Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide

Abstract

1. Introduction

2. Materials and Experimental Programs

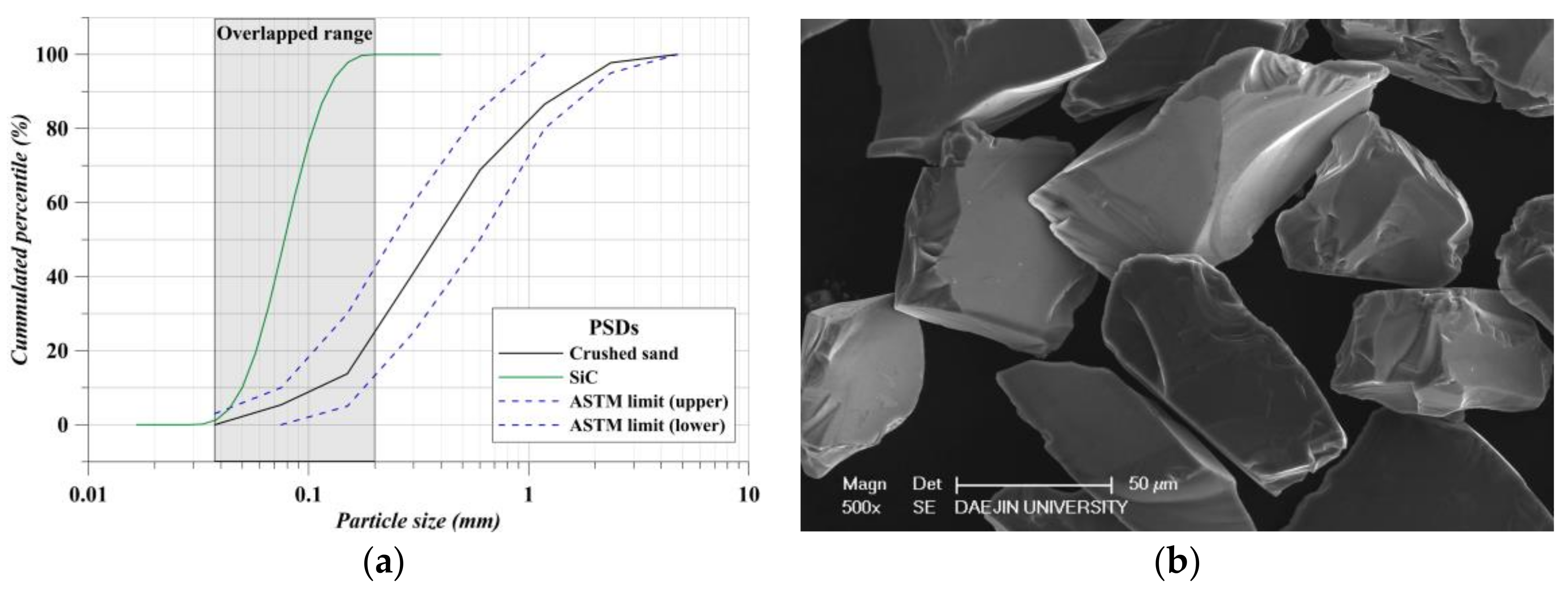

2.1. Materials

2.2. Specimen Preparation

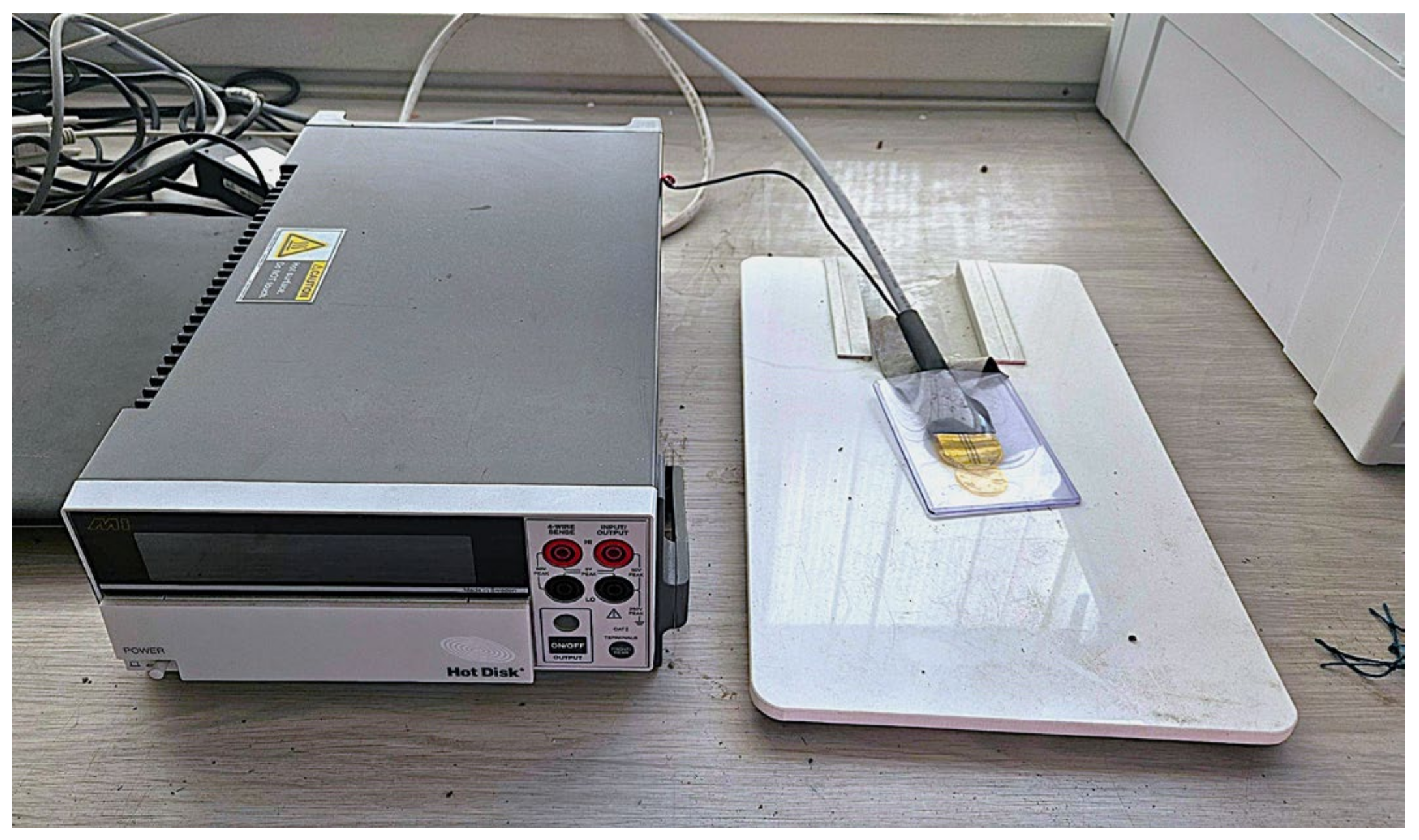

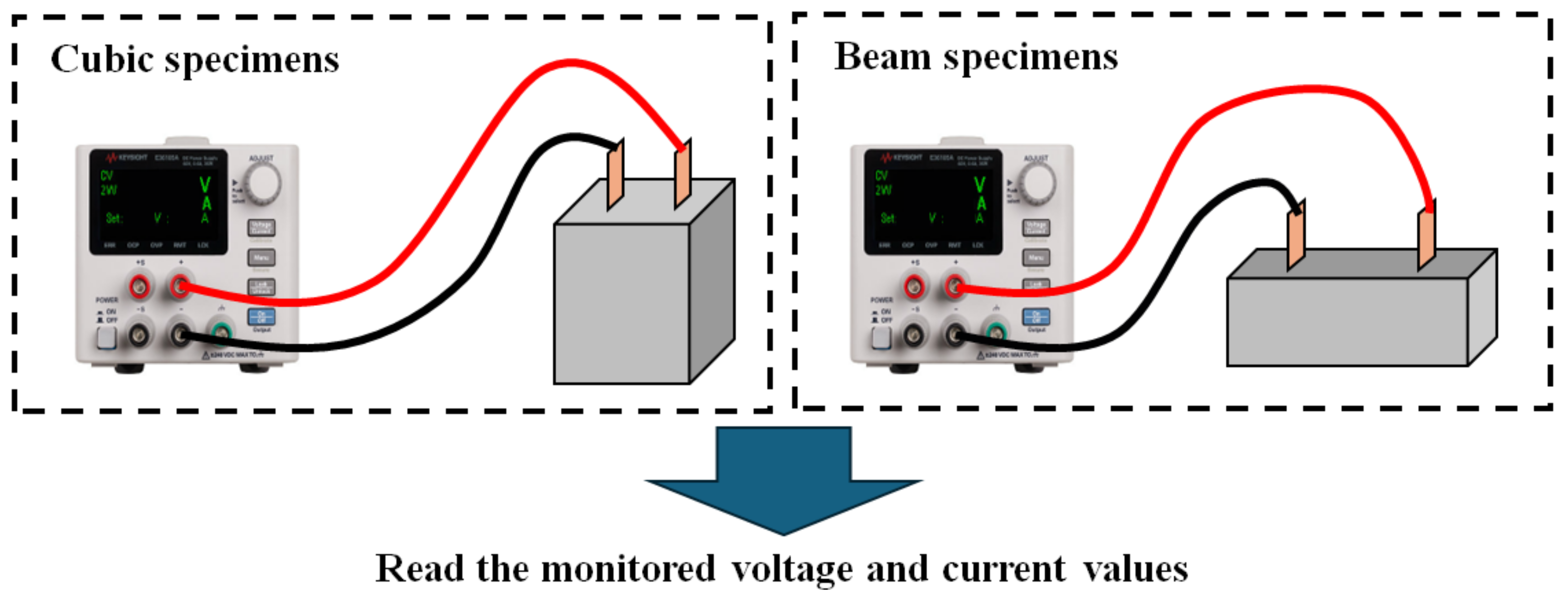

2.3. Measurement of Thermal Conductivity and Electrical Conductivity

2.4. Mechanical Properties

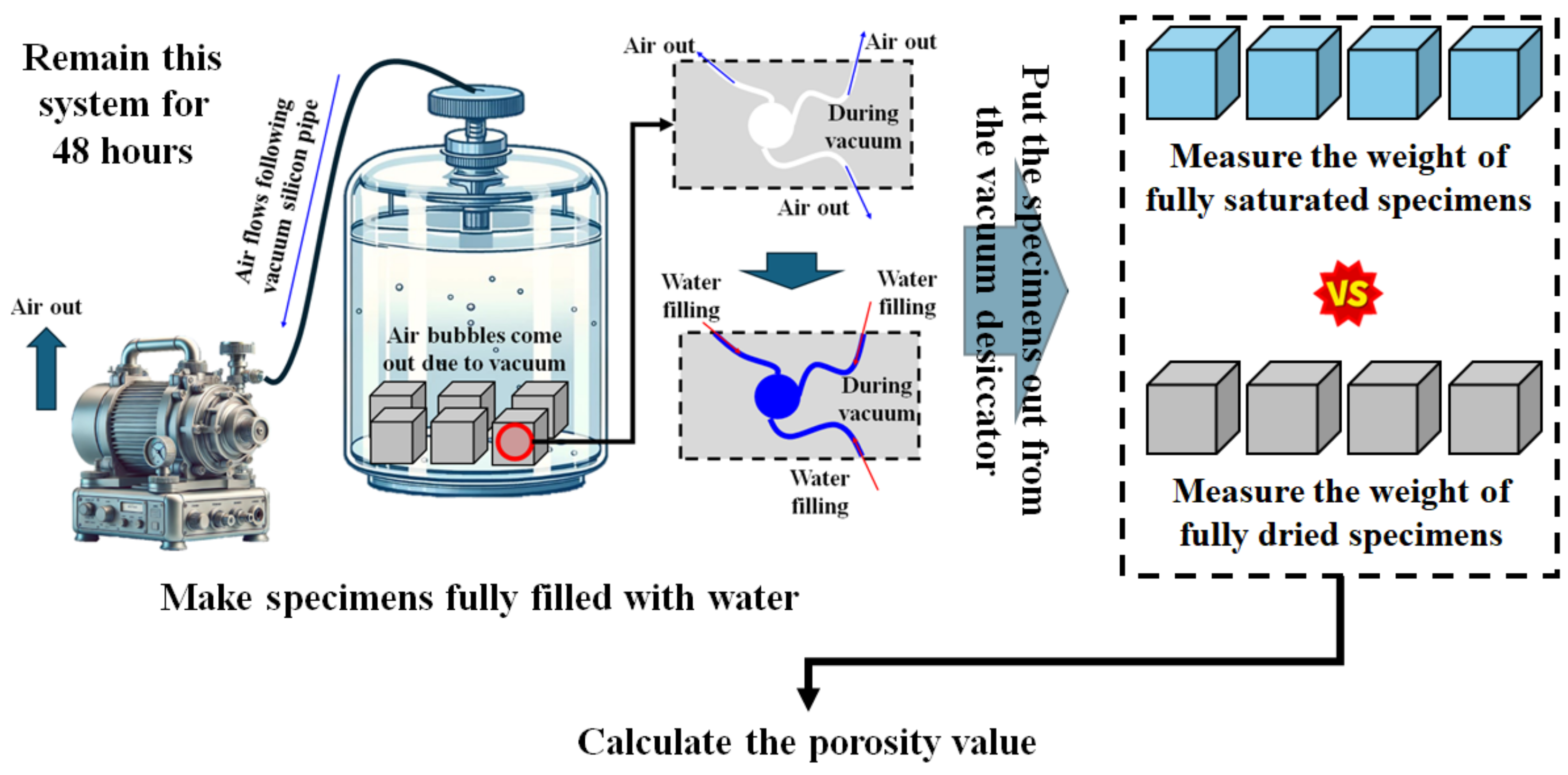

2.5. Porosity

2.6. Thermoelectric Voltage Measurement

3. Results and Discussion

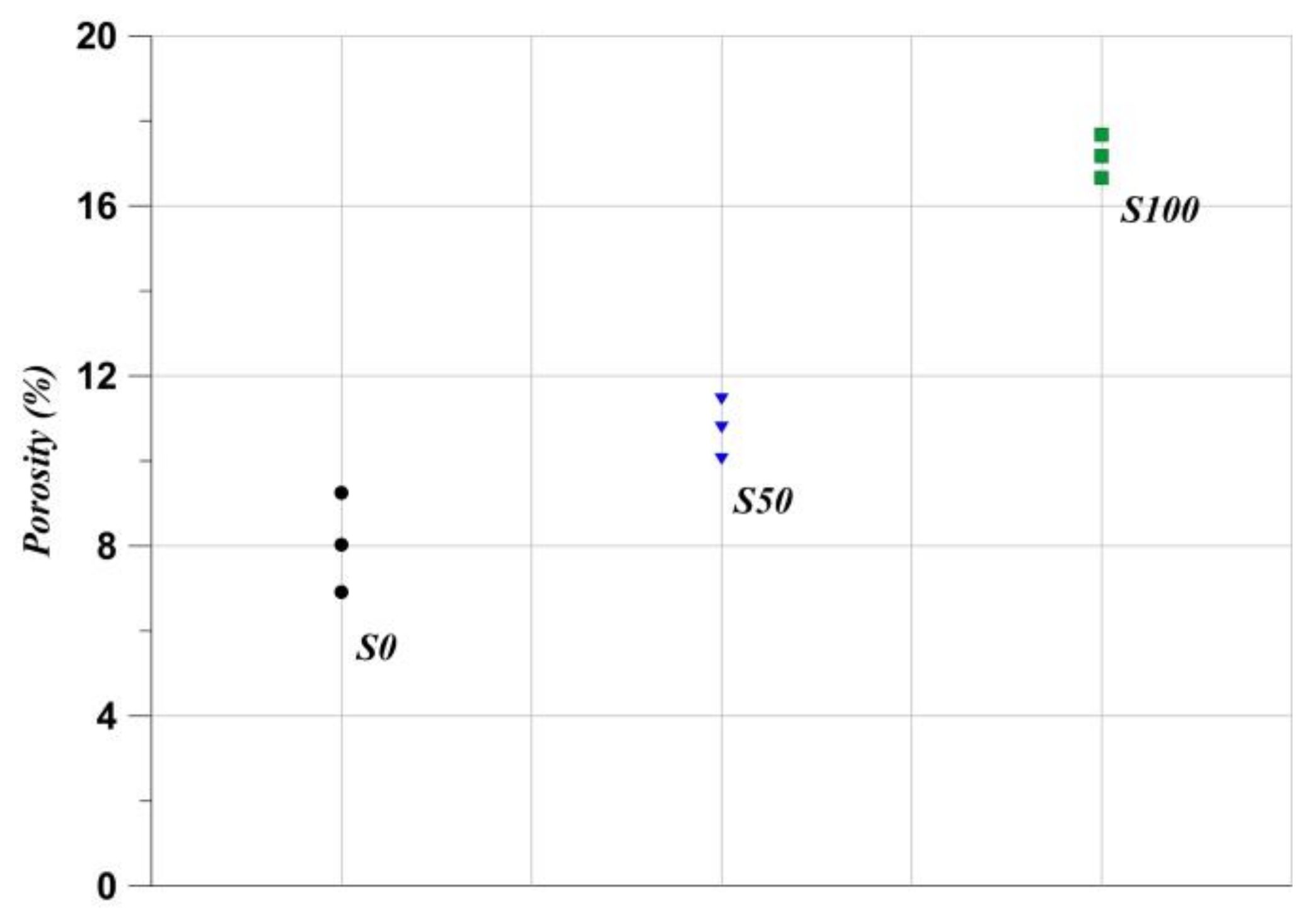

3.1. Porosity Results

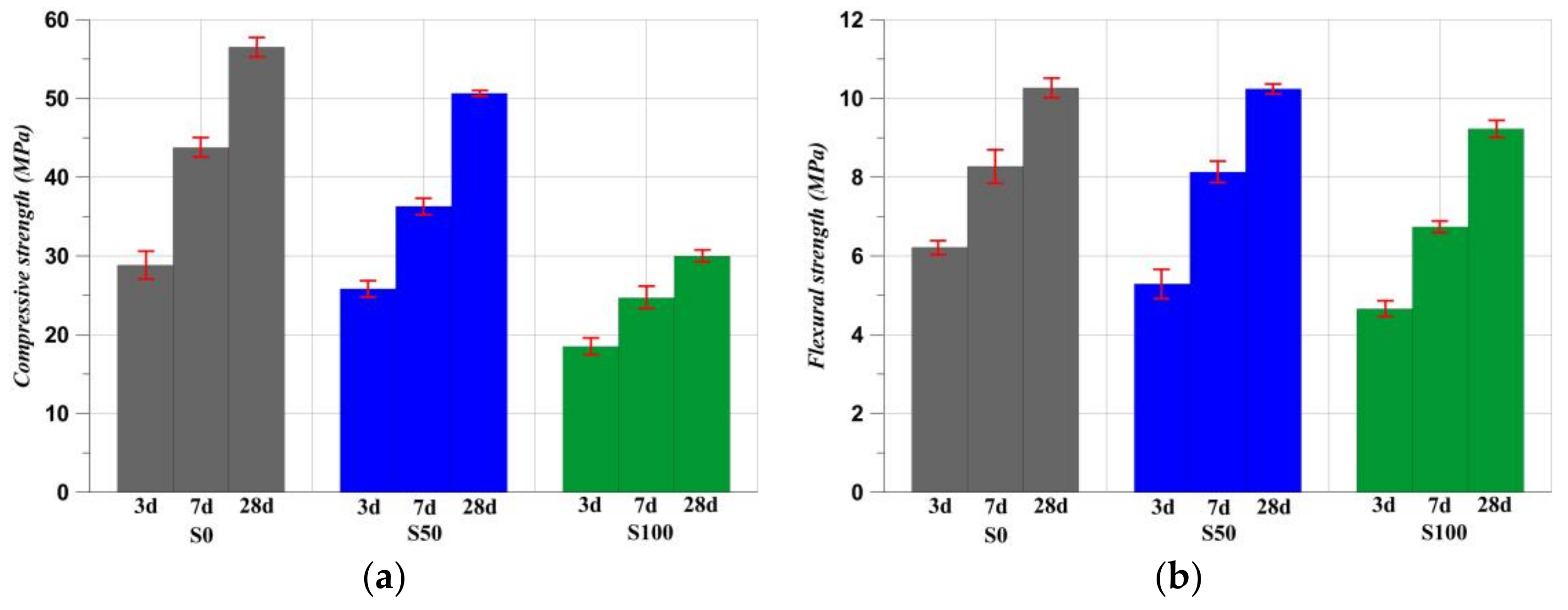

3.2. Mechanical Properties Results

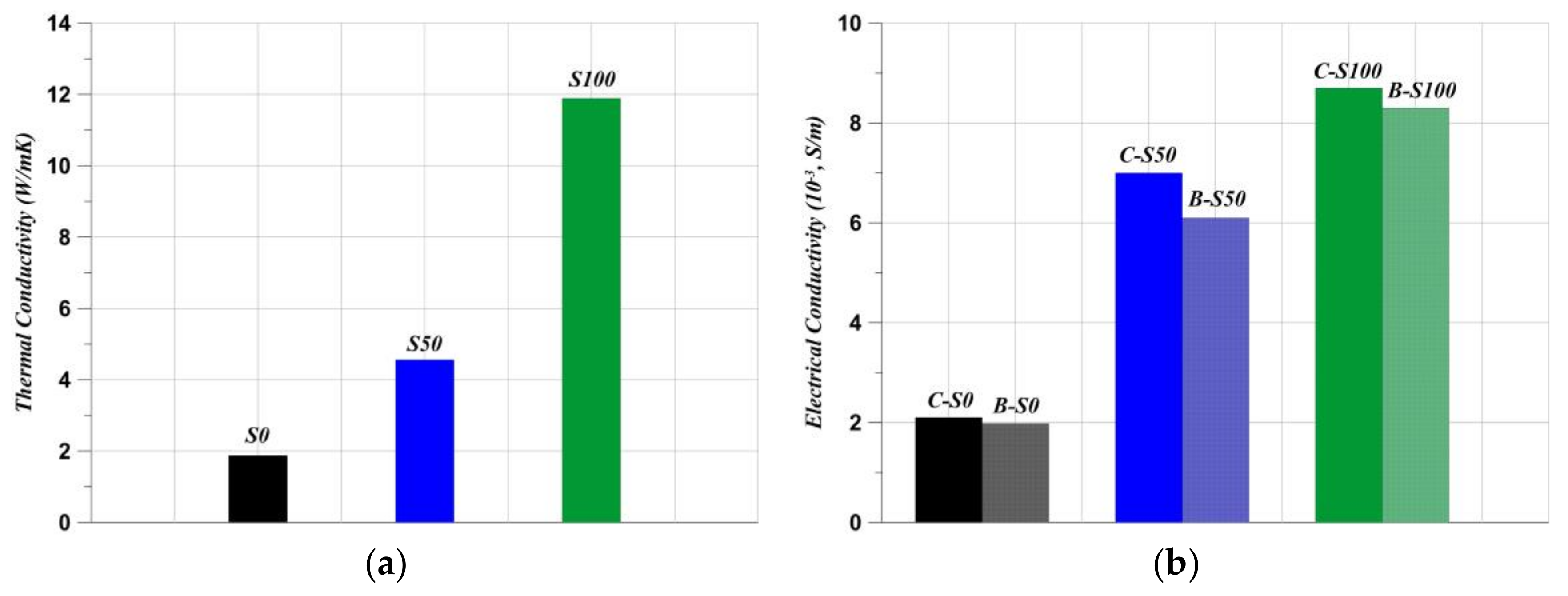

3.3. Thermal and Electrical Conductivity Results

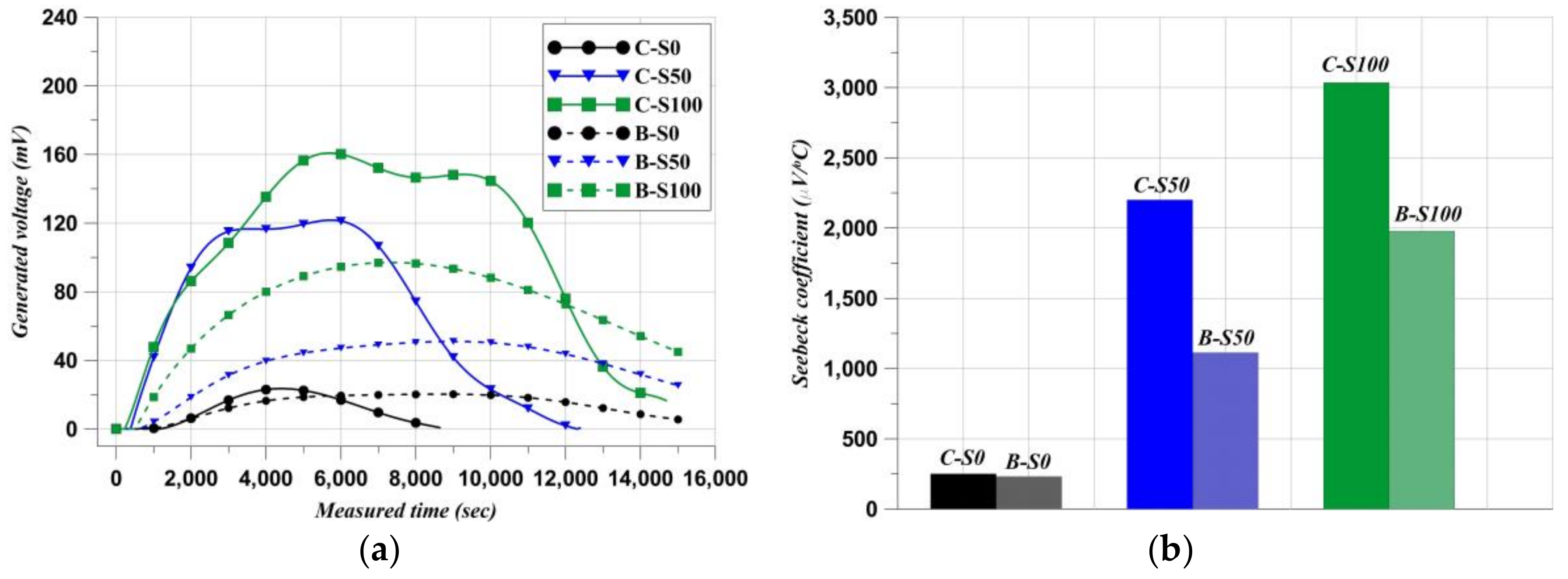

3.4. Generated Voltages and Seebeck Coefficient Results

4. Conclusions

- (1)

- The porosity increased as the substitution ratio of SiC increased. As a result, a high porosity led to a decrease in strength of the specimens. In particular, a significant strength decrease was confirmed in the S100 specimen. In other studies, severe strength decreases such as the decrease observed for S100 were concluded as unusable. However, in this study, it is concluded that S100 needs to be studied further when considering meaningful SC values and high voltage generation.

- (2)

- In the case of TC and EC, the porosity was almost overcome. Due to the beneficial thermal–electrical properties of SiC, the S50 and S100 specimens showed higher conductive values than the S0 specimen. The aggregate substitution of SiC exceeded the limit of the volume fraction; eventually, results showed meaningful values in this study.

- (3)

- Through this TE experiment, the size effect was clearly confirmed, as shown in Figure 9. Specimen size differences significantly affected the thermal energy distances between the cold and hot sides, with the cubic specimens showing rapid voltage increments due to shorter copper plate distances. The beam specimens exhibited a less sharp voltage generation gradient. Shorter specimens showed faster voltage generation, resulting in higher and quicker voltage outputs. However, rapid voltage generation in the C-S series led to a shorter voltage maintenance duration compared to the B-S series. This study concludes that shorter thermal distances result in higher SC values and voltages.

- (4)

- It could be concluded that the energy-harvesting efficiency was higher in the small-dimension specimens than in the large-dimension specimens. In particular, the short distance between the hot and cool sides is the most important factor.

- (5)

- Considering the significantly enhanced thermoelectric properties achieved by optimizing specimen size and SiC substitution, the resulting improvement in SC indicates a direct potential for energy harvesting from temperature gradients in building structures. Practically, applying this technology in renewable energy systems, such as integrating it into thermoelectric-based passive heating and cooling systems, could lead to measurable reductions in building energy consumption. Thus, the demonstrated improvement in thermoelectric efficiency is expected to contribute notably to renewable energy system advancements by enabling more sustainable and energy-efficient built environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forster, P.M.; Smith, C.; Walsh, T.; Lamb, W.F.; Lamboll, R.; Hall, B.; Hauser, M.; Ribes, A.; Rosen, D.; Gillett, N.P.; et al. Indicators of Global Climate Change 2023: Annual Update of Key Indicators of the State of the Climate System and Human Influence. Earth Syst. Sci. Data 2024, 16, 2625–2658. [Google Scholar] [CrossRef]

- Cervelli, A.; Rabaglia, S.; Sioli, M. A New Detector for Glaciers Melting Monitoring through Muon Tomography. Nucl. Instrum. Methods Phys. Res. A 2024, 1064, 169305. [Google Scholar] [CrossRef]

- Cheng, L.; Abraham, J.; Trenberth, K.E.; Boyer, T.; Mann, M.E.; Zhu, J.; Wang, F.; Yu, F.; Locarnini, R.; Fasullo, J.; et al. New Record Ocean Temperatures and Related Climate Indicators in 2023. Adv. Atmos. Sci. 2024, 41, 1068–1082. [Google Scholar] [CrossRef]

- Lee, J.B.; Kim, J.H.; Min, B.G.; Woo, B.H. Performance Assessment of Carbon Dioxide Sequestration in Cement Composites with a Granulation Technique. Materials 2024, 17, 53. [Google Scholar] [CrossRef]

- Eloneva, S.; Teir, S.; Salminen, J.; Fogelholm, C.J.; Zevenhoven, R. Fixation of CO2 by Carbonating Calcium Derived from Blast Furnace Slag. Energy 2008, 33, 1461–1467. [Google Scholar] [CrossRef]

- Song, K.I.; Song, J.K.; Lee, B.Y.; Yang, K.H. Carbonation Characteristics of Alkali-Activated Blast-Furnace Slag Mortar. Adv. Mater. Sci. Eng. 2014, 2014, 326458. [Google Scholar] [CrossRef]

- Park, S.; Yu, J.; Oh, J.E.; Pyo, S. Effect of Silica Fume on the Volume Expansion of Metakaolin-Based Geopolymer Considering the Silicon-to-Aluminum Molar Ratio. Int. J. Concr. Struct. Mater. 2022, 16, 20. [Google Scholar] [CrossRef]

- Nayak, D.K.; Abhilash, P.P.; Singh, R.; Kumar, R.; Kumar, V. Fly Ash for Sustainable Construction: A Review of Fly Ash Concrete and Its Beneficial Use Case Studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Menassa, C.C.; Kamat, V.R.; Lee, S.; Azar, E.; Feng, C.; Anderson, K. Conceptual Framework to Optimize Building Energy Consumption by Coupling Distributed Energy Simulation and Occupancy Models. J. Comput. Civ. Eng. 2014, 28, 50–62. [Google Scholar] [CrossRef]

- Kim, J.; Naganathan, H.; Moon, S.-Y.; Chong, W.K.O.; Ariaratnam, S.T. Applications of Clustering and Isolation Forest Techniques in Real-Time Building Energy-Consumption Data: Application to LEED Certified Buildings. J. Energy Eng. 2017, 143, 04017052. [Google Scholar] [CrossRef]

- Weigel, B.A. Estimation of Potential Transportation and Building Energy Performance of Commercial Office Site Alternatives. J. Urban Plan. Dev. 2015, 141, 04014016. [Google Scholar] [CrossRef]

- Li, Q.; Ju, Z.; Wang, Z.; Ma, L.; Jiang, W.; Li, D.; Jia, J. Thermal Performance and Economy of PCM Foamed Cement Walls for Buildings in Different Climate Zones. Energy Build. 2022, 277, 112470. [Google Scholar] [CrossRef]

- Abuelnuor, A.A.A.; Omara, A.A.M.; Saqr, K.M.; Elhag, I.H.I. Improving Indoor Thermal Comfort by Using Phase Change Materials: A Review. Int. J. Energy Res. 2018, 42, 2084–2103. [Google Scholar] [CrossRef]

- Shi, X.; Memon, S.A.; Tang, W.; Cui, H.; Xing, F. Experimental Assessment of Position of Macro Encapsulated Phase Change Material in Concrete Walls on Indoor Temperatures and Humidity Levels. Energy Build. 2014, 71, 80–87. [Google Scholar] [CrossRef]

- Frąc, M.; Pichór, W.; Szołdra, P.; Szudek, W. Cement Composites with Expanded Graphite/Paraffin as Storage Heater. Constr. Build. Mater. 2021, 275, 122126. [Google Scholar] [CrossRef]

- Almousa, N.H.; Alotaibi, M.R.; Alsohybani, M.; Radziszewski, D.; AlNoman, S.M.; Alotaibi, B.M.; Khayyat, M.M. Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development. Crystals 2021, 11, 951. [Google Scholar] [CrossRef]

- Hasanabadi, S.; Sadrameli, S.M.; Soheili, H.; Moharrami, H.; Heyhat, M.M. A Cost-Effective Form-Stable PCM Composite with Modified Paraffin and Expanded Perlite for Thermal Energy Storage in Concrete. J. Therm. Anal. Calorim. 2019, 136, 1201–1216. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Thermal Performance of Concrete Bricks Based Phase Change Material Encapsulated by Various Aluminium Containers: An Experimental Study under Iraqi Hot Climate Conditions. J. Energy Storage 2021, 40, 102710. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Woo, B.H.; Ryou, J.S. Assessment of PCM/SiC-Based Composite Aggregate in Concrete: Energy Storage Performance. Constr. Build. Mater. 2020, 258, 119637. [Google Scholar] [CrossRef]

- Ates, F.; Woo, B.H.; Jang, C.; Kim, H.G. Enhancing Cementitious Composites with PCM-Impregnated Cork Granules for Sustainable and Energy-Efficient Building Elements. Constr. Build. Mater. 2024, 416, 135071. [Google Scholar] [CrossRef]

- Wang, Y.P.; Chen, W.; Huang, Y.Y.; Liu, X.; Su, C.Q. Performance Study on a Thermoelectric Generator with Exhaust-Module-Coolant Direct Contact. Energy Rep. 2022, 8, 729–738. [Google Scholar] [CrossRef]

- Ambrosi, R.M.; Williams, H.; Watkinson, E.J.; Barco, A.; Mesalam, R.; Crawford, T.; Bicknell, C.; Samara-Ratna, P.; Vernon, D.; Bannister, N.; et al. European Radioisotope Thermoelectric Generators (RTGs) and Radioisotope Heater Units (RHUs) for Space Science and Exploration. Space Sci. Rev. 2019, 215, 55. [Google Scholar] [CrossRef]

- Yang, S.; Li, Y.; Deng, L.; Tian, S.; Yao, Y.; Yang, F.; Feng, C.; Dai, J.; Wang, P.; Gao, M. Flexible Thermoelectric Generator and Energy Management Electronics Powered by Body Heat. Microsyst. Nanoeng. 2023, 9, 106. [Google Scholar] [CrossRef] [PubMed]

- Ghahari, S.A.; Ghafari, E.; Lu, N. Effect of ZnO Nanoparticles on Thermoelectric Properties of Cement Composite for Waste Heat Harvesting. Constr. Build. Mater. 2017, 146, 755–763. [Google Scholar] [CrossRef]

- Ji, T.; Zhang, X.; Zhang, X.; Zhang, Y.; Li, W. Effect of Manganese Dioxide Nanorods on the Thermoelectric Properties of Cement Composites. ASCE J. Mater. Civ. Eng. 2018, 132, 31–39. [Google Scholar] [CrossRef]

- Wei, J.; Hao, L.; He, G.; Yang, C. Enhanced Thermoelectric Effect of Carbon Fiber Reinforced Cement Composites by Metallic Oxide/Cement Interface. Ceram. Int. 2014, 40, 8261–8263. [Google Scholar] [CrossRef]

- Wei, J.; Nie, Z.; He, G.; Hao, L.; Zhao, L.; Zhang, Q. Energy Harvesting from Solar Irradiation in Cities Using the Thermoelectric Behavior of Carbon Fiber Reinforced Cement Composites. RSC Adv. 2014, 4, 48128–48134. [Google Scholar] [CrossRef]

- Wei, J.; Fan, Y.; Zhao, L.; Xue, F.; Hao, L.; Zhang, Q. Thermoelectric Properties of Carbon Nanotube Reinforced Cement-Based Composites Fabricated by Compression Shear. Ceram. Int. 2018, 44, 5829–5833. [Google Scholar] [CrossRef]

- Tzounis, L.; Liebscher, M.; Fuge, R.; Leonhardt, A.; Mechtcherine, V. P- and n-Type Thermoelectric Cement Composites with CVD Grown p- and n-Doped Carbon Nanotubes: Demonstration of a Structural Thermoelectric Generator. Energy Build. 2019, 191, 151–163. [Google Scholar] [CrossRef]

- Woo, B.-H.; Yoo, D.-H.; Kim, S.-S.; Lee, J.-B.; Ryou, J.-S.; Kim, H.-G. Effects of Thermal Conductive Materials on the Freeze-Thaw Resistance of Concrete. Materials 2021, 14, 4063. [Google Scholar] [CrossRef]

- Park, K.T.; Kim, H.G.; Kim, J.S.; Woo, B.H. Improving the Thermoelectric Performance of Cement Composites by Substituting Fine Aggregate with Silicon Carbide. Constr. Build. Mater. 2024, 416, 135068. [Google Scholar] [CrossRef]

- Woo, B.H.; Jeon, I.K.; Yoo, D.H.; Kim, H.G.; Ryou, J.-S. Ice-Melting Performance Assessment of Cement Composites Using Silicon Carbide as Fine Aggregate. Appl. Therm. Eng. 2021, 194, 117113. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C33; Standard Specifications for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- Ioannidou, D.; Meylan, G.; Sonnemann, G.; Habert, G. Is Gravel Becoming Scarce? Evaluating the Local Criticality of Construction Aggregates. Resour. Conserv. Recycl. 2017, 126, 25–33. [Google Scholar] [CrossRef]

- Woo, B.-H.; Yoo, D.-H.; Jeon, I.-K.; Kim, J.-S.; Yoo, K.-S.; Kim, H.G. Estimation of the Thermal Conductivity of Cement Composites Using Bayesian Statistical Approach. Compos. Part B Eng. 2022, 243, 110073. [Google Scholar] [CrossRef]

- Park, K.T. Investigation on the Thermoelectric Energy Harvesting Using Cement Composites Incorporating the Ceramic-Type Carbon Material as Fine Aggregate. Master’s Thesis, Hanyang University, Seoul, Republic of Korea, 2024. [Google Scholar]

- ASTM C109; A Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-Mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2002.

- C348; A Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- Liu, C.; Qian, R.; Liu, Z.; Liu, G.; Zhang, Y. Multi-Scale Modelling of Thermal Conductivity of Phase Change Material/Recycled Cement Paste Incorporated Cement-Based Composite Material. Mater. Des. 2020, 191, 108646. [Google Scholar] [CrossRef]

- Kultayeva, S.; Ha, J.H.; Malik, R.; Kim, Y.W.; Kim, K.J. Effects of Porosity on Electrical and Thermal Conductivities of Porous SiC Ceramics. J. Eur. Ceram. Soc. 2020, 40, 996–1004. [Google Scholar] [CrossRef]

- Jeon, I.K.; Qudoos, A.; Jakhrani, S.H.; Kim, H.G.; Ryou, J.S. Investigation of Sulfuric Acid Attack upon Cement Mortars Containing Silicon Carbide Powder. Powder Technol. 2020, 359, 181–189. [Google Scholar] [CrossRef]

- Kantel, T.; Ślosarczyk, A. Influence of Silicon Carbide and Electrocorundum on the Thermal Resistance of Cement Binders with Granulated Blast-Furnace Slag. Proc. Eng 2017, 172, 497–504. [Google Scholar]

- Yinfei, D.; Wei, H.; Mingxin, D.; Weizheng, L. Using Silicon Carbide to Increase Thermal Conductivity of Cement Composite for Improving Heating Efficiency of Floor Heating System. Constr. Build. Mater. 2022, 325, 126707. [Google Scholar] [CrossRef]

- Mendoza Reales, O.A.; Carisio, P.A.; dos Santos, T.C.; Pearl, W.C.; Toledo Filho, R.D. Effect of Pozzolanic Micro and Nanoparticles as Secondary Fillers in Carbon Nanotubes/Cement Composites. Constr. Build. Mater. 2021, 281, 122603. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Carbonaceous Micro-Filler for Cement: Effect of Particle Size and Dosage of Biochar on Fresh and Hardened Properties of Cement Mortar. Sci. Total Environ. 2019, 662, 952–962. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Influence of Porosity on Compressive and Tensile Strength of Cement Mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Ambroziak, A.; Ziolkowski, P. Concrete Compressive Strength under Changing Environmental Conditions during Placement Processes. Materials 2020, 13, 4577. [Google Scholar] [CrossRef]

- Wu, S.; Moges, K.A.; Vashistha, P.; Pyo, S. Sustainable Cementitious Composites with 30% Porosity and a Compressive Strength of 30 MPa. J. Mater. Res. Technol. 2023, 25, 5494–5505. [Google Scholar] [CrossRef]

- MejiaCruz, Y.; Caicedo, J.M.; Matta, F. Probabilistic Comparative Assessment of Structural Cement Composite Compressive Strength–Porosity Models. J. Struct. Eng. 2024, 150, 04024165. [Google Scholar] [CrossRef]

- Lin, X.; Xu, Q.; Deng, T.; Yang, B.; Chen, L. Improving Thermal Conductivity of Al/SiC Composites by Post-Oxidization of Reaction-Bonded Silicon Carbide Preforms. Sci. Rep. 2024, 14, 16610. [Google Scholar] [CrossRef]

- Román-Manso, B.; Chevillotte, Y.; Osendi, M.I.; Belmonte, M.; Miranzo, P. Thermal Conductivity of Silicon Carbide Composites with Highly Oriented Graphene Nanoplatelets. J. Eur. Ceram. Soc. 2016, 36, 3987–3993. [Google Scholar] [CrossRef]

- Wei, Y.; Cui, Y.; Wang, Y. Ionic Thermoelectric Effect of Pure Cement Paste and Its Temperature Sensing Performance. Constr. Build. Mater. 2023, 364, 129898. [Google Scholar] [CrossRef]

- Ail, U.; Jafari, M.J.; Wang, H.; Ederth, T.; Berggren, M.; Crispin, X. Thermoelectric Properties of Polymeric Mixed Conductors. Adv. Funct. Mater. 2016, 26, 6288–6296. [Google Scholar] [CrossRef]

| Chemical Composition (%) | |||||

|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

| 21.3 | 6.3 | 3.2 | 62.1 | 3.2 | 2.3 |

| Physical properties | |||||

| Fineness (cm2/g) | Specific gravity (ton/m3) | ||||

| 3.197 | 3.149 | ||||

| Chemical Composition (%) | |||||

|---|---|---|---|---|---|

| Density (ton/m3) | Mohs’ Hardness | Elastic Modulus (GPa) | Resistivity (Ω·m) | Thermal Conductivity (W/mK) | Purity of SiC (%) |

| 3.22 | 9.5 | 192 | 25 | 25.5 | 94 |

| Specimens | Mix Ratio | ||||

|---|---|---|---|---|---|

| Water | Cement | Fine Agg | SiC | Water Reducer | |

| B-S0 | 0.4 | 1 | 2 | 0 | 0.005 |

| B-S50 | 1 | 1 | |||

| B-S100 | 0 | 2 | |||

| C-S0 | 2 | 0 | |||

| C-S50 | 1 | 1 | |||

| C-S100 | 0 | 2 | |||

| Measurement Categories | Specimen Types (Used Number of Specimens) | Shapes |

|---|---|---|

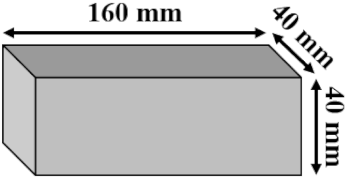

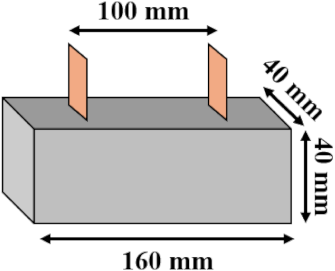

| For measuring mechanical properties | Beam (flexural, 3 specimens applied, and results averaged) |  |

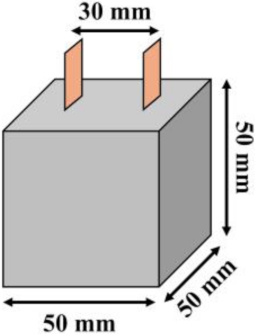

| Cubic (compressive, 3 specimens applied, and results averaged) |  | |

| For measuring SC and EC | Beam (1 specimen applied to SC and 1 specimen applied to EC) |  |

| Cubic (1 specimen applied to SC and 1 specimen applied to EC) |  | |

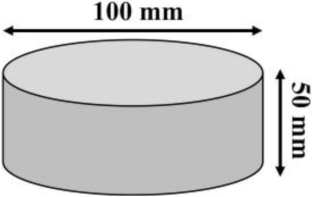

| For measuring TC/ porosity | Disc (1 specimen applied to TC and 3 specimens applied to porosity) |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woo, B.-H.; Park, K.-T.; Yoo, K.-S.; Kim, J.-S. Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide. Clean Technol. 2025, 7, 33. https://doi.org/10.3390/cleantechnol7020033

Woo B-H, Park K-T, Yoo K-S, Kim J-S. Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide. Clean Technologies. 2025; 7(2):33. https://doi.org/10.3390/cleantechnol7020033

Chicago/Turabian StyleWoo, Byeong-Hun, Kyu-Tae Park, Kyung-Suk Yoo, and Jee-Sang Kim. 2025. "Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide" Clean Technologies 7, no. 2: 33. https://doi.org/10.3390/cleantechnol7020033

APA StyleWoo, B.-H., Park, K.-T., Yoo, K.-S., & Kim, J.-S. (2025). Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide. Clean Technologies, 7(2), 33. https://doi.org/10.3390/cleantechnol7020033