Induced Effects of Nano-Patterned Substrates on the Electrical and Photo-Electrical Properties of PTB7-Th:ICBA (1:1, wt.%) Bulk-Heterojunction Solar Cells

Abstract

1. Introduction

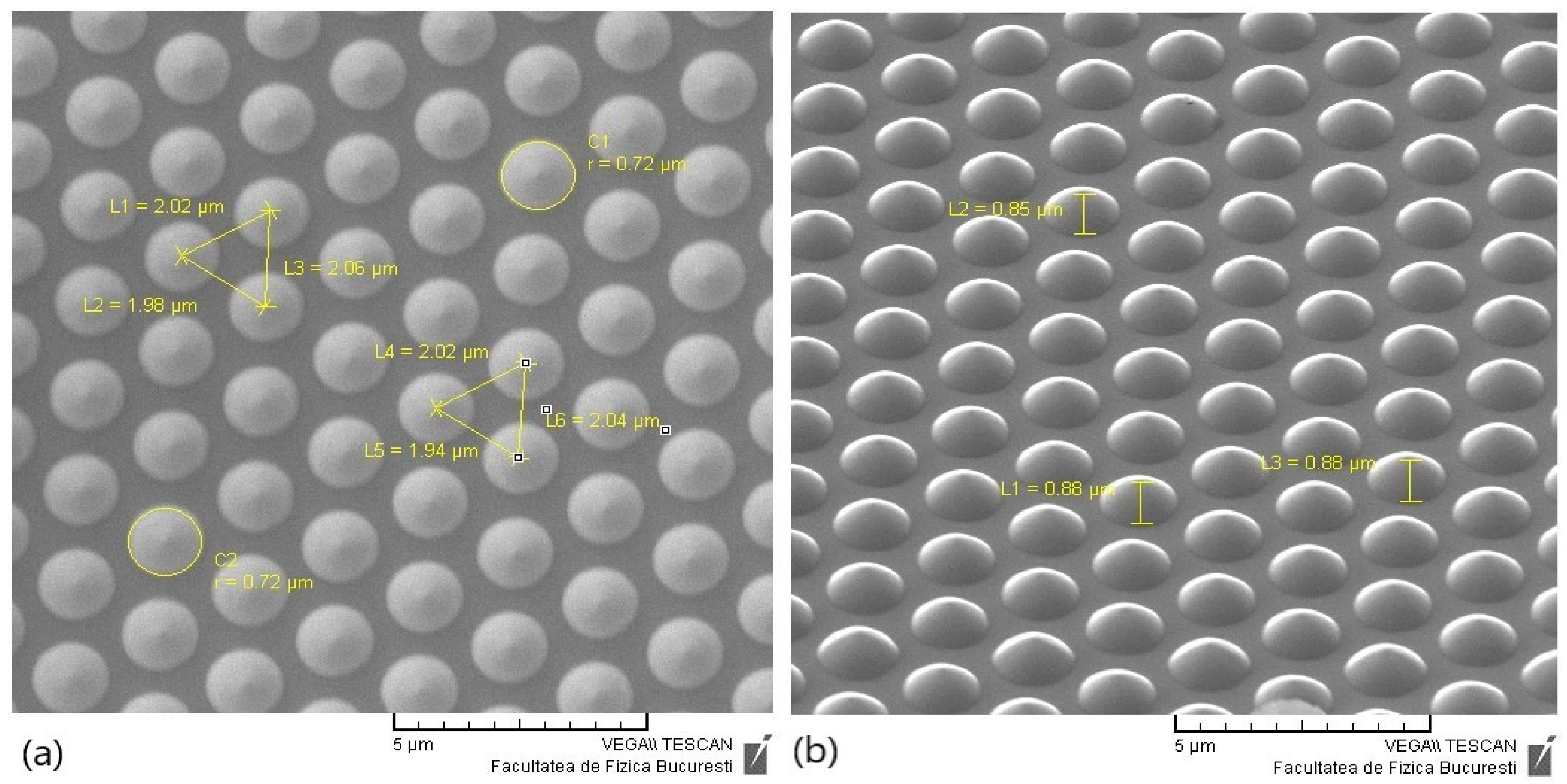

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Characterization

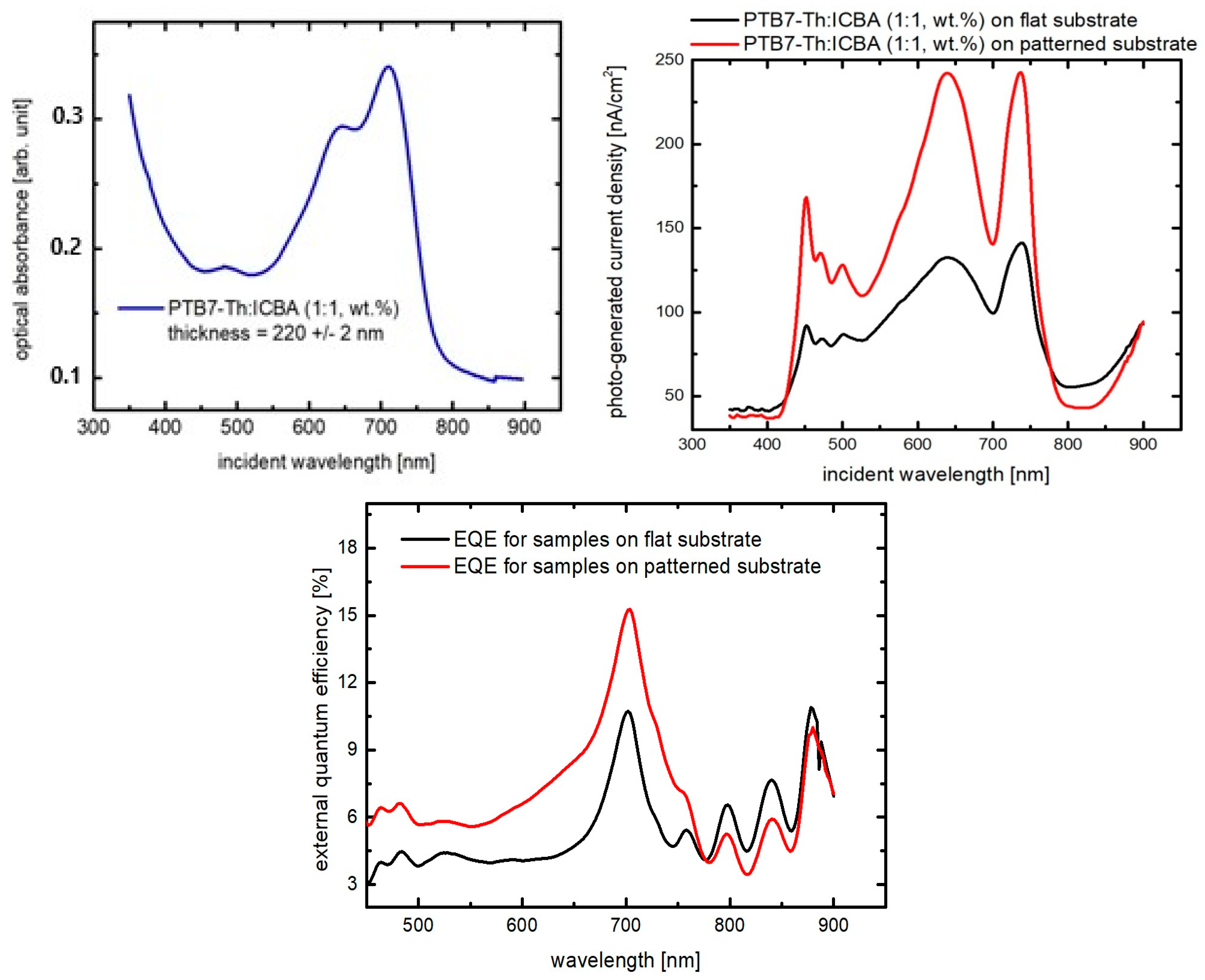

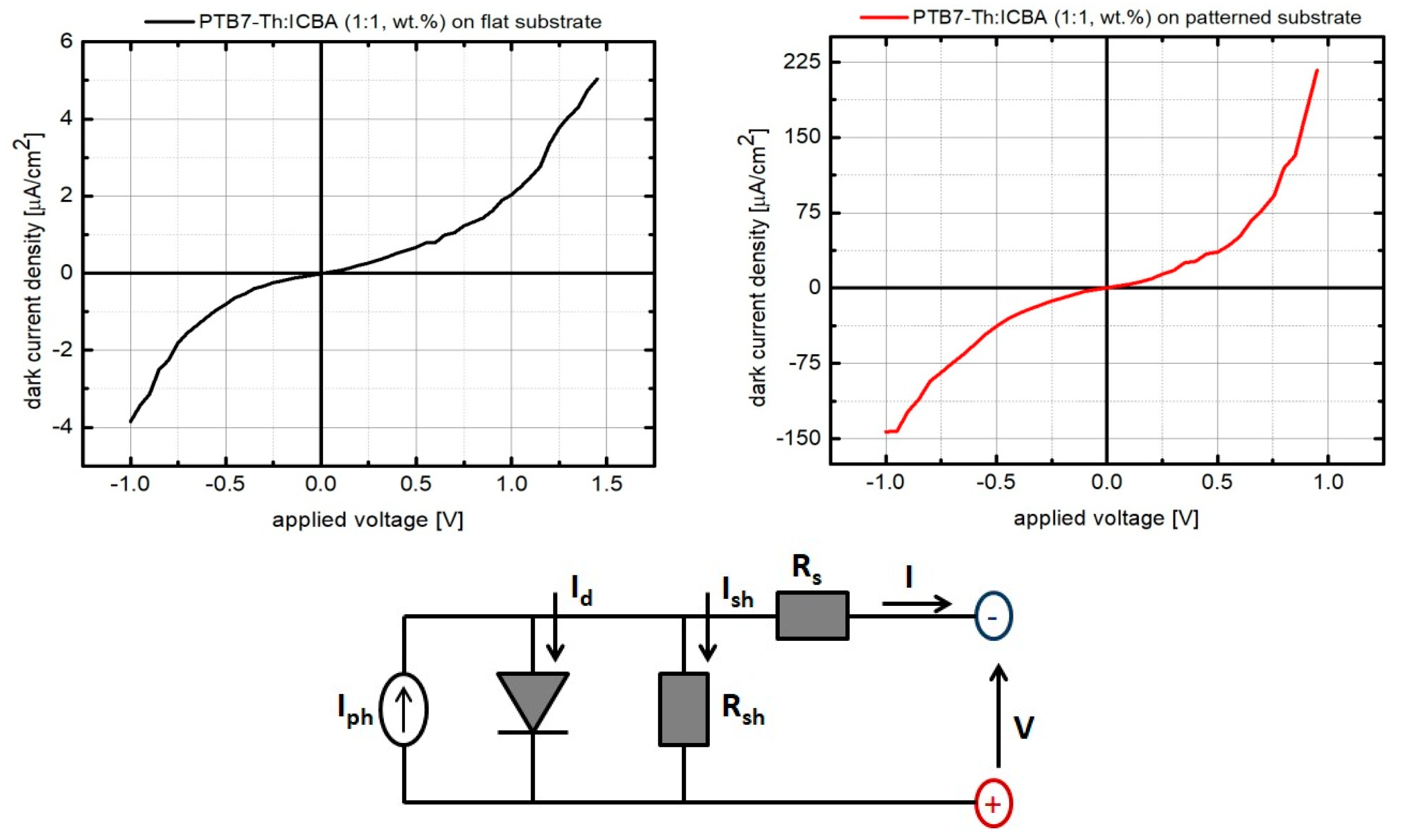

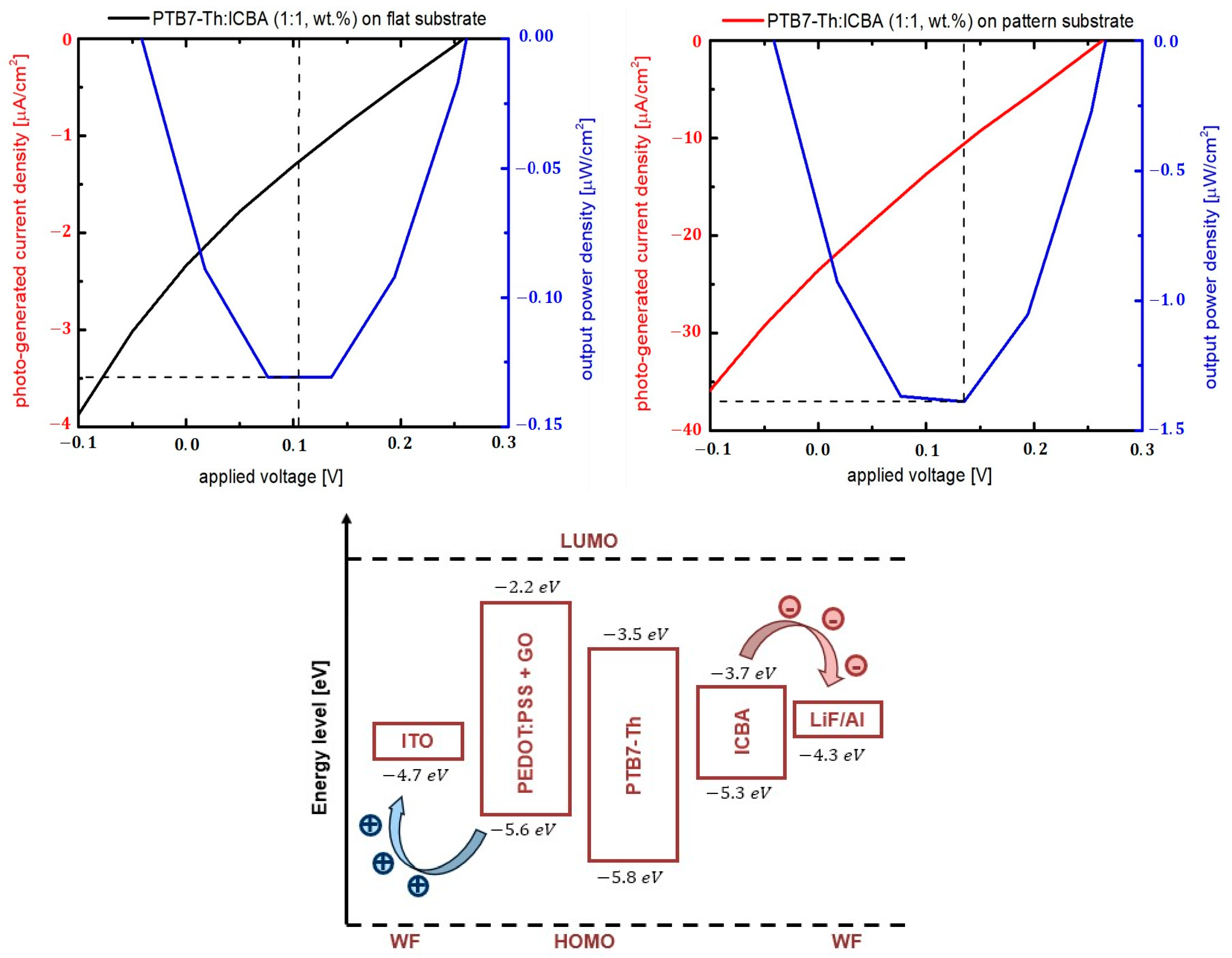

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.; Keane, J.C.; Dhere, R.G.; DeHart, C.; Albin, D.S.; Duda, A.; Gessert, T.A.; Asher, S.; Levi, D.H.; Sheldon, P. 16.5% Efficient CdS/CdTe polycrystalline thin film solar cell. In Proceedings of the 17th Conference IEEE European Photovoltaic Solar Energy, Munich, Germany, 22–26 October 2001; pp. 995–1000. [Google Scholar]

- Seck, S.M.; Ndiaye, E.N.; Fall, M.; Charvet, S. Study of efficiencies CdTe/CdS photovoltaic solar cell according to electrical properties by SCAPS Simulation. Nat. Resour. 2020, 11, 147–155. [Google Scholar] [CrossRef]

- Dursun, S.; Gezgin, S.Y.; Kilic, H.S. J-V and C-V characteristic of CdS/CdTe solar cell modeled by SCAPS-1D program. J. Mater. Manuf. 2022, 2, 41–52. [Google Scholar]

- Jeong, M.; Choi, I.W.; Go, E.M.; Cho, Y.; Kim, M.; Lee, B.; Jeong, S.; Jo, Y.; Choi, H.W.; Lee, J.; et al. Stable perovskite solar cells with efficiency exceeding 24.8% and 0.3-V voltage loss. Science 2020, 369, 1615–1620. [Google Scholar] [CrossRef] [PubMed]

- Bai, P.; Abdelkhalik, M.S.; Castanheira, D.G.A.; Rivas, J.G. Evolutionary optimization of the short-circuit current enhancement in organic solar cells by nanostructured electrodes. J. Appl. Phys. 2022, 132, 153103. [Google Scholar] [CrossRef]

- Mumyatov, A.V.; Troshin, P.A. A review on fullerene derivatives with reduced electron affinity as acceptor materials for organic solar cells. Energies 2023, 16, 1924. [Google Scholar] [CrossRef]

- Zhang, F.; Inganas, O.; Zhou, Y.; Vandewal, K. Development of polymer-fullerene solar cells. Natl. Sci. Rev. 2016, 3, 222–239. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, L.; Zhao, W.; Liu, D.; Yao, H.; Hou, J. Side chain selection for designing highly efficient photovoltaic polymers with 2D-conjugated structures. Macromolecules 2014, 47, 4653–4659. [Google Scholar] [CrossRef]

- He, Y.; Chen, H.-Y.; Hou, J.; Li, Y. Indene-C60 Bisadduct: A new acceptor for high-performance polymer solar cells. J. Am. Chem. Soc. 2010, 132, 1377–1382. [Google Scholar] [CrossRef]

- Tetreault, A.R.; Dang, M.-T.; Bender, T.P. PTB7 and PTB7-Th as universal polymers to evaluate materials development aspects of organic solar cells including interfacial layers, new fullerenes, and non-fullerene electron acceptors. Synth. Met. 2022, 287, 117088. [Google Scholar] [CrossRef]

- Liu, S.; Li, H.; Wu, X.; Chen, D.; Zhang, L.; Meng, X.; Tan, L.; Hu, X.; Chen, Y. Pseudo-planar heterojunction organic photovoltaics with optimized light utilization for printable solar window. Adv. Mater. 2022, 34, 2201604. [Google Scholar] [CrossRef]

- Sharma, M.; Negi, C.M.S.; Alvi, P.A.; Gupta, S.K. Bulk heterojunction PTB7-Th: ICBA-based optoelectronic devices. In Proceedings of the 2022 5th International Conference on Multimedia, Signal Processing and Communication Technologies (IMPACT), Aligarh, India, 26–27 November 2022. [Google Scholar]

- Huang, W.; Gann, E.; Chandrasekaran, N.; Prasad, S.K.K.; Chang, S.-Y.; Thomsen, L.; Kabra, D.; Hodgkiss, J.M.; Cheng, Y.-B.; Yang, Y.; et al. Influence of fullerene acceptor on the performance, microstructure, and photophysics of low bandgap polymer solar cells. Adv. Energy Mater. 2017, 7, 1602197. [Google Scholar] [CrossRef]

- Castro-Chacón, A.; Castro-Carranza, A.; Amargós-Reyes, O.; Maldonado, J.-L.; Hernández-Cristóbal, O.; Guzmán-Caballero, D.; Mejía, I.; Vázquez, A.; Gutowski, J.; Nolasco, J.C. Relationship between the VOC Tuning Effect and the Interface Activation Energy Due to the Third Component Concentration in Ternary Organic Solar Cells. ACS Appl. Energy Mater. 2022, 5, 4288–4295. [Google Scholar] [CrossRef]

- Borse, K.; Sharma, R.; Sagar, H.P.; Reddy, P.A.; Gupta, D.; Yella, A. Efficient light trapping and interface engineering for performance enhancement in PTB7-Th: PC70BM organic solar cells. Org. Electron. 2017, 41, 280–286. [Google Scholar] [CrossRef]

- Sharma, R.; Lee, H.; Gupta, V.; Kim, H.; Kumar, M.; Sharma, C.; Chand, S.; Yoo, S.; Gupta, D. Photo-physics of PTB7, PCBM and ICBA based ternary solar cells. Org. Electron. 2016, 34, 111–117. [Google Scholar] [CrossRef]

- Balling, P.; Christiansen, J.; Christiansen, R.E.; Eriksen, E.; Lakhotiya, H.; Mirsafaei, M.; Møller, S.H.; Nazir, A.; Vester-Petersen, J.; Jeppesen, B.R.; et al. Improving the efficiency of solar cells by upconverting sunlight using field enhancement from optimized nano structures. Opt. Mater. 2018, 83, 279–289. [Google Scholar] [CrossRef]

- Hong, S.H.; Hwang, J.Y.; Lee, H.; Lee, H.C.; Choi, K.W. UV nanoimprint using flexible polymer template and substrate. Microelectron. Eng. 2009, 86, 295–298. [Google Scholar] [CrossRef]

- Socol, M.; Preda, N.; Breazu, C.; Petre, G.; Stanculescu, A.; Stavarache, I.; Popescu-Pelin, G.; Stochioiu, A.; Socol, G.; Iftimie, S.; et al. Effects of Solvent Additive and Micro-Patterned Substrate on the Properties of Thin Films Based on P3HT:PC70BM Blends Deposited by MAPLE. Materials 2023, 16, 144. [Google Scholar] [CrossRef]

- Baracu, A.M.; Avram, M.A.; Breazu, C.; Bunea, M.-C.; Socol, M.; Stanculescu, A.; Matei, E.; Thrane, P.C.V.; Dirdal, C.A.; Dinescu, A.; et al. Silicon Metalens Fabrication from Electron Beam to UV-Nanoimprint Lithography. Nanomaterials 2021, 11, 2329. [Google Scholar] [CrossRef]

- Li, K.; Morton, K.; Veres, T.; Cui, B. 5.11—Nanoimprint Lithography and Its Application in Tissue Engineering and Biosensing. In Comprehensive Biotechnology, 2nd ed.; Moo-Young, M., Ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 125–139. [Google Scholar]

- Kang, M.-G.; Kim, M.-S.; Kim, J.; Guo, L.J. Organic Solar Cells Using Nanoimprinted Transparent Metal Electrodes. Adv. Mater. 2008, 20, 4408–4413. [Google Scholar] [CrossRef]

- Yakoob, M.A.; Lamminaho, J.; Petersons, K.; Prajapati, A.; Destouesse, E.; Patil, B.R.; Rubahn, H.-G.; Shalev, G.; Stensborg, J.; Madsen, M. Efficiency-enhanced scalable organic photovoltaics using roll-to-roll nanoimprint lithography. ChemSusChem 2022, 15, e202101611. [Google Scholar] [CrossRef]

- Brincoveanu, O.; Ioanid, A.; Iftimie, S.; Antohe, S. Influence of the PEDOT: PSS layer on the performance of the photovoltaic devices. Rom. Rep. Phys. 2016, 68, 1097–1107. [Google Scholar]

- Zhang, S.; Kumar, P.; Nouas, A.S.; Fontaine, L.; Tang, H.; Cicoira, F. Solvent-induced changes. APL Mater. 2015, 3, 014911. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Zhang, H.; Xie, M.; Duan, X. PEDOT: PSS: From conductive polymers to sensors. Nanotechnol. Precis. Eng. 2021, 4, 045004. [Google Scholar] [CrossRef]

- Khodagholy, D.; Rivnay, J.; Sessolo, M.; Gurfinkel, M.; Leleux, P.; Jimison, L.H.; Stanivridou, E.; Herve, T.; Sanaur, S.; Owens, R.M.; et al. High transconductance organic electrochemical transistors. Nat. Commun. 2013, 4, 2133. [Google Scholar] [CrossRef]

- Mohan, V.B.; Brown, R.; Jayaraman, K.; Bhattacharyya, D. Characterisation of reduced grapheme oxide: Effects of reduction variables on electrical conductivity. Mater. Sci. Eng. B 2015, 193, 49–60. [Google Scholar] [CrossRef]

- Tarcan, R.; Todor-Boer, O.; Petrovai, I.; Leordean, C.; Astilean, S.; Botiz, I. Reduced grapheme oxide today. J. Mater. Chem. C 2020, 8, 1198–1224. [Google Scholar] [CrossRef]

- Brinkmann, M. Structure and morphology control in thin films of regioregular poly(3-hexylthiophene). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1218–1233. [Google Scholar] [CrossRef]

- Radu, A.; Locovei, C.; Antohe, V.A.; Socol, M.; Coman, D.; Manica, M.; Dumitru, A.; Dan, L.; Radu, C.; Raduta, A.M.; et al. Effects of annealing on the physical properties of ITO thin films grown by radio frequency magnetron sputtering. Dig. J. Nanomater. Biostruct. 2020, 15, 679–687. [Google Scholar] [CrossRef]

- Magherusan, L.; Skraba, P.; Besleaga, C.; Iftimie, S.; Dina, N.; Bulgariu, M.; Bostan, C.G.; Tazlaoanu, C.; Radu, A.; Ion, L.; et al. Electrical and photoelectrical properties of organic photovoltaic cells based on polymer blends ITO/PEDOT/P3HT:PCBM (1:1). J. Optoelectron. Adv. Mater. 2010, 12, 212–218. [Google Scholar]

- Champory, R.; Mandorlo, F.; Seassal, C.; Fave, A. Influence of patterning the TCO layer on series resistance of thin film HIT solar cells. EPJ Photovolt. 2017, 8, 80101. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, S.H.; Xu, J.; Zhao, L.; Sun, H.C.; Li, J.; Mu, W.W.; Xu, L.; Chen, K.J. Broadband antireflection and absorption enhancement by forming nano-patterned Si structures for solar cells. Opt. Express 2011, 19, A1051–A1056. [Google Scholar] [CrossRef] [PubMed]

- Radu, A.I.; Antohe, V.A.; Iftimie, S.; Antohe, I.; Filipescu, M.; Radu, A.; Coman, D.; Stingescu, M.L.; Dinescu, M.; Antohe, S. Study of a new composite based on SnO2 nanoparticles—P3HT:PC71BM co-polymer blend, used as potential absorber in bulk heterojunction photovoltaic cells. Mater. Today Commun. 2022, 33, 104757. [Google Scholar] [CrossRef]

- Auger, A.; Mullera, A.J.; Swarts, J.C. Remarkable isolation, structural characterisation and electrochemistry of unexpected scrambling analogues of 5-ferrocenyl-10,20-diphenylporphyrin. Dalton Trans. 2007, 33, 3623–3633. [Google Scholar] [CrossRef] [PubMed]

| Sample | Thickness [nm] | Evaluation Method |

|---|---|---|

| ITO | 350 ± 4 nm | P |

| PEDOT:PSS + GO | 33 ± 0.5 nm | P |

| PTB7-Th:ICBA (1:1, wt.%) | 220 ± 2 nm | P |

| LiF | 10 ± 2 nm | QCM |

| Al | 250 ± 3 nm | P |

| PTB7-Th:ICBA (1:1, wt.%) on flat substrate | Rs (MΏ) 13 | Rsh (MΏ) 2.2 | n 2.1 |

| PTB7-Th:ICBA (1:1, wt.%) on patterned substrate | Rs (Ώ) 270 | Rsh (kΏ) 50 | n 1.2 |

| PTB7-Th:ICBA (1:1, wt.%) on flat substrate | Jsc (µA/cm2) 2.35 | Voc (V) 0.26 | Pmax (µW/cm2) 0.08 | FF (%) 13 |

| PTB7-Th:ICBA (1:1, wt.%) on patterned substrate | Jsc (µA/cm2) 26.3 | Voc (V) 0.26 | Pmax (µW/cm2) 1.03 | FF (%) 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suteu, T.; Antohe, V.-A.; Antohe, S.; Stavarache, I.; Balasin, M.C.; Socol, G.; Socol, M.; Rasoga, O.; Iftimie, S. Induced Effects of Nano-Patterned Substrates on the Electrical and Photo-Electrical Properties of PTB7-Th:ICBA (1:1, wt.%) Bulk-Heterojunction Solar Cells. Surfaces 2025, 8, 30. https://doi.org/10.3390/surfaces8020030

Suteu T, Antohe V-A, Antohe S, Stavarache I, Balasin MC, Socol G, Socol M, Rasoga O, Iftimie S. Induced Effects of Nano-Patterned Substrates on the Electrical and Photo-Electrical Properties of PTB7-Th:ICBA (1:1, wt.%) Bulk-Heterojunction Solar Cells. Surfaces. 2025; 8(2):30. https://doi.org/10.3390/surfaces8020030

Chicago/Turabian StyleSuteu, Tudor, Vlad-Andrei Antohe, Stefan Antohe, Ionel Stavarache, Maria Cristina Balasin, Gabriel Socol, Marcela Socol, Oana Rasoga, and Sorina Iftimie. 2025. "Induced Effects of Nano-Patterned Substrates on the Electrical and Photo-Electrical Properties of PTB7-Th:ICBA (1:1, wt.%) Bulk-Heterojunction Solar Cells" Surfaces 8, no. 2: 30. https://doi.org/10.3390/surfaces8020030

APA StyleSuteu, T., Antohe, V.-A., Antohe, S., Stavarache, I., Balasin, M. C., Socol, G., Socol, M., Rasoga, O., & Iftimie, S. (2025). Induced Effects of Nano-Patterned Substrates on the Electrical and Photo-Electrical Properties of PTB7-Th:ICBA (1:1, wt.%) Bulk-Heterojunction Solar Cells. Surfaces, 8(2), 30. https://doi.org/10.3390/surfaces8020030