1. Introduction

The main tactical advantage of a submarine is its possibility to operate undetected by an enemy. To conceal the sound signature of a submarine, researchers and manufactures reduce the emitted sound power of modern vehicles. In addition to passive measures, such as adding damping materials, active noise control (ANC) has already been proposed for submarines with diesel engines. This method shows a promising noise reduction of the engine exhaust system [

1]. But even if the vehicle itself operates quietly, it can still be detected using an active sonar. Developed in the First World War for submarine detection, this sonar has evolved into the modern mono- and bistatic systems through continuous improvements [

2]. The risk of detection using an active sonar is directly dependent on the object’s target strength. The target strength, often considered as an object’s acoustic size, is not only dependent on the dimensions, but also on the material, geometric and inner structure of the object [

3,

4]. The majority of studies researching the target strength of submarines are based on numerical methods to test designs, since measurements are often not feasible due to high costs and confidentiality constraints. In [

5,

6], the benchmark target echo strength simulation (BeTSSi) is used. Nolte et al.’s study focuses on a comparison of the performance of different solvers and numerical methods. Sathish et al. used the Helmholtz–Kirchhoff method and FEM in their studies, in which they concluded that an anti-reflection coating should be used to absorb high-frequency sonar signals. In [

7], the authors Fang et al. drew the same conclusion based on a different submarine model and simulation environment. Kwonn et al., in [

8], also validated their simulations based on the Kirchhoff approximation, using measurements of a downscaled model. They claim to be able to predict the effect of material and geometric changes on the target strength with their simulation. These numerical studies all draw the same conclusions and suggest the use of absorbing materials as coatings to dampen higher-frequency sonar signals, thus decreasing the target strength of submarines. Nonetheless, a major drawback of absorbing materials is that they require increasing the layer thickness as the sonar frequency is reduced. For lower frequencies, it is not feasible to rely on the absorption characteristics of the outer skin of a vehicle. Another strategy to reduce the target strength is to inhibit the reception of reflected signals by choosing a stealth form. This approach is well established and well known for military aircraft with stealth shapes that are optimized to avoid detection by radar. The goal of the stealth shape is to deflect the incident sound waves away from the radar’s or sonar’s direction. In the field of submarines, this concept is still under research and development. One example can be found in [

9,

10], where the authors carried out extensive simulations to compare the target strength of a stealth submarine form to a classic cylindrical shape. The investigation based on BeTSSi also includes absorbing materials on the outer hull and distinct oceanic regions around the world. However, at frequencies below 1500 Hz, the desired effect is less pronounced, and parts of the sound waves are directly reflected to the sonar’s position. To effectively protect against detection—even in the frequency range below 1500 Hz—active measures could be a promising solution. A classic ANC system minimizes the sound pressure locally by applying the principle of the destructive interference of sound waves. In the present report, the wall impedance of the surface shall be manipulated in order to minimize reflections of the incident sound waves. This method is often called active impedance control (AIC) and was demonstrated for an air-filled impedance tube in [

11,

12,

13]. As part of this project, a preliminary study [

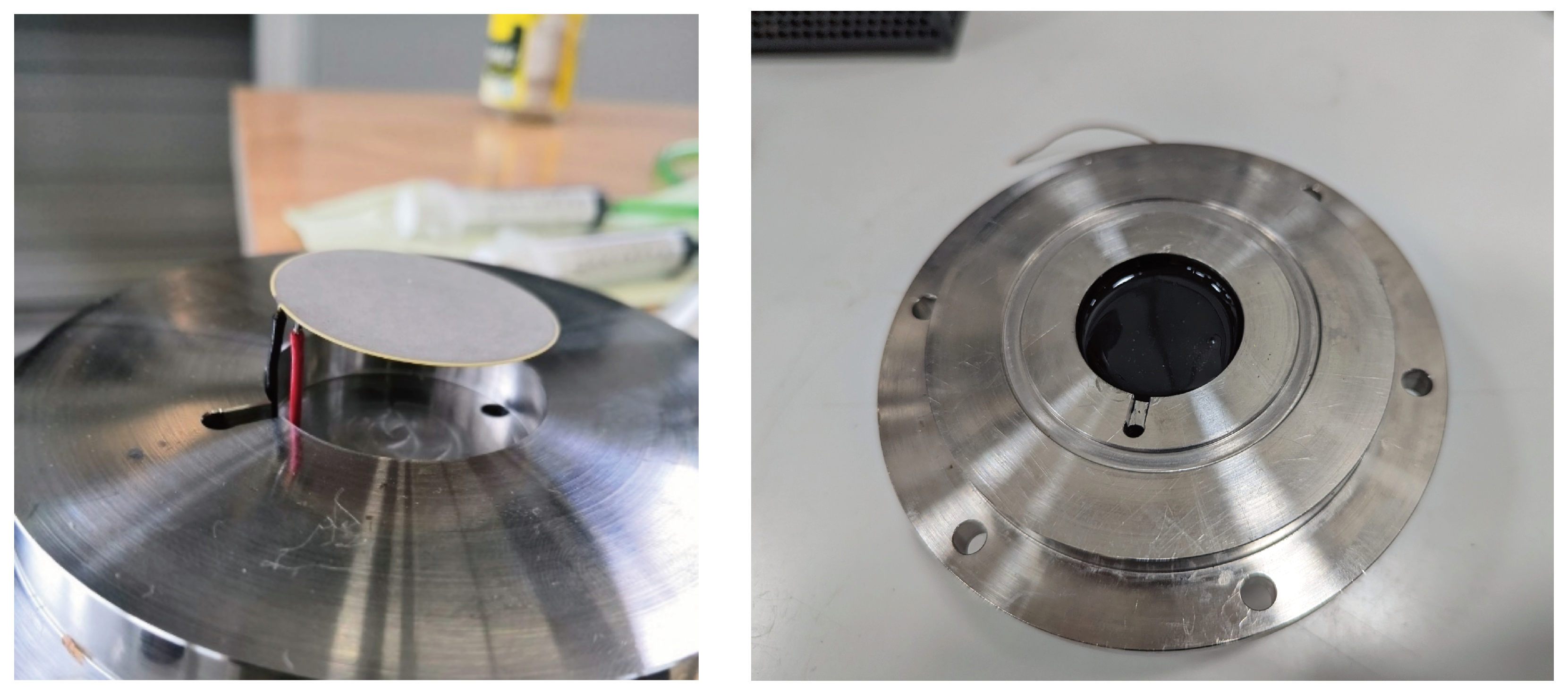

14] was conducted to develop a demonstrator to minimize the reflective properties of a submerged steel surface. This was based on a water-filled impedance tube that contained a Tonpilz transducer at one end as the primary actuator in order to emulate the sonar signal. The opposite end was realized using a thin piezoceramic as a secondary actuator representing the vehicle surface. Several sensors were located in the tube to measure the sound pressure distribution. The piezo-actuator was controlled by means of an adaptive controller in the frequency domain, the effectiveness of which was demonstrated in a series of experiments. The presented system in [

14] had several drawbacks, such as its dependence on the internal reference of the signal generator and the limitation to only stationary tonal signals.

In this paper, the adaptive control system is redesigned and implemented in the time domain to improve its capabilities. The measurement setup is extended to an impedance tube up to 9.81 m, which can be equipped with several sensor modules. This allows for the detection of the incident sound wave with physical sensors, which is necessary for adapting the active control system to vehicles in the future. As a result, the system is able to minimize the reflections of sonar-like signals inside the impedance tube and delivers a proof-of-concept for further research on active surfaces for submarines.

3. Results

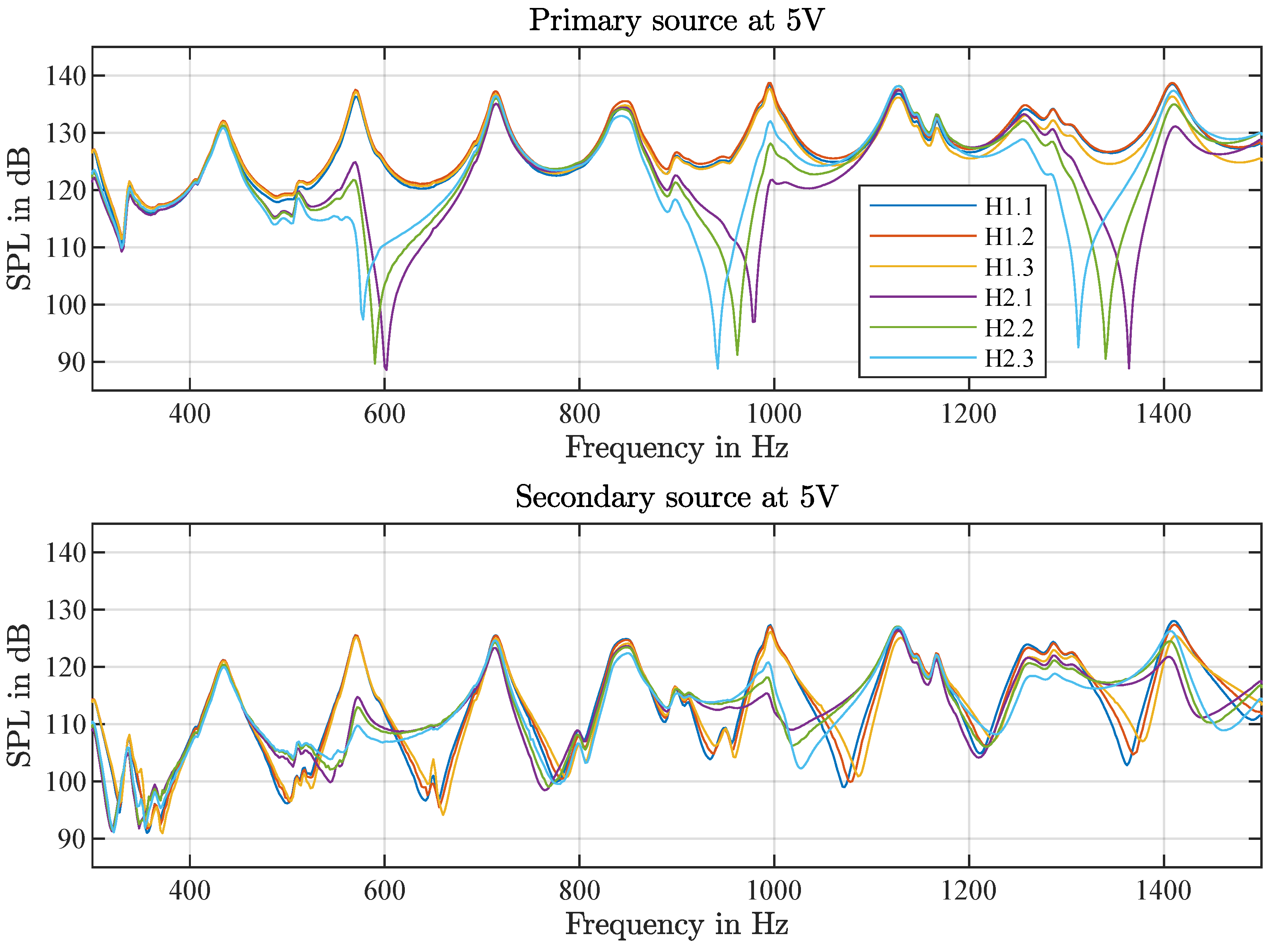

To get an overview of the sound field inside the tube and of the system properties, the Tonpilz transducer and the experimental piezo-actuator were first examined individually without active control. Both actuators were driven separately after each other using a sine sweep from 300 Hz to 1500 Hz with a frequency increase of

. The amplifiers were set to an output voltage of 5 V in both cases.

Figure 5 shows a comparison of the measured sound pressure level (SPL) of all sensors generated by both actuators, respectively, located on opposite sides of the tube, as shown in

Figure 1. The tube was configured to a length of 5.03 m, and the hydrophone positions are stated in

Table 1. The primary reason for using a reduced length were resonance effects that will be further analyzed and discussed in the following.

When only the primary actuator (Tonpilz transducer) was active, there were significant minima of the SPL at the position of measurement module two. These minima occurred at the vibration nodes caused by standing waves inside the tube. Their positions within the tube depended on the wavelength and thus on the frequency. The arrangement of the piezoceramic on the steel construction realized a hard acoustic boundary condition and reflected the sound waves with minimal energy loss. This behavior can also be observed in the following investigation of the reflection coefficient. Comparing the sound pressure caused by the secondary actuator and by the Tonpilz transducer, different behaviors of the actuators can be observed. The 0.2 mm piezoceramic was less efficient than the Tonpilz using the same 5 V driving voltage, which is not surprising, because a Tonpilz transducer is optimized for sound radiation and typically actuated via a piezo stack (pp. 98–106, [

18]). As a passive end element of the tube, the Tonpilz also resulted in a different boundary condition, absorbing more energy of the incident sound wave. As a result, the pressure minima occurring at measurement module two were less pronounced. The

k resonance frequencies of a water column with sound pressure and sound velocity boundary conditions are as follows:

This depended on the speed of sound

c and the inner length of the tube

l. The higher eigenfrequencies were at 293 Hz, 439 Hz, 586 Hz, 732 Hz, 879 Hz, 1024 Hz, 1172 Hz, 1317 Hz and 1465 Hz. These caused anomalies in the measured pressure with both actuators, which had a direct impact on the active system. These frequencies can be identified in

Figure 5 as maxima of the SPL, independent of the actuator used. It should be noted that the pressure maximum around 1317 Hz was less defined compared to the other eigenfrequencies. Regardless of the actuator type selected, mode splitting was noticeable, as shown in

Figure 5, for example, around 1172 Hz. This behavior could potentially be attributed to several factors. One possible explanation is the presence of residual air bubbles within the tube. Another consideration is the interaction occurring at the boundary between the water and the steel surface of the tube. Additionally, the interaction between the fluid acoustics within the tube, and the propagation of acoustic waves through the steel material of the tube, could also contribute to this phenomenon. In the next step, the results of the active system will be discussed. To achieve optimal results, the sampling rate

was set to 40 kHz in the following experiments. A complete overview of the parameters of the experiment is presented in

Table 2.

In our study, the FxLMS parameters were not individually adjusted for each design iteration that used a different reference signal. This decision was made to facilitate a more straightforward and objective comparison of the results across various designs. Prior to the final experiments, we selected a set of parameters for the FxLMS algorithm based on empirical data and our prior experience.

The synthesis of the feedforward FxLMS including the wave separation resulted in a hardware utilization of the Xilinx Kintex-7 XC7K325T FPGA, as displayed in

Table 3.

The resources with the highest usage were the configurable logic blocks (CLBs) and lookup tables (LUTs) with up to 16.04% of their available capacity being used. The resource utilizations of the other components were below 10%, leaving headroom for future experiments with more complex setups with multiple actuators and more sensors. All the following results are based on this configuration.

In the following measurements, the Tonpilz was again driven by the same 5 V sine sweep as in

Figure 5 (Top). In addition, the adaptive control system was then active. The results of the measurements with the three types of reference signals are displayed in

Figure 6.

The top row shows the system with the internal reference, the middle row is based on the measured SPL of H2.3 and the bottom uses a reference based on the incident sound wave calculated using Equation (

8), using H2.1 and H2.3. The SPL with active control became mostly constant compared to

Figure 5. The SPL rose slightly from around 115 dB below 400 Hz to 125 dB above 1400 Hz, showing a more efficient sound radiation of the transducers for higher frequencies. The equality of the sound pressure distribution indicated that the incident wave was no longer reflected at the piezoceramic. Therefore, no standing wave field was building up. The best results were achieved by the controller using the internal reference (Top), which was to be expected. Even in this case, the system showed some irregularities that corresponded to the resonance frequencies at 586 Hz, 879 Hz, 1172 Hz and 1317 Hz. The effects could also be observed with designs based on the other reference signals. The worst result at all sensors, in terms of a flat amplitude frequency response, was achieved by the controller using only a single pressure sensor as reference (

Figure 6, Middle). Moreover, there were three frequency ranges of diverging amplitude frequency response, around 600 Hz, 950 Hz and 1350 Hz. These corresponded to the nodes at module 2, as seen in

Figure 5 (Top). In this case, the SPL at the reference sensor was low and not representative of the incident sound wave arriving at the active surface. As a result, the algorithm may diverge, and the output reaches the pre-specified threshold. Consequently, the adaptive filter weights were reset. The reference signal based on the wave separation faced the same problem (

Figure 6, Bottom), but the controller appeared to be more robust, especially for higher frequencies. Using the two observation points within the tube to calculate the incident wave probably achieved a better coherence between the reference and the error signal of the controller.

The SPL is a good indicator for the effectiveness of the active system. However, the reflection coefficient delivered more information because it shows the ratio of the incident and reflected wave directly.

Figure 7 displays the magnitude of the reflection coefficient, calculated from H1.1 and H1.3, when applying a sine sweep from 300 Hz to 1500 Hz with

.

The blue line represents the measurement without control. The magnitude of the reflection coefficient was slightly below one for most of the observed frequency range. This observation matches the assumption that the experimental piezo-actuator acts as a hard acoustic boundary condition. The red, yellow and purple lines represent the measurements with the three different reference signals. In a wide frequency range, the magnitude of the reflection coefficient can be reduced to approximately 0.1. All three implementations show better results for higher frequencies, which were probably caused by the higher signal-to-noise ratios (SNRs) of the signals. Preparatory measurements showed that the background noise below 500 Hz was high (spikes of up to 90 dB SPL in the spectrum and a floor of 65 dB), compared to the measured SPL in

Figure 5 and

Figure 6. The controller based on the internal reference struggled, in particular, at three multiples of the resonance frequency (586 Hz, 879 Hz and 1317 Hz). The controller with the pressure-based reference signal caused problems when the signal at H2.3 was low (see

Figure 5, Top). The critical frequency ranges were 500 Hz–700 Hz, 950 Hz–1050 Hz and 1300 Hz to 1425 Hz. This result is in line with the observations in

Figure 6 (Middle). The performance of the system with the wave separation reference was not as good as the other designs under 950 Hz. But, above this frequency, the system with wave separation performed better compared to the system with pressure as a reference signal. Contrary to our expectations, it even outperformed the internal reference design at an eigenfrequency of 1317 Hz. It achieved a reflection coefficient of 0.1 compared to 0.35.

The active system, independent of the reference signal used, was less effective below 500 Hz. It should be noted that the SNR at these frequencies was worse, since the actuators were less efficient in that frequency range and there was a significant amount of low frequency noise present in the signals. Unfortunately, the driving voltage of the experimental piezoceramic had to be limited to 25 V in order to minimize the risk of damaging the actuator. In addition, multiples of the mains frequency of 50 Hz had a negative impact on this experiment. This can be observed in

Figure 7 at 350 Hz, where the reflection coefficient was overestimated. The magnitude of the reflection coefficient also showed local maxima at 450 Hz, 650 Hz and 750 Hz in the experiments.