Non-Destructive Textural Characterization of Southern Romanian Neolithic and Chalcolithic Pottery Using Digital Image Analysis on Tomographically Reconstructed Sections

Abstract

:1. Introduction

1.1. Southern Romania Neolithic and Chalcolithic Pottery

1.2. Objectives

2. Materials and Methods

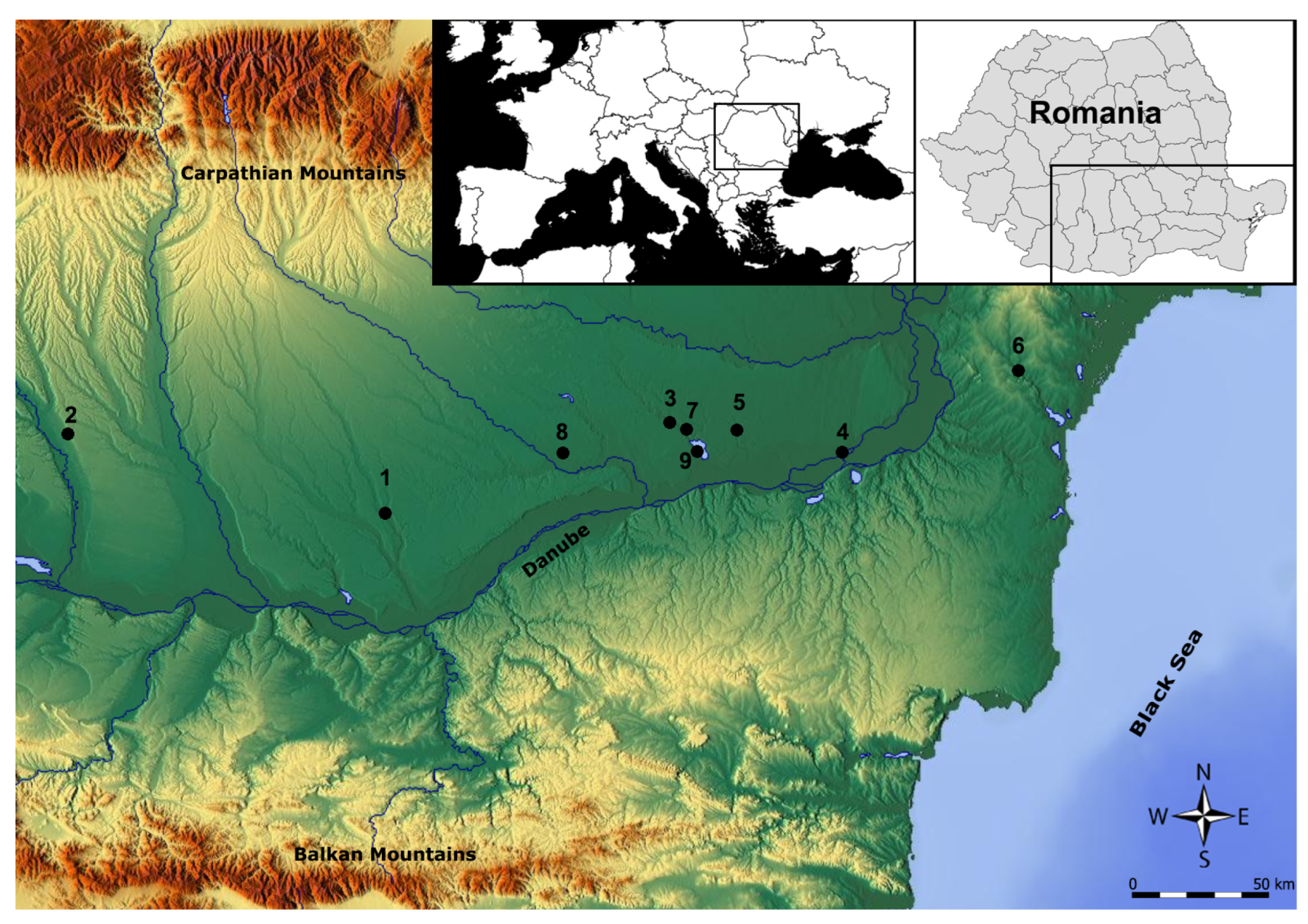

2.1. Pottery Samples

2.2. X-ray Computed Tomography

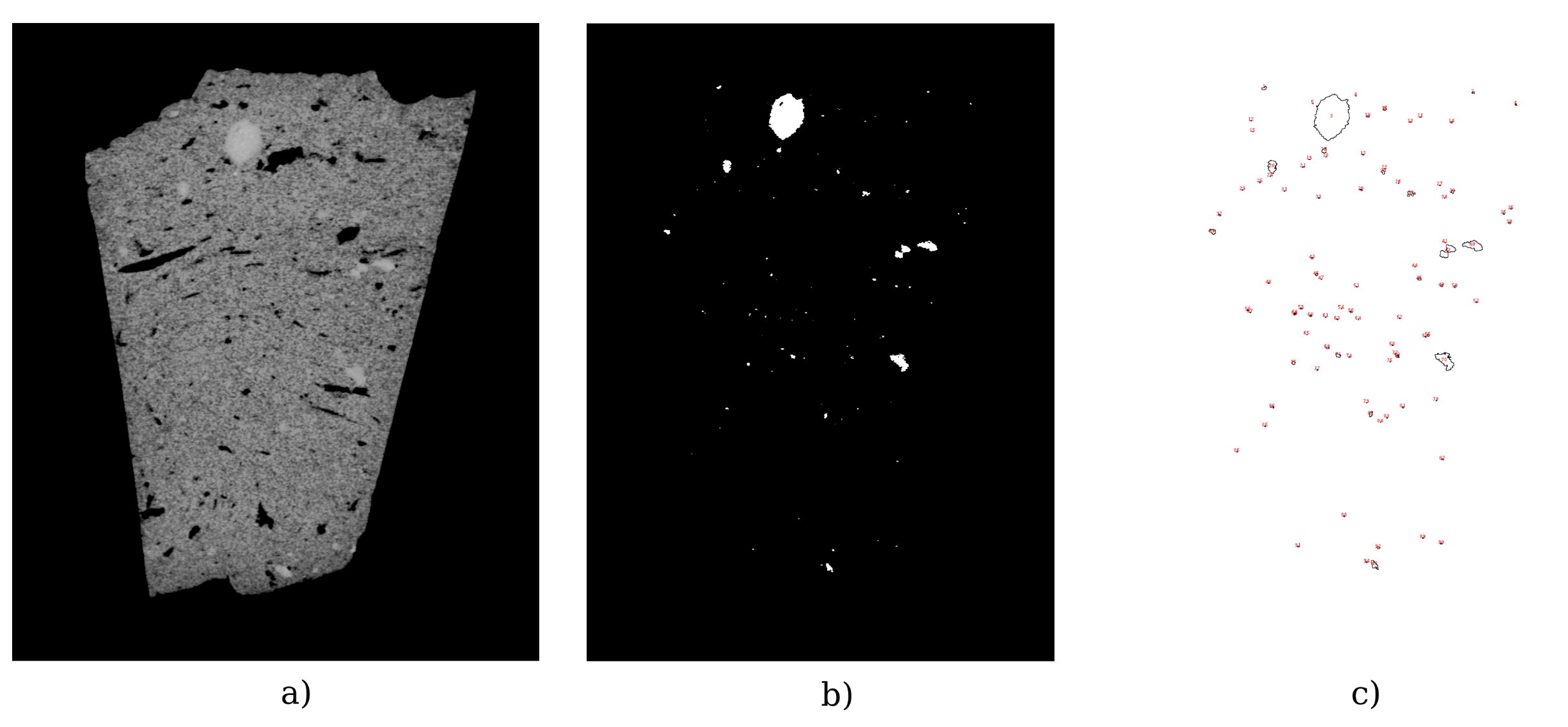

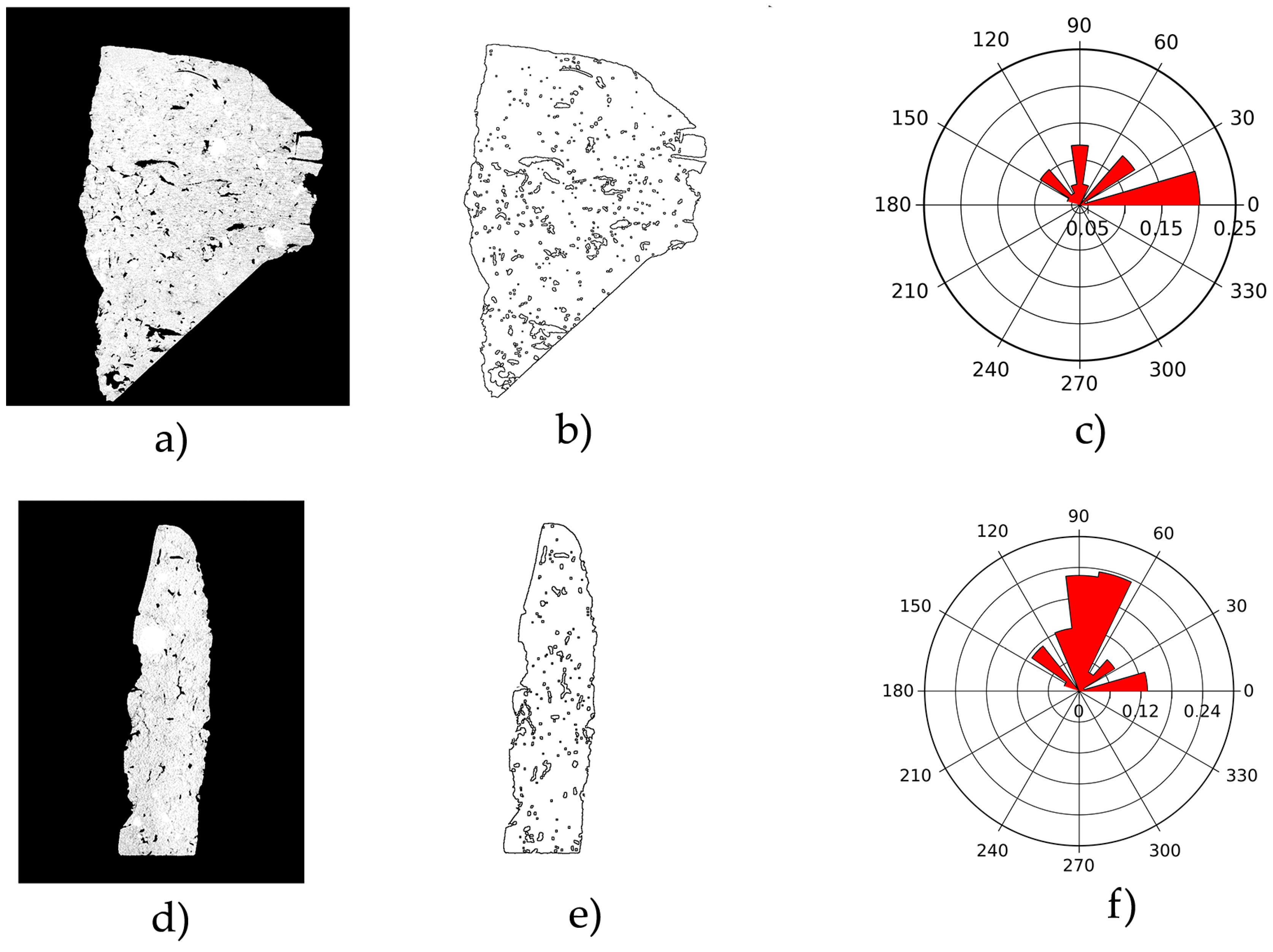

2.3. Image Analysis

3. Results

3.1. Inclusion Analysis

3.2. Voids Analysis

4. Discussion

4.1. Clay Selection and Preparation

4.2. Pottery Tempering

4.3. Primary Forming Techniques

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gomart, L.; Weiner, A.; Gabriele, M.; Durrenmath, G.; Sorin, S.; Angeli, L.; Colombo, M.; Fabbri, C.; Maggi, R.; Panelli, C.; et al. Spiralled patchwork in pottery manufacture and the introduction of farming to Southern Europe. Antiquity 2017, 91, 1501–1514. [Google Scholar] [CrossRef]

- Heimann, R.B.; Maggetti, M. The struggle between thermodynamics and kinetics: Phase evolution of ancient and historical ceramics. In EMU Notes in Mineralogy: The Contribution of Mineralogy to Cultural Heritage; Artioli, G., Oberti, R., Eds.; Mineralogical Society: London, UK, 2019; Volume 20, pp. 233–281. [Google Scholar]

- Gordon, R.; Bender, R.; Herman, G.T. Algebraic reconstruction techniques (ART) for three-dimensional electron microscopy and X-ray photography. J. Theor. Biol. 1970, 29, 471–481. [Google Scholar] [CrossRef]

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical cone-beam algorithm. J. Opt. Soc. Am. A 1984, 1, 612–619. [Google Scholar] [CrossRef]

- Beister, M.; Kolditz, D.; Kalender, W.A. Iterative reconstruction methods in X-ray CT. Phys. Med. 2012, 28, 94–108. [Google Scholar] [CrossRef]

- Hsieh, J.; Nett, B.; Yu, Z.; Sauer, K.; Thibault, J.B.; Bouman, C.A. Recent advances in CT image reconstruction. Curr. Radiol. Rep. 2013, 1, 39–51. [Google Scholar] [CrossRef]

- Berg, I. Looking through pots: Recent advances in ceramics X-radiography. J. Archaeol. Sci. 2008, 35, 1177–1188. [Google Scholar] [CrossRef]

- Rye, O.S. Pottery Technology: Principles and Reconstruction; Taraxacum: Washington, DC, USA, 1981; Volume 4. [Google Scholar]

- Carr, C. Advances in ceramic radiography and analysis: Applications and potentials. J. Archaeol. Sci. 1990, 17, 13–34. [Google Scholar] [CrossRef]

- Kahl, W.-A.; Ramminger, B. Non-destructive fabric analysis of prehistoric pottery using high-resolution X-ray microtomography: A pilot study on the late Mesolithic to Neolithic site Hamburg-Boberg. J. Archaeol. Sci. 2012, 39, 2206–2219. [Google Scholar] [CrossRef]

- Abraham, E.; Bessou, M.; Ziéglé, A.; Hervé, M.C.; Szentmiklósi, L.; Kasztovszky, Z.S.; Kis, Z.; Menu, M. Terahertz, X-ray and neutron computed tomography of an Eighteenth Dynasty Egyptian sealed pottery. Appl. Phys. A 2014, 117, 963–972. [Google Scholar] [CrossRef]

- Kozatsas, J.; Kotsakis, K.; Sagris, D.; David, K. Inside out: Assessing pottery forming techniques with micro-CT scanning. An example from Middle Neolithic Thessaly. J. Archaeol. Sci. 2018, 100, 102–119. [Google Scholar] [CrossRef]

- Takenouchi, K.; Yamahana, K. Fine pottery shaping techniques in Predynastic Egypt: A pilot study on non-destructive analysis using an X-ray CT scanning system. J. Archaeol. Sci. Rep. 2021, 37, 102989. [Google Scholar] [CrossRef]

- Gait, J.; Bajnok, K.; Szilágyi, V.; Szenti, I.; Kukovecz, Á.; Kis, Z. Quantitative 3D orientation analysis of particles and voids to differentiate hand-built pottery forming techniques using X-ray microtomography and neutron tomography. Archaeol. Anthropol. Sci. 2022, 14, 223. [Google Scholar] [CrossRef]

- Spataro, M.; Taylor, J.; O’Flynn, D. A technological study of Assyrian clay tablets from Nineveh, Tell Halaf and Nimrud: A pilot case study. Archaeol. Anthropol. Sci. 2023, 15, 68. [Google Scholar] [CrossRef]

- Barron, A.; Denham, T. A microCT protocol for the visualization and identification of domesticated plant remains within pottery sherds. J. Archaeol. Sci. Rep. 2018, 21, 350–358. [Google Scholar] [CrossRef]

- Ketcham, R.A.; Carlson, W.D. Acquisition, optimization and interpretation of X-ray computed tomographic imagery: Applications to the geosciences. Comput. Geosci. 2001, 27, 381–400. [Google Scholar] [CrossRef]

- Kyle, J.R.; Ketcham, R.A. Application of high resolution X-ray computed tomography to mineral deposit origin, evaluation, and processing. Ore Geol. Rev. 2015, 65, 821–839. [Google Scholar] [CrossRef]

- Dal Sasso, G.; Maritan, L.; Salvatori, S.; Mazzoli, C.; Artioli, G. Discriminating pottery production by image analysis: A case study of Mesolithic and Neolithic pottery from Al Khiday (Khartoum, Sudan). J. Archaeol. Sci. 2014, 46, 125–143. [Google Scholar] [CrossRef]

- Jordan, P.; Gibbs, K.; Hommel, P.; Piezonka, H.; Silva, F.; Steele, J. Modelling the diffusion of pottery technologies across Afro-Eurasia: Emerging insights and future research. Antiquity 2016, 90, 590–603. [Google Scholar] [CrossRef]

- Thissen, L. The First Balkan Neolithic in the Lower Danube Plain and the Making of a Pottery Tradition. In Going West? The Dissemination of Neolithic Innovations between the Bosporus and the Carpathians. Proceedings of the EAA Conference, Istanbul, Turkey, 11 September 2014; Reingruber, A., Tsirtsoni, Z., Nedelcheva, P., Eds.; Themes in Contemporary Archaeology; Routledge: London, UK, 2017; Volume 3, pp. 79–90. [Google Scholar]

- Mathieson, I.; Alpaslan-Roodenberg, S.; Posth, C.; Szécsényi-Nagy, A.; Rohl, N.; Mallick, S.; Olalde, I.; Broomandkhoshbacht, N.; Candilio, F.; Cheronet, O.; et al. The Genomic History of Southeastern Europe. Nature 2018, 555, 197–203. [Google Scholar] [CrossRef]

- Spataro, M. Starčevo Ceramic Technology: The First Potters of the Middle Danube Basin; Dr. Rudolf Habelt Verlag: Bonn, Germany, 2019. [Google Scholar]

- Dimache, M.; Știrbescu, R.M.; Ştefan, C.E. Unele observaţii asupra tehnologiei ceramicii din aşșezarea de la Milcovu din Deal. In Cercetări Interdisciplinare în Aşezarea Neolitică de la Milcovu din Deal (jud. Olt, România); Ştefan, C.E., Ed.; Cetatea de Scaun: Târgovişte, Romania, 2021; pp. 145–174. [Google Scholar]

- Opriş, V.; Ignat, T.; Lazăr, C. Technological analysis of Boian pottery from Sultana. Stud. Preist. 2017, 14, 93–109. [Google Scholar]

- Koutouvaki, E.; Amicone, S.; Kristew, A.; Ștefan, C.E.; Berthold, C. Shared traditions and shard conservatism: Pottery making at the Chalcolithic site of Radovanu (Romania). Archaeol. Anthropol. Sci. 2021, 13, 206. [Google Scholar] [CrossRef]

- Thissen, L. Ceramics from an Early Neolithic (Criş I) site in S Romania: Măgura Buduiasca—Boldul lui Moş Ivănuş. Bul. Muzeului Judeţ. Teleorman 2015, 7, 5–44. [Google Scholar]

- Opriş, V.; Petruneac, M.; Focșăneanu, M.; Sirbu, R.; Boroneant, A.; Golea, M.; Bonsall, C. Early Neolithic pottery at Schela Cladovei. A comparative study of archaeological and experimental vessels from the perspective of computed tomography. In Recreating Artefacts and Ancient Skills: From Experiment to Interpretation; Mărgărit, M., Boroneanţ, A., Eds.; Cetatea de Scaun: Târgoviște, Romania, 2022; pp. 279–294. [Google Scholar]

- Ignat, T.; Bugoi, R.; Constantin, F.; Parnic, V.; Lazăr, C. Identifying the chaîne opératoire of prehistoric clay figurines using experimental archeology and imaging methods. Appl. Nucl. Tech. (CRETE17). Int. J. Mod. Phys. Conf. Ser. 2018, 48, 1860107. [Google Scholar] [CrossRef]

- Manea, B.; Lechintan, M.; Popescu, G.; Ignat, T.; Opriş, V.; Constantin, F.; Dimache, M.; Parnic, V.; Bugoi, R.; Lazăr, C. Looking beyond appearances. A multi-analytical approach on the prehistoric clay weight. Herit. Sci. 2019, 7, 88. [Google Scholar] [CrossRef]

- Opriş, V.; Manea, B.; Lechiţan, M.; Bugoi, R.; Constantin, F.; Ignat, T.; Lazar, C. Between object and subject: Multiple approaches on a prehistoric human-shape pot from Romania. Doc. Praehist. 2022, 49, 406–421. [Google Scholar] [CrossRef]

- GNU Image Manipulation Program. Available online: https://www.gimp.org/ (accessed on 7 March 2022).

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Folk, R.L.; Ward, W.C. Brazos River bar [Texas]; a study in the significance of grain size parameters. J. Sediment. Petrol. 1957, 27, 3–26. [Google Scholar] [CrossRef]

- Williams, J.; Arsenault, M.A.; Buczkowski, B.J.; Reid, J.A.; Flocks, J.G.; Kulp, M.A.; Penland, S.; Jenkins, C.J. Surficial Sediment Character of the Louisiana Offshore Continental Shelf Region: A GIS Compilation, U.S. Geological Survey Open-File Report 2006-1195; 2006. Available online: https://pubs.usgs.gov/of/2006/1195/index.htm (accessed on 2 October 2023).

- Jipa, D.; Anastasiu, N. Texturi şi Structuri Sedimentare; ed. Tehnică: Bucharest, Romania, 1983. [Google Scholar]

- Thér, R. Ceramic technology. How to reconstruct and describe pottery-forming practices. Archaeol. Anthropol. Sci. 2020, 12, 172. [Google Scholar] [CrossRef]

- Thér, R.; Květina, P.; Neumannová, K. Coiling or slab building: Potential of orientation analysis for identification of forming techniques used by Early Neolithic potters. J. Archaeol. Sci. Rep. 2019, 26, 101877. [Google Scholar] [CrossRef]

| Nr. Crt | Sample Name | Construction Zone | Archaeological Site | Period | Culture/Phase | Dating |

|---|---|---|---|---|---|---|

| 1 | P0006 | body | Măgura Buduiasa | Early Neolithic | Starčevo-Criş/I | ca. 6000–5900 |

| 2 | P0023 | body | Măgura Buduiasa | Early Neolithic | Starčevo-Criş/I | ca. 6000–5900 |

| 3 | P0040 | body | Măgura Buduiasa | Early Neolithic | Starčevo-Criş/III | ca. 5800–5500 |

| 4 | P0046 | body | Măgura Buduiasa | Early Neolithic | Starčevo-Criş/III | ca. 5800–5500 |

| 5 | P0073 | body | Măgura Buduiasa | Middle Neolithic | Dudeşti | ca. 5500–5200 |

| 6 | P0082 | body | Măgura Buduiasa | Middle Neolithic | Vădastra | ca. 5200–4800 |

| 7 | P0083 | body | Măgura Buduiasa | Middle Neolithic | Vădastra | ca. 5200–4800 |

| 8 | P0102 | rim | Cârcea Viaduct | Middle Neolithic | Vădastra | ca. 5200–4800 |

| 9 | P0147 | shoulder | Lunca | Middle Neolithic | Boian/I | ca. 5200–4800 |

| 10 | P0149e | body | Lunca | Middle Neolithic | Boian/I | ca. 5200–4800 |

| 11 | P0150a | body | Grădiştea Coslogeni | Middle Neolithic | Hamangia/II | ca. 5200–4800 |

| 12 | P0159 | rim | Grădiştea Coslogeni | Middle Neolithic | Hamangia/II | ca. 5200–4800 |

| 13 | P0173a | body | Gălăţui-Movila Berzei | Middle Neolithic | Boian/II | ca. 5100–4600 |

| 14 | P0177c | body | Gălăţui-Movila Berzei | Middle Neolithic | Boian/II | ca. 5100–4600 |

| 15 | P0112 | rim | Cheia | Early Chalcolithic | Hamangia/III | ca. 5000–4700 |

| 16 | P0116 | body | Cheia | Early Chalcolithic | Hamangia/III | ca. 5000–4700 |

| 17 | P0118d | rim | Vlădiceasca | Early Chalcolithic | Boian/III | ca. 4900–4600 |

| 18 | P0126d | body | Vlădiceasca | Early Chalcolithic | Boian/III | ca. 4900–4600 |

| 19 | P0131 | body | Vidra | Early Chalcolithic | Boian/III | ca. 4900–4600 |

| 20 | P0124a | shoulder | Vlădiceasca | Developed Chalcolithic | Gumelniţa/I | ca. 4600–4300 |

| 21 | P0125b | shoulder | Vlădiceasca | Developed Chalcolithic | Gumelniţa/I | ca. 4600–4300 |

| 22 | P0106 | rim | Sultana Malu Roşu | Gumelniţa/II-III | ca. 4350–3900 |

| Nr. Crt | Sample Name | Voxel Size (μm) | Source-to-Object Distance (mm) |

|---|---|---|---|

| 1 | P0006 | 25.71 | 196.97 |

| 2 | P0023 | 35.77 | 274.09 |

| 3 | P0040 | 27.66 | 211.95 |

| 4 | P0046 | 38.43 | 294.45 |

| 5 | P0073 | 38.95 | 298.46 |

| 6 | P0082 | 60.20 | 461.22 |

| 7 | P0083 | 27.78 | 212.23 |

| 8 | P0102 | 63.95 | 489.59 |

| 9 | P0147 | 51.02 | 390.92 |

| 10 | P0149e | 29.30 | 224.44 |

| 11 | P0150a | 40.93 | 313.62 |

| 12 | P0159 | 41.20 | 315.61 |

| 13 | P0173a | 42.98 | 329.34 |

| 14 | P0177c | 79.86 | 611.42 |

| 15 | P0112 | 51.42 | 393.94 |

| 16 | P0116 | 50.49 | 386.85 |

| 17 | P0118d | 30.71 | 235.32 |

| 18 | P0126d | 44.38 | 339.99 |

| 19 | P0131 | 67.08 | 513.95 |

| 20 | P0124a | 60.30 | 462.02 |

| 21 | P0125b | 67.23 | 515.13 |

| 22 | P0106 | 68.87 | 527.14 |

| Sample | Section | Method of Moments | Graphic Method | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Skewness | K | Mean | Skewness | Kurtosis | ||||

| P0006 | frontal | 2.69 | 0.37 | −1.22 | 3.54 | 2.65 | 0.30 | −0.56 | 0.86 |

| longitudinal | 2.97 | 0.55 | −1.00 | 1.68 | 3.02 | 0.46 | −0.03 | 0.91 | |

| P0023 | frontal | 2.30 | 0.58 | −0.95 | 0.08 | 2.31 | 0.56 | −0.38 | 0.99 |

| longitudinal | 2.39 | 0.86 | −2.38 | 7.38 | 2.52 | 0.52 | −0.67 | 0.83 | |

| P0046 | frontal | 2.42 | 0.52 | −0.64 | −0.37 | 2.46 | 0.51 | 0.05 | 1.32 |

| longitudinal | 2.37 | 0.64 | −1.06 | 0.26 | 2.44 | 0.58 | −0.43 | 0.78 | |

| P0073 | frontal | 2.40 | 0.67 | −1.80 | 3.90 | 2.46 | 0.56 | −0.47 | 1.10 |

| longitudinal | 2.44 | 0.57 | −1.61 | 3.15 | 2.48 | 0.52 | −0.43 | 0.93 | |

| P0149e | frontal | 2.20 | 1.09 | −1.29 | 1.52 | 2.22 | 0.98 | −0.47 | 0.83 |

| longitudinal | 2.43 | 1.39 | −1.55 | 1.89 | 2.57 | 1.11 | −0.60 | 1.27 | |

| P0173a | frontal | 2.14 | 0.65 | −1.27 | 1.31 | 2.13 | 0.61 | −0.44 | 0.95 |

| longitudinal | 2.41 | 0.53 | −2.14 | 5.59 | 2.49 | 0.44 | −0.79 | 1.36 |

| Sample | Section | Circularity | Aspect Ratio | Roundness | |||

|---|---|---|---|---|---|---|---|

| Mean | Median | Mean | Median | Mean | Median | ||

| P0006 | frontal | 0.96 | 1.00 | 1.47 | 1.46 | 0.73 | 0.68 |

| longitudinal | 0.87 | 0.90 | 1.38 | 1.36 | 0.75 | 0.74 | |

| P0023 | frontal | 0.85 | 0.88 | 1.57 | 1.47 | 0.69 | 0.68 |

| longitudinal | 0.87 | 0.94 | 1.34 | 1.25 | 0.79 | 0.80 | |

| P0046 | frontal | 0.94 | 0.99 | 1.39 | 1.29 | 0.76 | 0.77 |

| longitudinal | 0.92 | 0.99 | 1.37 | 1.28 | 0.76 | 0.73 | |

| P0073 | frontal | 0.77 | 0.81 | 1.75 | 1.60 | 0.62 | 0.63 |

| longitudinal | 0.76 | 0.77 | 1.81 | 1.64 | 0.61 | 0.61 | |

| P0149e | frontal | 0.71 | 0.76 | 1.65 | 1.67 | 0.63 | 0.60 |

| longitudinal | 0.80 | 1.00 | 1.65 | 1.34 | 0.67 | 0.74 | |

| P0173a | frontal | 0.63 | 0.64 | 2.12 | 1.89 | 0.54 | 0.53 |

| longitudinal | 0.69 | 0.70 | 1.96 | 1.81 | 0.56 | 0.55 |

| Sample | Section | Mean Angle () | Circular Standard Deviation () |

|---|---|---|---|

| P0023 | frontal | 76.64 | 68.79 |

| longitudinal | 84.15 | 32.77 | |

| P0040 | frontal | 50.80 | 57.91 |

| longitudinal | 87.77 | 37.52 | |

| P0046 | frontal | 90.82 | 34.99 |

| longitudinal | 84.22 | 36.04 | |

| P0083 | frontal | 67.36 | 59.08 |

| longitudinal | 258.16 | 32.26 | |

| P0147 | frontal | 261.93 | 42.43 |

| longitudinal | 262.41 | 34.35 | |

| P0149e | frontal | 50.88 | 61.74 |

| longitudinal | 63.04 | 60.98 | |

| P0173a | frontal | 85.22 | 62.27 |

| longitudinal | 75.66 | 41.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoicescu, D.; Duliu, O.G.; Opriş, V.; Manea, B.; Mariş, I.; Voinea, V.; Mirea, P.; Parnic, V.; Dimache, M.; Lazăr, C. Non-Destructive Textural Characterization of Southern Romanian Neolithic and Chalcolithic Pottery Using Digital Image Analysis on Tomographically Reconstructed Sections. Heritage 2023, 6, 6634-6647. https://doi.org/10.3390/heritage6100347

Stoicescu D, Duliu OG, Opriş V, Manea B, Mariş I, Voinea V, Mirea P, Parnic V, Dimache M, Lazăr C. Non-Destructive Textural Characterization of Southern Romanian Neolithic and Chalcolithic Pottery Using Digital Image Analysis on Tomographically Reconstructed Sections. Heritage. 2023; 6(10):6634-6647. https://doi.org/10.3390/heritage6100347

Chicago/Turabian StyleStoicescu, Daniel, Octavian G. Duliu, Vasile Opriş, Bogdan Manea, Izabela Mariş, Valentina Voinea, Pavel Mirea, Valentin Parnic, Mădălina Dimache, and Cătălin Lazăr. 2023. "Non-Destructive Textural Characterization of Southern Romanian Neolithic and Chalcolithic Pottery Using Digital Image Analysis on Tomographically Reconstructed Sections" Heritage 6, no. 10: 6634-6647. https://doi.org/10.3390/heritage6100347

APA StyleStoicescu, D., Duliu, O. G., Opriş, V., Manea, B., Mariş, I., Voinea, V., Mirea, P., Parnic, V., Dimache, M., & Lazăr, C. (2023). Non-Destructive Textural Characterization of Southern Romanian Neolithic and Chalcolithic Pottery Using Digital Image Analysis on Tomographically Reconstructed Sections. Heritage, 6(10), 6634-6647. https://doi.org/10.3390/heritage6100347