Abstract

Volatile fatty acids (VFAs) are important precursors used in various industrial applications. Generally, these carboxylic acids are produced from oil, but recently focus has been on the development of biological methods for substituting the fossil raw material with organic waste and lignocellulosic materials. This is possible by stopping the anaerobic digestion process at the level of VFA through elimination of the final step of methanogenesis. The primary barrier to commercial viability of VFA production is the costly downstream processing needed for separation of the VFA’s. Existing separation techniques, such as adsorption and liquid–liquid extraction, achieve nearly complete VFA recovery from fermentation broths but require substantial chemical inputs and extensive preprocessing. In contrast, membrane-based separation processes could potentially overcome the need for chemical additions and provide a more sustainable way of separation. In this review we examine the current state of the art of membrane technology for VFA separation. We assessed and compared the capital and operational costs associated with different membrane technologies and identified the major hurdles impeding their commercialization. Furthermore, we examine hybrid and emerging membrane technologies that previous studies have suggested to reduce both energy and capital costs. Finally, we present future perspectives for the development of cost-effective membrane technologies suitable for industrial-scale applications.

1. Introduction

Production of (bio)chemical and fuels continues to gain increasing interest [1]. The raw materials used for producing sustainable (bio)chemicals and fuel can be obtained from low-cost renewable resources, including agricultural, industrial, and municipal solid waste (MSW), which are abundantly available yet underutilized. For example, the generation of organic fractions of MSW (OFMSW) reached 292.4 million tons in 2020, with only 69 million tons of total OFMSW being utilized, while the remaining fraction is landfilled [2]. An effective strategy for managing these types of waste is to enhance their value by converting them into valuable chemicals such as volatile fatty acids (VFAs) [3].

VFAs are linear short-chain aliphatic mono-carboxylic acids such as acetic acid (C2), propionic acid (C3), and butyric acid (C4). In 2020, the global market demand for volatile fatty acids (VFAs), including acetic, propionic, and butyric acids, reached approximately 18.5 million tons, with an average market value of around $1200–$1500 per ton of VFA, depending on the specific acid and its purity. The acetic acid market alone is projected to reach a valuation of USD 28.89 billion by 2032, expanding at a compound annual growth rate (CAGR) of 6.52% from 2024 to 2032 [3]. These chemicals have wide-ranging applications as intermediates in the cosmetic, petrochemical, pharmaceutical, and aviation industries [4]. However, current VFA synthesis processes primarily rely on fossil-based oil and chemical routes with a high carbon intensity score [5].

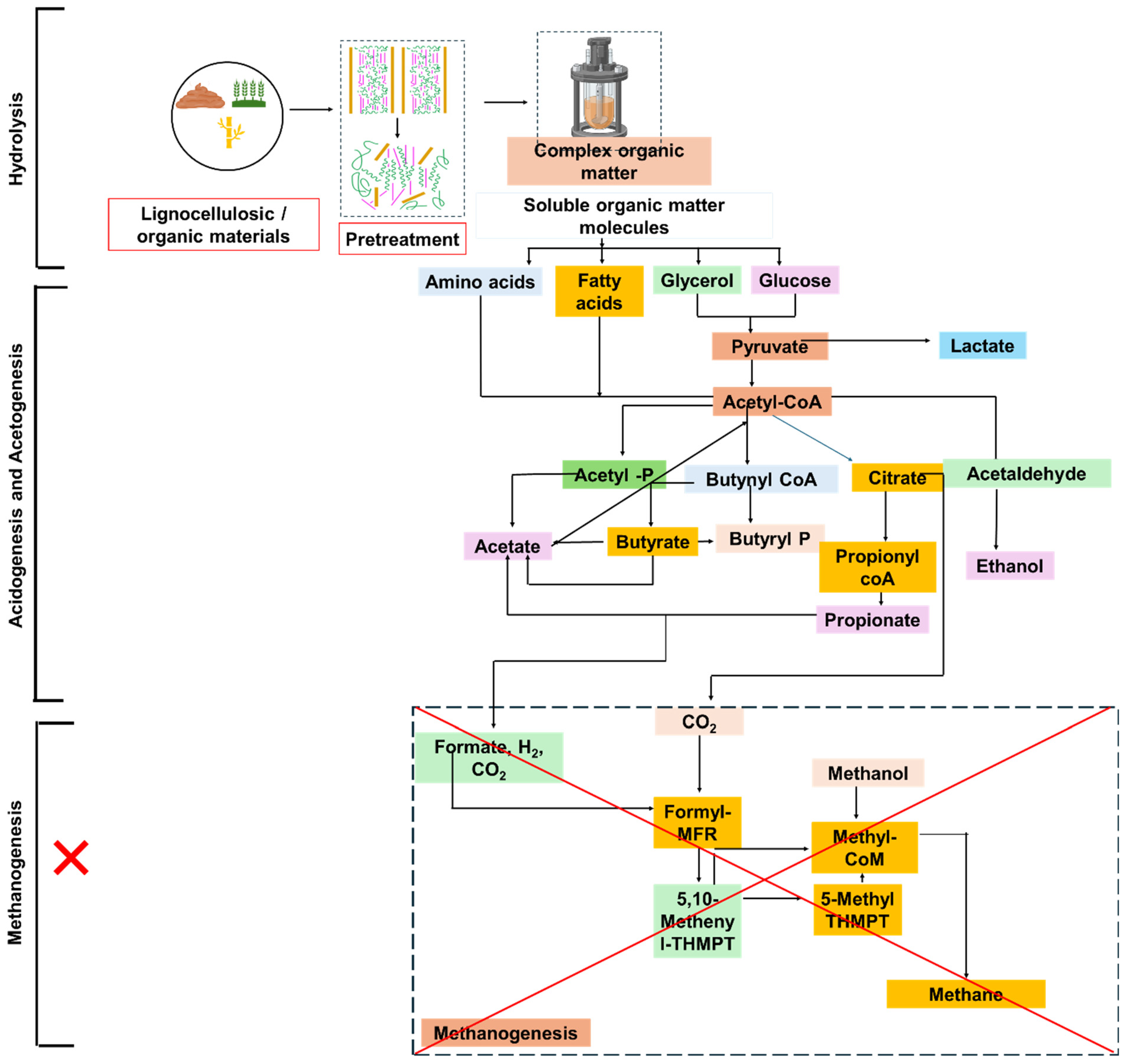

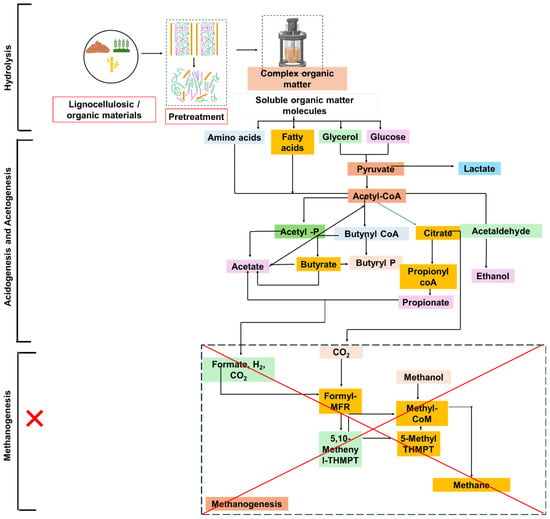

Biological processes, such as arrested anaerobic digestion (AAD) shown in Figure 1, offer an economically viable alternative. Every stage of anaerobic digestion is dominated by certain groups of microbes. The hydrolysis stage is dominated by bacillus, bacteroides, clostridia, etc., and for acidogenesis, bacteria like actinomyces, bacillus, klebsiella, etc. Furthermore, for acetogenesis bacteria like acetoanaerobium, acetonema, thermoanaerobacter, etc., these VFAs are produced by fermentative bacteria in acidogenesis stage. The varied VFA profile and diversity is caused by the shift in microbial microflora or pH, substrate type, etc. Understanding these interactions enables the design of integrative biorefinery strategies aimed at coupling VFA accumulation with downstream processes such as hydrogen production, polyhydroxyalkanoate synthesis, or chain elongation for medium-chain fatty acid recovery.

Figure 1.

VFA production through arrested anaerobic digestion where methanogenesis has been suppressed (red cross).

AAD operates under mild temperature conditions (30–70 °C) [6], requires minimal chemical additives [7], and utilizes waste materials as feedstock [8]. The AAD process is a modification of anaerobic digestion (AD). By suppressing methanogenesis, the AD process is stopped after VFA production, allowing for accumulation of intermediates normally converted into methanogenic substrates. Methanogenesis can be controlled by controlling operational conditions (pH, hydraulic retention time (HRT), and organic loading rate (OLR)) [9], adding methanogen inhibitors [10], and applying heat shock [11]. Previous studies have reported VFA production using various raw materials under different conditions. Food waste treated with BES at 37 °C, pH 6, and an HRT of 11 days yielded 0.89 g VFA/g vs. [6]. Wastewater sludge combined with pretreated bagasse at 55 °C, pH 7, with iodoform (20 g/L) and an HRT of 14 days produced 0.36 g VFA/g vs. [12]. The highest VFA yield of 3.64 g VFA/g vs. was achieved using yard waste treated at 37 °C, pH 9, with BES (10 mM) and an HRT of 40 days [10]. Other substrates, including rice straw with chicken manure [5], cheese whey with brewery wastewater [7], also showed varying yields depending on temperature, pH, inhibitors, and retention times.

Extensive research on AAD for VFA production from waste has been conducted, ranging from bench-scale to pilot plant-scale studies [12], including techno-economic analyses (TEA) [13]. TEA of VFA production has revealed that downstream processing significantly contributes to the total production cost, accounting for up to 40% of the cost [13,14]. Thus, implementing cost-effective separation and purification methods could substantially reduce the overall cost of VFA production.

Separation and purification technologies for VFAs widely reported in the literature includes solvent extraction [15], chemical precipitation [16], adsorption [17], liquid–liquid extraction (LLE) [18], distillation [19], and gas stripping [20]. These technologies have successfully recovered VFAs at rates exceeding 75%. However, these processes present several drawbacks that impact the cost of downstream processes. For example, operational costs were affected by the need for solvent replacement in extraction, adsorption/desorption, and ion exchange. The requirement of a significant amount of gas for gas stripping [20] and the high energy demand for distillation [19] also affect the operational cost of VFA production. The difficulties recovering chemicals in these separation processes for reuse further lead to waste with negative environmental impact. Therefore, environmentally friendly VFA separation and purification methods with low energy requirements and no need for chemical additions, such as membrane technology, could be more economical and environmentally safe.

Membrane-based processes for VFA separation and purification have been extensively studied and have been shown to recover VFAs at rates of up to 80% using techniques like nanofiltration (NF), reverse osmosis (RO), or NF coupled with distillation or electrodialysis (ED) [21,22,23]. Because this technology is suitable and promising in the future for the VFA recovery, several articles have previously reviewed specific membrane separations of VFA’s [24], including pressure-driven membrane processes [25], forward osmosis (FO) [26], vacuum-driven membranes [27], membrane contactors (MC) [28], and membrane bioreactors (MBRs) [29]. These processes each have unique advantages and limitations depending on wastewater composition, target VFA concentration, and scale. For instance, MF and UF are often employed as pre-treatment steps to remove solids and colloids, while NF and RO excel in achieving high selectivity and near-complete VFA separation, albeit with higher energy costs and potential fouling challenges. PV and FO provide additional options for selective VFA recovery from dilute streams, offering potential synergies when integrated with other processes. Overall, integrating these membrane technologies into VFA production platforms could significantly enhance efficiency, product quality, and sustainability of bioprocessing systems.

The present review will offer an overview of the different membrane technologies for VFA recovery while further identifying bottlenecks at the current stage of technology. The bottleneck discussion includes issues such as membrane fouling, energy consumption, selectivity and permeability, chemical, thermal, and mechanical stability, membrane material limitations, environmental impacts, and-scale up, all related to VFA recovery. An economic evaluation of current membrane technology is further presented. Innovative modifications of membrane-based processes, such as hybrid membranes, will further be discussed. Finally, the review will present future perspectives on developing cost-effective membrane technologies for industrial upscaling of VFA production.

2. Criteria for Choosing Specific Membrane Technologies

Membrane technology selection for volatile fatty acid (VFA) separation from waste-derived streams—such as anaerobic digestate, food waste hydrolysates, or manure effluents—requires a careful evaluation of multiple criteria to ensure technical feasibility and economic viability. These waste streams are typically complex, containing high levels of suspended solids, organic matter, and microbial residues, which impose significant fouling risks and require robust pretreatment steps, often via ultrafiltration (UF) [30]. The VFA concentration and composition (acetic, propionic, butyric acids, etc.) also vary with feedstock and digestion conditions, influencing membrane selectivity and recovery efficiency. Nanofiltration (NF) and reverse osmosis (RO) are commonly used for VFA concentration and purification, but their performance is strongly affected by feed pH, ionic strength, and membrane fouling—necessitating operation at optimized transmembrane pressures and periodic cleaning cycles [31]. Forward osmosis (FO), though less mature, shows promise in handling high-fouling feeds with low energy input, especially when integrated with draw solution regeneration systems [31]. Electrodialysis (ED) is highly effective for ionized VFAs at alkaline pH but demands low-solid, clarified input streams [32]. Other considerations include membrane material compatibility with acidic environments, capital and operational costs, scalability, and the extent of recovery required for downstream valorization. Hence, membrane technology selection for waste-derived VFAs must be guided by a systems-level understanding of feed composition, desired separation outcomes, and process integration strategies.

3. Developments in Membrane-Based Processes for VFA Separation and Purification

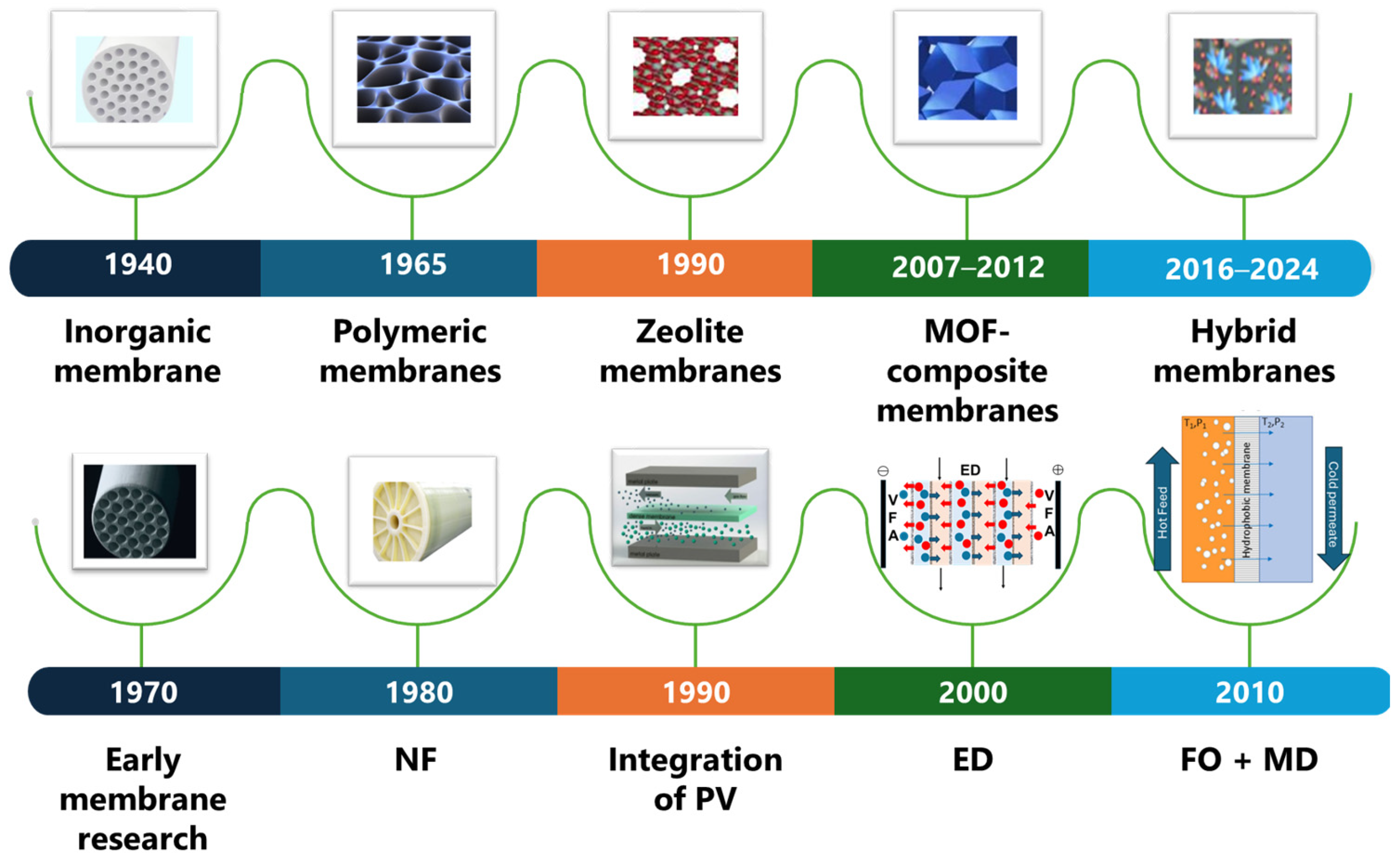

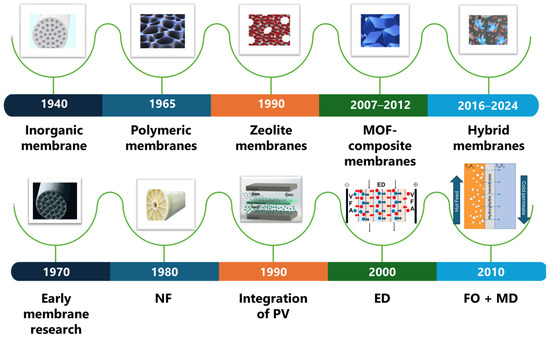

The advancement in downstream VFA recovery processes has made remarkable developments over the last years. Early membrane technologies were primarily focused on chemical separations, such as desalination and gas separations through adsorption and desorption. The 1990s marked a turning point, with advancements in polymer chemistry leading to the development of more selective and robust membrane materials as shown in Figure 2 [33]. This development of membranes technology has progressed significantly over the years, starting with inorganic membranes in the 1940s, which were used for filtration and gas separation but lacked flexibility. In 1965, polymeric membranes emerged, offering greater flexibility and cost-effectiveness for applications like reverse osmosis. By the 1990s, zeolite membranes were introduced, providing selective permeability for efficient separation processes. Between 2007 and 2012, Metal–Organic Framework (MOF)-composite membranes were developed, combining the tunable properties of MOFs with membrane technology for improved performance in gas separation and catalysis. The most recent advancement, hybrid membranes (2016–2024), integrate inorganic and organic materials to enhance mechanical strength, stability, and selectivity across diverse applications [34].

Figure 2.

The development of membrane material and membrane-based technology used for separation of VFAs from fermentation broth.

Post the early membrane research began in the 1970s, focusing on understanding the basic principles of membrane separation and laying the foundation for future innovations. In the 1980s, NF membranes were introduced, bridging the gap between reverse osmosis and ultrafiltration, with a focus on selective separation of ions and small molecules. The integration of pressure-driven processes like pervaporation (PV) emerged in the 2000s, enhancing the efficiency of separation in applications like dehydration and solvent recovery. By 2000, ED, a membrane-based ion separation technique, was further refined for applications in desalination and wastewater treatment. In 2010, the combination of Forward Osmosis (FO) and Membrane Distillation (MD) emerged as a novel hybrid process, offering improved energy efficiency for desalination and water treatment [34]. These milestones in membrane research and technology are summarized in Figure 2.

These developments resulted in the creation of membrane technologies such as microfiltration (MF), ultrafiltration (UF), and NF. In recent years, more attention has been given to the development of RO and membrane distillation (MD) as discussed in Table 1 [34,35,36]. Research by Zacharof et al. highlighted a VFA recovery rate of 75% for compounds like acetic acid and butyric acid using NF membranes [37]. Earlier studies statistically analyzed VFA separation by various technologies, including RO, NF, and forward osmosis (FO), to assess their effectiveness in separating VFAs from anaerobic effluents [21]. The first membrane-based process for VFA recovery was ED, which emerged in the mid-20th century. It separated VFAs as anions using ion-exchange membranes in an electric field. Over time, challenges like fouling and energy costs led to the development of alternative processes such as MD, which leveraged temperature gradients for selective vapor transport, and FO, which utilized osmotic pressure for concentration. Later advancements included pertraction (membrane-based solvent extraction) for continuous VFA recovery and ED with bipolar membranes (EDBM), which enabled direct acid recovery.

Table 1.

VFA separation using different membrane technologies.

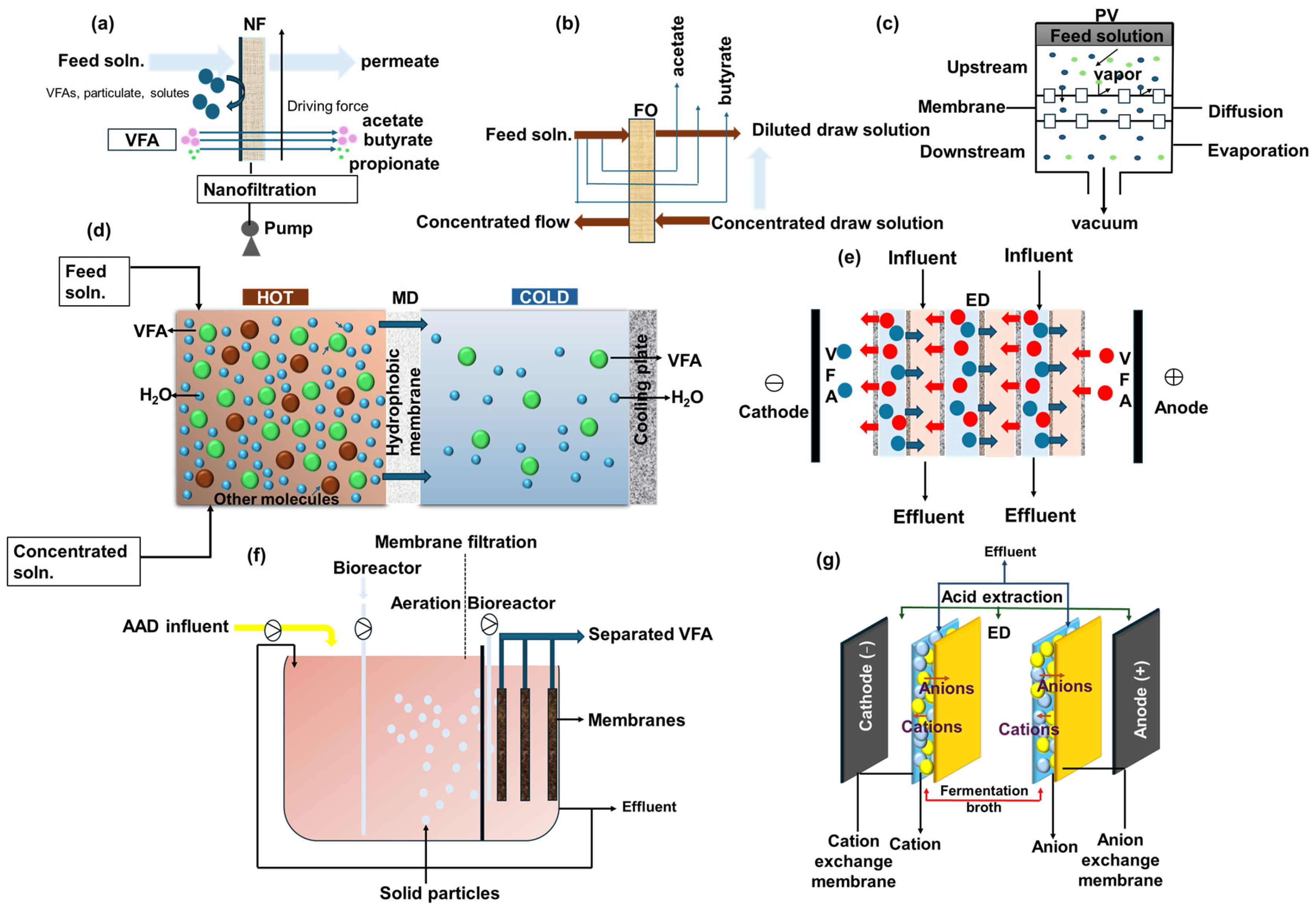

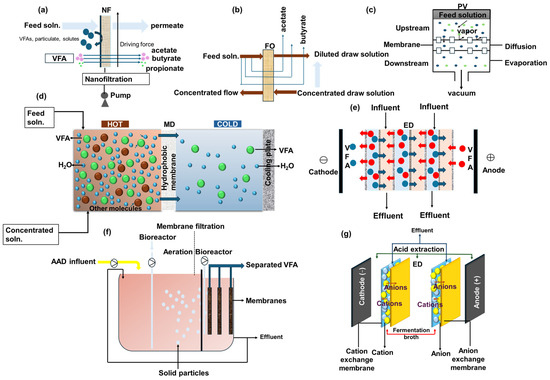

Figure 3 illustrates the mechanisms behind various membrane filtration technologies, including NF, PV, FO, and MD. NF membranes reject divalent ions and large organic molecules while allowing smaller monovalent ions and water to pass through [21]. MF membranes are often used as a pre-treatment stage before VFA separation [35]. RO employs a semi-permeable membrane under high pressure to overcome osmotic pressure, concentrating on VFAs and removing water from the effluents while rejecting a wide range of solutes, including salts and organic molecules [41]. ED operates on the principle of ion-exchange [42]. It uses an electric field to separate ions from the aqueous solution, with cation and anion exchange membranes selectively attracting positive or negative ions toward their respective electrodes. Additionally, MD is a thermally driven process that uses hydrophobic and microporous membranes to create a temperature difference across the membrane [19]. MD selectively separates VFAs based on their volatility and is considered more energy-efficient than traditional distillation methods, as it operates at lower temperatures and pressures.

Figure 3.

Mechanism of (a) nanofiltration (NF); (b) forward osmosis (FO); (c) pervaporation (PV); (d) membrane distillation (MD); (e) electrodialysis (ED); (f) membrane bioreactor (MBR); (g) electrodeionization (EDI) for volatile fatty acid separation and purification.

3.1. Pressure-Driven Membrane

Pressure-driven membrane technologies, including MF, UF, NF, and RO, have become essential tools for separating and recovering VFAs from various waste substrates. These technologies operate by applying hydraulic pressure across a semi-permeable membrane to selectively separate different components based on their size, charge, and molecular properties. The choice of membrane material and pore size plays a crucial role in determining the efficiency of VFA recovery. The different pressure-driven membrane technologies have been explored in Table 2 below.

MF membranes, typically having pore sizes in the range of 0.1 to 10 microns, are often used in the initial stages of VFA recovery to remove larger particles and suspended solids from waste streams. However, due to their larger pore sizes compared to the size of VFAs (approximately 0.3–0.5 nm), MF membranes cannot efficiently separate smaller organic molecules such as VFAs. For example, Zacharof et al. employed membralox ceramic filter elements (α-Al2O3) for MF to recover acetic acid (21.08 mM) and butyric acid (15.81 mM) from straw; however, VFA recovery remained limited, highlighting the need for more selective separation methods [42]. Similarly, Kim et al., demonstrated that MF, using ceramic microfiltration modules, achieved 95% VFA recovery from pretreated raw sludge [43]. However, the VFA recovery with MF remains lower compared to other technologies due to its inability to effectively separate small molecular VFAs from larger organic matter. This limitation shows that MF mainly removes larger components, such as bacteria and suspended particles, via size exclusion, making it unsuitable for capturing small molecules like VFAs.

While MF provides initial filtration, UF, with pore sizes ranging from 1 to 100 nm, offers a more refined separation, particularly for small organic molecules like VFAs. The smaller pore sizes of UF membranes allow for better retention of VFAs in the eluent while filtering out larger particles, leading to more efficient recovery. Microfiltration alone has limited selectivity for VFA recovery, which can be improved by integrating UF or using a combination of MF and UF. For instance, Pervez et al. demonstrated that an integrated MF-UF system using hydrophilic polyether sulfone (PES) membranes (10 kDa) could recover VFAs from food waste, achieving a total VFA concentration of 6.58 g/L [25]. The smaller pores of UF membranes improve VFA retention by selectively allowing smaller molecules to pass through while rejecting larger contaminants. This significant improvement in VFA recovery efficiency can be attributed to UF’s enhanced ability to separate small organic molecules that MF could not effectively capture. Moreover, Mineo et al. used UF with polyvinyl fluoride hollow fiber membranes to recover VFAs from wastewater, achieving 1.092 g/L of VFA recovery, though UF still has limitations in separating larger VFA molecules [44].

Despite improvements made by UF, its selective separation remains somewhat limited when dealing with complex mixtures of VFAs. This challenge led to the development of NF, which operates with even smaller pore sizes (typically 1–10 nm) and offers enhanced molecular selectivity. NF membranes, particularly those with a molecular weight cutoff (MWCO) ranging from 200 to 1000 Da, are highly effective for separating small organic molecules, including VFAs, while retaining divalent ions. NF has demonstrated impressive VFA recovery, as seen in studies where NF membranes were used for food waste and agricultural wastewater by Pervez et al., achieving recovery rates of 75% and VFA concentrations up to 16.94 g/L using 200–1000 Da NF membranes during cross-flow filtration [25]. Similarly, Zacharof et al. applied thin-film composite polyamide NF membranes to recover 75% VFA from digested agricultural wastewater, with specific concentrations of acetate (53.94 mM) and butyrate (28.38 mM) [45]. The enhanced efficiency of NF can be attributed to both the smaller pore size and the electrostatic interactions between the charged membrane surface and the solute molecules, which enable the selective passage of VFAs and reject unwanted components. The mechanisms of VFA separation using NF are described in Figure 3a. Ernst et al. suggested that the Donnan effect and steric hindrance play significant roles in the retention of charged molecules, further improving separation efficiency compared to UF [46]. Additionally, NF allows for the concentration of VFAs, thus enhancing the overall recovery rate. Xiong et al. also achieved 90% VFA recovery from fermented whole willow chips using NF, further highlighting its potential for high-efficiency VFA separation [47].

Although NF has shown considerable improvements over MF and UF, RO provides the highest level of molecular selectivity and can concentrate VFAs to higher levels, making it highly effective for specific recovery applications. RO membranes, with pore sizes ranging from 0.001 to 0.0001 μm, operate under high pressures (10–15 bar) to achieve greater separation efficiency [21]. However, the energy requirements of RO are higher compared to UF and NF, which can limit its cost-effectiveness for large-scale applications. RO and NF integration, however, offers a synergistic approach by combining the concentration power of RO with the selective filtration ability of NF [48]. This combination has been shown to significantly improve VFA recovery. For instance, Domingos et al. employed TFC polyamide membranes in RO and NF to recover 8 g/L of VFA from f grape pomace, fruits, vegetable waste, and urban waste [21]. The high-pressure operation of RO enhances the driving force for separation, while increased pH can convert VFAs into their ionic forms (e.g., acetate), which are more likely to be retained by the membrane. This makes RO highly effective for separating VFAs from complex mixtures. Furthermore, Pratofiorito et al. demonstrated that RO could recover 6 g/L of acetic acid from feed solutions containing total VFA using crossflow flat sheet membrane modules [49]. This progression from MF to UF, NF, and RO highlights the importance of the specific membrane design in improving recovery efficiency and the development of more sustainable, energy-efficient processes for VFA separation. The ongoing advancements in membrane materials and process integration continue to push the boundaries of VFA recovery, offering significant potential for future applications in waste treatment and resource recovery.

Table 2.

Recovery percentage of VFA produced from different types of waste with different membrane-based processes, membrane materials, and pressure.

Table 2.

Recovery percentage of VFA produced from different types of waste with different membrane-based processes, membrane materials, and pressure.

| Raw Materials [-] | Total VFA Production [g/L] | Membrane-Based Process [-] | Membrane Materials [-] | Pressure [Bar] | Recovery [%] | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| Acetic Acid | Butyric Acid | Other Acids | VFA | ||||||

| Straw | 2.9 | MF | Ceramic filter (α-Al2O3) | 1.03 | 60 | 40 | NA | 76.4 | [42] |

| Pretreated sludge | 8 | MF | Ceramic | 0.3–2 | NA | NA | NA | 87 | [43] |

| Food waste | 17 | NF | Cross flow filtration cell | 15 | 90 | 72 | 73 | 96 | [25] |

| Agriculture wastewater | 21 | NF | Composite polyamide | 10 | 65 | 34 | NA | 75 | [45] |

| Wastewater | 11 | UF | Polyvinyl fluoride | 0.95 | NA | NA | NA | 45 | [44] |

| VFA mixture | 13 | RO | Flat sheet membrane modules | 25 | 35 | NA | NA | NA | [49] |

| Fruits and vegetables | 8–20 | RO+NF | TFC polyamide | 30 | 40 | NA | NA | NA | [21] |

| Willow chips | 14 | NF | Cross flow filtration | 41 | NA | NA | 75 | 87 | [47] |

| Synthetic VFA soln. | 18 | NF | NF270 | 12 | 95 | NA | NA | 99 | [50] |

NA means Not Applicable.

The progression from MF to UF, NF, and RO technologies highlights the critical role of membrane pore size and properties of the membranes in improving VFA recovery efficiency. Membranes with smaller pores and advanced materials, such as polyamide thin-film composite (TFC) membranes used in NF and RO, have significantly enhanced the selectivity and separation performance for VFAs. By optimizing membrane pore size, material properties, and process integration, these pressure-driven technologies have evolved to overcome the limitations of earlier methods, leading to higher VFA recovery rates and offering new possibilities for industrial-scale applications in waste treatment and resource recovery. Ongoing innovations in membrane materials and process integration continue to push the boundaries of VFA recovery, making membrane-based separation processes more efficient, sustainable, and suitable for large-scale applications.

3.2. Concentration-Driven Membranes

Concentration-driven membrane technologies operate on the principle of a concentration gradient across a semi-membrane, where solutes move from regions of higher concentration to regions of lower concentration [51]. Unlike pressure-driven processes, these technologies rely on the natural diffusion process induced by the concentration difference, rather than external pressure, to achieve separation. This principle enables the selective recovery of specific compounds, such as VFAs, ions, or other small molecules. In this section, we will discuss the three primary concentration-driven membrane technologies for VFA separation: pervaporation, carrier-mediated separation, and forward osmosis.

Pervaporation is a membrane separation process that uses both solution flow and diffusion to separate liquid mixtures. It operates under the principle that when a vacuum is applied to one side of the membrane, volatile compounds, including VFAs, diffuse from the liquid phase to the vapor phase and pass through the membrane to the permeate side [52]. The process occurs in three steps: first, the substance dissolves in the feed; second, it diffuses through the membrane; and finally, it evaporates on the permeate side as vapor (Figure 3c).

The membranes used in pervaporation are often made from mixed matrix composites consisting of polymers and nanofillers. The membrane pore sizes typically range from 0.2 to 0.5 µm, which helps selectively separate VFAs, particularly acetic acid. Studies by Zhang et al., demonstrated the development of a novel membrane composed of sodium alginate cast over nitrogen plasma-modified polypropylene, crosslinked with Ca2+ and Al3+, to separate VFAs from feed solutions [53]. This separation relies on the differing solubility and diffusivity of VFAs, with membranes tailored to selectively separate acetic acid, butyric acid, and other VFA components.

Choudhari et al., studied pervaporation for separating butyric acid from an aqueous solution derived from AD [54]. The AD of grass generated a VFA mixture with concentrations of acetic acid (0.52 g/L), propionic acid (0.23 g/L), butyric acid (5.95 g/L), and valeric acid (0.60 g/L), totaling 7.3 g/L of VFA. Using PEBA-based composite membranes, the separation process achieved 0.0773 g of VFA over a 2 h period. The presence of nanofillers in the membrane resulted in a slight decrease in flux but improved the separation efficiency [54]. Despite its effectiveness, the process faces challenges like reduced flux and slight membrane fouling due to the presence of nanofillers, which can decrease long-term performance. However, ongoing advancements in membrane material composition and process optimization continue to enhance the efficiency of pervaporation in VFA recovery.

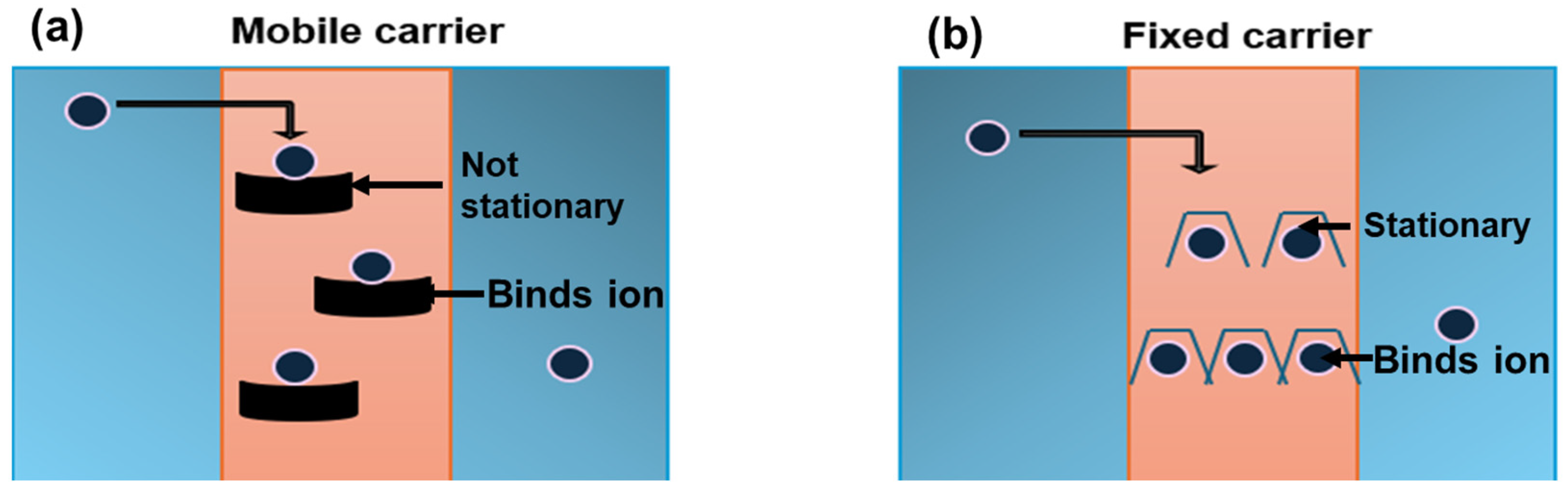

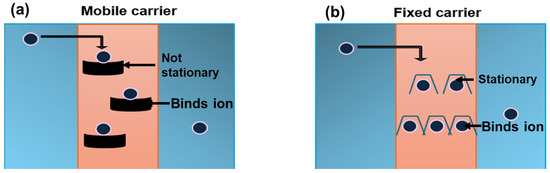

Carrier-mediated separation is a technique that uses chemical carriers to specifically bind with VFAs and transport them across a membrane as shown in Figure 4. This technology is particularly useful for separating VFAs from complex substrates such as fermented wastewater, where conventional methods often prove inefficient and costly. The carrier molecules have a high affinity for VFAs and form complexes with them, which then move across the membrane driven by the concentration difference or changes in environmental conditions (e.g., pH changes) [35].

Figure 4.

The mechanisms of carrier-mediated membrane technology: (a) Mobile carrier (b) Fixed carrier.

In carrier-mediated separation, once the carrier-bound VFA reaches the opposite side of the membrane, the VFA is separated due to changes in the concentration gradient, pH, or other environmental factors. This approach has been explored for the separation of propionic acid (PA), which has been difficult to commercialize due to its low product concentration and the high cost of extraction. The mechanism has been shown in Figure 4. Furthermore, the process also aims to eliminate inhibitory substances that could interfere with the fermentation process.

While studies have focused on liquid membrane systems to separate carboxylic acids, challenges remain to be solved such as the toxicity of amine extractants and carriers, as well as the instability of the system in contact with aqueous phases. Research by Wodzki et al., and others has shown that improved carrier-mediated separation can enhance VFA recovery [55,56]. However, some carriers have been criticized for their toxicity to microbial components and for instability over extended periods of time, particularly when interacting with the aqueous phase.

A promising development is the Membrane Hybrid System (MHS) for carboxylic acid transport, which combines strong basic polymeric membranes with a hydrophobic liquid membrane. The system operates via the solution-diffusion mechanism, where polyelectrolytes at the membrane interface enhance sorption and improve transmembrane flux. This hybrid system ensures selective transport of weak acids like propionic acid by reacting with dissociated ions and undissociated species [55]. Table 3 below shows the different concentration-driven separation technologies, which have been used in separating VFA from different sources of waste.

Table 3.

Recovery percentage of VFA produced from different types of waste using different membrane-based processes, membrane materials for concentration-driven technology.

To further optimize the system of pertraction, sequential extraction, diffusion, and re-extraction have been tested. This process accelerates transport by neutralizing dissociated ions and overcoming slow diffusion rates. However, MHS performance remains concentration-dependent, with optimal operation at 0.1–0.8 M concentrations, making it less effective for dilute solutions typically found in fermentation broths. Long-term challenges include membrane fouling, solvent evaporation, and degradation under prolonged use, as well as selectivity issues in complex mixtures. To overcome these limitations, future developments may focus on dynamic membrane regeneration, nanocomposite materials, and improved stability, thus enhancing the system’s robustness and applicability for industrial-scale VFA recovery.

3.3. Thermally Driven Membrane

Thermally driven membrane separation is an innovative technology that uses temperature gradients to selectively separate VFAs from complex mixtures like wastewater and fermentation broths. This approach offers a more sustainable and energy-efficient alternative to traditional VFA recovery methods, which are often energy-intensive and costly, involving multiple distillation or chemical extraction steps. By leveraging heat from other processes, thermally driven membrane processes minimize energy consumption, making them a promising solution for industrial applications and environmental management [60]. Different thermally driven technologies have been discussed in Table 4 below.

Table 4.

Recovery percentage of VFA produced from different types of waste using different membrane-based processes, membrane materials for thermally driven technology.

One prominent thermally driven membrane technology for VFA recovery is MD. In MD, a hydrophobic membrane is used to allow only vapor to pass through its pores. The feed solution, which contains volatile substances like VFAs, is heated to create a temperature difference, causing the VFAs to evaporate due to the induced vapor pressure difference. This vapor moves through the membrane, condenses on the permeate side, and the volatile components, such as acetic acid, butyric acid, and valeric acid, are recovered as the permeate. The hydrophobic nature of the membrane prevents liquid from passing through, ensuring that only vapor transport occurs [64].

Direct Contact Membrane Distillation (DCMD) and Air Gap Membrane Distillation (AGMD) are variations of MD [65]. In DCMD, both the feed and permeate sides are in direct contact with the membrane, while in AGMD, an air gap is introduced between the membrane and the condensing surface to improve heat and mass transfer control. The use of hydrophobic membranes made from materials like PVDF, PTFE, and PP is common in these systems, as they facilitate gas–liquid separation and enhance vapor transport efficiency [66].

The separation of VFAs, such as acetic acid, butyric acid, and valeric acid, using MD is particularly effective because these short-chained fatty acids have high volatility, making them well-suited for vapor-phase separation. Studies suggest that MD can achieve VFA concentrations in the range of 1 to 4 g/L, depending on pH conditions and feed composition [19]. However, despite its potential, MD has not yet been scaled up for large-scale due to challenges in optimizing module efficiency and membrane packing density.

To summarize, thermally driven membrane technologies, especially MD, DCMD, and AGMD are promising for the selective recovery of VFAs from fermentation broths and wastewater. These technologies offer enhanced selectivity and energy efficiency compared to traditional methods, but challenges like module construction and performance optimization need to be addressed before they can be upscaled.

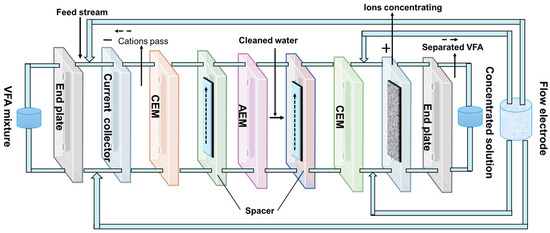

3.4. Electricity-Driven Membrane

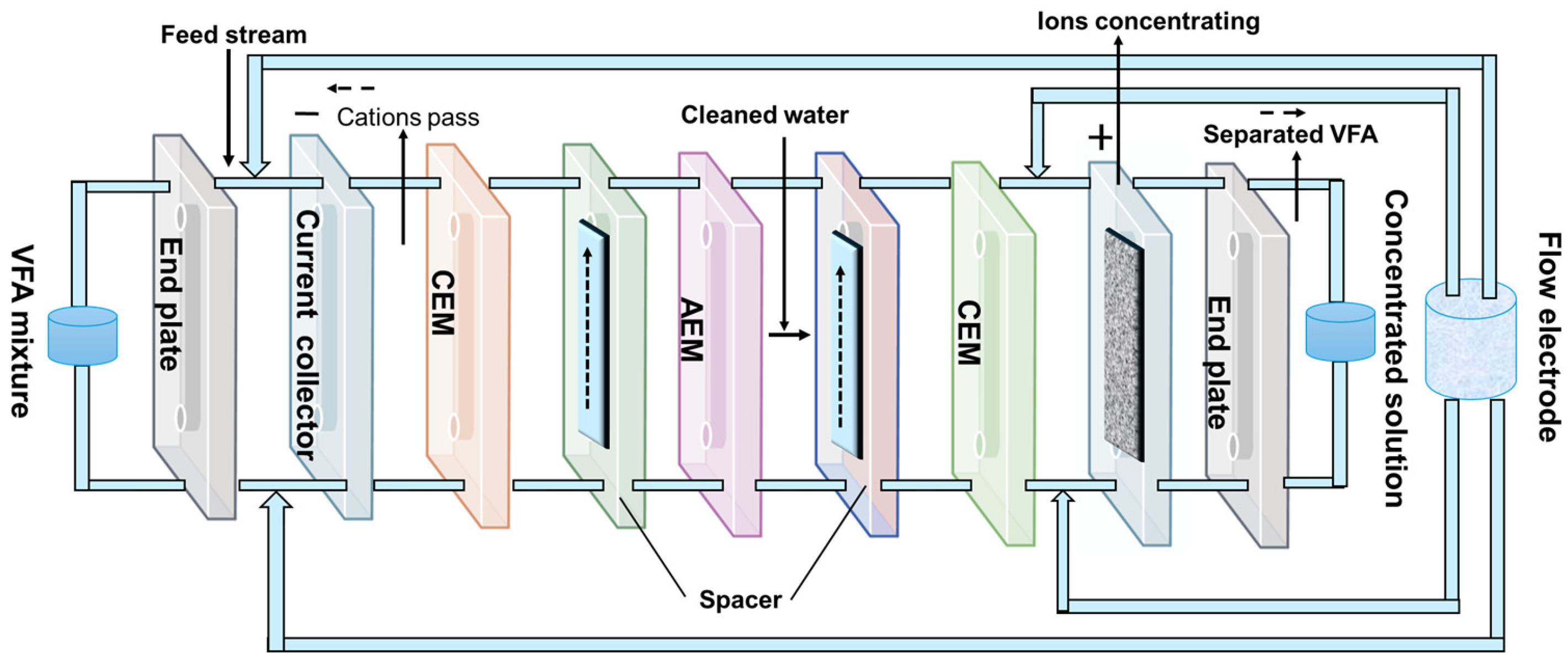

Electricity-driven membrane separation methods represent an emerging approach for selectively separating VFAs from complex mixtures, such as fermentation broths or wastewater. These technologies, including ED, electrochemical membrane processes, and electrodeionization (EDI), operate by applying an electric field across ion-selective membranes [67,68]. The electric field induces ionization of VFAs, converting them into ionic forms (e.g., acetate, propionate, butyrate) that migrate toward the oppositely charged electrode (the anode). Different electricity-driven technologies have been discussed in Figure 5. Furthermore, the recovery % of the VFAs by the electricity0driven membrane technologies have been discussed in Table 5.

Figure 5.

The mechanism of flow-electrode capacitive deionization (FCDI); where AEM stands for Anion exchange membrane and CEM stands for Cathode exchange membrane.

ED is a hybrid process combining membrane and electrochemical principles, where selective ion-exchange membranes are used to separate VFAs from other ions based on their electric potential differences [67]. In commercial applications, ED can be challenging when recovering and concentrating VFAs from complex feedstocks such as cheese whey and food waste. However, high separation efficiency with relatively low energy consumption has been demonstrated, especially when combining this process with for pervaporation for initial solid separation. For example, a study investigating the use of PTFE membranes in a three-stage process for anaerobically digested grass reported a significant enhancement in VFA concentration, from 287 to 404 mgVFA/gVS, after subjecting the feed to ED [69]. Despite its potential, ED systems are prone to membrane fouling, particularly due to the accumulation of suspended solids and microbial growth, which can impact long-term performance.

In addition to traditional ED, microbial electrochemical systems (MESs) offer promising advancements in bioenergy and waste treatment applications. MESs utilize exoelectrogenic bacteria to oxidize organic matter at the anode, enabling waste valorization and energy recovery with lower electricity requirements compared to conventional ED [70,71]. A recent innovation in MESs is the microbial bipolar ED cell (MBEDC), which addresses the challenges of waste-derived VFA recovery while simultaneously production of hydrogen (H2) [72]. Operating in a fed-batch condition with an applied voltage of 1.2 V, the MBEDC demonstrated a 98.3% VFA recovery efficiency and an H2 yield of 18.4 mL from a synthetic fermentation broth. The advantages of this technology include reduced electricity consumption and the elimination of costly electrodes and catalysts, making it a more cost-effective and energy-efficient solution for VFA recovery [72]. However, challenges such as dramatic pH fluctuations during operation and the risk of VFA degradation by bacteria need to be addressed to improve system stability.

EDI, a technology typically used for water purification, combines ion exchange resins and ion exchange membranes with an electric field to remove ionized particles from a solution. In the context of VFA recovery, EDI operates similarly to ion-exchange resins swapping ions with hydrogen and hydroxide ions, while ion-exchange membranes selectively allow the passage of either cations or anions. Flow-electrode capacitive deionization (FCDI) is a variation of this technology, where the system’s electrochemical characteristics are utilized to separate VFA and recover phosphate, demonstrating high energy efficiency with minimal chemical use [68]. A study on FCDI revealed that 32% phosphorus and 9% acetate were selectively removed to the anodic chamber, with an acetate yield of 92% after long-term operation [68]. This process consumed 1.89 kWh/kg, making it an energy-efficient alternative to more traditional methods of VFA separation. The mechanism of FCDI is portrayed in Figure 5.

In summary, these electricity-driven membrane separation methods; MES, and EDI—offers a range of benefits for VFA recovery, particularly in terms of selectivity, energy efficiency, and cost-effectiveness. Challenges do, however, remain in scaling up these technologies for industrial applications, particularly in managing membrane fouling, optimizing performance, and reducing system complexity.

Table 5.

Recovery percentage of VFA produced from different types of waste across different membrane-based processes and membrane materials for electricity driven technology.

Table 5.

Recovery percentage of VFA produced from different types of waste across different membrane-based processes and membrane materials for electricity driven technology.

| Raw Materials [-] | Total VFA Production [g/L] | Membrane-Based Process [-] | Membrane Materials [-] | Recovery [%] | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| Acetic Acid | Propionic Acid | Butyric Acid | Total VFA | |||||

| Anaerobically digested grass | 16 | ED | PTFE Membrane | 54 | 45 | NA | 99 | [73] |

| Synthetic fermentation broth | 1.68 | MBEDC | Activated carbon with titanium nanowire | 99 | 95 | 97 | 91 | [74] |

| Wastewater | 2 | FCDI | Ion-exchange membranes | 83 | 87 | 66 | 99 | [75] |

| Grass | 4.5 | ED | PTFE Membrane | 68 | NA | NA | 78 | [32] |

| Cow manure | NA | ED | Polyelectrolyte | 60 | NA | NA | 80 | [76] |

| Wastewater | 10 | ED | Bipolar | 70 | NA | NA | 70 | [77] |

NA means Not Applicable.

3.5. Membrane Contactor

MC is an advanced separation technology used for the selective extraction of volatile fatty acids (VFAs) from complex mixtures. This technique consists of the unique properties of the membranes to facilitate the mass transfer of VFAs from one phase type to another phase without mixing [78]. The principle is based on selective permeability of the membranes, which allows certain molecules like VFAs to pass through while retaining the rest of the organic molecules behind [79].

When the membrane contactor was integrated with a leach bed reactor, it helped in separation of acetic acid, butyric acid, and caproic acid from the leachate. This idea was extended by Aydin et al., 2018 [80], with the application of an extractant-filled membrane with tertiary amines and tridodecylamine for VFA separation from a mixture of municipal waste, landfill leachate, and manure digestate [80]. Integration of the membrane contactors with the PTFE membranes demonstrated a higher removal efficiency for VFAs present in the fermentation broth with removal efficiency of 86–95% for VFAs of propionic acid, butyric acid, valeric acid, and caproic acid extracted from synthetic solutions and from fermentations [81]. The butyric acid and acetic acid recovery efficiency are 21.55 and 7% with application of silicone membrane contactor indicating that the silicone membrane contactor was feasible for VFA recovery from the fermentation broth [24,79].

In another study, a comparative analysis was conducted to compare the experimental and theoretical yield of acetic acid when separated from a mixture of synthetic solution and from organic fraction of municipal solid waste (OFMSW) by a membrane contactor [28]. Here the separation of the VFA was performed through gas-filled hydrophobic PTFE membranes. The study investigated the VFA separation from a mixture of synthetic VFA and leachate from fermentation broth of solid waste using a counter current flow liquid–liquid contactor [82]. The alkaline reactive strip has the optimum strength and helps in having the highest acetic acid mass transfer having a flow rate of 31.5 ± 0.9 mL/min and pH of 3.0 [82]. Hence, the gas filler counter current membrane contactor method proved to be a cost-effective and eco-friendly method due to the elimination of extracts made of organic materials. The recovery of different VFAs has been summarized in Table 6 below.

Table 6.

Recovery percentage of VFA produced from different types of waste across different membrane-based processes, membrane materials for MC.

3.6. Membrane Bioreactors

Membrane bioreactors are an advanced hybrid technology where the biological treatment processes are combined with a separation unit. In an MBR system, the microbial breakdown the organic materials under anaerobic or aerobic conditions, while producing intermediary VFAs together with other by-products [84]. The MBRs allow for simultaneous removal of VFAs from the feed liquid, preventing end-product inhibition and for recovery of the VFAs. In MBRs, technologies like MF, UF, NF, and RO are used for separation as discussed in Table 7 below. In a study where apple pomace and potato protein liquor were co-digested, the highest VFA concentration was 27 g/L at an OLR of 3.7 gVS/L [85]. The membrane reactor faces certain challenges like TSS accumulation in the reactor. The accumulation problem was remediated by increasing the HRT to 20 or 30 days. The increase in the OLR enhances the VFA concentration to 28.6 g/L. Longer HRT allows higher membrane filtration efficiency leading to a yield of 40 g/L. The membrane used was an integrated permeate channel (IPC) flat sheet and was made of two layers of PES membranes having polyester spacer fabric as coatings [86].

Table 7.

Recovery percentage of VFA along with VFA production produced from different types of waste across different membrane-based processes, operating conditions, and membrane materials for electricity-driven technologies.

In another reported study with pretreated citrus waste to remove d-limonen, the VFA yield increased to 0.84 gVFA/g vs. [29]. When the OLR was increased, the yield decreased, and more waste was present after the digestion. The significant volatile fatty acids produced were acetate, butyrate, propionate, and caproate [89]. The final composition of the separate VFA was 37%, 21%, and 18% for acetate, butyrate, and propionate, respectively. In conclusion, the study suggested the application of the tubular membranes for VFA separation.

Wainaina et al. have used a submerged flat sheet MBR to enhance VFA production from food waste. It was observed that immersed MBR was not suitable for VFA enhancement when the operating conditions like temperature and pH were different from that of the filtration [86]. This was due to the direct contact of the membrane to the bulk medium. Moreover, the membrane fouling is higher in immersed MBR [87,90]. A study where anaerobic membrane bioreactors have been used to produce VFA from sewage sludge using an anaerobic membrane bioreactor (AnMBRs) with an ultrafiltration membrane for separation. The VFA contributed 42% of the soluble chemical oxygen demand [91].

4. Challenges of VFA Separation and Purification by Membrane-Based Processes

The main challenges of separation and purification of the VFAs using membrane-based processes include membrane fouling due to presence of suspended solids in the feed stream, low VFA concentration, complex mixture composition and high capital costs. There is an important need for the careful optimization of operating conditions to achieve high performance and ensure that large-scale applications are economic. Near-complete separation allows for the selective recovery of high-value nutrients and compounds, improving the economic viability of waste treatment processes. It also reduces the need for downstream treatment, enabling more efficient reuse or disposal of effluent streams. Efficient separation further allow for use of the nutrient-rich permeates as substrate for microbial fermentations.

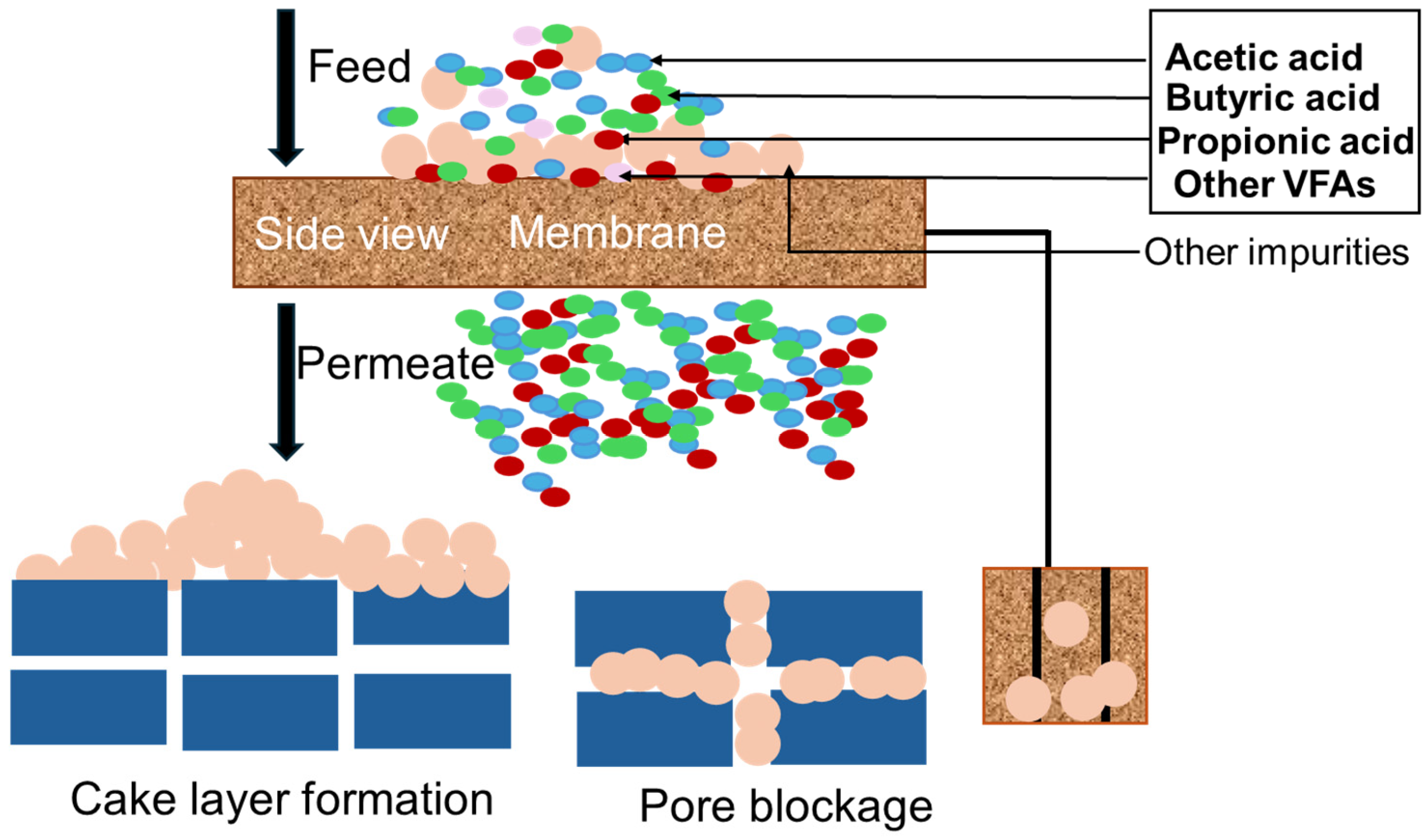

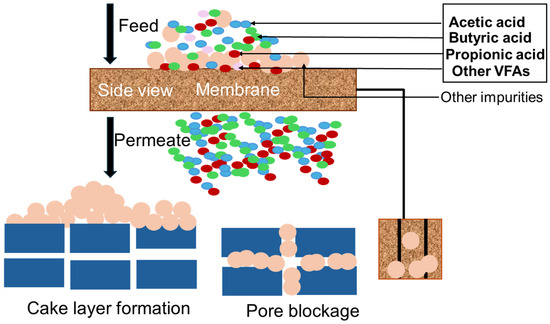

4.1. Fouling

The most crucial challenge is membrane fouling caused by the accumulation of solids like microbial cells and other particles present in the fermentation broth. The presence of these solids like microbial cells and small particles significantly reduces membrane performance over time and requires frequent cleaning cycles portrayed in Figure 6 [92]. The typical fouling substances include organic compounds, salt crystals, and microbial biomass, which results in lower permeated flux and selectivity. The process of fouling occurs when particles, solutes, or other substances accumulate on the membrane surfaces and plug up the pores, reducing its efficiency [93]. There are different types of membrane fouling in VFA separation, including organic fouling, inorganic fouling, colloidal fouling, and biofouling. While membrane separation technologies have been implemented in several biotechnological applications, including water desalination, wastewater treatment, bioethanol dehydration, and protein purification, the selective recovery of VFAs has challenges. Unlike simpler systems, VFA-containing broths are complex, containing a mixture of ionic and non-ionic species, suspended solids, microbial metabolites, and residual nutrients. These not only affect membrane selectivity and flux but also exacerbates fouling and concentration polarization. Moreover, VFAs such as acetic, propionic, and butyric acids exist in dissociated or undissociated forms depending on pH, which further complicates their transport across membranes such as nanofilters, electrodialysis or forward osmosis membranes.

Figure 6.

Mechanism of membrane fouling.

Biofouling occurs when microbial cells adhere to the membrane surface and form biofilms. During fermentation, bacteria and fungi present in the broth attach to the membrane, secreting extracellular polymeric substances (EPS), which further strengthen biofilm formation. The presence of carbon sources and nutrients accelerates this process. Once biofilms develop, they are difficult to remove and require aggressive chemical or enzymatic cleaning methods [94].

Organic fouling is caused by macromolecules such as proteins, polysaccharides, and other organic compounds present in the feed solution. These molecules interact with the membrane surface through hydrophobic interactions and hydrogen bonding, leading to their accumulation. Since VFAs are extracted from complex fermentation mixtures, the presence of organic substances contributes significantly to fouling. Over time, organic fouling reduces membrane efficiency and flux, requiring frequent cleaning [95].

Inorganic scaling occurs when dissolved salts, such as calcium carbonate and magnesium salts, precipitate on the membrane surface. Fermentation feedstocks, including wastewater and animal manure, often contain multivalent cations. Under certain pH conditions, these ions exceed their solubility limits and form solid deposits, creating a layer of inorganic scale. This reduces membrane permeability and increases energy consumption. In severe cases, inorganic scaling can permanently damage the membrane [96].

Colloidal fouling results from the accumulation of fine suspended particles on membrane pores. These particles, which may include microbial debris and coagulated organic matter, form a layer on the membrane surface. This increases flow resistance and reduces permeate flux. Over time, colloidal fouling significantly lowers membrane efficiency and requires additional filtration steps to mitigate its impact [97].

4.2. Energy Requirement Analysis

Membrane-based separation processes are gaining attention for their potential in VFA recovery due to their energy efficiency and lower environmental impact compared to traditional methods. For instance, MF and UF are among the most energy-efficient membrane processes, consuming between 0.1 and 1.0 kWh/m3 [98]. NF and reverse osmosis (RO) offer higher separation capabilities but require more energy, with consumption ranging from 1.0 to 8.0 kWh/m3. In contrast, traditional thermal separation methods like evaporation are significantly more energy-intensive, consuming between 50 and 150 kWh/m3, making them 10–20 times more energy-demanding than membrane processes [99].

The economic feasibility of membrane-based VFA recovery depends on both capital and operating costs. Capital costs include investments in membrane modules, pumps, electronics, and pretreatment systems, while operating costs primarily consist of energy, maintenance, and membrane replacement expenses. In many cases, membrane processes require 10–50% lower capital investment than distillation, making them a cost-effective alternative in the long run. Additionally, pressure-driven processes like RO and NF are more energy-efficient than thermal evaporation, reducing energy consumption by up to 90% while still maintaining effective separation [100].

Membrane efficiency is driven by factors such as pressure gradient (MF, UF, NF, RO), concentration gradient (diffusion-based systems), and electrochemical potential (ED, EDI). While increasing the driving force enhances flux, it also raises energy demand. For instance, RO membranes require higher osmotic pressure, making them less energy-efficient than MF or UF. Therefore, optimizing membrane selection and process conditions is essential to balancing energy efficiency and cost-effectiveness in VFA recovery.

4.3. Selectivity and Permeability

Membrane-based separation processes are widely employed for the recovery of VFAs from complex effluents, leveraging principles of size exclusion, charge repulsion, and solubility-diffusivity differences. These processes, including NF, RO, UF, and PV, rely on the selective permeability of membranes to separate VFAs from contaminants. The performance of these membranes is governed by two critical metrics: permeability, which determines the flux of VFAs through the membrane, and selectivity, which ensures the preferential separation of VFAs over other solutes [101]. However, achieving a balance between these metrics remains a challenge due to the inherent trade-off—higher permeability often compromises selectivity, and vice versa. Recent advancements in membrane materials and operational strategies have sought to address this trade-off, enabling more efficient and sustainable VFA recovery. The selectivity and permeability along with the VFA recovery has been discussed in the table below (Table 8).

Table 8.

Recovery percentage of VFA produced from different types of waste using different membrane-based processes, membrane materials, their permeability, selectivity for different membrane technologies.

NF membranes, such as NF90 and NF270, have demonstrated significant potential for VFA recovery due to their ability to operate at moderate pressures and their high selectivity for ionized VFAs [108]. For instance, NF90, with a permeability of 1.67 L/(m2·h·bar), achieves a remarkable 78% recovery of acetic acid, outperforming NF270, which has a higher permeability of 3.88 L/(m2·h·bar) but lower recovery rates. This highlights the importance of membrane material and pore size in optimizing selectivity. Similarly, RO membranes, such as RO 98pHt, have shown improved recovery rates at higher feed concentrations, with acetic acid recovery increasing from 50% to 55% as the concentration rose from 10 to 50 g/L [109]. These findings underscore the role of operational parameters, such as pressure and feeding concentration, in enhancing membrane performance.

In addition to NF and RO, PV and UF have emerged as promising alternatives for VFA separation. PV membranes, such as TDDA-PTFE, leverage ion-pair formation to achieve high selectivity, retaining up to 75% of VFAs while maintaining superior flux. UF membranes, like ES10, though less permeable, have demonstrated higher recovery rates for acetic acid compared to NF270, emphasizing the importance of membrane design in achieving targeted separation [110]. Ceramic membranes, while offering high permeability, often lag behind polymeric membranes in recovery efficiency, with recovery rates of 82% compared to 92.9% for polymeric counterparts. This difference highlights the need for material innovations to enhance both permeability and selectivity [111].

Recent advancements in membrane technology have focused on addressing the permeability-selective trade-off and on mitigating fouling, a major challenge that reduces membrane lifespan and efficiency. These innovations, coupled with optimized operational strategies such as pH control and pressure modulation, are paving the way for more efficient and sustainable VFA recovery processes.

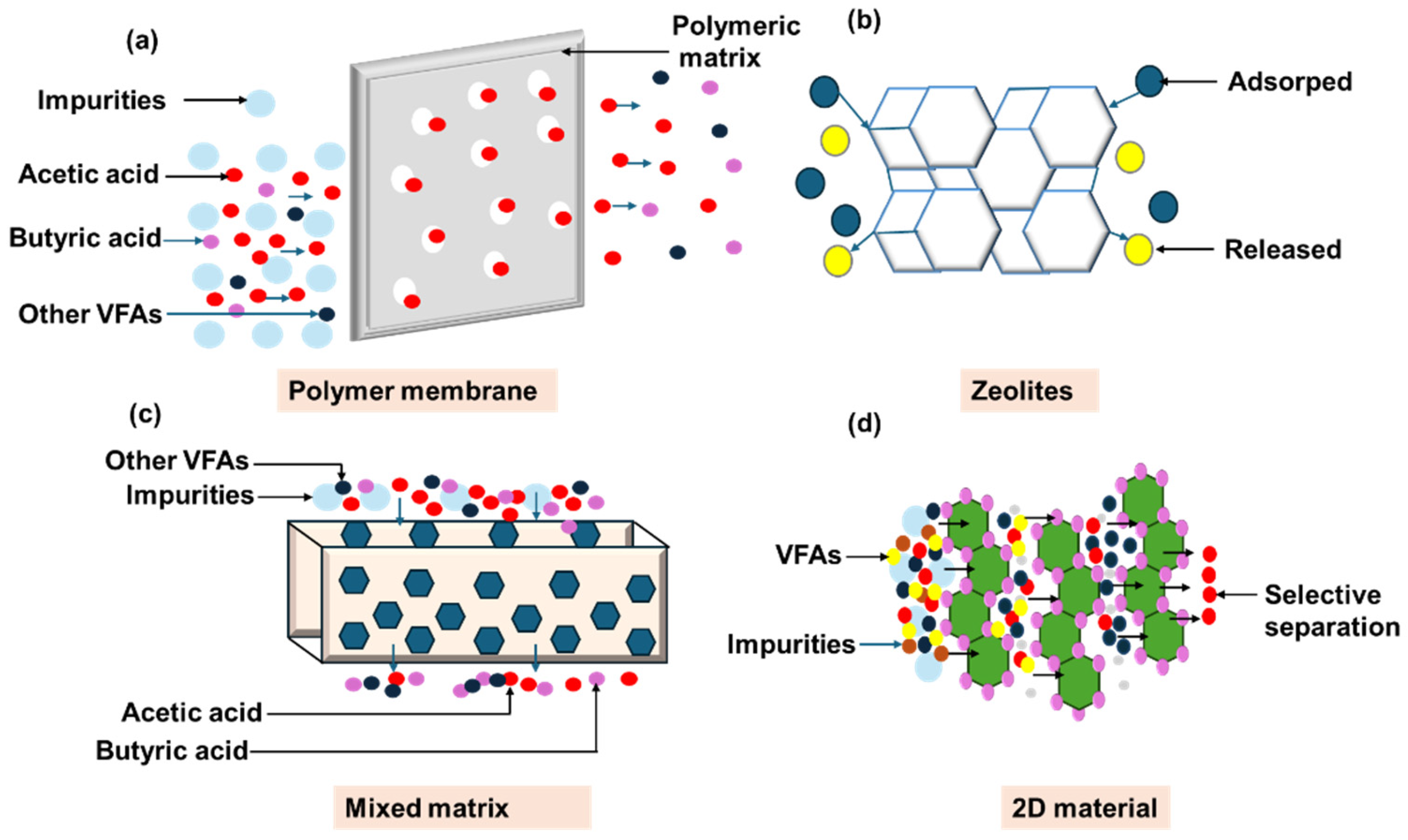

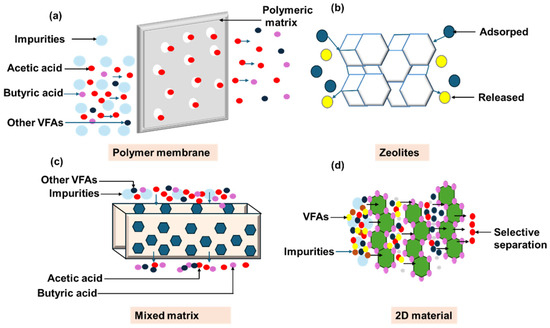

4.4. Membrane Material and Its Stability

Membrane stability is crucial for effective VFA separation, particularly under harsh conditions such as high acidity. Polymeric membranes (e.g., cellulose acetate, polysulfone, and polyamide) are widely used because they are cost-effective and flexible. However, they tend to suffer from hydrolytic degradation when exposed to high concentrations of VFAs, resulting in recovery rates of approximately 65–75% under mild acidic conditions (pH 5–7) and operational lifetimes of around 1500 h [35]. In contrast, ceramic membranes composed of alumina, silica, or zirconia offers high chemical stability and excellent resistance to acid-induced degradation, achieving recovery rates of about 80–85% with lifetimes exceeding 2000 h, albeit at a higher cost [112]. The different types of membrane materials being used nowadays have been shown in Figure 7. Advanced membrane technologies can further enhance both stability and performance. Composite membranes fabricated via layer-by-layer (LBL) assembly, which form polyelectrolyte multilayers (PEMs) on ultrafiltration substrates, exhibit improved selectivity and resistance to oxidants and fouling, delivering VFA recovery of 78–80% with operational lifetimes of 2500–3000 h [113].

Figure 7.

Types of membrane materials (a) Polymer membranes (b) Zeolitic membrane (c) Mixed matrix (d) 2D material.

Additionally, supported ionic liquid membranes (SILMs) offer a unique, polarity-driven separation mechanism, achieving around 70% recovery under optimal conditions (25–40 °C), while systems employing ion exchange resins combined with hydrophobic membranes like PTFE and PVDF provide high fouling resistance and competitive recovery performance (PTFE: >75% recovery at low pH; PVDF: 70–80% recovery) [114]. Table 9 summarizes these key findings and highlights the tradeoffs among different membrane materials for VFA separation.

Table 9.

Recovery in percentage of VFA produced from different types of waste using different membrane-based processes and membrane materials for different membrane technologies.

4.5. Environmental Challenges

Membrane separation methods for VFA recovery present several environmental challenges beyond fouling. These processes, particularly pressure-driven methods like NF and RO, are energy-intensive, with energy demands ranging from 2 to 10 kWh/m3, contributing to a higher carbon footprint and limiting their sustainability in large-scale applications. The production of specialized membranes, often derived from petrochemical-based polymers, further exacerbates environmental impacts due to greenhouse gas emissions and resource-intensive manufacturing processes. Additionally, the sensitivity of polymer-based membranes to harsh chemical environments, such as acidic fermentation broths, often need stabilizing chemicals like antiscalants or pH adjusters, which can lead to environmental contamination if not managed properly [119].

Waste generation is another significant concern. The retentate streams produced during VFA separation contain concentrated non-VFA components, such as proteins, salts, and microbial biomass, which require careful disposal to avoid environmental pollution. For instance, retentate from food waste effluents may contain fats, oils, and residual carbohydrates, while industrial effluents can contain heavy metals or toxins. Cleaning processes generate wastewater containing chemicals such as disinfectants (e.g., chlorine or peroxides). Furthermore, the disposal of used membranes, which are often non-biodegradable and resistant to degradation, adds to landfill waste. Emerging technologies like MCs and PV offer more sustainable alternatives. PV, for example, operates with lower energy requirements (1–3 kWh/m3) and avoids harmful chemicals, making it environmentally friendly and compatible with anaerobic digestion systems [120]. However, the overall sustainability of these methods depends on optimizing membrane materials and processes to minimize waste and energy use, ensuring a balance between efficiency and environmental impact.

4.6. Scale-Up

Scaling up membrane technologies for VFA separation presents significant challenges in maintaining performance, cost-efficiency, and environmental sustainability. While lab-scale membrane systems demonstrate high selectivity and efficiency, replicating these results on an industrial scale is difficult due to issues such as membrane defects, inconsistent pore size distribution, and fouling management across larger membrane areas. For instance, maintaining precise pore morphology and uniform separation efficiency becomes increasingly complex as membrane surface area expands, leading to variability in performance [121]. Additionally, VFA separation membranes are highly sensitive to pH fluctuations, which are pronounced at larger scales, affecting membrane affinity, permeability, and flux [122]. This sensitivity complicates the treatment of fermentation broths or wastewater streams, which often have variable pH levels.

Another challenge is the high operational cost associated with scaling up, including energy consumption and the need for chemical stabilizers like antiscalants or pH adjusters. For example, pressure-driven processes like NF and RO require significant energy (2–10 kWh/m3), increasing their carbon footprint and limiting economic viability for large-scale applications [123]. Furthermore, the retentate streams generated during VFA separation contain concentrated non-VFA components, such as salts, proteins, and microbial biomass, which require specialized disposal or treatment to avoid environmental pollution. At the pilot scale, volatile fatty acids (VFAs) were recovered from municipal wastewater using a sieving and filtration process. The wastewater was initially sieved using a rotating belt filter, which effectively removed 50% of suspended solids, thereby facilitating downstream VFA separation. VFAs were subsequently recovered by filtration at pH 9, achieving a recovery efficiency of 51%, corresponding to a VFA yield of 521 mgCOD/gVS [124]. Volatile fatty acids (VFAs) were separated from biogas plant hydrolysates using a two-step membrane filtration process, involving ultrafiltration (UF) followed by nanofiltration/reverse osmosis (NF/RO). The overall VFA recovery achieved was approximately 25%, with the RO membrane (SWC4) concentrating the VFAs up to 134.6 g/L [36].

Emerging technologies like MD and FO show promise but face challenges such as membrane wettability, reverse solute diffusion, and fouling, which must be addressed to improve scalability and efficiency [92,93]. Developing durable, high-performance membranes with consistent permeability and selectivity remains a critical hurdle for industrial-scale VFA separation [101]. Addressing these challenges requires innovative materials, optimized processes, and integration with sustainable practices to ensure economic and environmental feasibility. This asks us to delve into the advanced technologies which would be economical and producing higher yields.

5. Advanced Membrane Technology

Advanced membrane technologies are essential for overcoming the limitations of conventional methods in VFA recovery, such as fouling, environmental concerns, and scalability issues. Innovations like mixed matrix membranes (MMMs), which incorporate nanomaterials into polymer matrices, have demonstrated improved separation performance, effectively addressing the permeability-selectivity trade-off [125]. These advancements are crucial for developing scalable and economically viable VFA recovery methods, aligning with the goals of waste valorization and the circular economy.

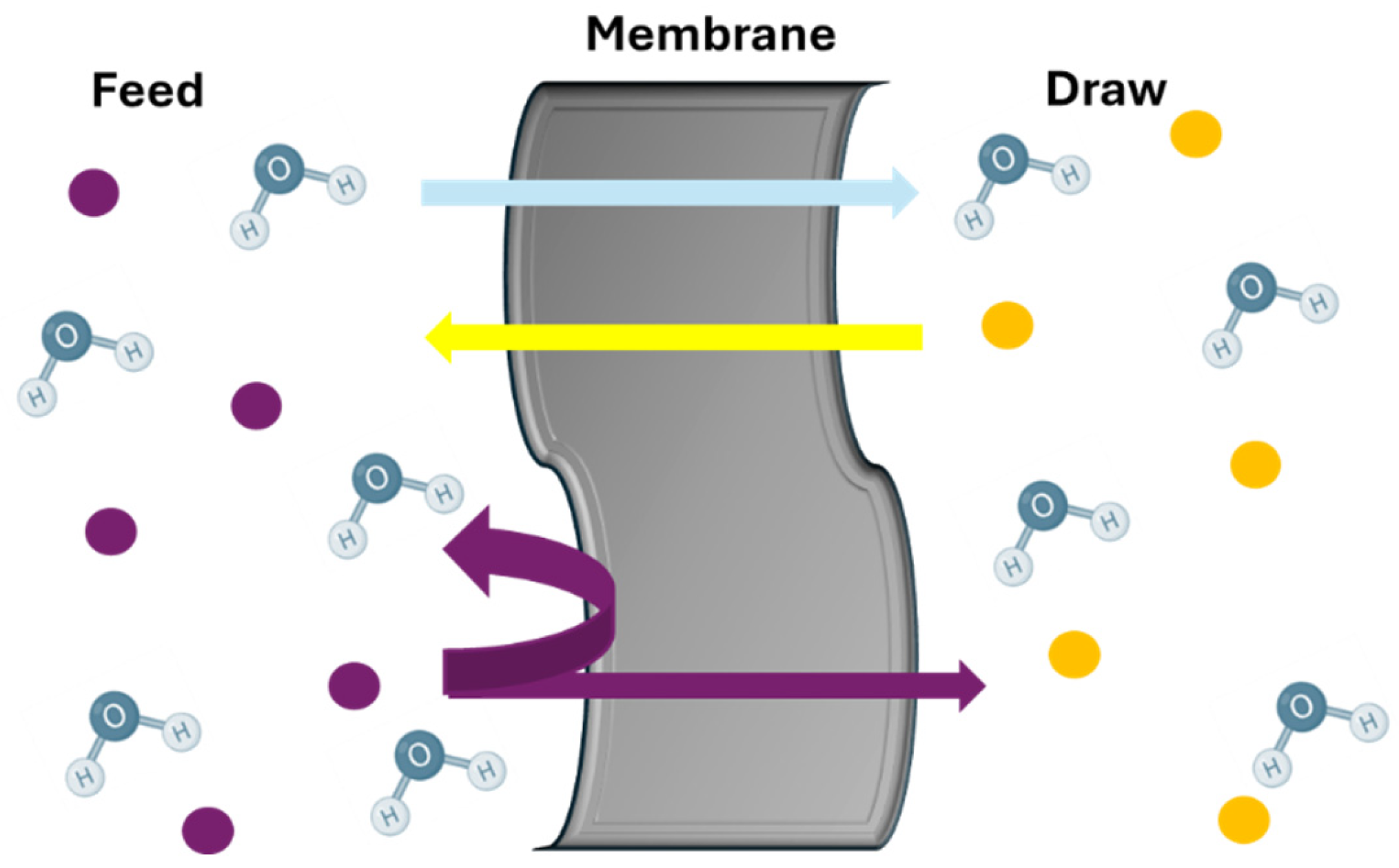

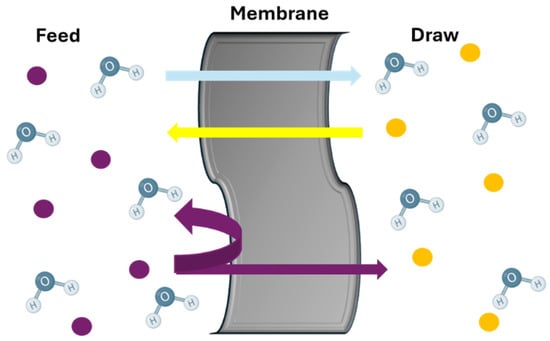

5.1. Forward Osmosis

FO has demonstrated significant potential in the recovery of VFAs from various waste streams. Recent studies have provided quantitative insights into its effectiveness under different operational conditions. The mechanism of FO has been discussed in Figure 8.

Figure 8.

Mechanism of Forward osmosis, where the blue arrow stands for water transport, yellow and purple stands for the VFAs and other impurities.

In a study published in Chemosphere, researchers evaluated the recovery efficiency of VFAs using a polyamide-based thin-film composite membrane. They observed that at a pH above the pKa values of the VFAs, the rejection rates ranged from 80% to 97%, with concentration factors (CF) between 1.0 and 4.8. Conversely, at a pH below the pKa, rejection rates were significantly lower, between 23% and 36%, and CFs ranged from 0.20 to 1.90 [26]. These findings highlight the importance of maintaining appropriate pH levels to enhance VFA recovery efficiency. Another investigation reported a high VFA recovery rate of approximately 90% from domestic wastewater at pH 7.5 using the FO method. This underscores the method’s efficacy in treating real wastewater streams [26].

FO is recognized for its low energy consumption compared to traditional pressure-driven membrane processes. For instance, a study on landfill leachate treatment reported energy consumption ranging from 0.005 to 0.276 kWh/m3, depending on operational parameters such as recirculation rates and draw solution concentrations. In the context of VFA recovery, specific energy consumption data is limited; however, the passive nature of FO suggests similar energy efficiency [126]. The economic feasibility of FO in wastewater treatment has been evaluated in various studies. One assessment compared different FO-based treatment scenarios and found that costs varied depending on system configuration. For example, integrating FO with an anaerobic membrane bioreactor resulted in higher costs compared to microfiltration, primarily due to the larger required membrane surface area. However, when FO was combined with an anaerobic membrane bioreactor and partial nitrification/anammox process, the treatment cost was approximately $1.11 per m3, comparable to traditional methods [31].

While specific cost data for VFA recovery is scarce, these findings indicate that FO can be economically competitive, especially when integrated with complementary processes. The environmental impact of FO processes has also been studied. In the assessment, the integration of FO with anaerobic treatment processes resulted in greenhouse gas emissions as low as 0.93 kg CO2 equivalent per m3, which was lower than other configurations. This suggests that FO can offer a reduced carbon footprint, particularly when optimized within an integrated treatment system [127].

In summary, while specific data on energy consumption, costs, and carbon footprint for FO-based VFA recovery are limited, existing studies on related applications suggest that FO is an energy-efficient and potentially cost-effective technology with a favorable environmental profile.

5.2. Hybrid Membranes

Advancements in membrane technology have led to the development of hybrid and composite membranes that address limitations such as fouling, environmental challenges, and scalability issues inherent in conventional systems. For instance, integrating covalent triazine framework particles into PDMS matrices has resulted in hybrid membranes with enhanced separation efficiency. These membranes have demonstrated a high separation factor of 63 and a permeate flux of 2816 g/m2·h in butanol–water mixtures. Similarly, thin-film composite membranes utilizing polymers of intrinsic microporosity have shown improved performance in butanol recovery [128].

Additionally, electroactive membranes with conductive surfaces have been explored for their antifouling and self-cleaning capabilities. Applying an electric potential to the membrane surface facilitates direct cleaning of organic, inorganic, and microbial contaminants with reduced energy consumption. These membranes also enable the recovery of ammonia and hydrogen from anaerobic digestion processes by facilitating electron transfer at the membrane-water interface [129]. For example, electrocatalytic membrane electrodes have been developed to transfer ammonium ions towards the electrode through an electric potential, allowing immediate recovery while repelling negatively charged organics and microbes, which decreases fouling. Such strategies hold potential for VFA recovery, offering innovative solutions to existing challenges in membrane-based separation processes [130].

Furthermore, solar-assisted heating of interfacial membranes containing photothermal materials has been investigated to reduce energy consumption in MD processes [131]. Nanophotonics-enabled MD processes have demonstrated the recovery of 4 L·m−2·day−1 of clean water under sunlight-assisted conditions. Combining photothermal evaporators with membranes has proven effective in removing salts and organics from water, thereby enhancing VFA recovery by improving vapor mass transfer and reducing energy consumption [132]. Integrating hybrid processes, such as combining MD with photothermal evaporators and NF or RO, enables the separation of VFAs at higher purity levels, particularly in systems with high VFA concentrations from anaerobic digestion [35]. Continuous removal of VFAs from fermentation systems can enhance production within reactors. For instance, integrating a vapor permeation membrane contactor system with anaerobic fermenters treating organic-rich solid wastes allows for constant VFA removal, increasing yields and facilitating the recovery of valuable commodity chemicals [133].

Innovative membrane reactors have also been explored for VFA recovery. Pressure-driven anaerobic membrane bioreactors with ED chambers offer potential for VFA separation. Alternative membrane configurations, such as rotating membrane modules, have been considered to reduce energy consumption. For example, a study by the National Renewable Energy Laboratory suggests that using rotating ceramic disks combined with progressive cavity pumps can effectively remove solids, microbial particles, and other organic contaminants before subsequent processing steps. This approach applies to shearing force rather than pressure, resulting in reduced energy consumption [134].

In another study, isoelectric precipitation was integrated with NF to enhance VFA recovery efficiency. Isoelectric precipitation, optimized at a pH of 4.8, was used as a pretreatment step to reduce membrane fouling. Following precipitation, NF was applied to recover VFAs, while the lactate-rich retentate from NF was repurposed in anaerobic digestion to produce hydrogen and additional VFAs [135]. This integrated approach offers a sustainable and efficient method for VFA recovery, though its performance is influenced by factors such as pH and acid composition, highlighting the need for optimization tailored to specific feedstocks and process conditions.

Recently, superhydrophobic hybrid membranes for vacuum membrane distillation (VMD) applications have been examined. For example, a poly(vinylidene fluoride) (PVDF) membrane modified with ZnO nanorods and coated with 1H,1H,2H,2H-perfluorodecyltriethoxysilane (PDTS) was developed to address fouling and wetting issues during high-salinity water treatment. This membrane exhibited a stable superhydrophobic surface (contact angle ~152°), excellent thermal and mechanical stability, and retained high permeate quality over 8 h of operation with 200 g/L NaCl solution. Its antifouling and antiwetting properties were attributed to the micro/nano hierarchical structure, low surface energy, and strong adhesion of ZnO nanorods, enabling effective and reusable VMD performance [136]. Another approach involves coupling deep eutectic solvents (DESs) with an omniphobic membrane in a membrane contactor system, enabling selective and low-energy extraction of anhydrous VFAs. Unlike conventional NaOH-driven extraction using hydrophobic membranes, this system leverages reversible adsorption at the membrane-solvent interface, significantly enhancing separation efficiency. Mechanistic modeling demonstrated that high vapor pressures of short-chain VFAs and low Nernst distribution coefficients of longer-chain VFAs favor DES-driven transport, which is especially suited for continuous and in situ recovery. This strategy minimizes water carryover and energy input, while offering a tunable platform for downstream VFA distillation or valorization [137].

As hybrid membrane technologies continue to evolve, their application in industrial processes is expected to expand, offering scalable and energy-efficient solutions for complex separations. Future research should focus on optimizing material combinations, improving fouling resistance, and integrating hybrid membranes into large-scale systems to maximize efficiency and sustainability. These advancements will play a crucial role in addressing global challenges in resource recovery and sustainable process engineering.

6. Techno-Economic Analysis and Life Cycle Assessment

The widespread adoption of membrane-based technologies for volatile fatty acid (VFA) recovery from waste streams is strongly correlated with their cost efficiency compared to conventional waste treatment and chemical production methods. However, estimating the costs of these processes is complex, as it involves multiple factors such as capital expenditure (CAPEX), operational expenditure (OPEX), labor, energy consumption, and waste transportation. Table 10 below discusses the different economic aspects of different membrane technologies for VFA separation over time. For instance, preliminary energy cost studies in unoptimized membrane filtration (MF) systems have shown that the energy cost per cubic meter of sludge processing is approximately $1.15, with potable water usage contributing significantly to the overall cost. However, replacing potable water with rainwater can reduce costs substantially, from $1.15 to $0.20 per cubic meter. Additionally, the recovery of valuable materials such as ammonia, phosphate, and VFAs has been estimated at $1.77 per kg, highlighting the potential for cost-effective resource recovery from waste streams [52].

Table 10.

Techno-economic aspects of different membrane technologies for VFA separation.

Among the various membrane technologies, MD stands out for its high revenue potential, with an estimated annual revenue of $50.6 million against a CAPEX of $21.8 million and OPEX of $1.2 million per year (including maintenance). MD is particularly cost-effective for VFA separation, making it a promising option for large-scale applications [13]. Similarly, ED has demonstrated effective VFA recovery, with a CAPEX of $17.91 million (including ED unit, stripping column, and absorbing column) and an energy cost of 5.43 kWh/kg-VFA. However, the minimum selling price (MSP) of biobutanol produced through ED is highly dependent on substrate quality, emphasizing the need for optimization of the feedstock selection [138].

On the other hand, RO and NF present contrasting economic profiles. RO systems, while effective, incur high initial costs, with a CAPEX of $57.95 million and significant OPEX due to regular membrane maintenance ($7.63 million/year). In contrast, NF systems are more economical for smaller-scale applications, with a lower CAPEX of $1.34 million and OPEX of $107,360 per year. Hybrid systems, such as RO + MD combine the benefits of both technologies but come with increased complexity and higher costs, with a combined CAPEX of $5.02 million and OPEX of $8.60 million per year [24,139,140].

Overall, the economic viability of membrane-based VFA recovery technologies depends on optimization of both CAPEX and OPEX while maximizing revenue from recovered products. General cost analyses indicate that maintenance typically accounts for 3% of CAPEX, with utilities contributing a major part of OPEX. The potential profit margin for VFA production is estimated at $296 per ton of volatile solids (VS), underscoring the importance of cost optimization in scaling these systems. As the field advances, replacing costly inputs like potable water with alternatives such as rainwater or water reuse and leveraging hybrid systems could further enhance the economic feasibility of these technologies, paving the way for their broader adoption in waste valorization and circular economy initiative.

In addition to techno-economic analysis, life cycle assessment (LCA) is essential for evaluating the environmental sustainability of membrane-based VFA separation processes, particularly in terms of carbon emissions and overall ecological impact. One major concern is that membrane cleaning often requires harsh chemicals such as chlorine or peroxides, which generate chemically contaminated wastewater. Furthermore, polymer-based membranes, which are commonly used in these processes, tend to be sensitive to acidic fermentation broths, necessitating the use of stabilizing agents like antiscalants and pH adjusters. These additives can pose risks of environmental contamination. Waste generation is another critical issue, especially from retentate streams, which can contain concentrated non-VFA components including salts, proteins, fats, microbial biomass, and in some cases, heavy metals requiring careful handling and disposal to avoid secondary pollution. Additionally, spent membranes are often non-biodegradable and resistant to degradation and need to be landfilled. While these environmental impacts justify the need for comprehensive LCA, there are currently a lack of detailed LCA studies focused on membrane technologies for VFA separation. This gap highlights the urgent need for future research to incorporate LCA frameworks to holistically assess the environmental impact of these emerging technologies.

7. Future Direction

The field of membrane technologies has seen significant advancements, particularly in the context of separation and recovery processes for industrial and environmental applications. For the recovery of VFAs, membrane-based systems hold immense potential, but their commercial application still faces notable challenges that need to be addressed to unlock their full potential. The future of membrane technology for VFA recovery lies in developing innovative solutions to overcome bottlenecks, improve efficiency, reduce costs, and ensure environmental sustainability. Hybrid membranes, which combine the properties of organic and inorganic materials, offers a promising approach to overcome the limitations of conventional membranes. For example, membranes that incorporate porous organic polymers (POPs), covalent organic frameworks (COFs), or metal–organic frameworks (MOFs) are being explored for their exceptional selectivity and thermal and chemical stability, which are particularly advantageous for the recovery of VFAs. These materials can significantly enhance VFA recovery by offering improved selectivity, flux, and fouling resistance. Additionally, the incorporation of catalytic or reactive sites within membranes could enable simultaneous separation and chemical transformation of VFAs, potentially opening new avenues in bioprocessing and waste valorization.

The high cost of membrane fabrication remains a significant barrier to the commercialization of VFA recovery systems. Future research should focus on developing cost-effective membranes specifically tailored for VFA recovery, using abundant, biodegradable, or recyclable materials. Fouling is one of the most significant bottlenecks in the application of membrane technologies for VFA recovery. Future membranes for VFA applications should prioritize the development of anti-fouling and self-cleaning properties to extend operational lifespans and minimize maintenance costs. This can be achieved through surface modifications, coatings, or the incorporation of hydrophilic or zwitterionic materials that repel fouling agents. Stimuli-responsive membranes that utilize external triggers, such as pH, temperature, or electric fields, to induce self-cleaning behavior also hold great promise for VFA recovery. For example, electroactive membranes have been shown to reduce fouling by releasing electrical pulses, which dislodge flocculants without the need for harsh chemical cleaning agents. Moreover, the development of membranes that operate effectively at low energy consumption, such as FO, can further reduce energy consumption in VFA recovery processes, making these systems more viable for large-scale applications.