Tribocorrosion and Stress Corrosion Cracking Risk Assessment of Novel Hybrid Stainless Steel–Carbon Fibre Tubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructural Analysis

2.3. X-Ray Residual Stress Analysis

2.4. Tribocorrosion Analysis

2.5. SCC Susceptibility

3. Results

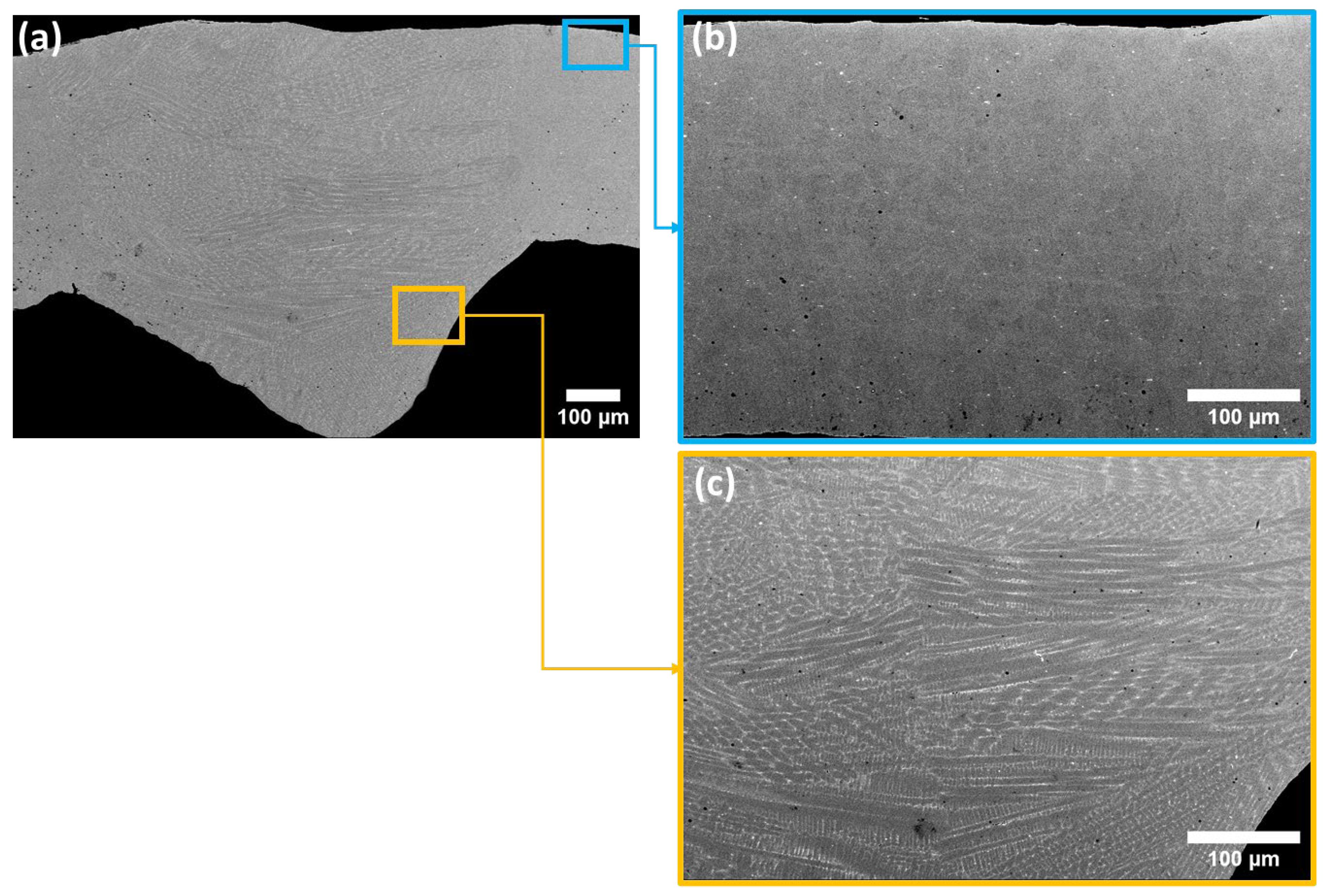

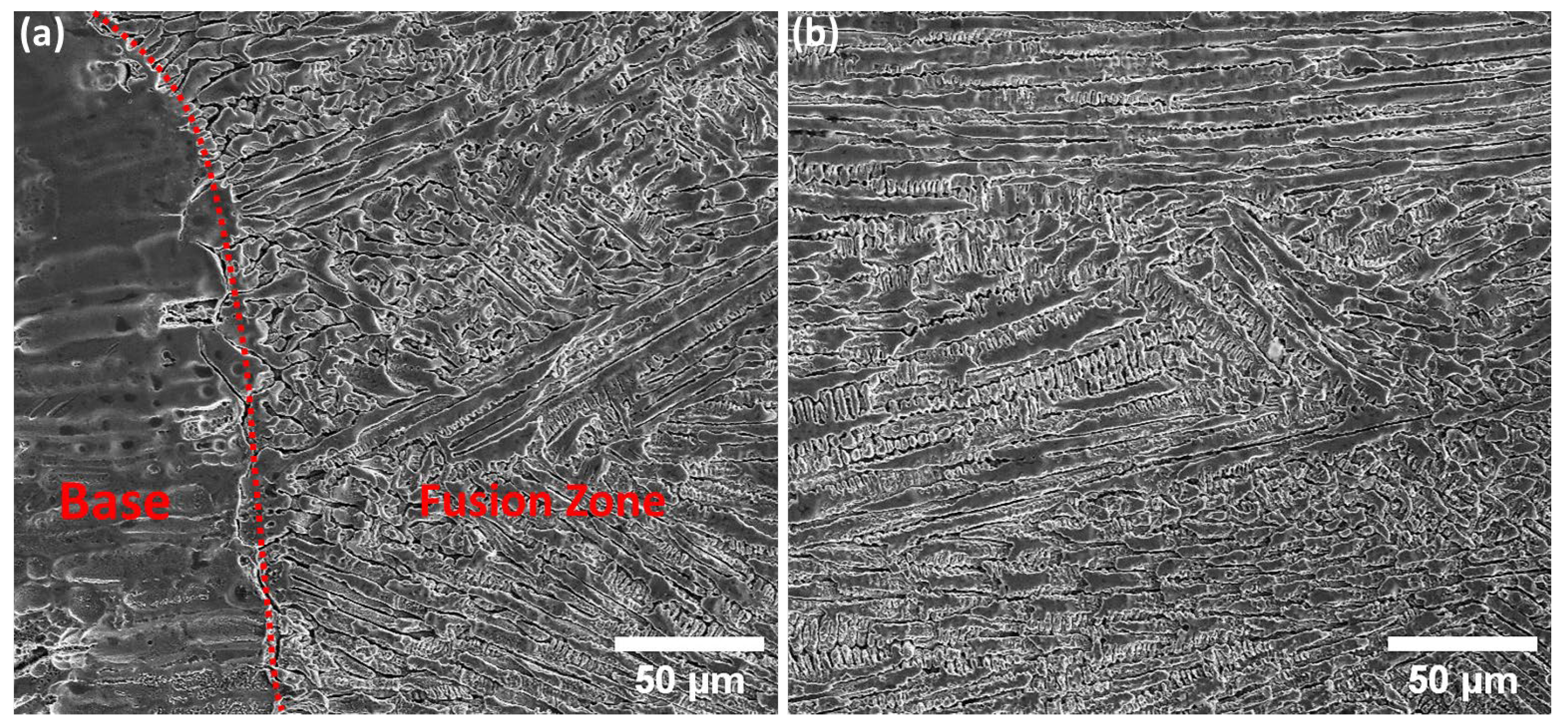

3.1. Microstructural Characterization

3.2. Residual Stress Analysis

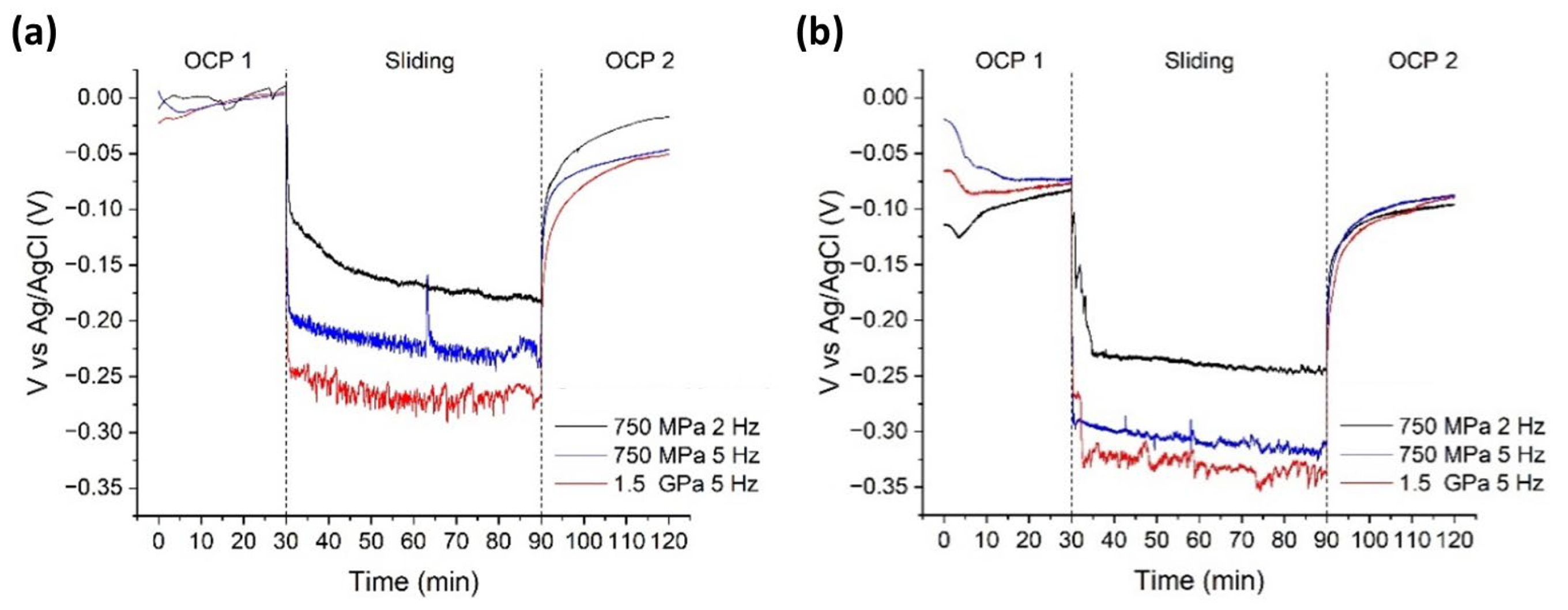

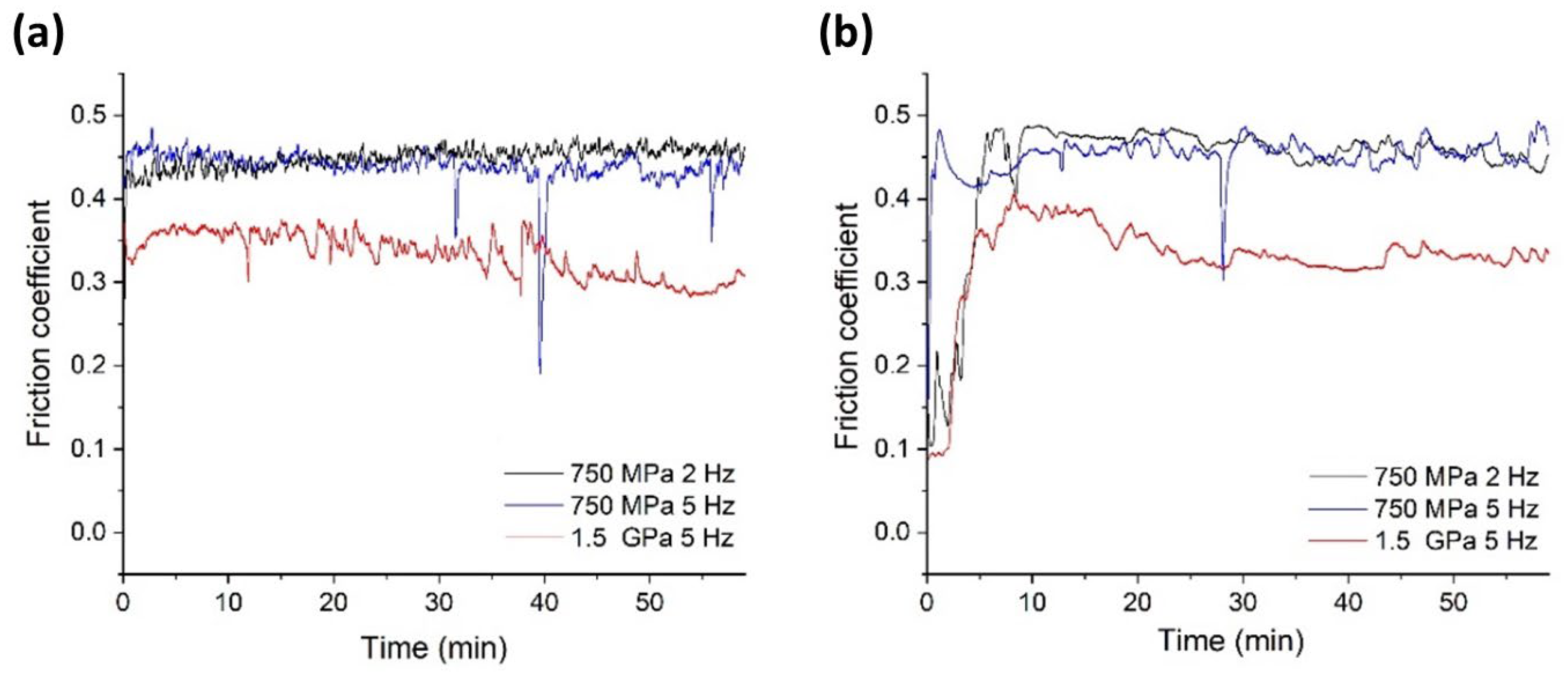

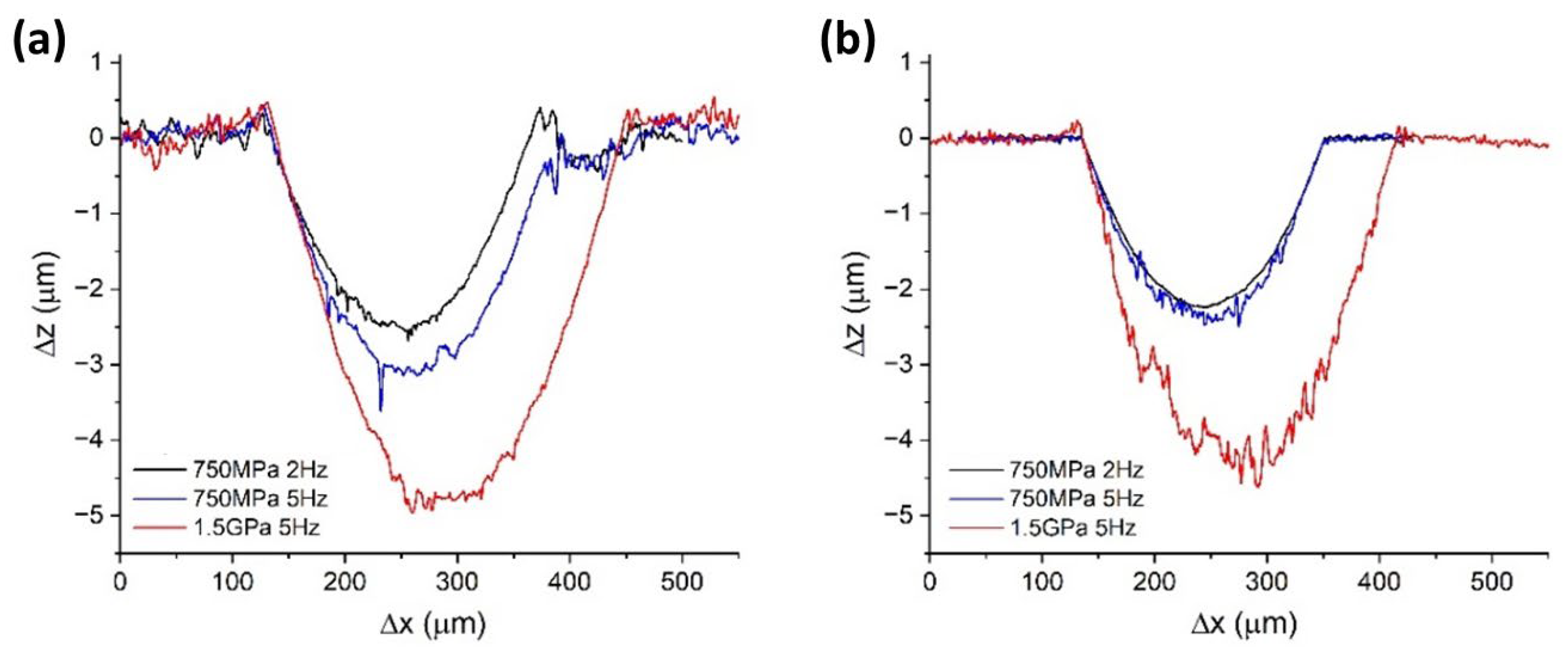

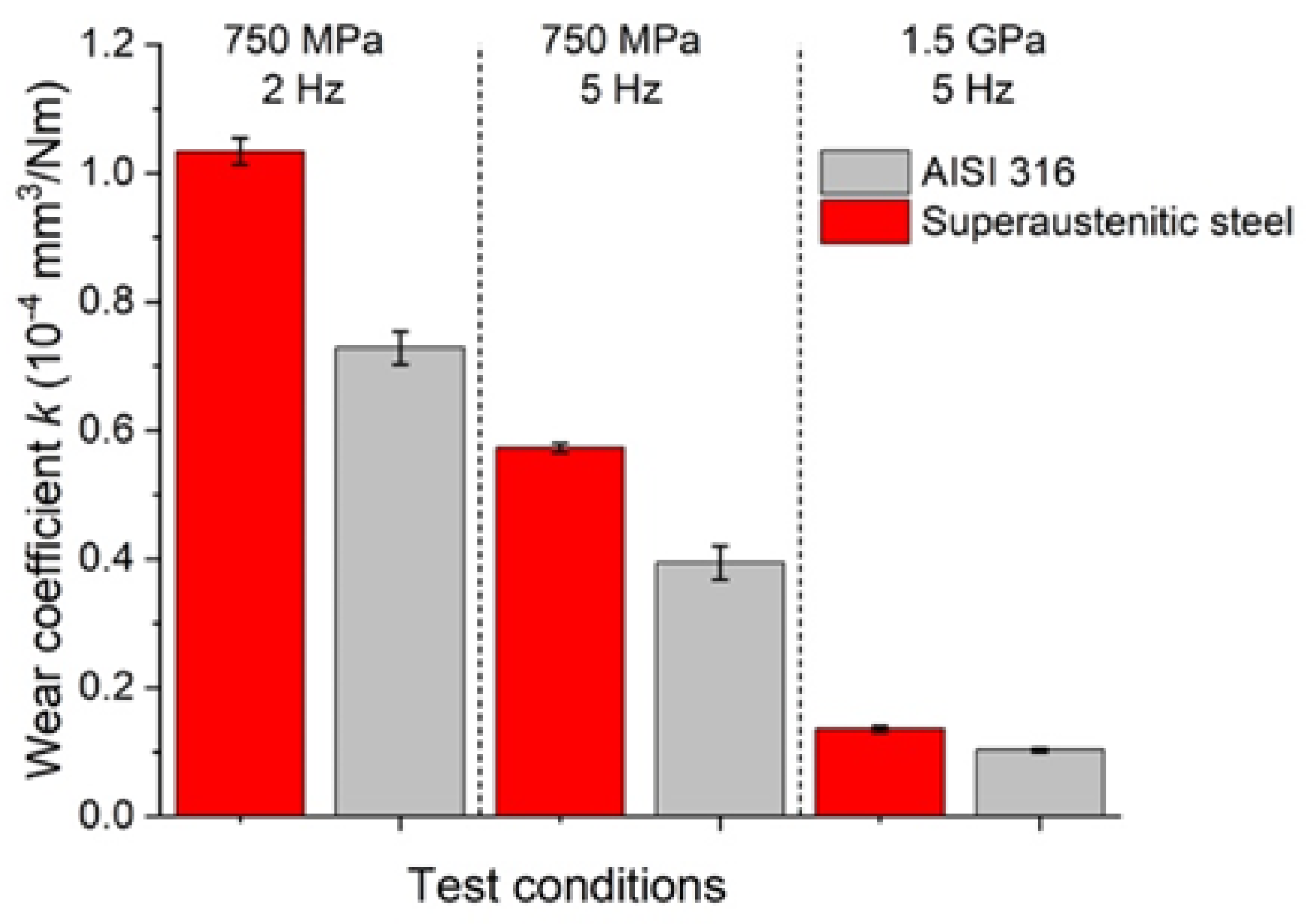

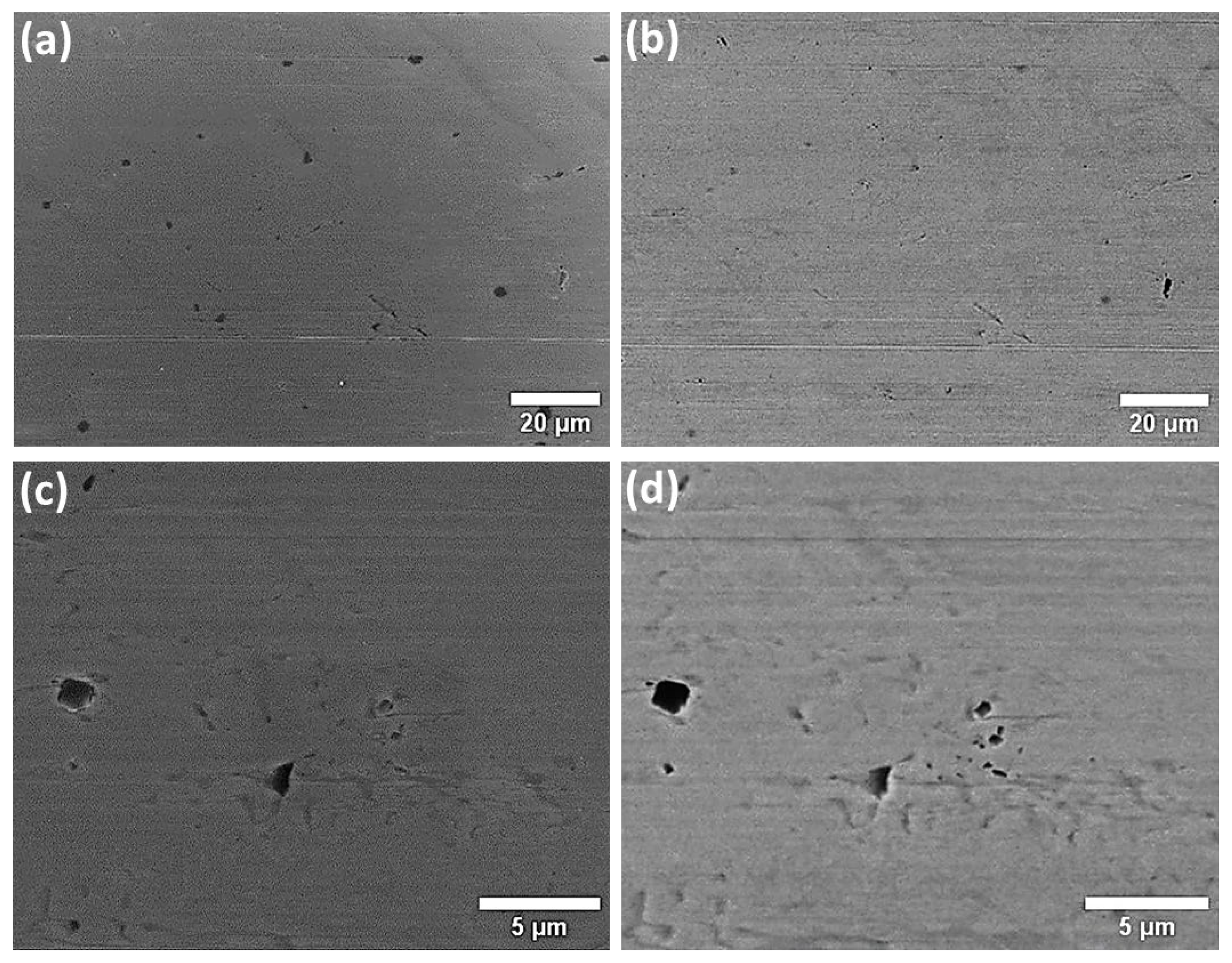

3.3. Tribocorrosion Behaviour

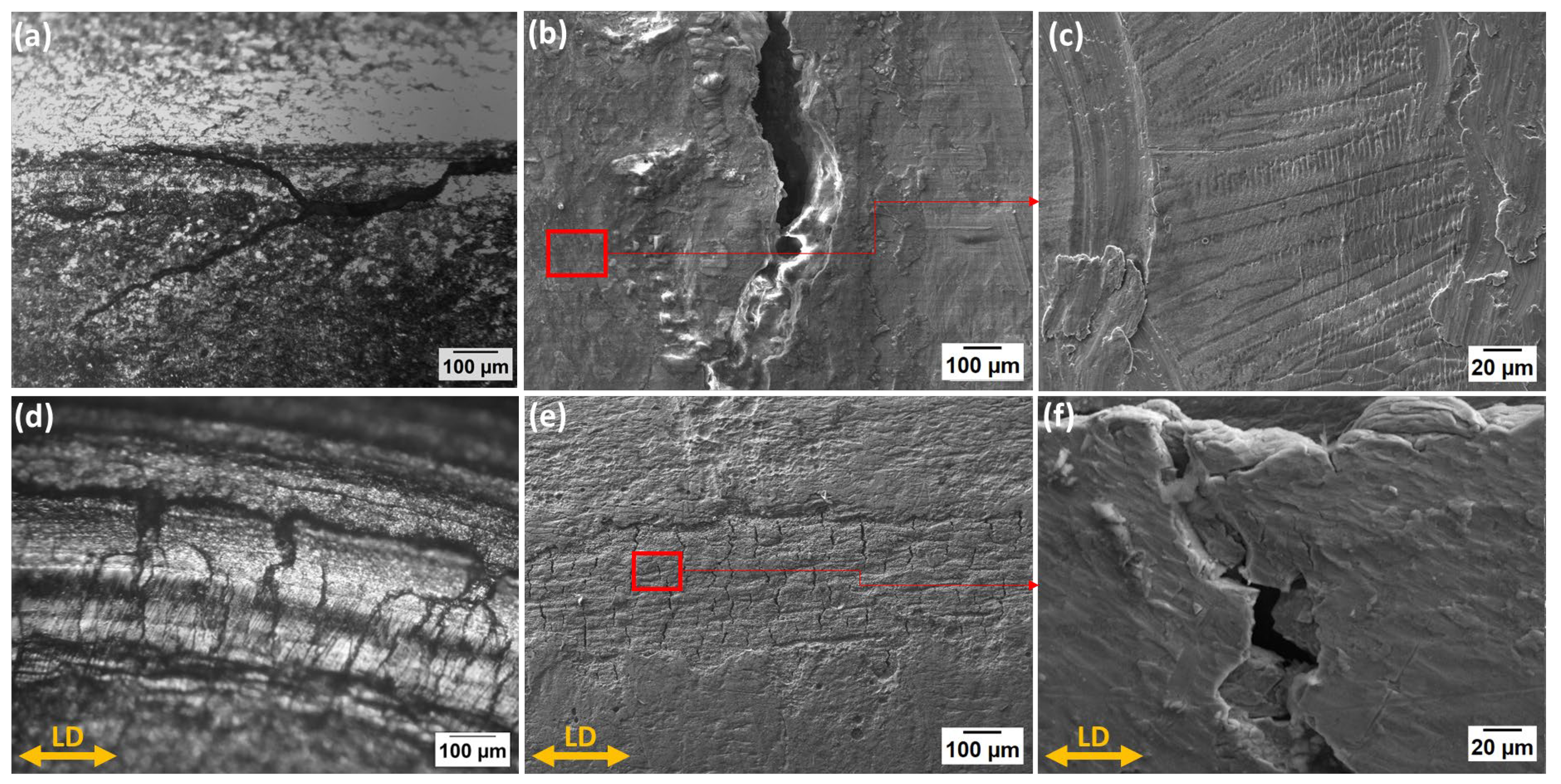

3.4. Stress Corrosion Cracking Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mouradi, H.; El Barkany, A.; El Biyaali, A. Steel wire ropes failure analysis: Experimental study. Eng. Fail. Anal. 2018, 91, 234–242. [Google Scholar] [CrossRef]

- Yang, Y.; Fahmy, M.F.; Guan, S.; Pan, Z.; Zhan, Y.; Zhao, T. Properties and applications of FRP cable on long-span cable-supported bridges: A review. Compos. Part B Eng. 2020, 190, 107934. [Google Scholar] [CrossRef]

- Wu, J.; Xian, G.; Li, H. A novel anchorage system for CFRP cable: Experimental and numerical investigation. Compos. Struct. 2018, 194, 555–563. [Google Scholar] [CrossRef]

- Noisternig, J.F. Carbon Fibre Composites as Stay Cables for Bridges. Appl. Compos. Mater. 2000, 7, 139–150. [Google Scholar] [CrossRef]

- Bambach, M.; Elchalakani, M.; Zhao, X. Composite steel–CFRP SHS tubes under axial impact. Compos. Struct. 2009, 87, 282–292. [Google Scholar] [CrossRef]

- Moy, S.S.J.; Bloodworth, A.G. Strengthening a steel bridge with CFRP composites. Proc. Inst. Civ. Eng.-Struct. Build. 2007, 160, 81–93. [Google Scholar] [CrossRef]

- Yao, Y.; Shi, P.; Qi, S.; Yan, C.; Chen, G.; Liu, D.; Zhu, Y.; Herrmann, A. Manufacturing and mechanical properties of steel-CFRP hybrid composites. J. Compos. Mater. 2020, 54, 3673–3682. Available online: https://journals.sagepub.com/doi/full/10.1177/0021998320918287?casa_token=NDSUSRT0Gt8AAAAA%3Aof9YsVpOhgTI_uephaoLH9_Sfdjx2XU6xJ0Mql8QranPFDQKkXtJmEMBjrNNYKF8UTfAvWcmcbqiWgI (accessed on 22 July 2024). [CrossRef]

- Xiong, W.; Cai, C.S.; Xiao, R.; Deng, L. Concept and analysis of stay cables with a CFRP and steel composite section. KSCE J. Civ. Eng. 2012, 16, 107–117. [Google Scholar] [CrossRef]

- Cai, H.; Aref, A.J. On the design and optimization of hybrid carbon fiber reinforced polymer-steel cable system for cable-stayed bridges. Compos. Part B Eng. 2015, 68, 146–152. [Google Scholar] [CrossRef]

- Bhandari, J.; Khan, F.; Abbassi, R.; Garaniya, V.; Ojeda, R. Modelling of pitting corrosion in marine and offshore steel structures—A technical review. J. Loss Prev. Process Ind. 2015, 37, 39–62. [Google Scholar] [CrossRef]

- Sunny, K.T.; Korra, N.N. A systematic review about welding of super austenitic stainless steel. Mater. Today Proc. 2021, 47, 4378–4381. [Google Scholar] [CrossRef]

- Gunasekaran, K.N.; Balamurugan, D.; Babin, M.; Raj, K.J.B.; Arun, S. Influence of Pitting Corrosion on TIG Welded Joints of AA2024 Aluminum Alloy Joints. J. Phys. Conf. Ser. 2021, 2115, 012052. [Google Scholar] [CrossRef]

- Dadfar, M.; Fathi, M.H.; Karimzadeh, F.; Dadfar, M.R.; Saatchi, A. Effect of TIG welding on corrosion behavior of 316L stainless steel. Mater. Lett. 2007, 61, 2343–2346. [Google Scholar] [CrossRef]

- Bilmes, P.D.; Llorente, C.L.; Saire Huamán, L.; Gassa, L.M.; Gervasi, C.A. Microstructure and pitting corrosion of 13CrNiMo weld metals. Corros. Sci. 2006, 48, 3261–3270. [Google Scholar] [CrossRef]

- Chaves, I.A.; Melchers, R.E. Pitting corrosion in pipeline steel weld zones. Corros. Sci. 2011, 53, 4026–4032. [Google Scholar] [CrossRef]

- Garcia, C.; de Tiedra, M.; Blanco, Y.; Martin, O.; Martin, F. Intergranular corrosion of welded joints of austenitic stainless steels studied by using an electrochemical minicell. Corros. Sci. 2008, 50, 2390–2397. [Google Scholar] [CrossRef]

- Kumar, M.V.; Balasubramanian, V.; Rajakumar, S.; Albert, S.K. Stress corrosion cracking behaviour of gas tungsten arc welded super austenitic stainless steel joints. Def. Technol. 2015, 11, 282–291. [Google Scholar] [CrossRef]

- Lu, B.T.; Chen, Z.K.; Luo, J.L.; Patchett, B.M.; Xu, Z.H. Pitting and stress corrosion cracking behavior in welded austenitic stainless steel. Electrochim. Acta 2005, 50, 1391–1403. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Franceschi, M.; Bergamo, G.; Bonesso, M.; Dabalà, M. On the exceptional stress corrosion cracking susceptibility of selective laser melted 316L stainless steel under the individual effect of surface residual stresses. Eng. Fail. Anal. 2022, 136, 106192. [Google Scholar] [CrossRef]

- Residual Stress Characterization of Welds Using X-Ray Diffraction Techniques|INIS, (n.d.). Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:28053342 (accessed on 22 July 2024).

- Yazdanpanah, A.; Pagot, G.; Franceschi, M.; Rebesan, P.; Venturin, M.; Botinha, J.; Gerhmann, B.; De Graeve, I.; Di Noto, V.; Revilla, R.I.; et al. Mechanism of alteration in passivity of additively manufactured Ni-Fe-Cr Alloy 718 caused by minor carbon variation. Electrochim. Acta 2024, 503, 144925. [Google Scholar] [CrossRef]

- ASTM G36-94(2018); Standard Practice for Evaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in a Boiling Magnesium Chloride Solution. ASTM: West Conshohocken, PA, USA, 2024.

- Mohammadzehi, S.; Mirzadeh, H. Cold unidirectional/cross-rolling of austenitic stainless steels: A review. Arch. Civ. Mech. Eng. 2022, 22, 129. [Google Scholar] [CrossRef]

- Kumar, B.; Singh, A.; Das, S.; Bhattacharya, D. Cold rolling texture in AISI 304 stainless steel. Mater. Sci. Eng. A 2004, 364, 132–139. [Google Scholar] [CrossRef]

- Chowdhury, S.G.; Das, S.; De, P. Cold rolling behaviour and textural evolution in AISI 316L austenitic stainless steel. Acta Mater. 2005, 53, 3951–3959. [Google Scholar] [CrossRef]

- Shaughnessy, B.M.; Eccleston, P.; Fereday, K.J.; Canfer, S.J.; Nørgaard-Nielsen, H.U.; Jessen, N.C. Thermal conductivity measurement below 40 K of the CFRP tubes for the Mid-Infrared Instrument mounting struts. Cryogenics 2007, 47, 348–352. [Google Scholar] [CrossRef]

- Bui, H.K.; Senghor, F.D.; Wasselynck, G.; Trichet, D.; Fouladgar, J.; Lee, K.; Berthiau, G. Characterization of Electrical Conductivity of Anisotropic CFRP Materials by Means of Induction Thermography Technique. IEEE Trans. Magn. 2018, 54, 1–4. [Google Scholar] [CrossRef]

- Adamczyk, W.P.; Pawlak, S.; Ostrowski, Z. Determination of thermal conductivity of CFRP composite materials using unconventional laser flash technique. Measurement 2018, 124, 147–155. [Google Scholar] [CrossRef]

- Hertzman, S.; Brolund, B.; Ferreira, P.J. An experimental and theoretical study of heat-affected zone austenite reformation in three duplex stainless steels. Metall. Mater. Trans. A 1997, 28, 277–285. [Google Scholar] [CrossRef]

- Wu, T.-H.; Wang, J.-J.; Li, H.-B.; Jiang, Z.-H.; Liu, C.-M.; Zhang, H.-Y. Effect of heat input on austenite microstructural evolution of simulated heat affected zone in 2205 duplex stainless steel. J. Iron Steel Res. Int. 2019, 26, 435–441. [Google Scholar] [CrossRef]

- Hamza, S.; Boumerzoug, Z.; Boumerzoug, E.R.; Delaunois, F. Simulated heat affected zone in welded stainless steel 304l. Acta Metall. Slovaca 2019, 25, 142–149. [Google Scholar] [CrossRef]

- Shankar, V.; Gill, T.P.S.; Mannan, S.L.; Sundaresan, S. Fusion zone and heat affected zone cracking susceptibility of stabilised austenitic stainless steels. Sci. Technol. Weld. Join. 1998, 3, 17–24. [Google Scholar] [CrossRef]

- Takalo, T.; Suutala, N.; Moisio, T. Austenitic solidification mode in austenitic stainless steel welds. Metall. Trans. A 1979, 10, 1173–1181. [Google Scholar] [CrossRef]

- Hänninen, H.; Minni, E. On grain boundary segregation in austenitic stainless steels. Metall. Trans. A 1982, 13, 2281–2285. [Google Scholar] [CrossRef]

- Suutala, N.; Takalo, T.; Moisio, T. Ferritic-austenitic solidification mode in austenitic stainless steel welds. Metall. Trans. A 1980, 11, 717–725. [Google Scholar] [CrossRef]

- Shankar, V.; Gill, T.P.S.; Mannan, S.L.; Sundaresan, S. Solidification cracking in austenitic stainless steel welds. Sadhana 2003, 28, 359–382. [Google Scholar] [CrossRef]

- Ramirez–Ledesma, A.L.; Acosta–Vargas, L.A.; Juarez–Islas, J.A. Suppression of interdendritic segregation during welding of a 347 austenitic stainless steel pipe reactors. Eng. Fail. Anal. 2020, 114, 104589. [Google Scholar] [CrossRef]

- Gasparrini, C.; Douglas, J.; Yazdanpanah, A.; Stroud, R.; Divitini, G.; Dabalà, M.; Scatigno, G.; Pedrazzini, S.; Wenman, M.; Badocco, D.; et al. Corrosion of 316L exposed to highly concentrated borated water used as shield in nuclear fusion experimental reactors cooling circuits. Corros. Sci. 2024, 230, 111902. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Revilla, R.I.; Franceschi, M.; Fabrizi, A.; Khademzadeh, S.; Khodabakhshi, M.; De Graeve, I.; Dabalà, M. Unveiling the impact of laser power variations on microstructure, corrosion, and stress-assisted surface crack initiation in laser powder bed fusion-processed Ni-Fe-Cr alloy 718. Electrochim. Acta 2024, 476, 143723. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Franceschi, M.; Rebesan, P.; Dabalà, M. Correlation of Lack of Fusion Pores with Stress Corrosion Cracking Susceptibility of L-PBF 316L: Effect of Surface Residual Stresses. Materials 2022, 15, 7151. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Biglari, F.R.; Arezoodar, A.F.; Dabalà, M. Role of grinding induced surface residual stress on probability of stress corrosion cracks initiation in 316L austenitic stainless steel in 3.5% sodium chloride aqueous solution. Corros. Eng. Sci. Technol. 2021, 56, 81–92. [Google Scholar] [CrossRef]

- Tribocorrosion of Stainless Steels (Review)-ProQuest. Available online: https://www.proquest.com/openview/5091c2defeb64df380e17232d0bfe0cb/1?cbl=2034508&pq-origsite=gscholar (accessed on 19 May 2025).

- Wood, R.J.K. Marine wear and tribocorrosion. Wear 2017, 376–377, 893–910. [Google Scholar] [CrossRef]

- López-Ortega, A.; Arana, J.L.; Bayón, R. Tribocorrosion of Passive Materials: A Review on Test Procedures and Standards. Int. J. Corros. 2018, 2018, 7345346. [Google Scholar] [CrossRef]

- Landolt, D.; Mischler, S. Tribocorrosion of Passive Metals and Coatings; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Mischler, S.; Debaud, S.; Landolt, D. Wear-Accelerated Corrosion of Passive Metals in Tribocorrosion Systems. J. Electrochem. Soc. 1998, 145, 750. [Google Scholar] [CrossRef]

- Landolt, D. Passivity Issues in Tribocorrosion. In Passivation of Metals and Semiconductors, and Properties of Thin Oxide Layers; Marcus, P., Maurice, V., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2006; pp. 477–487. [Google Scholar] [CrossRef]

- von der Ohe, C.B.; Johnsen, R.; Espallargas, N. Modeling the multi-degradation mechanisms of combined tribocorrosion interacting with static and cyclic loaded surfaces of passive metals exposed to seawater. Wear 2010, 269, 607–616. [Google Scholar] [CrossRef]

- Pintaude, G.; Sinatora, A.; Albertin, E. A review on abrasive wear mechanisms of metallic materials. In Proceedings of the Abrasion Wear Resistant Alloyed White Cast Iron for Rolling and Pulverizing Mills, Sao Paulo, Brazil, 14–17 August 2005. [Google Scholar] [CrossRef]

- Sin, H.; Saka, N.; Suh, N.P. Abrasive wear mechanisms and the grit size effect. Wear 1979, 55, 163–190. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Kilpi, L.; Hakala, T.J.; Carpen, L.; Ronkainen, H. Tribocorrosion study of martensitic and austenitic stainless steels in 0.01 M NaCl solution. Tribol. Int. 2016, 95, 358–371. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.-Z.; Yin, X.-Y.; Yan, F.-Y. Tribocorrosion behaviour of 304 stainless steel in different corrosive solutions. Mater. Corros. 2016, 67, 769–777. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, E.; Du, S.; Zhang, J.; Wang, L.; Du, H.; Cai, H. Tribocorrosion Behavior of Typical Austenitic, Martensitic, and Ferritic Stainless Steels in 3.5% NaCl Solution. J. Mater. Eng. Perform. 2021, 30, 6284–6296. [Google Scholar] [CrossRef]

- ASTM G133-02; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM: West Conshohocken, PA, USA, 2017.

- Williams, J.A.; Hyncica, A.M. Mechanisms of abrasive wear in lubricated contacts. Wear 1992, 152, 57–74. [Google Scholar] [CrossRef]

- Hokkirigawa, K.; Kato, K.; Li, Z.Z. The effect of hardness on the transition of the abrasive wear mechanism of steels. Wear 1988, 123, 241–251. [Google Scholar] [CrossRef]

- Murray, M.J.; Mutton, P.J.; Watson, J.D. Abrasive Wear Mechanisms in Steels. J. Lubr. Technol. 1982, 104, 9–16. [Google Scholar] [CrossRef]

- Kayaba, T.; Hokkirigawa, K.; Kato, K. Analysis of the abrasive wear mechanism by successive observations of wear processes in a scanning electron microscope. Wear 1986, 110, 419–430. [Google Scholar] [CrossRef]

- Wegrzyn, T. Delta ferrite in stainless steel weld metals. Weld. Int. 1992, 6, 690–694. [Google Scholar] [CrossRef]

- Sui, G.; Charles, E.A.; Congleton, J. The effect of delta-ferrite content on the stress corrosion cracking of austenitic stainless steels in a sulphate solution. Corros. Sci. 1996, 38, 687–703. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kwon, H.S.; Kim, H.S. Effect of Delta Ferrite on Corrosion Resistance of Type 316L Stainless Steel in Acidic Chloride Solution by Micro-Droplet Cell. Solid State Phenom. 2007, 124–126, 1533–1536. [Google Scholar] [CrossRef]

- Osoba, L.O.; Elemuren, R.A.; Ekpe, I.C. Influence of delta ferrite on corrosion susceptibility of AISI 304 austenitic stainless steel. Cogent Eng. 2016, 3, 1150546. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; De Pietri, A.; Ben Hjal, A.; Khodabakhshi, M.; Biasiolo, L.; Dabalà, M. Electrochemical and localized corrosion characteristics of kolsterised and DLC-coated 316LVM stainless steel for biomedical applications. Appl. Surf. Sci. 2025, 693, 162808. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Revilla, R.I.; Franceschi, M.; Pagot, G.; Khodabakhshi, M.; De Graeve, I.; Di Noto, V.; Dabalà, M.; Lozano-Perez, S. Exploring the mechanism of stress-induced passive layer degradation in additively manufactured Ni-Fe-Cr-based alloy 718. Corros. Sci. 2024, 241, 112523. [Google Scholar] [CrossRef]

- Kim, S.H.; Moon, H.K.; Kang, T.; Lee, C.S. Dissolution kinetics of delta ferrite in AISI 304 stainless steel produced by strip casting process. Mater. Sci. Eng. A 2003, 356, 390–398. [Google Scholar] [CrossRef]

- Pujar, M.G.; Dayal, R.K.; Gill, T.P.S.; Malhotra, S.N. Role of Delta-Ferrite in the Dissolution of Passive Films on the Austenitic Stainless-Steel Weld Metals. J. Mater. Sci. Lett. 1999, 18, 823–826. [Google Scholar] [CrossRef]

- Ben Rhouma, A.; Amadou, T.; Sidhom, H.; Braham, C. Correlation between microstructure and intergranular corrosion behavior of low delta-ferrite content AISI 316L aged in the range 550–700 °C. J. Alloys Compd. 2017, 708, 871–886. [Google Scholar] [CrossRef]

- Krivonosova, E.A. A Review of Stress Corrosion Cracking of Welded Stainless Steels. Open Access Libr. J. 2018, 5, 1. [Google Scholar] [CrossRef]

- Li, G.F.; Congleton, J. Stress corrosion cracking of a low alloy steel to stainless steel transition weld in PWR primary waters at 292°C. Corros. Sci. 2000, 42, 1005–1021. [Google Scholar] [CrossRef]

- Lucas, T.; Ballinger, R.G.; Hanninen, H.; Saukkonen, T. Effect of Thermal Aging on SCC, Material Properties and Fracture Toughness of Stainless Steel Weld Metals. In Proceedings of the 15th International Conference on Environmental Degradation of Materials in Nuclear Power Systems—Water Reactors, Colorado Springs, CO, USA, 7–11 August 2011; Busby, J.T., Ilevbare, G., Andresen, P.L., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 883–905. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Capuzzo, N.; Khodabakhshi, M.; Dabalà, M. Evaluation of stress-assisted corrosion performance of L-PBF processed Ti6Al4V: A microcapillary electrochemical approach. Eng. Fail. Anal. 2024, 166, 108891. [Google Scholar] [CrossRef]

- Stress Corrosion Cracking of Type 304 Stainless Steel Weldments in the Active State|CORROSION|Association for Materials Protection and Performance. Available online: https://content.ampp.org/corrosion/article-abstract/50/3/171/5725/Stress-Corrosion-Cracking-of-Type-304-Stainless?redirectedFrom=fulltext (accessed on 19 May 2025).

| Element | C | Si | Mn | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|

| wt. % | 0.02 | 0.18 | 0.65 | 20.30 | 6.30 | 17.80 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazdanpanah, A.; Zin, V.; Valentini, F.; Pezzato, L.; Brunelli, K. Tribocorrosion and Stress Corrosion Cracking Risk Assessment of Novel Hybrid Stainless Steel–Carbon Fibre Tubes. Corros. Mater. Degrad. 2025, 6, 22. https://doi.org/10.3390/cmd6020022

Yazdanpanah A, Zin V, Valentini F, Pezzato L, Brunelli K. Tribocorrosion and Stress Corrosion Cracking Risk Assessment of Novel Hybrid Stainless Steel–Carbon Fibre Tubes. Corrosion and Materials Degradation. 2025; 6(2):22. https://doi.org/10.3390/cmd6020022

Chicago/Turabian StyleYazdanpanah, Arshad, Valentina Zin, Francesca Valentini, Luca Pezzato, and Katya Brunelli. 2025. "Tribocorrosion and Stress Corrosion Cracking Risk Assessment of Novel Hybrid Stainless Steel–Carbon Fibre Tubes" Corrosion and Materials Degradation 6, no. 2: 22. https://doi.org/10.3390/cmd6020022

APA StyleYazdanpanah, A., Zin, V., Valentini, F., Pezzato, L., & Brunelli, K. (2025). Tribocorrosion and Stress Corrosion Cracking Risk Assessment of Novel Hybrid Stainless Steel–Carbon Fibre Tubes. Corrosion and Materials Degradation, 6(2), 22. https://doi.org/10.3390/cmd6020022