1. Introduction

In a 2019 strategic plan [

1], government authorities in the Philippines noted that each year, food- and water-borne diseases (FWBDs) lead through diarrheal illnesses to an estimated 1.8 million deaths worldwide. The plan acknowledged that FWBDs challenge public health, as they account for up to 80% of illnesses in developing countries [

1]. It also stressed that in the case of the Philippines, FWBDs rank among the top 10 causes of morbidity and fatality [

1].

In 2015, a total of 11,876 cases of acute bloody diarrhea were reported from sites across the Philippines; the same year saw 830 reported cases of hepatitis A; 74 cases of paralytic shellfish poisoning were also reported [

2]. Within the Philippines, the Visayas Islands (particularly Regions 7 and 8) in 2016 showed the highest incidences of FWBDs, with Region 7 showing the highest incidence of acute bloody diarrhea and the highest number of reported cases for both hepatitis A and typhoid [

2]. In one city of Region 7, 14,329 cases of FWBDs (including 183 deaths) were reported between 2013 and 2017 [

3]. As of 2021, these were still the most recent figures available from government sources.

Guidance for implementing the Philippines’ Food Safety Act is supplied in the document referred to as Implementing Rules and Regulations (IRR). Article 2 Section 4 of the IRR acknowledges risk analysis and defines it as consisting of three components termed risk assessment, risk management, and risk communication [

4]. This lines up well with the FAO’s emphasis on using risk analysis for science-based solutions to problems related to food safety [

5]. However, the FAO has also emphasized that, in many local contexts around the world, traditional food inspection has focused on assessing food establishments’ compliance with reference to regulations that may or may not be up to date [

6]. To a considerable extent, the effectiveness of traditional product-based inspection depends on the time available for inspectors to physically check facilities and their products. Compared with the number of available inspectors and resources, it is common to find a considerable number of establishments that need to be inspected. In some countries, inspectors must also add public markets and street vendors to their inspection portfolio [

6], and this is the case in the Philippines.

The Philippines’ Department of Agriculture and Food and Drug Administration (FDA) have introduced effective measures at national and regional levels, but the country’s local government units (LGUs) use various product-based inspection procedures to handle complex sets of critical responsibilities. This has left small- and micro-scale food processing businesses, catering and similar food service suppliers, and retail and public markets—businesses that together form one sector of the food chain—to be regulated using instructions issued in 2006 [

7]. These instructions were issued according to guidelines that were supplied in 1995 for sanitation in food establishments [

8]. Based on the most recent data provided by the Department of Health, across the decade leading up to the date of their report, this sector presented most of the recorded outbreaks of foodborne illness in the Philippines [

9].

The WHO’s Western Pacific Regional Office, in its consultative dialogue with member states in 2016, recognized known outbreaks of FWBDs in the region as incidents prompting the decision to assess needs and then develop national food control systems’ capacity [

10]. The aim of the dialogue was to complete a Regional Framework on Food Safety in the Western Pacific, outlining key strategies to address food safety.

Supporting the aim of the Western Pacific Regional Office’s dialogue, this study explored the needs corresponding to the framework’s strategies in the local context of one LGU in the Philippines. While the FAO’s guidelines for assessing and then building capacity suggested the methodology adopted in this study [

11], prominence was also given (based on the WHO’s framework [

12]) to risk-based food inspection and enforcement. This study was an extension of the same principal author’s work conducted in 2016 and published in 2019 as an article of research [

13]. The site for the study was a city in the Philippines. To protect the identity of each participant situated in the context of that city’s LGU, we will withhold the name of the city.

To illuminate how risk-based legislation was enacted, and to assess the LGU’s food inspection practices and needs, the central research question for this study was: What are the LGU’s current needs in relation to its food service inspection capacity and practices? This qualitative study, in its social-scientific framework, relied on data in the form of natural language and iterative analysis, aiming to highlight social practices that could promote full use of risk-based food inspection. This article presents findings from the study’s specific context, combining reflexive inquiry with the specific methods of a (qualitative) correlational study between legislative documents and focus-group discussions, followed through observational research toward analysis based on strengths, weaknesses, opportunities, and threats. A discursive approach, using qualitative methods to explain and describe the functions of discourse and social practices around the LGU’s needs and its capacity to uphold and enforce national regulations, characterizes the methods in this article.

2. Materials and Methods

We began with the research question: What are the LGU’s current needs in relation to its food service inspection capacity and practices? This was a qualitative study [

14], the techniques used in the research being selected for their potential to generate knowledge about human experiences and actions, including social practices, around this LGU. Our methods involved analysis not of numerical values but of natural language and other forms of expression in the documents, among participants in the focus groups, and in specific observations.

The FAO’s guidelines allowed for clarity on how to assess needs and begin to build capacities for food inspection [

11]; our study fundamentally followed these guidelines. For this article, it was also necessary to summarize how we applied the research design, adding specific notes on strategies for collecting and analyzing data.

2.1. Study Participants and Data Sources

The principal author of this study had already published one article based on research related to the phenomena under study in this article [

13]. A non-Filipino resident of the Philippines, fluent in English, he held an advanced degree in medicine. His prior research enhanced and structured his collection and analysis of data, all of which he supplied to the secondary author, whose task it was to present this article from the viewpoint of a specialist in qualitative research. The supporting author, a native user of English, had no prior experience with research on the phenomena under study.

We agreed on a discursive approach to inquiry. As reflected in this article, we began by analyzing legislative and official documents, went on to correlate findings from that analysis with patterns in the focus-group data, and followed through in an observational study of sanitation inspectors’ work.

This study was conducted in English, which is an official language in the Philippines. The principal author, despite having worked with inspectors and industry representatives in other cities around the Philippines, had no personal acquaintance with any of the participants in the LGU. Two research assistants, both being Filipinos and food safety experts, helped in data collection and analysis; in case any language problems come up, requiring them to interpret, neither assistant had any earlier acquaintance with the participants.

Before the four focus groups’ discussions, the principal researcher reviewed all the Philippine national laws and regulations, including department orders and standards. The LGU’s relevant documents and records were also examined.

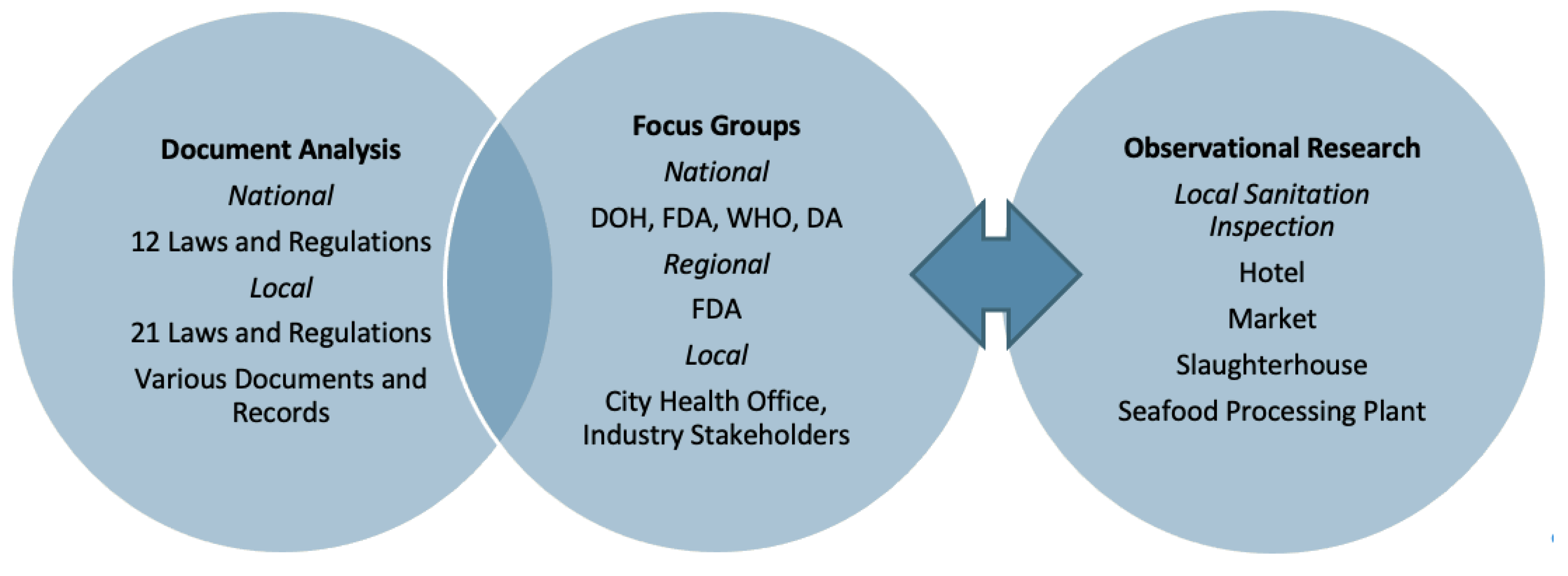

Figure 1 summarizes the sampling exercised in each technique.

As shown in

Figure 1, after analyzing the regulations and standards at the national, regional, and local levels, the principal author held discussions with four focus groups: one at the national level, one at the regional level, and two at the local level of administration. This formed a correlational study. To supplement the correlational study, observational research supplemented the data for this article.

2.2. Parcticipant Selection (Focus Groups and Observational Study)

Using limited resources while working with each focus group, purposeful sampling allowed for recruitment of information-rich participants who would have maximal knowledge, experience, and skills in the area being explored [

15,

16]. Email was used to recruit participants for each focus group, with telephone calls confirming the details as the date approached.

In the first focus group discussion, the 11 members spoke as representatives of the Department of Health, the Department of the Interior and Local Government, the WHO, and the Department of Agriculture. Environmental health officials from the national bodies were recruited using purposeful sampling with homogenous strategy. This strategy helped reduce differences in data and eased the in-depth analysis that would follow [

15]. The first focus group met in Manila on 2 October 2017.

All sanitation inspectors working with the City Health Office took part in a focus group made up of 43 individuals on 18 October. The following day, the principal author went with a crew of three sanitation inspectors on their rounds: this supplied data for the observational study. The inspectors visited a hotel’s restaurants and food storage/preparation areas, followed by a public market, a slaughterhouse, and a seafood processing plant.

The remaining two focus group discussions were held on 20 October. The principal author met with two regional representatives of the FDA and with a group of ten members recruited from among industry representatives including restaurant managers, hygiene managers, public market administrators, and so forth. When random sampling was insufficient because some representatives were unavailable or unwilling to take part, convenience-based purposive sampling was used to recruit a representative number of participants from each sector [

15].

Given the FAO’s guidelines but also limited resources, it was conveyed to all participants that the study was focused only on this one LGU. It had been selected for its prominence among regions with the highest incidences of FWBDs at the time of the study. Informed consent was obtained from all participants in the focus groups and the observational study; lunch was supplied for each of the focus groups, but no other incentive or compensation was involved.

2.3. Guidelines and Data Collection

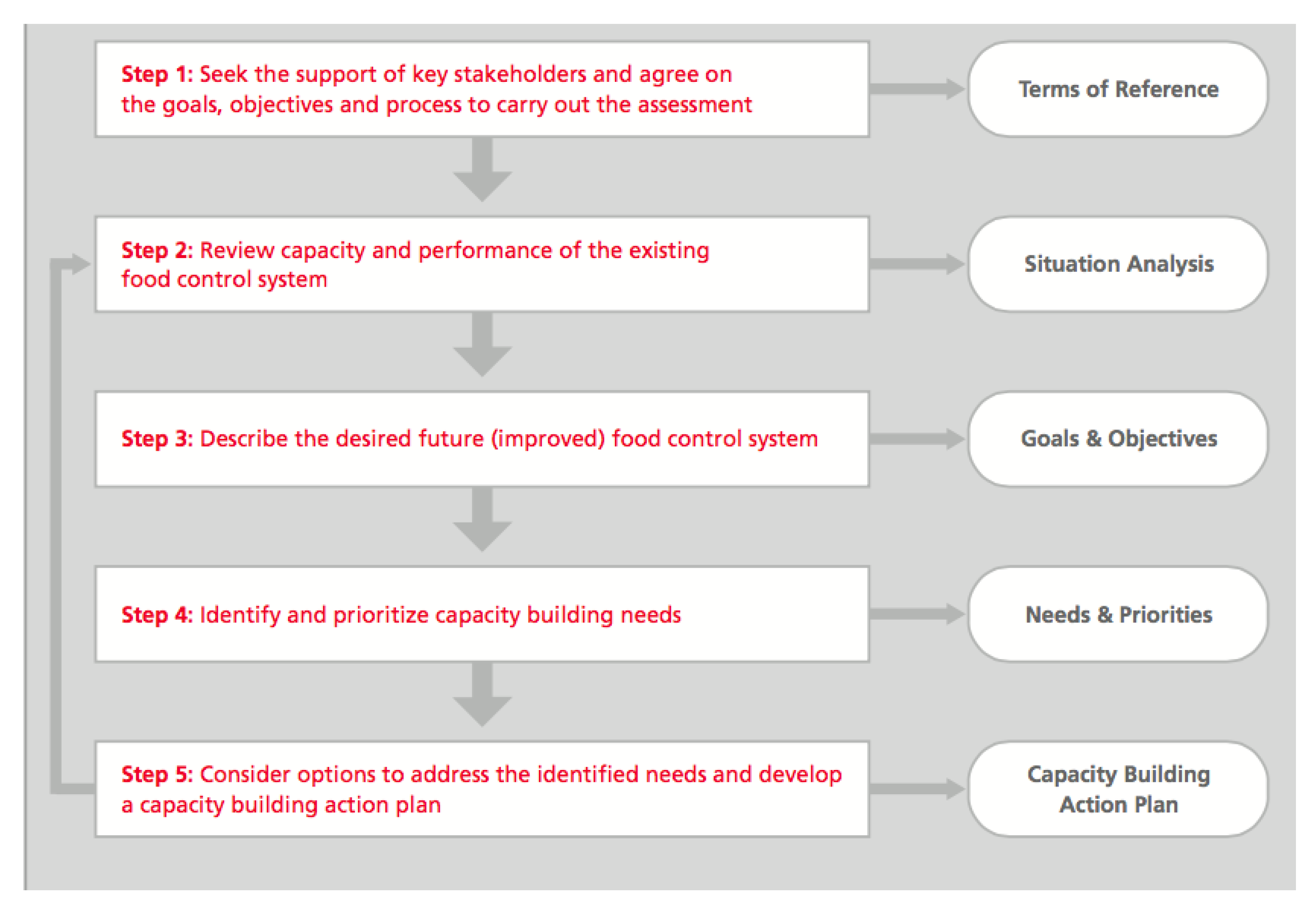

Figure 2 shows an outline of the FAO guidelines [

11] (p. 6), emphasizing the process from Step 1’s terms of reference through situation analysis, statement of goals, and assessment of needs to options for addressing needs and thus building capacity. The rationale for selecting this design (especially Steps 2–4) was a matter of holding the FAO’s mandate in balance with the local context and available resources including budget, time, coordination, weather conditions, human resources, and so forth.

As discussions in focus groups became central, the data collected during these discussions were to be correlated with naturalistic analysis of legislation and related documents. The focus groups would enable stakeholders such as sanitation inspectors, food producers, and caterers to supply their personal and contextualized views on food inspection. Meanwhile, as shown in

Figure 1, an observational study tracked sanitation inspectors’ activities at various food establishments, yielding field notes for further triangulation [

15]. This continuous triangulation was taken as a measure to confirm the validity of data [

16], allowing the researchers to use different data sources and thereby confirm accounts given in focus group discussions. For example, checking job descriptions allowed us to compare sanitation inspectors’ mandated roles and responsibilities with what they said in the focus group discussions. In this way we were able to map the data from the focus group against all the relevant legislation, documents, and records. This in turn allowed us to clarify salient substance and patterns in the real-life situation [

17]. Using multiple techniques to gather data was thus meant to offset the limitations of each technique, further enhancing validity and reliability in the data [

16].

With the focus groups on one side of the correlational study we planned, it was of key importance that the data be collected in an environment natural to the participants and their discussions, free of experimental manipulation. The purpose in this nonexperimental design was to notice, describe, and analyze relationships among variables of interest as they occurred naturally. Our first variables would begin to reveal how needs and capacity informed the LGU’s practices, and how those practices related to the legal framework. As the focus group discussions unfolded, the principal author was prepared for new variables to arise and, in the observational research, viewed participants’ characteristics, circumstances, and history independent of any input from the research process.

Data were first collected in the form of documentary evidence to name the current legal requirements, standards, and procedures. All available legislation and standards were analyzed, as were any critical documents and records relevant to food inspection.

Table 1 shows a list of the documents analyzed, including 12 national laws and regulations and 21 local laws and regulations, as well as the types of documents and records. Some were available online and the rest were to be obtained by formal request from government officials at various levels.

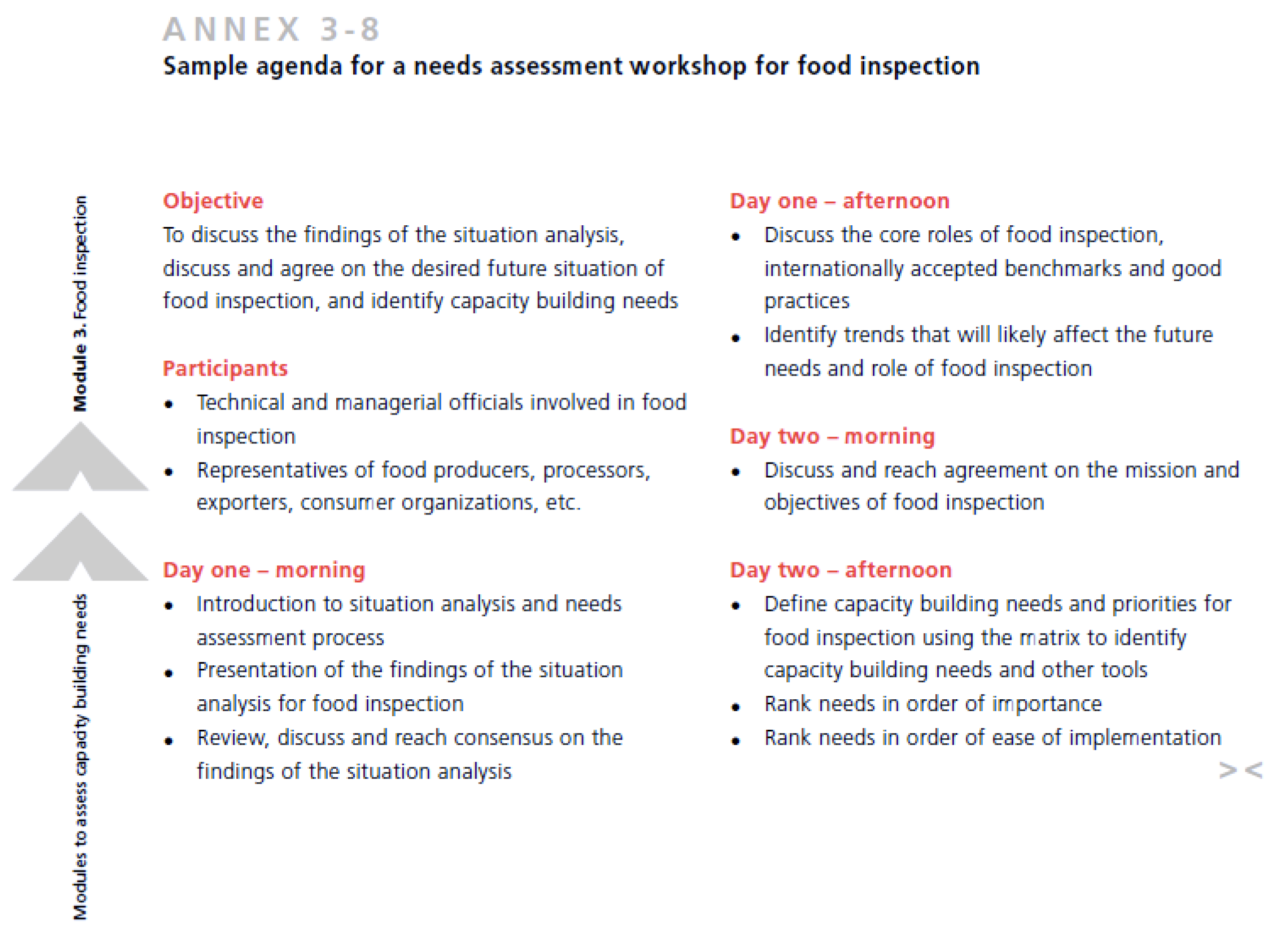

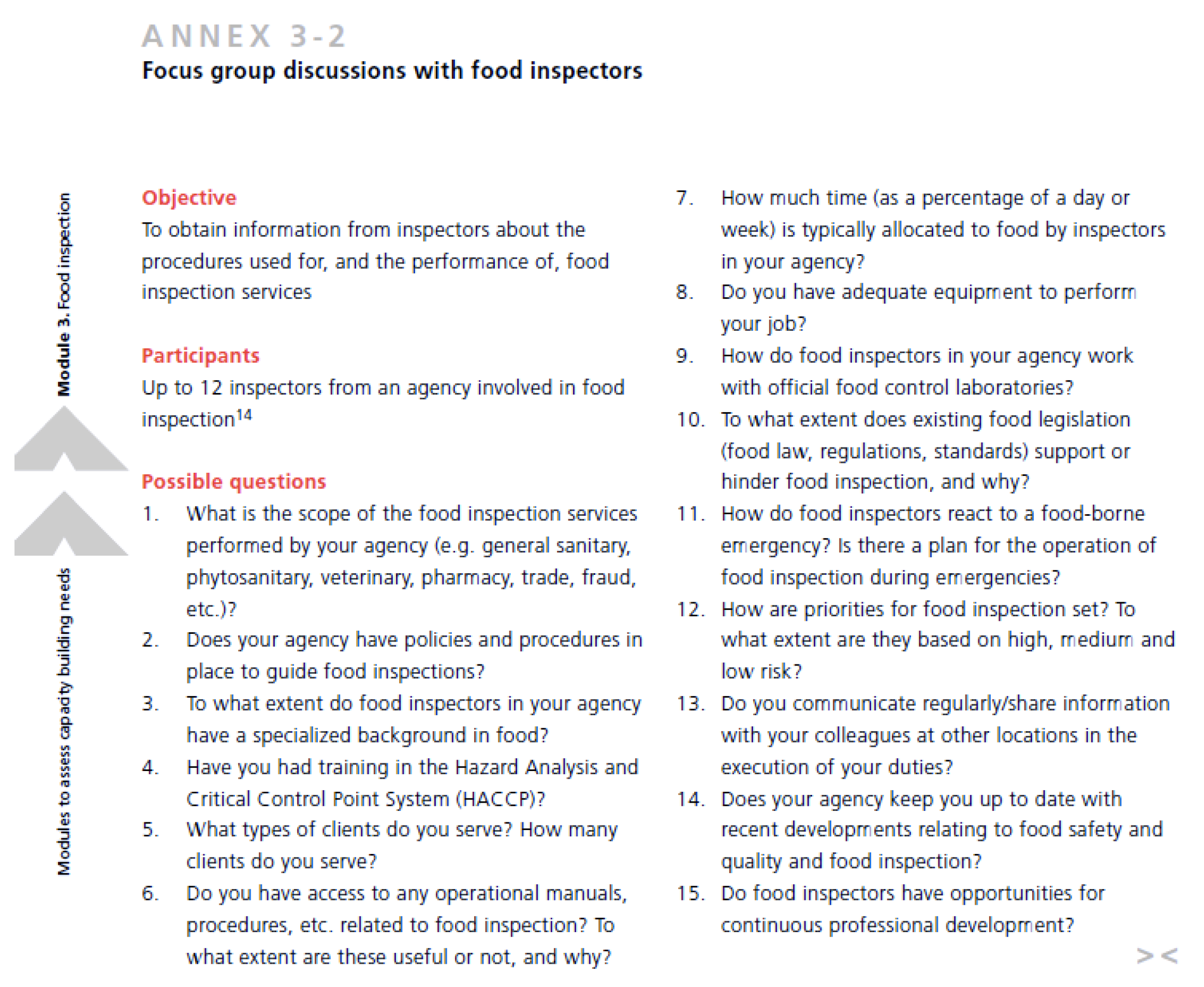

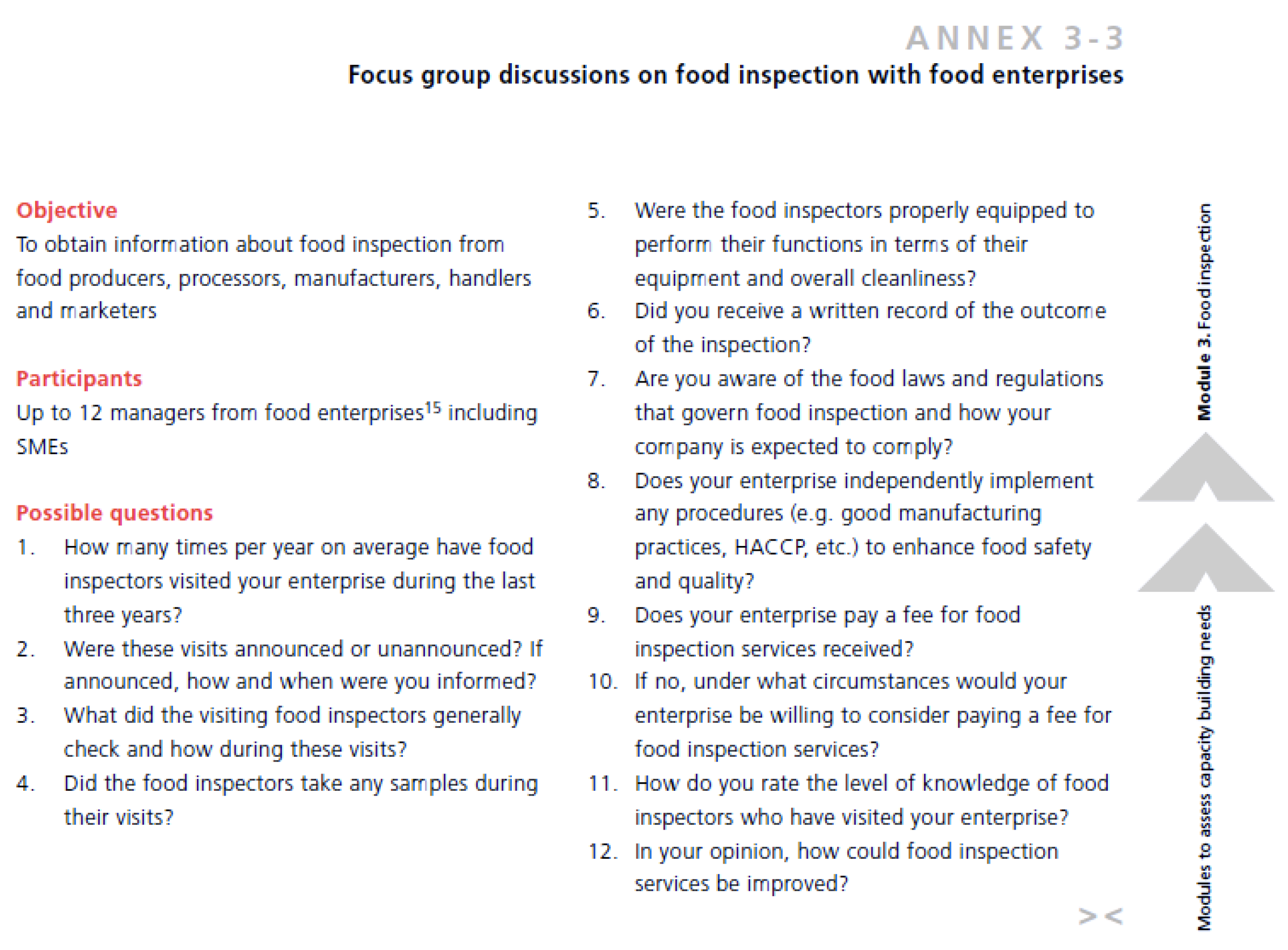

For each of the three focus groups (of national government officials, sanitation inspectors, and industry representatives), structured guidance was offered using a questionnaire. The respective questionnaires, in addition to clear agendas for the three groups’ meetings [

11], were obtained from the FAO. The focus group discussions were conducted in English, with one or both research assistants attending and taking notes, interpreting if needed, and audio-recording the sessions. Each session took about six hours. Each participant received a copy of the questionnaire.

Appendix A shows the main FAO documents used for their series of questions in the focus groups.

The principal author read the questions and then led discussions among members of each focus group to explore the questions in turn. He then gave feedback and finally asked participants to write down their final answers on a form he provided.

For the observational study, the principal author joined a random sanitation inspectors’ team based on their daily schedule, following the team’s activities during one full day of their work. He watched and took notes, photos, and videos, without direct interference or interaction, while they inspected different food service and production establishments under the authority of the LGU.

2.4. Analytic Strategies

For the document analysis, we followed an international benchmarking approach recommended by the FAO to reveal needs in the current practices in food hygiene requirements and recommendations with respect to the legislation and standards as compared to international equivalents [

11].

Table 1 lists and categorizes the various documents that were analyzed. Correlating these and the focus group data, we also mapped the focus groups’ answers on their respective questionnaires against the local legal requirements. This effort to trace discursive practices and name any shortfalls was kept up as we analyzed field notes from the observational study.

To follow the FAO guidelines and thus construct a discursive understanding of the needs presented in this LGU concerning food inspection standards and practice, all data was collected in English if possible. Where English was not used, the two research assistants carried out any necessary translations, cross-checking back and forth to gather the data in English. The assistants also made transcripts of the tape recordings from focus group sessions, comparing and cross-checking the content in comparison to the answers given in writing by the various participant stakeholders. Once we had the raw data organized, we applied a thematic content analysis using Word 2016 (Microsoft, Redmond, WA, USA) to code different themes. The main themes were selected prior to the analysis, based on the FAO’s [

11] suggestion for assessing needs using a matrix to find strengths, weaknesses, opportunities, and threats (SWOT). The unit of analysis was the answer to a question. That is, each point of information obtained in the document analysis was taken as one answer, and each answer obtained in the focus group discussions was equally one unit for the purposes of our analysis.

To maximize rigor during data analysis, every procedure and detail through the study was properly documented and reviewed to make sure there would be an “audit trail” available for transparency and tracking. For reliability, the principal author analyzed the full set of data and compared notes to discuss themes and patterns with the research assistants who each took part in the coding [

17].

3. Results

The results of our SWOT-based analysis revealed real-life practices around food safety inspection in the LGU. To present the results in a manner compatible with the study design we used, we selected for illustration the most salient findings. The findings lend to a detailed assessment of needs and the potential they show for capacity building, as found in the specific context of this LGU.

3.1. Correlational Study

The focus group discussions revealed several points of correlation supporting the results from document analysis. The findings of this correlational study showed that, for paperwork and action involving food inspections, the LGU’s administrative process was based on the Sanitation Code of the Philippines. Meanwhile, the FDA in its authority for Region 7 was conducting adequate and effective efforts on food control for medium- and large-scale processing plants and distributors, and this agreed with the FDA’s IRR as issued in 2009. The Food Safety Act of 2013 and the related IRR of 2015, along with other regulations and administrative orders, supplied a good foundation for an integrated food control system. The 1991 Local Government Code had assigned a city veterinarian and agriculturist to control primary production of animals and plants as sources of food within the LGU. This provision, and the provision placing the city health officer (through the work of sanitation inspectors) in control of food in public dining sites, was upheld in practice. There was also a policy manual in use, on services and protocols, that had guidelines for investigating FWBD outbreaks. Most sanitation inspectors agreed to the idea of a food safety force composed of specialized food inspectors whose work would be set apart from that of the sanitation inspectors. This would be in keeping with the Food Safety Act’s 2015 IRR. Given sanitation inspectors’ willingness to learn and improve, these points can all be listed as strengths and opportunities in the LGU’s practices concerning risk-based food inspection.

However, the 1991 Local Government Code did not specify who exactly should oversee food processing and manufacturing in LGUs. The Act said the FDA oversaw food manufacturing and processing at the national level, while LGUs were responsible at the local level. The Act did not clarify through which channel the LGUs should oversee food manufacturing and processing in their jurisdictions. Nor did it distinguish large- and medium-scale processing sites (currently regulated by the FDA) from small- and micro-scale processing operations. Regarding the matter from the local viewpoint, document analysis revealed that the FDA was not mentioned in the Local Government Code. Given the FDA’s authority as described under the IRR of 2015, the Local Government Code left the LGU responsible for small- and micro-scale processing. However, the same IRR made the LGU responsible for the primary-production roles of the city agriculturist and veterinarian, and for selling or serving food. The main weakness and threat in practice around the LGU was thus the fact that secondary production (i.e., processing) could only be accounted for in legislation concerning the FDA. Like the Department of Agriculture for primary production at the local level, the FDA handled food manufacturing at the national and regional level. The LGU needed to coordinate sanitary food service at restaurants, in catering, and at points of sale.

The only available regulations for catering, retail, and restaurant service, like those for public markets, were in Chapter 3 and part of Chapter 4 of the IRR for the national sanitation code as issued in 1995 and 1998. This document referred exclusively to the Department of Health and mentioned no particular role for that body; this may explain why we found no office outside of the Department of Health in charge of catering and end service. So, unlike the presence of the FDA for manufacturing and of the Department of Agriculture for primary production, there seemed to be a need for clear coverage of food service.

3.2. Observational Research

Observing the practice of sanitation inspectors, we found that industry stakeholders were willing to cooperate and to offer help when needed. This lined up well with what we had gathered in the focus groups. However, food processing presented a puzzle because, in the case of small- and micro-scale operations, it was not clear what consistent coordination might join the FDA’s authority and the LGU’s ordinance. As in the legislation, so in the local practice: Specific regulation of micro-scale food processing was difficult to account for.

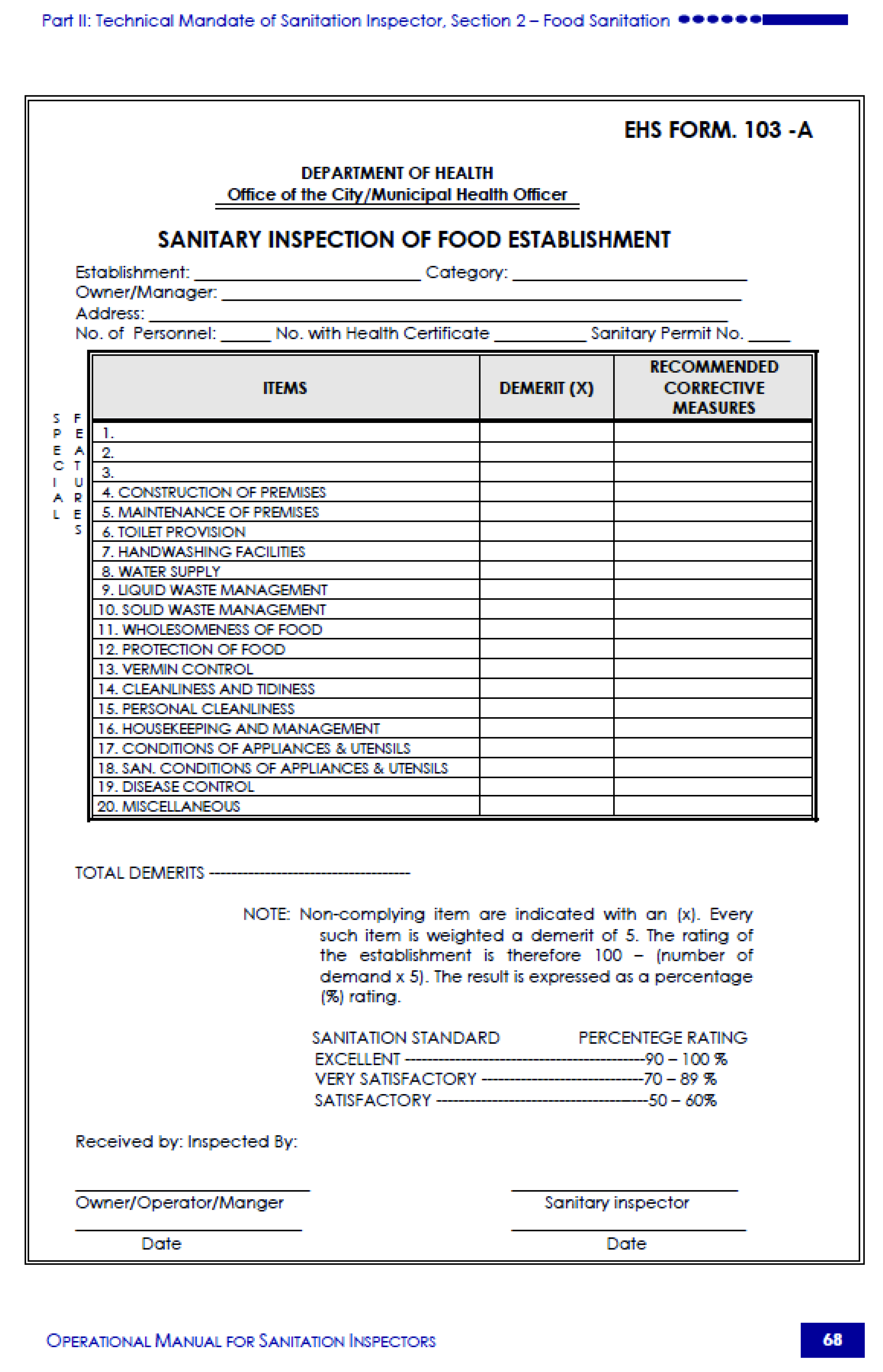

The checklist for food establishments, as used by sanitation inspectors (see

Figure 3), supplied 16 specific points to work with and added space for inspectors to record other observations. This checklist, shown in

Figure 3, needed to address sanitation issues and would require special interpretation on the inspectors’ part if it were to be used for risk-based food inspection. This checklist did not mention, for example, specifics of potential cross contamination from raw to ready-to-eat products, or proper temperatures for cooking or holding food. Such specifics would refer to the WHO’s outline of universal risk factors [

6]; they would mark a dramatic improvement in the utility of this checklist, provided by the national government in its manual for sanitation inspectors. It would then be possible to build capacity throughout the country’s LGUs in accordance with the national government’s official policy.

4. Discussion

Our observational research uncovered a need for updated specialization in food safety inspection. The FAO’s guidelines for risk-based food inspection describe as necessary the use of equipment including proper attire (including coats, goggles, gloves, and hard hats) and a variety of tools for selection, separation, and transport of samples from inspection sites [

6,

18]. These and thorough training would have the potential to increase the LGU’s capacity in food inspection practices, essentially adding to the capacity of the city’s sanitation inspectors a new range of specific skills and implements. It would also allow for the creation of a specialized food safety officer’s role, as required under the 2015 IRR to the Food Safety Act.

The focus group discussions revealed duplicate inspections of large- and medium-scale food production establishments. The FDA would issue accreditation, and the LGU would issue a sanitary permit. The FDA would also check on sanitation. One body carrying responsibility would make more sense for these larger food production establishments. Within the FDA, if attention goes first to large- and medium-scale plants, human resources may not be adequate to cover small- and micro-scale processors.

Meanwhile, all members of the City Health Office staff attended the focus group discussion held on their premises, and it was revealed that the title of Food Safety Officer was not on the roster. Sanitation inspectors handled a full spectrum of sanitation issues, including those related to food. Until the nation gives the mandate, the LGU cannot create this designation. Until then, the LGU’s training programs for inspectors (like others in Asian countries) could begin by including a focus on risk-based inspection methods [

13,

18,

19,

20].

This study’s central contribution was local in focus, exploring the discourse and needs around food inspection in one LGU. In that local context, the practices around national legislation and mandates revealed considerable potential for similar studies in the Philippines. Between product-based inspection and risk-based regulation systems, there is room for further studies. Quantitative studies to update the statistics and epidemiology of the situation will be of interest, and qualitative studies like this one could investigate any number of LGUs, beginning to get a picture of what various local contexts have in common, and what sets some apart from others. For now, it is known that risk-based assessment holds real promise for Asian countries including the Philippines [

18,

19,

20]; in the Philippines, frequency and priority of food inspection could begin to be assigned based on risk levels and categories among food businesses.

Practices in focus group methods reveal that, regardless how small a group is in number, the data it generates can allow for transferability in the findings. This potential transferability to other contexts depends on the findings’ ability to develop not quantitative estimates of error and generalizations to populations but deep, contextualized understandings which readers may then apply. This study’s focus on practices found in one LGU was therefore intended to allow readers to see the results and their analysis in context. We aimed to present as much depth of detail as possible, allowing readers to evaluate the understandings we developed through our results and analysis.

Our discursive approach in this article has confirmed that clear legal statements concerning the role of inspectors from different agencies in this LGU, compared to national regulations, call for clarification of the roles the FDA could assume within the LGU [

19]. Whether this example was enacted through the FDA itself, or the FDA had a clear mandate to focus on large- and medium-scale food processing and distribution operations, it could officially make small- and micro-scale processing operations the LGU’s clear responsibility [

19]. With the FDA’s potential to offer professional training for the LGU in this endeavor, such a measure could strengthen the control of sanitation inspectors for food safety inspection purposes. It could begin with their enhanced training in risk-based assessment of food safety. Specifically, as has been found in similar studies [

18,

19,

20], a new designation of specialized food inspectors would be helpful in the case of this LGU. Such inspectors, grouped under a food safety officer, could take integrated control of risk-based inspection for farm-to-fork food safety under the LGU’s mandate, as specified by the Food Safety Act [

4].

The national government’s most recent work in this area appears to be moving toward classroom education, hands-on training in the field, controlled examination, certification, and refresher training [

1], as required by the Food Safety Act. This is to be applauded and, now that it has been proposed, it will remain interesting to continue conducting studies like the one this article has presented.

Governmental recognition of the need to control the risk of FWBDs in the Philippines may now include (but need not be limited to) food risk assessment, risk management, emergency response and investigation, antimicrobial resistance, traceability, industry training, and consumer education [

18,

19,

20]. With adequate resources for food inspection activities, LGUs like the one we studied could include considerations of budget, workforce, infrastructure (including internet), computers, tools, and other equipment [

19]. Internal auditing procedures could ensure continual improvement [

19]. While this study may be the first of its kind in the Philippines at the LGU level, we acknowledge its main limitation: it was focused on discursive practices and needs in one LGU. The results discussed here may be transferable, but we urge caution and further study before beginning to generalize from this LGU to others in the Philippines, except through that aspect of the study’s findings which is related to national regulations.