Substitution of Fossil-Based Solvents in Organic Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Solvent Catalog

2.2. Chemicals, Coating Formulation and Curing

2.3. Optical, Mechanical and Thermal Characterization of Cured Organic Coatings

2.4. Life Cycle Assessment (LCA) of Solvents

2.5. Assessment of Economic Aspects

3. Results and Discussion

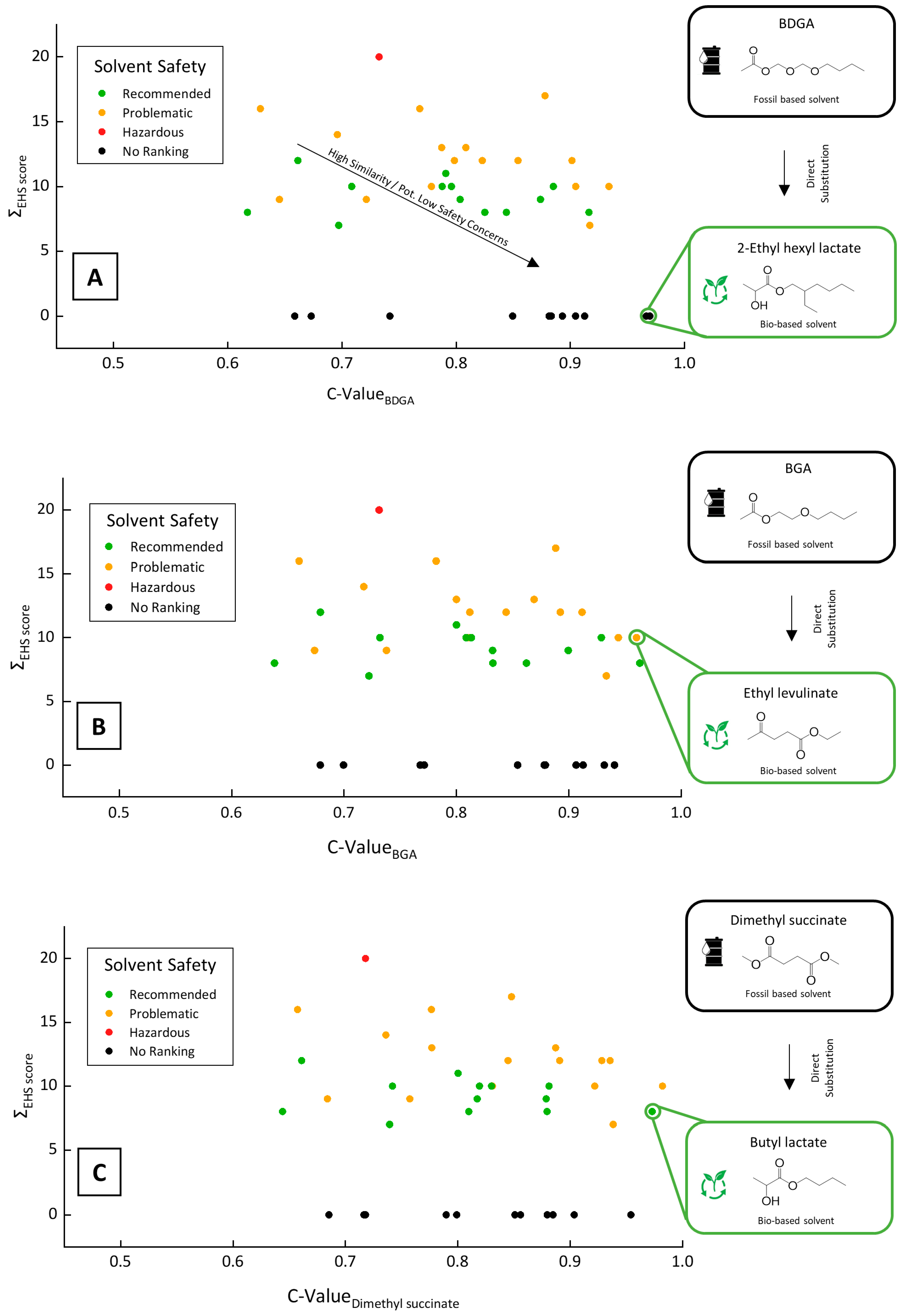

3.1. Solvent Catalog

3.2. Optical, Mechanical and Thermal Characterization of Cured Coatings

3.3. Economical and Sustainability Aspects

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Caretto, A.; Passoni, V.; Brenna, N.; Sitta, M.; Ogliosi, L.; Catel, G.; Turri, S.; Griffini, G. Fully Biobased Polyesters Based on an Isosorbide Monomer for Coil Coating Applications. ACS Sustainable Chem. Eng. 2018, 6, 14125–14134. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. From wood waste to wood protection: New application of black bio renewable water-based dispersions as pigment for bio-based wood paint. Prog. Org. Coat. 2023, 180, 107577. [Google Scholar] [CrossRef]

- Calvo-Flores, F.G.; Monteagudo-Arrebola, M.J.; Dobado, J.A.; Isac-García, J. Green and Bio-Based Solvents. Top. Curr. Chem. 2018, 376, 18. [Google Scholar] [CrossRef] [PubMed]

- Marturano, V.; Marotta, A.; Salazar, S.A.; Ambrogi, V.; Cerruti, P. Recent advances in bio-based functional additives for polymers. Prog. Mater. Sci. 2023, 139, 101186. [Google Scholar] [CrossRef]

- Clark, J.H.; Farmer, T.J.; Hunt, A.J.; Sherwood, J. Opportunities for Bio-Based Solvents Created as Petrochemical and Fuel Products Transition towards Renewable Resources. Int. J. Mol. Sci. 2015, 16, 17101–17159. [Google Scholar] [CrossRef] [PubMed]

- European Comission. Commission Delegated Regulation (EU) 2022/692 of 16 February amending, the puropses of its adapfor the purposes of its adaptation to technical and scientific progress, Regulation (EC) No 1272/2008 of the European Parliament and of the Council on classification, labelling and packaging of substances and mixtures. OJ L 129. 2022, pp. 1–17. Available online: https://eur-lex.europa.eu/eli/reg_del/2022/692/oj/eng (accessed on 26 August 2025).

- Pilon, L.; Day, D.; Maslen, H.; Stevens, O.P.J.; Carslaw, N.; Shaw, D.R.; Sneddon, H.F. Development of a solvent sustainability guide for the paints and coatings industry. Green Chem. 2024, 26, 9697–9711. [Google Scholar] [CrossRef]

- Prat, D.; Hayler, J.; Wells, A. A survey of solvent selection guides. Green Chem. 2014, 16, 4546–4551. [Google Scholar] [CrossRef]

- Prat, D.; Wells, A.; Hayler, J.; Sneddon, H.; McElroy, C.R.; Abou-Shehada, S.; Dunn, P.J. CHEM21 selection guide of classical- and less classical-solvents. Green Chem. 2016, 18, 288–296. [Google Scholar] [CrossRef]

- Tobiszewski, M.; Tsakovski, S.; Simeonov, V.; Namieśnik, J.; Pena-Pereira, F. A solvent selection guide based on chemometrics and multicriteria decision analysis. Green Chem. 2015, 17, 4773–4785. [Google Scholar] [CrossRef]

- Conte, E.; Gani, R.; Ng, K.M. Design of formulated products: A systematic methodology. AIChE J. 2011, 57, 2431–2449. [Google Scholar] [CrossRef]

- Enekvist, M.; Liang, X.; Zhang, X.; Dam-Johansen, K.; Kontogeorgis, G.M. Computer-aided design and solvent selection for organic paint and coating formulations. Prog. Org. Coat. 2022, 162, 106568. [Google Scholar] [CrossRef]

- Yoon, K. A Reconciliation Among Discrete Compromise Solutions. J. Oper. Res. Soc. 1987, 38, 277–286. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Lai, Y.-J.; Liu, T.-Y. A new approach for multiple objective decision making. Comput. Oper. Res. 1993, 20, 889–899. [Google Scholar] [CrossRef]

- DIN EN 13523-11: 2019-12; Coil coated metals—Test methods—Part 11: Resistance to solvents (rubbing test). Beuth Verlag: Berlin, Germany, 2019.

- DIN EN 13523-7: 2022-01; Coil coated metals—Test methods—Part 7: Resistance to cracking on bending (T-bend test). Beuth Verlag: Berlin, Germany, 2022.

- DIN EN 13523-6: 2020-08; Coil coated metals—Test methods—Part 6: Adhesion after indentation (cupping test). Beuth Verlag: Berlin, Germany, 2020.

- DIN EN ISO 1522: 2007-04; Paints and varnishes—Pendulum damping test. Beuth Verlag: Berlin, Germany, 2007.

- DIN EN ISO 14577-1: 2015-11; Metallic materials—Instrumented indentation test for hardness and materials parameters—Part 1: Test method. Beuth Verlag: Berlin, Germany, 2015.

- DIN EN 13523-5: 2014-08; Coil coated metals—Test methods—Part 5: Resistance to rapid deformation (impact test). Beuth Verlag: Berlin, Germany, 2014.

- DIN EN 13523-12: 2024-06; Coil coated metals—Test methods—Part 12: Resistance to scratching. Beuth Verlag: Berlin, Germany, 2024.

- Garvin, J. Calculate heats of combustion for organics. Chem. Eng. Prog. 1998, 94, 43–45. [Google Scholar]

- Marlair, G.; Vwiklinski, C.; Tewarson, A. An analysis of some practical methods for estimating heats of combustion in fire safety studies. Interflam 1999, 99. Available online: https://ineris.hal.science/ineris-00972167/ (accessed on 26 August 2025).

- Abbott, S.; Hansen, C.M.; Hiroshi, Y. Hansen Solubility Parameters in Practice, version 5; Hansen-Solubility: Boca Raton, FL, USA, 2015. [Google Scholar]

- Díaz de los Ríos, M.; Hernández Ramos, E. Determination of the Hansen solubility parameters and the Hansen sphere radius with the aid of the solver add-in of Microsoft Excel. SN Appl. Sci. 2020, 2, 676. [Google Scholar] [CrossRef]

- Takashi, S.; Sadaro, A.; Masato, M.; Ryuzo, T.; Hideki, Y. Comparison of Hansen solubility paramter of asphaltenes extracted from bitumen produced in different geographical regions. Energy Fuels 2014, 28, 891–897. [Google Scholar]

- Freitag, W.; Stoye, D. Paints, coatings and solvents; Wiley-VCH: Weinheim, Germany, 1993. [Google Scholar]

- Fitzsimons, B.; Parry, T. Coating Failures and Defects; ASM International: Novelty, OH, USA, 2015. [Google Scholar]

- Johansson, K.; Johansson, M. The effect of fatty acid methyl esters on the curing performance and final properties of thermally cured solvent-borne coil coatings. Prog. Org. Coat. 2007, 59, 146–151. [Google Scholar] [CrossRef]

- Patra, N.; Ramesh, P. Investigating the role of solvents in modulating glass transition and dynamic mechanical characteristics of polystyrene film. Colloids Surf. A Physiochem. Eng. Asp. 2024, 703, 135230. [Google Scholar] [CrossRef]

- 1-Methyl-2-pyrrolidinone ReagentPlus, 99 872-50-4. Available online: https://www.sigmaaldrich.com/AT/en/product/sigald/m79603 (accessed on 23 July 2025).

- Cyrene BioRenewable 53716-82-8. Available online: https://www.sigmaaldrich.com/AT/en/product/sial/807796?srsltid=AfmBOopq2-bLYxuNk6_HtsEpUdC_0wlBwpsbyxRjSDLmFaAF8fcK8NmD (accessed on 23 July 2025).

- Gao, F.; Bai, R.X.; Ferlin, F.; Vaccaro, L.; Li, M.H.; Gu, Y.L. Replacement strategies for non-green dipolar aprotic solvents. Green Chem. 2020, 22, 6240–6257. [Google Scholar] [CrossRef]

- Papasavva, S.; Kia, S.; Claya, J.; Gunther, R. Characterization of automotive paints: An environmental impact analysis. Prog. Org. Coat. 2001, 43, 193–206. [Google Scholar] [CrossRef]

- EUR-Lex–52023DC0654–EN–EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52023DC0654 (accessed on 23 July 2025).

| Entry Nr. | Solvent | Method | Bio-Solvent | C-ValueDirect | C-ValueIndirect | Paint 1/wt.% | Paint 2/wt.% |

|---|---|---|---|---|---|---|---|

| 1 | BDGA | Direct | EHL | 0.97 | - | 4.5 | 2.3 |

| 2 | n-Butanol | Direct | n-Butanol | 1.00 | - | 0.0 | 0.1 |

| 3 | BGA | Direct | ELE | 0.96 | - | 1.3 | 0.3 |

| 4 | BG | Direct | 2-Octanol | 0.96 | - | 1.2 | 0.0 |

| 5 | BDG | Direct | EDDP | 0.92 | - | 0.0 | 0.2 |

| 6 | Xylene | - | Elsol XR | - | - | 0.0 | 3.3 |

| 7 | PGME | Direct | EL | 0.93 | - | 0.8 | 0.0 |

| 8 | DBE | Direct | Bio-DBE | - | - | 1.3 | 2.4 |

| 9 | Solvesso 100 | Indirect | Bio 100 | - | 0.53 | 0.0 | 1.0 |

| 10 | Solvesso 150 | Indirect | Bio 150 | - | 0.45 | 4.9 | 3.7 |

| 11 | Solvesso 200 | Indirect | Bio 200 | - | 0.40 | 1.6 | 0.3 |

| Sum | - | - | - | - | - | 15.6 | 13.6 |

| Test Parameter | Functionality | Paint 1 | Bio-Solvent Paint 1 | Paint 2 | Bio-Solvent Paint 2 |

|---|---|---|---|---|---|

| Gloss at 60°/GU | Gloss | 83 ± 1 | 66 ± 2 | 41 ± 1 | 51 ± 1 |

| MEK/Doublehubs | Solvent resistance | >150 | >150 | >150 | >150 |

| T-Bend (Adhesion)/T | Adhesion | 0.5 ± 0.5 | 1 ± 0.5 | 1 ± 0 | 1 ± 0 |

| T-Bend (Flexibility)/T | Flexibility | 0 ± 0 | 0 ± 0 | 1.5 ± 0 | 1.5 ± 0 |

| Crosscut (Adhesion)/Gt | Adhesion | 0 ± 0 | 0 ± 0 | 0 ± 0 | 0 ± 0 |

| Impact (>7 mm) | Impact resistance | No cracks | No cracks | No cracks | No cracks |

| Depth penetration (>18 J)/Gt | Adhesion | 0 ± 0 | 0 ± 0 | 0 ± 0 | 0 ± 0 |

| Scratch resistance/g | Scratch resistance | 3 540 ± 60 | 3 330 ± 120 | 3 230 ± 160 | 3 260 ± 200 |

| Microhardness/N mm−2 | Hardness | 47 ± 7 | 51 ± 9 | 43 ± 9 | 46 ± 3 |

| CIT/% | Deformation | 48 ± 2 | 48 ± 2 | 48 ± 2 | 48 ± 2 |

| Pendulum hardness/DH | Hardness | 90 | 90 | 90 | 89 |

| Erichsen Cupping | Ductility | No cracks | No cracks | No cracks | No cracks |

| Method | Test Parameter | Paint 1 | Bio-Solvent Paint 1 | Paint 2 | Bio-Solvent Paint 2 |

|---|---|---|---|---|---|

| TMA | Tg1/°C | 38.3 | 37.9 | 33.5 | 31.2 |

| Tg2/°C | - | - | 56.0 | 60.9 | |

| DSC | Tg1/°C | 27.9 | 27.6 | 25.2 | 27.0 |

| Paint | Relative Price/% |

|---|---|

| Paint 1 | 100 |

| Bio-Solvent Paint 1 | 129 |

| Paint 2 | 100 |

| Bio-Solvent Paint 2 | 120 |

| Paint | Heat of Combustion/kWh kg−1 | Difference to Bio-Solvent Paint/% |

|---|---|---|

| Paint 1 | 9.4 | −10% |

| Bio-Solvent Paint 1 | 8.4 | |

| Paint 2 | 9.9 | −17% |

| Solvent | Relative Climate Change Total /% CO2 equivalent kg−1 | Relative Climate Change Total Including Biogenic C Storage /% CO2 equivalent kg−1 | Relative Climate Change Total Including Fossil Emissions at Incineration /% CO2 equivalent kg−1 |

|---|---|---|---|

| Butyl glycol acetate | 56 | 56 | 100 |

| Naphtha | 13 | 13 | 87 |

| Ethyl acetate | 72 | 29 | 72 |

| Ethyl levulinate | 53 | 3 | 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rippatha, E.; Mendez Rossal, H.R.; Strauß, B.; Schwarzinger, C. Substitution of Fossil-Based Solvents in Organic Coatings. Clean Technol. 2025, 7, 88. https://doi.org/10.3390/cleantechnol7040088

Rippatha E, Mendez Rossal HR, Strauß B, Schwarzinger C. Substitution of Fossil-Based Solvents in Organic Coatings. Clean Technologies. 2025; 7(4):88. https://doi.org/10.3390/cleantechnol7040088

Chicago/Turabian StyleRippatha, Elias, Hector Rolando Mendez Rossal, Bernhard Strauß, and Clemens Schwarzinger. 2025. "Substitution of Fossil-Based Solvents in Organic Coatings" Clean Technologies 7, no. 4: 88. https://doi.org/10.3390/cleantechnol7040088

APA StyleRippatha, E., Mendez Rossal, H. R., Strauß, B., & Schwarzinger, C. (2025). Substitution of Fossil-Based Solvents in Organic Coatings. Clean Technologies, 7(4), 88. https://doi.org/10.3390/cleantechnol7040088