An Analysis of the Pore Distribution in Ceramic Vessels from the Akterek Burial Archeological Site Using Neutron Tomography Data

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Studied Ceramic Materials

2.2. Experimental Methods

3. Results

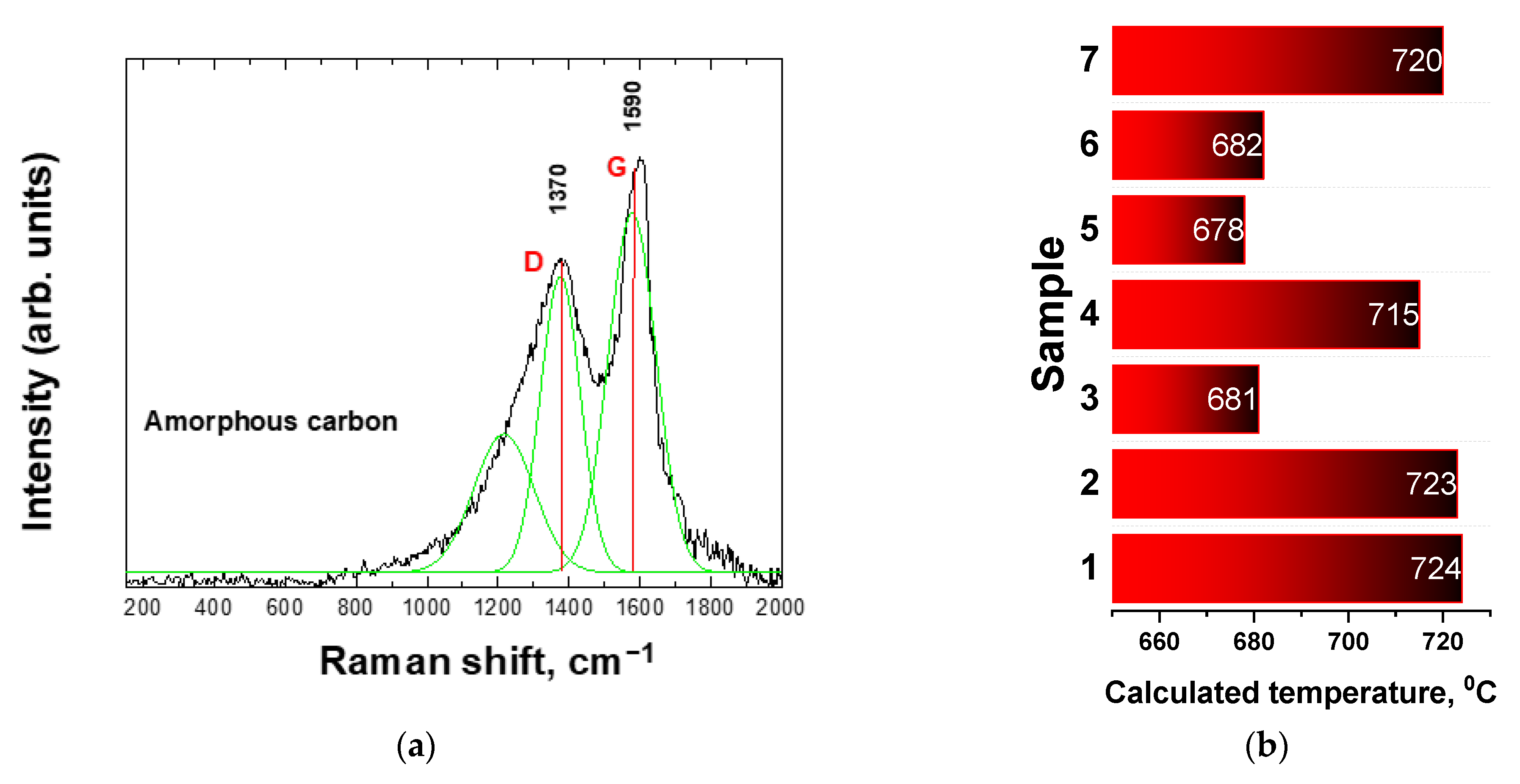

3.1. Raman Spectroscopy

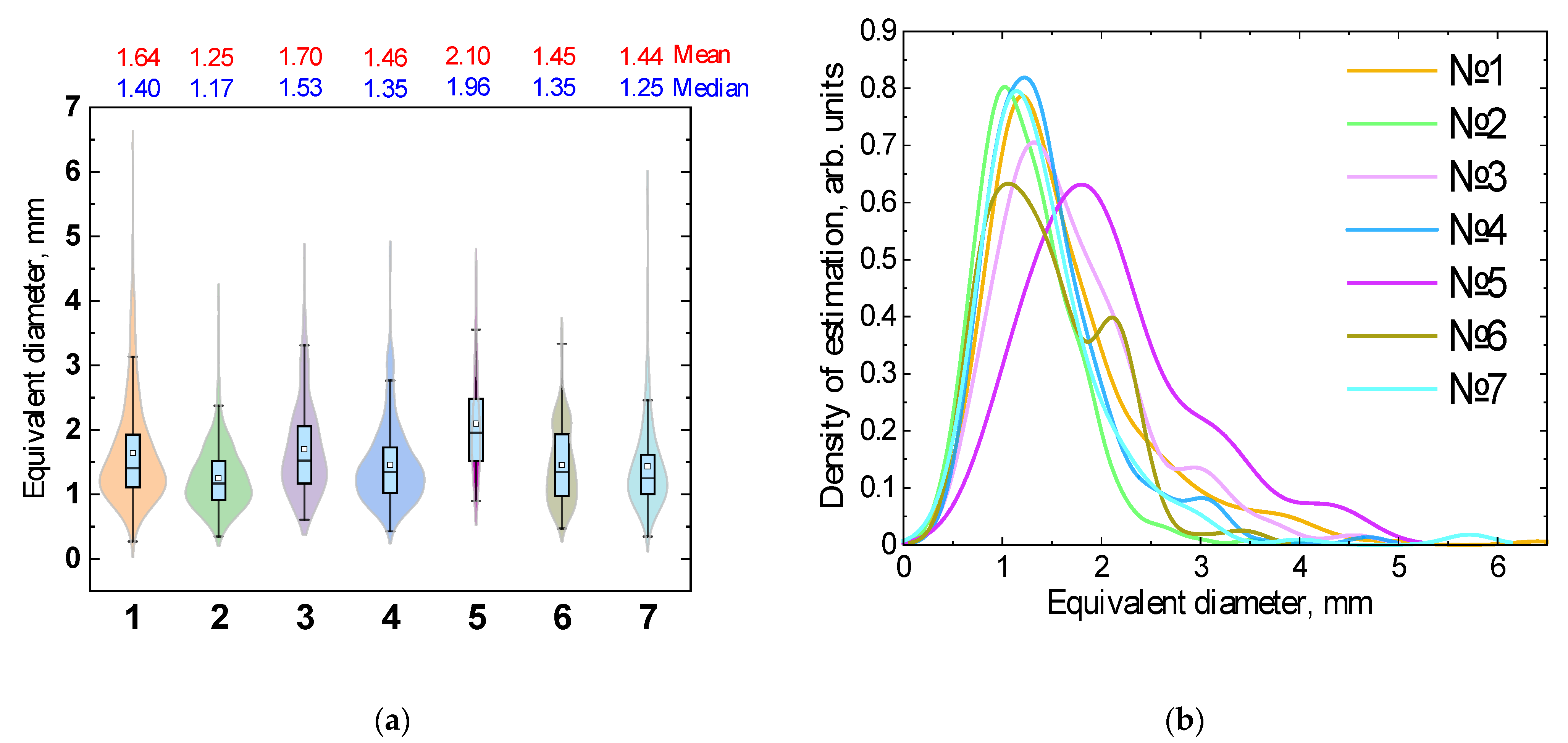

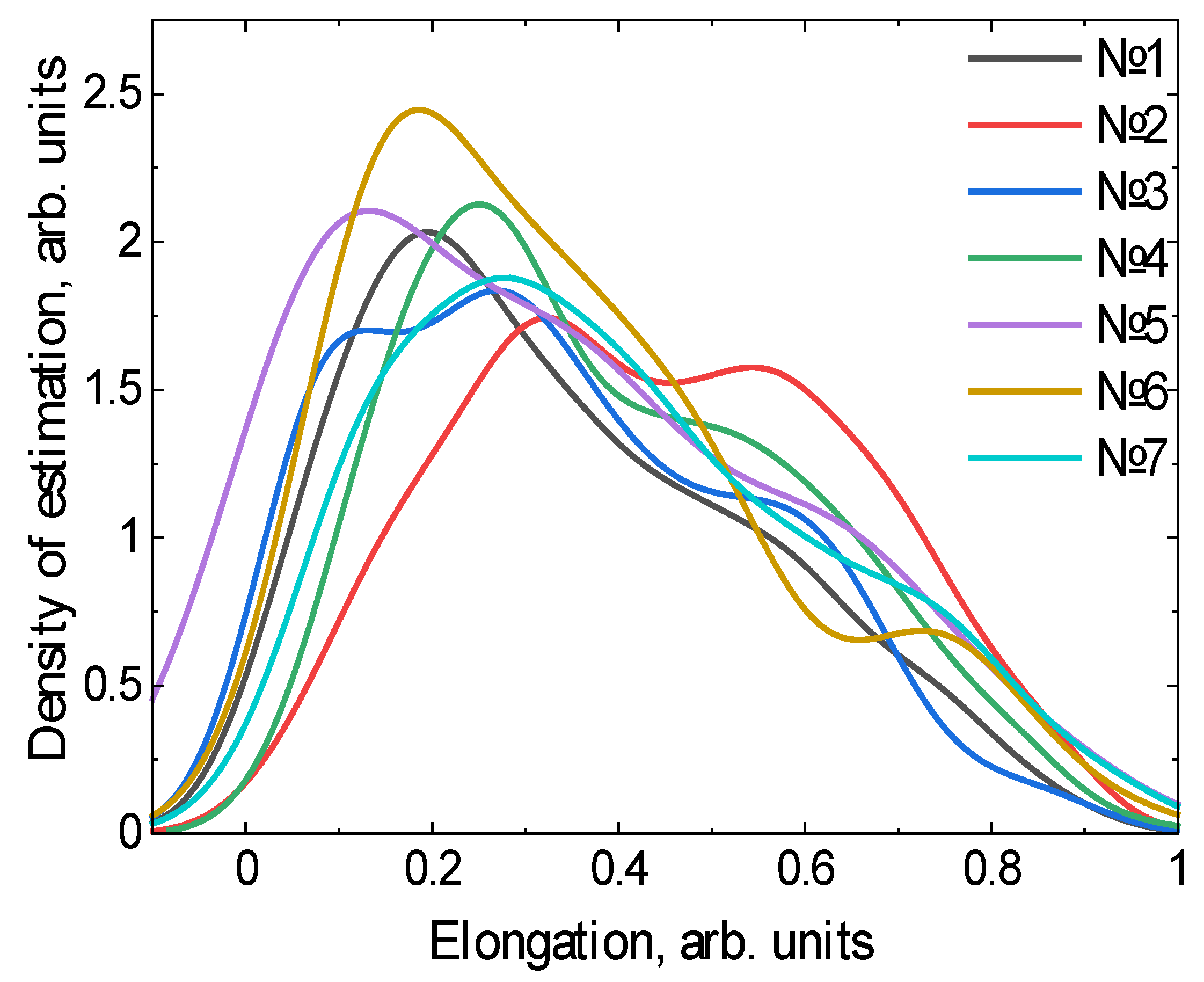

3.2. Neutron Tomography

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, P.; Mal, E.; Khare, A.; Sharma, S. A study of archaeological pottery of Northeast India using laser induced breakdown spectroscopy (LIBS). J. Cult. Herit. 2018, 33, 71–82. [Google Scholar] [CrossRef]

- Medeghini, L.; Lottici, P.P.; De Vito, C.; Mignardi, S.; Bersani, D. Micro-Raman spectroscopy and ancient ceramics: Applications and problems. J. Raman Spectrosc. 2014, 45, 1244–1250. [Google Scholar] [CrossRef]

- Colomban, P. Raman spectrometry, a unique tool to analyze and classify ancient ceramics and glasses. Appl. Phys. 2024, 79, 167–170. [Google Scholar] [CrossRef]

- Mommsen, H.; Kreuser, A.; Weber, J. A method for grouping pottery by chemical composition. Archaeometry 1988, 30, 47–57. [Google Scholar] [CrossRef]

- Kardjilov, N.; Fiori, F.; Giunta, G.; Hilger, A.; Rusticheli, F.; Strobl, M.; Banhart, J.; Triolo, R. Neutron tomography for archaeological investigations. J. Neutron. Res. 2006, 14, 29–36. [Google Scholar] [CrossRef]

- Kockelmann, W.; Kirfel, A.; Hähnel, E. Non-destructive Phase Analysis of Archaeological Ceramics using TOF Neutron Diffraction. J. Archaeol. Sci. 2001, 28, 213–222. [Google Scholar] [CrossRef]

- Stelzner, J.; Ebinger-Rist, N.; Peek, C.; Schillinger, B. The application of 3D computed tomography with X-rays and neutrons to visualize archaeological objects in blocks of soil. Stud. Conserv. 2010, 55, 95–106. [Google Scholar] [CrossRef]

- Teixeira, J.; Magli, R.; Loupiac, C. Neutron scattering and imaging: A tool for archaeological studies. Eur. J. Mineral. 2015, 27, 289–296. [Google Scholar] [CrossRef]

- Fedrigo, A.; Strobl, M.; Williams, A.R.; Lefmann, K.; Lindelof, P.E.; Jørgensen, L.; Pentz, P.; Bausenwein, D.; Schillinger, B.; Kovyakh, A. Neutron Imaging Study of ‘pattern-welded’ Swords from the Viking Age. Archaeol. Anthropol. Sci. 2018, 10, 1249–1263. [Google Scholar] [CrossRef]

- Grazzi, F.; Cantini, F.; Salvemini, F.; Scherillo, A.; Schillinger, B.; Kaestner, A.; Edge, D.; Williams, A. The Investigation of Indian and Central Asian Swords through Neutron Methods. J. Archaeol. Sci. Rep. 2018, 20, 834–842. [Google Scholar] [CrossRef]

- Mednikova, M.; Saprykina, I.; Kichanov, S.; Kozlenko, D. The Reconstruction of a Bronze Battle Axe and Comparison of Inflicted Damage Injuries Using Neutron Tomography, Manufacturing Modeling, and X-Ray Microtomography Data. J. Imaging 2020, 6, 45. [Google Scholar] [CrossRef] [PubMed]

- Bakirov, B.; Smirnova, V.; Kichanov, S.; Shaykhutdinova, E.; Murashev, M.; Kozlenko, D.; Sitdikov, A. Structural Features of the Fragments from Cast Iron Cauldrons of the Medieval Golden Horde: Neutron Tomography Data. J. Imaging 2023, 9, 97. [Google Scholar] [CrossRef] [PubMed]

- Gait, J.; Bajnok, K.; Szilágyi, V.; Szenti, I.; Kukovecz, A.; Kis, Z. Quantitative 3D orientation analysis of particles and voids to differentiate hand-built pottery forming techniques using X-ray microtomography and neutron tomography. Archaeol. Anthropol. Sci. 2022, 14, 223. [Google Scholar] [CrossRef]

- Salvemini, F.; Olsen, S.R.; Luzin, V.; Garbe, U.; Davis, J.; Knowles, T.; Sheedy, K. Neutron tomographic analysis: Material characterization of silver and electrum coins from the 6th and 5th centuries BCE. Mater. Charact. 2016, 118, 175–185. [Google Scholar] [CrossRef]

- Herringer, S.H.; Ryzewski, K.; Bilheux, H.Z.; Bilheux, J.C.; Sheldon, B.W. Evaluation of segregation in Roman sestertius coins. J. Mater. Sci. 2017, 53, 2161–2170. [Google Scholar] [CrossRef]

- Bakirov, B.; Saprykina, I.; Kichanov, S.; Mimokhod, R.; Sudarev, N.; Kozlenko, D. Phase Composition and Its Spatial Distribution in Antique Copper Coins: Neutron Tomography and Diffraction Studies. J. Imaging 2021, 7, 129. [Google Scholar] [CrossRef]

- Smirnova, V.; Kichanov, S.E.; Petrov, F.; Panteleeva, L.; Bakirov, B.; Kozlenko, D. Structural Studies of a Bronze Zoomorphic Pommel from the Pekunovsky Settlement Using Neutron Diffraction and Tomography Methods. Phys. Part. Nucl. Lett. 2022, 19, 434–439. [Google Scholar] [CrossRef]

- Kardjilov, N.; Giulia, F. Neutron Methods for Archaeology and Cultural Heritage; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3–171. [Google Scholar]

- Rinaldi, R. The contribution of neutron scattering to cultural heritage research. Notiz. Neutron. Luce Sincrotr. 2002, 7, 30–37. [Google Scholar]

- Saprykina, I.A.; Khairedinova, E.A.; Kichanov, S.E.; Rutkauskas, A.V.; Belozerova, N.M.; Kozlenko, D.P. Golden Amulet-boxes and their Contents from the Excavations of the Roman Time Burial Ground Frontovoe 3. Stratum plus. Archaeol. Cult. Anthropol. 2022, 4, 167–181. [Google Scholar] [CrossRef]

- Andreani, C. A neutron study of sealed pottery from the grave-goods of Kha and Merit. J. Anal. At. Spectrom. 2017, 32, 1342–1347. [Google Scholar] [CrossRef]

- Kis, Z.; Sciarretta, F.; Szentmiklósi, L. Water uptake experiments of historic construction materials from Venice by neutron imaging and PGAI methods. Mater. Struct. 2017, 50, 159. [Google Scholar] [CrossRef]

- Aloupi-Siotis, E. Ceramic technology: How to characterise black Fe-based glass-ceramic coatings. Archaeol. Anthropol. Sci. 2020, 12, 191. [Google Scholar] [CrossRef]

- Gualtieri, S. Ceramic raw materials: How to establish the technological suitability of a raw material. Archaeol. Anthropol. Sci. 2020, 12, 183. [Google Scholar] [CrossRef]

- Hein, A.; Müller, N.S.; Day, P.M.; Kilikoglou, V. Thermal conductivity of archaeological ceramics: The effect of inclusions, porosity and firing temperature. Thermochim. Acta 2008, 480, 35–42. [Google Scholar] [CrossRef]

- Maltsev, A.; Pashkova, G.; Fernández-Ruiz, R.; Demonterova, E.; Shuliumova, A.; Umarova, N.; Shergin, D.; Mukhamedova, M.; Chubarov, V.; Mikheeva, E. Characterization of archaeological ceramics from eastern Siberia by total-reflection X-ray fluorescence spectrometry and principal component analysis. Spectrochim. Acta B Atom. Spectr. 2021, 175, 106012. [Google Scholar] [CrossRef]

- Abdurakhimov, B.A.; Kichanov, S.E.; Talmaţchi, C.; Kozlenko, D.P.; Talmaţchi, G.; Belozerova, N.M.; Bǎlǎșoiu, M.; Belc, M.C. Studies of ancient pottery fragments from Dobrudja region of Romania using neutron diffraction, tomography and Raman spectroscopy. J. Archaeol. Sci. Rep. 2021, 35, 102755. [Google Scholar] [CrossRef]

- Bakirov, B.; Zhomartova, A.; Kichanov, S.E.; Zhumatayev, R.; Toleubayev, A.T.; Nazarov, K.; Kozlenko, D.; Nazarova, A.M. Non-destructive neutron structural studies of ancient ceramic fragments of the cultural heritage of the Republic of Kazakhstan. Eur. J. Phys. Funct. Mater. 2022, 6, 56–70. [Google Scholar] [CrossRef]

- Gehres, B.; Querré, G. Analysis of mica inclusions using LA-ICP-MS: A new approach for sourcing raw material of ceramics. J. Archaeol. Sci. Rep. 2018, 21, 912–920. [Google Scholar] [CrossRef]

- Myakisheva, O.A.; Torezhanova, N.Z. Archaeological monuments of Akterek as an open-air museum. Bull. Hist. 2021, 103, 183–193. [Google Scholar] [CrossRef]

- Ageeva, E.I. On the question of the types of ancient burials in the Alma Ata region. New materials on archeology and ethnography of Kazakhstan. House Acad. Sci. Kazakh SSR 1961, 12, 21–40. [Google Scholar]

- Torezhanova, N.Z.; Myakisheva, O.A. The history of the study of archaeological monuments of the Akterek tract. Sci. Eur. 2021, 85, 181–189. [Google Scholar]

- Coccato, A. Raman spectroscopy for the investigation of carbon-based black pigments. J. Raman Spectrosc. 2015, 46, 1003–1015. [Google Scholar] [CrossRef]

- Nazarov, K.M.; Muhametuly, B.; Kenzhin, E.A.; Kichanov, S.E.; Kozlenko, D.P.; Lukin, E.V.; Shaimerdenov, A.A. New neutron radiography and tomography facility TITAN at the WWR-K reactor. Nucl. Instru. Methods Phys. Res. A 2020, 982, 164572. [Google Scholar] [CrossRef]

- Dyussambayev, D.S.; Aitkulov, M.T.; Shaimerdenov, A.A.; Mukhametuly, B.; Nazarov, K.; Kaestner, A.; Pessoa Barradas, N.; Sairanbayev, D.S.; Dikov, A.S.; Bazarbayev, E.M. TITAN neutron imaging facility performance. Nucl. Instru. Methods Phys. Res. A 2022, 1039, 167078. [Google Scholar] [CrossRef]

- Nazarov, K.M.; Mukhametuly, B.; Kichanov, S.E.; Zholdybayev, T.K.; Shaimerdenov, A.A.; Karakozov, K.B.; Dyussambayev, D.S.; Aitkulov, M.T.; Yerdauletov, M.; Napolskiy, P.; et al. Non-destructive analysis of materials by neutron imaging at the TITAN facility. Eur. J. Phys. Funct. Mater. 2021, 5, 6–14. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of Image Analysis. Nat. Meth. 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Brun, F.; Massimi, L.; Fratini, M.; Dreossi, D.; Billé, F.; Accardo, A.; Pugliese, R.; Cedola, A. SYRMEP Tomo Project: A Graphical. User Interface for Customizing CT Reconstruction Workflows. Adv. Struct. Chem. Imaging. 2017, 3, 4. [Google Scholar] [CrossRef]

- Götze, J.; Pan, Y.; Müller, A. Mineralogy and mineral chemistry of quartz: A review. Mineral. Mag. 2021, 85, 639–664. [Google Scholar] [CrossRef]

- Wilcox, M. Blue and Yellow Don’t Make Green; North Light Books: Cleveland, OH, USA, 2009; pp. 60–70. [Google Scholar]

- Huang, S.; Xue, B.; Zhao, Y.; Yang, J. Characterization of primary silicate minerals in Earth-like bodies via Raman spectroscopy. J. Raman Spectrosc. 2024, 55, 625–636. [Google Scholar] [CrossRef]

- Eramo, G. Ceramic technology: How to recognize clay processing. Archaeol. Anthropol. Sci. 2020, 12, 164. [Google Scholar] [CrossRef]

- Kellog, L. Ceramics; The Art Amateur: New York, NY, USA, 1885; pp. 2–10. [Google Scholar]

- Deldicque, D.; Rouzaud, J.N.; Velde, B. A Raman—HRTEM study of the carbonization of wood: A new Raman-based paleothermometer dedicated to archaeometry. Carbon 2016, 102, 319–329. [Google Scholar] [CrossRef]

- Mouraux, C.; Delarue, F.; Bardin, J. Assessing the carbonisation temperatures recorded by ancient charcoals for δ13C-based palaeoclimate reconstruction. Sci. Rep. 2022, 12, 14662. [Google Scholar] [CrossRef] [PubMed]

- Zel, I.Y.; Kenessarin, M.; Kichanov, S.E.; Balasoiu, M.; Kozlenko, D.P.; Nazarov, K.; Nicu, M.; Ionascu, L.; Dragolici, A.C.; Dragolici, F. Spatial distribution of graphite in cement materials used for radioactive waste conditioning: An approach to analysis of neutron tomography data. Cem. Concr. Compos. 2021, 119, 103993. [Google Scholar] [CrossRef]

- Angelidakis, V.; Nadimi, S.; Utili, S. Elongation, flatness and compactness indices to characterise particle form. Powder Technol. 2022, 396, 689–695. [Google Scholar] [CrossRef]

| Quartz SiO2 | Orthoclase KAlSi3O8 | Anatase TiO2 | Hematite Fe2O3 | Carbon | |

|---|---|---|---|---|---|

| № 1 | + | + | + | ||

| № 2 | + | + | + | + | |

| № 3 | + | + | + | ||

| № 4 | + | + | + | ||

| № 5 | + | + | + | + | |

| № 6 | + | + | + | ||

| № 7 | + | + | + | + |

| № | Total Volume, cm3 | Porosity, % | Average Wall Thickness, cm |

|---|---|---|---|

| 1 | 359.62 (1) | 0.39 (1) | 0.63 (1) |

| 2 | 491.83 (1) | 0.10 (1) | 0.67 (2) |

| 3 | 308.12 (2) | 0.29 (1) | 0.88 (2) |

| 4 | 416.53 (2) | 0.21 (1) | 0.61 (1) |

| 5 | 367.33 (1) | 0.08 (1) | 0.47 (1) |

| 6 | 276.33 (2) | 0.13 (1) | 0.57 (2) |

| 7 | 284.62 (1) | 0.21 (1) | 0.66 (1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kenessarin, M.; Nazarov, K.; Smirnova, V.; Kichanov, S.; Torezhanova, N.; Myakisheva, O.; Zhomartova, A.; Mukhametuly, B.; Nemkayeva, R.; Myrzabekova, E. An Analysis of the Pore Distribution in Ceramic Vessels from the Akterek Burial Archeological Site Using Neutron Tomography Data. Heritage 2025, 8, 210. https://doi.org/10.3390/heritage8060210

Kenessarin M, Nazarov K, Smirnova V, Kichanov S, Torezhanova N, Myakisheva O, Zhomartova A, Mukhametuly B, Nemkayeva R, Myrzabekova E. An Analysis of the Pore Distribution in Ceramic Vessels from the Akterek Burial Archeological Site Using Neutron Tomography Data. Heritage. 2025; 8(6):210. https://doi.org/10.3390/heritage8060210

Chicago/Turabian StyleKenessarin, Murat, Kuanysh Nazarov, Veronica Smirnova, Sergey Kichanov, Nabira Torezhanova, Olga Myakisheva, Ayazhan Zhomartova, Bagdaulet Mukhametuly, Renata Nemkayeva, and Elmira Myrzabekova. 2025. "An Analysis of the Pore Distribution in Ceramic Vessels from the Akterek Burial Archeological Site Using Neutron Tomography Data" Heritage 8, no. 6: 210. https://doi.org/10.3390/heritage8060210

APA StyleKenessarin, M., Nazarov, K., Smirnova, V., Kichanov, S., Torezhanova, N., Myakisheva, O., Zhomartova, A., Mukhametuly, B., Nemkayeva, R., & Myrzabekova, E. (2025). An Analysis of the Pore Distribution in Ceramic Vessels from the Akterek Burial Archeological Site Using Neutron Tomography Data. Heritage, 8(6), 210. https://doi.org/10.3390/heritage8060210