Use of Vegetable Waste for New Ecological Methods in Wool Fibre Treatments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Dyeing solutions were obtained from vegetable wastes, such as red cabbage, red pepper, and red and yellow peel onions, purchased from local producers;

- Washing was conducted with Felosan RG-N (CHT-Group) detergent;

- The bleaching treatment mixture used hydrogen peroxide, sodium silicate, ammonium hydroxide, and acetic acid;

- Mordant was the tannic acid;

- The enzymatic formulations were the pharmaceutical products betaine hydrochloride (bHCl) and lysine (l).

- The AATCC standardised Lander-Ömeter with stirring (SDL Atlas Company, Rock Hill, South Carolina —USA);

- A Datacolor 500 spectrophotometer (Datacolor Basel, Switzerland).

2.2. Methods

2.2.1. Wool Pre-Treatment

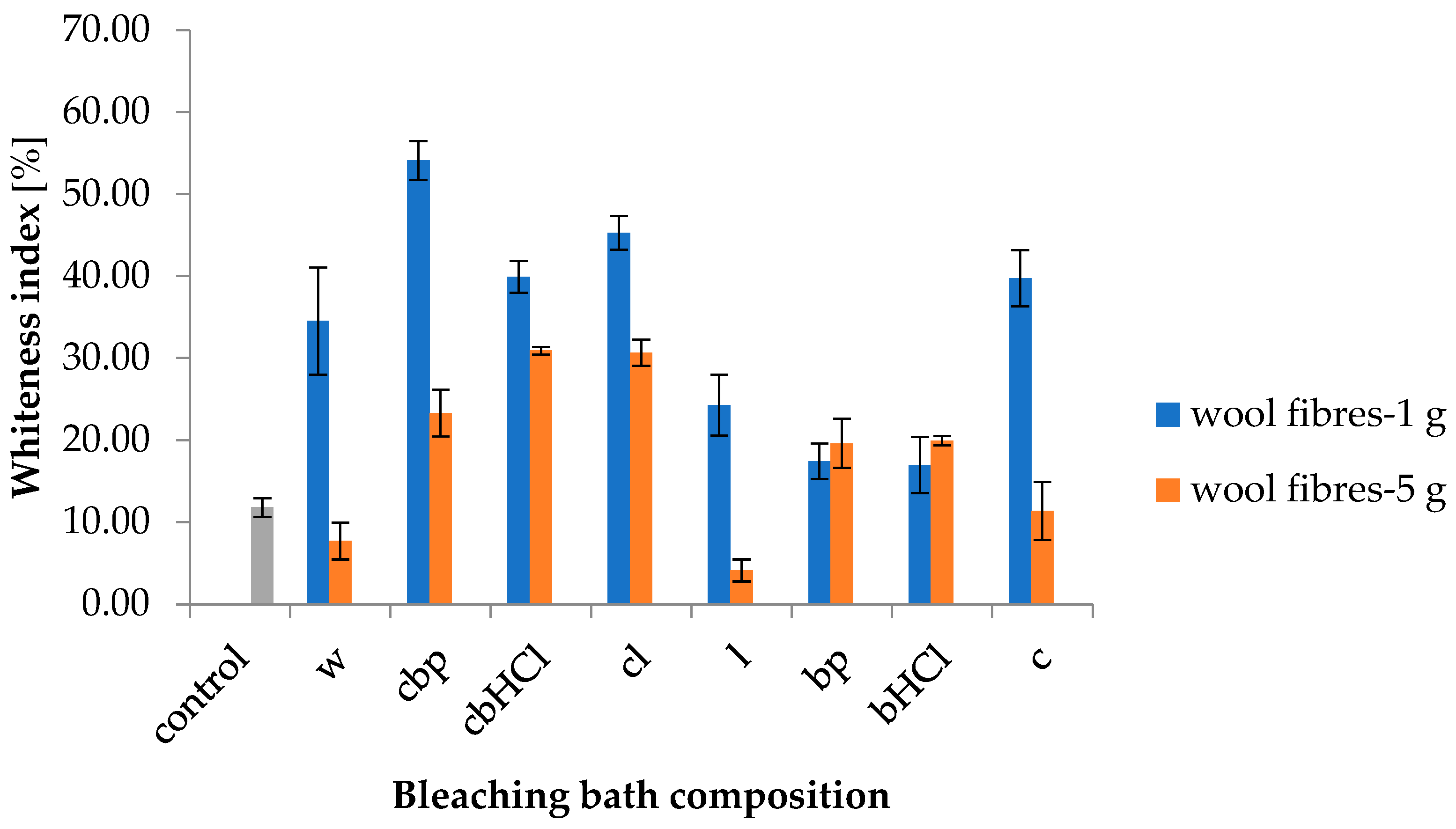

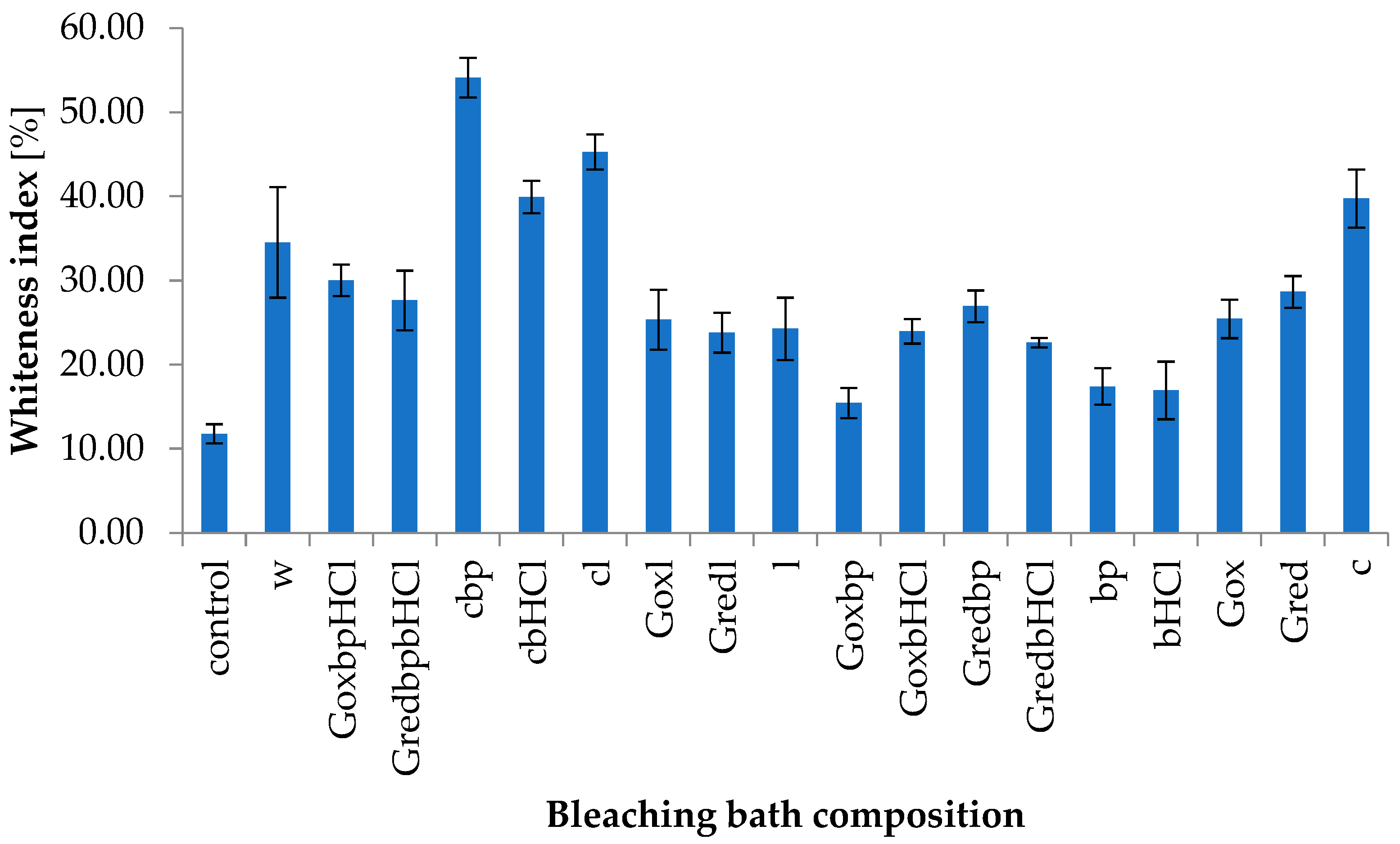

2.2.2. Bleaching Treatment

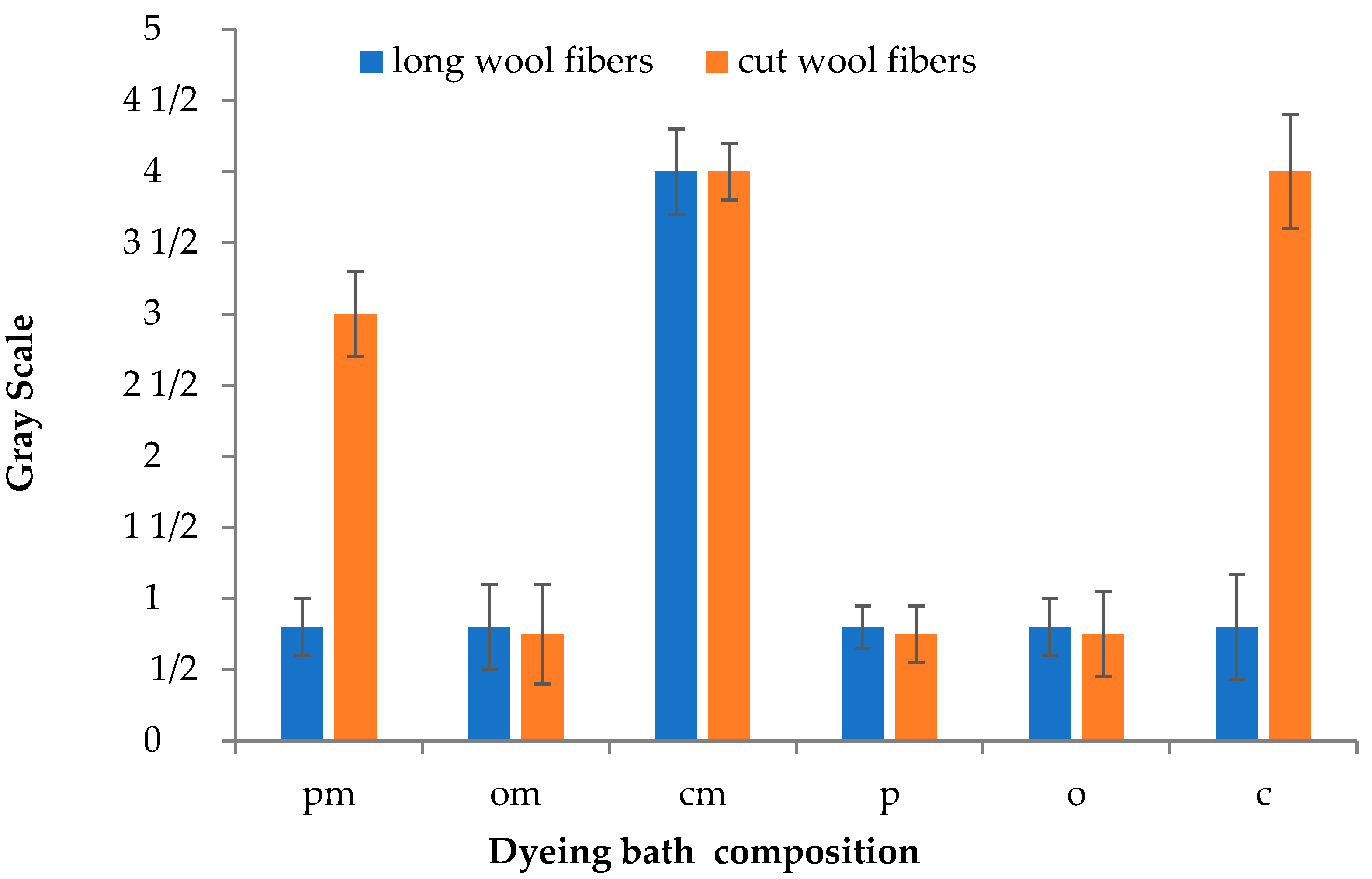

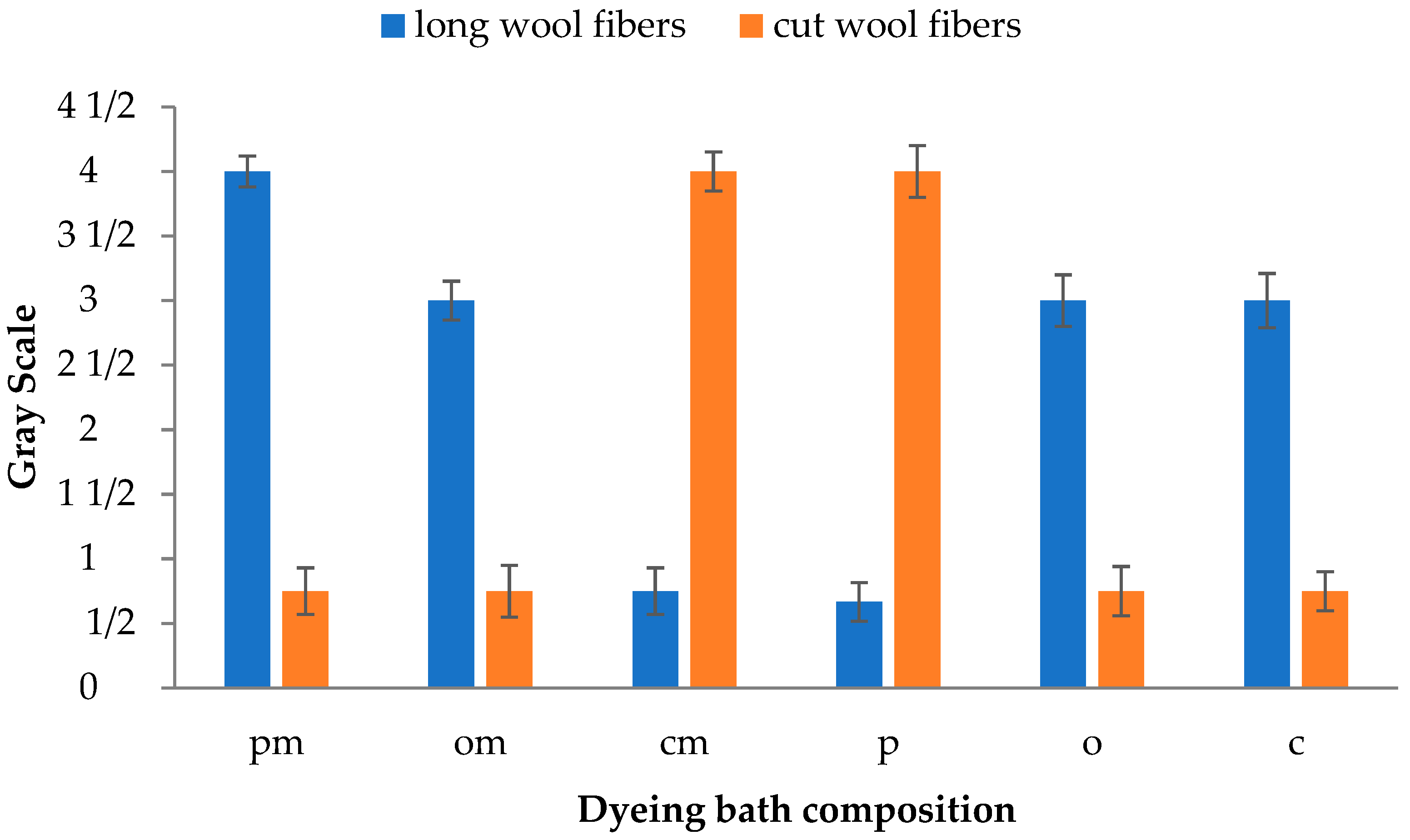

2.2.3. Dyeing Treatment

2.2.4. Whiteness Degree and Colour Measurements

2.2.5. Colourfastness to Accelerated Laundering

2.2.6. Colourfastness to Perspiration

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esparza, I.; Jimenez-Moreno, N.; Bimbela, F.; Ancin-Azpilicueta, C.; Gandia, L.M. Fruit and vegetable waste management: Conventional and emerging approaches. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Chen, H.; Vittuari, M.; Wu, J.; Wang, Y. Mapping quantity, composition, and embedded environmental impacts of post-consumer waste in the food service industry in China. Waste Manag. 2024, 187, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zhang, X.; An, L.; Liu, Y. A novel biochar-augmented enzymatic process for conversion of food waste to biofertilizers: Planting trial with leafy vegetable. Bioresour. Technol. 2024, 399, 130554. [Google Scholar] [CrossRef]

- Olawale, R.A.; Oladapo, B.I. Impact of community-driven biogas initiatives on waste vegetable reduction for energy sustainability in developing countries. Waste Manag. Bull. 2024, 2, 101–108. [Google Scholar] [CrossRef]

- Spendrup, S.; Bergstrand, K.-J.; Thörning, R.; Hultberg, M. Consumer attitudes towards hydroponic cultivation of vegetables—Specifically exploring the impact of the fertilisation strategy (using mineral origin or food waste as fertilisers). Food Qual. Prefer. 2024, 113, 105085. [Google Scholar] [CrossRef]

- Casson, A.; Ferrazzi, G.; Guidetti, R.; Bellettini, C.; Narote, A.D.; Rollini, M.; Piccardo, A.; Volturo, E.; Cosentino, M.; Limbo, S. Wholesale fruit and vegetable market in Milan: Turning food surpluses into environmental gains. J. Clean. Prod. 2024, 462, 142625. [Google Scholar] [CrossRef]

- Cakar, B. Bounce back of almost wasted food: Redistribution of fresh fruit and vegetables surpluses from Istanbul’s supermarkets. J. Clean. Prod. 2022, 362, 132325. [Google Scholar] [CrossRef]

- Chakraborty, D.; Chatterjee, S.; Althuri, A.; Palani, S.G.; Venkata Mohan, S. Sustainable enzymatic treatment of organic waste in a framework of circular economy. Bioresour. Technol. 2023, 370, 128487. [Google Scholar] [CrossRef]

- Ozcan, B.E.; Tetik, N.; Aloglu, H.S. Polysaccharides from fruit and vegetable wastes and their food applications: A review. Int. J. Biol. Macromol. 2024, 276, 134007. [Google Scholar] [CrossRef]

- Siddique, S.; Grassauer, F.; Arulnathan, V.; Sadiq, R.; Pelletier, N. A review of life cycle impacts of different pathways for converting food waste into livestock feed. Sustain. Prod. Consum. 2024, 46, 310–323. [Google Scholar] [CrossRef]

- Zahid, M.; Khalid, S.; Raana, S.; Amin, S.; Javaid, H.; Arshad, R.; Jahangeer, A.; Ahmad, S.; Hassan, S.A. Unveiling the anti-oxidative potential of fruits and vegetables waste in prolonging the shelf stability of vegetable oils. Future Foods 2024, 10, 100328. [Google Scholar] [CrossRef]

- Baseri, S. Environmentally sound recycling of agricultural waste: A sustainable approach to develop bio-functional art textile. J. Environ. Manag. 2024, 366, 121758. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Meng, C.; Zhang, G. Agricultural waste of Ipomoea batatas leaves as a source of natural dye for green coloration and bio-functional finishing for textile fabrics. Ind. Crops Prod. 2022, 177, 114440. [Google Scholar] [CrossRef]

- Otaviano, B.T.H.; Sannomiya, M.; de Lima, F.S.; Tangerina, M.M.P.; Tamayose, C.I.; Pena Ferreira, M.J.; Freeman, H.S.; Flor, J.P.; da Costa, S.A.; Costa, S.M.d. Pomegranate peel extract and zinc oxide as a source of natural dye and functional material for textile fibers aiming for photoprotective properties. Mater. Chem. Phys. 2023, 293, 126766. [Google Scholar] [CrossRef]

- Biswal, A.K.; Panda, L.; Chakraborty, S.; Pradhan, S.K.; Dash, M.R.; Misra, P.K. Production of a nascent cellulosic material from vegetable waste: Synthesis, characterization, functional properties, and its potency for a cationic dye removal. Int. J. Biol. Macromol. 2023, 242, 124959. [Google Scholar] [CrossRef]

- Peláez-Cid, A.-A.; Herrera-González, A.-M.; Salazar-Villanueva, M.; Bautista-Hernández, A. Elimination of textile dyes using activated carbons prepared from vegetable residues and their characterization. J. Environ. Manag. 2016, 181, 269–278. [Google Scholar] [CrossRef]

- Ma, X.; Liu, Y.; Zhang, Q.; Sun, S.; Zhou, X.; Xu, Y. A novel natural lignocellulosic biosorbent of sunflower stem-pith for textile cationic dyes adsorption. J. Clean. Prod. 2022, 331, 129878. [Google Scholar] [CrossRef]

- Pandey, V.; Singh, S.B.; Gupta, M.K.; Afroz, M.; Agrahari, S.; Singh, H.; Tandon, P.K. Removal of the cationic dyes with activated carbon obtained from low-cost ginger waste. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Ahmed Moussa, A.A.-A.; Gomaa, A.H.; El-Azabawy, R.E. Valorization Beetroot Waste for Eco-Friendly Extraction of Natural Dye for Textile and Food Applications. Egypt. J. Chem. 2022, 65, 725–736. [Google Scholar] [CrossRef]

- Bartolini, D.; Pallottelli, L.; Sgargetta, D.; Varfaj, I.; Macchiarulo, A.; Galli, F.; Romani, A.; Sardella, R.; Clementi, C. Natural cellulosic biofunctional textiles from onion (Allium cepa L.) skin extracts: A sustainable strategy for skin protection. Ind. Crops Prod. 2024, 212, 118295. [Google Scholar] [CrossRef]

- Sarker, M.K.U.; Haque, M.M.; Hasan, M.R.; Sultana, S.; Ray, S.K.; Shaikh, M.A.A. Utilization of factory tea (Camellia sinensis) wastes in eco-friendly dyeing of jute packaging fabrics. Heliyon 2024, 10, e30948. [Google Scholar] [CrossRef] [PubMed]

- Baaka, N.; El Ksibi, I.; Mhenni, M.F. Optimisation of the recovery of carotenoids from tomato processing wastes: Application on textile dyeing and assessment of its antioxidant activity. Nat. Product. Res. 2017, 31, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Kusumastuti, A.; Auliyana, N.; Rozana, M. Application of avocado seed as textile natural dye. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 104, 47–54. [Google Scholar] [CrossRef]

- Benli, H.; Bahtiyari, M.İ. An approach for the valorization of bio-waste pistachio shells (Pistacia vera L.): Dyeing of cellulose-based fabrics. J. Clean. Prod. 2024, 445, 141213. [Google Scholar] [CrossRef]

- Rossi, T.; Silva, P.M.S.; De Moura, L.F.; Araújo, M.C.; Brito, J.O.; Freeman, H.S. Waste from eucalyptus wood steaming as a natural dye source for textile fibers. J. Clean. Prod. 2017, 143, 303–310. [Google Scholar] [CrossRef]

- Che, J.; Yang, X. A recent (2009–2021) perspective on sustainable color and textile coloration using natural plant resources. Heliyon 2022, 8, e10979. [Google Scholar] [CrossRef] [PubMed]

- Lobregas, M.O.S.; Buniao, E.V.D.; Leaño, J.L. Alkali-enzymatic treatment of Bambusa blumeana textile fibers for natural fiber-based textile material production. Ind. Crops Prod. 2023, 194, 116268. [Google Scholar] [CrossRef]

- Tharanga, M.; Gunasekera, U. Characterization of new cellulosic fiber derived from Lasia spinosa (L.) thwaites rhizome and its potential use as biodegradable textile material. Heliyon 2024, 10, e31117. [Google Scholar] [CrossRef]

- Vera, R.E.; Vivas, K.A.; Urdaneta, F.; Franco, J.; Sun, R.; Forfora, N.; Frazier, R.; Gongora, S.; Saloni, D.; Fenn, L.; et al. Transforming non-wood feedstocks into dissolving pulp via organosolv pulping: An alternative strategy to boost the share of natural fibers in the textile industry. J. Clean. Prod. 2023, 429, 139394. [Google Scholar] [CrossRef]

- Gomes, C.V.; Araújo, J.C.; Chaves, D.M.; Fangueiro, R.; Ferreira, D.P. Improving textile circular economy through banana fibers from the leaves central rib: Effect of different extraction methods. Food Bioprod. Process. 2024, 146, 195–204. [Google Scholar] [CrossRef]

- Karuppuchamy, A.; Ramya, K.; Siva, R. Novel banana core stem fiber from agricultural biomass for lightweight textile applications. Ind. Crops Prod. 2024, 209, 117985. [Google Scholar] [CrossRef]

- Porubská, M.; Koóšová, K.; Braniša, J. The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment. Processes 2024, 12, 963. [Google Scholar] [CrossRef]

- Doyle, E.K.; Preston, J.W.; McGregor, B.A.; Hynd, P.I. The science behind the wool industry. The importance and value of wool production from sheep. Anim. Front. 2021, 11, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Zheljazkov, V.D.; Stratton, G.W.; Pincock, J.; Butler, S.; Jeliazkova, E.A.; Nedkov, N.K.; Gerard, P.D. Wool-waste as organic nutrient source for container-grown plants. Waste Manag. 2009, 29, 2160–2164. [Google Scholar] [CrossRef] [PubMed]

- Parlato, M.C.M.; Porto, S.M.C.; Valenti, F. Assessment of sheep wool waste as new resource for green building elements. Build. Environ. 2022, 225, 109596. [Google Scholar] [CrossRef]

- Mu, B.; Yu, X.; Yang, Y. Sustainable and green process for recycling waste wool textiles into high-quality protein fibers on a pilot scale. Resour. Conserv. Recycl. 2023, 198, 107190. [Google Scholar] [CrossRef]

- Navone, L.; Moffitt, K.; Hansen, K.-A.; Blinco, J.; Payne, A.; Speight, R. Closing the textile loop: Enzymatic fibre separation and recycling of wool/polyester fabric blends. Waste Manag. 2020, 102, 149–160. [Google Scholar] [CrossRef]

- Yin, H.; Wang, H.; Wang, D.; Shi, M.; Xu, X.; Yang, J. NH2-UiO-66 (Zr) modified waste wool fibers for efficient adsorption of dye from water. Desalination Water Treat. 2024, 318, 100305. [Google Scholar] [CrossRef]

- Vouvoudi, E.C.; Dimaki, M.I.; Ainali, N.M.; Koronaiou, L.-A.; Lambropoulou, D.A.; Nikolaidis, N.F.; Bikiaris, D.N. Alkali hydrolysis of wool fibres using microwave irradiation as a recycling approach for handling wool-waste. Polym. Degrad. Stab. 2024, 223, 110744. [Google Scholar] [CrossRef]

- Leaver, I.H.; Milligan, B. Fluorescent whitening agents—A survey (1974–82). Dye Pigment. 1984, 5, 109–144. [Google Scholar] [CrossRef]

- Zhang, H.; Millington, K.R.; Wang, X. The photostability of wool doped with photocatalytic titanium dioxide nanoparticles. Polym. Degrad. Stab. 2009, 94, 278–283. [Google Scholar] [CrossRef]

- Montazer, M.; Morshedi, S. Photo bleaching of wool using nano TiO2 under daylight irradiation. J. Ind. Eng. Chem. 2014, 20, 83–90. [Google Scholar] [CrossRef]

- Yilmazer, D.; Kanik, M. Bleaching of Wool with Sodium Borohydride. J. Eng. Fibers Fabr. 2009, 4, 155892500900400. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Q.; Yuan, J.; Cui, L.; Wang, P.; Yu, Y.; Fan, X. Highly efficient and eco-friendly wool degradation by L-cysteine-assisted esperase. J. Clean. Prod. 2018, 192, 433–442. [Google Scholar] [CrossRef]

- Su, C.; Gong, J.-S.; Qin, J.; He, J.-M.; Zhou, Z.-C.; Jiang, M.; Xu, Z.-H.; Shi, J.-S. Glutathione enables full utilization of wool wastes for keratin production and wastewater decolorization. J. Clean. Prod. 2020, 270, 122092. [Google Scholar] [CrossRef]

- Gaidau, C.; Epure, D.-G.; Enascuta, C.E.; Carsote, C.; Sendrea, C.; Proietti, N.; Chen, W.; Gu, H. Wool keratin total solubilisation for recovery and reintegration—An ecological approach. J. Clean. Prod. 2019, 236, 117586. [Google Scholar] [CrossRef]

- Assefi Pour, R.; Bagheri, R.; Naveed, T.; Ali, N.; Rehman, F.; He, J. Surface functionalization of wool via microbial-transglutaminase and bentonite as bio-nano-mordant to achieve multi objective wool and improve dyeability with madder. Heliyon 2020, 6, e04911. [Google Scholar] [CrossRef]

- Du, Z.; Ji, B.; Yan, K. Recycling keratin polypeptides for anti-felting treatment of wool based on L-cysteine pretreatment. J. Clean. Prod. 2018, 183, 810–817. [Google Scholar] [CrossRef]

- Wang, X.; Shen, X.; Xu, W. Effect of hydrogen peroxide treatment on the properties of wool fabric. Appl. Surf. Sci. 2012, 258, 10012–10016. [Google Scholar] [CrossRef]

- Chirila, L.; Popescu, A.; Cutrubinis, M.; Stanculescu, I.; Moise, V.I. The influence of gamma irradiation on natural dyeing properties of cotton and flax fabrics. Radiat. Phys. Chem. 2018, 145, 97–103. [Google Scholar] [CrossRef]

- McNeil, S.J.; McCall, R.A. Ultrasound for wool dyeing and finishing. Ultrason. Sonochem. 2011, 18, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Millington, K.R.; Church, J.S. The photodegradation of wool keratin II. Proposed mechanisms involving cystine. J. Photochem. Photobiol. B Biol. 1997, 39, 204–212. [Google Scholar] [CrossRef]

- Matyašovský, J.; Sedliačik, J.; Šimon, P.; Novák, I.; Jurkovič, P.; Duchovič, P.; Sedliačiková, M.; Cibulková, Z.; Mičušík, M.; Kleinová, A. Antioxidation activity of cysteine and cystine prepared from sheep wool. J. Am. Leather Chem. Assoc. 2020, 115, 166–175. [Google Scholar] [CrossRef]

- Popescu, V.; Blaga, A.C.; Pruneanu, M.; Cristian, I.N.; Pîslaru, M.; Popescu, A.; Rotaru, V.; Crețescu, I.; Cașcaval, D. Green chemistry in the extraction of natural dyes from colored food waste, for dyeing protein textile materials. Polymers 2021, 13, 3867. [Google Scholar] [CrossRef]

- Saha, M.; Mukherjee, S.; Das, S.; Chowdhury, M.; Das, M.; Sarkar, S.; Chatterjee, S. Phytonutrient screening and evaluation of in-vitro antibacterial activity of onion and garlic peels: A comparative study with the prospects of waste to wealth. Int. J. Herb. Med. 2022, 10, 39–44. [Google Scholar] [CrossRef]

- Verma, M.; Singh, S.S.J.; Rose, N.M. Phytochemical screening of onion skin (Allium cepa) dye extract. J. Pharmacogn. Phytochem. 2018, 7, 1414–1417. [Google Scholar]

- Zhou, Q.; Rather, L.J.; Ali, A.; Wang, W.; Zhang, Y.; Rizwanul Haque, Q.M.; Li, Q. Environmental friendly bioactive finishing of wool textiles using the tannin-rich extracts of Chinese tallow (Sapium sebiferum L.) waste/fallen leaves. Dye Pigment. 2020, 176, 108230. [Google Scholar] [CrossRef]

- Dulo, B.; De Somer, T.; Phan, K.; Roosen, M.; Githaiga, J.; Raes, K.; De Meester, S. Evaluating the potential of natural dyes from nutshell wastes: Sustainable colouration and functional finishing of wool fabric. Sustain. Mater. Technol. 2022, 34, e00518. [Google Scholar] [CrossRef]

- Kilinc, M.; Canbolat, S.; Merdan, N.; Dayioglu, H.; Akin, F. Investigation of the Color, Fastness and Antimicrobial Properties of Wool Fabrics Dyed with the Natural Dye Extracted from the Cone of Chamaecyparis Lawsoniana. Procedia Soc. Behav. Sci. 2015, 195, 2152–2159. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, L.; Luo, L.; King, M.W. Natural dye extracted from Chinese gall—The application of color and antibacterial activity to wool fabric. J. Clean. Prod. 2014, 80, 204–210. [Google Scholar] [CrossRef]

| Abbreviation | Components |

|---|---|

| c | the control sample washed with non-ionic detergent, 0.0375 mL/L |

| w | wool fibres kept in water |

| GoxbpHCl | oxidised glutathione, betaine + HCl and betaine + pepsin |

| GredbpHCl | reduced glutathione, betaine + HCl and betaine + pepsin |

| cbp | cysteine and betaine + pepsin |

| cbHCl | cysteine and betaine + HCl |

| cl | cysteine and lysine |

| Goxl | oxidised glutathione and lysine |

| Gredl | reduced glutathione and lysine |

| l | lysine |

| Goxbp | oxidised glutathione and betaine + pepsin |

| GoxHCl | oxidised glutathione and betaine + HCl |

| Gredbp | reduced glutathione and betaine + pepsin |

| GredHCl | reduced glutathione and betaine + HCl |

| bp | betaine + pepsin |

| bHCl | betaine + HCl |

| Gox | oxidised glutathione |

| Gred | reduced glutathione |

| c | cysteine |

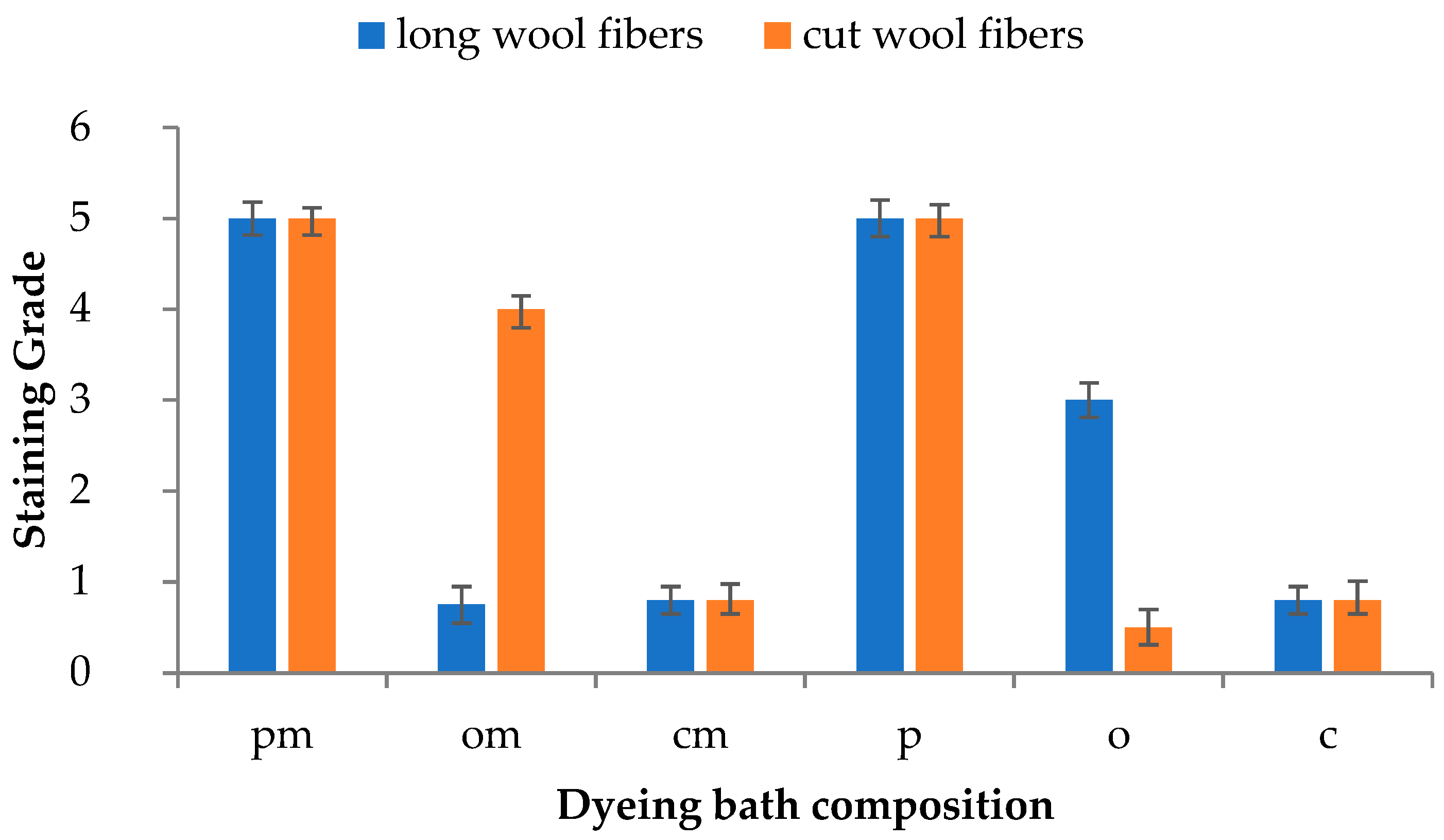

| Sample | Perspiration | Accelerated Laundering | |

|---|---|---|---|

| GSc | GSc | Staining | |

| pml | 4–5 | 4 | 5 |

| oml | 3–4 | 3 | 3–4 |

| cml | 4 | 3–4 | 4–5 |

| pl | 4–5 | 2–3 | 5 |

| ol | 4–5 | 3 | 3 |

| cl | 4–5 | 3 | 4–5 |

| pms | 3 | 3–4 | 5 |

| oms | 3–4 | 3–4 | 4 |

| cms | 4 | 4 | 4–5 |

| ps | 3–4 | 4 | 5 |

| os | 3–4 | 3–4 | 1–2 |

| cs | 4 | 3–4 | 4–5 |

| Abbreviation | Components |

|---|---|

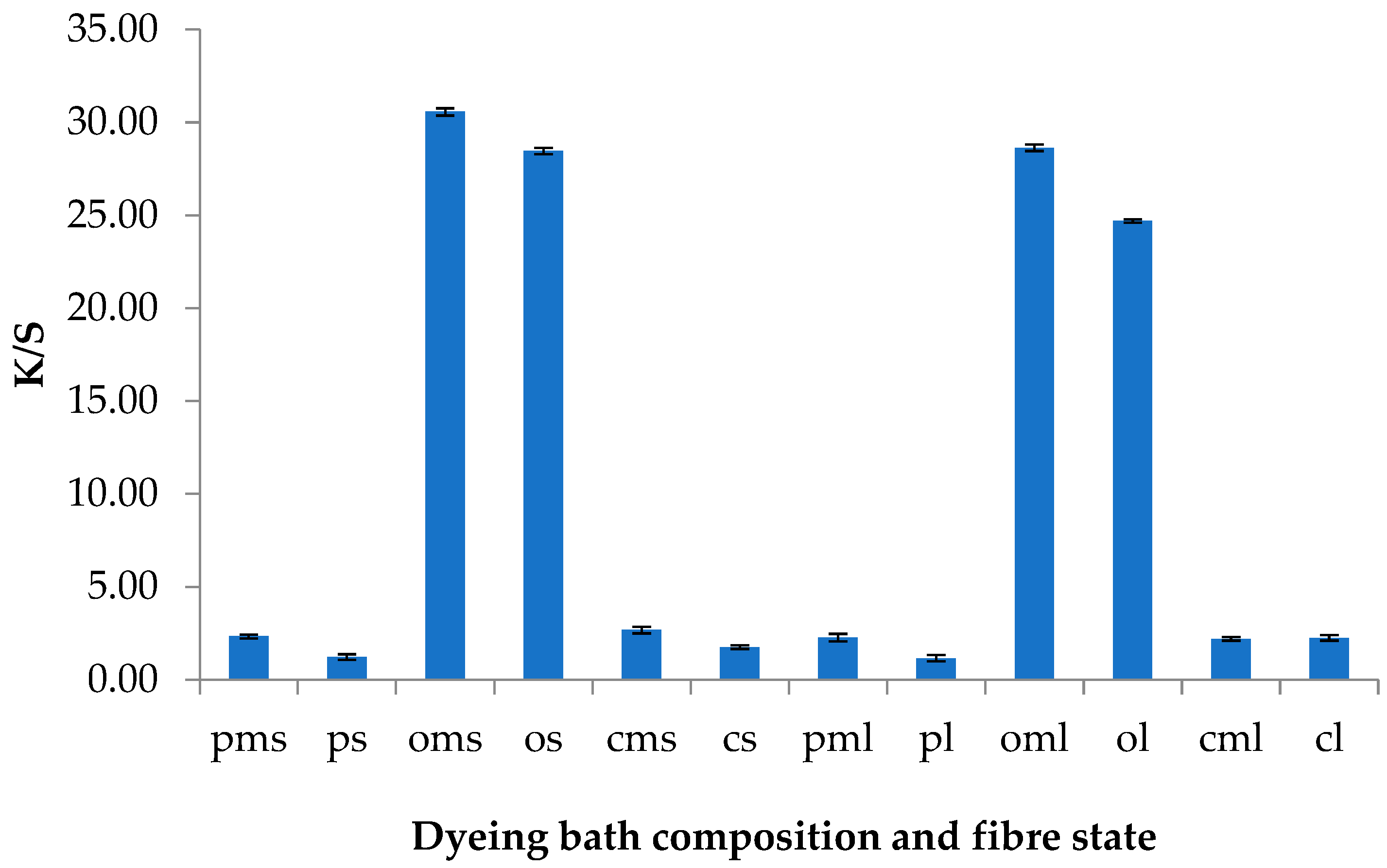

| pml | long wool fibres dyed with pepper and mordant |

| pl | long wool fibres dyed with pepper without mordant |

| pms | cut wool fibres dyed with pepper and mordant |

| ps | cut wool fibres dyed with pepper without mordant |

| oml | long wool fibres dyed with onion and mordant |

| ol | long wool fibres dyed with onion without mordant |

| oms | cut wool fibres dyed with onion and mordant |

| os | cut wool fibres dyed with onion without mordant |

| cml | long wool fibres dyed with red cabbage and mordant |

| cl | long wool fibres dyed with red cabbage without mordant |

| cms | cut wool fibres dyed with red cabbage and mordant |

| cs | cut wool fibres dyed with red cabbage without mordant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavrilaș, S.; Dochia, M.; Sărsan, A.-R.; Chereji, B.-D.; Munteanu, F.-D. Use of Vegetable Waste for New Ecological Methods in Wool Fibre Treatments. Clean Technol. 2024, 6, 1326-1339. https://doi.org/10.3390/cleantechnol6040063

Gavrilaș S, Dochia M, Sărsan A-R, Chereji B-D, Munteanu F-D. Use of Vegetable Waste for New Ecological Methods in Wool Fibre Treatments. Clean Technologies. 2024; 6(4):1326-1339. https://doi.org/10.3390/cleantechnol6040063

Chicago/Turabian StyleGavrilaș, Simona, Mihaela Dochia, Andreea-Raluca Sărsan, Bianca-Denisa Chereji, and Florentina-Daniela Munteanu. 2024. "Use of Vegetable Waste for New Ecological Methods in Wool Fibre Treatments" Clean Technologies 6, no. 4: 1326-1339. https://doi.org/10.3390/cleantechnol6040063

APA StyleGavrilaș, S., Dochia, M., Sărsan, A.-R., Chereji, B.-D., & Munteanu, F.-D. (2024). Use of Vegetable Waste for New Ecological Methods in Wool Fibre Treatments. Clean Technologies, 6(4), 1326-1339. https://doi.org/10.3390/cleantechnol6040063