Abstract

This article presents an analytical procedure developed to replicate, document, and analyse the formation and evolution of use-wear traces on task-specific ground stone tools. The purpose of this study is to build a reference collection for wear patterns that occurred during the processing of vegetal resources, specifically those compatible with the MIS 3 period. To create the collection, riverine slabs and pebbles were utilised and various aspects related to their use in the transformation of aerial and underground plant organs were explored. Moreover, the feasibility of using perishable supports, such as a wooden base, for processing tasks was examined. The experiments explored the transformation of pebble stone surfaces during repeated cycles of processing plant organs by monitoring and recording the features at fixed intervals. Several variables that affect the surface texture, morphology, distribution, and extent of use-wear traces are identified and discussed. The influential factors under control included the petrographic and morphological characteristics of the unused stones, the type and amount of transformed vegetables, and the duration of the process, as well as monitoring human factors. The documentation strategy applied at various stages of the experiment was found to be suitable for tracing the cumulative development of wear. The replicative collection was tailored to the morphological and petrographic characteristics of the ground stone tools retrieved from the level attributed to the Prut River culture of Brînzeni I, a cave site located in NW Moldova.

1. Introduction

The category of macrolithic/ground stone tools (GSTs) has gained some visibility in the last decades due to their occurrence across time and space, leading to a growing literature supporting their utilisation in the mechanical transformation of a wide range of organic and inorganic materials ([,,,,,,,], among others). However, GSTs retrieved in Marine Isotopic Stage 3 contexts (MIS 3, 60–25 ka) are often transparent to conventional archaeology techniques []; their tangible and intangible recording of past activities can be lost forever if not recognised as tools [,,].

Properly studied, these tools offer evidence of human past gestures and their capacity to transform the resources available in the environment. Upon devoted analysis, GSTs reveal the sophisticated cognitive abilities of Homo sapiens, who likely understood the different properties of various materials and mastered the complex relationships established during the transformation of both durable and perishable resources, such as those of rhizomes into flour, fibres into a string, or leaves into dye for daily use.

While the functional analysis of the flaked industry is widely investigated, a main challenge in identifying pebbles and slabs as putative GSTs in Late Pleistocene sites is the absence of obvious modifications to their shape and surfaces, which are characteristic of later periods’ macrolithic tools. Establishing an experimental reference collection that replicates the original ancient use of macrolithic tools is essential for supporting an informed use-wear trace analysis and investigating the formation process of diagnostic patterns as proxies for identifying and interpreting archaeological evidence [,]. Therefore, the importance of building devoted reference libraries for both use-wear traces and the associated residues, by using the types of lithologies available for the archaeological case study, is key. Studies that report on analyses of archaeological stone tools and the enactment of replicative experiments are available; although, they usually provide little detail in terms of tracking the frictional/tribological phenomena across their development by documenting the state of the surface over time. This is one of the main aspects of our innovative protocol, which is based on the permanent documentation of the original surfaces (T0) and their modification across different replicative utilisation intervals (T1–T5). Moreover, in order to compare analogous tribological behaviours in similar raw materials, we also considered petrographic features of geologically coeval rocks available in the Miocene Sarmatian formation (Edinet region, Moldova, Prut River Basin) and the Santa Fiora formation (Tuscany, Grosseto, Italy, Fiora River).

The collection was built through a combination of “replicative/actualistic” and “laboratory/controlled” experiments devoted to the transformation of both above- and under-surface plant storage organs. These experiments were tailored to tracing old gestures by replicating the putative activities carried out at the site of Brînzeni I, a cave in NW Moldova overlooking the Racovăt River, a tributary of the Prut River. During the site excavations, 114 pebbles were retrieved but not studied extensively; although, they were mapped and described as 28 quartzite and 86 sandstones, possibly used as ground stones for raw resource transformation [,,,].

This paper presents a design and analysis of the site-specific reference collection devoted to plant processing by documenting different trace patterns and their evolution over time. The comparison of these results with those obtained by the study of archaeological macrolithic tools from Brînzeni I, cultural layer III, is the topic of a work in progress by the authors. Our experiment design also provides a timely and detailed source of data intended to enhance the ability of heritage professionals to recognise and value an almost overlooked category of prehistoric objects: ground stone tools. Furthermore, GSTs help us recognise a diverse range of unrecorded, unpreserved, or hidden activities that can be included in the so-called perishable technologies and are part of our intangible heritage.

2. Materials and Methods

This study focuses on unmodified pebbles and slabs used as ground stones without evident preparation of the overall morphology or working surface, operating in their natural shape to grind and pound vegetable resources for their mechanical transformation into flour or to soften them for easier chewing and digestion. Although GSTs can be used for a wide range of transformations of different materials, such as ochre, bones, leather, and wood, in the case of plant processing, the action of grinding and pounding best describes the nature and functions of these objects. In the literature, the sub-category of grinding tools is distinct from the group of pounding implements [,,]. However, since the same stone or different parts of it can be used for various activities, we refer to our experimental tools as follows:

- -

- The term “passive tool” refers to the lower, stationary stones where the raw material to be treated is placed. This term encompasses grinding slabs, grinding stones, querns, and metates, as well as mortars;

- -

- The term “active tool” refers to the movable tools that fit ergonomically into the palm of the hand. This category includes handstones, manos, and grinders, as well as pestles.

2.1. On the Background of an Experimental GSTs Replicative Collection

The use of replicative experiments is a fundamental technique in archaeological research entailing the production or the transformation of different items characterised by specific physical attributes; this method is utilised to test and validate various hypotheses on their technological or functional operative chain. The design of an experimental reference collection is critical in facilitating functional analysis and investigating the formation processes of diagnostic use-wear patterns, which serve as means of studying tribological mechanisms and interpreting archaeological evidence [,,,,].

Scholars have classified and categorised various approaches for creating an experimental stone collection based on two main settings: “laboratory/controlled experiments” and “actualistic/field/natural experiments”. Laboratory experiments are generally conducted in a strictly controlled setting, with repeatability often achieved through the use of mechanical devices to control or perform measurements. In contrast, actualistic or field experiments involve newly-made replicas of authentic artefacts being used to produce past conditions, aiming at understanding how the tools were used and/or manufactured to perform certain tasks [,,,]. This approach implies loosening variables control when examining aggregate effects at a wide scale []. Among the possible variables, in both types of settings, the human factor is always the most challenging one. The performance of different behaviours and the variety of methods enacted to obtain a certain result complicate the analysis beyond the straightforward cause-and-effect interactions []. An attempt to control human factors in GST experimental replicas has been tested through a tailored mechanical setup [,,,]. This laboratory-controlled arrangement overcomes the limits of a more “natural” setting in terms of variable supervision while also having the undeniable advantages of being reproducible and allowing control over factors that are difficult to monitor, such as the number of strokes, their direction, or the pressure delivered [,,,,]. However, the design of the machinery itself can introduce variables absent in activities made by humans; when the results are compared with the original artefacts, this could unintentionally lead to misleading interpretations and equifinality issues. In our experience, a “sentient being” (the human operator) can make decisions and adjust a strategy to be more effective while performing a task, such as changing posture, gesture, direction, pressure and speed, as well as introducing an inherent randomness of gestures over time as the operator may accumulate fatigue during performance. There is a need to adjust the type of movement by evaluating the obtained results during the task. This evaluation can prompt the operator to modify the way the tools are held or the surface being used, in order to enhance the effectiveness of the action. This adjustment may involve changes the kinematics, customization in the localization of the processed media, stone surface and/or morphology implied, and the contact angle. These considerations are part of the decision-making process that operators go through during experimental reproductions, a process that our ancestors likely followed as well. It is worth emphasizing that machinery reproduction is unable to replicate the intelligent gestures inherent to the "human factor", which involve the ability to adapt one’s transformative capacity to the specific situation at hand. The human operator possesses a level of intelligence and flexibility that allows them to make real-time adjustments based on the feedback and requirements related with the different media processed. This adaptive capability is beyond the scope of machinery, which operates based on predefined instructions and lacks the inherent understanding and responsiveness of human intelligence. In light of the aforementioned considerations, our replicative experimental design did not consider the difference between “natural” and “laboratory” settings as a strict boundary; instead, our approach took the advantage of both approaches considering their diverse attitude towards variables control. Indeed, even without the employment of machinery, we carefully consider potential experimental variables by controlling and/or monitoring as many variables as possible, namely, petrography, roughness parameters, time of use, and type of processed medium, without losing the unpredictability, imagination, and adaptability that are typical of human beings. We further our control on the degree of development of the use-wear by taking moulds (imprints) of the surfaces and 3D reproductions of the tools’ morphologies at fixed experimental times, from the natural/unused stage until the end of the replicative task.

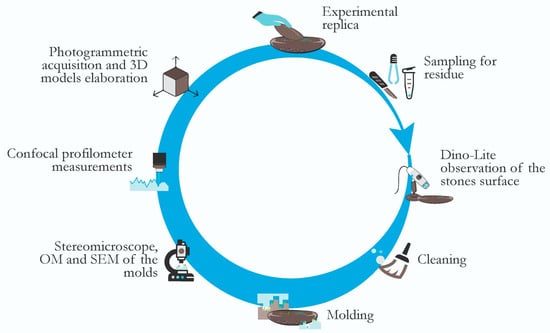

The topography and microtopography of the natural stone surface strongly influence wear development. Therefore, tribological analyses have increasingly incorporated the study of the lithic surface before and after experimental use to allow for comparison [,,,,,,,,]. Sequential experiments also consider intermediate stages of wear formation, enabling the analysis of the lithic surface before, during, and after experimental use. This approach has been applied to the study of the flaked industry [,,,,,] by tracking the response of the surface and the microscopic development of use-wear traces revealing their cumulative behaviours [,]. Observations of the intermediate stages of the gradual transformation of surface texture have been rarely reported for the study of ground stone tools [,,]. To track the occurrence and the development of the use-wear patterns, we structured our sequential experiments according to a recurrent recording of the features. All the morphological and textural transformations during the use of the GSTs were documented at a given time, beginning with T0 (not used) and then recording every 30 min at T1, T2, T3, up to T5, by means of a standardised documentation strategy at an increasing resolution and magnification capacity from the macro to sub-micro scale:

- -

- The geometry of stone objects was recorded through photogrammetry and the elaboration of 3D models, which proved to be useful to contextualise the original orientation and spatial distribution of the wear traces on the active surface [,];

- -

- The original stone surface was surveyed by means of Dino-Lite;

- -

- Moulding of the active surface at each given time (T0–T5) was carried out after residue removal (saved for further starch analyses); this procedure allowed for the permanent documentation of the punctual progression of the use-wear in time and space, a useful comparison since the cumulative phenomenon was acknowledged;

- -

- Surface texture and use-wear traces were observed on the moulds at increasing scales of magnification and resolution using different types of microscopes, such as the Stereomicroscope, the Optical Microscope (OM) used with reflected light, and the Scanning Electron Microscope (SEM);

- -

- Microtopography was reconstructed in 3D and measured with the confocal profilometer, which was essential for extracting tribological features at the qualitative and quantitative levels.

These operations enabled us to gain insight into GST usage at different scales of observation. At the microscale, comprehending the tribological mechanism behind surface roughness deformation can provide information on the raw material selection, time involved in the transformed medium (organic or inorganic), and mechanically processed substances (in our case, different parts of the plant). At the macroscale, understanding the gestures and know-how of the people thriving in a given environment— i.e., at the Brînzeni I cave—can provide insight into the knowledge acquired/shared by human groups venturing into new territories.

Here, we are detailing the experimental setup devoted to the mechanical transformation of aerial and underground plant organs (ASO and USO) collected seasonally and selected on the basis of their occurrence in the archaeological pollen list of the MIS 3 sites across the Pontic steppe []. In this perspective, original use-related biogenic residue (U-RBR) identification and characterization were crucial [,]. The mechanical processing of ASOs and USOs with riverine slabs and pebbles helped disentangle tribological mechanisms causing deformations, cracks/fractures, striations, and dulling of the grain tips []. The data from the thin sections of the pebbles drove the selection of the stones for replicative tasks due to their morphometric and petrographic consistency with archaeological GSTs from the sites attributed to the Prut River Culture in Moldova []. Controlled lab replications of ancestral gestures allowed for the recreation of main usage strategies and an understanding of the timing and interactions responsible for producing tribological modifications on lithic surfaces [].

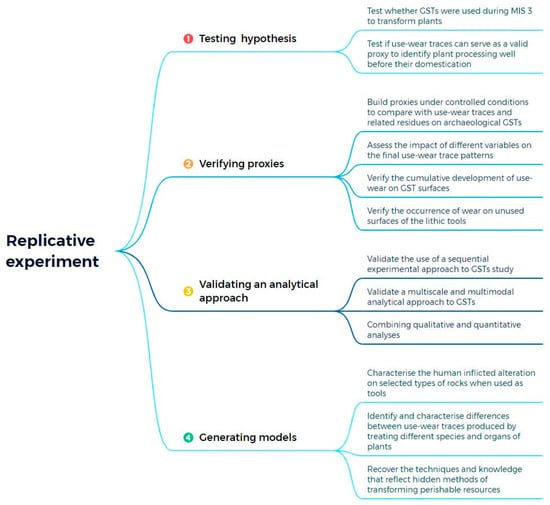

A replicative experiment can serve different purposes. It can be used to test a hypothesis, it can generate models and predictions through data from scenarios that have been experimentally tested and verified, and it can be used to validate an analytical approach []. The aims of our experiment were several and of a diverse nature, as summarised in Figure 1.

Figure 1.

Flowchart representing the aims of the replicative experiments.

The experiment was designed by considering different aspects, such as the selection of the rocks, the media being transformed, the duration of the experiments, and the human factor:

- -

- An evaluation of the intrinsic characteristics of the stones was conducted: the general rock classification and petrographic characteristics, the fabric (structure of the rock, including the arrangement of the granular component), and the texture properties (namely, granularity, cohesion of the emerging grains, and the porosity). All of these features can affect the response to mechanical stress and the capacity of the rock(s) to transform different media [,,];

- -

- The type and physical property of the medium transformed were considered. These factors influence the operator/s gesture and the kinematics, among the variable affecting the development and morphology of the use-wear traces;

- -

- The duration of tool use and the amount of processed media, both of which impact the development, distribution, and intensity of use-wear traces, were maintained at a constant rate. As the medium characteristics influence the selection of the shape, size, weight, and surface geometry of the GSTs, they also condition the operator’s gestures;

- -

- We prioritised the human factor over machine reproduction because it allowed for the adaptation of performance strategies regarding the actual steps and needs of the processing. Although the impact of human variability cannot be predicted, we did not standardise the operator’s gestures since they cannot be objectively evaluated. However, we monitored both the gestures through notes, pictures, videos and the modifications on GST surfaces through a multiscale and multimodal analytical strategy.

Therefore, a reasoned interdisciplinary approach to the replicative usage of ground stone cannot disregard these variables, some of which can be controlled—textural and petrographic properties, transformed medium and its quantity, the duration of the treatment, the avoidance of main environmental contaminants—and some of which can only be monitored, namely, gestures, pressure, and position of the operator. Our experimental design took a step forward by incorporating systematic control through a multiscale documentation strategy. This strategy, ranging from macro to sub-micro scales, included photogrammetry, microscopy, and moulding being taken at fixed intervals. It allowed us to document the rock in terms of geometry, macro-topography, micro-topography, and development of use-wear features over time. Although the object biography includes many phases that are relevant concerns when evaluating wear [,], we are reporting solely on the use stage of the life history of the tools.

2.2. Raw Materials

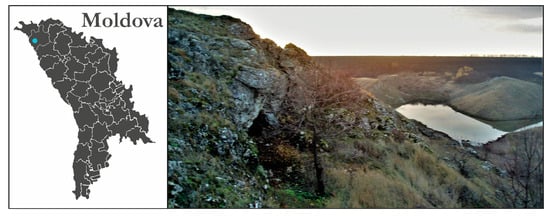

Upon stating that the petrographic characteristic influences stone tools’ response to mechanical stress [], we paid particular attention to the selection of the slabs and pebbles to be used as experimental replicas. The lithological characteristics of the Edinet district were studied based on a geological map that showed a formational context that was rather homogeneous, characterised by sandstone and limestone outcrops dating to the Miocene and the lower Pliocene []. Twenty-seven pebbles (named with the acronyms M#) were collected from the Racovăț River flowing just below the Brînzeni I cave (Figure 2).

Figure 2.

A: The Brînzeni I cave and the Racovăț River valley in NW Moldova (photograph L.L.).

The worked material selected for our replicative experiments is of the same sandstone variety recognised in the pebbles retrieved in cultural layer III of the Brînzeni I cave.

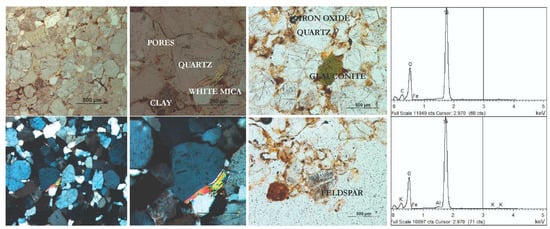

To confirm the coherence of the raw materials, a small stone fragment already detached from the tool (BZ#6742) was selected for thin-section analysis. The archaeological sample could be classified as quartz-arenite, a sedimentary rock of terrigenous origin. The sandstone had homogeneous grains—average size between 100 μm and 500 μm—and consisted of sub-spherical, rounded quartz and quartzite grains, formed by the erosion of granite or granitoid rocks. Some polycrystalline aggregates of quartz formed by the dismantling of metamorphic basements were also present, together with rare carbonates, amphiboles, feldspars, and iron oxides. The matrix was scarce, around 5%, and the cement, consisting of calcium carbonate, was <5%. The porosity was around 5% and could be considered closed as single pores were not in communication []. This quartz-arenite was hard but crumbly; thanks to its closed porosity, it was impermeable. To confirm the attribution, SEM-EDS analysis was also carried out, showing a composition of more than 99% quartz and a trace of iron (Fe); it was compatible with the previous attribution to quartz-arenite (Figure 3).

Figure 3.

BZ#6742: Representative microstructures and mineral assemblages of the quartz-arenite from the archaeological sample in transmitted and polarising light, as well as EDS analysis.

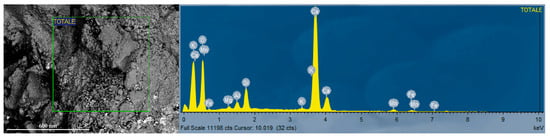

Moreover, a small fragment coming from the surface of the tool (BZ#442) was also analysed with SEM-EDS (the sample was too small for a thin-section analysis). In this case, the analysis showed a composition compatible with a calcareous rock, mainly made of calcite and to a lesser extent by clay and very fine-grained quartz (Figure 4).

Figure 4.

BZ#442: EDS analysis of the fragment.

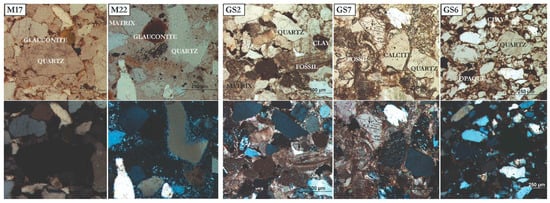

The majority of the pebbles collected from the Racovăț River exhibited similar characteristics to the sample from BZ#6742 (e.g., M17 in Figure 5). However, one sample (M22 in Figure 5) could be identified as greywacke, with a higher percentage of the clayey matrix that contains sub-millimetric angular quartz grains. Additionally, accessory minerals, such as glauconite, and opaque minerals (5–10%) were observed. The sample lacked cement and had a porosity of less than 5%. It could not be excluded that other lithotypes, such as greywacke, were also present in the archaeological collection; although, it was impossible to sample each pebble due to the invasive nature of the petrographic analysis.

Figure 5.

Representative microstructures and mineral assemblages of the collected stones in transmitted light at single polarised (on the top) and at crossed polarised (on bottom): on the left, those collected along the Racovăț River (M#); on the right, those collected along the Fiora River (GS#).

To broaden the experimental collection, raw materials from different geographical locations were considered. This could be useful in determining whether they were applicable as proxies in different contexts or if they were locally specific. By adding variability in the tribological response of rocks in terms of hardness, density, and roughness characteristics, raw materials from different geographical locations could help determine the extent of the outcomes []. In this context, an area characterised by sandstones of Miocene formation, similar in lithological terms to the Edinet region, was identified in the middle basin of the Fiora River near Manciano (Tuscany, Grosseto, Italy) and was selected []. During a survey of the banks of the Fiora River in 2020, sixty-five slabs and pebbles (named with the acronyms GS#) were selected and collected based on their shape, size, and weight in terms of their similarities to the archaeological tools. In all, four of the Moldovan pebbles and seven of those from the Fiora River were sampled to perform petrographic analysis (Figure 5 and Table 1).

Table 1.

Summary of the characteristics of the rocks involved in the replicative experiments. The asterisk (*) is used to indicate stones that were used for thin sections only.

The pebbles collected along the Fiora River were similar from a mineralogical point of view; however, they varied in the shape and size of the quartz grains, showing a general higher porosity, the presence of carbonate cement (or a greater quantity of matrix), the absence of glauconite, and the presence, in some cases, of bioclasts. They could be defined as sandstone, litharenite, and sublitharenite (GS2, GS7, GS6 in Figure 5). The Fiora group not only increased the number of experimental tools (with the COVID-19 pandemic resulting in a serious constraint on the raw materials access) but also the hardness, density, and roughness characteristics, broadening the variability of the responses to the mechanical stress.

The characteristics of all of the analysed samples collected from the experimental pebbles are summarised in Table 1. Since the materials herein considered had a quasi-brittle nature, the value of hardness, which is primarily correlated to material strength and plasticity, was not reported since it may have led to misleading interpretations. Other mechanical parameters, such as fracture toughness, would be more relevant for comparing the mechanical response of brittle and quasi-brittle materials, such as stones (see [] for a consistent theoretical and simulation-fracture-mechanics approach appropriate for rocks). To assess the fracture toughness, three-point bending tests on notched stone samples should be conducted instead of indentation tests; this is left for further research.

The selection of the plants to be processed during the experiments was based on the palynological analysis carried out in 1987 in cultural layer III, or compatibles with the biome of this area during MIS 3, and/or being attested by ethnographic data for consumption [,,,]. Although many of the plants can be eaten raw—leaving no traces on the GSTs—we selected plant organs that may need pre-treatment prior to consumption, such as tenderisation, grinding, pounding, etc.; these are actions that leave traces on the tools used for plant preparation. Our experience highlights the potential of grinding and pounding to obtain gross or finer flour, which can then be thermally processed to enhance the digestibility and absorption of dietary carbohydrates. Both mechanical tenderization and thermal treatment boost the action of the enzyme a-amylases on the amylose and amylopectin rings composing starch grains, which begins the breakdown of starches during the oral phase of digestion [].

The response of GSTs to the applied kinematics varied based on the dimensions, greasiness, stickiness, wetness, stringiness, and brittleness of the media, as well as the distribution and dispersion of residues, including crunchiness and lightness (such as achenes). The reference collection played a crucial role in interpreting the functional use of archaeological GSTs and inferring the variety of plant resources that may have been processed during MIS 3 in the Pontic Steppe, among the numerous plant collectables [].

Based on this consideration, both underground storage organs (USOs)—roots, rhizomes, tubers, and bulbs—and above surface storage organs (ASOs)—fruits, leaves, and seeds—were considered:

- -

- USO: (roots) Armoracia rusticana, Pastinaca sativa, Daucus carota, Cichorium intybus;

- -

- ASO: (achenes) Rumex crispus, Chenopodium album; (seeds) Echinochloa crus-galli; (acorns) Quercus sp., Quercus ilex; (nuts) Corylus avellana, Pinus sp.; (berries) Morus nigra; (pods) Ceratonia siliqua; (fruits) Trapa natans; (cambium) Pinus nigra.

2.3. The Replicative Experiments Design

The archaeological scenario of Brînzeni I cultural layer III provides information on the presence and the putative differentiated use of tools as active (pestles and handstones) and passive (grinding stones). The former outnumbers the latter; although, they are more frequently broken into pieces, as demonstrated by the refitting of specimens BZ#833 and BZ#2965 []. These occurrences made the case of intensive exploitation of GSTs in the cave; hence, the experimental design was driven by the archaeological context. This circumstance, as our experiment demonstrates, could be attributed to the fact that active stones break more easily than passive ones and may have been replaced. However, the lower number of passive supports could also be due to the use of perishable materials, such as wood, for grinding and smashing (third scenario Table 2); although, to the authors’ best knowledge, this kind of wooden tool is not reported for the Palaeolithic. It is worth noting that one flat grinding stone was refitted (in two fragments and still not complete) in the same level, namely, BZ#442 and BZ#NNo (without accession number); however, the use of the single fragments could also be hypothesised [].

Table 2.

The ground stone tools and the plant organs involved in the various cycles of the experiment (T1, T2 …T5). The stones named GS# are from the Fiora River (Italy) while the ones named M# are from the Racovăț River (Moldova). The last column reports the preparation strategy of the plant resources. In blue: actualistic experiment (1st scenario); in green: lab-controlled experiment (2nd scenario); in yellow: replicative experiments involving a wood plate and active stone tools (3rd scenario); in orange: experiments with multiple operators (4th scenario).

The experiments tested the mechanical processing of plant organs using pairs of stone, as well as pounding the plants with different stone active tools and a wooden passive plate (Fagus sp., beech tree) (Figure 6). Each pair of active and passive tools was associated with the mechanical processing of specific plant resources (Table 2). A standardised procedure was followed to remove adhering soil and other environmental remains from the surface. In order to create a clean state (T0): (i) the stones were first washed and brushed with running water, (ii) placed in a zip bag with deionised water and immersed in an ultrasonic tank for 30 min (Elmasonic S15H), and set in sweep mode to distribute the waves more homogeneously on the samples; (iii) since then, the stones were handled wearing powder-free gloves, (iv) dried in a lab oven at 37 °C (Binder FD23), (v) weighed (Table 3), (vi) and finally stored in the refrigerator in a new zip bag. This preparation dislodged the adhering residues from the stones, which were then collected in the bag, poured into test tubes (50 mL) with a few drops of ethanol (96%), and stored in a refrigerator as a reference to document the original contaminations.

Figure 6.

Some of the tools and resources involved in the experimental use: (A): Rumex crispus achenes treated with GS7 and GS8; the passive tool was leaned on the ground with a plastic wrap in between. (B): Quercus ilex acorn treated with M23 and M2; the passive tool was accommodated in a plastic box filled with polystyrene compound. (C): Armoracia rusticana dried roots treated with the active stone tool M9 and a wooden plate as a passive tool.

Table 3.

Table of stones weights before and after the use (T0–T-final). The values are expressed in grams.

The surfaces of the stones were mapped by creating a grid of 2 × 2 cm, drawn with India ink (Pelikan), which has a known composition and did not affect the residue analysis. The surfaces were observed with a Dino-Lite© (AnMo Electronics Corporation, New Taipei City, Taiwan). Replicas of the textures were taken using high-definition moulds, made with Provil Novo L (Hereutz–Kulzer) and stored in separate zip bags. Due to the size of the GSTs and the structural design of the microscopes, the original rock surfaces were observed only with the Dino-Lite, while all other observations at the microscopic scale were carried out on moulds, including SEM. The moulds were also analysed with a confocal profilometer (Leica DCM 3D; Leica Microsystems Srl, Buccinasco, Milan, Italy) to take measurements of specific areas. Finally, the geometry of each stone was documented with close-range photogrammetric modelling (for detailed settings, see []).

The plant organs selected to be treated during the experiments were either left to air dry for several months or were dried in the oven (e.g., acorns, at 40 °C for multiple cycles of 2 h within 7 days), while others were used fresh, or frosted and defrosted, prior to their use to preserve their water content (for detail see Table 2).

After preparing the stones using the aforementioned procedure (T0), the experiment was structured into four main scenarios (see Table 2).

The first scenario was set up as an “actualistic/natural experiment” and was performed outdoors. The passive tool was fixed on a shallow depression on the ground with a plastic wrap in between to collect the flour while the active stone was handled in one hand wearing powder-free gloves (Figure 6A).

During the second scenario, set up as a “controlled experiment”, the mechanical processing of plants was carried out in laboratory conditions to further minimise environmental contaminants, which could potentially affect residue analysis [,]. The passive tool was accommodated in a plastic box, previously filled with polystyrene compound and with a plastic wrap in between (to separate the passive stone from the polystyrene) (Figure 6B).

During these first two phases, the mechanical process was repeated multiple times (up to 120 min), each grinding cycle lasting 30 min (and denominated T1, T2, T3, T4), processing 15 g of resource each time (as a fixed amount); the first author was the only operator []. This strategy was chosen to gain confidence in the type of activities required, such as holding position, movements, and gestures necessary to achieve efficient grinding to obtain a fine grain size of the flour. It was also designed to limit the variability that multiple operators could introduce, such as differences in approach and ability to the activity, tool handling, or differences in body proportions and applied strength. Hence, in the experiments, the variables were controlled and cross-checked against two further constraints: limiting the effects of environmental contamination and, on the contrary, carrying out a comparison with the putative contaminants that may enter the experimental setup, as in the first scenario.

The third scenario, built as a “controlled experiment”, considered that the active and passive tools were made of different materials, such as stone for the former and wood for the latter. The replicative use was conducted by G.S., for what concerns GS9, and by multiple operators, including G.S. for M7 and M8. The mechanical process was organised in cycles of 30 min and repeated 3 times (named T1, T2, T3); the process took a total of 90 min (Figure 6C).

The last scenario involved 12 operators, selected among the PhD students of the University of Turin, who were briefly trained during a preliminary workshop. In this experiment, not only plant organs but also ochre was processed, as the analysis of the archaeological stones revealed the presence of red spots attributed to hematite based on microscopy observation and Raman analysis. The processing was once again carried out in controlled laboratory conditions. The passive tools were placed in plastic boxes, previously filled with soil and a plastic wrap in between to avoid direct contact. The mechanical process was repeated multiple times (up to 150 min and named T1, T2, T3, T4, and T5), with each grinding cycle lasting 30 min, during which the operators took notes, pictures, and videos. While in previous scenarios each pair of tools was used to treat only one resource, here, the transformation of multiple resources was also considered.

The kinematics change based on the resource treated and were adjusted according to the resistance to the mechanical transformation of the different media. In our experiment, the human factor was crucial in obtaining flour as the final functional goal. To process the 15 g of plant resources, small quantities of them were progressively placed on the passive tool surface. The active stone was used to perform horizontal linear or circular movements and/or a vertical motion while applying different pressures [,,]. The different characteristics, such as resistance, wetness, greasiness, and fibrosity, of the media were taken into consideration. For achenes (dry fruit with shelled pericarp containing a single seed), which are quite resistant, grinding, horizontal, bidirectional, and sometimes circular movements were prevalent. Furthermore, in the processing of this medium, the contact between the active and passive tools was only partially mitigated by the presence of the processed material. To efficiently process dry roots, short, fast, and repeated vertical pounding was applied and alternated with some axial rotation of the active stone on the root as well as pressing with the wrist; only at the end of the process, horizontal linear movements were needed to obtain finer flour. In the case of acorns, hazelnuts, pine nuts, and dry pods, which are greasy resources and maintain this characteristic even when dry, pounding with vertical strokes prevailed, implying fast and repeated contacts between the stones and the worked material that could result in direct friction of the two stones. In this context, horizontal movements were also needed, although to a lesser extent, to transform the small particles into flour: circular for pine nuts, circular and linear bidirectional for hazelnuts, and linear monodirectional for dry pods. To process the fresh acorn fruits, the gesture involved a continuous flow that started with vertical strokes and transitioned to horizontal linear motions, while applying pressure with the wrist on the active stone. In the case of roots, as occurs for the nuts, the contact between the stone’s surface was mediated by the fibres and/or by the paste that derives from the processing and adheres to the surface, making the processing of these resources more challenging. For dried berries, the gesture required horizontal, bidirectional, and circular movements with no contact between the stone surfaces due to the berries’ wetness, which produced a moist paste. In the processing of the Pinus nigra phloem, devoted to obtaining fibres, effective gestures required alternating horizontal and vertical unidirectional movements. In the case of ochre, the effective gesture implied a shift among vertical, horizontal linear, and circular motions.

In the third scenario the usage of a wooden base, with a light rim, had the advantage of granting better control over the achenes and seeds that usually scatter on the passive stone tool surface when they come into contact with the surface of the active instrument. Another benefit was that resources such as hazelnuts and roots did not adhere to the surface of the wood (Figure 6C). However, the wood demonstrated a lower friction than the stone because of its smoothness and plasticity, thus reducing the effectiveness in the case of the achenes transformation, resulting in a far longer process and in a less homogeneous powder. Accordingly, the gestures were different, involving primarily vertical motions, with the wrist applying pressure as it came into contact with the achenes so that the movement continued with a short horizontal motion. Both the flat and convex faces of the active stone were used. For what concerned the hazelnut, after crushing and removing the shells with a stroke, the fruits were ground into coarse particles through repeated light pounding actions inflicted by the flat part of the active tool. Finally, linear unidirectional and circular movements with the slim side of the active tool were used for powdering them into flour. The wooden base was particularly efficient for root treatments. In this case, the motion was primarily vertical with some linear and circular movements, resulting in an easier achievement of the expected result.

2.4. The Multi-Scale Documentation Strategy

After each replicative usage, the GSTs were rinsed with demineralised water in a graduated beaker to remove the adhering residues; then, the solution was collected in test tubes (50 mL), stabilised with a few drops of ethanol (96%), and stored in a refrigerator for further residues analysis. In order to minimise bacteria, fungi, and lichen colonisation after use, the stones were also stored in the refrigerator at 4 °C. At the end of the experimental study, the stones were weighed and compared with the original weight at T0 to verify the material depletion (Table 3). Due to the sensitivity of the measurements to environmental and climatic conditions, even though the weights were acquired in the lab (using Orma electronic model BC, up to 5 kg), we considered this analysis to be a semi-quantitative evaluation. Therefore, it should be noted that these values are useful for comparing the relative depletion of the tools, but not in terms of the absolute weight value.

The analytical strategy setup proceeded with the documentation of the surface modification acquired at multiple magnification scales (Figure 7). The stones involved in the replicative experiment performed by one operator were documented at the end of each experimental phase (30 min—T1, T2, T3, etc.) to monitor the change in overall geometry and used surface texture along with the development of use-wear traces recorded at the end of each cycle. We stress the relevance of the punctual and progressive chronicle of our documentation protocol that diarised, at different scales (at a fixed point in time and in a permanent manner), the stone surface modifications from its original appearance (T0) until the last cycle (T5). The detailing of the different factors—at fixed times and at different scales (see below)—granted both the repeatability and reproducibility of the experiment [,]; it also made available features that progressively changed in their appearance/look across the mechanical transformation. The continuation/advancement of the transformation modified the trace patterns, making it unlikely to retrieve previous states of trace development. As a result, the data for re-evaluation became unavailable without a recurrent documentation.

Figure 7.

Scheme of the various steps and techniques involved in the documentation and analysis of the tools’ experimental replicas.

For the analysis, several microscopes with increasing magnification were employed as complementary sources of information. The resolution of imaging systems, according to Abbe’s formula, determines the ability to distinguish two adjacent points and the capability to generate distinguishable images depending on the numerical aperture of the optical components and on the wavelength of the source beam. According to the source—visible light in the case of optical microscopy and electrons in the case of SEM—the detailing capacity of the different microscopes generates different images, down to about 0.2 µm for optical microscopy and 0.1 nm (10−10 m) for electron beams (for a recent discussion see Calandra and colleagues [] and the literature therein).

The documentation strategy recorded the original lithic surface by using a portable digital microscope equipped with polarised light (Dino-Lite Pro AM413ZTA). The images were taken at fixed magnifications: 30×, 50×, and 220×. To perform a more detailed observation, high-fidelity moulds were taken according to three main reasons: (a) the structural characteristics of the microscope rarely allow the placement of big samples beneath the objectives and, likewise, the original sizes of the stones do not fit the SEM chamber dimensions; (b) to create a comparative reference collection of the use-wear traces at different stages of development and at fixed times (T0, unused/original surface, to T5, each 30′); (c) to compare data from the reference collection with those observed on the archaeological GSTs. Due to the difficulty of studying the archaeological GSTs using these different scales and resolutions in a museum environment (namely in storage rooms) and usually with no direct access to the analytical devices (microscopes, etc.), even Brînzeni I GSTs’ surfaces were copied, with Provil Novo L (Hereutz–Kulzer) obtaining high-fidelity moulds of the surfaces. This A-silicon, also known as vinylpolysiloxane or VPS, primarily manufactured for human dental applications, was adopted because it exhibits excellent long-lasting dimensional stability, with deformation under the pressure of 3.1%, elastic recovery after deformation of 99.7%, and minimal distortion (linear shrinkage = −0.2%) []. This characteristic makes it a good choice also for imprints of stones’ cavities, crevices, scarring, and undercuts e.g., [,,,,,,,,,,,,,]. As highlighted by Macdonald and colleagues [], impression accuracy is limited by “the intrinsic texture of the moulding material”, resulting in a general smoothing of the original surface texture. Moreover, air could be trapped into the paste during the moulding process, resulting in circular smooth craters []; although, this was very easily identifiable at all scales of magnification (e.g., Figure 13 T1 and T3; Figure 14 stereomicroscope; Figure 17 stereomicroscope; and Figure 20 SEM). The accuracy of the moulds could also be influenced by the roughness and moisture of the artefacts’ surface and by the environmental conditions (room temperature and humidity). Accuracy could be enhanced by selecting a moulding compound with a medium/slow setting time and by controlling the VPS temperature. In order to lower the discrepancy with the original surface, our protocol involved keeping the Provil L in the refrigerator until each use to slow down the time of the reticulation process and finally ensuring the dryness of the stone surface.

The experimental replicas’ surface textures, use-wear traces, and their spatial distribution were observed on moulds using a stereomicroscope (Leica S9i; Leica Microsystems Srl, Buccinasco, Milan, Italy) with a large field of view (37.6 mm) and at magnification spanning from 12× to 110×. Then, the surfaces were scanned with an Olympus BX51 (Olympus Italia S.r.l., Segrate, Milan, Italy) reflected light microscope with vertical incident light, using the lenses: 4× (NA 0.10; WD 18.5 mm; FN 22); 10× (NA 0.30; WD 10 mm; FN 26.5); 50× (NA 0.5; WD 10.6 mm; FN 26.5). This allowed us to analyse the morphological characteristics of the traces and verify the presence of micro-polished areas. Several images of the same areas were acquired at different focal planes and combined using the plug-in “Stack Focuser” of the open-source software ImageJ (version 1.53t). Accurate scans of specific features were obtained with the SEM (ZEISS EVO 60 EP, Carl Zeiss S.p.A., Milan, Italy) used in extended pressure mode, by acquiring images at magnifications ranging from 65× to 800×. The working distance (WD) was kept at 10 mm and the EHT at 20 kV. The SEM was also used due to its capability to overcome the limited depth of field, a structural constraint for light/optical microscopes. Additionally, the SEM offers the chance to concentrate on the sample morphology without being affected by light reflection from the sample itself, or blurring.

Our experimental analysis protocol also included the use of a confocal profilometer (Leica DCM3D) with different magnification lenses (10×, 20×, 100×), available at the MUSAM-Lab of the IMT School for Advanced Studies Lucca. The 10× lens (numerical aperture 0.30; field of view 1270 × 950 μm, in-plane resolution 47 μm, vertical resolution < 30 nm) was used to scan about 25 areas of 850 μm2 within the reference square of 0.5 cm2 drawn in the middle of each tool surface. The confocal profilometer allowed for inspecting the out-of-plane geometry of the surface that could not be assessed using SEM imaging. The acquisition was performed on moulds after any cycle of the replicative process, leading to a 3D reconstruction of the microtopography of specific areas. The data were then processed and analysed with the open-source software Gwyddion (version 2.59) [] to characterise the scanned surfaces, providing quantitative data on tribological features.

The geometry of each stone was finally acquired after their rinsing with demineralised water. We employed photogrammetric techniques based on the Structure-from-Motion (SfM) and Multi-View Stereo reconstructions to generate 3D models of the GSTs, before their use and after each experimental cycle, in order to compare the degree of surface depletion in the different tools and at the different stages of the use. Several settings were tested for data acquisition and elaboration; we even included some conditions that could create potential sources of bias in the dataset (detailed analysis and results are reported in []).

The stones involved in the replicative use performed by multiple operators were documented with the same strategy at T0 and at the end of the use (T5); meanwhile, moulds were also taken at T3 (90 min).

This multiscale documentation was employed to establish a usage biography, encompassing the various stages from T0 (natural surface before use) to the final phase of mechanical processing (typically T4, after 120 min). In general, the possibility of comparison with the unused original surface at each stage of the replicative experiment guaranteed a punctual analysis and the detection of surface natural features (e.g., cracks, polish, striations, crystals roundness), not to be confused with human intentional use-related traces.

3. Results and Discussion

Considering the characteristics of the processed media, namely USOs and ASOs, this study highlights their primary impact on the process of use-wear trace formation and development. From the analysis, it emerged that the tools involved in achenes grinding originated morphological changes already visible at the macroscale: the concavity of the passive tools and the flattening of the active tools progressively increased with their use. At the microscale, use-wear traces were well-developed, especially in the form of striations and rubbed areas due to the hardness, small size, and dryness of the achenes, which did not create a homogenous layer between the two stone surfaces (as occurred with more plastic media, such as roots and acorns); this resulted in repeated direct contact between the lithic tools. Indeed, this was also confirmed by the analysis of the stone weight before and after use cycles (Table 3). Among all the tools, those used for grinding achenes showed the highest value of weight loss, followed by stones used for treating seeds/fruit and ochre/phloem. However, it is also clear that not only the medium processed but also the lithic type of the GST was important for the tools’ responsiveness to mechanical stress. Tools used to treat the same medium but coming from Italy or Moldova showed very different responses to mechanical stress, with stones from the Fiora River showing a higher depletion compared to those from the Racovăț River, also demonstrating the impact of the petrographic characteristics of the stones on the repeatability of the experiments. Finally, it is noteworthy that the passive tools exhibited a higher amount of mass loss compared to active ones.

It is relevant to report that the active stone M5, after ca. 100 min of replicative usage, was broken into two pieces while pounding acorns. The fracture observed resembled that of the Brînzeni active tool (pestle) that was retrieved in two fragments, BZ#833 and BZ#2965, which refit together [].

In our experimental design, we documented not only the working surface of the passive tool but also the ventral side, which remained idle facing the ground. Microscopy analysis of this side of the tools revealed traces affecting the matrix that was homogeneously worn. The hardest grains bulging were flattened, and in some cases, they were slightly polished on top and/or chipped as a consequence of the blows and recoils absorbed during the mechanical processing ongoing on the active surface (an example of the bottom side of GS10 in Figure 19).

The use of a wooden base as a passive tool for small seeds and achenes processing was demonstrated to facilitate the grinding since it was easier to keep them on the surface; however, their transformation into a homogeneous flour was less efficient and in the same amount of time (30 min), the obtained powder was coarser and required greater effort from the operator. Instead, the wooden base was particularly effective for greasy resources since it limited their adherence to the tools’ surfaces; in particular, it facilitated the treatment of dry roots that required a prevalence of vertical motions.

Furthermore, in parallel with the different kinematics required to process the various plant resources, we also observed the parallel need for different morphological characteristics of the selected pebbles to be effective: a concave and wide working surface was more efficient when horizontal movements were performed on the passive tool; whereas, for a vertical motion, a convex/flattish surface of the pestle was preferable.

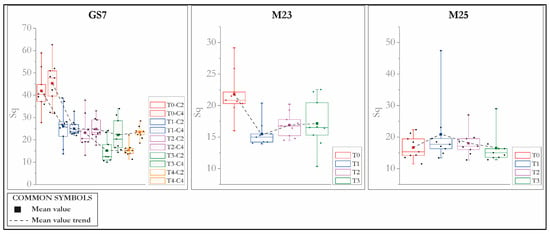

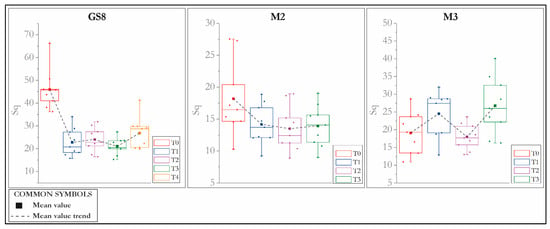

Confocal profilometry data collection allowed us to calculate the seven ISO 25178-2 height parameters for each analysed point (an area of 850 μm2) within the 0.5 cm2 reference squares at the different stages of the replicative use, including T0. Here, we report the data for the root mean square roughness (Sq) for the passive tools (GS7, M23, and M25, as shown in Figure 8) and active tools (GS8, M2, and M3, as shown in Figure 9). This parameter provides quantitative information on the standard deviation of the surface heights’ distribution with respect to the average plane. Therefore, the wear process is expected to primarily influence such a parameter through its reduction over time, as a result of a progressive smoothing of the surface asperity tips. On the other hand, an increase in Sq could be related to localised fracture events affecting isolated spots of the brittle stone, which cause new rough surfaces to be exposed. Moreover, a comparison between the time evolution of Sq for different stones also provides information on their wear resistance.

Figure 8.

Boxplot of the Sq (Root Mean Square Roughness) values expressed in µm of the passive tools GS7, M23, and M25 at the different T of the experiment. The coloured squares indicate the mean value, while the dashed lines show its trends.

Figure 9.

Boxplot of the Sq (Root Mean Square Roughness) values expressed in µm of the active tools GS8, M2, and M3 at the different T of the experiment. The coloured squares indicate the mean value, while the dashed lines show its trends.

The analysis clearly shows that the stones from the Fiora River initially had a higher roughness compared to the Moldovan ones. The raw material of the stones from the Racovăt River was primarily quartz-arenite with a few greywackes. The Fiora River pebbles were made out of litharenite and sublitharenite; they present a prevalent wear mechanism that leads to a fast progressive smoothing of the asperities over time, with a correspondence reduction of Sq. The tools M23 and M2, which were used in acorn processing through primarily grinding action, were of Moldovan origin. Acorns are a source of moisture and fat; the grinding action could thus result in a smoothing effect. The evolution of Sq for these stones was similar to that of the GS7 and GS8 tools but with a lower rate of reduction over time. This was likely due to their stronger textural composition, which opposed wear. M25 and M3 were also Moldovan stones but were used primarily in the pounding activities of dry roots. This may have led to new surface crack formation and, therefore, to an increase of Sq in specific time instances and a non-monotonic trend of Sq over time. The microscopy inspections confirmed the analysis.

3.1. Microscale Analysis of the Implements Involved in Achenes Processing

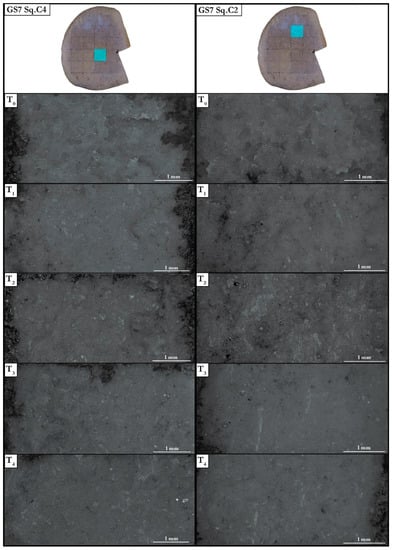

For the implements involved in achenes grinding (Rumex crispus, Chenopodium album), it was noticeable that at T0, both the grains and the matrix were clearly visible. At T1, the grains started losing definition on both of the GSTs, getting flattened on the active tool and having the first fine striations appear on the passive tool. At T2 and T3, groups of striations and microstriations developed on the passive tool. At T2 the surface showed a rubbed appearance; meanwhile, at T3, the striations were less abundant but long and better-defined than at T2. Additionally, small areas were characterised by developed polish and the entire microtopography seemed levelled, a process that continued through T4 when abraded areas and groups of shorter striations increased as compared to T3. This process, which was clear on the central part of the stone, where its use was quite intense, was even more evident on the peripheral areas of the used surface where the active tool ended its motion and the depletion of the surface was less intense (Figure 10).

Figure 10.

GS7: moulds of the surface of the passive tool used to process Rumex crispus achenes at different T and imaged with a stereomicroscope. Left: square C4, in the central part of the stone where the use is more intense, depicted from T0 to T4. Right: square C2, in a peripheral area of the used surface from T0 to T4.

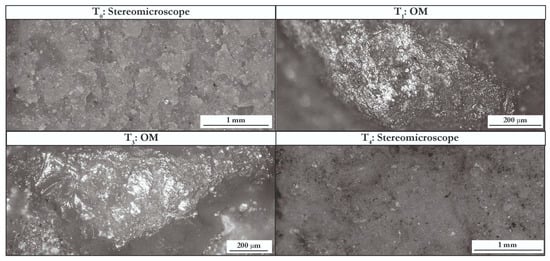

For the active tool, there was a gradual lowering of the matrix from T0 to T4 associated with the levelling of the grains. Groups of microstriations, mostly iso-oriented, appeared since T1 on the surface of the grains, decreasing in their quantity and in length at T4; meanwhile, since T3, the appearance of a few small polished areas was also detected (Figure 11).

Figure 11.

GS8: moulds of the surface of the active tool used to process Rumex crispus achenes depicted at T0, T1, T3 and T4 with a stereomicroscope and OM.

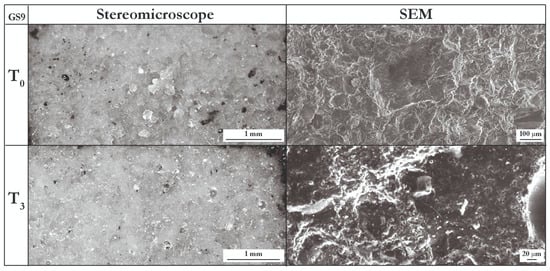

For what concerns the active tool (GS9) coupled with the wooden base, at T3, the surface appeared slightly levelled and homogeneously smoothed (Figure 12).

Figure 12.

GS9: moulds of the surface of the active tool paired with the wooden base used to process Rumex crispus achenes at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: the same feature at T0 and T3 acquired via SEM.

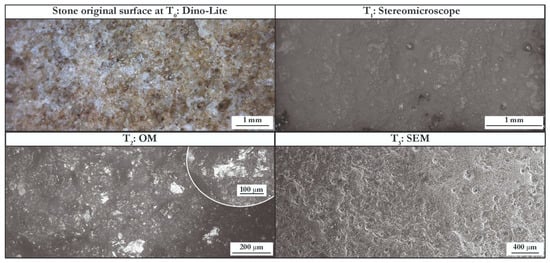

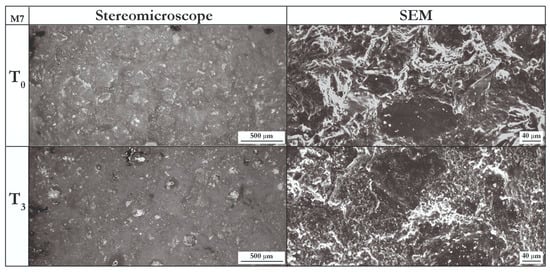

3.2. Microscale Analysis of the Implements Involved into Shelled Fruits Processing

M23, the Moldovan passive stone used to treat acorns, displayed a natural shine. The used surface at T1 was distinguished by large and well-defined rubbed areas. Additionally, small polished spots, conchoidal fractures, and very light striation could be observed. At T2, the abraded zones became smaller and less distinct. At T3, the surface levelled out and a smooth appearance and large areas of intense polish characterised by the use-surface started to occur (Figure 13).

Figure 13.

M23: stone surface (T0 original stone) and moulds of the passive tool used to process acorns at different T. Surface details imaged with different microscopes: T0: Dino-Lite, T1: stereomicroscope, T2: OM, and T3: SEM, highlighting the different scrutiny capacities of each microscope, magnification, and resolution.

The use-surface of the active stone, M2, seemed not to be much affected by the process; however, some natural cracks, already present on the natural surface, were propagating (Figure 14).

Figure 14.

M2: moulds of the surface of the active tool used to process acorns at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: the same area at T0 and T3 acquired via SEM.

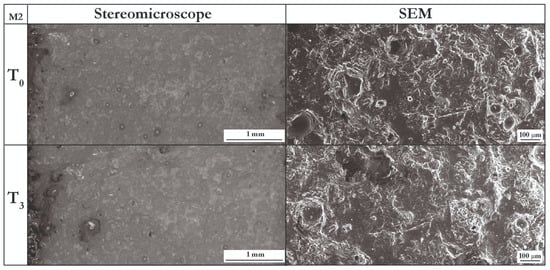

M7, the active tool paired with the wooden base used to treat hazelnuts, presented a levelled surface and a more intense roughness (Figure 15).

Figure 15.

M7: moulds of the surface of the active tool paired with the wooden base used to process hazelnuts at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: two different surface details within the same area at T0 and T3 acquired via SEM.

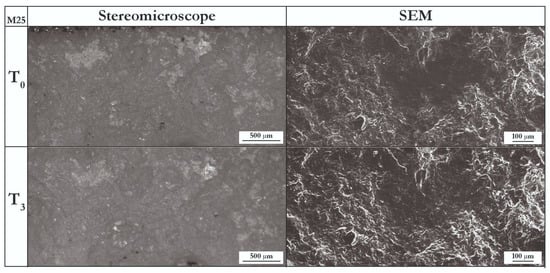

3.3. Microscale Analysis of the Implements Involved into Dry Roots Processing

The Moldovan stones (M25 and M3) used to process the USOs seemed to be not affected by the roots’ elaboration; at low magnification, no appreciable change was noticed. Increasing the magnification, areas characterised by polish became more evident and intensified over time. On the passive stone M25, very light striations were detected (Figure 16). SEM inspections confirmed that the surface showed very little change; however, at T3, areas that were smooth in the original surface exhibited a light roughness at the micro-topographical level, which was more intense in the active tool, M3, whose working surfaces showed broken grains, battering marks, and polish. Moreover, root debris were visible since the paste got easily trapped in the cavity of the stone, even more so in the active tools (Figure 17).

Figure 16.

M25: moulds of the active tool surface used to process Cichorium intybus roots at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: the same area at T0 and T3 acquired via SEM. In T0 a naturally polished area is visible, while in T3 this polish becomes slightly coarse.

Figure 17.

M3: stone surface (T3 on the left original stone) and moulds of the active tool used to process Cichorium intybus roots at T0 and T3. Left: T0 image acquired at the stereomicroscope and depicting the same area of T3 acquired via Dino-Lite; Right: the same area at T0 and T3 acquired via SEM. In T0, naturally polished areas are visible. In T3, the area of this polish increased.

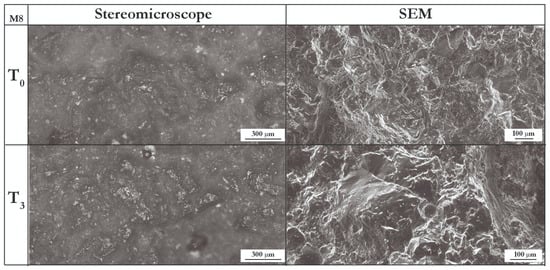

M8, the active tool used with the wooden base, when compared with M3, showed more appreciable changes in the surface morphology. At T3, the lowering of the surface was evident, as well as the increase of the rubbed and polished areas; the inspection acquired via SEM revealed some broken grains (Figure 18).

Figure 18.

M8: moulds of the surface of the active tool paired with the wooden base used to process Armoracia rusticana roots at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: two different surface details within the same area at T0 and T3 acquired via SEM.

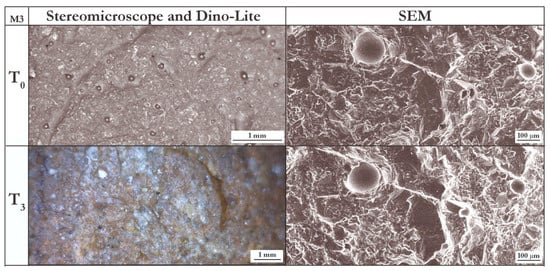

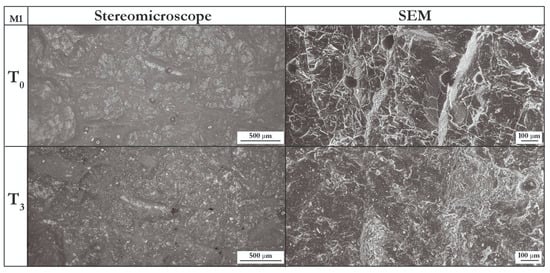

3.4. Microscale Analysis of the Implements Involved into Ochre Processing

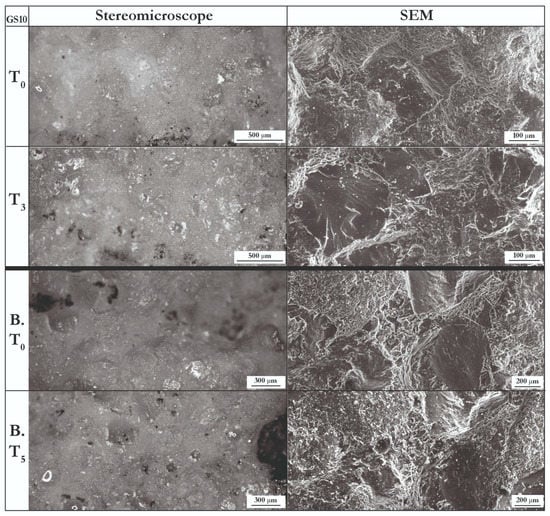

The tools used to treat ochre presented totally different patterns. The passive stone (GS10) was characterised by the levelling of the surface; the presence of broken grains and conchoidal fractures were visible already at low magnification (Figure 19). The active stone (M1) was also characterised by the levelling of the matrix and the rubbed appearance (Figure 20).

Figure 19.

GS10: moulds of the surfaces of the passive tool used to process ochre. Above: images of the same area of the used surface at T0 and T3 acquired via the stereomicroscope (on the left) and via SEM (on the right); Below: images of the same area of the bottom side of the tool (B., lying on the ground during processing) at T0 and T5 acquired via the stereomicroscope (on the left).

Figure 20.

M1: moulds of the active tool surface used to process ochre at T0 and T3. Left: the same area at T0 and T3 acquired via the stereomicroscope; Right: the same area at T0 and T3 acquired via SEM.

4. Conclusions

The described site-specific replicative experiments present a new protocol to record controlled proxies aiming at shedding light on the use-wear traces observed on the thirty-six sampled GSTs retrieved from cultural layer III of Brînzeni I, a leading site within the Prut River culture.

The raw materials available in the cave were petrographically characterised by means of thin sections and OM and SEM analysis. The original surface characteristics were crucially documented by our T0 (prior to use) and then we permanently recorded their modification after each cycle of usage (T1–T5). The appearance of specific use-related features was conveyed by the intensity and duration of use. Fixing parameters, such as length of use (duration) and amount of transformed media, allowed us to make an evaluation of the impact of the different media on use-wear development and a synchronic comparison of the surface modification across the tools.

The replicative experiment design unravelled qualitative and quantitative proxies for the recognition of analogue features on the archaeological GSTs. Although the human factor played a crucial role in our experimental design, an effort was made to standardise both the reference collection design and the documentation protocol based on parameters monitored at fixed times and at different scales, from macro (photogrammetry) to sub-micro (microscopy and profilometry). Our approach made the experimental design and the consistent documentation strategy preproducible []. Nonetheless, the outcome may differ since standardisation can be applied to machines but not to the creative and adjustable capacity distinctive of the human factor.

The use of stone tools is a destructive process that constantly modifies the surface texture and, to a certain extent, the stone geometry. Therefore, to document the qualitative and quantitative use-related patterns, 3D reconstructions and VPS moulds were taken at fixed and recurrent time intervals (T0 up to T5). These observations, along with those made at different scales, allowed us to “crystallize” the effects of wear on surface roughness over time. This way, the features are available for retrieving progressive deformation processes and for present and future comparisons. The site-specific reference collection also targeted the unused ventral surface of the passive stone. This approach disclosed useful details for an intelligent interpretation of certain wears observed on the archaeological GSTs, such as the effects of the blowing and recoiling imaged as the levelling of the matrix and the dulling of the crystals.

In all its complexity, our protocol is unprecedented as it allows analysts to monitor, permanently record, and ponder the usage biography/ies across the different stages of their mise en place through 3D models, moulds (physical copies), and different scales monitoring that permanently record the progressive depletion/modification occurring across the mechanical transformation to the stone surfaces. The use of pebble stones for processing plants opened the view on at least some of the perishable materials that were used and transformed by Homo sapiens; the GSTs are informative regarding our intangible knowledge of sapient gestures.

Author Contributions

Conceptualization, G.S.; Data curation, G.S.; Formal analysis, G.S., A.B. (petrography); Investigation, G.S.; Methodology, G.S., Resources, T.O., L.L., A.L.G. and G.S.; Supervision, L.L., A.L.G., M.P., and A.R.; Validation, A.L.G., L.L., M.P., and A.R., Visualization, G.S.; Writing—original draft, G.S.; Writing—review and editing, L.L. and G.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study is part of G.S. PhD research that has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 754511.

Data Availability Statement

The data presented in this study will be available upon request from the corresponding author starting from 2024. Please note that the data are currently not publicly available as they are part of G.S.’s ongoing PhD research, which has not yet been submitted.

Acknowledgments

The authors are grateful to the Scientific Laboratories of the Centro Conservazione e Restauro “La Venaria Reale” (Turin, Italy) and in particular to Anna Piccirillo for the access and support to the OM and SEM; to Federico Picollo and the PhD students of the group of Solid State Physics of the University of Turin for the access and support to their laboratory and stereomicroscope; and to Alessia Giordana for her support with RAMAN analysis. A special thanks for their contribution to the replicative experiment, goes to all the students that participated in the experimental archaeology workshop in October 2021 at the Physics Department of the University of Turin.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Revedin, A.; Aranguren, B.; Becattini, R.; Longo, L.; Mariotti Lippi, M.; Sinitsyn, A.A.; Skakun, N.; Spiridonova, E.A. 30,000 years old Flour: The oldest manufactured staple food. PNAS 2010, 107, 18815–18819. [Google Scholar] [CrossRef]

- De la Torre, I.; Benito-Calvo, I.; Arroyo, A.; Zupancich, A.; Proffitt, T. Experimental protocols for the study of battered stone anvils from Olduvai Gorge (Tanzania). J. Archaeol. Sci. 2013, 40, 313–332. [Google Scholar] [CrossRef]

- Caruana, M.V.; Carvalho, S.; Braun, D.R.; Presnyakova, D.; Haslam, M.; Archer, W.; Bobe, R.; Harris, J.W.K. Quantifying Traces of Tool Use: A Novel Morphometric Analysis of Damage Patterns on Percussive Tools. PLoS ONE 2014, 9, e113856. [Google Scholar] [CrossRef]

- Caricola, I.; Zupancich, A.; Moscone, D.; Mutri, G.; Falcucci, A.; Duches, R.; Duches, R.; Peresani, M.; Cristiani, C. An integrated method for understanding the function of macro-lithic tools. Use wear, 3D and spatial analyses of an Early Upper Palaeolithic assemblage from North Eastern Italy. PLoS ONE 2018, 13, e0207773. [Google Scholar] [CrossRef] [PubMed]

- Longo, L.; Altieri, S.; Birarda, G.; Cagnato, C.; Cefarin, N.; Graziani, V.; Obada, T.; Pantyukhina, I.; Ricci, P.; Skakun, N.; et al. A Multi-Dimensional Approach to Investigate Use-Related Biogenic Residues on Palaeolithic Ground Stone Tools. Environ. Archaeol. 2021. [Google Scholar] [CrossRef]

- Hayes, E.H.; Field, J.H.; Coster, A.C.F.; Fullagar, R.; Matheson, C.; Florin, S.A.; Nango, M.; Djandjomerr, D.; Marwick, B.; Wallis, L.A.; et al. Holocene grinding stones at Madjedbebe reveal the processing of starchy plant taxa and animal tissue. J. Archaeol. Sci. Rep. 2021, 35, 102754. [Google Scholar] [CrossRef]

- Hayes, E.H.; Fullagar, R.; Field, J.H.; Coster, A.C.F.; Matheson, C.; Nango, M.; Djandjomerr, D.; Marwick, B.; Wallis, L.A.; Smith, M.A.; et al. 65,000-years of continuous grinding stone use at Madjedbebe, Northern Australia. Sci. Rep. 2022, 12, 11747. [Google Scholar] [CrossRef]

- Paixão, E.; Marreiros, J.; Dubreuil, L.; Gneisinger, W.; Carver, G.; Prévost, M.; Zaidner, Y. Middle Paleolithic ground stones tools of Nesher Ramla unit V (Southern Levant): A multi-scale use-wear approach for assessing the assemblage functional variability. Quat. Int. 2022, 624, 94–106. [Google Scholar] [CrossRef]

- De Beaune, S. The invention of technology: Prehistory and cognition. Curr. Anthropol. 2004, 45, 139–162. [Google Scholar] [CrossRef]

- Longo, L.; Birarda, G.; Cagnato, C.; Badetti, E.; Covalenco, S.; Pantyukhina, I.; Skakun, N.; Vaccari, L.; Terekhina, V.; Sorrentino, G. Coupling the beams: How controlled extraction methods and FTIR-spectroscopy, OM and SEM reveal the grinding of starchy plants in the Pontic steppe 36,000 years ago. J. Archaeol. Sci. Rep. 2022, 41, 103333. [Google Scholar] [CrossRef]

- Coles, J. A theory. In Experimental Archaeology; Coles, J., Ed.; Academic Press: London, UK, 1979; pp. 1–7. [Google Scholar]

- Adams, J.L. Understanding grinding technology through experimentation. In Designing Experimental Research in Archaeology: Examining Technology through Production and Use; Ferguson, J.R., Ed.; University Press of Colorado: Boulder, CO, USA, 2010; pp. 129–151. [Google Scholar]

- Noiret, P.; Brynzeni, I. Le Paléolithique Supérieur de la Moldavie; Noiret, P., Ed.; Presses Universitaires de Liège: Liège, Belgium, 2009; pp. 425–470. [Google Scholar]

- Noiret, P.; Otte, M. Aurignacian and Gravettian occupations in Eastern Europe between 33,000 and 23,000 uncal BP. In Proceedings of the OIS 3 Conference, Brno, Czech Republic, 15–17 May 2010. [Google Scholar]

- Allsworth-Jones, P.; Borziac, I.A.; Chetraru, N.A.; French, C.A.I.; Medyanik, S.I. Brînzeni: A Multidisciplinary Study of an Upper Palaeolithic site in Moldova. Proc. Prehist. Soc. 2018, 84, 41–76. [Google Scholar] [CrossRef]

- Aranguren, B.M.; Longo, L.; Lunardi, A.; Revedin, A. Wear Traces, experimental archaeology and ethnoarchaeology: An integrated analysis of the Gravettian implements from the site of Bilancino (Tuscany, Italy). In Proceedings of the International Conference “Prehistoric Technology” 40 years later: Functional Studies and the Russian Legacy, Verona, Italy, 20–23 April 2005; pp. 121–130. [Google Scholar]

- Dubreuil, L.; Savage, D.; Delgado-Raack, S.; Plisson, H.; Stephenson, B.; De La Torre, I. Current analytical frameworks for studies of use–Wear on ground stone tools. In Use-Wear and Residue Analysis in Archaeology; Marreiros, J.M., Juan, F., Bao, G., Ferreira Bicho, N., Eds.; Springer: Cham, Switzerland, 2015; pp. 105–158. [Google Scholar]

- Lunardi, A. Studio tecno-funzionale degli strumenti in pietra per una ricostruzione del contesto socio-economico della Cultura dei vasi a bocca quadrata. L’esempio delle comunità di Fimon, Quinzano e Rivoli. Ph.D. Thesis, University of Siena, Siena, Italy, 2009. [Google Scholar]

- Adams, J.L.; Delgado-Raack, S.; Dubreuil, L.; Hamon, C.; Plisson, H.; Risch, R. Functional analysis of macro-lithic artefacts: A focus on working surface. In Non-Flint Raw Material use in Prehistory Old Prejudices and New Direction; Proceedings of UISPP Congress, Lisbon, Portugal, 4-9 September 2006; Sternke, F., Eigeland, L., Laurent-Jacques, C., Eds.; BAR-IS: Oxford, UK, 2009; pp. 43–66. ISBN 9781407307824. [Google Scholar]

- Outram, A.K. Introduction to experimental archeology. World Archaeol. 2008, 40, 1–6. [Google Scholar] [CrossRef]

- Eren, M.; Lycett, S.; Patten, R.; Buchanan, B.; Pargeter, J.; O’Brien, M. Test, model, and method validation: The role of experimental stone artifact replication in hypothesis-driven archeology. Ethnoarchaeology 2016, 8, 103–136. [Google Scholar] [CrossRef]

- Bamforth, D.B. Conducting experimental research as a basis for microwear analysis. In Designing Experimental Research in Archaeology, Examining Technology through Production and Use; Ferguson, J.R., Ed.; University Press of Colorado: Boulder, CO, USA, 2010; pp. 93–109. [Google Scholar]

- Marsh, E.J.; Jeffrey, R.F. Introduction. In Designing Experimental Research in Archaeology, Examining Technology through Production and Use; Ferguson, J.R., Ed.; University Press of Colorado: Boulder, CO, USA, 2010; pp. 1–12. [Google Scholar]

- Astruc, L.; Vargiolu, R.; Zahouani, H. Wear assessments of prehistoric instruments. Wear 2003, 255, 341–347. [Google Scholar] [CrossRef]

- Calandra, I.; Gneisinger, W.; Marreiros, J. A versatile mechanized setup for controlled experiments in archeology. Sci. Technol. Archaeol. Res. 2020, 6, 30–40. [Google Scholar] [CrossRef]

- Marreiros, J.; Calandra, I.; Gneisinger, W.; Paixão, E.; Pedergnana, A.; Schunk, L. Rethinking Use-Wear Analysis and Experimentation as Applied to the Study of Past Hominin Tool Use. J. Paleo Arch. 2020, 3, 475–502. [Google Scholar] [CrossRef]

- Paixão, E.; Pedergnana, A.; Marreiros, J.; Dubreuil, L.; Prévost, M.; Zaidner, Y.; Carver, G.; Gneisinger, W. Using mechanical experiments to study ground stone tool use: Exploring the formation of percussive and grinding wear traces on limestone tools. J. Archaeol. Sci. Rep. 2021, 37, 102971. [Google Scholar] [CrossRef]

- Delgado-Raack, S.; Gómez-Gras, D.; Risch, R. The mechanical properties of macrolithic artifacts: A methodological background for functional analysis. J. Archaeol. Sci. 2009, 36, 1823–1831. [Google Scholar] [CrossRef]

- Hayes, E.; Pardoe, C.; Fullagar, R. Sandstone grinding/pounding tools: Use-trace reference libraries and Australian archaeological applications. J. Archaeol. Sci. Rep. 2018, 20, 97–114. [Google Scholar] [CrossRef]

- Zupancich, A.; Mutri, G.; Caricola, I.; Carra, M.L.; Radini, A.; Cristiani, E. The application of 3D modeling and spatial analysis in the study of groundstones used in wild plants processing. Archaeol. Anthropol. Sci. 2019, 11, 4801–4827. [Google Scholar] [CrossRef]

- Arroyo, A.; Hirata, S.; Matsuzawa, T.; de la Torre, I. Nut cracking tools used by captive chimpanzees (pan troglodytes) and their comparison with early stone age percussive artefacts from Olduvai Gorge. PLoS ONE 2016, 11, e0166788. [Google Scholar] [CrossRef]

- Benito-Calvo, A.; Crittenden, A.N.; Livengood, S.V.; Sánchez-Romero, L.; Martínez-Fernández, A.; de la Torre, I.; Pante, M. 3D 360° surface morphometric analysis of pounding stone tools used by Hadza foragers of Tanzania: A new methodological approach for studying percussive stone artefacts. J. Archaeol. Sci. Rep. 2018, 20, 611–621. [Google Scholar] [CrossRef]

- Arroyo, A.; de la Torre, I. Pitted stones in the Acheulean from Olduvai Gorge Beds III and IV (Tanzania): A use-wear and 3D approach. J. Hum. Evol. 2020, 145, 102837. [Google Scholar] [CrossRef]

- Cristiani, E.; Zupancich, A. Sandstone Ground Stone Technology: A Multi-level Use Wear and Residue Approach to Investigate the Function of Pounding and Grinding Tools. J. Archaeol. 2020, 28, 704–735. [Google Scholar] [CrossRef]

- Zupancich, A.; Cristiani, E. Functional analysis of sandstone ground stone tools: Arguments for a qualitative and quantitative synergetic approach. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Tringham, R.; Cooper, G.; Odell, G.; Voytek, B.; Whitman, A. Experimentation in the Formation of Edge Damage: A New Approach to Lithic Analysis. J. Field Archaeol. 1974, 1, 171–196. [Google Scholar]

- Brink, J.W. The role of abrasives in the formation of lithic use-wear. J. Archaeol. Sci. 1978, 5, 363–371. [Google Scholar] [CrossRef]

- Fullagar, R.L.K. The role of silica in polish formation. J. Archaeol. Sci. 1991, 18, 1–24. [Google Scholar] [CrossRef]

- Lerner, H. Digital image analysis and use-wear accrual as a function of raw material: An example from Northwestern New Mexico. Lithic Technol. 2007, 32, 51–67. [Google Scholar] [CrossRef]

- Ollé, A.; Vergès, J.M. The use of sequential experiments and SEM in documenting stone tool microwear. J. Archaeol. Sci. 2014, 48, 60–72. [Google Scholar] [CrossRef]

- Pedergnana, A.; Ollé, A. Monitoring and interpreting the use-wear formation processes on quartzite flakes through sequential experiments. Quat. Int. 2017, 427, 35–65. [Google Scholar] [CrossRef]

- Calandra, I.; Schunk, L.; Rodriguez, A.; Gneisinger, W.; Pedergnana, A.; Paixão, E.; Pereira, T.; Iovita, R.; Marreiros, J. Back to the edge: Relative coordinate system for use-wear analysis. Archaeol. Anthropol. Sci. 2019, 11, 5937–5948. [Google Scholar] [CrossRef]