Evaluation of the Feasibility of the Prediction of the Surface Morphologiesof AWJ-Milled Pockets by Statistical Methods Based on Multiple Roughness Indicators

Abstract

1. Introduction

2. Materials and Methods

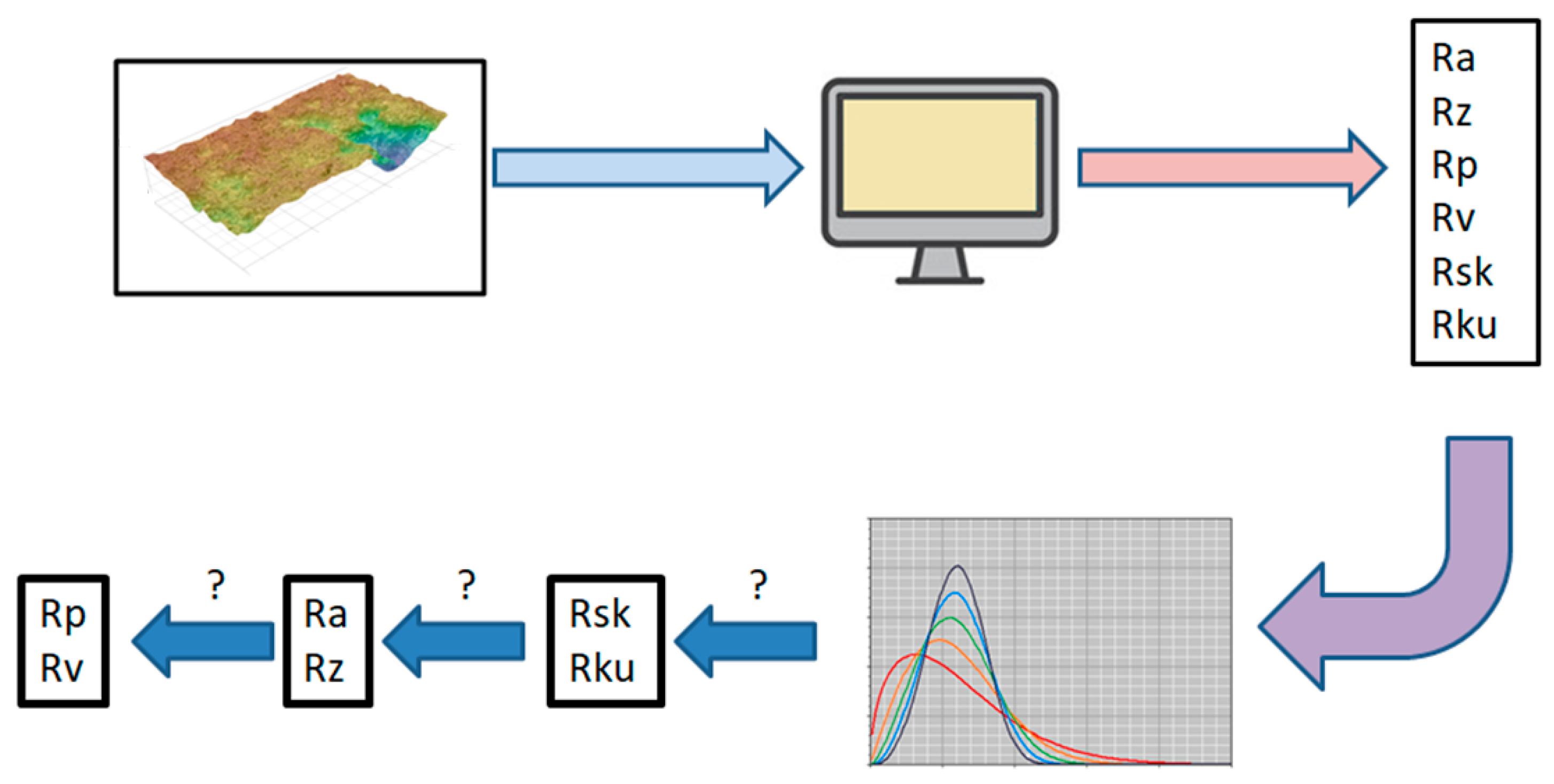

2.1. Scope of the Present Work

- (1)

- Determination of the feasibility of employing a statistical distribution as an alternative means of reliably simulating several characteristics of the surface roughness profile during AWJ pocket milling through modeling of its height distribution. In this case, a basic requirement is that the statistical distribution can accurately simulate fundamental indicators, such as Rsk and Rku or the Rp/Rv ratio, beyond the usual height parameters, such as Ra or Rz.

- (2)

- Determination of the most promising statistical distribution forrepresenting the surface roughness profile in the case of AWJ pocket milling by modeling its height distribution. In this case, a basic requirement is that the statistical distribution should not be very complicated in order for its implementation to be feasible without the need of highly specialized knowledge. The representation of the surface roughness profile should be based on multiple indicators, such as Ra, Rz, Rp, Rv, Rsk and Rku.

2.2. Description of Research Methodology

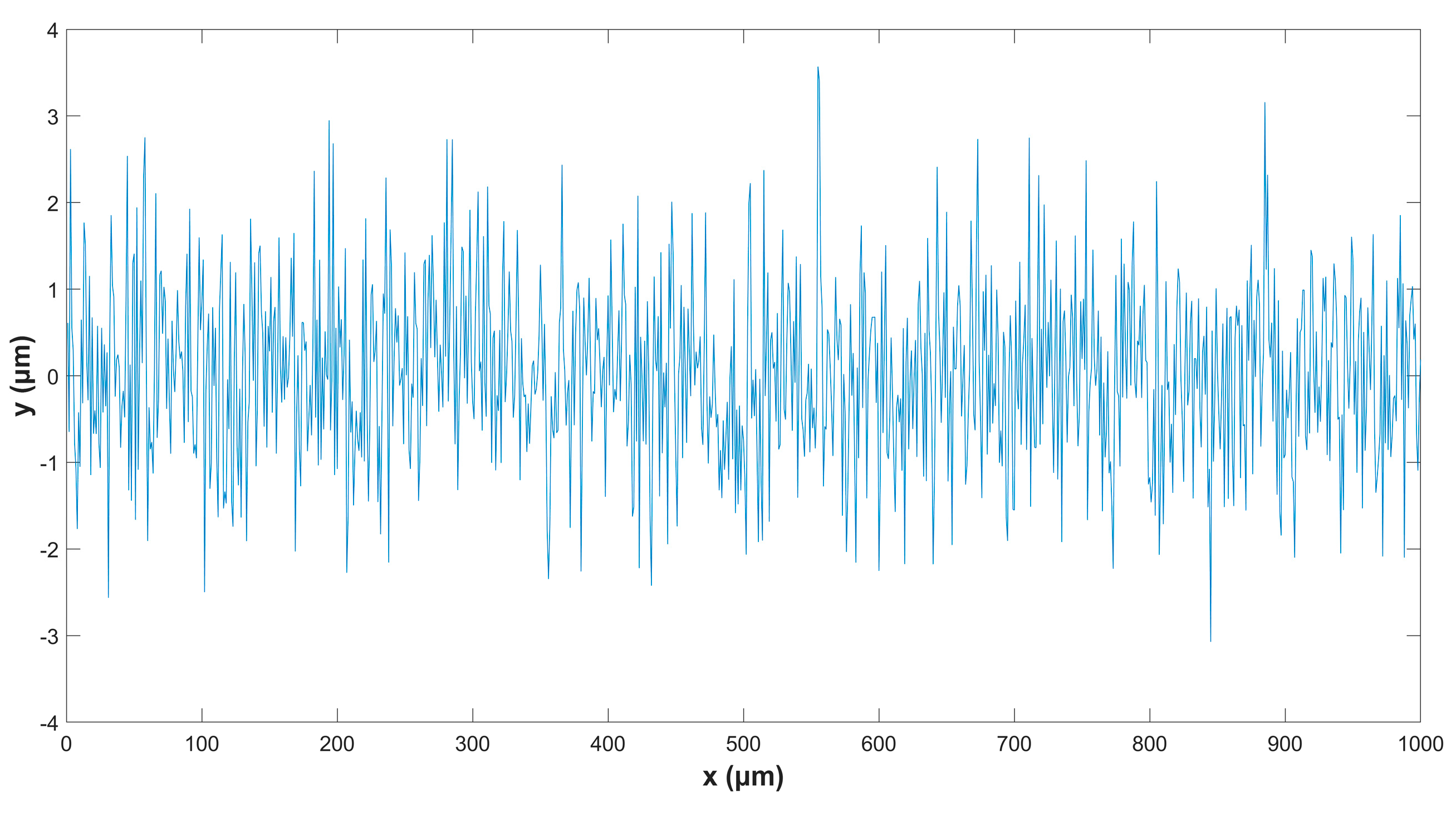

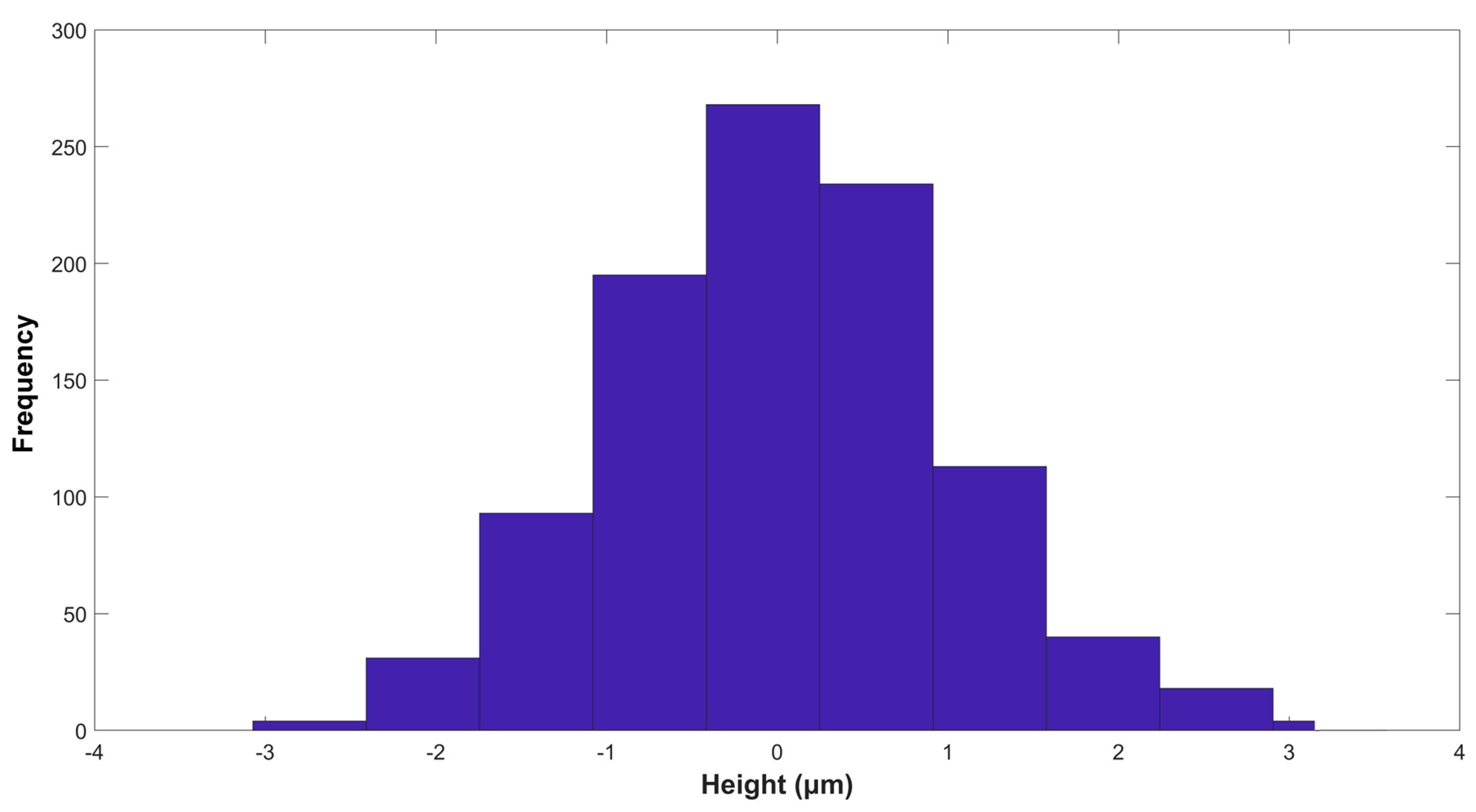

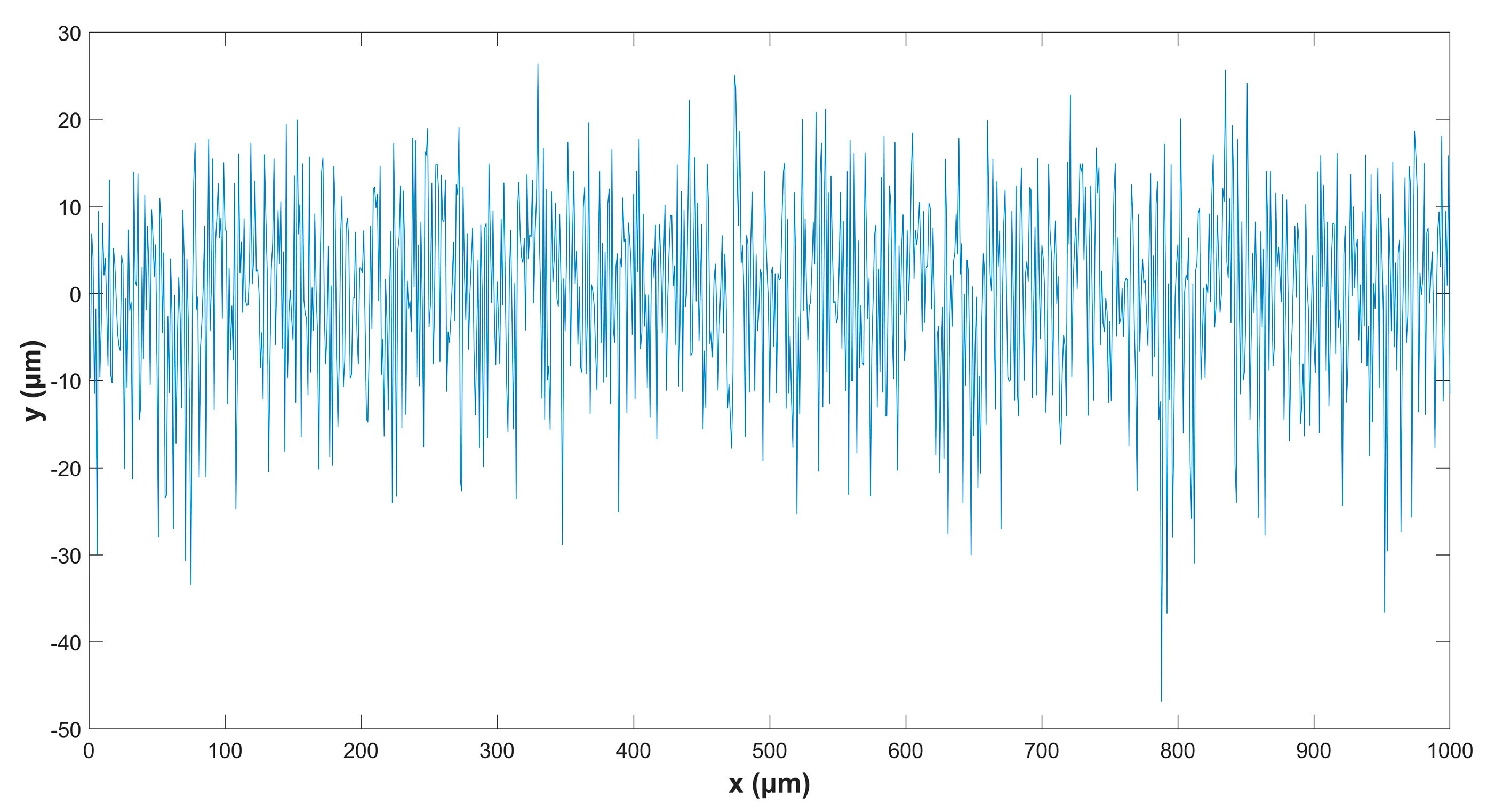

2.3. Experimental Details

3. Results

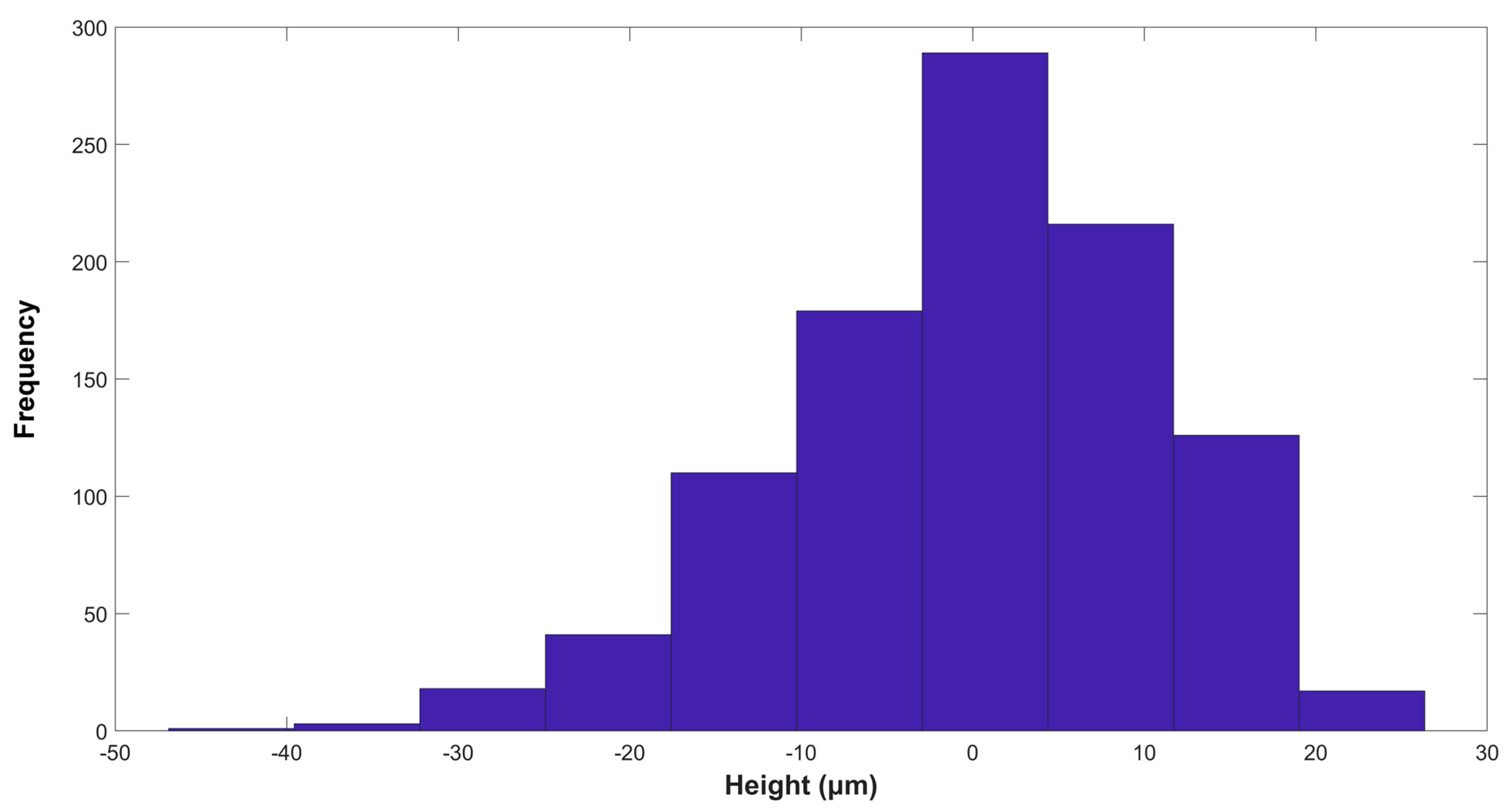

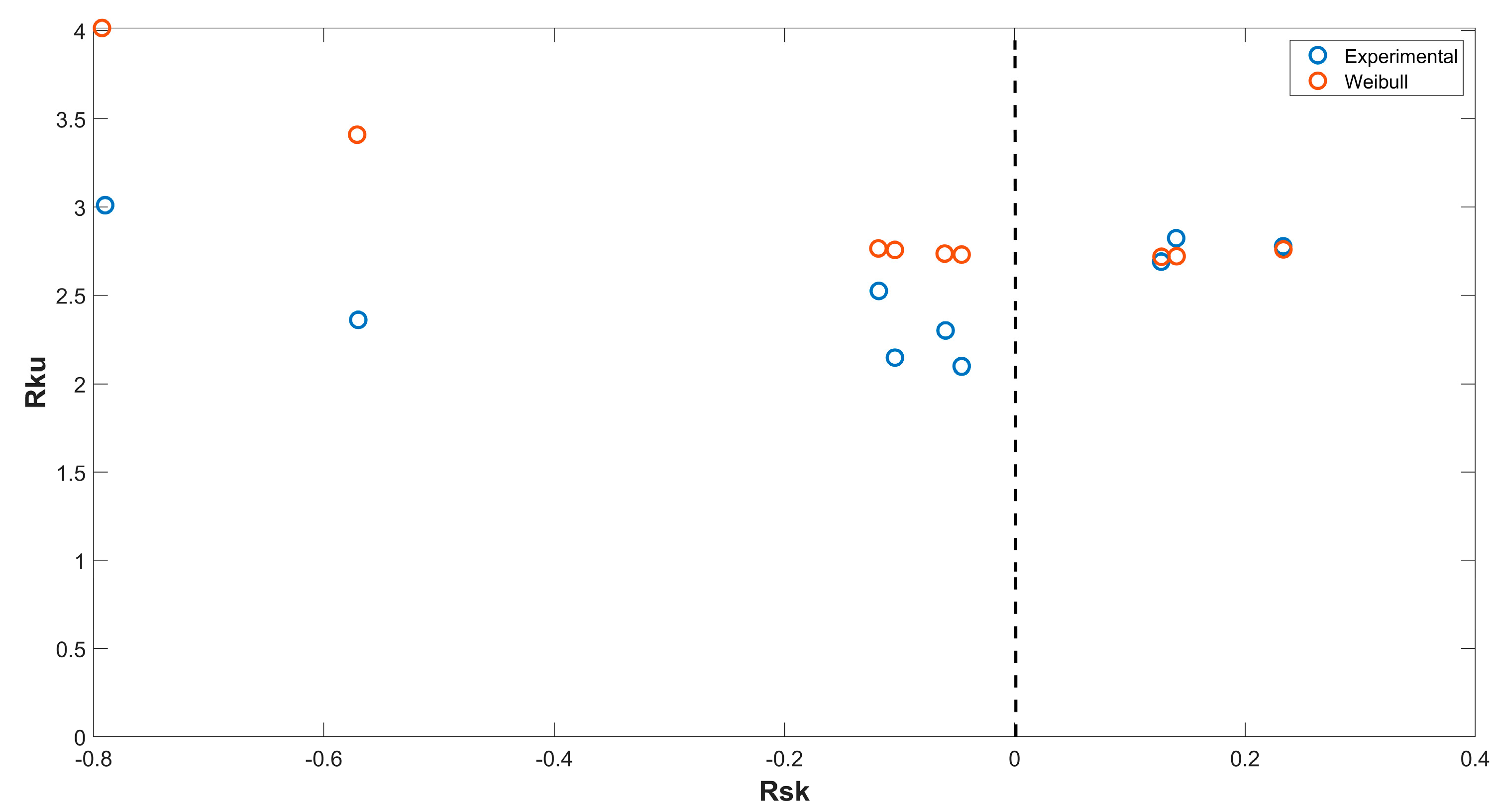

3.1. Evaluation of Rsk and Rku Prediction Based on Different Probability Distributions

3.2. Evaluation of Ra and Rz Prediction Based on Different Probability Distributions

3.3. Evaluation of Rp and Rv Prediction Based on Different Probability Distributions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pawlus, P.; Reizer, R.; Krolczyk, G.M. Modelling and prediction of surface textures after abrasive machining processes: A review. Measurement 2023, 220, 113337. [Google Scholar] [CrossRef]

- Qu, S.; Yao, P.; Gong, Y.; Chu, D.; Yang, Y.; Li, C.; Wang, Z.; Zhang, X.; Hou, Y. Environmentally friendly grinding of C/SiCs using carbon nanofluid minimum quantity lubrication technology. J. Clean Prod. 2022, 366, 132898. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, Y.; Chang, W.; Luo, X. Correlating and evaluating the functionality-related properties with surface texture parameters and specific characteristics of machined components. Int. J. Mech. Sci. 2018, 149, 62–72. [Google Scholar] [CrossRef]

- Molnar, V.; Sztankovics, I. Analysis of Roughness Parameters Determining Tribological Properties in Hard Turned Surfaces. Hung. J. Ind. Chem. 2021, 49, 77–84. [Google Scholar] [CrossRef]

- Molnar, V.; Szabo, G. Designation of minimum measurement area for the evaluation of 3D surface texture. J. Manuf. Process. 2022, 83, 40–48. [Google Scholar] [CrossRef]

- Molnar, V. Influence of Cutting Parameters and Tool Geometry on Topography of Hard Turned Surfaces. Machines 2023, 11, 665. [Google Scholar] [CrossRef]

- Nowicki, B. Surface roughness and measurement with new contact methods. Int. J. Mach. Tool Des. Res. 1996, 26, 61–68. [Google Scholar] [CrossRef]

- Nowicki, B.; Jarkiewicz, A. The in-process surface roughness measurement using fringe field capacitive (FFC) method. Int. J. Mach. Tools Manuf. 1998, 38, 725–732. [Google Scholar] [CrossRef]

- Goch, G.; Peters, J.; Lehmann, P.; Liu, H. Requirements for the application of speckle correlation techniques to on-line inspection of surface roughness. CIRP Ann. 1999, 48, 467–470. [Google Scholar] [CrossRef]

- Peters, J.; Lehmann, P.; Schoene, A. Measuring roughness with dichromatic speckle correlation. In Proceedings of the Optical Inspection and Micromeasurements, Besancon, France, 10–14 June 1996; Volume 2782. [Google Scholar]

- Pawlus, P.; Reizer, R.; Zelasko, W. Two-process random textures: Measurement, characterization, modeling and tribological impact: A review. Materials 2022, 15, 268. [Google Scholar] [CrossRef]

- Felhő, C.; Karpuschewski, B.; Kundrák, J. Surface roughness modelling in face milling. Procedia CIRP 2015, 31, 136–141. [Google Scholar] [CrossRef]

- Felhő, C.; Kundrák, J. A method for the determination of theoretical roughness in face milling considering the run-out of the inserts. Solid State Phenom. 2017, 261, 251–268. [Google Scholar] [CrossRef]

- Felhő, C.; Kundrák, J. 3D roughness parameters of surfaces face milled by special tools. Manuf. Technol. 2016, 16, 532–538. [Google Scholar]

- Kundrák, J.; Felhő, C. Topography of the machined surface in high performance face milling. Procedia CIRP 2018, 77, 340–343. [Google Scholar] [CrossRef]

- Felhő, C.; Varga, G. Theoretical roughness modeling of hard turned surfaces considering tool wear. Machines 2022, 10, 188. [Google Scholar] [CrossRef]

- Liu, C.; Gao, L.; Wang, G.; Xu, W.; Jiang, X.; Yang, T. Online reconstruction of surface topography along the entire cutting path in peripheral milling. Int. J. Mech. Sci. 2020, 185, 105885. [Google Scholar] [CrossRef]

- Cai, C.; An, Q.; Ming, W.; Chen, M. Modelling of machined surface topography and anisotropic texture direction considering stochastic tool grinding error and wear in peripheral milling. J. Mater. Process. Tech. 2021, 292, 117065. [Google Scholar] [CrossRef]

- Denkena, B.; Kruger, M.; Bachrathy, D.; Stepan, G. Model based reconstruction of milled surface topography from measured cutting forces. Int. J. Mach. Tools Manuf. 2012, 54–55, 25–33. [Google Scholar] [CrossRef]

- Gu, Q.; Deng, Z.; Lv, L.; Liu, T.; Teng, H.; Wang, D.; Yuan, J. Prediction research for surface topography of internal grinding based on mechanism and data model. Int. J. Adv. Manuf. Technol. 2021, 113, 821–836. [Google Scholar] [CrossRef]

- Kumar, H.; Ramkumar, J.; Venkatesh, K.S. Surface texture evaluation using 3D reconstruction from images by parametric anisotropic BRDF. Measurement 2018, 125, 612–633. [Google Scholar] [CrossRef]

- Gu, R.; Wang, Z.; Ma, L.; Nie, J. Calibration method of laser scanning measurement system for large-scale component using a free-form surface reconstruction model. Measurement 2023, 210, 112511. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zou, D.; Chen, N. Knowledge-based transfer fuzzy clustering with non-local spatial information for surface roughness measurement. Measurement 2021, 174, 109076. [Google Scholar] [CrossRef]

- Patel, D.R.; Kiran, M.B. A non-contact approach for surface roughness prediction in CNC turning using a linear regression model. Mater. Today Proc. 2020, 26, 350–355. [Google Scholar] [CrossRef]

- Shi, W.C.; Zheng, J.M.; Li, Y.; Li, X.B. Three-Dimensional Reconstruction Method for Machined Surface Topography Based on Gray Gradient Constraints. Appl. Sci. 2019, 9, 591. [Google Scholar] [CrossRef]

- Dhanasekar, B.; Ramamoorthy, B. Assessment of surface roughness based on super resolution reconstruction algorithm. Int. J. Adv. Manuf. Technol. 2008, 35, 1191–1205. [Google Scholar] [CrossRef]

- Thielen, S.; Magyar, B.; Piros, A. Reconstruction of three-dimensional turned shaft surfaces with fractal functions. Trib. Int. 2016, 95, 349–357. [Google Scholar] [CrossRef]

- Wang, H.; Chi, G.; Jia, Y.; Ge, C.; Yu, F.; Wang, Z.; Wang, Y. Surface roughness evaluation and morphology reconstruction of electrical discharge machining by frequency spectal analysis. Measurement 2021, 172, 108879. [Google Scholar] [CrossRef]

- Perez-Rafols, F.; Almqvist, A. On the stiffness of surfaces with non-Gaussian height distribution. Sci. Rep. 2021, 11, 1863. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Li, Z.; Zhu, R. Fractal simulation of surface topography and prediction of its lubrication characteristics. Surf. Topogr. Metrol. Prop. 2021, 9, 045038. [Google Scholar] [CrossRef]

- Pei, L.; Hyun, S.; Molinari, J.F.; Robbins, M.O. Finite element modeling of elasto-plastic contact between rough surfaces. J. Mech. Phys. Solid 2005, 53, 2385–2409. [Google Scholar] [CrossRef]

- Li, L.; Li, G.; Wang, J.; Fan, C.; Cai, A. Fretting wear mechanical analysis of double rough surfaces based on energy method. Proc. IMechE Part J J. Eng. Trib. 2023, 237, 356–368. [Google Scholar] [CrossRef]

- Han, J.; Zheng, W.; Chen, Q.; Sun, J.; Xu, S. Study on size effect of surface roughness based on the 3D Voronoi model and establishement of roughness prediction model in micro-metal forming. Coatings 2022, 12, 1659. [Google Scholar] [CrossRef]

- Bonari, J.; Paggi, M.; Dini, D. A new finite element paradigm to solve contact problems with roughness. Int. J. Solid Struct. 2022, 253, 111643. [Google Scholar] [CrossRef]

- Gao, W.; Wang, L.; Coffey, J.K.; Wu, H.; Daver, F. An attempt to simulate structure and realistic images of scratches on rough polymeric surfaces. J. Polym. Sci. 2020, 58, 3209–3218. [Google Scholar] [CrossRef]

- Megalingam, A.; Mayuram, M.M. Effect of surface parameters on finite element method based deterministic Gaussian rough surface contact model. Proc. IMechE Part J J. Eng. Trib. 2014, 228, 1358–1373. [Google Scholar] [CrossRef]

- Kartini; Saputra, E.; Ismail, R.; Jamari, J.; Bayuseno, A.P. Analysis of the contact area of smooth and rough surfaces in contact with sphere indenter using finite element method. MATEC Web Conf. 2016, 58, 04007. [Google Scholar] [CrossRef]

- Wang, B.B.; Chen, H.K.; Xu, G.T.; Zhang, J.W.; Zhao, M.H. A theoretical model for predicting the surface topography of inhomogeneous materials after shot peening. Int. J. Adv. Manuf. Technol. 2022, 119, 7533–7541. [Google Scholar] [CrossRef]

- Xie, J.; Rittel, D. Three-dimensional stochastic modeling of metallic surface roughness resulting from pure waterjet peening. Int. J. Eng. Sci. 2017, 120, 241–253. [Google Scholar] [CrossRef]

- Xie, J.; Rittel, D.; Chen, P. Modeling the topographic evolution of a rough metallic surface resulting from impact of water droplets. Int. J. Eng. Sci. 2019, 144, 103142. [Google Scholar] [CrossRef]

- Xie, J.; Rittel, D. The effects of waterjet peening on a random-topography metallic implant surface. Eur. J. Mech. A/Solids 2018, 71, 235–244. [Google Scholar] [CrossRef]

- Xie, J.; Chen, P.; Rittel, D. Finite element modeling of multiple water droplets impact onto a rough surface: Re-assessing Sa and surface wavelength. J. Mech. Behav. Biom. Mater. 2020, 110, 103816. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Cui, B.; Zhao, S.; Liu, Z.; Yu, J.; Li, C.; Yu, H.; Lei, C. Numerical simulation of surface topography and residual stress after abrasive water jet sequential peening. Proc. IMechE Part L J. Mat. Des. Appl. 2021, 235, 774–795. [Google Scholar] [CrossRef]

- Li, C.; Piao, Y.; Meng, B.; Hu, Y.; Li, L. Phase transition and plastic deformation mechanisms induced by self-rotating grinding of GaN single crystals. Int. J. Mach. Tools Manuf. 2022, 172, 103827. [Google Scholar] [CrossRef]

- Molnar, V. Asymmetric height distribution of surfaces machined by hard turning and grinding. Symmetry 2022, 14, 1591. [Google Scholar] [CrossRef]

- Ba, E.C.T.; Martins, P.S.; Dumont, M.R. Statistical study of surface texture and chip formation during turning of AISI 1020 steel: Emphasis on parameters Rsk, Rku, and Rk family and on the chip thickness ratio. Int. J. Adv. Manuf. Technol. 2022, 121, 8257–8283. [Google Scholar]

- Dzierwa, A. Influence of surface preparation on surface topography and tribological behaviours. Arch. Civil Mech. Eng. 2017, 17, 502–510. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Modeling of surface topography for reduced friction. In Proceedings of the 9th Biennial ASME Conference on Engineering Systems Design and Analysis ESDA 08, Haifa, Israel, 7–9 July 2008. [Google Scholar]

- Ba, E.C.T.; Dumont, M.R.; Martins, P.S.; Drumond, R.M.; da Cruz, M.P.M.; Vieira, V.F. Investigation of the effects of skewness Rsk and kurtosis Rku on tribological behavior in a pin-on-disc test of surfaces machined by conventional milling and turning processes. Mater. Res. 2021, 24, e20200435. [Google Scholar] [CrossRef]

- Peters, J.; Bryan, J.B.; Estler, W.T.; Evans, C.; Kunzmann, H.; Lucca, D.A.; Sartori, S.; Sato, H.; Thwaite, E.G.; Vanherck, P.; et al. Contribution of CIRP to the development of metrology and surface quality evaluation during the last fifty years. CIPR Ann. 2001, 50, 471–488. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Krolczyk, G. Material ratio curve as information on the state of surface topography—A review. Precis. Eng. 2020, 65, 240–258. [Google Scholar] [CrossRef]

- Mehl, A.C.S.B.; Benegra, M.; Pintaude, G. Surface characterization of the seating platform of titanium implant processed with different textures. J. Brazil Soc. Mech. Sci. Eng. 2021, 43, 130. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Characterization of the shape of height distribution of two-process profile. Measurement 2020, 153, 107387. [Google Scholar] [CrossRef]

- Grzesik, W.; Wanat, T. Comparative assessment of surface roughness produced by hard machining with mixed ceramic tools including 2D and 3D analysis. J. Mater. Process. Technol. 2005, 169, 364–371. [Google Scholar] [CrossRef]

- Horváth, R.; Drégelyi-Kiss, Á.; Mátyási, G. The examination of surface roughness parameters in the fine turning of hypereutectic aluminium alloys. UPB Sci. Bull. Ser. D Mech. Eng. 2015, 77, 205–216. [Google Scholar]

- Nowicki, B. Multiparameter representation of surface roughness. Wear 1985, 102, 161–176. [Google Scholar] [CrossRef]

- Lăpuşteanu, A.; Agop, M.; Paleu, V. Fractal dimension in tribology—An overview. IOP Conf. Ser. Mat. Sci. Eng. 2022, 1262, 012009. [Google Scholar] [CrossRef]

- Kang, M.C.; Kim, J.S.; Kim, K.H. Fractal dimension analysis of machined surface depending on coated tool wear. Surf. Coat. Technol. 2005, 193, 259–265. [Google Scholar] [CrossRef]

- Ling, F.F. Fractals, engineering surfaces and tribology. Wear 1990, 136, 141–156. [Google Scholar] [CrossRef]

- Thomopoulos, N.T. Continuous distributions. In Probability Distributions, 1st ed.; Thomopoulos, N.T., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 1–25. [Google Scholar]

- Ahrari, V.; Baratpour, S.; Habibirad, A.; Fakoor, V. Goodness of fit tests for Rayleigh distribution based on quantiles. Commun. Stat. Simul. Comput. 2022, 51, 341–357. [Google Scholar] [CrossRef]

- ISO 4288:1996; Geometrical Product Specifications (GPS). International Organization for Standardization: Geneva, Switzerland, 1996.

- Chang, L.; Jeng, Y.R. Effects of negative skewness of surface roughness on the contact and lubrication of nominally flat metallic surfaces. Proc. IMechE Part J J. Eng. Trib. 2012, 227, 559–569. [Google Scholar] [CrossRef]

- Sabino, T.S.; Carneiro, A.M.C.; Carvalho, R.P.; Pires, F.M.A. The impact of non-Gaussian height distributions on the statistics of isotropic random rough surfaces. Trib. Int. 2022, 173, 107578. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Wang, S.J.; Zhang, G.Q. A new representation with probability distribution for nanometric surface roughness in ultra-precision machining. Prec. Eng. 2016, 45, 445–449. [Google Scholar] [CrossRef]

- Thangaraj, M.; Ahmadein, M.; Alsaleh, N.A.; Elsheikh, A.H. Optimization of Abrasive Water Jet Machining of SiC Reinforced Aluminum Alloy Based Metal Matrix Composites Using Taguchi–DEAR Technique. Materials 2021, 14, 6250. [Google Scholar] [CrossRef] [PubMed]

- Muthuramalingam, T.; Vasanth, S.; Vinothkumar, P.; Geethapriyan, T.; Mohamed Rabik, M. Multi Criteria Decision Making of Abrasive Flow Oriented Process Parameters in Abrasive Water Jet Machining Using Taguchi–DEAR Methodology. Silicon 2021, 10, 2015–2021. [Google Scholar] [CrossRef]

| Case | h (mm) | ma (g/s) | P (MPa) | Ra (μm) | Rz (μm) | Rp (μm) | Rv (μm) | Rsk (−) | Rku (−) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 2 | 150 | 6.622 | 28.694 | 14.537 | 15.408 | −0.046 | 2.098 |

| 2 | 3 | 4 | 250 | 5.756 | 25.758 | 15.543 | 15.240 | −0.118 | 2.524 |

| 3 | 3 | 6 | 350 | 78.207 | 426.930 | 205.123 | 234.357 | −0.570 | 2.360 |

| 4 | 7 | 2 | 250 | 11.746 | 53.598 | 24.966 | 28.706 | −0.104 | 2.146 |

| 5 | 7 | 4 | 350 | 86.673 | 460.477 | 324.185 | 193.083 | 0.127 | 2.690 |

| 6 | 7 | 6 | 150 | 9.933 | 52.500 | 24.053 | 29.997 | −0.060 | 2.300 |

| 7 | 11 | 2 | 350 | 107.450 | 537.975 | 216.690 | 260.027 | −0.790 | 3.010 |

| 8 | 11 | 4 | 150 | 10.447 | 59.740 | 33.333 | 26.407 | 0.233 | 2.777 |

| 9 | 11 | 6 | 250 | 13.730 | 79.767 | 40.567 | 39.203 | 0.140 | 2.823 |

| Case | Rsk, Theor. | Rku, Theor. | Rsk, Exp. | Rku, Exp. | Error Rsk (%) | Error Rku (%) | Evaluation | |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 3 | −0.046 | 2.098 | N/A | −42.993 | U | U |

| 2 | 0 | 3 | −0.118 | 2.524 | N/A | −18.859 | U | MA |

| 3 | 0 | 3 | −0.570 | 2.360 | N/A | −27.119 | U | U |

| 4 | 0 | 3 | −0.104 | 2.146 | N/A | −39.795 | U | U |

| 5 | 0 | 3 | 0.127 | 2.690 | N/A | −11.524 | U | MA |

| 6 | 0 | 3 | −0.060 | 2.300 | N/A | −30.435 | U | U |

| 7 | 0 | 3 | −0.790 | 3.010 | N/A | 0.332 | U | A |

| 8 | 0 | 3 | 0.233 | 2.777 | N/A | −8.030 | U | A |

| 9 | 0 | 3 | 0.140 | 2.823 | N/A | −6.270 | U | A |

| Case | Rz, Theor. | Rz, Exp. | Percentage Error (%) | Evaluation |

|---|---|---|---|---|

| 1 | 28.694 | 31.600 | 10.128 | MA |

| 2 | 25.758 | 25.800 | 0.163 | A |

| 3 | 426.930 | 370.700 | −13.171 | MA |

| 4 | 53.598 | 56.350 | 5.135 | A |

| 5 | 460.477 | 412.000 | −10.528 | MA |

| 6 | 52.500 | 48.200 | −8.190 | A |

| 7 | 537.975 | 501.500 | −6.780 | A |

| 8 | 59.740 | 47.530 | −20.439 | U |

| 9 | 79.767 | 64.460 | −19.190 | MA |

| Case | Rp, Theor | Rp, Exp. | Rv, Theor. | Rv, Exp. | Percentage Error (%) | Percentage Error (%) | Evaluation | |

|---|---|---|---|---|---|---|---|---|

| 1 | 15.616 | 14.537 | 16.384 | 15.408 | 7.420 | 6.336 | A | A |

| 2 | 12.426 | 15.543 | 13.375 | 15.240 | −20.057 | −12.241 | U | MA |

| 3 | 152.331 | 205.123 | 218.369 | 234.357 | −25.737 | −6.822 | U | A |

| 4 | 27.231 | 24.966 | 29.118 | 28.706 | 9.072 | 1.437 | A | A |

| 5 | 212.332 | 324.185 | 189.668 | 193.083 | −34.503 | −1.769 | U | A |

| 6 | 19.563 | 24.053 | 28.637 | 29.997 | −18.667 | −4.534 | MA | A |

| 7 | 225.474 | 216.690 | 276.026 | 260.027 | 4.054 | 6.153 | A | A |

| 8 | 25.209 | 33.333 | 22.321 | 26.407 | −24.372 | −15.473 | U | MA |

| 9 | 33.360 | 40.567 | 31.100 | 39.203 | −17.766 | −20.669 | MA | U |

| Case | Rsk, Theor. | Rku, Theor. | Rsk, Exp. | Rku, Exp. | Error Rsk (%) | Error Rku (%) | Evaluation | |

|---|---|---|---|---|---|---|---|---|

| 1 | −0.046 | 3.004 | −0.046 | 2.098 | 0.457 | 43.174 | A | U |

| 2 | −0.118 | 3.025 | −0.118 | 2.524 | 0.008 | 19.840 | A | MA |

| 3 | −0.570 | 3.584 | −0.570 | 2.360 | 0.074 | 51.866 | A | U |

| 4 | −0.104 | 3.019 | −0.104 | 2.146 | 0.163 | 40.694 | A | U |

| 5 | 0.127 | 3.029 | 0.127 | 2.690 | 0.024 | 12.591 | A | MA |

| 6 | −0.060 | 3.006 | −0.060 | 2.300 | 0.017 | 30.713 | A | U |

| 7 | −0.790 | 4.131 | −0.790 | 3.010 | 0.041 | 37.235 | A | U |

| 8 | 0.233 | 3.097 | 0.233 | 2.777 | 0.006 | 11.511 | A | MA |

| 9 | 0.140 | 3.035 | 0.140 | 2.823 | 0.199 | 7.509 | A | A |

| Case | Rsk, Theor. | Rku, Theor. | Rsk, Exp. | Rku, Exp. | Error Rsk (%) | Error Rku (%) | Evaluation | |

|---|---|---|---|---|---|---|---|---|

| 1 | −0.046 | 3.014 | −0.046 | 2.098 | 0.075 | 43.681 | A | U |

| 2 | −0.118 | 3.051 | −0.118 | 2.524 | 0.014 | 20.865 | A | U |

| 3 | −0.570 | 3.414 | −0.570 | 2.360 | 0.081 | 44.654 | A | U |

| 4 | −0.104 | 3.043 | −0.104 | 2.146 | 0.061 | 41.790 | A | U |

| 5 | 0.127 | 3.056 | 0.127 | 2.690 | 0.000 | 13.600 | A | MA |

| 6 | −0.060 | 3.021 | −0.060 | 2.300 | 0.148 | 31.330 | A | U |

| 7 | −0.790 | 3.639 | −0.790 | 3.010 | 0.003 | 20.891 | A | U |

| 8 | 0.233 | 3.125 | 0.233 | 2.777 | 0.029 | 12.548 | A | MA |

| 9 | 0.140 | 3.063 | 0.140 | 2.823 | 0.000 | 8.522 | A | A |

| Case | Rsk, Theor. | Rku, Theor. | Rsk, Exp. | Rku, Exp. | Error Rsk (%) | Error Rku (%) | Evaluation | |

|---|---|---|---|---|---|---|---|---|

| 1 | −0.046 | 2.730 | −0.046 | 2.098 | −0.065 | −30.123 | A | U |

| 2 | −0.118 | 2.765 | −0.118 | 2.524 | −0.322 | −9.556 | A | A |

| 3 | −0.571 | 3.410 | −0.570 | 2.360 | −0.170 | −44.477 | A | U |

| 4 | −0.104 | 2.757 | −0.104 | 2.146 | −0.033 | −28.461 | A | U |

| 5 | 0.127 | 2.718 | 0.127 | 2.690 | −0.176 | −1.031 | A | A |

| 6 | −0.061 | 2.736 | −0.060 | 2.300 | −0.345 | −18.944 | A | MA |

| 7 | −0.793 | 4.014 | −0.790 | 3.010 | −1.316 | −33.369 | A | U |

| 8 | 0.233 | 2.760 | 0.233 | 2.777 | −0.086 | 0.628 | A | A |

| 9 | 0.140 | 2.721 | 0.140 | 2.823 | −0.286 | 3.616 | A | A |

| Case | Rp/Rv, Theor. | Rp/Rv, Exp. | Percentage Error (%) | Evaluation |

|---|---|---|---|---|

| 1 | 0.953 | 0.943 | 1.019 | A |

| 2 | 0.929 | 1.020 | −8.907 | A |

| 3 | 0.698 | 0.875 | −20.300 | U |

| 4 | 0.935 | 0.869 | 7.528 | A |

| 5 | 1.119 | 1.679 | −33.324 | U |

| 6 | 0.683 | 0.802 | −14.805 | MA |

| 7 | 0.817 | 0.833 | −1.977 | A |

| 8 | 1.129 | 1.262 | −10.527 | MA |

| 9 | 1.073 | 1.035 | 3.660 | A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karkalos, N.E.; Thangaraj, M.; Karmiris-Obratański, P. Evaluation of the Feasibility of the Prediction of the Surface Morphologiesof AWJ-Milled Pockets by Statistical Methods Based on Multiple Roughness Indicators. Surfaces 2024, 7, 340-357. https://doi.org/10.3390/surfaces7020021

Karkalos NE, Thangaraj M, Karmiris-Obratański P. Evaluation of the Feasibility of the Prediction of the Surface Morphologiesof AWJ-Milled Pockets by Statistical Methods Based on Multiple Roughness Indicators. Surfaces. 2024; 7(2):340-357. https://doi.org/10.3390/surfaces7020021

Chicago/Turabian StyleKarkalos, Nikolaos E., Muthuramalingam Thangaraj, and Panagiotis Karmiris-Obratański. 2024. "Evaluation of the Feasibility of the Prediction of the Surface Morphologiesof AWJ-Milled Pockets by Statistical Methods Based on Multiple Roughness Indicators" Surfaces 7, no. 2: 340-357. https://doi.org/10.3390/surfaces7020021

APA StyleKarkalos, N. E., Thangaraj, M., & Karmiris-Obratański, P. (2024). Evaluation of the Feasibility of the Prediction of the Surface Morphologiesof AWJ-Milled Pockets by Statistical Methods Based on Multiple Roughness Indicators. Surfaces, 7(2), 340-357. https://doi.org/10.3390/surfaces7020021