The Victoria and Albert Museum Plaster Casts by the Nineteenth-Century Workshops of the Notre-Dame Cathedral: Scientific Analysis and Conservation

Abstract

1. Introduction

1.1. Conservation of Casts at the V&A

1.2. The Nineteenth-Century Casts from the Notre-Dame Cathedral

2. Materials and Methods

2.1. Sampling

2.2. Technical Photography

2.3. Stereomicroscopy

2.4. Samples for Cross-Sectional Analysis

2.5. Visible Light Reflectance (VLR) and Ultraviolet Fluorescence (UVf) Optical Microscopy (OM)

2.6. X-ray Diffraction (XRD)

2.7. Scanning Electron Microscope (SEM)—Energy Dispersive X-ray Spectroscopy (EDS)

2.8. Fourier Transform Infrared Spectroscopy (FTIR) with Focal Plane Array (FPA) Imaging

2.9. Gas Chromatography/Mass Spectrometry (GC/MS) and Pyrolysis—Gas Chromatography/Mass Spectrometry (py—GC/MS)

2.10. Materials for the Conservation Treatments

3. Results

3.1. The Assessment of the Casts

3.2. The Characterization of the Materials of the Casts

3.3. The Conservation Treatments

3.3.1. Pouzadoux’s Casts

3.3.2. Malzieux’s Casts

4. Discussion

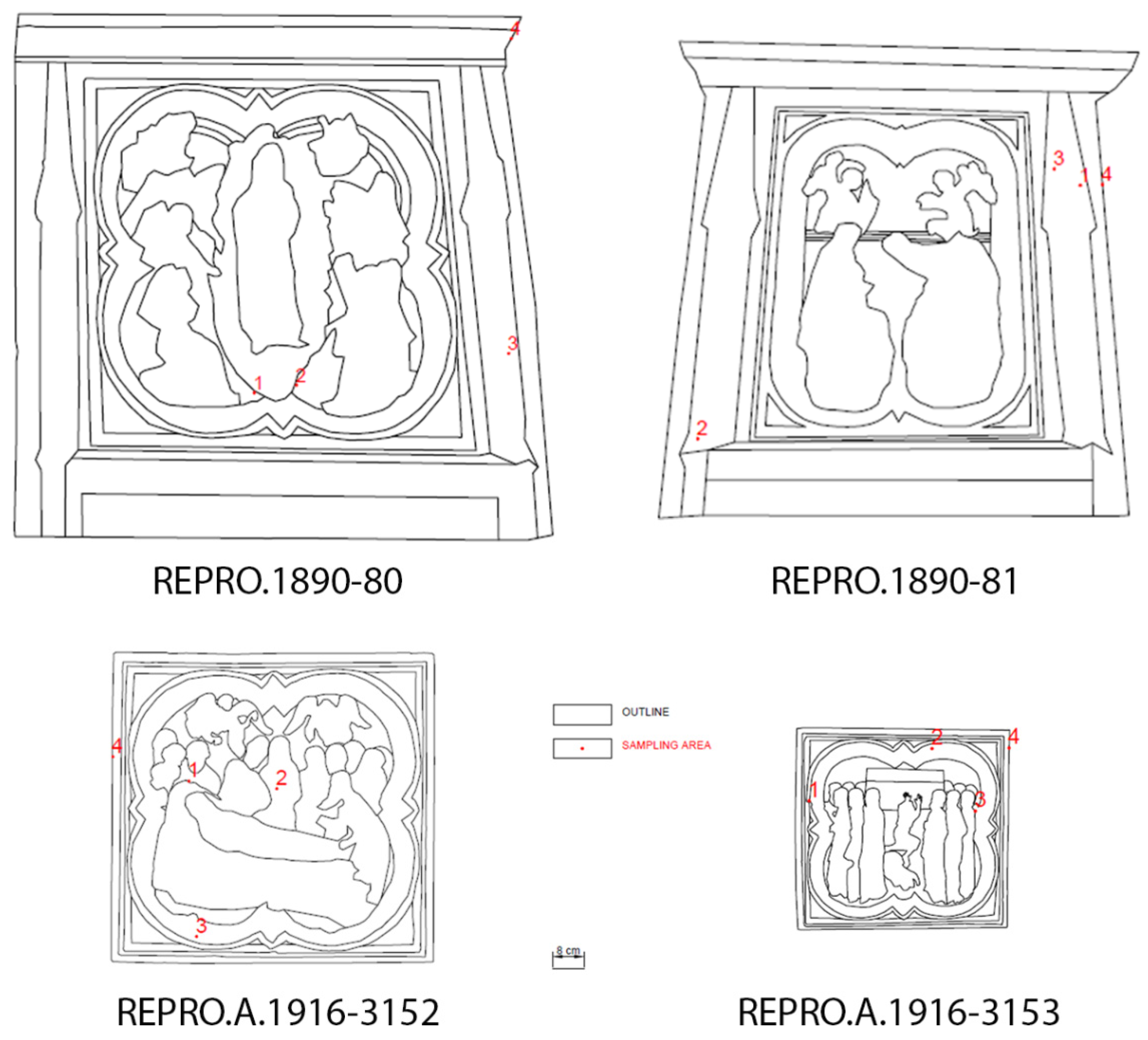

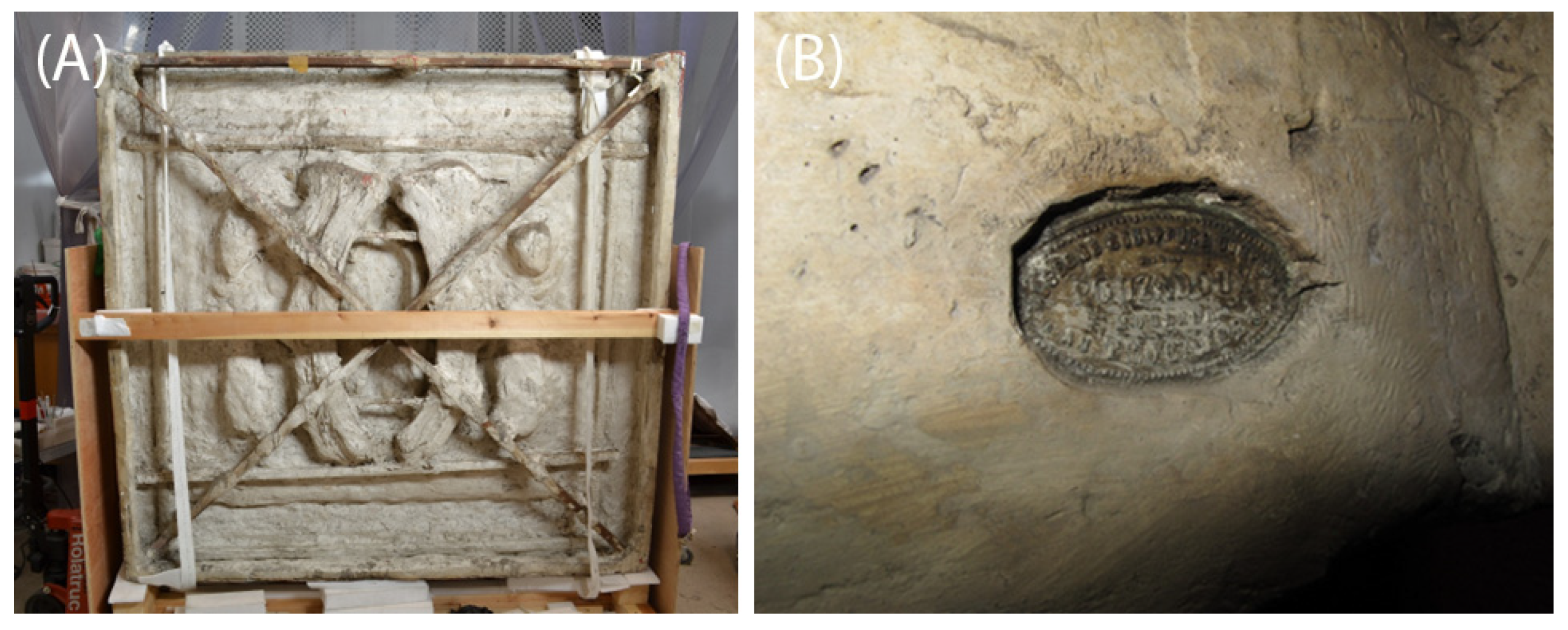

- Pouzadoux’s casts are considerably thinner and lighter and are built around a squared wooden structure (Figure 2). Wood is highly susceptible to hygrometric changes; thus, most of the conservation concerns about these two casts were regarding the movement of the wood causing flaking and the detachment of plaster. This was especially pronounced on the thinner areas of the panel, as well as the small plaster reinforcements on the back side and the lower edge. REPRO.1890-80 had a large crack running through the lower edge of the panel, showing some movement; this was a long-term structural concern caused by the movement of the wood. The surfaces of Pouzadoux’s panels are white and porous, and therefore the cleaning had to be aimed at a deeper level than that of Malzieux’s.

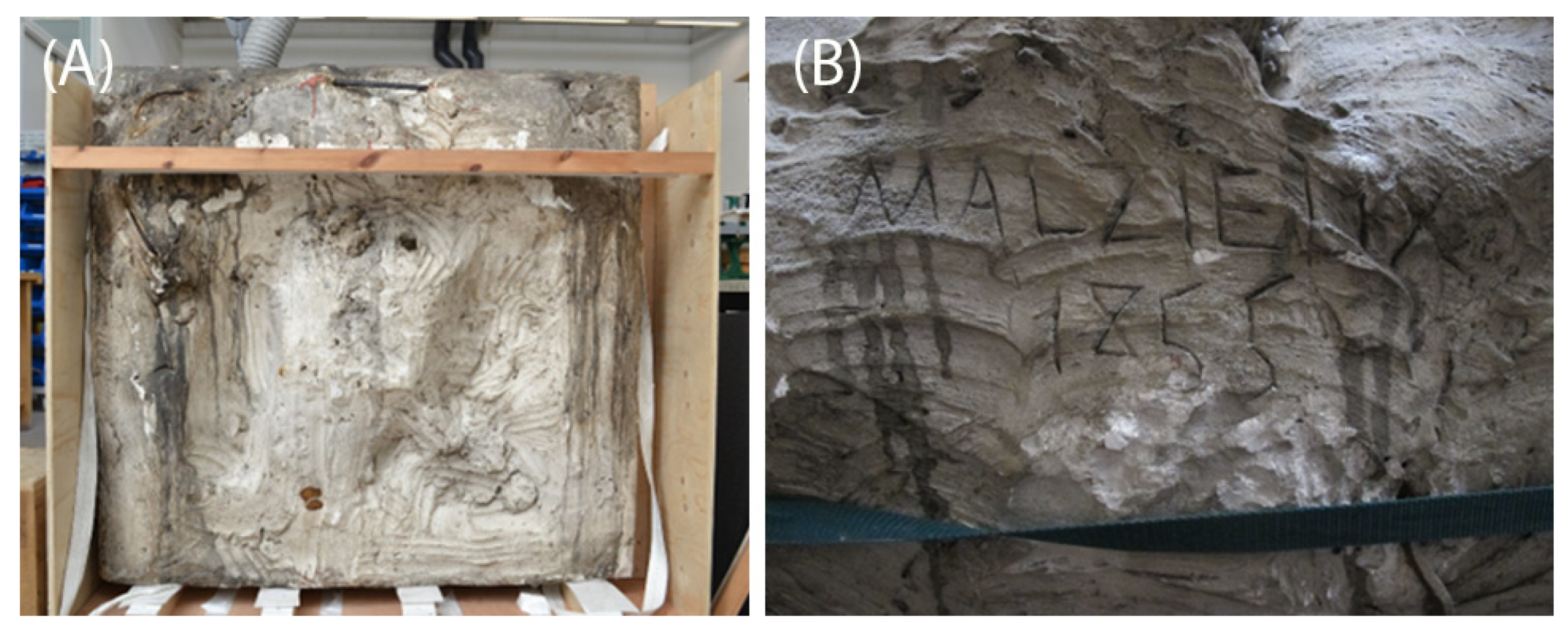

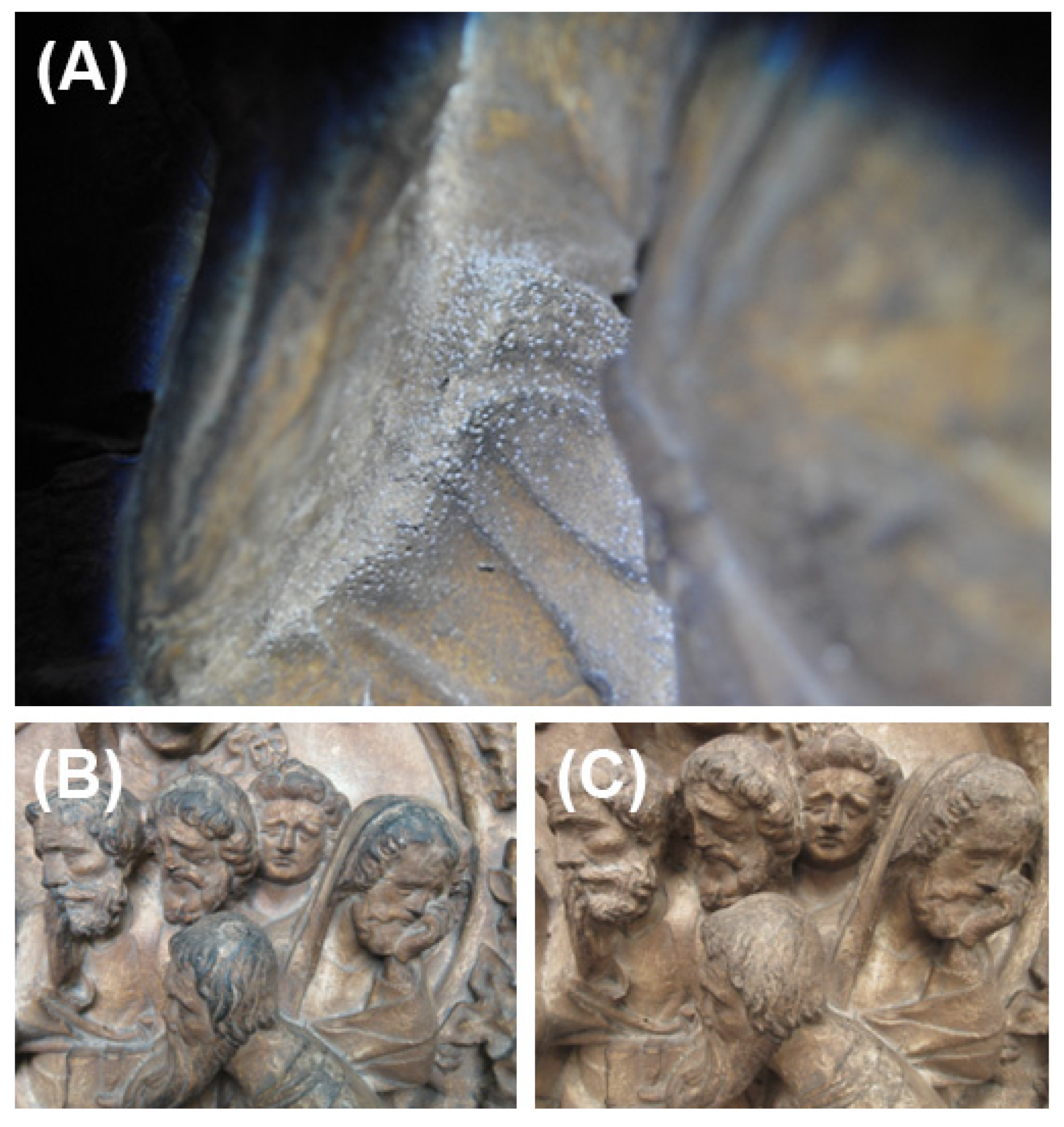

- Malzieux’s casts are heavier and are reinforced with a metallic structure, resulting in thicker, bulkier casts (Figure 3). It is quite possible that, during their time in the Architectural Association collection, they were patinated red, as many other casts acquired through this institution show similar patination and the same deterioration issues. Efflorescent salts on the surface (Figure 6) and ingrained dirt were the main issues flagged regarding the conservation of these panels, which were otherwise structurally stable.

- -

- Pouzadoux’s casts showed the presence of magnesium, silicon, and aluminium on the surface. The organic medium was identified as diterpenic resin in REPRO.1890-80 and shellac in REPRO.1890-81. In both cases, the additional presence of a drying oil could not be confirmed due to degradation and the characteristics of the samples.

- -

- The surface layers of Malzieux’s casts appear less straightforward. The samples taken from the front-facing side of REPRO.A.1916-3152 showed significant concentrations of lead, suggesting the possibility that these areas were highlighted with lead-based paint (also containing aluminium and silicon). Samples from the same object taken from marginal and recess areas showed the same stratigraphy as the other samples but did not contain lead. Additionally, some surface layers, fluorescing white-blue under UV illumination, were consistent with a layer of varnish. Analysis suggested the presence of diterpenic resin possibly mixed with a non-drying oil, which could have been applied to the surface or also mixed with the paint. The same medium was detected in REPRO.A.1916-3153, but in this case aluminium, silicon, and iron were the main elements on the surface layer. A sample likely taken from a repainted area showed a different layer of zinc–barium white paint.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Additional Images and Tables

| Object | Sample | Description |

|---|---|---|

| REPRO.1890-80 | 1 | Fragment taken from an area of loss along a crack, PR side. |

| 2 | Fragment taken from an area of loss along a crack, PL side. | |

| 3 | Fragment taken from an area of loss on the PL edge. | |

| 4 | Fragment taken from a large area of loss on the PL side, top rim. | |

| REPRO.1890-81 | 1 | Fragment taken from an area of loss on the PL architectural element. |

| 2 | Fragment taken from an area of loss on the PR, from the frame. | |

| 3 | Fragment taken from an area of loss on the PL, from the frame. | |

| 4 | Fragment taken from an area of loss on the PL, from the frame. | |

| REPRO.A.1916-3152 | 1 | Already detached fragment taken from the PR, under two figures. |

| 2 | Fragment, dust, and efflorescence taken from under the figure’s hand. | |

| 3 | Already detached fragment from an area of crack, bottom PR edge. | |

| 4 | Fragment taken from an area of loss, PR edge, red paint? | |

| REPRO.A.1916-3153 | 1 | Fragment taken from an area of loss on the relief’s PR |

| 2 | Dust and efflorescence taken from the top portion of the relief. | |

| 3 | Fragment taken from an undercut area on the PL of the relief. | |

| 4 | Fragment taken from an area of loss from the PL edge. |

| Label | Marker | m/z | RT 1 (min) |

|---|---|---|---|

| Fatty acid | |||

| 1 | Methyl azelate (A) | 42, 58, 74 (100), 87, 120, 138, 152, 171, 185 | 16.68–17.52 |

| 2 | Methyl palmitate (P) | 55, 74(100), 87, 101, 129, 145, 185, 199, 227, 239, 270 | 21.68–21.70 |

| 3 | Methyl stearate (S) | 74 (100), 87, 129, 143, 199, 255, 298 | 23.60–23.62 |

| Diterpene resin | |||

| 4 | Methyl 7-oxo-15-hydroxy-dehydroabietic acid | 58(100), 71, 85, 115, 149, 207, 219, 251, 270, 299, 331 | 22.79 |

| 5 | Methyl 7-Oxodehydroabietic acid | 44, 58, 74, 87, 129, 171, 187, 207, 239, 253(100), 281, 299, 314, 328 | 25.47 |

| 6 | Methyl dehydroabietate | 141, 155, 197, 239(100), 253, 314 | 25.57 |

| 7 | Methyl oxo-dehydroabietic acid | 44(100), 79, 115, 165, 191, 207, 227, 267, 281, 342 | 26.72 |

| Shellac | |||

| 8 | Jalaric acid | 59, 69, 83, 87, 105, 121, 135, 145, 167, 179, 191, 203, 208, 231, 247, 262(100), 275, 307, 322 | 23.35 |

| 9 | Shelloic acid | 55, 71, 97, 109, 137, 169, 201(100), 231, 261, 291, 304, 336 | 23.82 |

| 10 | Shellolic acid | 59, 79, 91, 129, 169, 206, 229, 238, 260, 288, 305, 320(100), 337 | 24.53 |

| 11 | Aleuritic acid | 44, 55, 71(100), 81, 109, 137, 159, 201, 207, 239, 312, 327 | 25.54–26.52 |

| Phthalic compound | |||

| 12 | Phthalic anhydride | 45, 55, 71(100), 85, 101, 111, 142, 147, 156 | 10.67–13.67 |

| 13 | Dimethyl phthalate | 58, 77, 92, 104, 133, 163(100), 194 | 16.35 |

| Sample | Stratigraphy (Layers) |

|---|---|

| REPRO.1890-80_1 | 1. Dark surface layer with dark particles 0. Calcium sulfate bulk with Sr, Mg, Al, and Si inclusions |

| REPRO.1890-80_2 | 2. Dark surface layer 1. Yellow interface layer 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.1890-80_3 | 2. Dark surface layer 1. Yellow interface layer 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.1890-80_4 | 2. Fluorescent coating layer * 1. Dark surface layer * 0. Calcium sulfate bulk with Al and Si inclusions |

| REPRO.1890-81_1 | 3. Fluorescent coating layer 2. Dark surface layer 1. Yellow interface layer 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.1890-81_2 | 2. Dark surface layer 1. Grey interface layer 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.1890-81_3 | 3. Fluorescent coating layer 2. Dark surface layer containing Mg and Si 1. Yellow interface layer 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.1890-81_4 | 2. Dark surface layer containing Mg and Pb ** 1. Yellow interface layer ** 0. Calcium sulfate bulk with Mg, Al, and Si inclusions |

| REPRO.A.1916-3152_1 | 2. Fluorescent coating layer 1. White layer mostly made of Si and Pb 0. Calcium sulfate bulk, rich in Pb and with Al and Si inclusions |

| REPRO.A.1916-3152_2 | 1. Dark surface layer 0. Calcium sulfate bulk, rich in Pb and with Al and Si inclusions |

| REPRO.A.1916-3152_3 | 1. Dark surface layer containing Sr, Al, and Si * 0. Calcium sulfate bulk with Sr, Al, and Si inclusions |

| REPRO.A.1916-3152_4 | 2. Fluorescent coating layer containing Sr, Al, and Si 1. Yellow interface layer with dark inclusions 0. Calcium sulfate bulk with Sr, Al, and Si inclusions |

| REPRO.A.1916-3153_1 | 2. Dark surface containing Al and Si 1. Yellow interface 0. Calcium sulfate bulk with Al and Si inclusions |

| REPRO.A.1916-3153_2 | Dust and efflorescence containing clay minerals, sulfates, and oxalates |

| REPRO.A.1916-3153_3 | 2. Dark surface containing Al, Si, and Fe * 1. Yellow interface * 0. Calcium sulfate bulk with Al and Si inclusions |

| REPRO.A.1916-3153_4 | 3. Dark surface layer 2. White layer made of Na, Zn, and Ba 1. Yellow interface layer with dark inclusions 0. Calcium sulfate bulk |

| Sample/Reference | 2θ [°] |

|---|---|

| REPRO.1890-80_2 | 11.63, 20.75, 29.10, 31.10, 33.36, 40.64, 43.31, 47.82, 48.34, 50.34, 51.37, 71.78 |

| REPRO.A.1916-3152_1 | 29.34, 31.39, 33.62, 43.65 |

| R040029 | 11.66, 20.77, 28.15, 29.14, 34.62, 36.00, 36.65, 37.41, 42.21, 44.23, 45.53, 46.46, 47.88, 48.40, 54.47, 55.19, 55.86, 60.36, 66.71 |

| R060509 | 11.69, 20.79, 28.16, 29.16, 36.01, 37.42, 45.55, 47.90, 48.42, 55.22 |

Appendix B. Characterization of the Organic Component in Mostly Inorganic Samples

References

- Frederiksen, R.; Marchand, E. (Eds.) Plaster Casts: Making, Collecting and Displaying from Classical Antiquity to the Present; Walter de Gruyter: Berlin, Germany, 2010; Volume 18. [Google Scholar]

- Bilbey, D.; Trusted, M. The Question of Casts—Collecting and Later Reassessment of the Cast Collections at South Kensington. In Plaster Casts: Making, Collecting and Displaying from Classical Antiquity to the Present; Frederiksen, R., Marchand, E., Eds.; Walter de Gruyter: Berlin, Germany, 2010; Volume 18, pp. 463–484. [Google Scholar]

- Foster, S.M.; Curtis, N.G.W. The Thing about Replicas—Why Historic Replicas Matter. Eur. J. Archaeol. 2016, 19, 122–148. [Google Scholar] [CrossRef]

- Brown, G.M. Art in the Age of Digital Reproduction. Available online: https://www.ft.com/content/74ffab6e-1b55-11e6-b286-cddde55ca122, (accessed on 20 February 2018).

- Payne, E.M. 3D imaging of the Parthenon sculptures: An assessment of the archaeological value of nineteenth-century plaster casts. Antiquity 2019, 93, 1625–1642. [Google Scholar] [CrossRef]

- Risdonne, V.; Hubbard, C.; Borges, V.H.L.; Theodorakopoulos, C. Materials and Techniques for the Coating of Nineteenth Century Plaster Casts: A Review of Historical Sources. Stud. Conserv. 2022, 67, 186–208. [Google Scholar] [CrossRef]

- Risdonne, V. Materials and Techniques for Coating of the Nineteenth-Century Plaster Casts. A Scientific and Archival Investigation of the Victoria & Albert Museum Cast Collection. Ph.D. Thesis, Northumbria University, Newcastle upon Tyne, UK, 2022. [Google Scholar]

- Kamel, A.M. Dehydration of gypsum component of plasters and stuccos in some Egyptian archaeological buildings and evaluation of K2SO4 activator as a consolidant. Sci. Cult. 2019, 5, 49–59. [Google Scholar] [CrossRef]

- Theologitis, A.; Kapridaki, C.; Kallithrakas-Kontos, N.; Maravelaki-Kalaitzaki, P.; Fotiou, A. Mortar and plaster analysis as a directive to the design of compatible restoration materials in Frangokastello (Crete). Mediterr. Archaeol. Archaeom. 2021, 21, 109–120. [Google Scholar] [CrossRef]

- Quilici, M.; French, C.; Chatzimpaloglou, P. Torba floors from the Maltese islands: A preliminary analytical study. Mediterr. Archaeol. Archaeom. 2022, 22, 183–192. [Google Scholar] [CrossRef]

- Ali, M.F.; Moussa, A.; El-Sayed, S.H. Analytical physicochemical survey of the recently excavated murals at the tomb of Iwrakhy/Hatia at Saqqara, Egypt. Sci. Cult. 2022, 8, 63–79. [Google Scholar] [CrossRef]

- Ashkenazi, D.; Shnabel, R.; Lichtenberger, A.; Tal, O. Chemical composition and microstructure analysis of plaster and pigments retrieved from a decorated house wall at Seleucid Tell Iẓṭabba (Nysa-Scythopolis, Beth She’an, Israel). Mediterr. Archaeol. Archaeom. 2021, 21, 89–122. [Google Scholar] [CrossRef]

- Da Riva, R.; Santos Arévalo, F.J.; Madrid i Fernández, M. The Mortars from rock-cut hydraulic structures of as-Sila (Sela) in Southern Jordan: Mineralogical characterization and Radiocarbon dating. Mediterr. Archaeol. Archaeom. 2021, 21, 37–67. [Google Scholar] [CrossRef]

- Roberto, G.; Eliano, D. Decay of red pigments on a wall painting adorning the church of ‘San Francesco Dei Capuccini’ in Racconigi (Italy): Archaeometric survey and restoration intervention. Mediterr. Archaeol. Archaeom. 2018, 18, 65–80. [Google Scholar] [CrossRef]

- Hubbard, C. Conservation of the Weston Cast Court at the V&A. Available online: https://3rd-dimensionpmsa.org.uk/features/2015-05-10-conservation-of-the-weston-cast-court-at-the-v-a (accessed on 26 October 2017).

- Miramón, J.G. Conservación y Restauración de Esculturas en Yeso en la Real Academia de Bellas Artes de San Fernando. Ph.D. Thesis, Universidad Complutense de Madrid, Madrid, Spain, 2019. [Google Scholar]

- Cast Courts: One Month to Go! Available online: https://www.vam.ac.uk/blog/caring-for-our-collections/cast-courts-one-month-to-go (accessed on 24 September 2022).

- V&A Website—Search the Collections. Available online: https://collections.vam.ac.uk/ (accessed on 10 December 2021).

- Hofman, J.M. Ephémères musées d’archéologie médiévale. La collection de moulages de l’humble M. Malzieux. Situ Rev. Patrim. 2016, 28. [Google Scholar] [CrossRef]

- Hofman, J.M. Rencontre avec un illustre inconnu Jean Pouzadoux (1829–1893), mouleur en plâtre. Conférence du 20 Janvier 2011. Bull. Société Hist. 6e Arrondiss. 2011, 24. [Google Scholar]

- BS EN 16085:2012; Conservation of Cultural Property. Methodology for Sampling from Materials of Cultural Property. General Rules. British Standards Institution (BSI): Loughborough, UK, 2012; ISBN 9780580705885.

- Risdonne, V.; Theodorakopoulos, C. Database of Results. V&A cast of the relief of The Assumption of the Virgin (REPRO1890-80). Northumbria University Figshare repository; v.1. 2021. Available online: https://figshare.northumbria.ac.uk/articles/dataset/Database_of_Results_V_A_cast_of_the_relief_of_The_Assumption_of_the_Virgin_REPRO1890-80_/14040080/1 (accessed on 17 October 2022).

- Risdonne, V.; Theodorakopoulos, C. Database of Results. V&A cast of the relief of The Coronation of the Virgin (REPRO1890-81). Northumbria University Figshare repository; v.1. 2021. Available online: https://figshare.northumbria.ac.uk/articles/dataset/Database_of_Results_V_A_cast_of_the_relief_of_The_Coronation_of_the_Virgin_REPRO1890-81_/14040182/1 (accessed on 17 October 2022).

- Risdonne, V.; Theodorakopoulos, C. Database of Results. V&A cast of the relief of The Death of the Virgin (REPRO.A.1916-3152). Northumbria University Figshare repository; v.1. 2021. Available online: https://figshare.northumbria.ac.uk/articles/dataset/Database_of_Results_V_A_cast_of_the_relief_of_The_Death_of_the_Virgin_REPRO_A_1916-3152_/14040224/1 (accessed on 17 October 2022).

- Risdonne, V.; Theodorakopoulos, C. Database of Results. V&A cast of the relief of The Entombment of the Virgin (REPRO.A.1916-3153). Northumbria University Figshare repository; v.1. 2021. Available online: https://figshare.northumbria.ac.uk/articles/dataset/Database_of_Results_V_A_cast_of_the_relief_of_The_Entombment_of_the_Virgin_REPRO_A_1916-3153_/14040251/1 (accessed on 17 October 2022).

- Risdonne, V.; Theodorakopoulos, C. Database of Results. Materials and techniques for coating of the nineteenth-century plaster casts. A scientific and archival investigation of the Victoria & Albert Museum cast collection. Northumbria University Figshare repository; v.1. 2021. Available online: https://figshare.northumbria.ac.uk/articles/dataset/Database_of_results_Materials_and_techniques_for_coating_of_the_nineteenth-century_plaster_casts_A_scientific_and_archival_investigation_of_the_Victoria_Albert_Museum_cast_collection_/14053985 (accessed on 17 October 2022).

- Lafuente, B.; Downs, R.T.; Yang, H.; Stone, N. The power of databases: The RRUFF project. In Highlights in Mineralogical Crystallography; Walter de Gruyter: Berlin, Germany, 2016; pp. 1–30. [Google Scholar]

- Gražulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Le Bail, A. Crystallography Open Database—An open-access collection of crystal structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef]

- Colombini, M.P.; Modugno, F. Organic Mass Spectrometry in Art and Archaeology; John Wiley & Sons: Chichester, UK, 2009. [Google Scholar]

- Singer, B.; McGuigan, R. The simultaneous analysis of proteins, lipids, and diterpenoid resins found in cultural objects. Ann. Di Chim. J. Anal. Environ. Cult. Herit. Chem. 2007, 97, 405–417. [Google Scholar] [CrossRef] [PubMed]

- Challinor, J.M. The development and applications of thermally assisted hydrolysis and methylation reactions. J. Anal. Appl. Pyrolysis 2001, 61, 3–34. [Google Scholar] [CrossRef]

- Challinor, J.M. The scope of pyrolysis methylation reactions. J. Anal. Appl. Pyrolysis 1991, 20, 15–24. [Google Scholar] [CrossRef]

- Linstrom, P.J.; Mallard, W.G. NIST chemistry WebBook, NIST standard reference database number 69, National Institute of Standards and Technology. J. Phys. Chem. Ref. Data Monogr. 1998, 9, 1–1951. [Google Scholar]

- Beauzac, J. L’histoire matérielle des moulages du musée de Sculpture comparée (1897–1927). Situ Rev. Patrim. 2016, 28, 8–12. [Google Scholar] [CrossRef][Green Version]

- Manfredi, M.; Barberis, E.; Rava, A.; Robotti, E.; Gosetti, F.; Marengo, E. Portable diffuse reflectance infrared Fourier transform (DRIFT) technique for the non-invasive identification of canvas ground: IR spectra reference collection. Anal. Methods 2015, 7, 2313–2322. [Google Scholar] [CrossRef]

- Gariani, G.; Lehuédé, P.; Leroux, L.; Wallez, G.; Goubard, F.; Bouquillon, A.; Bormand, M. First insights on the mineral composition of “stucco” devotional reliefs from Italian Renaissance Masters: Investigating technological practices and raw material sourcing. J. Cult. Herit. 2018, 34, 23–32. [Google Scholar] [CrossRef]

- Price, B.A.; Pretzel, B.; Lomax, S.Q. Infrared and Raman Users Group Spectral Database, 2007 ed.; IRUG: Philadelphia, PA, USA, 2009. [Google Scholar]

- Cox, K.G.; Price, N.B.; Harte, B. An Introduction to the Practical Study of Crystals, Minerals, and Rocks; Halsted Press: London, UK, 1974. [Google Scholar]

- Auerbach, A. Modelled Sculpture and Plaster Casting; Thomas Yoseloff: New York, NY, USA, 1961. [Google Scholar]

- Frederick, F.F. Plaster Casts and How They Are Made; Comstock: New York, NY, USA, 1899. [Google Scholar]

- Millar, W. Plastering, Plain & Decorative. A Practical Treatise on the Art & Craft of Plastering and Modelling, Including Full Description of the Various Tools, Materials, Processes and Appliances Employed; Donhead Publishing Ltd.: Dorset, UK, 1899. [Google Scholar]

- Wager, V.H. Plaster Casting for the Student Sculptor; Alec Tiranti: London, UK, 1963. [Google Scholar]

- Derrick, M.R.; Stulik, D.; Landry, J.M. Infrared Spectroscopy in Conservation Science; Getty Publications: Los Angeles, CA, USA, 2000. [Google Scholar]

- Vahur, S.; Teearu, A.; Peets, P.; Joosu, L.; Leito, I. ATR-FT-IR spectral collection of conservation materials in the extended region of 4000-80 cm–1. Anal. Bioanal. Chem. 2016, 408, 3373–3379. [Google Scholar] [CrossRef] [PubMed]

- Risdonne, V.; Hubbard, C.; Puisto, J.; Theodorakopoulos, C. A multi-analytical study of historical coated plaster surfaces: The examination of a nineteenth-century V&A cast of a tombstone. Herit. Sci. 2021, 9. [Google Scholar] [CrossRef]

- Chelazzi, D.; Poggi, G.; Jaidar, Y.; Toccafondi, N.; Giorgi, R.; Baglioni, P. Hydroxide nanoparticles for cultural heritage: Consolidation and protection of wall paintings and carbonate materials. J. Colloid Interface Sci. 2013, 392, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Toniolo, L.; Zerbi, C.M.; Bugini, R. Black layers on historical architecture. Environ. Sci. Pollut. Res. 2009, 16, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Poli, T.; Piccirillo, A.; Zoccali, A.; Conti, C.; Nervo, M.; Chiantore, O. The role of zinc white pigment on the degradation of shellac resin in artworks. Polym. Degrad. Stab. 2014, 102, 138–144. [Google Scholar] [CrossRef]

| Pouzadoux REPRO.1890-80 and REPRO.1890-81 | Malzieux REPRO.A.1916-3153 and REPRO.A.1916-3152 |

|---|---|

| Lightweight, wooden armature | Heavy, solid plaster, metal armature |

| Pale yellow patina | Brown-red patina |

| Acquired from Pouzadoux’s workshop in 1890 | Given by the Architectural Association in 1916 |

| Metal stamp with workshop name on lower half | Back side showing signature and date on fresh plaster, “Malzieux 1855” |

| Structurally weaker, detachment of plaster from wooden surfaces due to hygrometric changes. Large crack bottom edge on REPRO.1890-80 | Structurally in good condition, light corrosion on protruding metallic reinforcement, minor corrosion accretions |

| Stable semi-porous surface, ingrained dirt | Salt efflorescence, localized areas of powdery surfaces, ingrained dirt |

| Object | Bulk | Coating |

|---|---|---|

| REPRO.1890-80 | calcium sulfate with Mg, Sr, Si, and Al inclusions | dark under visible illumination, mostly containing Mg, Sr, Si, and Al, markers for diterpenic resin |

| REPRO.1890-81 | Calcium sulfate with Mg, Si, and Al inclusions | dark surface layer containing Mg and Si, markers for shellac, possible additional coating layer in protruding areas |

| REPRO.A.1916-3152 | from protruding areas: calcium sulfate bulk, rich in Pb, and with Al and Si inclusions from side or recess areas: calcium sulfate bulk with Sr, Al, and Si inclusions | Dark surface layer containing Sr, Al, and Si, markers for diterpenic resin repair: white layer mostly made of Si and Pb |

| REPRO.A.1916-3153 | calcium sulfate bulk with Al and Si inclusions | dark surface containing Al and Si (and Fe), markers for diterpenic resin repair: white layer mostly made of Na, Zn, and Ba |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Risdonne, V.; Francescutto Miró, A.; Morio, S.; Theodorakopoulos, C. The Victoria and Albert Museum Plaster Casts by the Nineteenth-Century Workshops of the Notre-Dame Cathedral: Scientific Analysis and Conservation. Heritage 2022, 5, 3427-3445. https://doi.org/10.3390/heritage5040176

Risdonne V, Francescutto Miró A, Morio S, Theodorakopoulos C. The Victoria and Albert Museum Plaster Casts by the Nineteenth-Century Workshops of the Notre-Dame Cathedral: Scientific Analysis and Conservation. Heritage. 2022; 5(4):3427-3445. https://doi.org/10.3390/heritage5040176

Chicago/Turabian StyleRisdonne, Valentina, Adriana Francescutto Miró, Sayuri Morio, and Charis Theodorakopoulos. 2022. "The Victoria and Albert Museum Plaster Casts by the Nineteenth-Century Workshops of the Notre-Dame Cathedral: Scientific Analysis and Conservation" Heritage 5, no. 4: 3427-3445. https://doi.org/10.3390/heritage5040176

APA StyleRisdonne, V., Francescutto Miró, A., Morio, S., & Theodorakopoulos, C. (2022). The Victoria and Albert Museum Plaster Casts by the Nineteenth-Century Workshops of the Notre-Dame Cathedral: Scientific Analysis and Conservation. Heritage, 5(4), 3427-3445. https://doi.org/10.3390/heritage5040176