Preserved 800-Year-Old Liquid Beer in a Jin Dynasty Vase: Evidence of Malted Sorghum–Wheat Fermentation in Xi’an, China

Abstract

1. Introduction

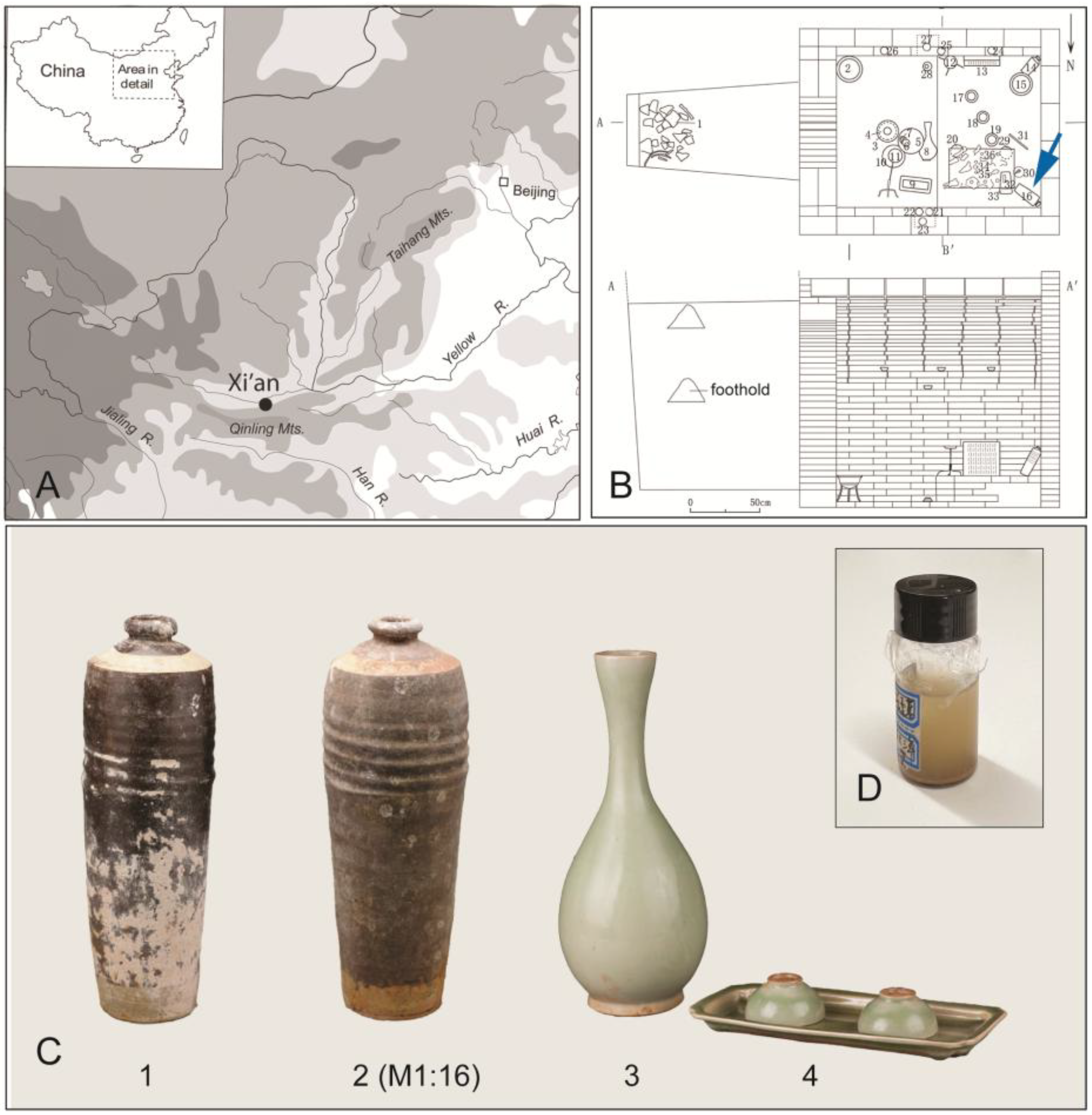

2. Archaeological Background and Previous Studies of the Residue

2.1. Archaeological Background

2.2. Previous Study of the Liquid

3. Materials and Methods

3.1. Microfossil Analysis

3.2. Identification of Fermented Starches Through Experimental Brewing and Ethnographic Observations

3.2.1. Experimental Brewing for Starch Identification

3.2.2. Identifying Traditional Fermentation Methods in China

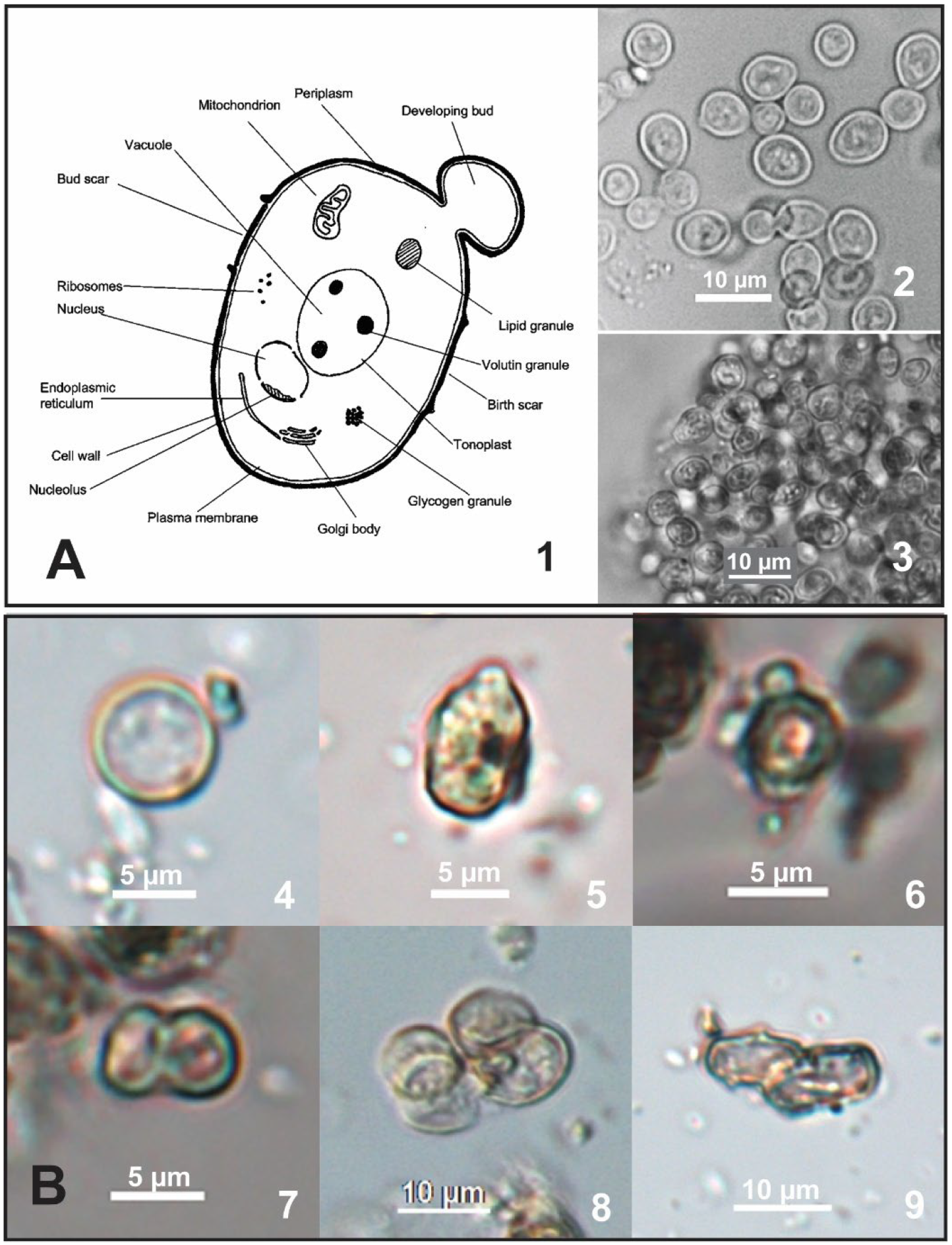

3.3. Identification of Yeast Cells in Fermented Beverages

3.4. Isotopic Analysis

4. Results

4.1. Results of Microfossil Analysis

4.1.1. Yeast Remains

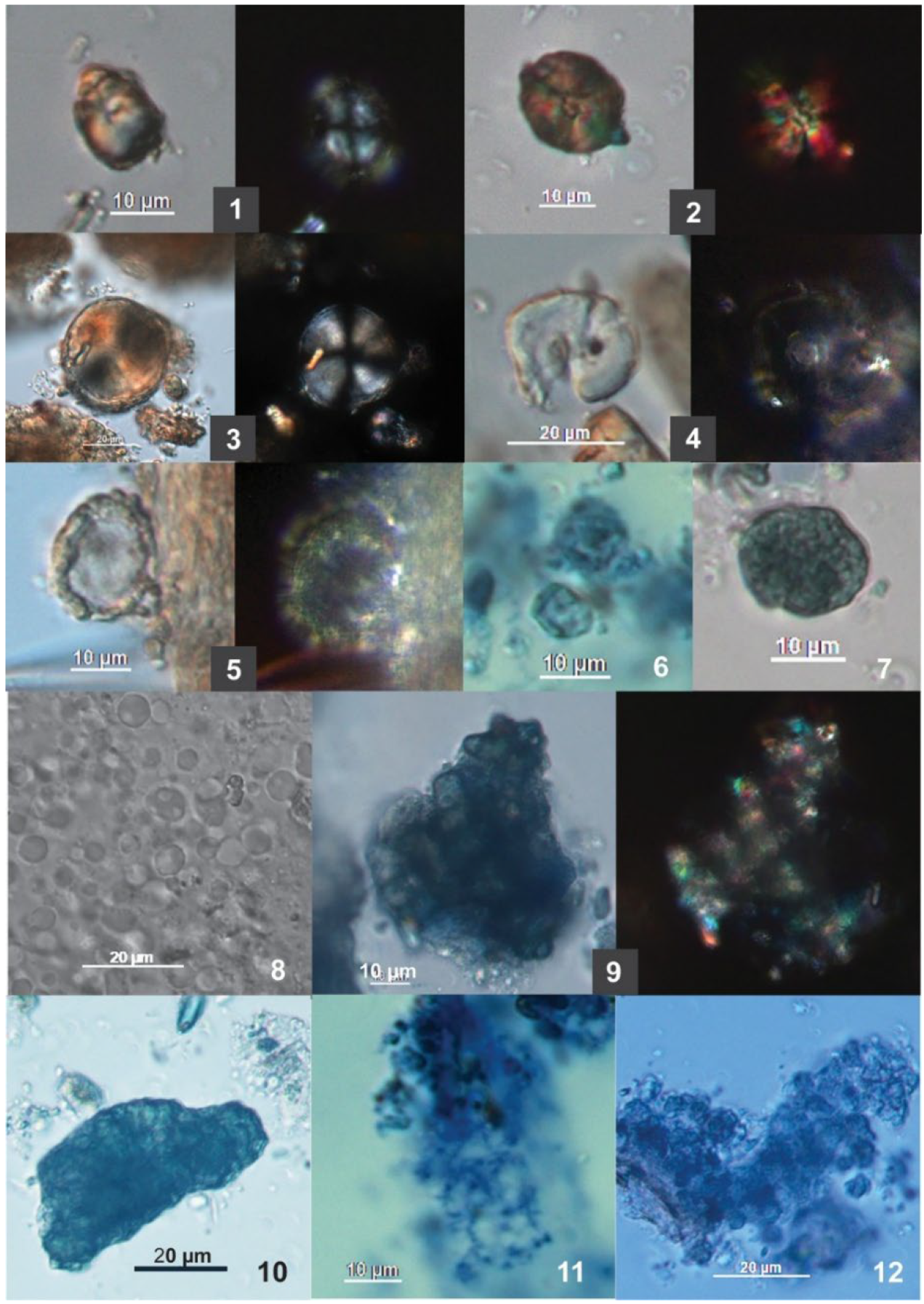

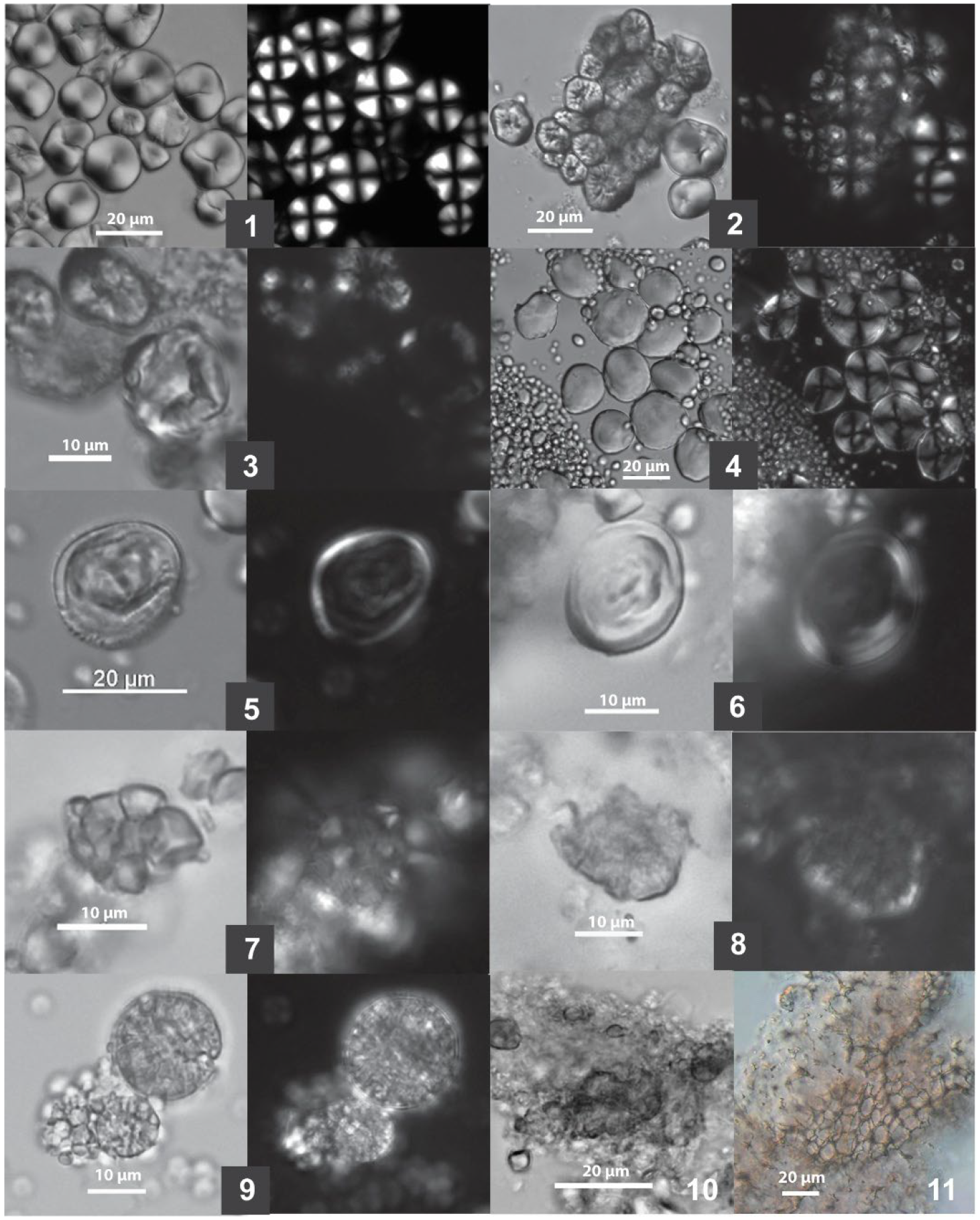

4.1.2. Starch Remains

4.2. Isotopic Results

5. Discussion

5.1. The Fermentation Method and Ingredients

5.2. C4 vs. C3 Plant Source

5.3. The Tradition of Making Li Beer

5.4. The Introduction of Sorghum and the Production of Sorghum Beer

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, L.; Zhang, J.; Li, J.; He, Y.; Gao, Z.; Jiang, L. Identification of 10,000-year-old rice beer at Shangshan in the Lower Yangzi River valley of China. Proc. Natl. Acad. Sci. USA 2024, 121, e2412274121. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Wang, H.; Sun, H.; Chen, X. Serving red rice beer to the ancestors ca. 9000 years ago at Xiaohuangshan early Neolithic site in south China. Holocene 2023, 33, 1012–1020. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, L.; Sun, H. Early evidence for beer drinking in a 9000-year-old platform mound in southern China. PLoS ONE 2021, 16, e0255833. [Google Scholar] [CrossRef] [PubMed]

- McGovern, P.E.; Zhang, J.; Tang, J.; Zhang, Z.; Hall, G.R.; Moreau, R.A.; Nunez, A.; Butrym, E.D.; Richards, M.R.; Wang, C.-S.; et al. Fermented beverages of pre- and proto-historic China. Proc. Natl. Acad. Sci. USA 2004, 101, 17593–17598. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Levin, M.J.; Sinnott-Armstrong, N.; Zhao, H.; Zhao, Y.; Shao, J.; Di, N.; Zhang, T. The origins of specialized pottery and diverse alcohol fermentation techniques in Early Neolithic China. Proc. Natl. Acad. Sci. USA 2019, 116, 12767–12774. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Zhao, Y.; Chen, X.; Gu, W. Beyond subsistence: Evidence for red rice beer in 8000-year old Neolithic burials, north China. J. Archaeol. Sci. Rep. 2023, 51, 104168. [Google Scholar] [CrossRef]

- McGovern, P.E.; Underhill, A.; Fang, H.; Luan, F.; Hall, G.; Yu, H.; Wang, C.; Cai, F.; Zhao, Z.; Feinman, G. Chemical identification and cultural implications of a mixed fermented beverage from late prehistoric China. Asian Perspect. 2005, 44, 249–275. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Ball, T.; Yu, L.; Li, Y.; Xing, F. Revealing a 5,000-y-old beer recipe in China. Proc. Natl. Acad. Sci. USA 2016, 113, 6444–6448. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Liu, H. The brewing function of the first amphorae in the Neolithic Yangshao culture, North China. J. Anthropol. Archaeol. Sci. 2020, 12, 118. [Google Scholar] [CrossRef]

- Feng, S.; Liu, L.; Wang, J.; Levin, M.J.; Li, X.; Ma, X. Red beer consumption and elite utensils: The emergence of competitive feasting in the Yangshao culture, North China. J. Anthropol. Archaeol. 2021, 64, 101365. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Chen, X.; Liang, Z. The quest for red rice beer: Transregional interactions and development of competitive feasting in Neolithic China. Archaeol. Anthropol. Sci. 2022, 14, 78. [Google Scholar] [CrossRef]

- Liu, L.; Chen, J.; Wang, J.; Zhao, Y.; Chen, X. Archaeological evidence for initial migration of Neolithic Proto Sino-Tibetan speakers from Yellow River valley to Tibetan Plateau. Proc. Natl. Acad. Sci. USA 2022, 119, e2212006119. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Liu, L.; Sun, Z.; Shao, J.; Di, N. “Proposing a toast” from the first urban center in the north Loess Plateau, China: Alcoholic beverages at Shimao. J. Anthropol. Archaeol. 2021, 64, 101352. [Google Scholar] [CrossRef]

- Liao, J.; Yang, Y.; Gu, W.; Yao, L.; Wei, Q.; Luo, W.; Gong, Y.; Ding, L.; Gu, C.; Zhang, J. A New Filtered Alcoholic Beverage: Residues Evidence From the Qingtai Site (ca. 5,500–4,750 cal. BP) in Henan Province, Central China. Front. Earth Sci. 2022, 10, 884630. [Google Scholar] [CrossRef]

- Liao, J.; Yang, Y.; Gu, W.; Gong, Y.; Sun, B.; Cui, Q.; Zhou, X.; Zhang, J. Pottery vessels and alcohol consumption at the late Neolithic Shuanghuaishu site in Central China. npj Herit. Sci. 2025, 13, 348. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Y.; Ge, W.; Lin, Z.; Sinnott-Armstrong, N.; Yang, L. Revealing the 2300-Year-Old Fermented Beverage in a Bronze Bottle from Shaanxi, China. Fermentation 2024, 10, 365. [Google Scholar] [CrossRef]

- Li, J.; Yang, J.; Cao, J.; Nan, P.; Gao, J.; Shi, D.; Han, B.; Yang, Y. Characterization of liquor remains in Beibaie site, central China during the 8th century BCE. Microchem. J. 2022, 177, 107293. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, G.; Nan, P.; Yang, J.; Cao, J.; Ma, Z.; Ge, W.; Wen, R. Wine or Beer? A reinvestigation of residues from bronze vessels from the Beibai’e cemetery, Shanxi China. Herit. Sci. 2023, 11, 184. [Google Scholar] [CrossRef]

- He, Y.; Zhao, H.; Liu, L.; Xu, H. Brewing and Serving Alcoholic Beverages to Erlitou Elites of Prehistoric China: Residue Analysis of Ceramic Vessels. Front. Ecol. Evol. 2022, 10, 845065. [Google Scholar] [CrossRef]

- Liu, L. Archaeological evidence for fermented alcoholic beverages in ritual feasts. In Microbial Fermentations in Nature and As Designed Processes; Hurst, C.J., Ed.; Wiley: Hoboken, NJ, USA, 2023; pp. 209–224. [Google Scholar]

- Sun, J. Tang Song shiqi de chaju yu jiuju [The tea and wine vessels of the Tang and Song Dynasties]. Zhongguo Lishi Bowuguan Guankan 1982, 00, 113–123. [Google Scholar]

- Franke, H.; Twitchett, D.C. The Cambridge History of China: Alien Regimes and Border States, 907–1368; Cambridge University Press: Cambridge, UK, 1978; Volume 6. [Google Scholar]

- Yu, C.; Miao, Y. Shaanxi Xi’an Jindai Li Jurou mu fajue jianbao [Preliminary excavation report of the Li Jurou tomb of Jin dynasty in Xi’an, Shaanxi]. Kaogu Yu Wenwu 2017, 2, 40–49. [Google Scholar]

- Zhu, Z.; Yu, C.; Miao, Y.; Lu, Z.; Yang, J. Mass spectrometry identification of the liquor contained in the plum vase excavated from Jurou Li’s Grave of the Jin Dynasty (1115–1234 CE) in Xi’an, Shannxi, China. Herit. Sci. 2018, 6, 45. [Google Scholar] [CrossRef]

- Barton, H. Starch residues on museum artefacts: Implications for determining tool use. J. Archaeol. Sci. 2007, 34, 1752–1762. [Google Scholar] [CrossRef]

- Torrence, R.; Barton, H. (Eds.) Ancient Starch Research; Left Coast Press: Walnut Creek, CA, USA, 2006. [Google Scholar]

- Wang, J.; Liu, L.; Georgescu, A.; Le, V.V.; Ota, M.H.; Tang, S.; Vanderbilt, M. Identifying ancient beer brewing through starch analysis: A methodology. J. Archaeol. Sci. Rep. 2017, 15, 150–160. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z. Millet Beer Brewing in North China: Exploring Traditional Methods and their Significance in Archaeological Research. Ethnoarchaeology 2023, 15, 138–152. [Google Scholar] [CrossRef]

- Henry, A.G.; Hudson, H.F.; Piperno, D.R. Changes in starch grain morphologies from cooking. J. Archaeol. Sci. 2009, 36, 915–922. [Google Scholar] [CrossRef]

- Chen, R. Red Rice Alcohol in Southern China: Two Ways of Traditional Brewing and Their Implications for Archaeological Research. Ethnoarchaeology 2024, 16, 281–302. [Google Scholar] [CrossRef]

- Ling, C. Zhongguo jiu zhi qiyuan [The origins of alcohol in China]. Bull. Inst. Hist. Philol. 1958, 29, 883–901. [Google Scholar]

- St-Germain, G.; Summerbell, R. Identifying Fungi: A Clinical Laboratory Handbook; Star Publishing Company: Belmont, CA, USA, 2011. [Google Scholar]

- Boulton, C.; Quain, D. Brewing Yeast and Fermentation; Blackwell Science Ltd.: Oxford, UK, 2001. [Google Scholar]

- Brooks, J.R.; Buchmann, N.; Phillips, S.; Ehleringger, B.; Evans, R.D.; Lott, M.; Martinelli, L.A.; Pockman, W.T.; Sandquist, D.; Sparks, J.P.; et al. Heavy and Light Beer: A Carbon Isotope Approach To Detect C4 Carbon in Beers of Different Origins, Styles, and Prices. J. Agric. Food Chem. 2002, 50, 6413–6418. [Google Scholar] [CrossRef]

- Choi, J.Y.; Hwang, H.J.; Cho, W.Y.; Choi, J.I.; Lee, P.C. Differences in the Fatty Acid Profile, Morphology, and Tetraacetylphytosphingosine-Forming Capability Between Wild-Type and Mutant Wickerhamomyces ciferrii. Front. Bioeng. Biotechnol. 2021, 9, 662979. [Google Scholar] [CrossRef]

- Bioresource Collection and Research Center. Nadsonia fulvescens. 1989. Available online: https://mcoddb.bcrc.firdi.org.tw/detail.jsp?bcrc_id=22844 (accessed on 8 April 2025).

- Ho, P.-T. The introduction of American food plants into China. Am. Anthropol. 1955, 57, 191–201. [Google Scholar] [CrossRef]

- Zeng, X. Lun xiaomai zai gudai zhongguo zhi kuozhang [Expansion of wheat in ancient China]. Zhongguo Yinshi Wenhua 2005, 1, 99–133. [Google Scholar]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Stern, L.A.; Chamberlain, C.P.; Blum, J.D.; Fogel, M.L. Isotopic Lessons in a Beer Bottle. J. Geosci. Educ. 1997, 45, 157–161. [Google Scholar] [CrossRef]

- DeNiro, M.J.; Epstein, S. Mechanism of Carbon Isotope FractionationAssociated with Lipid Synthesis. Science 1977, 197, 261–263. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, Y.; Chen, Z.; Zhang, C. Study on Fermentation Technology of Beer Brewing from Euryale Ferox. Bioprocess 2022, 12, 248–256. [Google Scholar] [CrossRef]

- Arthur, J.W. Beer: A Global Journey Through the Past and Present; Oxford University Press: Oxford, UK, 2022. [Google Scholar]

- Hobbie, E.A.; Werner, R.A. Intramolecular, compound-specific, and bulk carbon isotope patterns in C(3) and C(4) plants: A review and synthesis. New Phytol. 2004, 161, 371–385. [Google Scholar] [CrossRef]

- Bogaard, A.; Heaton, T.H.E.; Poulton, P.; Merbach, I. The impact of manuring on nitrogen isotope ratios in cereals: Archaeological implications for reconstruction of diet and crop management practices. J. Archaeol. Sci. 2007, 34, 335–343. [Google Scholar] [CrossRef]

- Wen, S.; Yuan, T. Yinxu Buci Yanjiu: Kexue Jishu Pian [A Study of Oracle Bones from Yinxu: Science and Technolgy]; Sichuansheng Shehui Kexueyuan Chubanshe: Chengdu, China, 1983. [Google Scholar]

- Fan, S. “Shijing” yu jiu wenhua [“Classic of Poetry” and alcohol culture]. Shijing Yanjiu Congkan 2004, 6, 201–214. [Google Scholar]

- Liu, L.; Crawford, G.; Lee, G.-A.; Chen, X.; Ma, X.; Li, J.; Zhang, J. Zhengzhou Dahecun Yangshao Wenhua “gaoliang” yicun de zai yanjiu [Re-analyse of the Yangshao “sorghum” remains at Dahecun in Zhengzhou]. Kaogu 2012, 1, 91–96. [Google Scholar]

- Zhao, L. Shilun Gaoliang Chuanru Zhongguo de Shijian, Lujing Ji Chubu Tuiguang [Discuss on the Time, Path of Sorghum’s Introduction into China and its Preliminary Popularization]. Zhongguo Nongshi 2019, 1, 3–14. [Google Scholar]

- Watson, A.M. Agricultural Innovation in the Early Islamic World: The Diffusion of Crops and Farming Techniques, 700–1100; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Ge, F.; Xie, P.; Wu, Y.; Xie, Q. Genetic architecture and molecular regulation of sorghum domestication. aBIOTECH 2023, 4, 57–71. [Google Scholar] [CrossRef]

- Beijing Institute of Archaeology. Xinshidai Beijing kaogu gongzuo huigu yu zhanwang [A review and outlook of Archaeological work in Beijing in the New Era]. Zhongguo Wenwubao. 23 September 2022, p. 5. Available online: https://mp.weixin.qq.com/s/H4106ldTB2GIAy6vK9GTZw (accessed on 6 October 2025).

- Zhang, L.; Ding, Y.; Xu, J.; Gao, X.; Cao, N.; Li, K.; Feng, Z.; Cheng, B.; Zhou, L.; Ren, M.; et al. Selection Signatures in Chinese Sorghum Reveals Its Unique Liquor-Making Properties. Front. Plant Sci. 2022, 13, 923734. [Google Scholar] [CrossRef]

- Han, M.L. Historical Agricultural Geography of China; Peking University Press: Beijing, China, 2012. [Google Scholar]

- Arthur, J.W. Brewing beer: Status, wealth and ceramic use alteration among the Gamo of South-Western Ethiopia. World Archaeol. 2003, 34, 516–528. [Google Scholar] [CrossRef]

| Stach Type | I | II | III | IV | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Taxon | Yeast (round, oval) | Yeast (elonga-ted) | Yeast total | Sorghum | Wheat A-type | Wheat B-type | Rice (cluster) | Rice (individual granules) | Foxnut (aggre- gates) | Foxnut (individual granules) | UNID | Gelati- nized mass | Retro- graded starch | Starch total |

| Total N | 56 | 10 | 66 | 46 | 13 | 49 | 2 | 8 | 25 | 15 | 2 | 160 | ||

| Total % | 84.8 | 15.2 | 100.0 | 28.8 | 8.1 | 30.6 | 1.3 | 5.0 | 15.6 | 9.4 | 1.3 | 100.0 | ||

| Identified starch N | 46 | 62 | 2 | 8 | 118 | |||||||||

| Identified starch % | 39.0 | 52.5 | 1.7 | 6.8 | 100.0 | |||||||||

| Measured N | 56 | 10 | 46 | 13 | 49 | 12 | 6 | 29 | ||||||

| Min length | 4.22 | 7.48 | 4.79 | 11.16 | 3.3 | 3.28 | 13.06 | 1.43 | ||||||

| Max length | 11.5 | 12.68 | 25.07 | 29.36 | 9.84 | 6.13 | 46.27 | 3.88 | ||||||

| Average length | 7.68 | 10.03 | 12.14 | 21.82 | 5.84 | 4.48 | 25.19 | 2.05 | ||||||

| Starch Type/Taxon | Shape | Size Range (μm) | Hilum | Extinction Cross | Damaged Characteristics |

|---|---|---|---|---|---|

| Ancient Type I. Sorghum | Polygonal and circular | 4.79–25.07 | Mostly centric | Mostly straight arms | Deep fissures; blurry or missing extinction cross; hollowed center |

| Modern sorghum | Polygonal and circular | 5.90–26.81 | Mostly centric; some with fissure | Mostly straight arms | |

| Ancient Type II. Triticeae, A-type | Lenticular | 11.16–29.36 | Centric | Straight arms | Deep fissures; missing parts; central depression; hollowed center |

| Modern wheat, A-type | Lenticular | 10.00–35.00 | Centric | Straight arms | |

| Ancient Type II. Triticeae, B-type | Circular | 3.30–9.84 | Not observed | Not observed | No birefringence observed |

| Modern wheat, B-type | Circular | 1.00–10.00 | Centric | Straight arms | |

| Ancient Type III. rice | Compound grains composed of many small polygonal granules | 3.28–6.13 | Not observed | Some birefringent; no extinction cross observed | Only detected by staining with trypan blue |

| Modern rice | Isolated single granules polygonal; compound grains composed of many small polygonal granules | 3.19–9.63 | Centric | Straight arms | |

| Ancient Type VI. foxnut | Round/oval compound aggregates containing small polygonal granules | Compound: 13.06–46.27; granule: 1.43–3.88 | Not observed | Not observed | Most granules blurry; clearer after trypan blue staining; gelatinized compound larger than normal size |

| Modern foxnut | Round/oval compound aggregates containing small polygonal granules | Compound: 9.51–32.33; granule: 1.71–3.96 | Centric | Straight arms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Liu, X.; Yu, C.; Miao, Y. Preserved 800-Year-Old Liquid Beer in a Jin Dynasty Vase: Evidence of Malted Sorghum–Wheat Fermentation in Xi’an, China. Heritage 2025, 8, 426. https://doi.org/10.3390/heritage8100426

Liu L, Liu X, Yu C, Miao Y. Preserved 800-Year-Old Liquid Beer in a Jin Dynasty Vase: Evidence of Malted Sorghum–Wheat Fermentation in Xi’an, China. Heritage. 2025; 8(10):426. https://doi.org/10.3390/heritage8100426

Chicago/Turabian StyleLiu, Li, Xinyi Liu, Chunlei Yu, and Yifei Miao. 2025. "Preserved 800-Year-Old Liquid Beer in a Jin Dynasty Vase: Evidence of Malted Sorghum–Wheat Fermentation in Xi’an, China" Heritage 8, no. 10: 426. https://doi.org/10.3390/heritage8100426

APA StyleLiu, L., Liu, X., Yu, C., & Miao, Y. (2025). Preserved 800-Year-Old Liquid Beer in a Jin Dynasty Vase: Evidence of Malted Sorghum–Wheat Fermentation in Xi’an, China. Heritage, 8(10), 426. https://doi.org/10.3390/heritage8100426