1. Introduction

The historic built heritage consists in part of listed buildings that are in a state of decay, neglect, or have poor maintenance conditions [

1,

2,

3,

4]. The rehabilitation of this heritage is one of the objectives of European directives [

5,

6], implemented at the national level through specific implementing regulations. Given that the construction sector is responsible for a significant environmental impact, interventions must not only be sustainable on time, but must also be able to promote virtuous mechanisms in the territory. It is necessary to act by considering the entire life cycle of both the building and its constituent materials/components. In the case of life cycles after the first, the place of “supply and extraction of materials” becomes the demolition site, the proper management of which is therefore fundamental in order to ensure the sustainability of the entire process. In Europe, there are functional processes to ensure a quality demolition process, with indication of the pre-demolition phases, the waste management plan, the execution phase and the post-demolition verification phase. In the waste management phase, the flows to be followed for delivery to end-of-life scenarios are indicated but no indication is given regarding functional tracking for reuse [

7,

8,

9].

Various scientific researches have demonstrated the close relationship between the retrofit/redevelopment of built heritage and environmental sustainability [

10,

11,

12,

13,

14,

15,

16,

17]. Many studies refer to energy and structural retrofitting, with the main objective of improving performance compatibly with the protection of values [

18]: Jiang et al. propose multi-objective analysis where energy consumption, greenhouse gas emissions (GGE) and life cycle cost (LCC) are estimated and compared through comprehensive multi-objective (energy savings, low-carbon and economy) comparison methods [

19]; Buda et al., by analyzing the European Standard EN 16883:2017, suggest existing computer-based tools for evaluating specific retrofit solutions for individual application cases with the aim of bridging the regulatory gaps [

20]; Okutan presents a socio-mathematical approach, based on Pareto front, to address the conflict between conservation perception and energy retrofit [

21].

On the other hand, while retrofit studies focus on the performance of the product, other studies pose the problem of which values to protect in a sustainable refurbishment [

22]. If the charter of Burra and Venice [

23,

24] suggest the policy of minimal interventions, the need for energy improvement imposed by European actions [

5,

6] seeks the balance between conservation and innovation [

21,

25,

26,

27,

28,

29,

30,

31], but it is oriented towards a deeper improvement of assets [

30]. For this purpose, speaking generically of values is no longer enough: in-depth studies, classifications, categorizations of historical materials and components are needed [

32,

33,

34,

35,

36].

However, the aspect of environmental sustainability of refurbishment must be addressed from a global point of view, including the analysis of the improvement of the thermal characteristics of the building envelope, but not limiting to them. In fact, numerous studies contextualize the reuse and recovery of architectural heritage in the analysis of circular economy and life cycle [

37,

38,

39]. Interesting results have been seen in the life cycle assessment of building components, materials, structural elements [

40,

41]: these studies confirm the need to redefine the processes of the recovery site in order to guarantee the possibility of reusing the original materials in the redevelopment process. The original material must be preserved in order to maintain the historical value of the built heritage or monument, but when there are not proper structural and safety conditions and must be removed from its original position, it is necessary to identify virtuous processes such as to safeguard its historical and artistic value or performance, considering also the aesthetic dimension of built heritage rehabilitation.

The new European directive aims to achieve the goal of climate neutrality by 2050, as envisioned by the Green Deal, and in March 2022 it proposed a package that includes an action plan dedicated to the circular economy to reduce waste and make products more sustainable. There is to be a shift from a “produce-use-waste” type of society to a vision that contemplates an additional step: “produce-use-waste-reuse”. One of the key issues in the field relates precisely to the Building Materials Regulation and new European-level rules on packaging, which will have to be legibly labelled and incentivize reuse and recycling [

42].

The analysis of the bibliography returns the existence of databases aimed at tracking the life of the building and the materials/components that are placed ex novo in the building. However, there are no databases that contemplate specific information pertaining to valuable historic components/materials and provide information regarding the previous life cycle, and residual and potential performance of the same. The life of the building and the materials/components represents valuable information because it allows us to identify how they have responded to specific boundary conditions related to land events, climate and the way the building has been used. In addition, the possibility of reuse of valuable components also has a symbolic value. One thinks of the reuse of materials/components that became widespread in the Roman Empire in the IV–V centuries AD due to both the difficulty of finding raw materials and the symbolic value that certain components took on.

The objective of the research is, therefore, to identify a path for the sustainable on-site management of valuable materials in the rehabilitation of the built heritage and apply it to an experimental case study in the territory of L’Aquila, through collaboration with a construction company that is intervening in post-seismic reconstruction.

3. Analysis of Methodological Frame

3.1. Knowledge of Material Performance through Building History

Knowing the history of the building makes it possible to obtain information useful for identifying the materials that will result from selective demolition and parallelly identifying their characteristics. Therefore, the historical evolution of the building should be analysed, its evolutionary stages identified, and the materials and construction techniques related to it. A distinction should be made between the incongruous evolutionary phases that, for that reason, can be entirely demolished, generating waste materials [

43] and the valuable phases that, on the other hand, should be safeguarded by using materials compatible with them in order to reconstitute their symbolic value. Knowledge of the building’s construction history also allows for the identification of traditional construction techniques related to local materials, emphasizing the need to also enhance the intangible heritage related to craftsmanship or the specificity of certain production processes linked to the territory. Exceptional events (e.g., earthquakes or floods) that have occurred in a given place must also be analysed and how a given building system and its functional layers have allowed for the survival or caused the collapse of a part or the entire building.

The proposed method provides information from previous uses of the material and therefore already related to the way the material has been used in a given environment (indoor or outdoor) and climate. This information when using new materials is not available, it can only be assumed with respect to technical characteristics. In the case of reused materials, on the other hand, it is proven and substantiated by their history. Therefore, it is possible to use this additional information to choose a use in the subsequent life cycle that optimises the performance of the component also with respect to context conditions (weather conditions, geological setting, etc.).

Further analysis should be carried out by correlating the climate of the building location and how a specific component is used. The standardization of components due to industrial processes and related quality control allows the performance compliance of the material in a given context. In the case of historical value elements, the presence of a handcrafted production process and empirical, non-scientific quality control generates a predictive impossibility from a performance point of view, which can be overcome by analysis of the building’s previous life cycles. The craftsmanship of the component produces the uniqueness of the part of which, through the analysis of its history, performance information can be obtained. Think, for example, of the frost resistance of a handmade tile in the early 1900s in a harsh winter climate. Similarly, think of the moisture resistance of a wooden element used in roofing, traditionally cut and seasoned according to lunar cycles, whose history, as an anisotropic material, allows us to identify the compatible use class [

44].

Knowing the history of the material and the performance it has achieved also allows us to know the residual and potential performance that is functional for effective reuse. The demolition of the building should therefore be done selectively with attention to the integrity of valuable materials that have been identified as potentially reusable. In fact, it is integrity that allows for expanding the reuse possibilities of the component by optimizing its potential performance. The information derived from the analysis of the material/component’s history and that relating to the way in which it was put into use from a constructional point of view should be noted in the material’s identity card (Material’s ID). It is noteworthy that no other methods on the reuse have been codified before; on the contrary, there are a lot of generic recommendations on the reuse of valuable components, without explaining how and without tracing the information present in the life cycle of the specific material. On the contrary, the approach described in this work allows for the acquisition and storage of relevant material data. Therefore, the material’s ID is also useful for LCA, providing information that makes it possible to assess the impact of each phase of the life cycle of the material based on solid data from direct surveys (primary data), updating the currently used LCA calculation method which is based on international databases (secondary data).

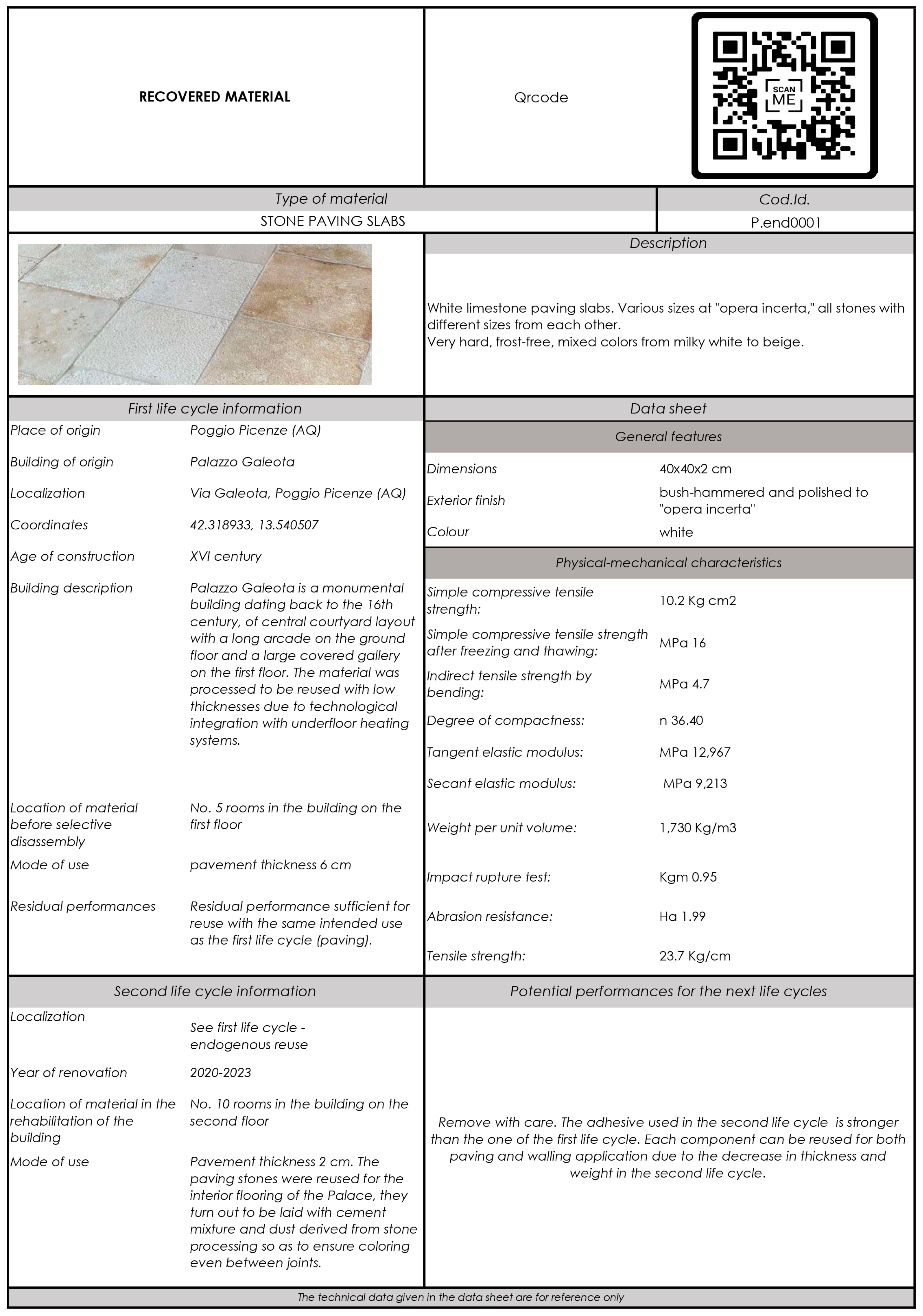

3.2. Material’s ID

An important step in the methodological process is the material cataloguing phase, which contemplates the populating of a database containing salvage materials open to practitioners in the area, which can be implemented at each selective demolition. Cataloguing presents as output a list of uniquely identified materials/components. With this code, it is possible to proceed to the traceability of each material/component, which makes it possible to identify its location over time, from its production or reuse to its final destination. In order to be able to track the activity status of the product, it is necessary for it to have an identification code associated with a “dynamic” data sheet, updated “n times” according to the use of the same material until its disposal.

Newly applied materials can be distinguished, with products that have diverted from the normal distribution chain.

Each material will be accompanied by an alphanumeric code to enable the acquisition of useful information for environmental impact verification: each code will be associated with the past and present location, mode of use, kilometres travelled, years of life, type of use, and residual and potential performance. In the material’s ID, all data related to the material of both a descriptive and technical nature are entered in order to identify new performance and possible future applications (

Figure 2).

A change in the boundary conditions of the material will correspond to an update of the material’s ID or associated information. The material’s ID is thus a dynamic document that evolves in parallel with the passage of the component’s life. Traceability will make it possible to create a database of timely information, overcoming the problem of finding material life cycle data, the main cause of often approximate LCA assessments. The process will be implemented through an online digital platform, accessible and usable by each partner within a network dedicated to the exchange of information and resources. This is a harvest map of the territory optimized in order to provide information not only on the current location of the component and how it is used, but capable of tracing the history of each component and consequently facilitating its reuse in subsequent cycles.

The possibility of associating a dynamic and updatable QR code with the product’s material’s ID as it is reused and reclassified facilitates the consultation of information through an online platform containing zero-mile materials used or usable by the construction supply chain.

This platform is integrated as part of the use of innovative technological systems such as building BIM models (or HBIM) that enable the identification of structures and components used in the implementation of the intervention, increasing transparency and cooperation between actors.

3.3. Endogenous Reuse and Exogenous Reuse

The material’s ID provides information needed to assess whether the component has the characteristics (material, technological and performance) to be reused in the redevelopment site of the same building in which it has already experienced its last life cycle [

45]. If it is compatible, a zero-meter reuse, called endogenous reuse, is configured. Compatibility is conditioned not only by the characteristics of the component, but also by the type and timing of the reconditioning work that can be carried out on site in order to achieve the performance necessary to meet the design requirements. Thus, knowledge of the component (ensured by the functional analyses for the drafting of the material’s ID) and a consequent detailed analysis of the workings that can be carried out in situ with an indication of the advantages/disadvantages with respect to the achievement of certain performances is necessary. An assessment that puts on the environmental and economic scales the advantage derived from reuse with the burdens (time and cost) is required for reconditioning operations. Such work, therefore, must be considered within the work schedule as an integral part of the building redevelopment process. In this way, congruence will be possible between the time schedule of works as scheduled and that actually executed, with assurance in terms of the quality of the result and certainty of time and cost for both the client and the contractor.

Otherwise, if the component is not compatible for endogenous reuse, compatibility for reuse at a redevelopment site located in a local dimension [

46] may be assessed through exogenous reuse [

45]; this is to ensure that the environmental and economic benefit from reuse is marred by the incidence of transportation. In the time between the selective demolition phase and the exogenous reuse phase, components will need to be temporarily stored under conditions that ensure that their performance is maintained. To this end, the creation of a local digital network for the exchange of materials, aimed at increasing the chances of reuse by reducing the time spent in temporary storage, is of paramount importance. The temporary storage stay, in fact, should not exceed the estimated time of six months, in order not to burden the construction operator with long-term storage (with consequent difficulties, including logistical ones), which could turn into a deterrent to voluntary exogenous reuse processes.

The reuse of a material/component is a sustainable operation in itself. In order not to compromise this sustainability, the intervention on the building in which the component is reused must also be done according to sustainability parameters. The reuse project, whether exogenous or endogenous, must therefore start from locally available materials and support its choices on the information provided by the material’s ID. It follows that, following the definition of reuse patterns, the material’s ID should be updated.

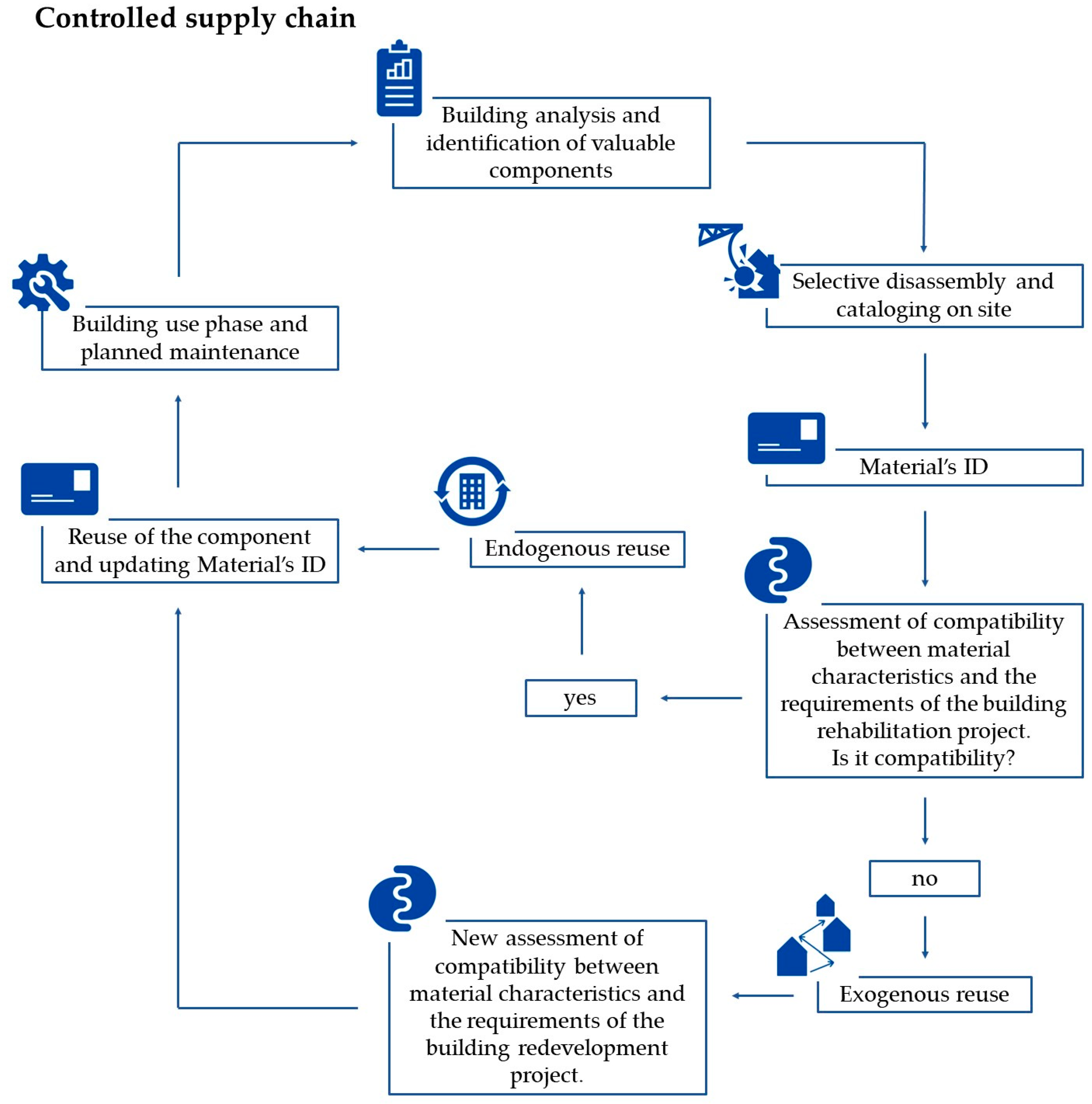

3.4. Controlled Supply Chain

Some materials removed during the execution of works from their original location can be repositioned or acquire a new location “zero meter” within the same building; for others it is necessary to make different assessments so that we equally have the objective of a new, more sustainable construction mode intended to reduce environmental impact, but also to use materials compatible with the territory in which they are reused.

It is in this direction that certain paradigms of the construction sector are modified, facilitating technological evolutions and circular economy, enhancing the territory through the concept of “short supply chain”.

Some circularity strategies can be applied in the construction industry:

to apply solutions to regenerate resources;

to maintain and protect what is realized;

to use waste as a resource;

to think about a new model of construction;

to incorporate digital technologies;

to collaborate to add value.

The last point holistically embraces a series of activities that cover the entire life cycle of the building. In order to have continuous monitoring of a building and an exact snapshot of its current state, an essential tool, already referred to in the previous paragraphs, turns out to be the BIM model, through which different parties with different skills can interact remotely and enter technological updates but also all the constructive and material information of the building. The application of technological elements to increase the level of instantaneousness in readings and data retrieval results in the basis of this type of approach.

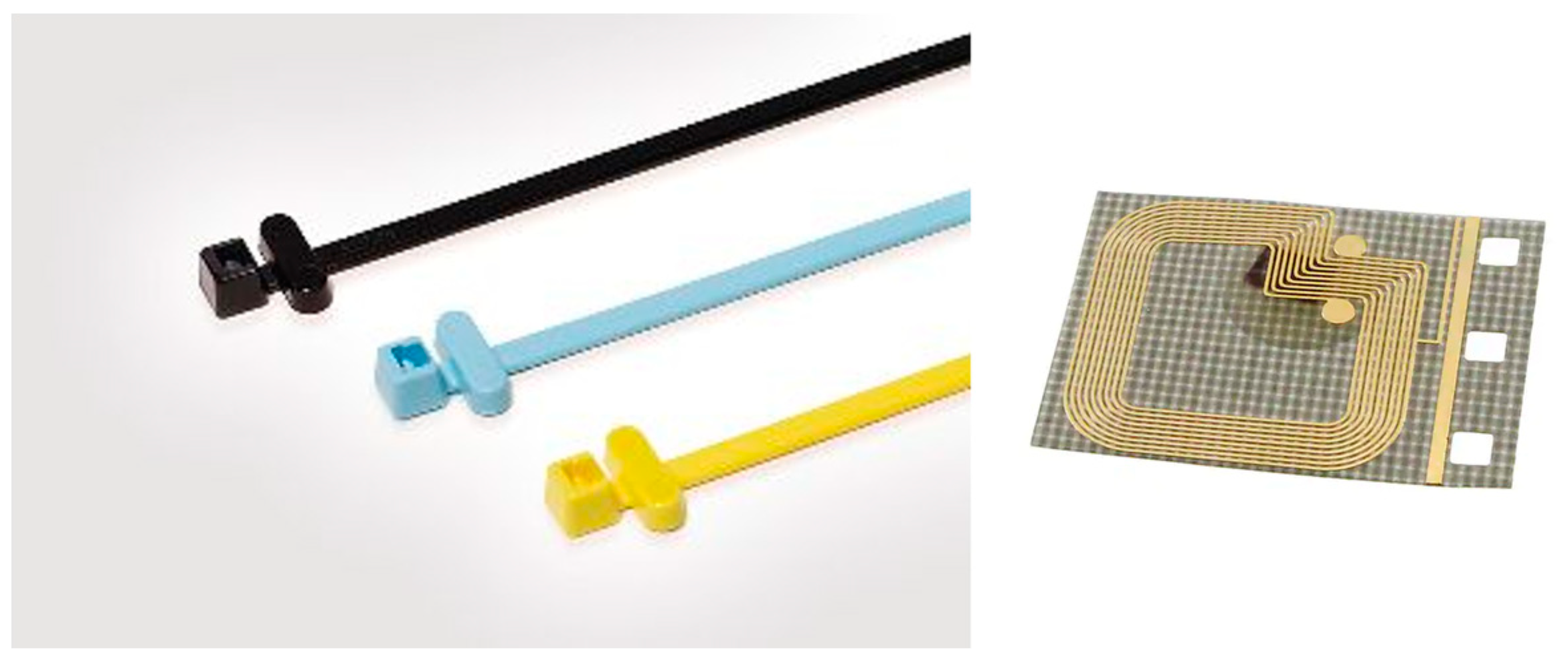

The digital tools that can address this need may be different depending on the purpose of use. In fact, while the QR code can be a dynamic device in updating data and data sheets, it is not a suitable system if one wants to “communicate” with the product remotely, since reading it must be done through an electronic device. There are other technologies on the market, including RFID and RTLS, which use radio waves to automatically identify objects with a transmission of information through electromagnetic waves (

Figure 3) [

47]. The use of transponders equipped with these technologies, which can also be applied through metal bands, makes it possible to have a unique product identification code by automatically creating and managing a product inventory.

Such technologies can implement QR code readings, if the material to be tracked involves use that is exogenous from the worksite of origin, as they allow an object with a tag to be remotely identified and tracked.

The aim is to build a true digital product passport, with the goal of extending the life expectancy of all supply chain products.

4. A Case Study at L’Aquila

The city of L’Aquila and surrounding areas are affected by the reconstruction and redevelopment of the built heritage following the 2009 earthquake. This is the largest open-air construction site in Europe [

48] that from 2009 to date has involved a number of interventions with 97% related to the City of L’Aquila [

49], while for the municipalities of the crater, the result is 46% of private buildings being rebuilt [

49]. Among these, about 30% concern buildings characterized by historical, artistic or symbolic value and therefore subject to constraint. Exceptional conditions due to the earthquake generated “atypical” waste, i.e., valuable materials/components that under ordinary conditions were not present in the area because they belonged to listed buildings. In particular, the collapses resulting from the earthquake and the need to intervene sometimes with partial demolitions functional to securing the building have returned significant amounts of valuable components (such as hand-formed roof tiles, hand-formed solid bricks, wooden elements, stones, stone pavements and ceramics). For such elements, Italian legislation [

50,

51] provides for the possibility of reuse. A reuse, however, is not compulsory, but linked to the will of the company, having the same as an alternative the possibility of storing such materials in storage or providing for their disposal. Moreover, no specific process has been defined for the reuse of such materials, such as to enhance the information that the component’s history has provided. In this context, therefore, the use of strategies for the sustainable management of materials in the post-seismic reconstruction site is a relevant field of application not only for the purpose of verifying its reliability, but also for the positive repercussions it can have on the territory, given the large number of valuable materials available.

Now, 14 years after the 2009 earthquake, in many historic buildings undergoing post-earthquake reconstruction, materials coeval with the building such as flooring (Venetian tiles, terrazzo tiles, paving stones) sanitary ware, stone elements, wood, etc., removed to allow for structural work, have been reused in a minimal percentage compared to the actual possibility of recovery. This happened because cataloguing, cleaning and relocation are often additional burdens that slow down the execution of works, together with the work required to adapt the ancient material to the new technological needs of the building. This aspect is controversial if one thinks of a general approach of the interventions also regulated by a reconstruction plan that could have already provided in the design phase, a system of communication of the different construction sites in order to put in place all the necessary circularity procedures so that, precisely in a place that has for years been called the largest construction site in Europe, a good practice of “circular reconstruction” could be developed where materials no longer suitable for one building, could be in accordance with the needs of application on other property under reconstruction within the same earthquake crater.

The case in question refers to an intervention following the earthquake of 6 April, 2009, in L’Aquila. The method applied in this case involves the creation of a territorial laboratory as an incubator for all the recovery materials to be sorted in the various post-earthquake construction sites. This laboratory could be managed by the special offices for reconstruction (USRA and USRC) which represent a hub linking the designers and the contractors (

Figure 4). The designers will have to enter the preliminary technical data sheets of the recycled materials which are subsequently implemented by the company on the basis of the as built and finally the technical data will have to be tested and entered in the laboratory in order to certify the material for subsequent use in other reconstruction buildings. All information on materials must be available on a platform open to sector operators.

The following is an experimental application case of the circular process to illustrate and confirm its validity. The intervention concerns the redevelopment of a building of historical monumental character, named “Palazzo Galeota”, located in Galeota Street and pertaining to the noble family of the same name, in the Municipality of Poggio Picenze in the Province of L’Aquila (

Figure 5).

It is a building of considerable size and monumental appearance and is a good example of 19th-century renovation dating back to the 16th century. It has a central courtyard layout with a long portico on the ground floor and a large, covered gallery on the first floor. Some cornices and window brackets are visible on the facades. The main elevation shows a very high main floor with a large portal, 19th century, flanked by smooth pilasters, set to a severe linearity and characterized by sober architectural decoration.

Above, well-spaced out, are classic windows of slender proportions protected by a simple wooden eave overhang. The facade to the side presents a peculiar balance between solids and voids and expresses a restful sense of measured monumental will: it consists of a ground floor, a first floor and a second floor, on which, as an enrichment in the vast plastered wall, the fine framing of windows of the classical type with flat frieze and corbels supporting the balconies stand out. Picturesque and vaguely scenic is the spacious courtyard, co-equal to a cozy and refined environment with a portico on the ground floor and a loggia on the upper floor. The interior preciously preserves the decorative elements as well as the original plan layout.

Palazzo Galeota has exposed cantonments, differentiated decorations for each order of windows, an upper frieze and a wooden roof; on the main facade, there is an important stone frieze on the entrance portal that surmounts two molded jambs.

Inside in the entrance hall, there is a stone well characterizing the building, under which there is a cistern communicating with the cellar in which large ancient wine barrels are stored. Communicating with the underground cellar is a room probably used as a prison, as it is closed by an iron gate.

On the upper floors, there are fine terracotta floors, decorated cement tiles and in two rooms, central Venetian decorations. The lower floors also feature paving stones and cobblestone pavements. The stairs are also topped by stone steps (

Figure 6).

The palace enclosure walls also represent the ancient city wall, on which the ancient fountain from which the aggregate takes its name (“Fonte Sant’Anna”) stands (

Figure 7).

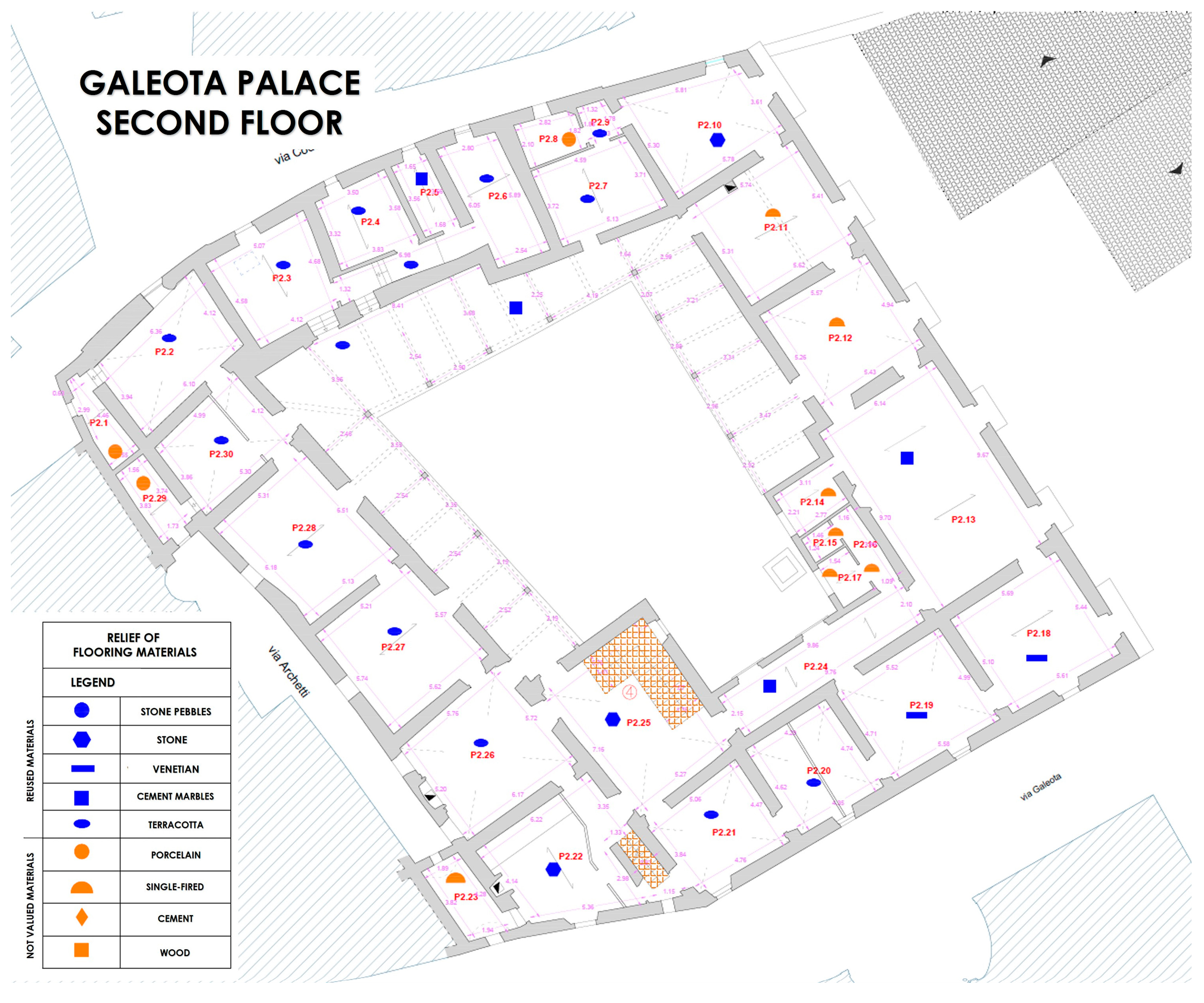

Already in the design phase, an analysis of the existing pavements was carried out with a hypothesis of intervention on each type to be safeguarded, as in the plan in

Figure 8.

The building underwent a recovery intervention with seismic improvement following the damage suffered by the earthquake. In particular, the following structural interventions were carried out which led to the consequent refurbishment of all systems and finishing works:

- −

Complete makeover of the wooden roof;

- −

Consolidation of the vaults with carbon fiber tapes;

- −

Consolidation of the walls with fiberglass mesh and metal connectors.

The interventions involved the removal of plaster and existing technical systems and the removal of all flooring to allow for the consolidation of the walls and floors.

Figure 8 shows the mapping of the floors in order to identify the valuable floors to be recovered. The floors that have been removed and reassembled inside the same building are stone pavers, terracotta, Venetian, marble and stone pebbles. The remaining part of the flooring was removed and replaced with a new material.

During the execution of the work, the removed pavements were catalogued and stacked in order to make an executive design of the new constructions.

One type of paving that required more careful design is related to local white stone paving slabs. This material is about 6 cm thick. This pavement was removed to allow for the consolidation of the vaults underneath with the subsequent installation of an underfloor radiant panel heating system (

Figure 9,

Figure 10 and

Figure 11).

As part of the selective removal of the reclaimed material, which was subsequently stacked in the inner courtyard of the Palace, it was necessary to catalogue and reclassify it through a process of reducing the thickness from 6 cm to 2 cm, with additional material to be used on other rooms of the same building as well, in order to obtain adequate thicknesses of the flooring compatible with the new walking plazas, using materials coeval with the building with endogenous recovery (

Figure 9 and

Figure 10).

The information inherent in the first life cycle of white stone paving slabs and how each paving component was processed and reused and was entered into the material’s ID; the information is available by scanning the QR code (

Figure 11). To enable the proper application of circularity criteria, a proper regulatory and economic approach cannot be ignored. The former should also provide for dictates in the form of protocols, indicating the procedures to be followed in order to proceed to a proper selective removal and cataloguing of materials; the latter should provide for a rating system that can turn into an economic as well as a social incentive, in applying these protocols with the aim of accelerating the green transition with incisive measures and with more sustainable models construction and reconstruction.

5. Conclusions

The approach described, also illustrated through an experimental case, can trigger virtuous processes from an environmental, economic and social point of view. Indeed, the safeguarding of materials makes it possible to optimize the grey energy incorporated in them by reducing the environmental impact due to the extraction of raw materials, the processing of materials and their installation, while reducing the incidence of the impact of transportation. From an economic point of view, it represents an advantage for industry players who avoid temporary site storage costs, landfill costs and the cost of sourcing new material. At the same time, such an approach promotes the specialization of construction operators in the reuse of valuable materials/components, linked to traditional supply chains and craftsmanship, the knowledge of which is part of the intangible heritage of the area, partly forgotten with the use of globalization-related materials, techniques and technologies. The validation through experimentation at a reconstruction site in the L’Aquila area demonstrated the usefulness of this approach and at the same time made it possible to introduce an innovative process in the territory, raising awareness among those working in the sector of the value of choices that have environmental and economic advantages, strongly linked to the historical moment that a given place experiences. A knowledge that is therefore representative of the territory and that is transformed into the flywheel of new circular economies.

On the other hand, the acquisition and storage of such a large amount of data on equally numerous materials and components represents a risk for the management of the amount of information to be synthesized in order to be effectively used. Therefore, a future development of the research will consist in the definition of a data control and management method that can represent the potential of the material in the reuse phases, allowing it to be categorized and standardized on the basis of synthetic indicators to be related to the new use.