Multilayer WO3/BiVO4 Photoanodes for Solar-Driven Water Splitting Prepared by RF-Plasma Sputtering

Abstract

1. Introduction

2. Materials and Methods

2.1. Photoanodes Preparation

2.2. Photoanodes Characterization

2.3. Photoelectrocatalytic Water Splitting Tests

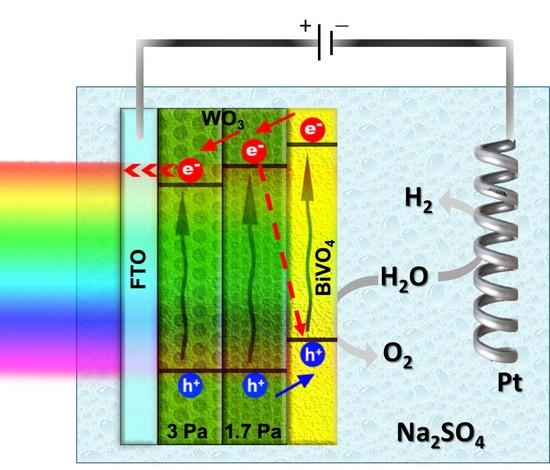

3. Results and Discussion

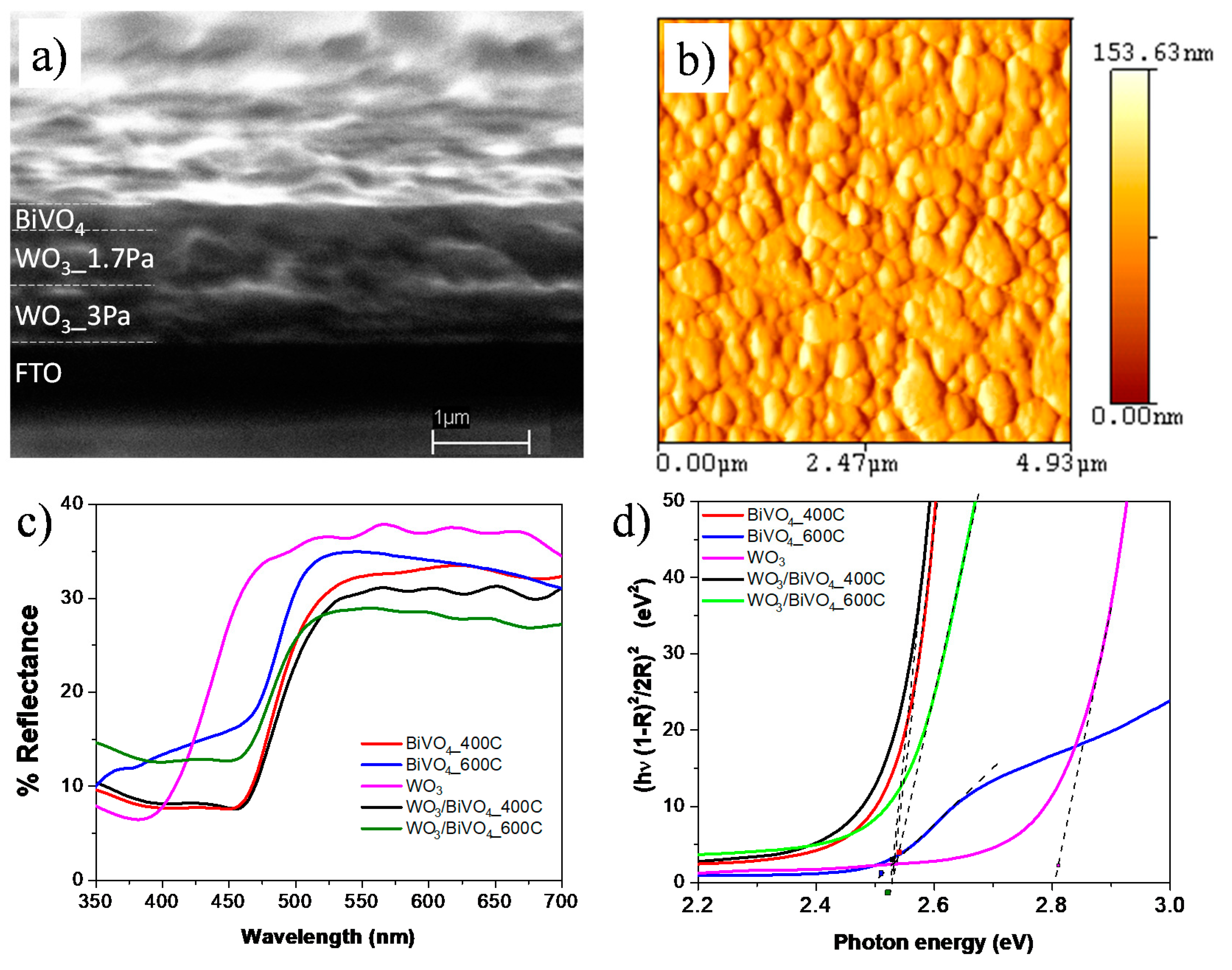

3.1. Photoanodes Characterization

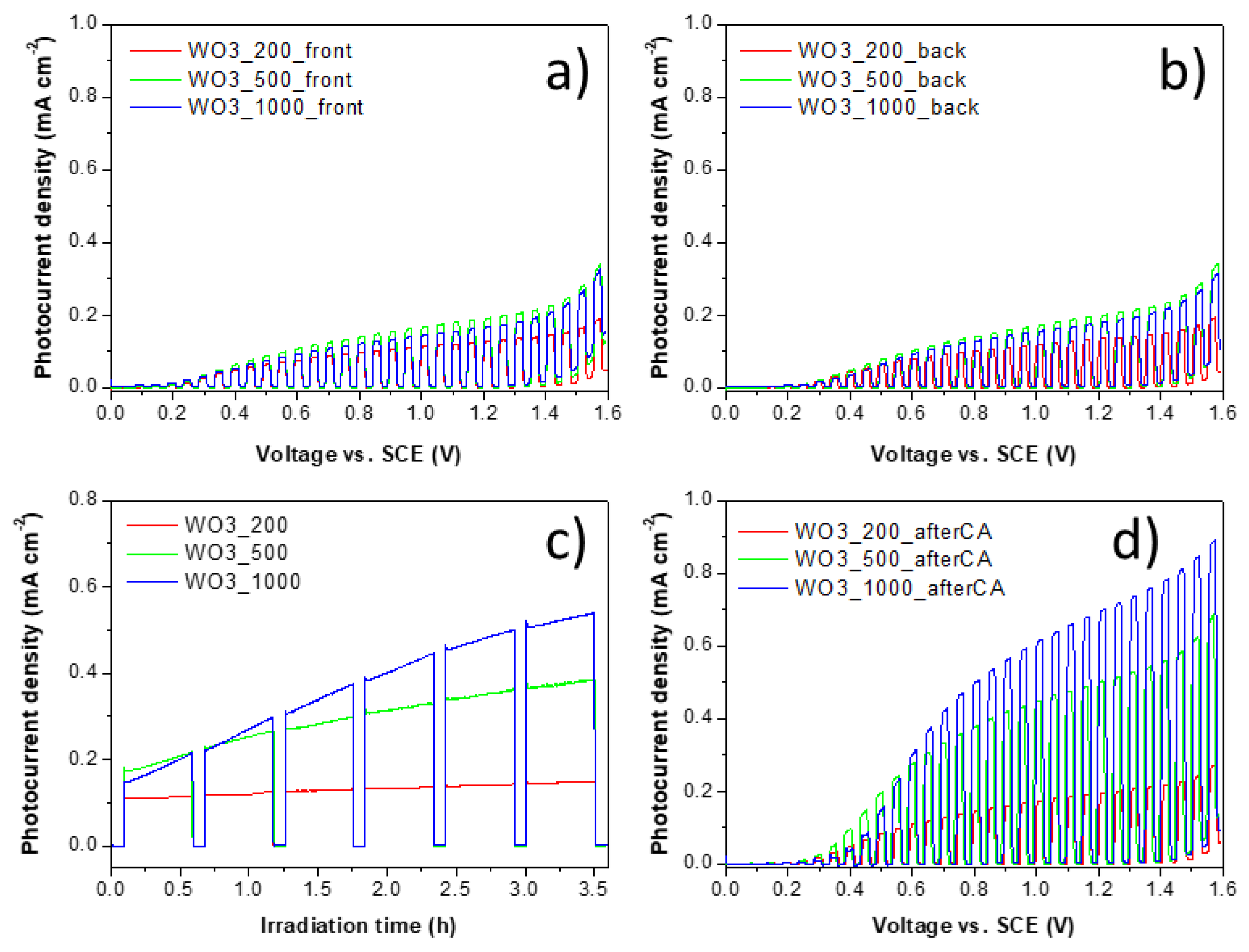

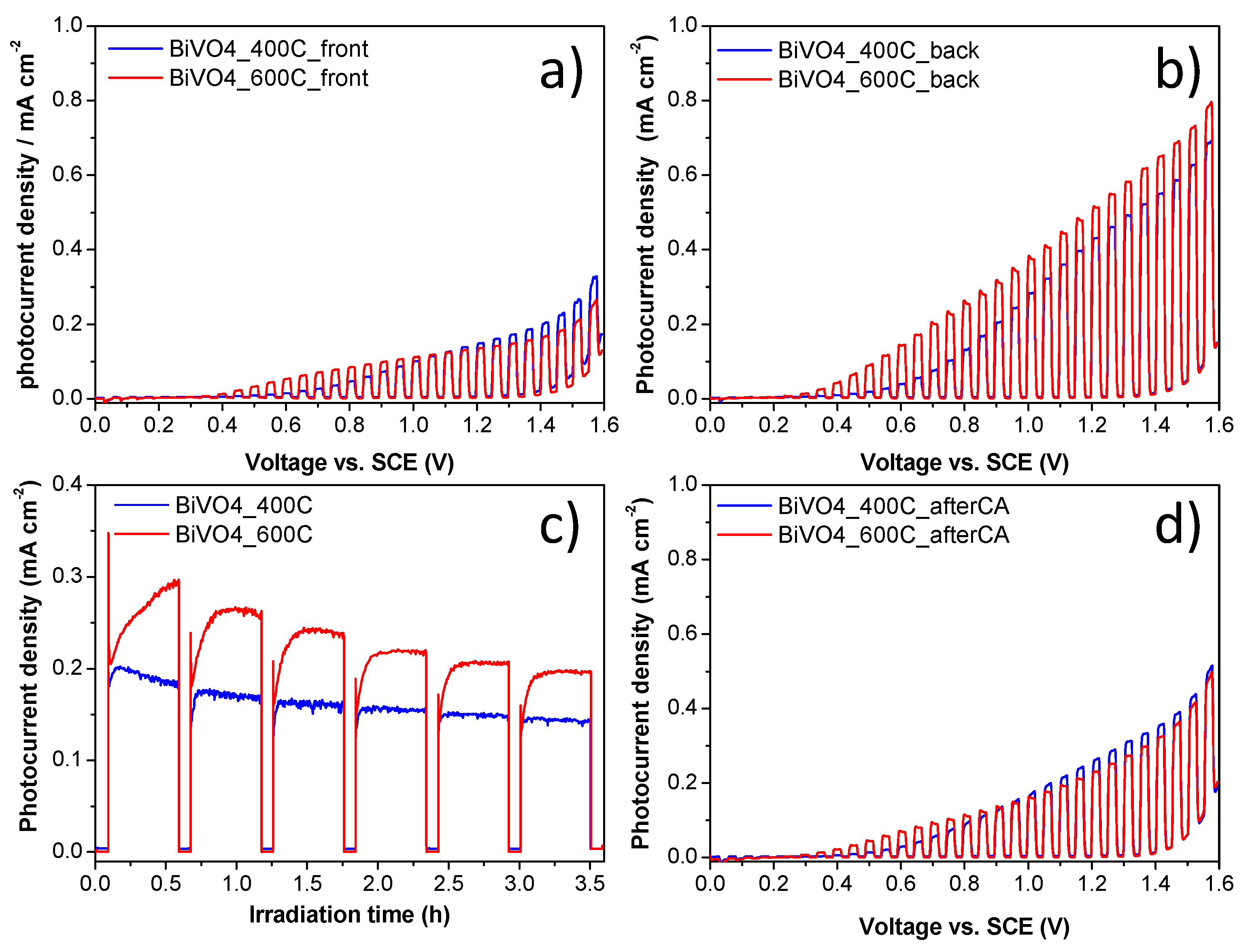

3.2. PEC Performance of Individual WO3 and BiVO4 Photoanodes

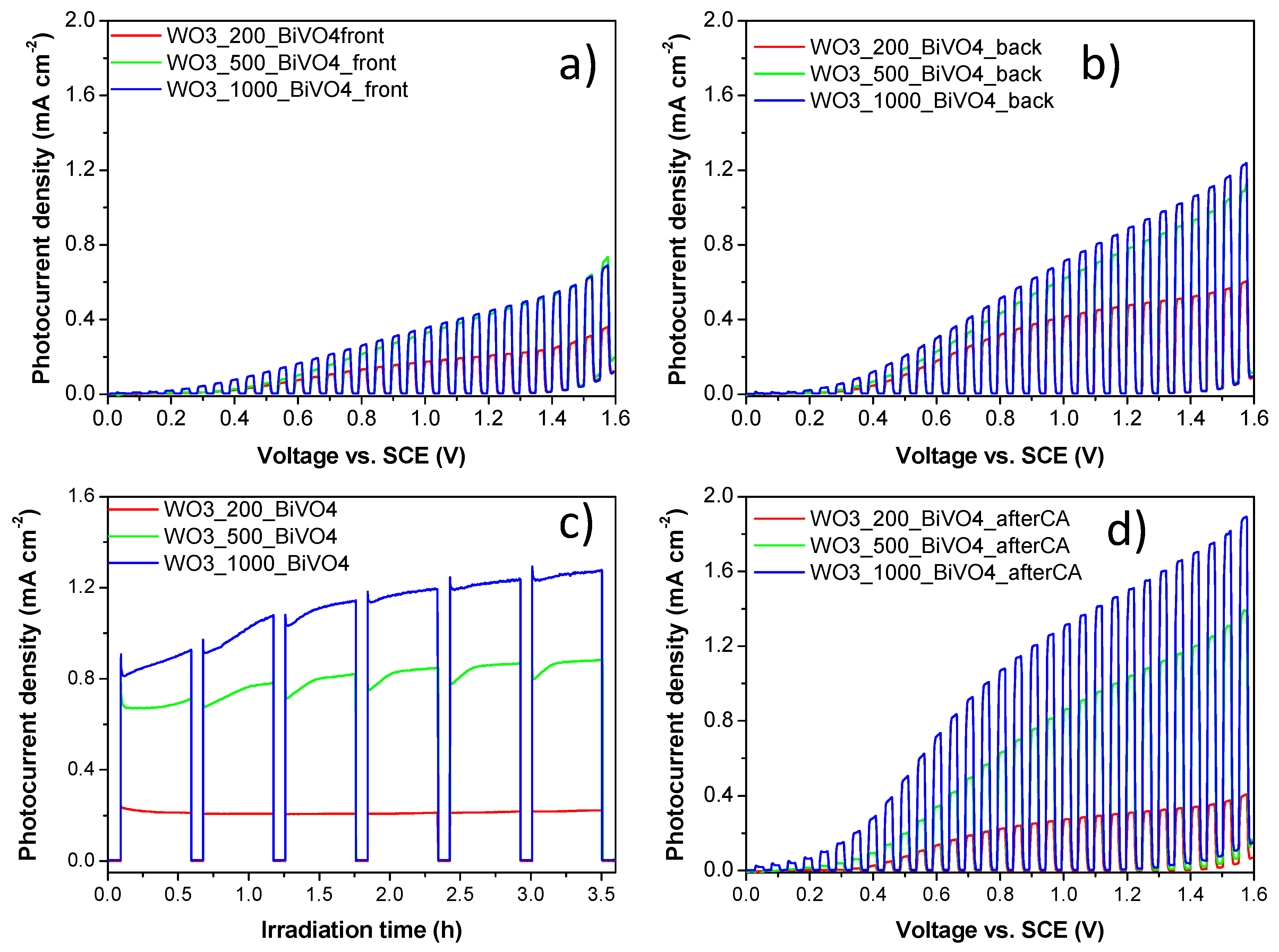

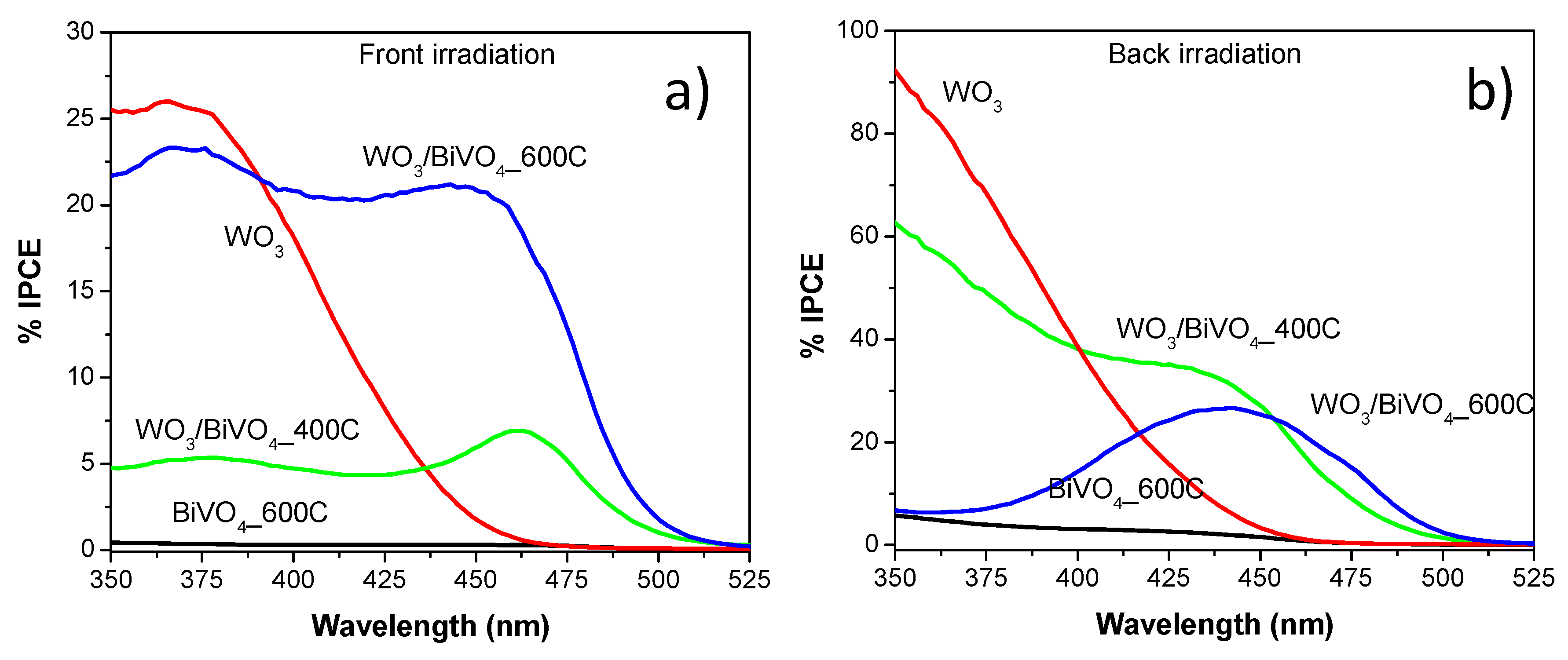

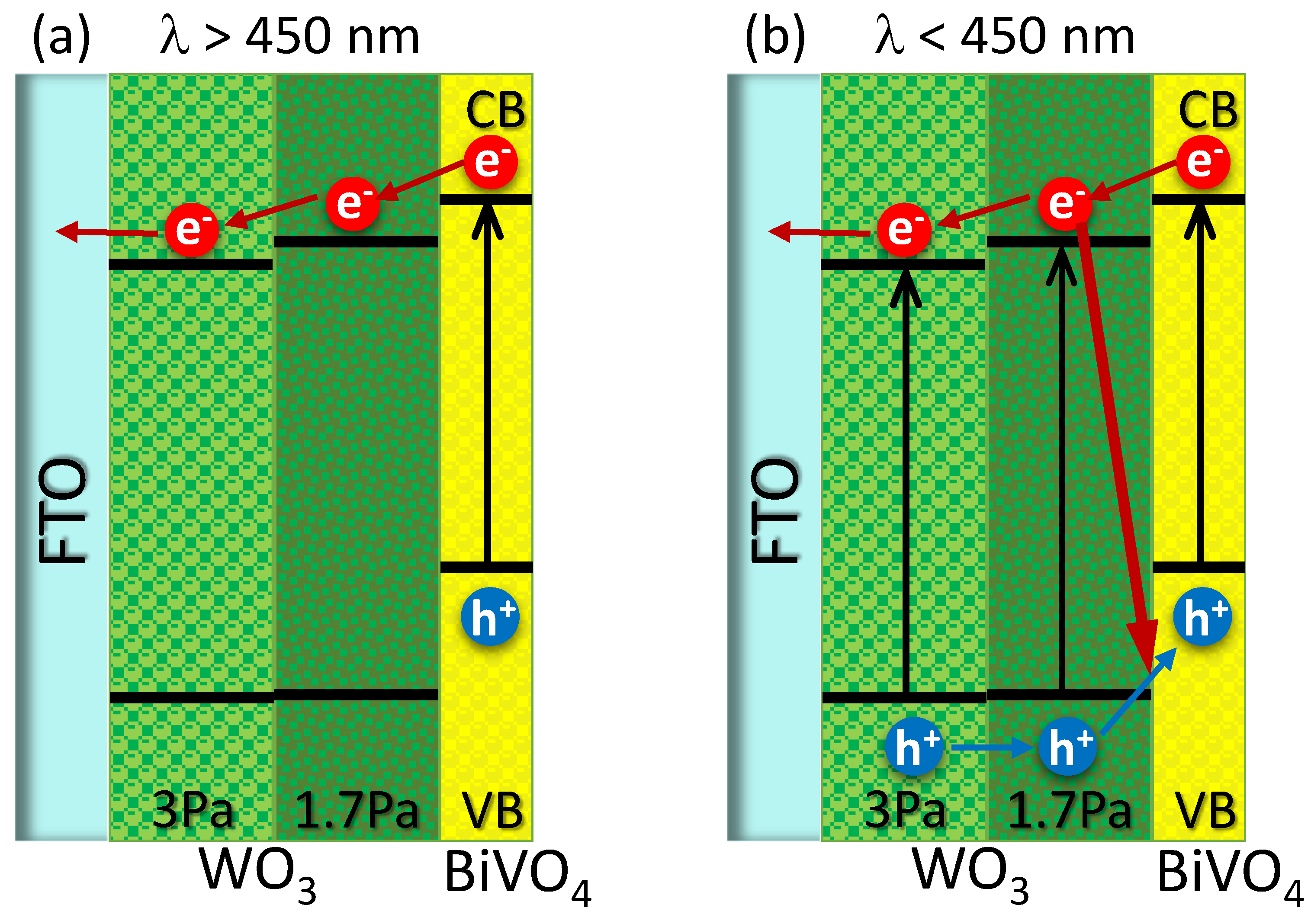

3.3. PEC Performance of the WO3/BiVO4 Heterojunction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Marszewski, M.; Cao, S.; Yu, J.; Jaroniec, M. Semiconductor-based photocatalytic CO2 conversion. Mater. Horizons 2015, 2, 261–278. [Google Scholar] [CrossRef]

- Li, X.; Wen, J.; Low, J.; Fang, Y.; Yu, J. Design and fabrication of semiconductor photocatalyst for photocatalytic reduction of CO2 to solar fuel. Sci. China Mater. 2014, 57, 70–100. [Google Scholar] [CrossRef]

- Furukawa, H.; Yaghi, O.M. Storage of hydrogen, methane, and carbon dioxide in highly porous covalent organic frameworks for clean energy applications. J. Am. Chem. Soc. 2009, 131, 8875–8883. [Google Scholar] [CrossRef] [PubMed]

- Chalk, S.G.; Miller, J.F. Key challenges and recent progress in batteries, fuel cells, and hydrogen storage for clean energy systems. J. Power Sources 2006, 159, 73–80. [Google Scholar] [CrossRef]

- Ganguly, P.; Harb, M.; Cao, Z.; Cavallo, L.; Breen, A.; Dervin, S.; Dionysiou, D.D.; Pillai, S.C. 2D Nanomaterials for Photocatalytic Hydrogen Production. ACS Energy Lett. 2019, 4, 1687–1709. [Google Scholar] [CrossRef]

- Hisatomi, T.; Kubota, J.; Domen, K. Recent advances in semiconductors for photocatalytic and photoelectrochemical water splitting. Chem. Soc. Rev. 2014, 43, 7520–7535. [Google Scholar] [CrossRef]

- Sivula, K.; van de Krol, R. Semiconducting materials for photoelectrochemical energy conversion. Nat. Rev. Mater. 2016, 1, 15010. [Google Scholar] [CrossRef]

- Huang, Q.; Ye, Z.; Xiao, X. Recent progress in photocathodes for hydrogen evolution. J. Mater. Chem. A 2015, 3, 15824–15837. [Google Scholar] [CrossRef]

- Chen, L.; Alarcón-Lladó, E.; Hettick, M.; Sharp, I.D.; Lin, Y.; Javey, A.; Ager, J.W. Reactive sputtering of bismuth vanadate photoanodes for solar water splitting. J. Phys. Chem. C 2013, 117, 21635–21642. [Google Scholar] [CrossRef]

- Grigioni, I.; Stamplecoskie, K.G.; Selli, E.; Kamat, P.V. Dynamics of photogenerated charge carriers in WO3/BiVO4 heterojunction photoanodes. J. Phys. Chem. C 2015, 119, 20792–20800. [Google Scholar] [CrossRef]

- Chatchai, P.; Murakami, Y.; Kishioka, S.-Y.; Nosaka, A.Y.; Nosaka, Y. FTO∕SnO2∕BiVO4 composite photoelectrode for water oxidation under visible light irradiation. Electrochem. Solid State Lett. 2008, 11, H160. [Google Scholar] [CrossRef]

- Xia, L.; Bai, J.; Li, J.; Zeng, Q.; Li, L.; Zhou, B. High-performance BiVO4 photoanodes cocatalyzed with an ultrathin α-Fe2O3 layer for photoelectrochemical application. Appl. Catal. B Environ. 2017, 204, 127–133. [Google Scholar] [CrossRef]

- Li, L.-P.; Liu, M.; Zhang, W.-D. Electrodeposition of CdS onto BiVO4 films with high photoelectrochemical performance. J. Solid State Electrochem. 2018, 22, 2569–2577. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, G.; Oh, K.H.; Kang, S.H.; Lee, H.C.; Cho, S.K.; Nam, K.M. Analysis of charge separation processes in WO3 -BiVO4 composite for efficient photoelectrochemical water oxidation. J. Electroanal. Chem. 2017, 789, 17–23. [Google Scholar] [CrossRef]

- Huang, Z.; Song, J.; Pan, L.; Zhang, X.; Wang, L.; Zou, J. Tungsten oxides for photocatalysis, electrochemistry, and phototherapy. Adv. Mater. 2015, 27, 5309–5327. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.J.; Lee, S.; Jang, J.S.; Lee, J.S. Heterojunction BiVO4/WO3 electrodes for enhanced photoactivity of water oxidation. Energy Environ. Sci. 2011, 4, 1781. [Google Scholar] [CrossRef]

- Fujimoto, I.; Wang, N.; Saito, R.; Miseki, Y.; Gunji, T.; Sayama, K. WO3/BiVO4 composite photoelectrode prepared by improved auto-combustion method for highly efficient water splitting. Int. J. Hydrogen Energy 2014, 39, 2454–2461. [Google Scholar] [CrossRef]

- Chae, S.Y.; Lee, C.S.; Jung, H.; Joo, O.-S.; Min, B.K.; Kim, J.H.; Hwang, Y.J. Insight into charge separation in WO3/BiVO4 heterojunction for solar water splitting. ACS Appl. Mater. Interfaces 2017, 9, 19780–19790. [Google Scholar] [CrossRef]

- Pilli, S.K.; Janarthanan, R.; Deutsch, T.G.; Furtak, T.E.; Brown, L.D.; Turner, J.A.; Herring, A.M. Efficient photoelectrochemical water oxidation over cobalt-phosphate (Co-Pi) catalyst modified BiVO4/1D-WO3 heterojunction electrodes. Phys. Chem. Chem. Phys. 2013, 15, 14723. [Google Scholar] [CrossRef]

- Pihosh, Y.; Turkevych, I.; Mawatari, K.; Asai, T.; Hisatomi, T.; Uemura, J.; Tosa, M.; Shimamura, K.; Kubota, J.; Domen, K.; et al. Nanostructured WO3/BiVO4 photoanodes for efficient photoelectrochemical water splitting. Small 2014, 10, 3692–3699. [Google Scholar] [CrossRef]

- Shi, X.; Choi, I.Y.; Zhang, K.; Kwon, J.; Kim, D.Y.; Lee, J.K.; Oh, S.H.; Kim, J.K.; Park, J.H. Efficient photoelectrochemical hydrogen production from bismuth vanadate-decorated tungsten trioxide helix nanostructures. Nat. Commun. 2014, 5, 4775. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, W.; Yang, Y.; Cheng, C. 3D WO3/BiVO4/Cobalt phosphate composites inverse opal photoanode for efficient photoelectrochemical water splitting. Small 2017, 13, 1603840. [Google Scholar] [CrossRef]

- Pihosh, Y.; Turkevych, I.; Mawatari, K.; Uemura, J.; Kazoe, Y.; Kosar, S.; Makita, K.; Sugaya, T.; Matsui, T.; Fujita, D.; et al. Photocatalytic generation of hydrogen by core-shell WO3/BiVO4 nanorods with ultimate water splitting efficiency. Sci. Rep. 2015, 5, 11141. [Google Scholar] [CrossRef]

- Pedroni, M.; Chiarello, G.L.; Haghshenas, N.; Canetti, M.; Ripamonti, D.; Selli, E.; Vassallo, E. Bismuth vanadate photoanodes for water splitting deposited by radio frequency plasma reactive co-sputtering. J. Vac. Sci. Technol. B 2020, 38, 012203. [Google Scholar] [CrossRef]

- Chiarello, G.L.; Bernareggi, M.; Pedroni, M.; Magni, M.; Pietralunga, S.M.; Tagliaferri, A.; Vassallo, E.; Selli, E. Enhanced photopromoted electron transfer over a bilayer WO3 n–n heterojunction prepared by RF diode sputtering. J. Mater. Chem. A 2017, 5, 12977–12989. [Google Scholar] [CrossRef]

- Pedroni, M.; Canetti, M.; Chiarello, G.L.; Cremona, A.; Inzoli, F.; Luzzati, S.; Pietralunga, S.M.; Tagliaferri, A.; Zani, M.; Vassallo, E. Tungsten oxide thin film photo-anodes by reactive RF diode sputtering. Thin Solid Films 2016, 616, 375–380. [Google Scholar] [CrossRef]

- Luo, W.; Yang, Z.; Li, Z.; Zhang, J.; Liu, J.; Zhao, Z.; Wang, Z.; Yan, S.; Yu, T.; Zou, Z. Solar hydrogen generation from seawater with a modified BiVO4 photoanode. Energy Environ. Sci. 2011, 4, 4046. [Google Scholar] [CrossRef]

- Grigioni, I.; Dozzi, M.V.; Selli, E. Photoinduced electron transfer in WO3/BiVO4 heterojunction photoanodes: effects of the WO3 layer thickness. J. Phys. Condens. Matter 2020, 32, 014001. [Google Scholar] [CrossRef]

- Grigioni, I.; Stamplecoskie, K.G.; Jara, D.H.; Dozzi, M.V.; Oriana, A.; Cerullo, G.; Kamat, P.V.; Selli, E. Wavelength-Dependent Ultrafast Charge Carrier Separation in the WO3/BiVO4 Coupled System. ACS Energy Lett. 2017, 2, 1362–1367. [Google Scholar] [CrossRef]

- Grigioni, I.; Abdellah, M.; Corti, A.; Dozzi, M.V.; Hammarström, L.; Selli, E. Photoinduced Charge-Transfer Dynamics in WO3/BiVO4 Photoanodes Probed through Midinfrared Transient Absorption Spectroscopy. J. Am. Chem. Soc. 2018, 140, 14042–14045. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedroni, M.; Chiarello, G.L.; Vassallo, E.; Selli, E. Multilayer WO3/BiVO4 Photoanodes for Solar-Driven Water Splitting Prepared by RF-Plasma Sputtering. Surfaces 2020, 3, 105-115. https://doi.org/10.3390/surfaces3010010

Pedroni M, Chiarello GL, Vassallo E, Selli E. Multilayer WO3/BiVO4 Photoanodes for Solar-Driven Water Splitting Prepared by RF-Plasma Sputtering. Surfaces. 2020; 3(1):105-115. https://doi.org/10.3390/surfaces3010010

Chicago/Turabian StylePedroni, Matteo, Gian Luca Chiarello, Espedito Vassallo, and Elena Selli. 2020. "Multilayer WO3/BiVO4 Photoanodes for Solar-Driven Water Splitting Prepared by RF-Plasma Sputtering" Surfaces 3, no. 1: 105-115. https://doi.org/10.3390/surfaces3010010

APA StylePedroni, M., Chiarello, G. L., Vassallo, E., & Selli, E. (2020). Multilayer WO3/BiVO4 Photoanodes for Solar-Driven Water Splitting Prepared by RF-Plasma Sputtering. Surfaces, 3(1), 105-115. https://doi.org/10.3390/surfaces3010010