Chitosan-Based Composites for Sustainable Textile Production: Applications Across the Lifecycle

Abstract

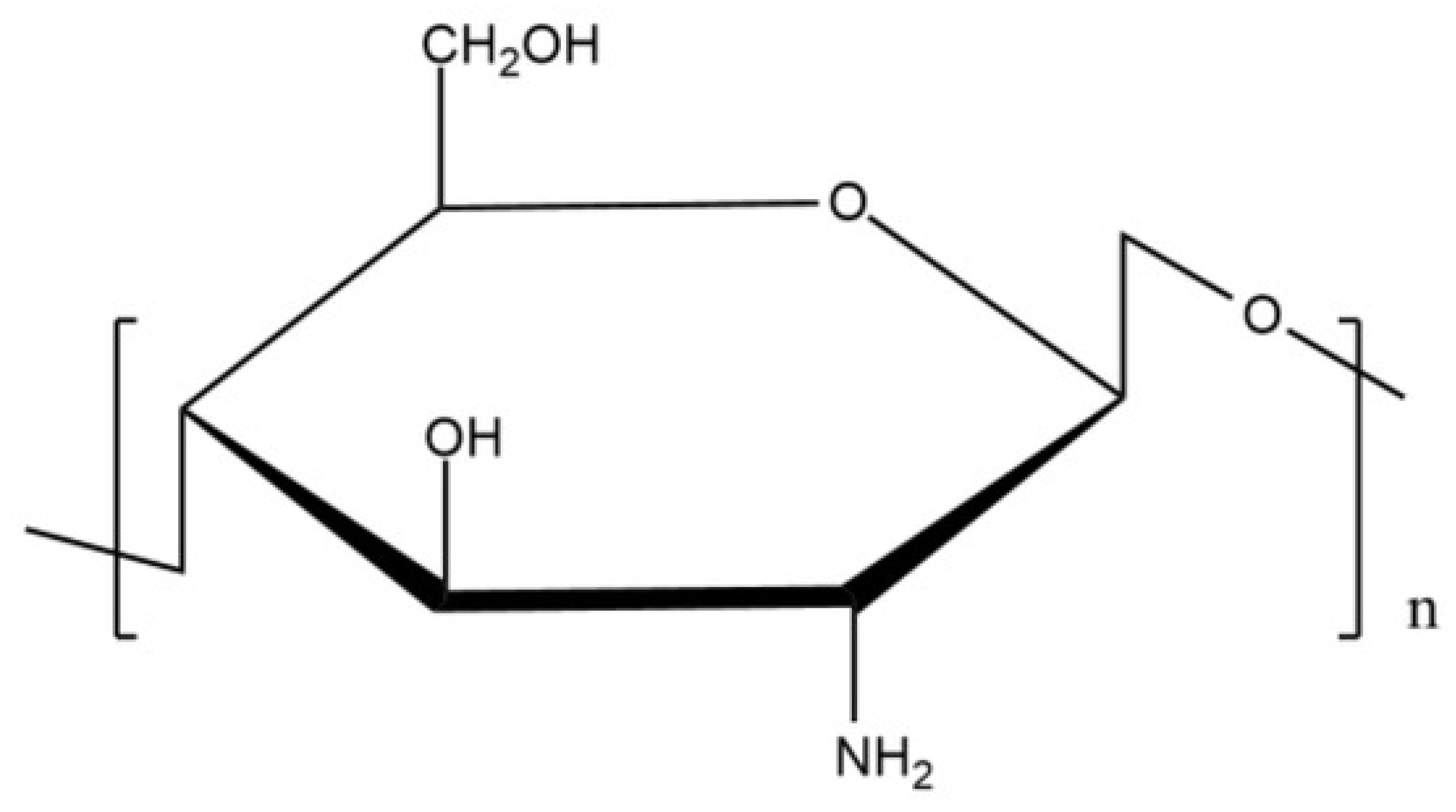

1. Introduction

2. Production of Chitosan-Based Textile Materials

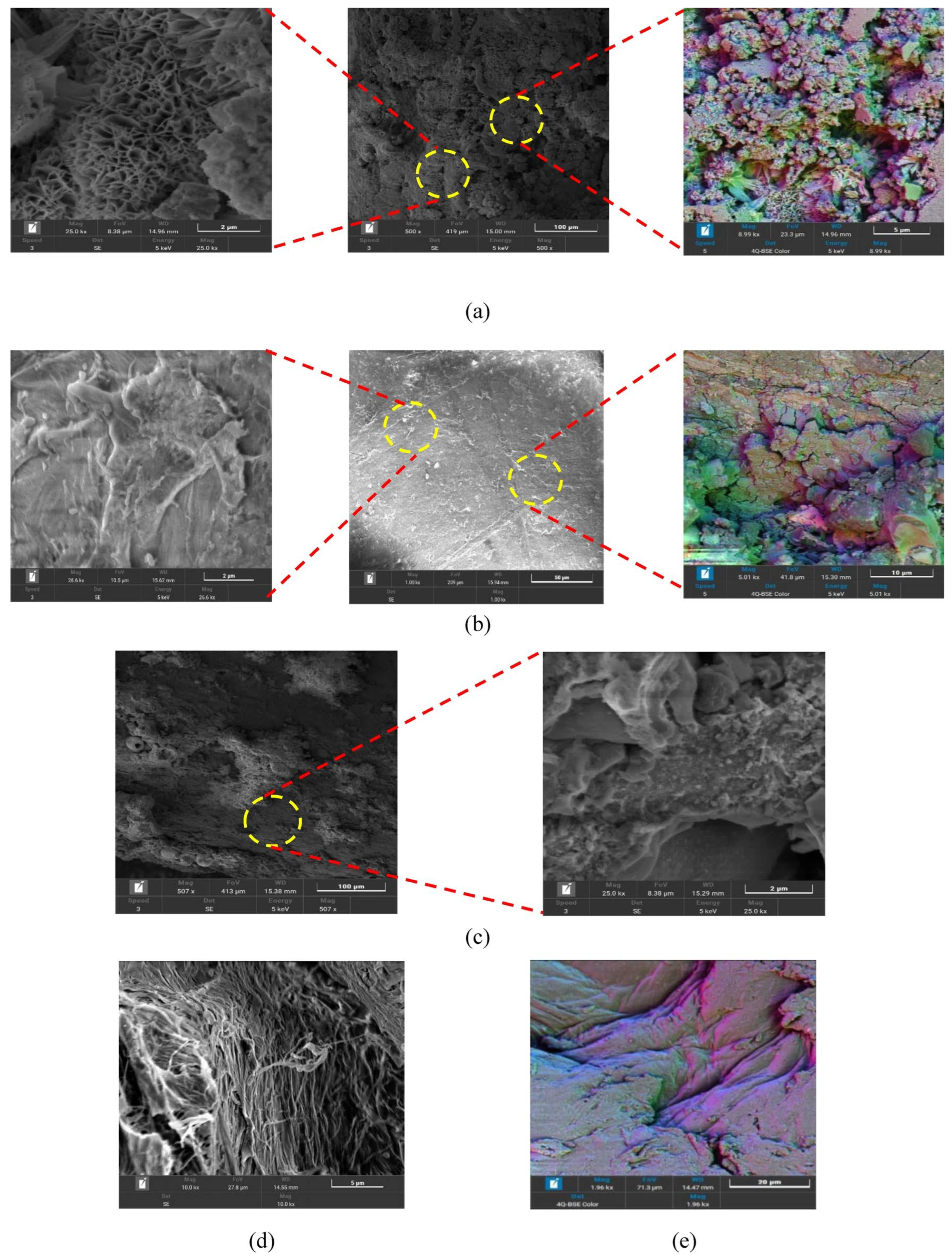

2.1. Fibre Morphology and Spinning Techniques of Chitosan-Based Materials

2.2. Mechanical Properties and Structural Characteristics of Chitosan Fibres

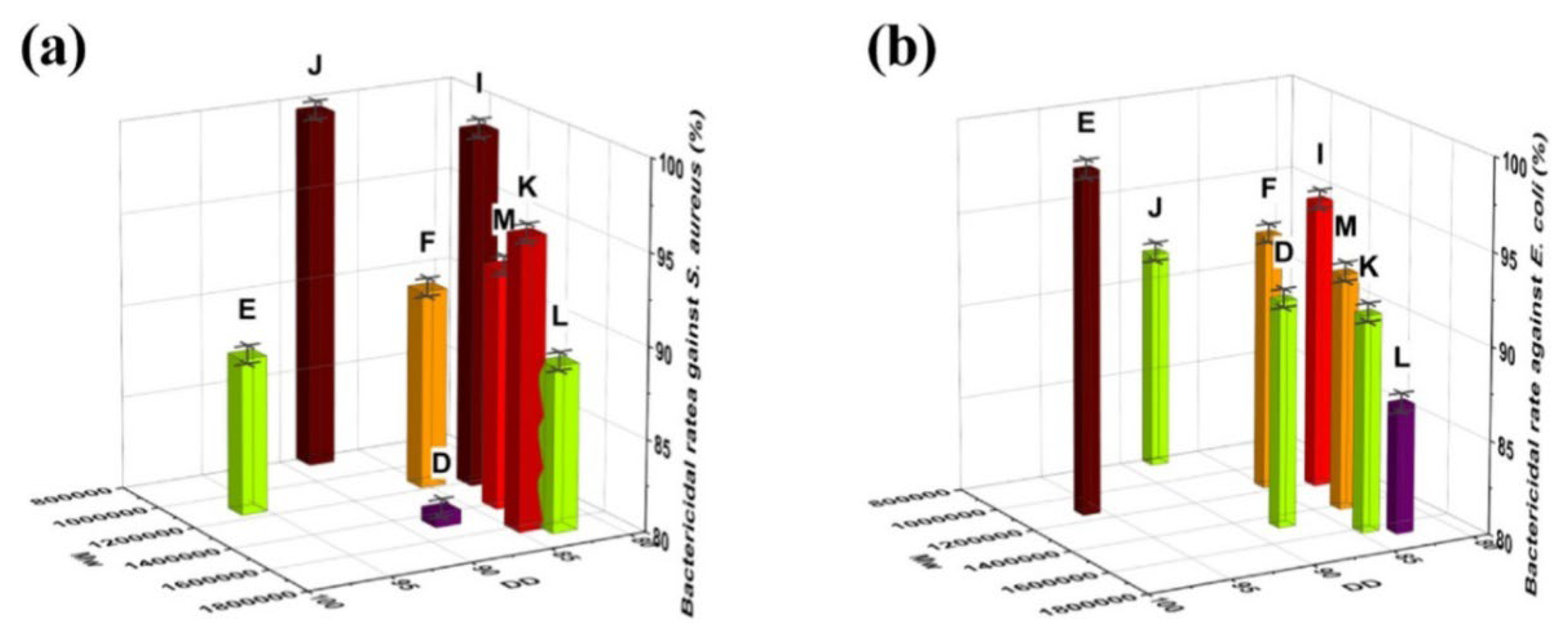

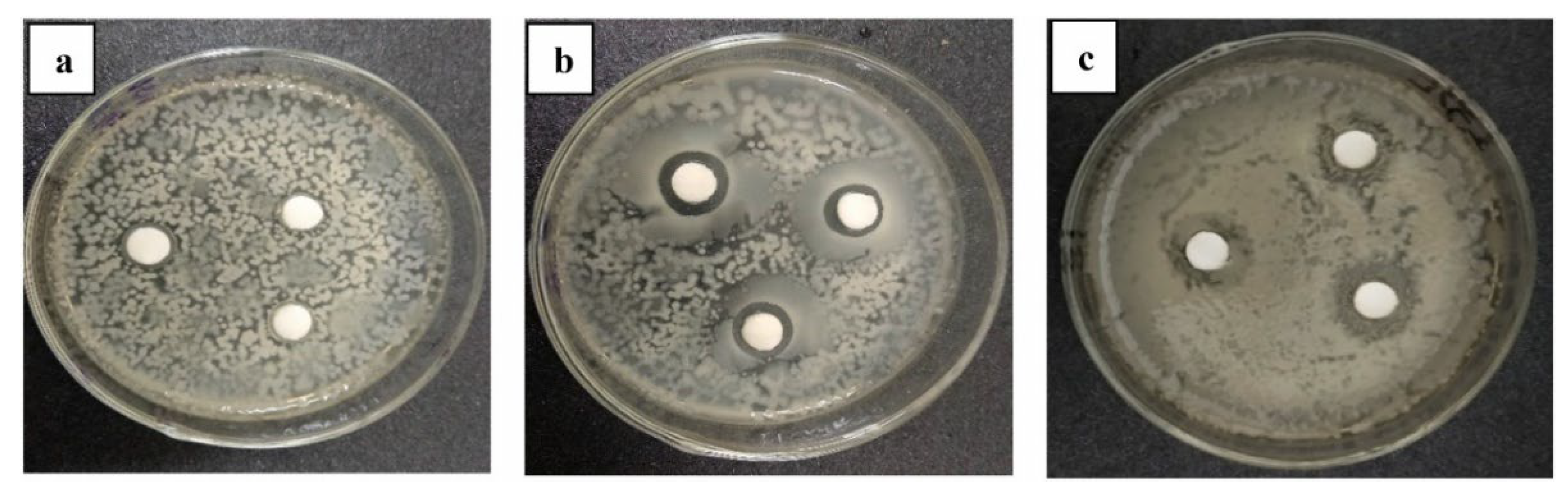

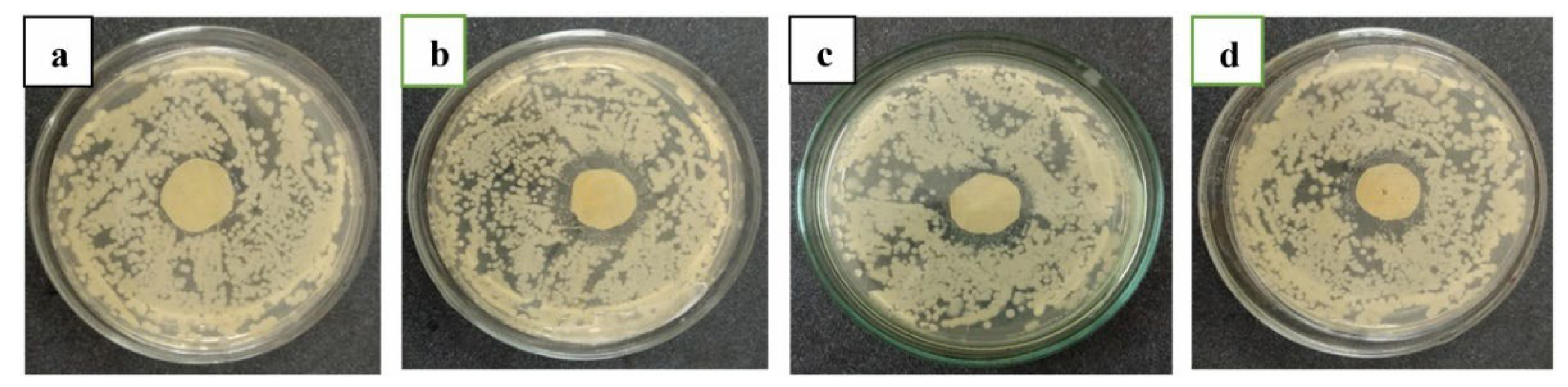

2.3. Antibacterial Properties of Chitosan-Based Fibres

3. Application of Chitosan in Textile Dyeing

3.1. Enhancement of Colour Strength

3.2. Improvement of Dye Fastness

4. Application of Chitosan in Textile Finishing

4.1. Ultraviolet Protection

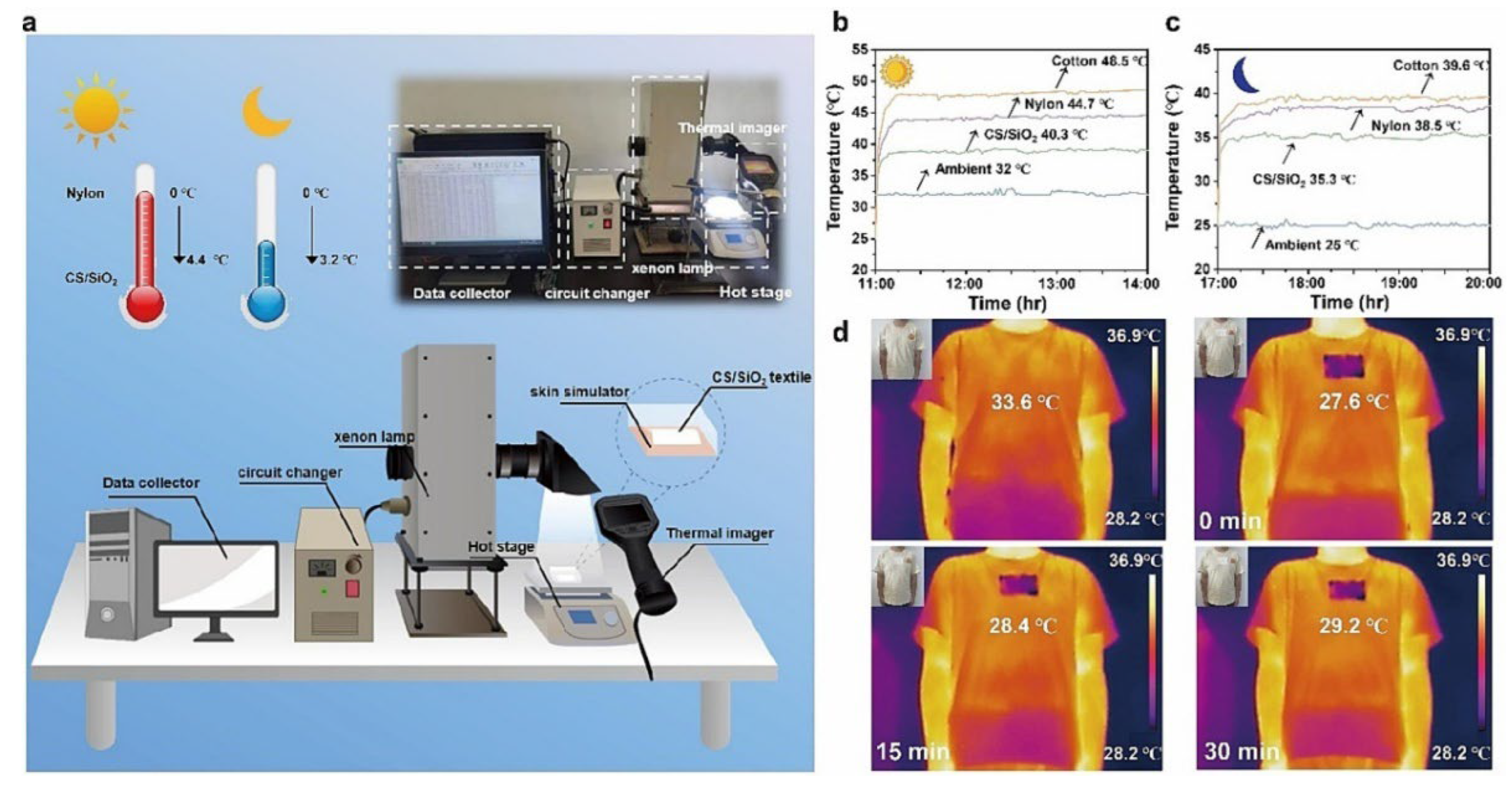

4.2. Thermal Regulation in Textiles

4.3. Antioxidant Functional Finishing

4.4. Water-Repellent and Multi-Functional Activity

5. Application of Chitosan in Textile Waste Management

5.1. Challenges in Textile Wastewater Treatment and the Functional Roles of Chitosan

5.2. Application of Chitosan in Dye Removal

5.3. Adsorption Performance and Treatment Efficiency of Chitosan-Based Composites

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ray, S.; Nayak, L. Marketing sustainable fashion: Trends and future directions. Sustainability 2023, 15, 6202. [Google Scholar] [CrossRef]

- Pucker, K.P. The myth of sustainable fashion. Harv. Bus. Rev. 2022, 13, 2022. [Google Scholar]

- Khandual, A.; Pradhan, S. Fashion brands and consumers approach towards sustainable fashion. In Fast Fashion, Fashion Brands and Sustainable Consumption; Springer: Singapore, 2019; pp. 37–54. [Google Scholar]

- Aakko, M.; Koskennurmi-Sivonen, R. Designing sustainable fashion: Possibilities and challenges. Res. J. Text. Appar. 2013, 17, 13–22. [Google Scholar] [CrossRef]

- Gornostaeva, G. Design and sustainability in the fashion industry: The example of independent labels in London. Clean. Responsible Consum. 2024, 15, 100221. [Google Scholar] [CrossRef]

- Chen, L.; Haider, M.J.; He, J. Should “green information” be interactive? The influence of green information presentation on consumers’ green participation behavior for driving sustainable consumption of fashion brands. J. Clean. Prod. 2024, 470, 143329. [Google Scholar] [CrossRef]

- Iliana, P.; Georgia, C.; Jose Navarro, P.; Irene, V.; María, B.; Antonis, A.Z. Building a new mind set in tomorrow fashion development through circular strategy models in the framework of waste management. Curr. Opin. Green Sustain. Chem. 2022, 36, 100638. [Google Scholar] [CrossRef]

- Stella, F.; Fraterrigo Garofalo, S.; Cavallini, N.; Fino, D.; Deorsola, F.A. Closing the loop: Analysis of biotechnological processes for sustainable valorisation of textile waste from the fast fashion industry. Sustain. Chem. Pharm. 2024, 38, 101481. [Google Scholar] [CrossRef]

- Voukkali, I.; Papamichael, I.; Loizia, P.; Economou, F.; Stylianou, M.; Naddeo, V.; Zorpas, A.A. Fashioning the Future: Green chemistry and engineering innovations in biofashion. Chem. Eng. J. 2024, 497, 155039. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R.; Nadeem, S.P.; Riccio, E. Sustainability trends and gaps in the textile, apparel and fashion industries. Environ. Dev. Sustain. 2023, 26, 2837–2864. [Google Scholar] [CrossRef]

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and Sustainability of the Clothing and Textile Industry. Mater. Circ. Econ. 2021, 3, 12. [Google Scholar] [CrossRef]

- Patwary, S. Clothing and Textile Sustainability. Text. Leather Rev. 2020, 3, 158–173. [Google Scholar] [CrossRef]

- Stenton, M.; Kapsali, V.; Blackburn, R.S.; Houghton, J.A. From Clothing Rations to Fast Fashion: Utilising Regenerated Protein Fibres to Alleviate Pressures on Mass Production. Energies 2021, 14, 5654. [Google Scholar] [CrossRef]

- Carvalho Garcia, C. Fashion futuring: Intertwining speculative design, foresight and material culture towards sustainable futures. Futures 2023, 153, 103242. [Google Scholar] [CrossRef]

- Ermini, C.; Visintin, F.; Boffelli, A. Understanding supply chain orchestration mechanisms to achieve sustainability-oriented innovation in the textile and fashion industry. Sustain. Prod. Consum. 2024, 49, 415–430. [Google Scholar] [CrossRef]

- Kozlowski, A.; Bardecki, M.; Searcy, C. Environmental Impacts in the Fashion Industry. J. Corp. Citizsh. 2012, 2012, 16–36. [Google Scholar] [CrossRef]

- Rathore, D.B. Future of Textile: Sustainable Manufacturing & Prediction via ChatGPT. Eduzone Int. Peer Rev./Ref. Acad. Multidiscip. J. 2023, 12, 52–62. [Google Scholar] [CrossRef]

- Mazotto, A.M.; de Ramos Silva, J.; de Brito, L.A.A.; Rocha, N.U.; de Souza Soares, A. How can microbiology help to improve sustainability in the fashion industry? Environ. Technol. Innov. 2021, 23, 101760. [Google Scholar] [CrossRef]

- Gonçalves, A.; Silva, C. Looking for Sustainability Scoring in Apparel: A Review on Environmental Footprint, Social Impacts and Transparency. Energies 2021, 14, 3032. [Google Scholar] [CrossRef]

- Pranta, A.D.; Tareque Rahaman, M.; Reazuddin Repon, M.; Shikder, A.A.R. Environmentally sustainable apparel merchandising of recycled cotton-polyester blended garments: Analysis of consumer preferences and purchasing behaviors. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100357. [Google Scholar] [CrossRef]

- Gbolarumi, F.T.; Wong, K.Y.; Olohunde, S.T. Sustainability Assessment in The Textile and Apparel Industry: A Review of Recent Studies. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012099. [Google Scholar] [CrossRef]

- Dragović, N.; Urošević, S.; Vuković, M. Innovation of using 3D printing for textile fibers. In Proceedings of the 7th International Scientific Conference Contemporary Trends and Innovations in Textile Industry—CT&ITI 2024—Zbornik Radova, Belgrade, Serbia, 19–20 September 2024; pp. 274–284. [Google Scholar]

- Mazzi, A. Environmental and safety risk assessment for sustainable circular production: Case study in plastic processing for fashion products. Heliyon 2023, 9, e21352. [Google Scholar] [CrossRef]

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.-L.; Heldeweg, M. A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Acierno, D. Eco-Sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World. Polymers 2020, 13, 134. [Google Scholar] [CrossRef]

- Rehman, M.; Petrillo, A.; Ortíz-Barrios, M.; Forcina, A.; Baffo, I.; De Felice, F. Sustainable fashion: Mapping waste streams and life cycle management. J. Clean. Prod. 2024, 444, 141279. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, J.; Geng, L. Beyond buying less: A functional matching perspective on sustainable fashion product purchasing. J. Environ. Psychol. 2024, 95, 102283. [Google Scholar] [CrossRef]

- Frazier, R.M.; Vivas, K.A.; Azuaje, I.; Vera, R.; Pifano, A.; Forfora, N.; Jameel, H.; Ford, E.; Pawlak, J.J.; Venditti, R.; et al. Beyond cotton and polyester: An evaluation of emerging feedstocks and conversion methods for the future of fashion industry. J. Bioresour. Bioprod. 2024, 9, 130–159. [Google Scholar] [CrossRef]

- Abdelmeguid, A.; Tsironis, G.; Afy-Shararah, M.; Tsagarakis, K.P.; Salonitis, K. Insights into sustainability and circular economy trends in luxury fashion: A LinkedIn topic modelling study. Clean. Responsible Consum. 2024, 15, 100228. [Google Scholar] [CrossRef]

- Nayak, R.; Jajpura, L.; Khandual, A. Traditional fibres for fashion and textiles: Associated problems and future sustainable fibres. In Sustainable Fibres for Fashion and Textile Manufacturing; Woodhead Publishing: Sawston, UK, 2023; pp. 3–25. [Google Scholar]

- Singh, G.B.; Vinayak, A.; Mudgal, G.; Kesari, K.K. Azo dye bioremediation: An interdisciplinary path to sustainable fashion. Environ. Technol. Innov. 2024, 36, 103832. [Google Scholar] [CrossRef]

- Li, K.; Zhang, J.; Li, Y.; Li, Z.; Wang, J.; Yu, Y.; Wang, Q.; Wang, P. Conjugation of chitosan oligosaccharide to papain for controllable anti-felting finishing of wool textiles. Ind. Crops Prod. 2024, 222, 119531. [Google Scholar] [CrossRef]

- Kaur, A.; Kumar, A.; Singh, N. Innovative integration of chitosan biopolymer for felt-free woolen fabric: A synergistic approach with digital textile printing. Sustain. Chem. Pharm. 2024, 42, 101769. [Google Scholar] [CrossRef]

- Preethi, S.; Abarna, K.; Nithyasri, M.; Kishore, P.; Deepika, K.; Ranjithkumar, R.; Bhuvaneshwari, V.; Bharathi, D. Synthesis and characterization of chitosan/zinc oxide nanocomposite for antibacterial activity onto cotton fabrics and dye degradation applications. Int. J. Biol. Macromol. 2020, 164, 2779–2787. [Google Scholar] [CrossRef]

- Chopra, S.S.; Dong, L.; Kaur, G.; Len, C.; Ki Lin, C.S. Sustainable process design for circular fashion: Advances in sustainable chemistry for textile waste valorisation. Curr. Opin. Green Sustain. Chem. 2023, 39, 100747. [Google Scholar] [CrossRef]

- Junceda-Mena, I.; Garcia-Junceda, E.; Revuelta, J. From the problem to the solution: Chitosan valorization cycle. Carbohydr. Polym. 2023, 309, 120674. [Google Scholar] [CrossRef]

- Keßler, L.; Matlin, S.A.; Kümmerer, K. The contribution of material circularity to sustainability—Recycling and reuse of textiles. Curr. Opin. Green Sustain. Chem. 2021, 32, 100535. [Google Scholar] [CrossRef]

- Rahman, M.; Billah, M.M.; Hack-Polay, D.; Alam, A. The use of biotechnologies in textile processing and environmental sustainability: An emerging market context. Technol. Forecast. Soc. Change 2020, 159, 120204. [Google Scholar] [CrossRef]

- Schiros, T.N.; Mosher, C.Z.; Zhu, Y.; Bina, T.; Gomez, V.; Lee, C.L.; Lu, H.H.; Obermeyer, A.C. Bioengineering textiles across scales for a sustainable circular economy. Chem 2021, 7, 2913–2926. [Google Scholar] [CrossRef]

- Joshi, M. THE FUTURE OF FASHION: BIOTECH AND NANOTECHNOLOGY IN SMART CLOTHING. Am. J. Interdiscip. Innov. Res. J. Text. Appar. 2024, 6, 21–27. [Google Scholar]

- Amobonye, A.; Lalung, J.; Awasthi, M.K.; Pillai, S. Fungal mycelium as leather alternative: A sustainable biogenic material for the fashion industry. Sustain. Mater. Technol. 2023, 38, e00724. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Raj, S.A.; Kandasamy, J.; Baghdadi, M.A.; Shahzad, M.A. Chitosan: A Sustainable Material for Multifarious Applications. Polymers 2022, 14, 2335. [Google Scholar] [CrossRef] [PubMed]

- Maliki, S.; Sharma, G.; Kumar, A.; Moral-Zamorano, M.; Moradi, O.; Baselga, J.; Stadler, F.J.; Garcia-Penas, A. Chitosan as a Tool for Sustainable Development: A Mini Review. Polymers 2022, 14, 1475. [Google Scholar] [CrossRef]

- Kostag, M.; El Seoud, O.A. Sustainable biomaterials based on cellulose, chitin and chitosan composites—A review. Carbohydr. Polym. Technol. Appl. 2021, 2, 100079. [Google Scholar] [CrossRef]

- Shahid Ul, I.; Butola, B.S. A synergistic combination of shrimp shell derived chitosan polysaccharide with Citrus sinensis peel extract for the development of colourful and bioactive cellulosic textile. Int. J. Biol. Macromol. 2020, 158, 94–103. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, S. Chitosan-based materials: Preparation, modification and application. J. Clean. Prod. 2022, 355, 131825. [Google Scholar] [CrossRef]

- Elamri, A.; Zdiri, K.; Hamdaoui, M.; Harzallah, O. Chitosan: A biopolymer for textile processes and products. Text. Res. J. 2022, 93, 1456–1484. [Google Scholar] [CrossRef]

- Costa, E.M.; Silva, S.; Veiga, M.; Baptista, P.; Tavaria, F.K.; Pintado, M.E. Textile dyes loaded chitosan nanoparticles: Characterization, biocompatibility and staining capacity. Carbohydr. Polym. 2021, 251, 117120. [Google Scholar] [CrossRef]

- Raza Naqvi, S.A.; Kaif, U.-W.; Adeel, S.; Mia, R.; Hosseinnezhad, M.; Rather, L.J.; Imran, M. Modern ecofriendly approach for extraction of luteolin natural dye from weld for silk fabric and wool yarn dyeing. Sustain. Chem. Pharm. 2024, 39, 101554. [Google Scholar] [CrossRef]

- Shirvan, A.R.; Shakeri, M.; Bashari, A. Recent advances in application of chitosan and its derivatives in functional finishing of textiles. In The Impact and Prospects of Green Chemistry for Textile Technology; Woodhead Publishing: Sawston, UK, 2019; pp. 107–133. [Google Scholar]

- Cheng, C.; Xiaoyu, J.; Xiaorui, L.; Mingyang, S.; Jiayi, H.; Mengyao, S.; Shuwang, W.; Hongliang, D.; Xingang, W.; Hongya, G. Scalable wet-spinning of wearable chitosan-silica textile for all-day radiative cooling. Chem. Eng. J. 2023, 475, 146307. [Google Scholar] [CrossRef]

- Ali, I.H.; Elkashlan, A.M.; Hammad, M.A.; Hamdi, M. Antimicrobial and anti-SARS-CoV-2 activities of smart daclatasvir-chitosan/gelatin nanoparticles-in-PLLA nanofibrous medical textiles; in vitro, and in vivo study. Int. J. Biol. Macromol. 2023, 253, 127350. [Google Scholar] [CrossRef]

- Fu, X.; Shen, Y.; Jiang, X.; Huang, D.; Yan, Y. Chitosan derivatives with dual-antibacterial functional groups for antimicrobial finishing of cotton fabrics. Carbohydr. Polym. 2011, 85, 221–227. [Google Scholar] [CrossRef]

- Yan, B.; Dai, Y.; Xin, L.; Li, M.; Zhang, H.; Long, H.; Gao, X. Research progress in the degradation of printing and dyeing wastewater using chitosan based composite photocatalytic materials. Int. J. Biol. Macromol. 2024, 263, 130082. [Google Scholar] [CrossRef] [PubMed]

- de Medeiros, A.D.L.M.; da Silva Junior, C.J.G.; de Amorim, J.D.P.; do Nascimento, H.A.; Converti, A.; Costa, A.F.d.S.; Sarubbo, L.A. Biocellulose for Treatment of Wastewaters Generated by Energy Consuming Industries: A Review. Energies 2021, 14, 5066. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef] [PubMed]

- Gosavi, V.D.; Sharma, S. A general review on various treatment methods for textile wastewater. J. Environ. Sci. Comput. Sci. Eng. Technol. 2014, 3, 29–39. [Google Scholar]

- Qamar, S.A.; Ashiq, M.; Jahangeer, M.; Riasat, A.; Bilal, M. Chitosan-based hybrid materials as adsorbents for textile dyes–A review. Case Stud. Chem. Environ. Eng. 2020, 2, 100021. [Google Scholar] [CrossRef]

- Vakili, M.; Rafatullah, M.; Salamatinia, B.; Abdullah, A.Z.; Ibrahim, M.H.; Tan, K.B.; Gholami, Z.; Amouzgar, P. Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: A review. Carbohydr. Polym. 2014, 113, 115–130. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Bikiaris, D.N.; Mitropoulos, A.C. Chitosan adsorbents for dye removal: A review. Polym. Int. 2017, 66, 1800–1811. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Eid, B.M.; El-Aziz, E.A.; Elmaaty, T.M.A.; Ramadan, S.M. Loading of chitosan—Nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multifunctions. Int. J. Biol. Macromol. 2017, 105, 769–776. [Google Scholar] [CrossRef] [PubMed]

- Tien, N.D.; Lyngstadaas, S.P.; Mano, J.F.; Blaker, J.J.; Haugen, H.J. Recent Developments in Chitosan-Based Micro/Nanofibers for Sustainable Food Packaging, Smart Textiles, Cosmeceuticals, and Biomedical Applications. Molecules 2021, 26, 2683. [Google Scholar] [CrossRef]

- Lingait, D.; Rahagude, R.; Gaharwar, S.S.; Das, R.S.; Verma, M.G.; Srivastava, N.; Kumar, A.; Mandavgane, S. A review on versatile applications of biomaterial/polycationic chitosan: An insight into the structure-property relationship. Int. J. Biol. Macromol. 2024, 257, 128676. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Li, C.; Xie, X.; Li, G.; Hu, Z.; Li, S. Research Progress of Chitosan-Based Biomimetic Materials. Mar. Drugs 2021, 19, 372. [Google Scholar] [CrossRef]

- Lee, D.; Lim, H.; Chong, H.; Shim, W. Advances in Chitosan Material and its Hybrid Derivatives: A Review. Open Biomater. J. 2009, 1, 10–20. [Google Scholar] [CrossRef]

- Picos-Corrales, L.A.; Morales-Burgos, A.M.; Ruelas-Leyva, J.P.; Crini, G.; Garcia-Armenta, E.; Jimenez-Lam, S.A.; Ayon-Reyna, L.E.; Rocha-Alonzo, F.; Calderon-Zamora, L.; Osuna-Martinez, U.; et al. Chitosan as an Outstanding Polysaccharide Improving Health-Commodities of Humans and Environmental Protection. Polymers 2023, 15, 526. [Google Scholar] [CrossRef]

- Roy, J.; Salaün, F.; Giraud, S.; Ferri, A.; Guan, J. Chitosan-Based Sustainable Textile Technology: Process, Mechanism, Innovation, and Safety. In Biological Activities and Application of Marine Polysaccharides; Books on Demand: Norderstedt, Germany, 2017. [Google Scholar]

- Yang, S.; Song, Z.; He, Z.; Ye, X.; Li, J.; Wang, W.; Zhang, D.; Li, Y. A review of chitosan-based shape memory materials: Stimuli-responsiveness, multifunctionalities and applications. Carbohydr. Polym. 2024, 323, 121411. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Ikram, S. Chitosan & its derivatives: A review in recent innovations. Int. J. Pharm. Sci. Res. J. Text. Appar. 2015, 6, 14–30. [Google Scholar]

- Karamchandani, B.M.; Dalvi, S.G.; Bagayatkar, M.; Banat, I.M.; Satpute, S.K. Prospective applications of chitosan and chitosan-based nanoparticles formulations in sustainable agricultural practices. Biocatal. Agric. Biotechnol. 2024, 58, 103210. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, L.; Zhao, X.; Luo, Y.; Zheng, K.; Wu, M. Highly effective antibacterial AgNPs@hinokitiol grafted chitosan for construction of durable antibacterial fabrics. Int. J. Biol. Macromol. 2022, 209, 963–971. [Google Scholar] [CrossRef] [PubMed]

- Chakravarty, J.; Edwards, T.A. Innovation from waste with biomass-derived chitin and chitosan as green and sustainable polymer: A review. Energy Nexus 2022, 8, 100149. [Google Scholar] [CrossRef]

- Zhou, B.C.-E.; Kan, C.-w.; Sun, C.; Du, J.; Xu, C. A Review of Chitosan Textile Applications. AATCC J. Res. 2022, 6, 8–14. [Google Scholar] [CrossRef]

- Nwabike Amitaye, A.; Elemike, E.E.; Akpeji, H.B.; Amitaye, E.; Hossain, I.; Mbonu, J.I.; Aziza, A.E. Chitosan: A sustainable biobased material for diverse applications. J. Environ. Chem. Eng. 2024, 12, 113208. [Google Scholar] [CrossRef]

- Mishra, A.; Omoyeni, T.; Singh, P.K.; Anandakumar, S.; Tiwari, A. Trends in sustainable chitosan-based hydrogel technology for circular biomedical engineering: A review. Int. J. Biol. Macromol. 2024, 276, 133823. [Google Scholar] [CrossRef]

- Kim, H.C.; Mun, S.; Ko, H.-U.; Zhai, L.; Kafy, A.; Kim, J. Renewable smart materials. Smart Mater. Struct. 2016, 25, 073001. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Liang, H.; Zhou, J.; Zong, M.; Cao, Y.; Lou, W. A review of advancements in chitosan-essential oil composite films: Better and sustainable food preservation with biodegradable packaging. Int. J. Biol. Macromol. 2024, 274, 133242. [Google Scholar] [CrossRef]

- Tabassum, Z.; Mohan, A.; Girdhar, M. Insight into recent trends in ZnO nanoparticle reinforced chitosan-based composite films for sustainable packaging: A critical review on its current status, challenges and perspective. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, W.; Yuan, Z.; Wang, Z.; Ma, R.; Chen, K. Preparation of strawberry chitosan composite microcapsules and their application in textiles. Colloids Surf. A Physicochem. Eng. Asp. 2022, 652, 129845. [Google Scholar] [CrossRef]

- Tamzid, F.; Sakhawat, S.B.; Rashid, T.U. Chitosan based electrospun nanofibrous materials: A sustainable alternative for food packaging. Trends Food Sci. Technol. 2024, 151, 104617. [Google Scholar] [CrossRef]

- Rahmadhani, D.; Yuliani, K.D.; Frida, E.; Taufiq, A. Hydrophobic and antibacterial properties of textiles using nanocomposite chitosan and SiO2 from rice husk ash as-coating. S. Afr. J. Chem. Eng. 2024, 48, 366–374. [Google Scholar] [CrossRef]

- Rahaman, M.T.; Khan, M.S.H. Applications of green nano textile materials for environmental sustainability and functional performance: Past, present and future perspectives. Nano-Struct. Nano-Objects 2024, 40, 101332. [Google Scholar] [CrossRef]

- Massella, D.; Giraud, S.; Guan, J.; Ferri, A.; Salaün, F. Manufacture Techniques of Chitosan-Based Microcapsules to Enhance Functional Properties of Textiles. In Sustainable Agriculture Reviews 35. Sustainable Agriculture Reviews; Springer: Cham, Switzerland, 2019; pp. 303–336. [Google Scholar]

- Massella, D.; Giraud, S.; Guan, J.; Ferri, A.; Salaün, F. Textiles for health: A review of textile fabrics treated with chitosan microcapsules. Environ. Chem. Lett. 2019, 17, 1787–1800. [Google Scholar] [CrossRef]

- Ivanoska-Dacikj, A.; Oguz-Gouillart, Y.; Hossain, G.; Kaplan, M.; Sivri, C.; Ros-Lis, J.V.; Mikucioniene, D.; Munir, M.U.; Kizildag, N.; Unal, S.; et al. Advanced and Smart Textiles during and after the COVID-19 Pandemic: Issues, Challenges, and Innovations. Healthcare 2023, 11, 1115. [Google Scholar] [CrossRef]

- Desore, A.; Narula, S.A. An overview on corporate response towards sustainability issues in textile industry. Environ. Dev. Sustain. 2017, 20, 1439–1459. [Google Scholar] [CrossRef]

- Hou, Z.; Liu, X.; Tian, M.; Zhang, X.; Qu, L.; Fan, T.; Miao, J. Smart fibers and textiles for emerging clothe-based wearable electronics: Materials, fabrications and applications. J. Mater. Chem. A 2023, 11, 17336–17372. [Google Scholar] [CrossRef]

- Cavallaro, G.; Micciulla, S.; Chiappisi, L.; Lazzara, G. Chitosan-based smart hybrid materials: A physico-chemical perspective. J. Mater. Chem. B 2020, 9, 594–611. [Google Scholar] [CrossRef] [PubMed]

- Foong, S.Y.; Chan, Y.H.; Yiin, C.L.; Lock, S.S.M.; Loy, A.C.M.; Lim, J.Y.; Yek, P.N.Y.; Wan Mahari, W.A.; Liew, R.K.; Peng, W.; et al. Sustainable CO2 capture via adsorption by chitosan-based functional biomaterial: A review on recent advances, challenges, and future directions. Renew. Sustain. Energy Rev. 2023, 181, 113342. [Google Scholar] [CrossRef]

- Teli, M.D.; Sheikh, J.; Bhavsar, P. Multifunctional finishing of cotton using chitosan extracted from bio-waste. Int. J. Biol. Macromol. 2013, 54, 125–130. [Google Scholar] [CrossRef]

- Thambiliyagodage, C.; Jayanetti, M.; Mendis, A.; Ekanayake, G.; Liyanaarachchi, H.; Vigneswaran, S. Recent Advances in Chitosan-Based Applications-A Review. Materials 2023, 16, 2073. [Google Scholar] [CrossRef]

- Li, J.; Tian, X.; Hua, T.; Fu, J.; Koo, M.; Chan, W.; Poon, T. Chitosan Natural Polymer Material for Improving Antibacterial Properties of Textiles. ACS Appl. Bio Mater. 2021, 4, 4014–4038. [Google Scholar] [CrossRef]

- Korkmaz, A.; Babaarslan, O. Chitosan Added Composite Viscose Yarn and Its Potential Application for Denim Fabric Development. Fibres Text. 2023, 30, 93–98. [Google Scholar] [CrossRef]

- Yudin, V.E.; Dobrovolskaya, I.P.; Neelov, I.M.; Dresvyanina, E.N.; Popryadukhin, P.V.; Ivan’kova, E.M.; Elokhovskii, V.Y.; Kasatkin, I.A.; Okrugin, B.M.; Morganti, P. Wet spinning of fibers made of chitosan and chitin nanofibrils. Carbohydr. Polym. 2014, 108, 176–182. [Google Scholar] [CrossRef]

- Mohammadkhani, G.; Kumar Ramamoorthy, S.; Adolfsson, K.H.; Mahboubi, A.; Hakkarainen, M.; Zamani, A. New solvent and coagulating agent for development of chitosan fibers by wet spinning. Polymers 2021, 13, 2121. [Google Scholar] [CrossRef]

- Kuznik, I.; Kruppke, I.; Cherif, C. Pure Chitosan-Based Fibers Manufactured by a Wet Spinning Lab-Scale Process Using Ionic Liquids. Polymers 2022, 14, 477. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fu, J.; Tian, X.; Hua, T.; Poon, T.; Koo, M.; Chan, W. Characteristics of chitosan fiber and their effects towards improvement of antibacterial activity. Carbohydr. Polym. 2022, 280, 119031. [Google Scholar] [CrossRef]

- Qin, C.; Li, H.; Xiao, Q.; Liu, Y.; Zhu, J.; Du, Y. Water-solubility of chitosan and its antimicrobial activity. Carbohydr. Polym. 2006, 63, 367–374. [Google Scholar] [CrossRef]

- Bashari, A.; Hemmati Nejad, N.; Pourjavadi, A. Applications of stimuli responsive hydrogels: A textile engineering approach. J. Text. Inst. 2013, 104, 1145–1155. [Google Scholar] [CrossRef]

- Shukla, S.K.; Mishra, A.K.; Arotiba, O.A.; Mamba, B.B. Chitosan-based nanomaterials: A state-of-the-art review. Int. J. Biol. Macromol. 2013, 59, 46–58. [Google Scholar] [CrossRef]

- Vo-An, Q.; Nguyen, C.T.; Pham, U.T.; Nguyen, T.A.; Nguyen, D.T.; Hoang, D.T.; Le, L.T.; Ngo, Q.T.C.; Thai, H. Antibacterial and Anti-Inflammatory Activity of Chitosan Film with Rhodomyrtus Tomentosa Leaf Extract Prepared Via 3D-Printing Method. ChemistryOpen 2024, 14, e202400302. [Google Scholar] [CrossRef]

- Fernandes, J.C.; Tavaria, F.K.; Fonseca, S.C.; Ramos, Ó.S.; Pintado, M.E.; Malcata, F.X. In vitro screening for antimicrobial activity of chitosans and chitooligosaccharides, aiming at potential uses in functional textiles. J. Microbiol. Biotechnol. 2010, 20, 311–318. [Google Scholar] [CrossRef]

- Arshad, N.; Javaid, M.A.; Zia, K.M.; Hussain, M.T.; Arshad, M.M.; Tahir, U. Development of biocompatible aqueous polyurethane dispersions using chitosan and curcumin to improve physicochemical properties of textile surfaces. Int. J. Biol. Macromol. 2023, 251, 126196. [Google Scholar] [CrossRef]

- Luo, X.; Yao, M.Y.; Li, L. Application of chitosan in the form of textile: Production and sourcing. Text. Res. J. 2022, 92, 3522–3533. [Google Scholar] [CrossRef]

- Öktem, T. Surface treatment of cotton fabrics with chitosan. Color. Technol. 2006, 119, 241–246. [Google Scholar] [CrossRef]

- Şahan, G.; Demir, A. A green application of nano sized chitosan in textile finishing. Text. Appar. 2016, 26, 414–420. [Google Scholar]

- Mondal, M.I.H.; Sarker, S.C.; Ahmed, F.; Pervez, M.N.; Saha, J. Fabrication of sustainable functional cotton fabric with silk sericin and chitosan for protective textiles. Heliyon 2024, 10, e39250. [Google Scholar] [CrossRef]

- Yu, J.; Pang, Z.; Zhang, J.; Zhou, H.; Wei, Q. Conductivity and antibacterial properties of wool fabrics finished by polyaniline/chitosan. Colloids Surf. A Physicochem. Eng. Asp. 2018, 548, 117–124. [Google Scholar] [CrossRef]

- Huang, L.; Xiao, L.; Yang, G. Chitosan application in textile processing. Curr. Trends Fash. Technol. Text. Eng. 2018, 4, 32–34. [Google Scholar] [CrossRef]

- Bhuiyan, M.A.R.; Shaid, A.; Khan, M.A. Cationization of Cotton Fiber by Chitosan and Its Dyeing with Reactive Dye without Salt. Chem. Mater. Eng. 2014, 2, 96–100. [Google Scholar] [CrossRef]

- Lim, S.H.; Hudson, S.H. Application of a fibre-reactive chitosan derivative to cotton fabric as a zero-salt dyeing auxiliary. Color. Technol. 2006, 120, 108–113. [Google Scholar] [CrossRef]

- Chatha, S.S.; Hussain, A.; Ali, S.; Saif, M.J.; Mallhi, A.; Sagir, M.; Naz, M. Significance of chitosan to improve the substantivity of reactive dyes. J. Chil. Chem. Soc. 2016, 61, 2895–2897. [Google Scholar] [CrossRef]

- Ke, G.; Zhu, K.; Chowdhury, M.H. Dyeing of Cochineal Natural Dye on Cotton Fabrics Treated with Oxidant and Chitosan. J. Nat. Fibers 2019, 18, 317–329. [Google Scholar] [CrossRef]

- Ferrero, F.; Periolatto, M. Antimicrobial finish of textiles by chitosan UV-curing. J Nanosci Nanotechnol 2012, 12, 4803–4810. [Google Scholar] [CrossRef]

- Taurino, R.; Cannio, M.; Caporali, S.; Martinuzzi, S.; Boccaccini, D. Design and characterization of based chitosan sol-gel films for textile substrates: Traditional and 3D printing processes approach. In Proceedings of the 13th International Colloids Conference, Sitges, Spain, 9–12 June 2024. [Google Scholar]

- Priyadarshi, R.; El-Araby, A.; Rhim, J.W. Chitosan-based sustainable packaging and coating technologies for strawberry preservation: A review. Int. J. Biol. Macromol. 2024, 278, 134859. [Google Scholar] [CrossRef]

- Zheng, G.; Cui, Y.; Jiang, Z.; Zhou, M.; Yu, Y.; Wang, P.; Wang, Q. Fiber-based photothermal, UV-resistant, and self-cleaning coatings fabricated by silicon grafted copolymers of chitosan derivatives and gallic acid. Int. J. Biol. Macromol. 2022, 222, 1560–1577. [Google Scholar] [CrossRef]

- Peng, X.; Umer, M.; Pervez, M.N.; Hasan, K.M.F.; Habib, M.A.; Islam, M.S.; Lin, L.; Xiong, X.; Naddeo, V.; Cai, Y. Biopolymers-based microencapsulation technology for sustainable textiles development: A short review. Case Stud. Chem. Environ. Eng. 2023, 7, 100349. [Google Scholar] [CrossRef]

- Tian, W.; Chen, L.; Zhang, X.; Wu, Y. Anti-pilling of Cashmere Knitted Fabric Based on Siloxane-Modified Chitosan. Fibers Polym. 2023, 24, 4287–4300. [Google Scholar] [CrossRef]

- AbdElhady, M.M. Preparation and Characterization of Chitosan/Zinc Oxide Nanoparticles for Imparting Antimicrobial and UV Protection to Cotton Fabric. Int. J. Carbohydr. Chem. 2012, 2012, 840591. [Google Scholar] [CrossRef]

- Muzaffar, S.; Abbas, M.; Siddiqua, U.H.; Arshad, M.; Tufail, A.; Ahsan, M.; Alissa, S.A.; Abubshait, S.A.; Abubshait, H.A.; Iqbal, M. Enhanced mechanical, UV protection and antimicrobial properties of cotton fabric employing nanochitosan and polyurethane based finishing. J. Mater. Res. Technol. 2021, 11, 946–956. [Google Scholar] [CrossRef]

- Abd El-Hady, M.M.; Farouk, A.; Saeed, S.E.; Zaghloul, S. Antibacterial and UV Protection Properties of Modified Cotton Fabric Using a Curcumin/TiO(2) Nanocomposite for Medical Textile Applications. Polymers 2021, 13, 4027. [Google Scholar] [CrossRef]

- Turkoğlu, G.C.; Sarıışık, A.M.; Erkan, G.; Kayalar, H.; Kontart, O.; Öztuna, S. Determination of antioxidant capacity of capsule loaded textiles. Indian J. Fibre Text. Res. (IJFTR) 2017, 42, 189–195. [Google Scholar]

- Ali, M.A.; Abdel-Moein, N.M.; Owis, A.S.; Ahmed, S.E.; Hanafy, E.A. Eco-friendly lignin nanoparticles as antioxidant and antimicrobial material for enhanced textile production. Sci. Rep. 2024, 14, 17470. [Google Scholar] [CrossRef]

- Mazzon, G.; Contardi, M.; Quilez-Molina, A.; Zahid, M.; Zendri, E.; Athanassiou, A.; Bayer, I.S. Antioxidant and hydrophobic Cotton fabric resisting accelerated ageing. Colloids Surf. A Physicochem. Eng. Asp. 2021, 613, 126061. [Google Scholar] [CrossRef]

- Guzmán, E.; Ortega, F.; Rubio, R.G. Chitosan: A Promising Multifunctional Cosmetic Ingredient for Skin and Hair Care. Cosmetics 2022, 9, 99. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, N.A.; Philipchenko, A.B. Superhydrophobic chitosan-based coatings for textile processing. Appl. Surf. Sci. 2012, 263, 783–787. [Google Scholar] [CrossRef]

- Patankar, K.C.; Biranje, S.; Pawar, A.; Maiti, S.; Shahid, M.; More, S.; Adivarekar, R.V. Fabrication of chitosan-based finishing agent for flame-retardant, UV-protective, and antibacterial cotton fabrics. Mater. Today Commun. 2022, 33, 104637. [Google Scholar] [CrossRef]

- Flincec Grgac, S.; Tarbuk, A.; Dekanic, T.; Sujka, W.; Draczynski, Z. The Chitosan Implementation into Cotton and Polyester/Cotton Blend Fabrics. Materials 2020, 13, 1616. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Cho, J.-S.; Cho, G. Antimicrobial and Blood Repellent Finishes for Cotton and Nonwoven Fabrics Based on Chitosan and Fluoropolymers. Text. Res. J. 1999, 69, 104–112. [Google Scholar] [CrossRef]

- Abdel-Halim, E.S.; Abdel-Mohdy, F.A.; Al-Deyab, S.S.; El-Newehy, M.H. Chitosan and monochlorotriazinyl-β-cyclodextrin finishes improve antistatic properties of cotton/polyester blend and polyester fabrics. Carbohydr. Polym. 2010, 82, 202–208. [Google Scholar] [CrossRef]

- Klinkhammer, K.; Hohenbild, H.; Hoque, M.T.; Elze, L.; Teshay, H.; Mahltig, B. Functionalization of Technical Textiles with Chitosan. Textiles 2024, 4, 70–90. [Google Scholar] [CrossRef]

- Gobalakrishnan, M.; Saravanan, D.; Das, S. Sustainable Finishing Process Using Natural Ingredients. In Sustainability in the Textile and Apparel Industries; Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Cham, Switzerland, 2020; pp. 129–146. [Google Scholar]

- Khan, S.; Malik, A. Toxicity evaluation of textile effluents and role of native soil bacterium in biodegradation of a textile dye. Environ. Sci. Pollut. Res. 2018, 25, 4446–4458. [Google Scholar] [CrossRef]

- Elzahar, M.M.H.; Bassyouni, M. Removal of direct dyes from wastewater using chitosan and polyacrylamide blends. Sci. Rep. 2023, 13, 15750. [Google Scholar] [CrossRef]

- Hevira, L.; Ighalo, J.O.; Sondari, D. Chitosan-based polysaccharides for effective synthetic dye adsorption. J. Mol. Liq. 2024, 393, 123604. [Google Scholar] [CrossRef]

- El Sayed, N.A.A.; El-Bendary, M.A.; Ahmed, O.K. A sustainable approach for linen dyeing and finishing with natural lac dye through chitosan bio-mordanting and microwave heating. J. Eng. Fibers Fabr. 2023, 18, 15589250231155882. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Alhalafi, M.H.; Emam, E.M.; Ibrahim, H.; Mosaad, R.M. A Review of Chitosan and Chitosan Nanofiber: Preparation, Characterization, and Its Potential Applications. Polymers 2023, 15, 2820. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.; Boudrant, J.; Meyer, D.; Manno, N.; DeMarchis, M.; Paoletti, M.G. Current views on fungal chitin/chitosan, human chitinases, food preservation, glucans, pectins and inulin: A tribute to Henri Braconnot, precursor of the carbohydrate polymers science, on the chitin bicentennial. Carbohydr. Polym. 2012, 87, 995–1012. [Google Scholar] [CrossRef]

- Sirajudheen, P.; Poovathumkuzhi, N.C.; Vigneshwaran, S.; Chelaveettil, B.M.; Meenakshi, S. Applications of chitin and chitosan based biomaterials for the adsorptive removal of textile dyes from water—A comprehensive review. Carbohydr. Polym. 2021, 273, 118604. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.; Natarajan, S. Chitosan—A Promising Biomaterial for Dye Elimination. In Novel Materials for Dye-containing Wastewater Treatment; Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Singapore, 2021; pp. 59–83. [Google Scholar]

- Le, H.Q.; Sekiguchi, Y.; Ardiyanta, D.; Shimoyama, Y. CO(2)-Activated Adsorption: A New Approach to Dye Removal by Chitosan Hydrogel. ACS Omega 2018, 3, 14103–14110. [Google Scholar] [CrossRef]

- Indu, G.; Murthy, E.K.; Mahalakshmi, V.; Srinivasulu, K. Study on Bio-Based Textile Fibers. Front. Health Inform. 2024, 13, 8059–8074. [Google Scholar]

- Kulka, K.; Sionkowska, A. Chitosan Based Materials in Cosmetic Applications: A Review. Molecules 2023, 28, 1817. [Google Scholar] [CrossRef] [PubMed]

| Concentration | RSA% of Sericin-Treated Fabric | RSA% of Chitosan-Treated Fabric | RSA% of Chitosan–Sericin-Treated Fabric |

|---|---|---|---|

| 2 mg/mL | 29.36 ± 0.63 | 25.04 ± 0.85 | 27.10 ± 0.60 |

| 4 mg/mL | 35.02 ± 0.83 | 29.24 ± 0.59 | 32.43 ± 0.58 |

| 6 mg/mL | 42.33 ± 0.51 | 33.42 ± 0.51 | 38.44 ± 0.60 |

| 8 mg/mL | 48.12 ± 0.44 | 38.14 ± 0.31 | 42.13 ± 0.78 |

| 10 mg/mL | 53.04 ± 0.23 | 42.35 ± 0.40 | 47.44 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, A.; Qi, B.; Ku, L. Chitosan-Based Composites for Sustainable Textile Production: Applications Across the Lifecycle. Clean Technol. 2025, 7, 95. https://doi.org/10.3390/cleantechnol7040095

Liu A, Qi B, Ku L. Chitosan-Based Composites for Sustainable Textile Production: Applications Across the Lifecycle. Clean Technologies. 2025; 7(4):95. https://doi.org/10.3390/cleantechnol7040095

Chicago/Turabian StyleLiu, An, Buer Qi, and Lisbeth Ku. 2025. "Chitosan-Based Composites for Sustainable Textile Production: Applications Across the Lifecycle" Clean Technologies 7, no. 4: 95. https://doi.org/10.3390/cleantechnol7040095

APA StyleLiu, A., Qi, B., & Ku, L. (2025). Chitosan-Based Composites for Sustainable Textile Production: Applications Across the Lifecycle. Clean Technologies, 7(4), 95. https://doi.org/10.3390/cleantechnol7040095