characteristics of 345 MPa normal-strength steel and 460 MPa high-strength steel. Int. J. Steel Struct. 2021, 21, 154–166. [Google Scholar] [CrossRef]

- Mukherjee, A.; Banerjee, A. Analysis of acoustic emission signal for crack detection and distance measurement on steel structure. Acoust. Aust. 2021, 49, 133–149. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abolle-Okoyeagu, C.J.; Fatukasi, S.; Reuben, B. Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes. Acoustics 2024, 6, 620-637. https://doi.org/10.3390/acoustics6030034

Abolle-Okoyeagu CJ, Fatukasi S, Reuben B. Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes. Acoustics. 2024; 6(3):620-637. https://doi.org/10.3390/acoustics6030034

Chicago/Turabian StyleAbolle-Okoyeagu, Chika Judith, Samuel Fatukasi, and Bob Reuben. 2024. "Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes" Acoustics 6, no. 3: 620-637. https://doi.org/10.3390/acoustics6030034

APA StyleAbolle-Okoyeagu, C. J., Fatukasi, S., & Reuben, B. (2024). Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes. Acoustics, 6(3), 620-637. https://doi.org/10.3390/acoustics6030034