Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques

Abstract

1. Introduction

2. Materials and Methods

2.1. Gold Leaf Reference Sets

2.2. X-ray Fluorescence (XRF) Analysis

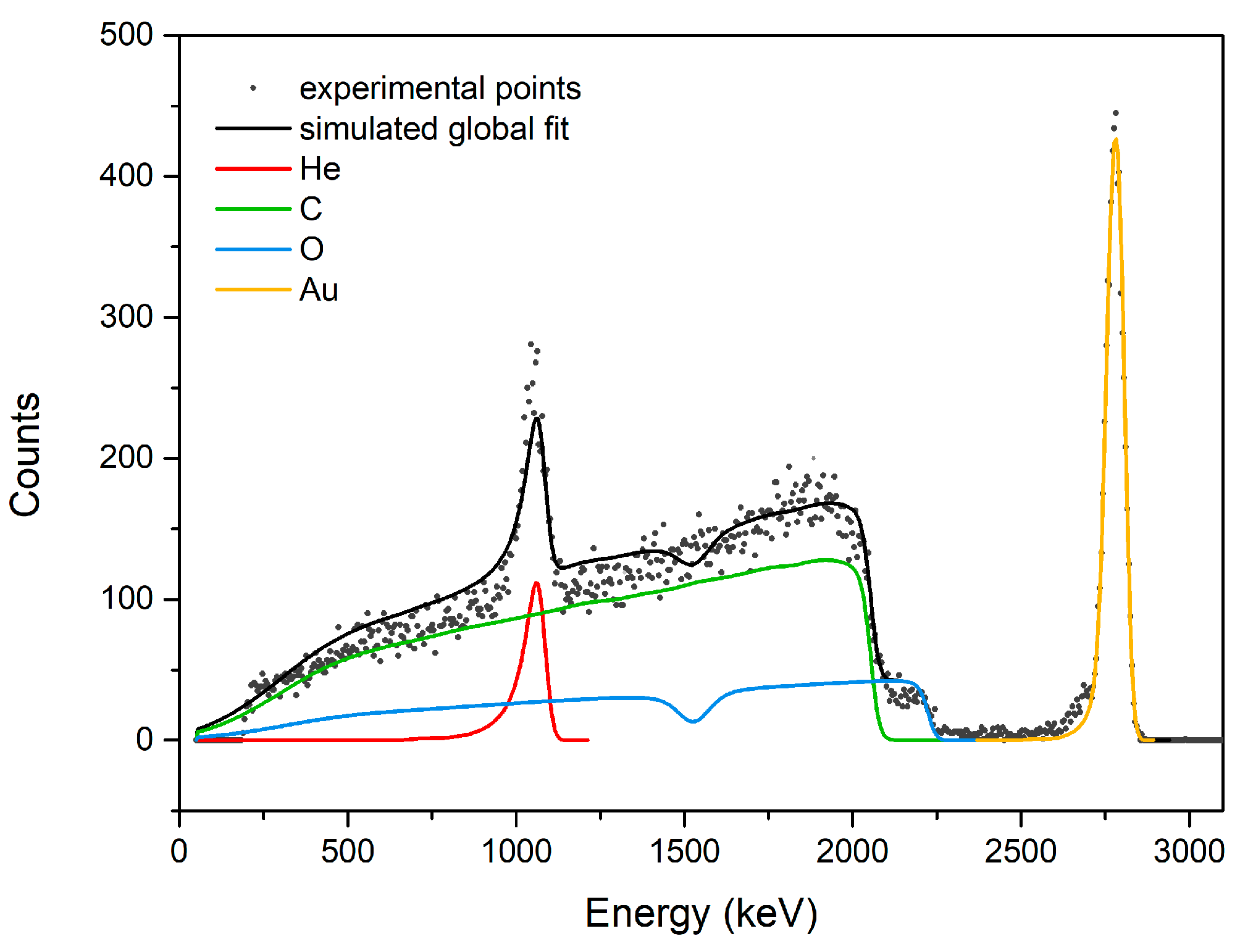

2.3. Particle-Induced X-ray Emission (PIXE) and Rutherford Backscattering Spectrometry (RBS) Analyses

3. Results and Discussion

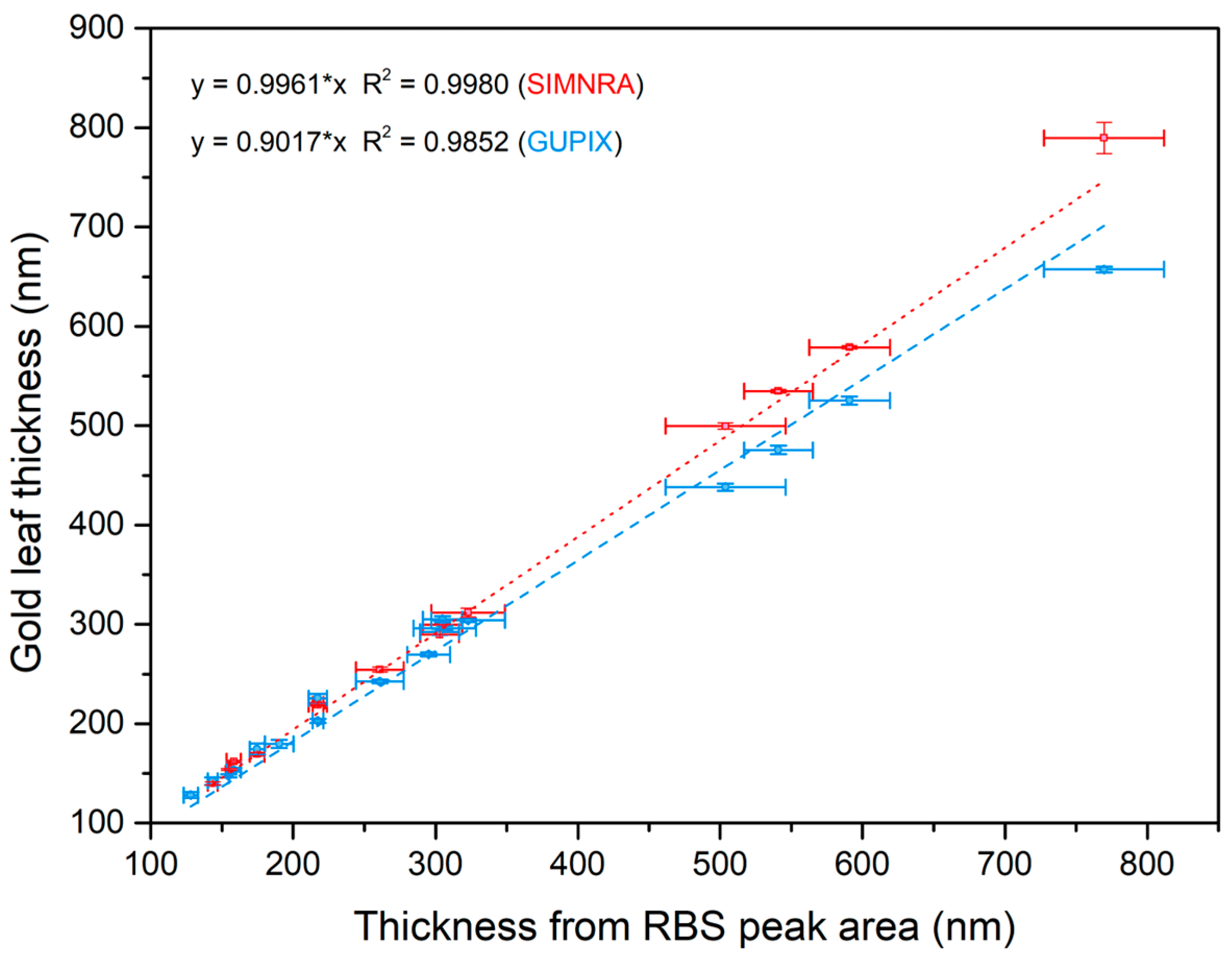

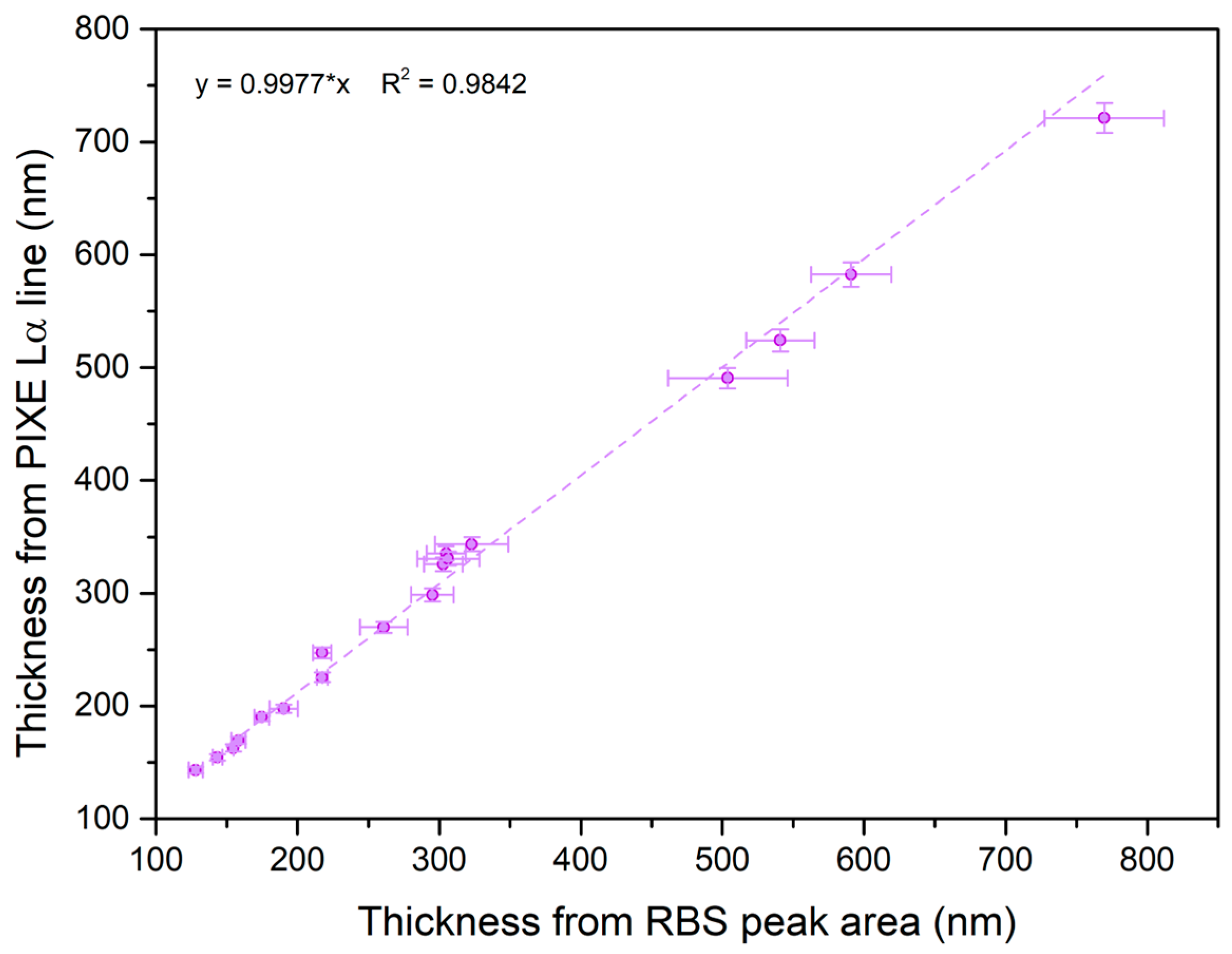

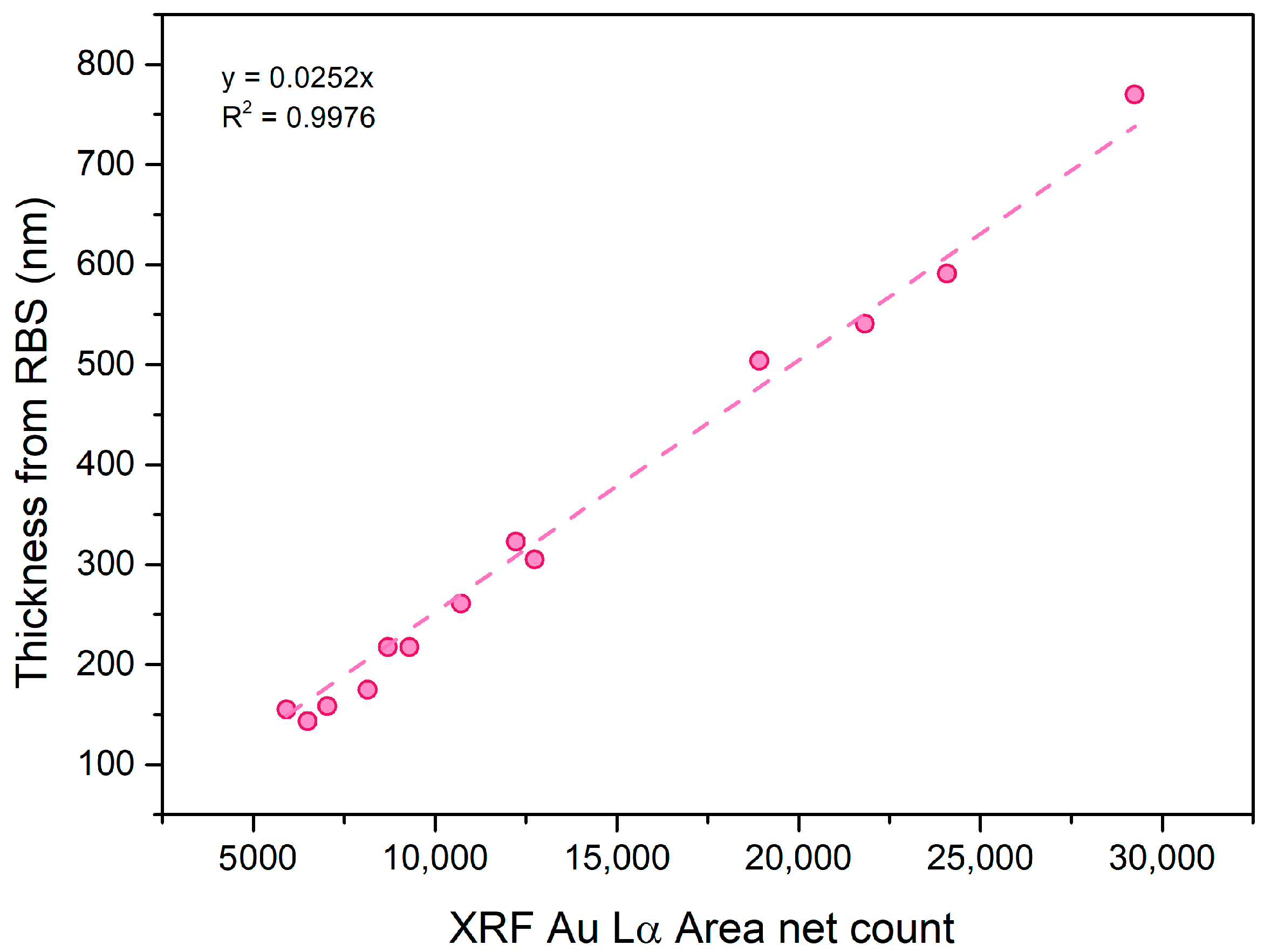

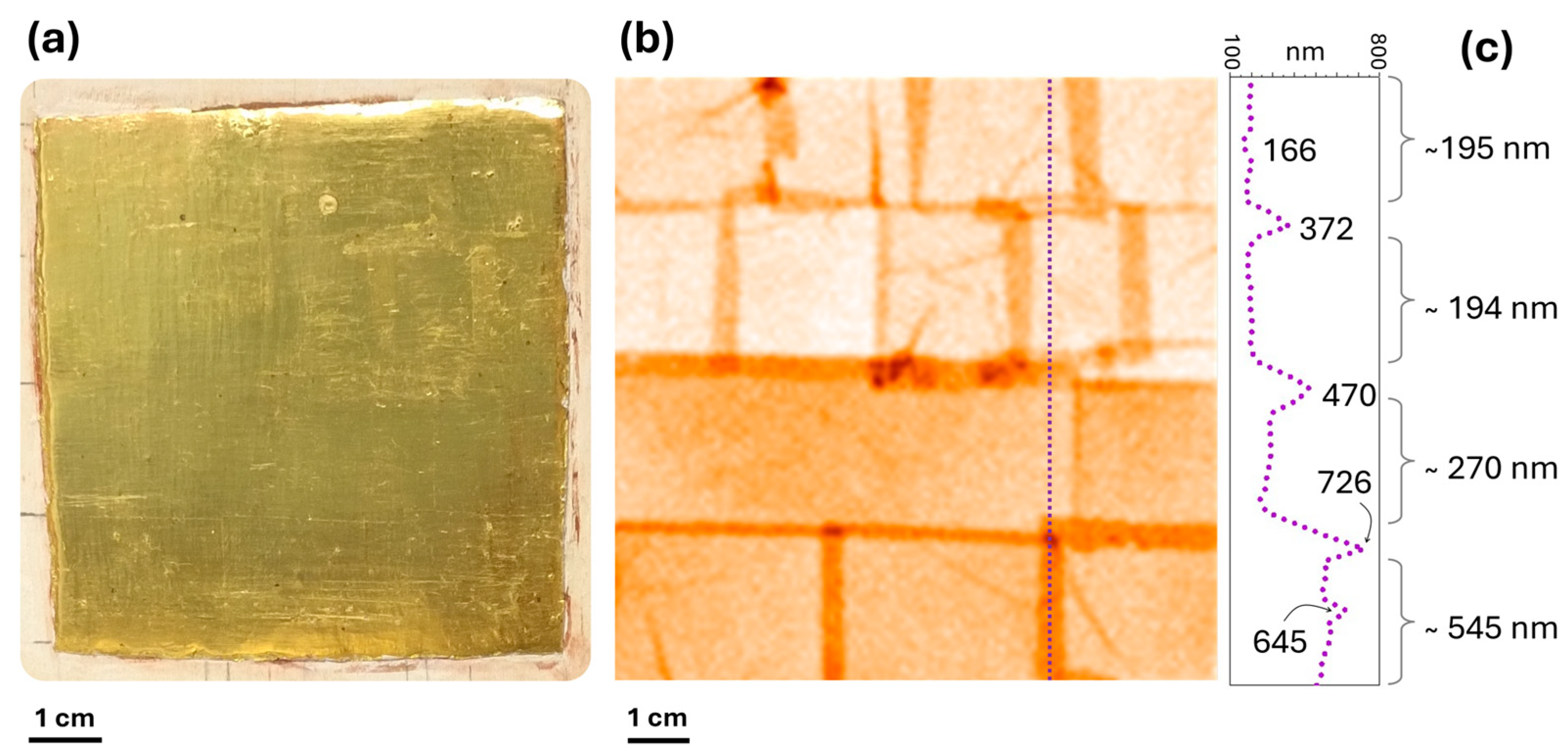

3.1. Measurement of Gold Leaf Thickness

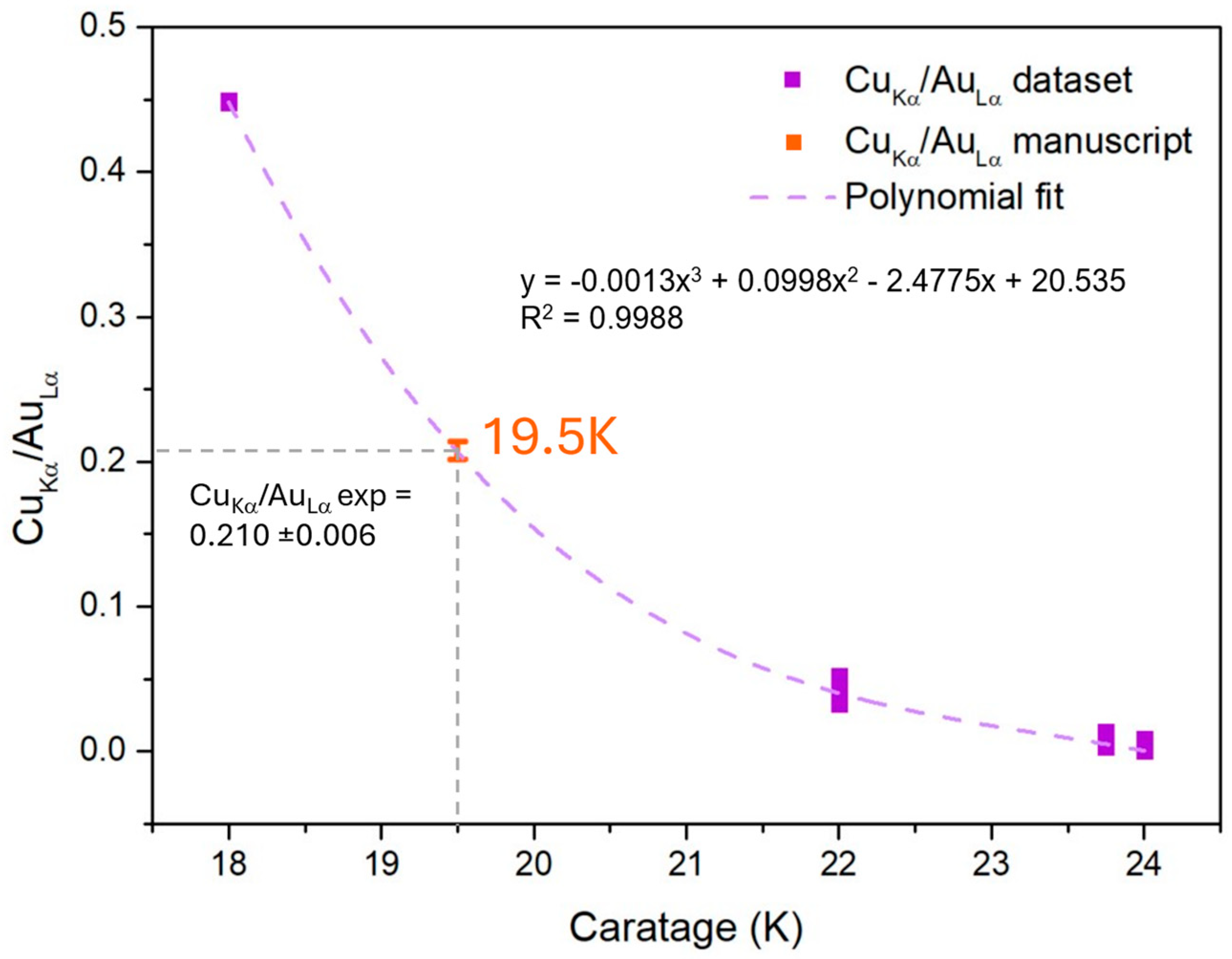

3.2. Calibration of the ELIO Setup and XRF Analysis of Historic Samples

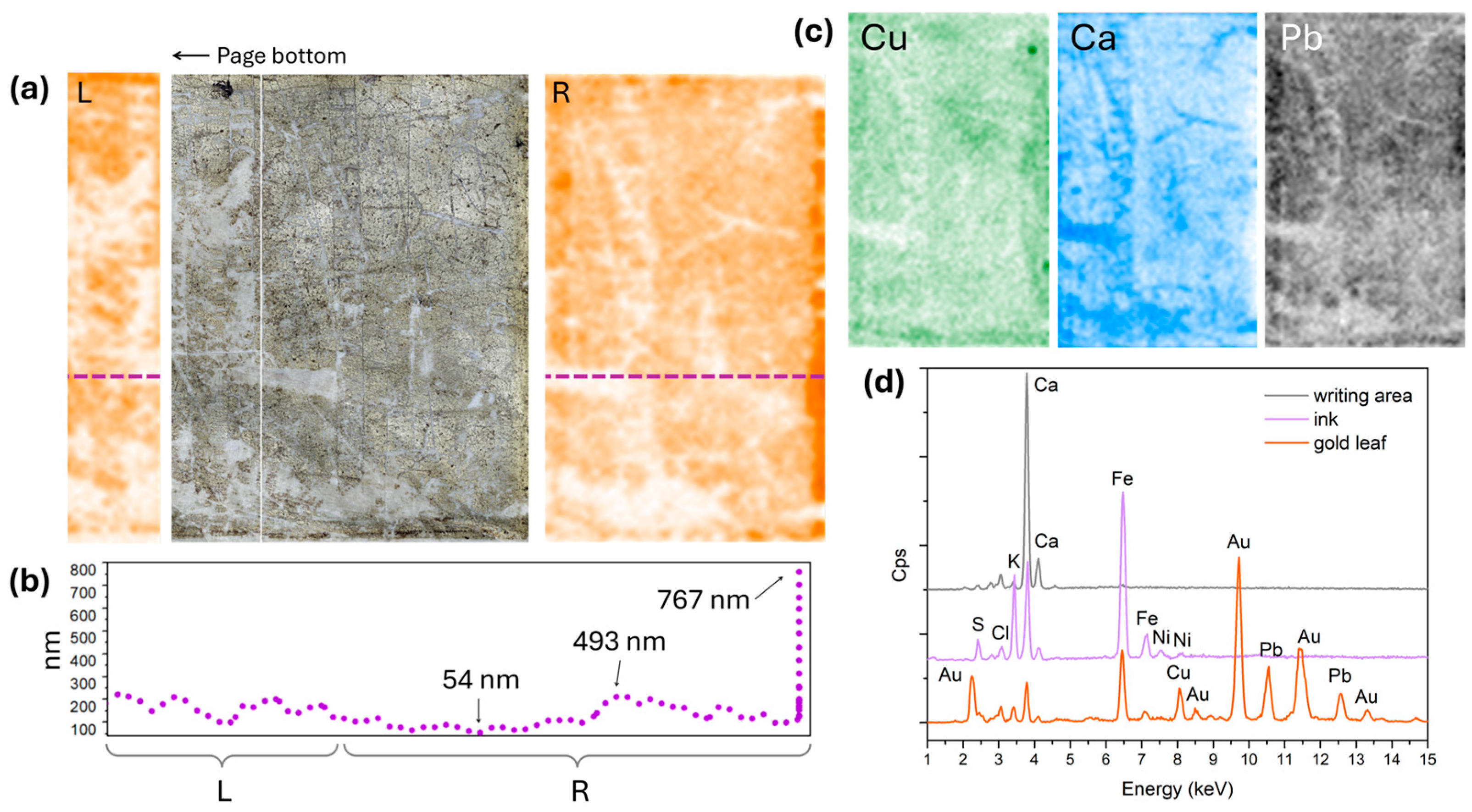

3.3. Characterization of the Manuscript

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pesenti, F.R. La disputa a Genova del 1590 sull’Arte della Pittura e Giovanni Battista Paggi. In La Pittura in Liguria: Artisti del primo Seicento; Stringa Editore: Genova, Italy, 1986; pp. 9–12. [Google Scholar]

- Lukehart, P.M. Contending Ideals: The Nobility of G. B. Paggi and the Nobility of Painting; The John Hopkins University: Baltimore, MD, USA, 1987. [Google Scholar]

- Ciarlo, L. Vicende Corporative e Professione dell’Indoratore a Genova nel Seicento, Qualche Dato a Confronto; Collana di Studi e Ricerche dell’Accademia Ligure di Scienze e Lettere: Genova, Italy, 2020; Volume LXIV. [Google Scholar]

- Orengo, M.T. L’arte dei Brea tra Francia e Italia. In Proceedings of the Conservazione e Valorizzazione; All’insegna del Giglio: Genova, Italy, 2005. [Google Scholar]

- Di Fabio, C. Il Polittico della Cervara di Gerard David; Silvana Editoriale: Milano, Italy, 2005. [Google Scholar]

- Baldinucci, F. Vocabolario Toscano Dell’arte del Disegno; Per Santi Franchi al Segno della Passione: Firenze, Italy, 1681; 115p. [Google Scholar]

- Marini, M. Giorgio Vasari, Le Vite dei più Eccellenti Pittori, Scultori e Architetti (1568); Newton Compton Editori: Roma, Italy, 2012. [Google Scholar]

- Marabelli, M.; Basile, G. Le lamine metalliche utilizzate nella decorazione dei dipinti murali giotteschi. In Giotto nella Cappella degli Scrovegni: Materiali per la Tecnica Pittorica; Istituto poligrafico e Zecca dello Stato: Roma, Italy, 2005. [Google Scholar]

- Ciarlo, L. Storia Dell’arte e Valorizzazione del Patrimonio Artistico (Art History and Valorization of Artistic Heritage). Master’s Thesis, University of Genoa, Genoa, Italy, 12 December 2017, unpublished. [Google Scholar]

- Ciarlo, L. Il Mestiere del Battiloro a Genova fra i Secoli XV e XVII: La Testimonianza dei Verberatores Auri in Folio; 1986; pp. 5–34. ISBN 978-88-97099-39-0. ISSN 2037-7134. Available online: https://www.storiapatriagenova.it/Scheda_vs_info.aspx?Id_Scheda_Bibliografica=6101 (accessed on 20 May 2024).

- Sanguineti, D. Assetti corporativi tra obblighi e rivendicazioni: Gli scultori in legno e i bancalari nella Repubblica di Genova. Atti Soc. Stor. Patria 2013, 53, 149–195. [Google Scholar]

- Ottavi, C. Supporti metallici. In I Supporti nelle Arti Pittoriche. Storia, Tecnica, Restauro; Maltese, C., Ed.; Mursia: Milano, Italy, 1990. [Google Scholar]

- Galliano Lalli, G.; Innocenti, F. La doratura nelle tecniche artistiche. OPD Restauro 2016, 28, 340–348. [Google Scholar]

- Sandu, I.; Afonso, L.; Murta, E.; De Sa, M. Gilding techniques in religious art between east and west, 14th–18th Centuries. Int. J. Conserv. Sci. 2010, 1, 47–62. [Google Scholar]

- Brocchieri, J.; Sabbarese, C. Thickness determination of the gilding on brass materials by XRF technique. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2021, 496, 29–36. [Google Scholar] [CrossRef]

- Martinuzzi, S.; Giovani, C.; Giurlani, W.; Galvanetto, E.; Calisi, N.; Casale, M.; Fontanesi, C.; Ciattini, S.; Innocenti, M. A robust and cost-effective protocol to fabricate calibration standards for the thickness determination of metal coatings by XRF. Spectrochim. Acta Part B At. Spectrosc. 2021, 182, 106255. [Google Scholar] [CrossRef]

- Lopes, F.; Melquiades, F.L.; Appoloni, C.R.; Cesareo, R.; Rizzutto, M.; Silva, T.F. Thickness determination of gold layer on pre-Columbian objects and a gilding frame, combining pXRF and PLS regression. X-Ray Spectrom. 2016, 45, 344–351. [Google Scholar] [CrossRef]

- Fiorini, C.; Gianoncelli, A.; Longoni, A.; Zaraga, F. Determination of the thickness of coatings by means of a new XRF spectrometer. X-Ray Spectrom. 2002, 31, 92–99. [Google Scholar] [CrossRef]

- Cesareo, R.; Rizzutto, M.A.; Brunetti, A.; Rao, D.V. Metal location and thickness in a multilayered sheet by measuring Kα/Kβ, Lα/Lβ and Lα/Lγ X-ray ratios. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2009, 267, 2890–2896. [Google Scholar] [CrossRef]

- Barcellos Lins, S.A.; Ridolfi, S.; Gigante, G.E.; Cesareo, R.; Albini, M.; Riccucci, C.; di Carlo, G.; Fabbri, A.; Branchini, P.; Tortora, L. Differential X-Ray Attenuation in MA-XRF Analysis for a Non-invasive Determination of Gilding Thickness. Front. Chem. 2020, 8, 1–9. [Google Scholar] [CrossRef]

- Wu, Q.; Watts, B.; Döbeli, M.; Müller, J.; Butz, B.; Lombardo, T.; Schmidt-Ott, K.; Fink, R.; Nolting, F.; Ganz, D. Medieval nanotechnology: Thickness determination of Zwischgold samples. J. Cult. Herit. 2021, 49, 211–221. [Google Scholar] [CrossRef]

- Osticioli, I.; Lavacchi, A.; Capozzoli, L.; Berretti, E.; Gallo, L.; Berberich, C.; Agresti, J.; Siano, S. Novel insights on the study of a fifteenth-century oro di metà/Zwischgold gilding by means of ion and electron microscopy: Characterization of the stratigraphy avoiding cross-sections preparation. J. Cult. Herit. 2020, 44, 297–306. [Google Scholar] [CrossRef]

- Moro, D.; Ulian, G.; Valdrè, G. Monte Carlo SEM-EDS micro- and nanoanalysis of ultrathin gold leaves in glass mosaic tesserae: Thickness effects and measurement strategy. Meas. J. Int. Meas. Confed. 2018, 129, 211–217. [Google Scholar] [CrossRef]

- Figueiredo, E.; Silva, R.J.C.; Araújo, M.F.; Senna-Martinez, J.C. Identification of ancient gilding technology and Late Bronze Age metallurgy by EDXRF, Micro-EDXRF, SEM-EDS and metallographic techniques. Microchim. Acta 2010, 168, 283–291. [Google Scholar] [CrossRef]

- Chiari, M. External Beam IBA Measurements for Cultural Heritage. Appl. Sci. 2023, 13, 3366. [Google Scholar] [CrossRef]

- Corsi, M.; Cristoforetti, G.; Palleschi, V.; Salvetti, A.; Tognoni, E. A fast and accurate method for the determination of precious alloys caratage by Laser Induced Plasma Spectroscopy. Eur. Phys. J. D 2001, 13, 373–377. [Google Scholar] [CrossRef]

- Le Gac, A.; Seruya, A.I.; Lefftz, M.; Alarcão, A. The main altarpiece of the Old Cathedral of Coimbra (Portugal). ArchéoSciences 2009, 33, 423–432. [Google Scholar] [CrossRef]

- Otero, V.; Sanches, D.; Montagner, C.; Vilarigues, M.; Carlyle, L.; Lopes, J.A.; Melo, M.J. Characterisation of metal carboxylates by Raman and infrared spectroscopy in works of art. J. Raman Spectrosc. 2014, 45, 1197–1206. [Google Scholar] [CrossRef]

- Mihalic, I.B.; Fazinic, S.; Barac, M.; Karydas, A.G.; Migliori, A.; Doracic, D.; Desnica, V.; Mudronja, D.; Krstic, D. Multivariate analysis of PIXE + XRF and PIXE spectral images. J. Anal. At. Spectrom. 2021, 36, 654–667. [Google Scholar] [CrossRef]

- MacLennan, D.; Llewellyn, L.; Delaney, J.K.; Dooley, K.A.; Patterson, C.S.; Szafran, Y.; Trentelman, K. Visualizing and measuring gold leaf in fourteenth- and fifteenth-century Italian gold ground paintings using scanning macro X-ray fluorescence spectroscopy: A new tool for advancing art historical research. Herit. Sci. 2019, 7, 25. [Google Scholar] [CrossRef]

- Hradil, D.; Hradilová, J.; Bezdička, P.; Serendan, C. Late Gothic/early Renaissance gilding technology and the traditional poliment material “Armenian bole”: Truly red clay, or rather bauxite? Appl. Clay Sci. 2017, 135, 271–281. [Google Scholar] [CrossRef]

- Cennini, C. Il Libro Dell’arte o Trattato Della Pittura; Frezzato, F., Ed.; Editore Neri Pozza: Venezia, Italy, 2009. [Google Scholar]

- Chiari, M.; Barone, S.; Bombini, A.; Calzolai, G.; Carraresi, L.; Castelli, L.; Czelusniak, C.; Fedi, M.E.; Gelli, N.; Giambi, F.; et al. LABEC, the INFN ion beam laboratory of nuclear techniques for environment and cultural heritage. Eur. Phys. J. Plus 2021, 136, 472. [Google Scholar] [CrossRef]

- Chiari, M.; Migliori, A.; Mandò, P.A. Measurement of low currents in an external beam set-up. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2002, 188, 162–165. [Google Scholar] [CrossRef]

- Mayer, M. SIMNRA User’s Guide; Max Planck Institute for Plasma Physics: Garching, Germany, 1997. [Google Scholar]

- Campbell, J.L.; Cureatz, D.J.T.; Flannigan, E.L.; Heirwegh, C.M.; Maxwell, J.A.; Russell, J.L.; Taylor, S.M. The Guelph PIXE Software Package V. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2021, 499, 77–88. [Google Scholar] [CrossRef]

- Franceschi, E.; Locardi, F. Strontium, a new marker of the origin of gypsum in cultural heritage? J. Cult. Herit. 2014, 15, 522–527. [Google Scholar] [CrossRef]

- De Viguerie, L.; Rochut, S.; Alfeld, M.; Walter, P.; Astier, S.; Gontero, V.; Boulc, F. XRF and reflectance hyperspectral imaging on a 15th century illuminated manuscript : Combining imaging and quantitative analysis to understand the artist ’ s technique. Herit. Sci. 2018, 6, 11. [Google Scholar] [CrossRef]

- Duran, A.; López-montes, A.; Castaing, J.; Espejo, T. Analysis of a royal 15th century illuminated parchment using a portable XRF e XRD system and micro-invasive techniques. J. Archaeol. Sci. 2014, 45, 52–58. [Google Scholar] [CrossRef]

- Note, T.; Cappa, F. Non-Invasive Physico-Chemical and Biological Analysis of Parchment Manuscripts—An Overview und biologische Analyse von Pergamenthandschriften—Ein Überblick. Restaurator 2022, 43, 127–142. [Google Scholar]

- Pouyet, E.; Devine, S.; Grafakos, T.; Kieckhefer, R.; Salvant, J.; Smieska, L.; Woll, A.; Katsaggelos, A.; Cossairt, O.; Walton, M. Analytica Chimica Acta Revealing the biography of a hidden medieval manuscript using synchrotron and conventional imaging techniques. Anal. Chim. Acta 2017, 982, 20–30. [Google Scholar] [CrossRef]

- Carsote, C.; Library, R.A.; Badea, E. Bindings of Rare Books from the Collections of the Romanian Academy Library—A Multidisciplinary Study. Rev. Piel. Incaltaminte 2018, 18, 307. [Google Scholar] [CrossRef]

- Magkanas, G.; Bagan, H.; Sistach, M.C.; García, J.F. Illuminated manuscript analysis methodology using MA-XRF and NMF : Application on the Liber Feudorum Maior. Microchem. J. 2021, 165, 106112. [Google Scholar] [CrossRef]

- Sandu, C.A.I.; De Sá, M.H.; Pereira, M.C. Ancient “gilded” art objects from European cultural heritage: A review on different scales of characterization. Surf. Interface Anal. 2011, 43, 1134–1151. [Google Scholar] [CrossRef]

| Dataset | Caratage (K) | Substrate | Sample Name | Thickness (g) 1 | Nominal Thickness (nm) |

|---|---|---|---|---|---|

| Thickness calibration | 24 K | mordant | C1 | 20 | 160 |

| C2 | 22 | 180 | |||

| C3 | 32 | 260 | |||

| C4 | 40 | 320 | |||

| 24 K | guazzo | C5 | 20 | 160 | |

| C6 | 22 | 180 | |||

| C7 | 32 | 260 | |||

| C8 | 40 | 320 | |||

| M1 | 20 + 22 | 340 | |||

| M2 | 22 + 22 | 360 | |||

| M3 | 32 + 40 | 580 | |||

| M4 | 40 + 40 | 640 | |||

| M5 | 32 + 40 + 40 | 900 | |||

| Caratage calibration | 18 K | guazzo | K1 | 32 | 260 |

| 22 K | K2 | 32 | 260 | ||

| 23 3/4 K | K3 | 32 | 260 | ||

| 24 K | K4 | 32 | 260 |

| Sample | RBS | PIXE | |||||

|---|---|---|---|---|---|---|---|

| Thickness from Au RBS Peak Area | Thickness from SIMNRA Fit | Thickness from Au Lα Peak Area | Thickness from GUPIX Fit | ||||

| DAu (nm) | Err [%] | DAu (nm) | Err [%] | DAu (nm) * | DAu (nm) | Err [%] | |

| C1 | 304.9 | 4.51 | 299.5 | 0.02 | 332.1 | 305.1 | 1.1 |

| C2 | 217.4 | 2.96 | 219.7 | 0.76 | 237.5 | 225.7 | 1.98 |

| C3 | 143.3 | 2.41 | 140 | 1.09 | 154.7 | 142.2 | 2.73 |

| C4 | 174.7 | 2.91 | 169.4 | 1.07 | 190.7 | 174.5 | 3.25 |

| C5 | 260.9 | 6.46 | 254.4 | 0.95 | 271.0 | 242.6 | 0.81 |

| C6 | 217.3 | 1.74 | 219.1 | 0.1 | 227.9 | 202.9 | 0.94 |

| C7 | 154.7 | 0.04 | 154.1 | 0.55 | 164.4 | 147.5 | 1.17 |

| C8 | 158.2 | 3.16 | 161.9 | 0.74 | 170.3 | 153.6 | 1.08 |

| M1 | 322.9 | 7.97 | 311.9 | 1.47 | 343.7 | 304.1 | 0.58 |

| M2 | 503.7 | 8.38 | 499.7 | 0.67 | 493.3 | 438.2 | 0.82 |

| M3 | 540.9 | 4.47 | 534.7 | 0.35 | 527.1 | 475.5 | 0.92 |

| M4 | 590.9 | 4.8 | 578.9 | 0.28 | 585.9 | 525.3 | 0.74 |

| M5 | 769.6 | 5.47 | 789.7 | 1.99 | 724.9 | 657.2 | 0.46 |

| Historic Samples | XRF Au Lα Area Net Count | XRF Thickness (nm) | |||||

|---|---|---|---|---|---|---|---|

| Min | Average | Max | Min | Average | St. Dev | Max | |

| S1 | 4910 | 8815 | 12,501 | 124 | 222 | 78 | 315 |

| S2 | 5826 | 8429 | 14,395 | 146 | 212 | 70 | 362 |

| S3 | 1071 | 5635 | 11,534 | 26 | 142 | 98 | 290 |

| S4 | 2147 | 4280 | 5689 | 54 | 107 | 34 | 143 |

| S5 | 5498 | 9345 | 14,074 | 138 | 235 | 68 | 354 |

| S6 | 5611 | 8461 | 17,043 | 141 | 213 | 94 | 429 |

| S7 | 4373 | 8284 | 14,979 | 110 | 208 | 108 | 377 |

| S8 | 6091 | 10,285 | 19,430 | 153 | 259 | 129 | 489 |

| S9 | 3797 | 5293 | 8060 | 95 | 133 | 43 | 203 |

| S10 | 5535 | 10,458 | 16,443 | 139 | 263 | 103 | 414 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciarlo, L.; Chiari, M.; Galassi, M.C.; Ferretti, M.; Sideras-Haddad, E.; Zucchiatti, A.; Castagnotto, E. Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques. Heritage 2024, 7, 3630-3642. https://doi.org/10.3390/heritage7070172

Ciarlo L, Chiari M, Galassi MC, Ferretti M, Sideras-Haddad E, Zucchiatti A, Castagnotto E. Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques. Heritage. 2024; 7(7):3630-3642. https://doi.org/10.3390/heritage7070172

Chicago/Turabian StyleCiarlo, Letizia, Massimo Chiari, Maria Clelia Galassi, Maurizio Ferretti, Elias Sideras-Haddad, Alessandro Zucchiatti, and Elena Castagnotto. 2024. "Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques" Heritage 7, no. 7: 3630-3642. https://doi.org/10.3390/heritage7070172

APA StyleCiarlo, L., Chiari, M., Galassi, M. C., Ferretti, M., Sideras-Haddad, E., Zucchiatti, A., & Castagnotto, E. (2024). Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques. Heritage, 7(7), 3630-3642. https://doi.org/10.3390/heritage7070172