Understanding the Char-Bending Technique in Shipwreck Planks

Abstract

:1. Introduction

1.1. Ancient Written Evidence

1.2. Shipwreck Evidence

1.3. Modern Evidence (20th–21st Centuries)

2. Materials and Methods

3. Methodology

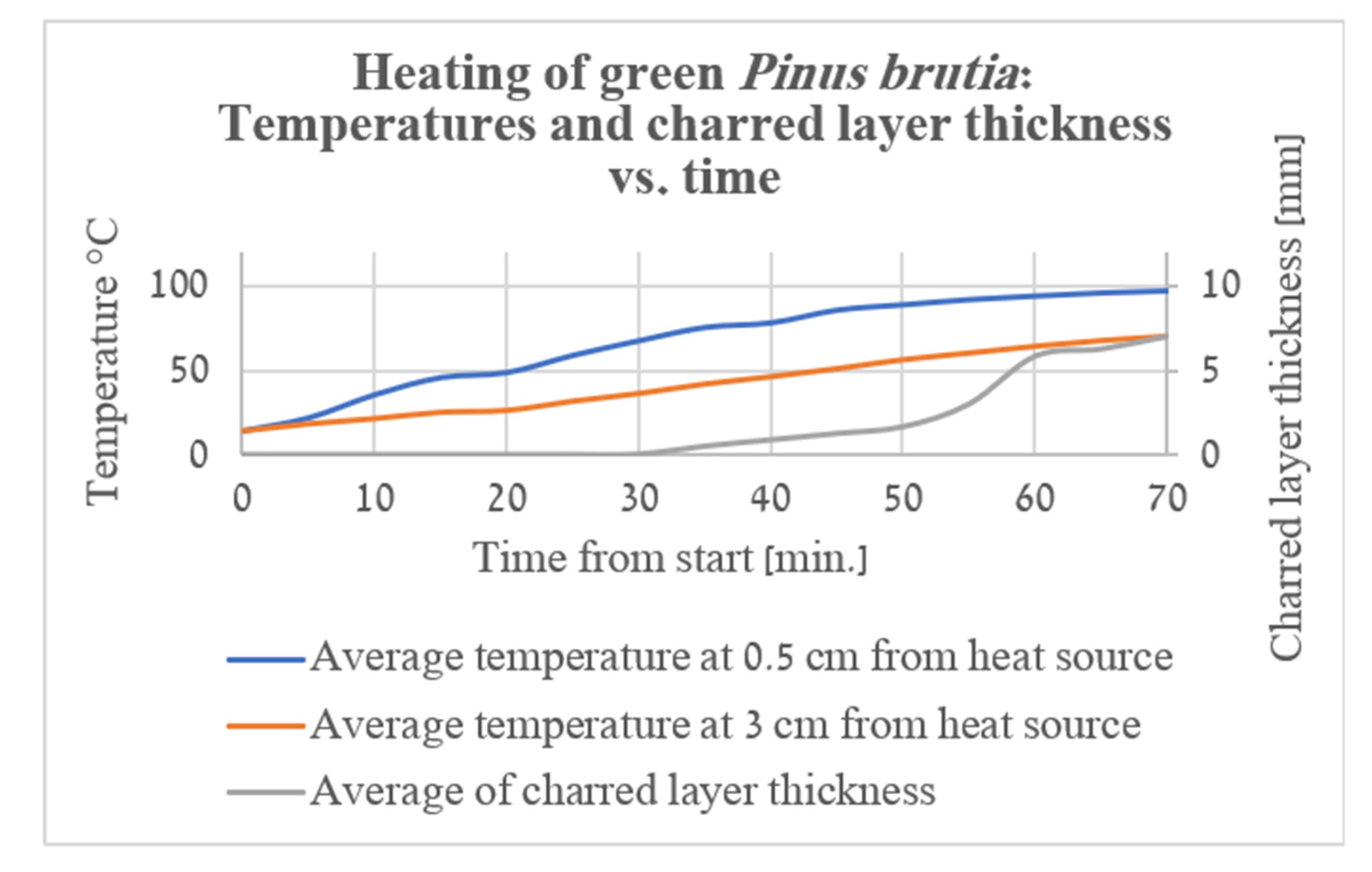

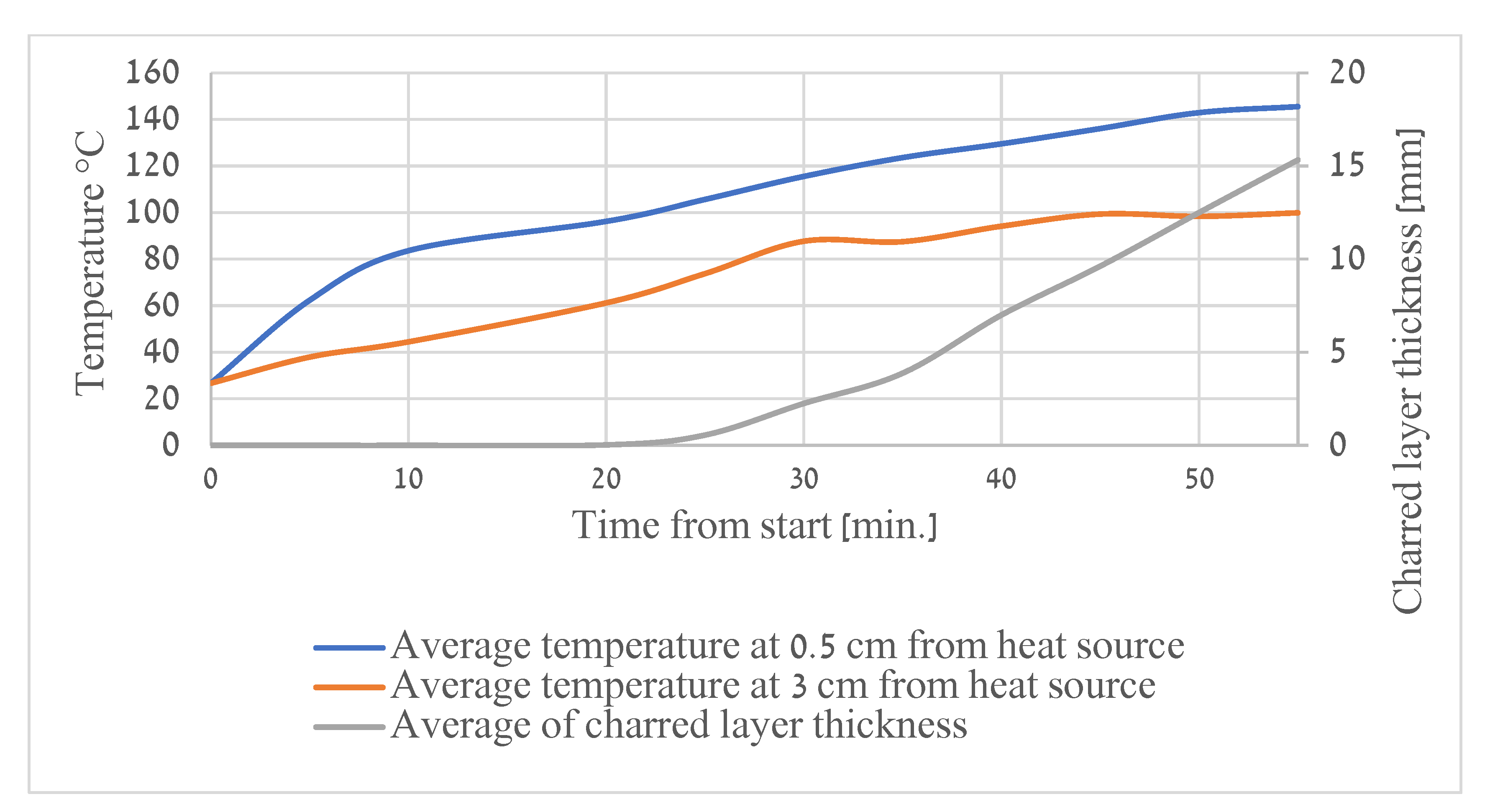

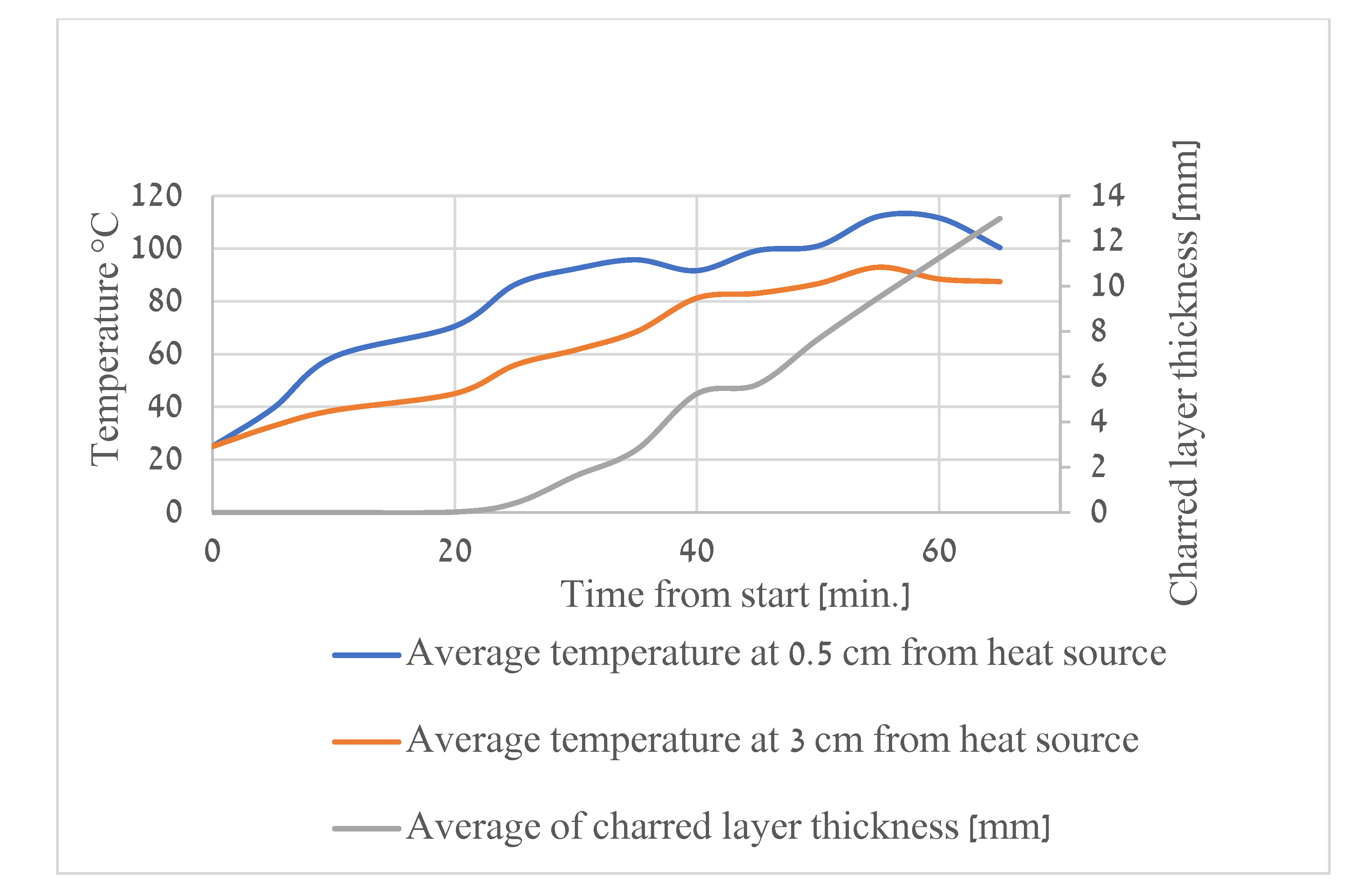

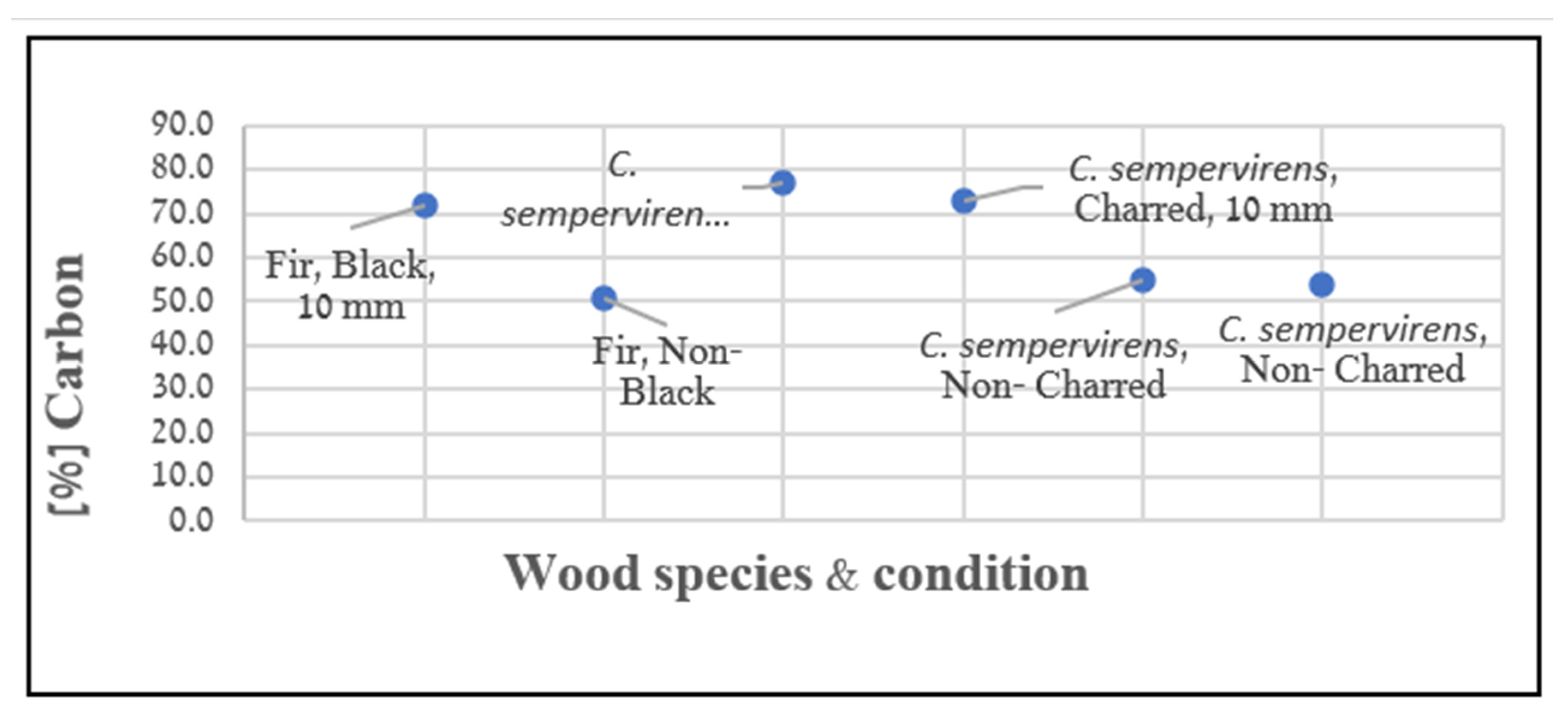

- Three sets of timbers were cut from P. brutia. The first set was of green wood, the second of seasoned wood, and the third of wet-seasoned wood. The temperature in the wood was measured with thermocouples located inside holes positioned 0.5 and 3 cm from the side facing the heat source.

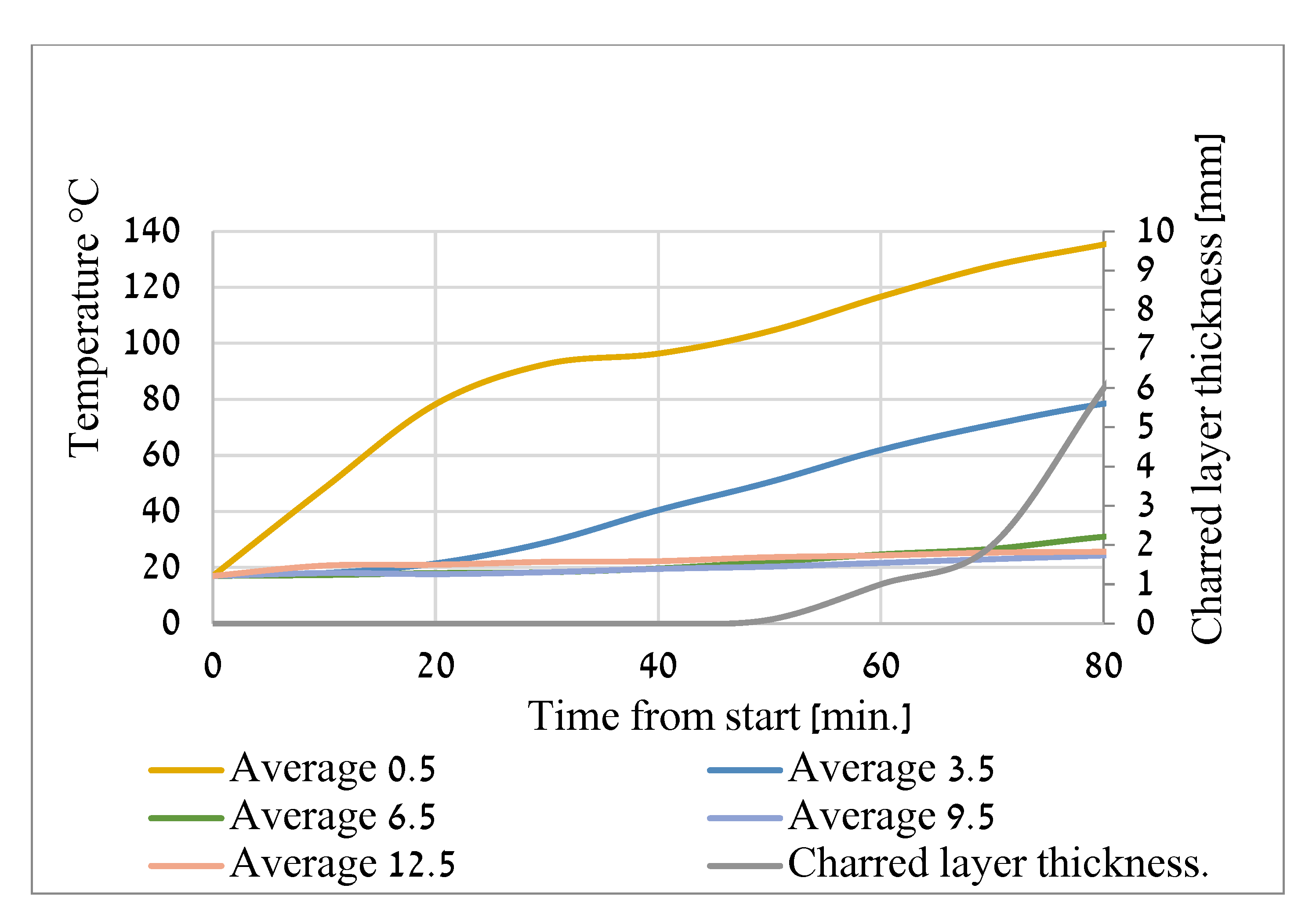

- Two sets of timbers were cut from a trunk of C. sempervirens. One was seasoned and the other was wet-seasoned. The temperature in the wood was measured with thermocouples located inside holes positioned 0.5, 3.5, 6.5 and 9.5 cm inside the wood on the side facing the heat source.

4. Results

The Special and Unique Case (So Far) of the Charred Stringer from the Ma‘agan Mikhael B Wreck

5. Discussion

- Char-bending

- Prevention or extermination of T. navalis infestation

- Accidental fire in the ship

- Thickness reduction.

- Proximity to heat source in the ship—the galley stove.

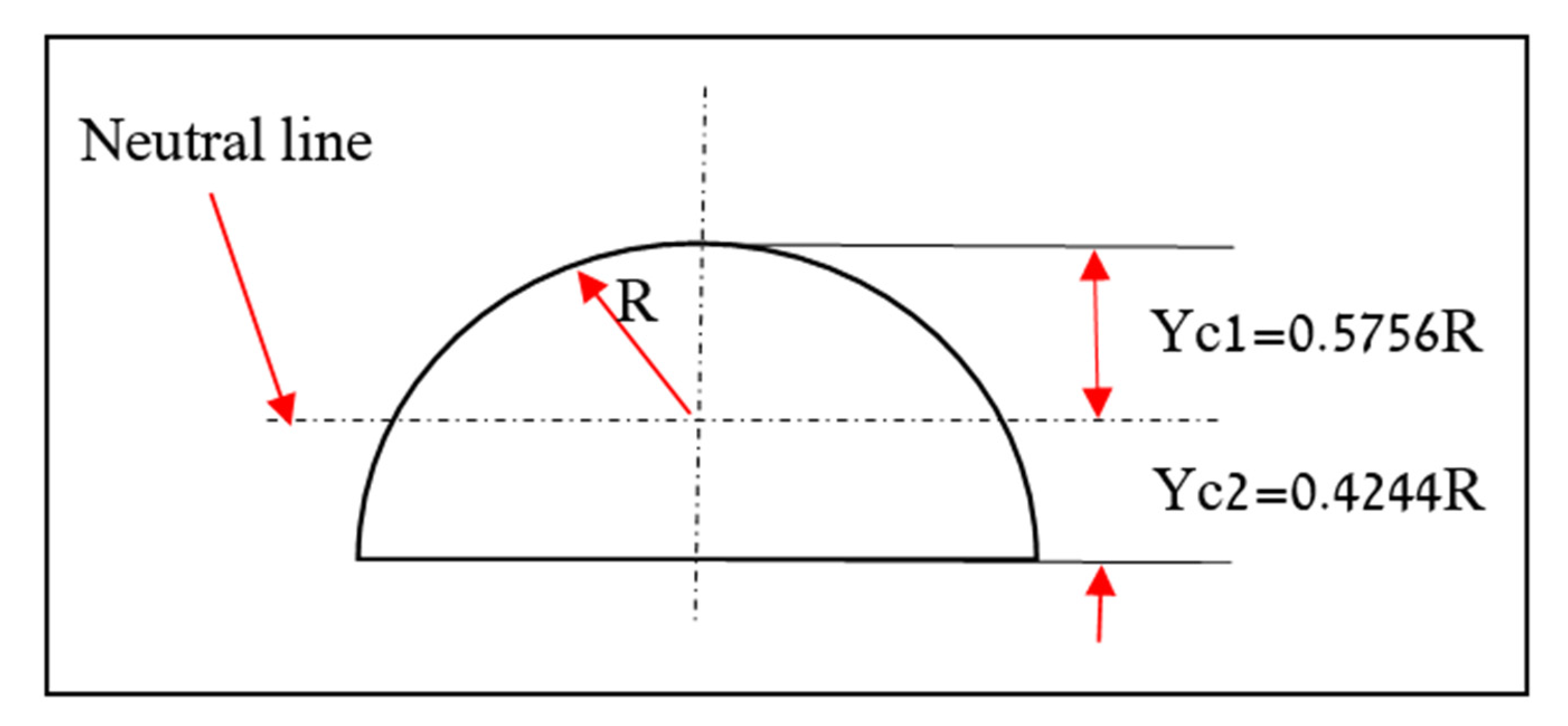

Why Does Charring Occur on the Concave Side of Planks, Wales, or Stringers?

- (a)

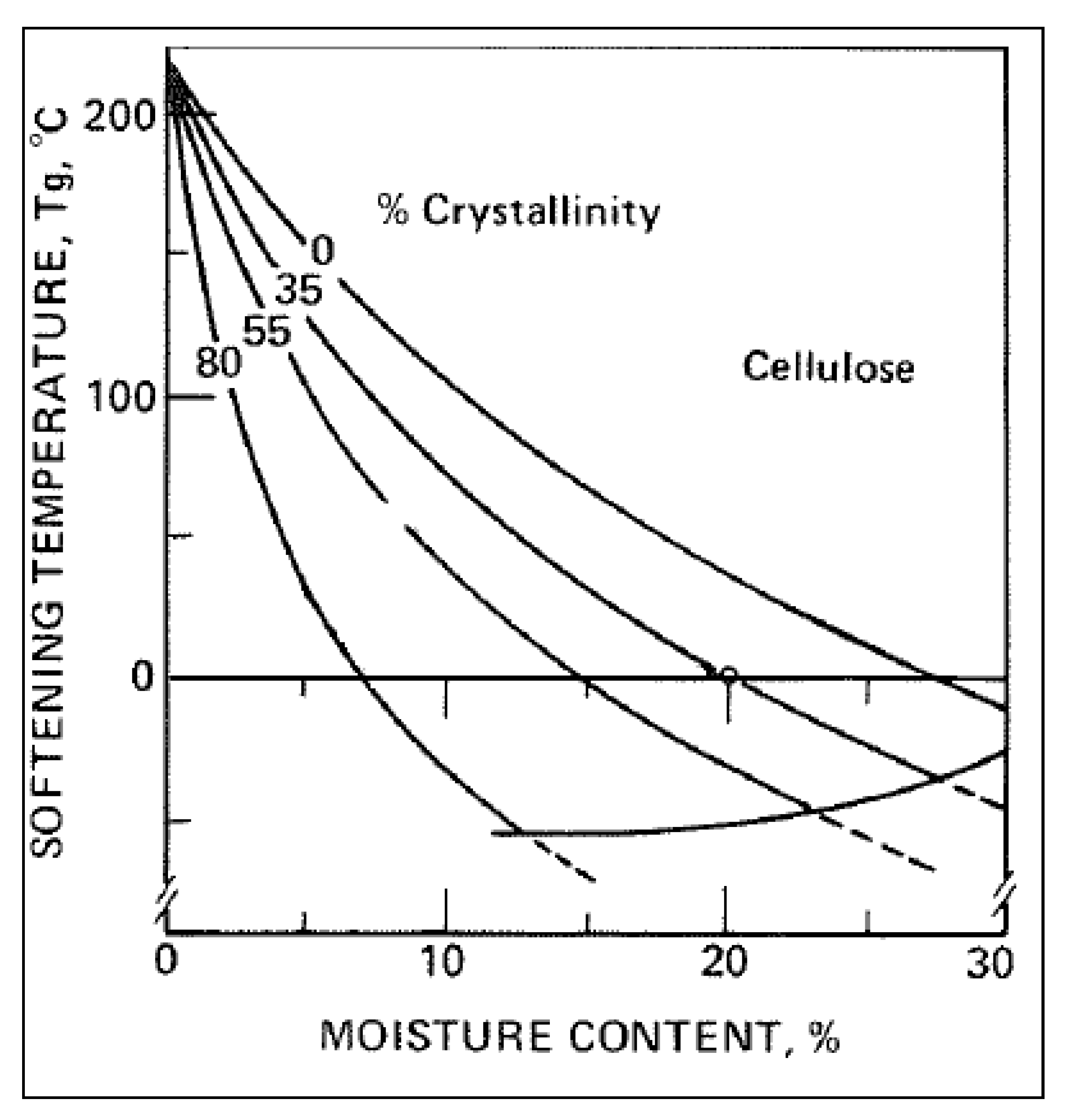

- Reducing the water content on this side, to prevent possible cracking during bending, due to excess water pressure [31].

- (b)

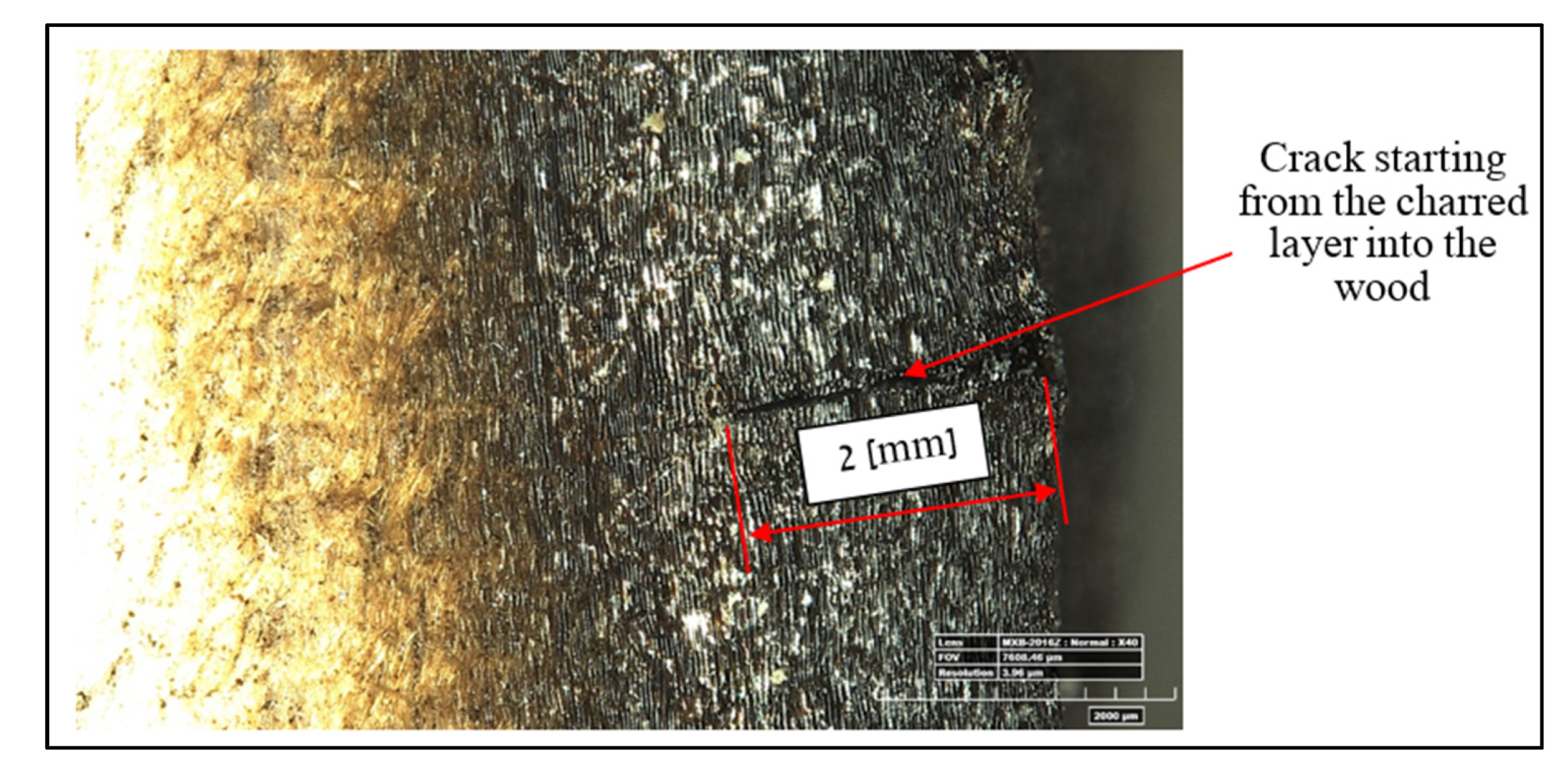

- Charred layer on wood is cracked (Figure 15) and cannot carry any load. If the cracked area is subjected to tension, as on the convex side of a bent beam, such cracks could be sites of stress concentration, causing a crack that might extend into the wood under the charred layer

- (c)

- The heat source evaporates the water on the side it faces, causing the plank to bend.

6. Conclusions

- a.

- Of all the various methods for preparation of wooden planks for bending, the one involving soaking in water and heating over open fire was probably the most widely used by shipwrights. Wherever such a preparation was deemed necessary for ship building, the charring of the planks was an unwanted side effect only, because it almost always leads to a reduced thickness and thus reduced strength and also to the cracking of the planks and thus to damaging the ship. Ideally, the shipwrights would have preferred to avoid it altogether, although in some cases, such as bending relatively thick planks, charring is unavoidable. To prevent that from happening, another preparation method would have to be used.

- b.

- When heating a plank over an open fire the side facing the heat source usually contracts (due to evaporation). Therefore, as a preparation for bending, it was almost always done by exposing to the fire the side that at the end of the process would be the concave face of the plank (generally—the inner side of the hull).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

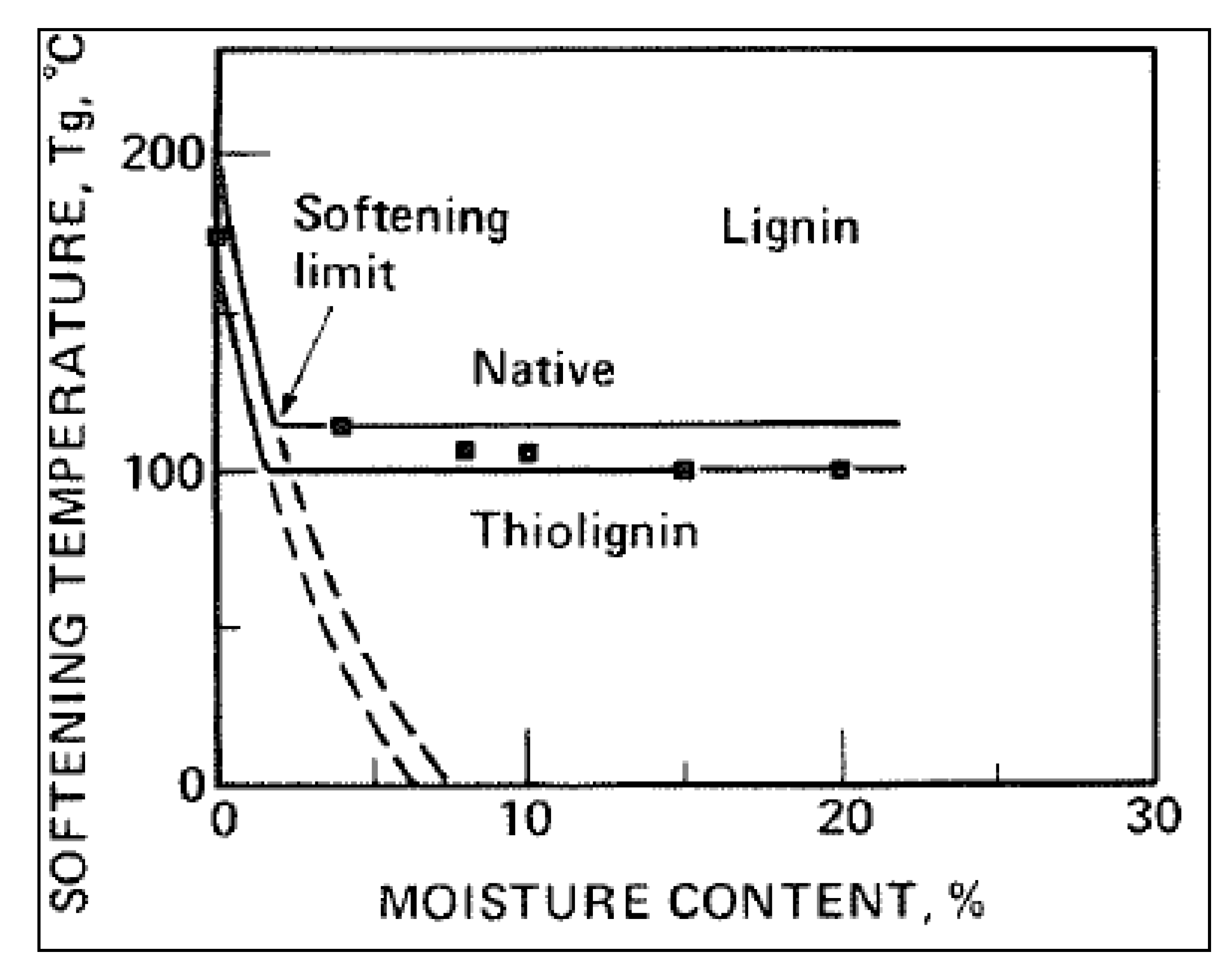

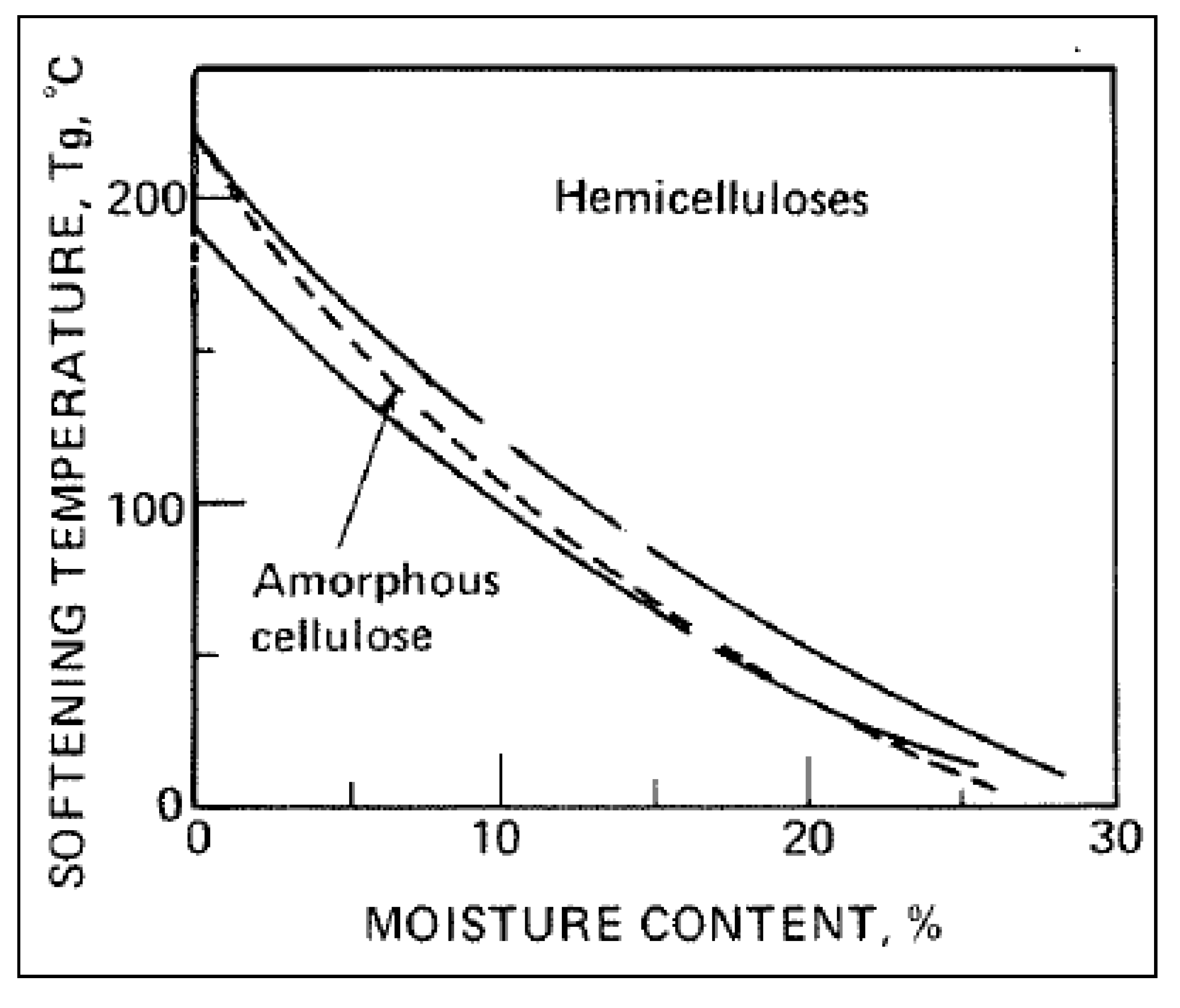

- Navi, P.; Sandberg, D. Thermo-Hydro-Mechanical Processing of Wood; Taylor & Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Flaccus, G.V. Argonautica; Loeb Classical Library, Harvard University Press: Cambridge, MA, USA, 1963. [Google Scholar]

- Claesson Rålamb, Å. Skepsbyggerij eller adlig öfning tionde tom (Shipwrightry or Noble Practice); Stockholm, Sweden, 1691. [Google Scholar]

- Steffy, J.R. The Kyrenia Ship-An Interim Report on its Hull Construction. Am. J. Archaeol. 1985, 89, 71–101. [Google Scholar] [CrossRef]

- Van de Moortel, A. Medieval boats and ships of Germany, the Low Countries, and northeast France-Archaeological evidence for shipbuilding traditions. In Shipbuilding Resources, Trade, and Communication, Proceedings of the Rivers as Communication and Trade Routes, Bremerhaven, Germany, 5–7 November 2009; Leidorf: Rahden/Westf, Germany, 2011. [Google Scholar]

- Beltrame, C. Preliminary Analysis of the Hull of the Roman Ship from Grado, Gorizia, Italy. Int. J. Naut. Archaeol. 2006, 36, 138–147. [Google Scholar] [CrossRef]

- Santamaria, C. L’épave Dramont “E” à Saint-Raphaël (Ve siècle ap. J.-C.). Archaeonautica 1995, 13, 5–198. [Google Scholar] [CrossRef]

- Kingsley, S.A. A Sixth-Century AD Shipwreck Off the CARMEL Coast, Israel: Dor D and Holy Land Wine Trade; BAR Publishing: Oxford, UK, 2002. [Google Scholar]

- Kahanov, Y.; Mor, H. The Dor 2001/1 Byzantine Shipwreck, Israel: Final report. Int. J. Naut. Archaeol. 2014, 43, 41–65. [Google Scholar] [CrossRef]

- Navri, R.; Kahanov, Y.; Cvikel, D. The Byzantine period Dor 2006 shipwreck, Israel: Preliminary hull construction report. Int. J. Naut. Archaeol. 2013, 42, 305–325. [Google Scholar] [CrossRef]

- Kahanov, Y. A Byzantine shipwreck (‘Tantura A’) in Tantura lagoon, Israel, its hull construction. In Tropis VI, Proceedings of the 6th International Symposium on Ship Construction in Antiquity Lamia, 28–30 August 1996; Tzalas, H., Ed.; Hellenic Institute for the Preservation of Nautical Tradition: Athens, Italy, 2001; pp. 265–271. [Google Scholar]

- Israeli, E.; Kahanov, Y. The 7th–9th Century Tantura E Shipwreck, Israel: Construction and reconstruction. Int. J. Naut. Archaeol. 2014, 43, 369–388. [Google Scholar] [CrossRef]

- Barkai, O.; Kahanov, Y. The Tantura F shipwreck: Hull remains and finds-final report. Int. J. Naut. Archaeol. 2016, 45, 6–28. [Google Scholar] [CrossRef]

- Cohen, M.; Cvikel, D. Ma-agan Mikhael B, Israel: A preliminary report of a Late Byzantine–Early Islamic period shipwreck. Int. J. Naut. Archaeol. 2019, 48, 189–207. [Google Scholar]

- Ingram, R. The Hull of Yenikapı Shipwreck YK 11: A 7th-century merchant vessel from Constantinople’s Theodosian Harbour. Int. J. Naut. Archaeol. 2018, 47, 103–139. [Google Scholar] [CrossRef]

- Jones, M.R. The Hull Construction of Yenikapı 14 (YK 14), A Middle Byzantine Shipwreck from Constantinople’s Theodosian Harbour, Istanbul, Turkey. Int. J. Naut. Archaeol. 2017, 46, 253–283. [Google Scholar] [CrossRef]

- Türkmenoğlu, E. Preliminary Report on the Yenikapı 17 Shipwreck. In Between Continents: Proceedings of the Twelfth Symposium on Boat and Ship Archaeology, Istanbul 2009; Gunsenin, N., Ed.; Ege Yayinlari: Istanbul, Turkiye, 2009; pp. 121–125. [Google Scholar]

- Kocabaş, U. Yenikapı Shipwrecks. In The ‘Old Ships’ of the ‘New Gate’; Ege Yayinlari: Istanbul, Turkiye, 2008; Volume I. [Google Scholar]

- Schweitzer, H. Drogheda boat: A story to tell. In Between Continents: Proceedings of the Twelfth Symposium on Boat and Ship Archaeology, Istanbul 2009; Günsenin, N., Ed.; Ege Yayinlari: Istanbul, Turkiye, 2009; pp. 225–231. [Google Scholar]

- Lemée, C.P.P. The Renaissance Shipwrecks from Christianshavn; Viking Ship Museum, National Museum of Denmark: Copenhagen, Denmark, 2006. [Google Scholar]

- Cvikel, D.; Kahanov, Y. The 19th-Century Akko 1 Shipwreck, Israel: Hull-construction report. Int. J. Naut. Archaeol. 2013, 42, 167–187. [Google Scholar] [CrossRef]

- Greenhill, B. Japanese inshore fishing boats. Mar. Mirror 1959, 45, 3–13. [Google Scholar] [CrossRef]

- Greenhill, B.; Hill, C. The boats of East Pakistan a preliminary study-1. Mar. Mirror 1957, 43, 106–134. [Google Scholar] [CrossRef]

- Greenhill, B.; Hill, C. The boats of East Pakistan a preliminary study-2. Mar. Mirror 1957, 43, 203–215. [Google Scholar] [CrossRef]

- Richards, A. Sailing boats of western Sarawak. Mar. Mirror 1967, 53, 161–169. [Google Scholar] [CrossRef]

- De Leeuwe, R. Seascape and Sailing Ships of the Swahili Shores. Master’s Thesis, University of Leiden, Leiden, The Netherlands, 2004. [Google Scholar]

- Steffy, J.R. Wooden Shipbuilding and the Interpretation of Shipwrecks; Texas A&M University Press: College Station, TX, USA, 1994. [Google Scholar]

- Cohen, M.; Cvikel, D. Rigging of the Ma‘agan Mikhael B shipwreck (7th–8th centuries AD): New finds. Int. J. Naut. Archaeol. 2020, 49, 291–302. [Google Scholar] [CrossRef]

- Young, W.C.; Budynas, R.G. Roark’s Formulas for Stress and Strain, 7th ed.; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Shi, J.L.; Kocaefe, D.; Zhang, J. Mechanical behavior of Quebec wood species heat-treated using thermowood process. Holz Als Roh-Und Werkst. 2007, 65, 255–259. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood Handbook-Wood as an Engineering Material; General Technical Report FPL-GTR-190; USDA Forest Service Madison: Wisconsin, WI, USA, 1999. [Google Scholar]

- Back, E.L.; Salmén, L. Glass transitions of wood components hold implications for molding and pulping process. J. Tech. Assoc. Pulp Pap. Ind. 1982, 65, 107–110. [Google Scholar]

- Staatsarchiv des Kantons Bern. B II 632. Council of War of Berne, Governor of Nyon. 28 December 1663; 213–214. [Google Scholar]

- Desmond, C. Wooden Shipbuilding; The Rudder Publishing Company: New York, NY, USA, 1919. [Google Scholar]

| Shipwreck | Date | Component | Side Charred | Location on Component | Component Thickness [cm] | Interpretation | Reference |

|---|---|---|---|---|---|---|---|

| Kyrenia | 4th c. BCE | Wales | Concave inner face | Few 30-cm-long sections. All other places trimmed off | 6.1, 8 | Char-bending | [4] |

| Expanded log boat | 1st c. BCE | – | Concave inner face | – | – | – | [5] |

| Grado | 2nd c. CE | Garboard | Concave inner face | Extremities | 5 | Char-bending | [6] |

| Dramont E | 5th c. CE | Garboard | Concave inner face | Extremities | 4.8–5 | Char-bending | [7] |

| Dor D | 6th c. CE | Strake | Concave inner face | Extremities | 3 | Char-bending | [8] |

| Dor 2001/1 | 6th c. CE | Strake | Concave inner face | Extremities | 2.3 | Char-bending | [9] |

| Dor 2006 | 7th c. CE | Strake, wale | Concave inner face | Extremities | 3.2, 16.1 | Char-bending | [10] |

| Tantura A | 6th c. CE | Strakes | Concave inner face | Extremities | 2.5 | Char-bending | [11] |

| Tantura E | 7th–9th c. CE | Strakes | Concave inner face | Extremities | 1.9–2.9 | Char-bending, killing T. navalis | [12] |

| Tantura E | 7th–9th c. CE | Stringers | Concave inner face | Extremities | 4–7.6 | Char-bending, Killing T. navalis | [12] |

| Tantura F | 7th–8th c. CE | Strakes | Concave inner face | Extremities | 2.7 | Char-bending | [13] |

| MMB | 7th–8th c. CE | Stringer | Convex outer face | Extremities | 10 | Char-bending | [14] |

| MMB | 7th–8th c. CE | Strakes | Concave inner face | Extremities | 3.1–4.2 | Char-bending | [14] |

| YK 11 | 7th c. CE | Strakes | Concave inner face | Extremities | 1.8–2.5 | Char-bending | [15] |

| YK 14 | 9th c. CE | Strakes | Concave inner face | Extremities | 0.8–3.6 | Char-bending | [16] |

| YK 14 | 9th c. CE | Garboard | Concave inner face | Extremities | 1.1–4.4 | Char-bending | [16] |

| YK 14 | 9th c. CE | Wale | Concave inner face | Extremities | 3.6–7.2 | Char-bending | [16] |

| YK 17 | 8th c. CE | Wale | Concave inner face | Whole length | 14 | Char-bending | [17] |

| YK 3 | 10th–11th c. CE | Wale | Concave inner face | – | 10 | Char-bending | [18] |

| Drogheda Boat | 16th c. CE | Strakes | Concave inner face | All over | 2.2 | Char-bending, killing T. navalis | [19] |

| B&W I | 16th–17th c. CE | Strakes | Concave inner face | Extremities | 4.5 | Char-bending | [20] |

| Akko 1 | 19th c. CE | Garboard | Concave inner face | Extremities | 4.5 | – | [21] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bram, M.; Me-Bar, Y. Understanding the Char-Bending Technique in Shipwreck Planks. Heritage 2023, 6, 1754-1767. https://doi.org/10.3390/heritage6020093

Bram M, Me-Bar Y. Understanding the Char-Bending Technique in Shipwreck Planks. Heritage. 2023; 6(2):1754-1767. https://doi.org/10.3390/heritage6020093

Chicago/Turabian StyleBram, Moshe, and Yoav Me-Bar. 2023. "Understanding the Char-Bending Technique in Shipwreck Planks" Heritage 6, no. 2: 1754-1767. https://doi.org/10.3390/heritage6020093

APA StyleBram, M., & Me-Bar, Y. (2023). Understanding the Char-Bending Technique in Shipwreck Planks. Heritage, 6(2), 1754-1767. https://doi.org/10.3390/heritage6020093