Valorization of Biomass and Industrial Wastes as Alternative Fuels for Sustainable Cement Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Test Methods

3. Results and Discussion

4. Conclusions

- (a)

- Sawdust, pecan nutshell, industrial hose waste, and plastic waste have been demonstrated as viable alternative fuels for partially substituting fossil fuels in cement kilns, as their properties, including heating value, moisture, ash, heavy metals, and chlorides content, align with the recommended specifications for alternative fuel sources.

- (b)

- Among the samples evaluated, industrial hose waste and plastic waste are the most promising candidates for alternative fuels in cement kilns as they exhibit optimal characteristics that conform to all the recommended parameters. Notably, these two wastes have the highest calorific values and elevated carbon and hydrogen content, making them energetically dense and well suited to partially replace conventional fossil fuels while minimizing environmental impact.

- (c)

- The substantial generation of certain uncommon wastes like wind blade waste and automotive shredder residue (ASR) has raised significant concerns about their disposal. However, these two wastes, together with tire-derived fuel, do not meet all the recommended criteria, making them less desirable as alternative fuels. Specifically, wind blade waste and automotive shredder residue exhibit an excessively high ash content, which can adversely impact the combustion process. In addition, the former does not reach the desired heating value threshold and exceeds the acceptable chloride content limit, further diminishing its suitability as an alternative fuel in cement kilns.

- (d)

- Tire-derived fuel and automotive shredder residue exhibit elevated levels of heavy metals, surpassing the recommended thresholds for their utilization as alternative fuels.

- (e)

- Consequently, to effectively exploit the potential of wind blade waste, tire-derived fuel, and automotive shredder residue as alternative fuels in cement kilns, a proper blending strategy would be necessary. This approach would involve the use of these wastes with other alternative fuels and fossil fuels in optimized proportions.

- (f)

- The findings of this research will serve as the basis for developing a computational model, currently under progress, to optimize the blending of alternative fuels with fossil fuels for cement production. Optimal blending would not only help mitigate the adverse impacts of excessive ash, chlorides, and heavy metals but also ensure the maintenance of clinker quality and facilitate an efficient combustion process within the kiln system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Makul, N. Advanced smart concrete—A review of current progress, benefits and challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- Concrete Future. The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete; Global Cement and Concrete Association (GCCA): London, UK, 2021. [Google Scholar]

- Global Cement and Concrete Industry Announces Roadmap to Achieve Groundbreaking ‘Net Zero’ CO2 Emissions by 2050; Global Cement and Concrete Association (GCCA): London, UK, 2021.

- Cement Best Practices and Reporting. 2019. Available online: https://gccassociation.org/sustainability-innovation/cement-best-practices-and-reporting/ (accessed on 29 May 2024).

- Cement Industry Net Zero Progress Report. 2023. Available online: https://gccassociation.org/cement-industry-net-zero-progress/ (accessed on 29 May 2024).

- GCCA Sustainability Framework Guidelines; Global Cement and Concrete Association (GCCA): London, UK, 2022.

- GCCA Sustainability Guidelines for the Monitoring and Reporting of Emissions from Cement Manufacturing; Global Cement and Concrete Association (GCCA): London, UK, 2019.

- GCCA Sustainability Guidelines for Co-Processing Fuels and Raw Materials in Cement Manufacturing; Global Cement and Concrete Association (GCCA): London, UK, 2019.

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- GCCA Sustainability Guidelines for the Monitoring and Reporting of CO2 Emissions from Cement Manufacturing; Global Cement and Concrete Association (GCCA): London, UK, 2019.

- Karstensen, K.H. Formation, release and control of dioxins in cement kilns. Chemosphere 2008, 70, 543–560. [Google Scholar] [CrossRef] [PubMed]

- Zieri, W.; Ismail, I. Alternative fuels from waste products in cement industry. In Handbook of Ecomaterials; Springer Nature: Cham, Switzerland, 2018. [Google Scholar]

- Rahman, A.; Rasul, M.G.; Khan, M.M.K.; Sharma, S.C. Assessment of energy performance and emission control using alternative fuels in cement industry through a process model. Energies 2017, 10, 1996. [Google Scholar] [CrossRef]

- Chatterjee, A.; Sui, T. Alternative fuels–effects on clinker process and properties. Cem. Concr. Res. 2019, 123, 105777. [Google Scholar] [CrossRef]

- Hashem, F.S.; Razek, T.A.; Mashout, H.A. Rubber and plastic wastes as alternative refused fuel in cement industry. Constr. Build. Mater. 2019, 212, 275–282. [Google Scholar] [CrossRef]

- Karpan, B.; Raman, A.A.A.; Aroua, M.K.T. Waste-to-energy: Coal-like refuse derived fuel from hazardous waste and biomass mixture. Process Saf. Environ. Prot. 2021, 149, 655–664. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Kohli, I.; Srivatsa, S.C.; Das, O.; Devasahayam, S.; Singh Raman, R.K.; Bhattacharya, S. Pyrolysis of Automotive Shredder Residue (ASR): Thermogravimetry, In-Situ Synchrotron IR and Gas-Phase IR of Polymeric Components. Polymers 2023, 15, 3650. [Google Scholar] [CrossRef]

- Acha, E.; Lopez-Urionabarrenechea, A.; Delgado, C.; Martinez-Canibano, L.; Perez-Martinez, B.B.; Serras-Malillos, A.; Caballero, B.M.; Unamunzaga, L.; Dosal, E.; Montes, N.; et al. Combustion of a Solid Recovered Fuel (SRF) Produced from the Polymeric Fraction of Automotive Shredder Residue (ASR). Polymers 2021, 13, 3807. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Messina, F.; Di Palma, L.; Cioffi, R. Recycling of non-metallic automotive shredder residues and coal fly-ash in cold-bonded aggregates for sustainable concrete. Compos. Part B Eng. 2017, 116, 46–52. [Google Scholar] [CrossRef]

- ASTM D7582-15; Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D4208-19; Standard Test Method for Total Chlorine in Coal by the Oxygen Vessel Combustion/Ion Selective Electrode Method. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM D5865/D5865M-19; Standard Test Method for Gross Calorific Value of Coal and Coke. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM E873-82(2019); Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM D291/D291M-20; Standard Test Method for Bulk Density of Crushed Bituminous Coal. ASTM: West Conshohocken, PA, USA, 2020.

- Alsop, P.A. Cement Plant Operations Handbook: For Dry Process Plants; Tradeship Publications Ltd.: Luxembourg, 2007. [Google Scholar]

- Riaza, J.; Gibbins, J.; Chalmers, H. Ignition and combustion of single particles of coal and biomass. Fuel 2017, 202, 650–655. [Google Scholar] [CrossRef]

- Arisanti, R.; Yusuf, M.; Faizal, M. Study of the effect of proximate, ultimate, and calorific value analysis on methane gas emission (CH4) on combustion of coal for sustainable environment. Sci. Technol. Indones. 2018, 3, 100–106. [Google Scholar] [CrossRef]

- Equipment, C. Fuels in the Cement Industry. 5 May 2024. Available online: https://www.cementequipment.org/home/fuels-in-the-cement-industry/ (accessed on 5 May 2024).

- Zbogar, A.; Frandsen, F.J.; Jensen, P.A.; Glarborg, P. Heat transfer in ash deposits: A modelling tool-box. Prog. Energy Combust. Sci. 2005, 31, 371–421. [Google Scholar] [CrossRef]

- Demirbas, A. Effects of moisture and hydrogen content on the heating value of fuels. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 649–655. [Google Scholar] [CrossRef]

- Rahman, A.; Rasul, M.G.; Khan, M.M.K.; Sharma, S. Impact of alternative fuels on the cement manufacturing plant performance: An overview. Procedia Eng. 2013, 56, 393–400. [Google Scholar] [CrossRef]

- Galan, I.; Glasser, F.P. Chloride in cement. Adv. Cem. Res. 2015, 27, 63–97. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, H.; Jiang, X.; Lv, G.; Yan, J. Study on the evolution and transformation of Cl during Co-incineration of a mixture of rectification residue and raw meal of a cement kiln. Waste Manag. 2019, 84, 112–118. [Google Scholar] [CrossRef]

- Yu’nan, Z.; Jianzhong, L.; Liang, D.; Wei, S.; Weijuan, Y.; Junhu, Z. Effect of particle size and oxygen content on ignition and combustion of aluminum particles. Chin. J. Aeronaut. 2017, 30, 1835–1843. [Google Scholar]

- Varma, A.K.; Mondal, P. Physicochemical characterization and pyrolysis kinetics of wood sawdust. Energy Sources Part A: Recovery Util. Environ. Eff. 2016, 38, 2536–2544. [Google Scholar] [CrossRef]

- Aldana, H.; Lozano, F.J.; Acevedo, J.; Mendoza, A. Thermogravimetric characterization and gasification of pecan nut shells. Bioresour. Technol. 2015, 198, 634–641. [Google Scholar] [CrossRef] [PubMed]

- Ge, L.; Xu, C.; Feng, H.; Jiang, H.; Li, X.; Lu, Y.; Sun, Z.; Wang, Y.; Xu, C. Study on isothermal pyrolysis and product characteristics of basic components of waste wind turbine blades. J. Anal. Appl. Pyrolysis 2023, 171, 105964. [Google Scholar] [CrossRef]

- Geng, J.; Li, L.F.; Wang, W.L.; Chang, J.M.; Xia, C.L.; Cai, L.P.; Shi, S.Q. Fabrication of activated carbon using two-step co-pyrolysis of used rubber and larch sawdust. BioResources 2017, 12, 8641–8652. [Google Scholar] [CrossRef]

- Erliyanti, N.K.; Sangian, H.F.; Susianto, S.; Altway, A. The preparation of fixed carbon derived from waste tyre using pyrolysis. Sci. Study Res. Chem. Chem. Eng. 2015, 16, 343–352. [Google Scholar]

- Pan, D.L.; Jiang, W.T.; Guo, R.T.; Huang, Y.; Pan, W.G. Thermogravimetric and Kinetic Analysis of Co-Combustion of Waste Tires and Coal Blends. ACS Omega 2021, 6, 5479–5484. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, S.K.; Kibria, M.A.; Uddin, M.H.; Bhattacharya, S. Pretreatment of Automotive Shredder Residues, Their Chemical Characterisation, and Pyrolysis Kinetics. Sustainability 2021, 13, 10549. [Google Scholar] [CrossRef]

- Harder, M.; Forton, O. A Critical Review of Developments in the Pyrolysis of Automotive Shredder Residue. J. Anal. Appl. Pyrolysis 2007, 79, 387–394. [Google Scholar] [CrossRef]

- Dubdub, I.J.; Al-Yaari, M. Pyrolysis of Mixed Plastic Waste: I. Kinetic Study. Materials 2020, 13, 4912. [Google Scholar] [CrossRef]

- Abderrahim, B.; Abderrahman, E.; Mohamed, A.; Fatima, T.; Abdesselam, T.; Krim, O. Kinetic thermal degradation of cellulose, polybutylene succinate and a green composite: Comparative study. World J. Environ. Eng. 2015, 3, 95–110. [Google Scholar]

- Caban, R. FTIR-ATR spectroscopic, thermal and microstructural studies on polypropylene-glass fiber composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Wu, Z.; Li, S.; Liu, M.; Wang, Z.; Liu, X. Liquid oxygen compatible epoxy resin: Modification and characterization. RSC Adv. 2015, 5, 11325–11333. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless melt-electrospinning of polypropylene nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Tariq, A.; Afzal, A.; Rashid, I.A.; Shakir, M.F. Study of thermal, morphological, barrier and viscoelastic properties of PP grafted with maleic anhydride (PP-g-MAH) and PET blends. J. Polym. Res. 2020, 27, 1–10. [Google Scholar] [CrossRef]

- Asefnejad, A.; Khorasani, M.T.; Behnamghader, A.; Farsadzadeh, B.; Bonakdar, S. Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method: Physical properties and in vitro assay. Int. J. Nanomed. 2011, 6, 2375–2384. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, M.; Awasthi, K. Functionalized Pd-decorated and aligned MWCNTs in polycarbonate as a selective membrane for hydrogen separation. Int. J. Hydrogen Energy 2016, 41, 23057–23066. [Google Scholar] [CrossRef]

- Murat, M.; Sorrentino, F. Effect of large additions of Cd, Pb, Cr, Zn, to cement raw meal on the composition and the properties of the clinker and the cement. Cem. Concr. Res. 1996, 26, 377–385. [Google Scholar] [CrossRef]

- Nivethitha, D.; Dharmar, S. Effect of zinc oxide nanoparticle on strength of cement mortar. IJSTE-Int. J. Sci. Technol. Eng. 2016, 3, 123–127. [Google Scholar]

- Barros, A.M.; Espinosa, D.C.R.; Tenório, J.A.S. Effect of Cr2O3 and NiO additions on the phase transformations at high temperature in Portland cement. Cem. Concr. Res. 2004, 34, 1795–1801. [Google Scholar] [CrossRef]

| Sample | Description | Identification |

|---|---|---|

| Sawdust | Irregularly shaped wood shavings | SD |

| Pecan nutshell | Irregularly shaped crushed pecan nutshell | PNS |

| Wind blade waste | Pieces of wind blade exhibiting varying proportions of glass fiber (WBW-GF), resin (WBW-RS), and sawdust (WBW-SD) | WBW |

| Industrial hose waste | Pieces consisting of a mixture of various types of hoses | IHW |

| Tire-derived fuel | Irregularly shaped tire parts | TDF |

| Plastic waste | Pieces composed of a blend of rubber (PW-RB), polyurethane (PW-PL), resin (PW-RS), car dashboard (PW-CD), and fabrics (PW-FB) combined in balanced proportions | PW |

| Automotive shredder residue | Irregularly shaped plastic and metal parts | ASR |

| SD | PNS | WBW | IHW | TDF | PW | ASR | Coal | |

|---|---|---|---|---|---|---|---|---|

| Proximate analysis (wt%) | ||||||||

| Moisture | 5.2 | 4.1 | 2.0 | 0.4 | 0.7 | 0.2 | 1.2 | 3.0 |

| Volatile matter | 86.7 | 72.5 | 38.9 | 73.2 | 67.2 | 89.4 | 59.5 | 41.5 |

| Fixed carbon | 7.4 | 19.0 | 4.1 | 21.2 | 27.5 | 9.4 | 18.6 | 45.8 |

| Ash | 0.7 | 4.4 | 55.0 | 5.2 | 4.9 | 1.0 | 20.7 | 10.7 |

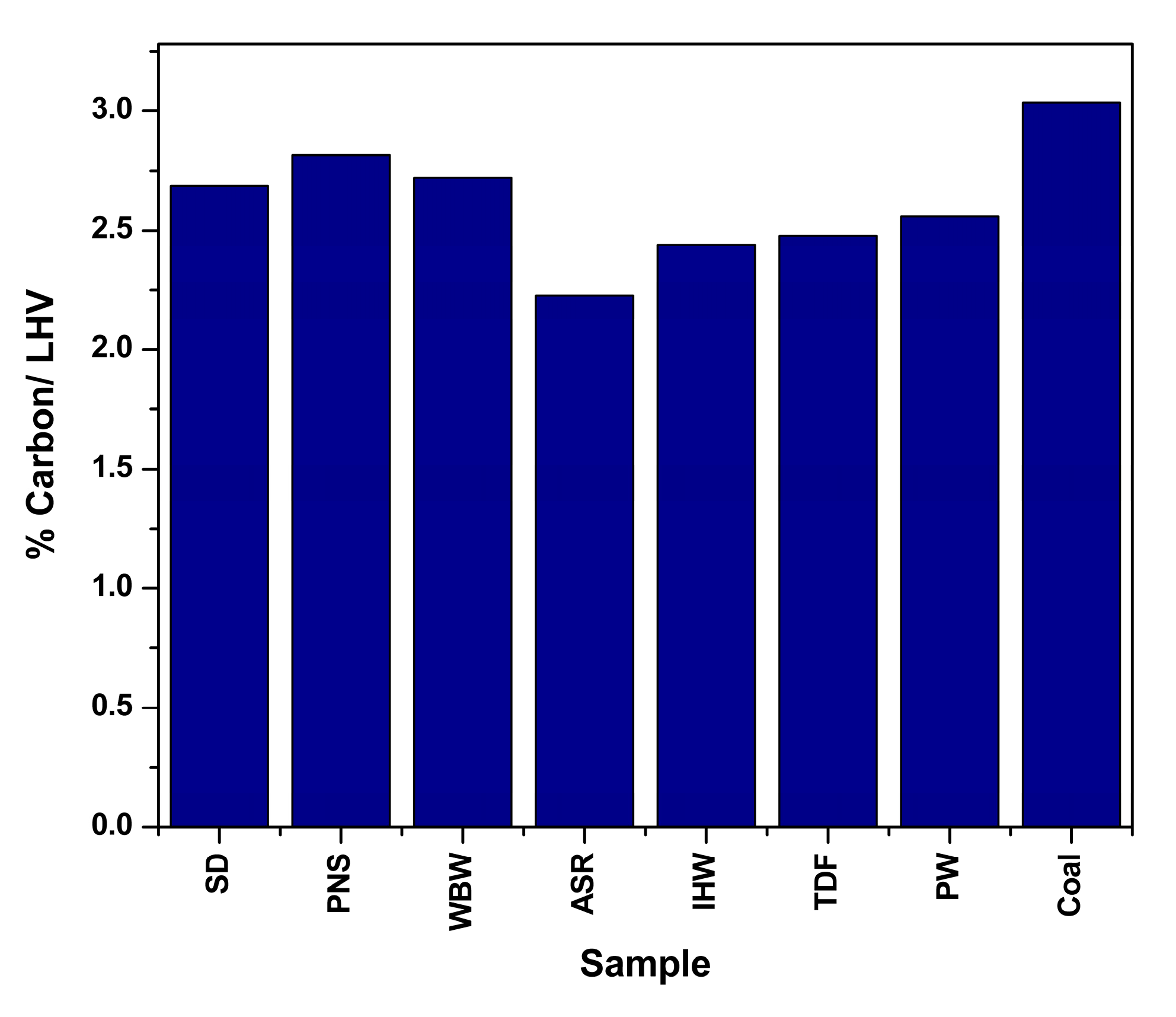

| Elemental analysis on dry basis (wt%) | ||||||||

| C | 45.50 | 50.80 | 31.30 | 82.86 | 90.0 | 77.40 | 49.10 | 84.26 |

| H | 5.80 | 5.90 | 3.51 | 5.23 | 7.98 | 8.10 | 5.90 | 3.27 |

| O | 40.50 | 32.76 | 10.95 | 7.58 | 1.06 | 13.26 | 17.86 | 9.83 |

| N | - | - | 1.26 | 2.70 | 0.34 | 1.17 | 1.08 | 2.64 |

| S | 0.03 | 0.03 | - | - | 0.14 | - | - | 0.83 |

| Cl− | 0.01 | - | 1.11 | 0.03 | 0.17 | 0.05 | 0.15 | 0.04 |

| Physical analysis | ||||||||

| LHV (MJ/kg) | 16.9 | 18.0 | 11.5 | 34.0 | 36.5 | 29.0 | 22.0 | 27.8 |

| Bulk density (g/cm3) | 0.29 | 0.82 | 0.40 | 0.37 | 0.39 | 0.20 | 0.44 | 0.62 |

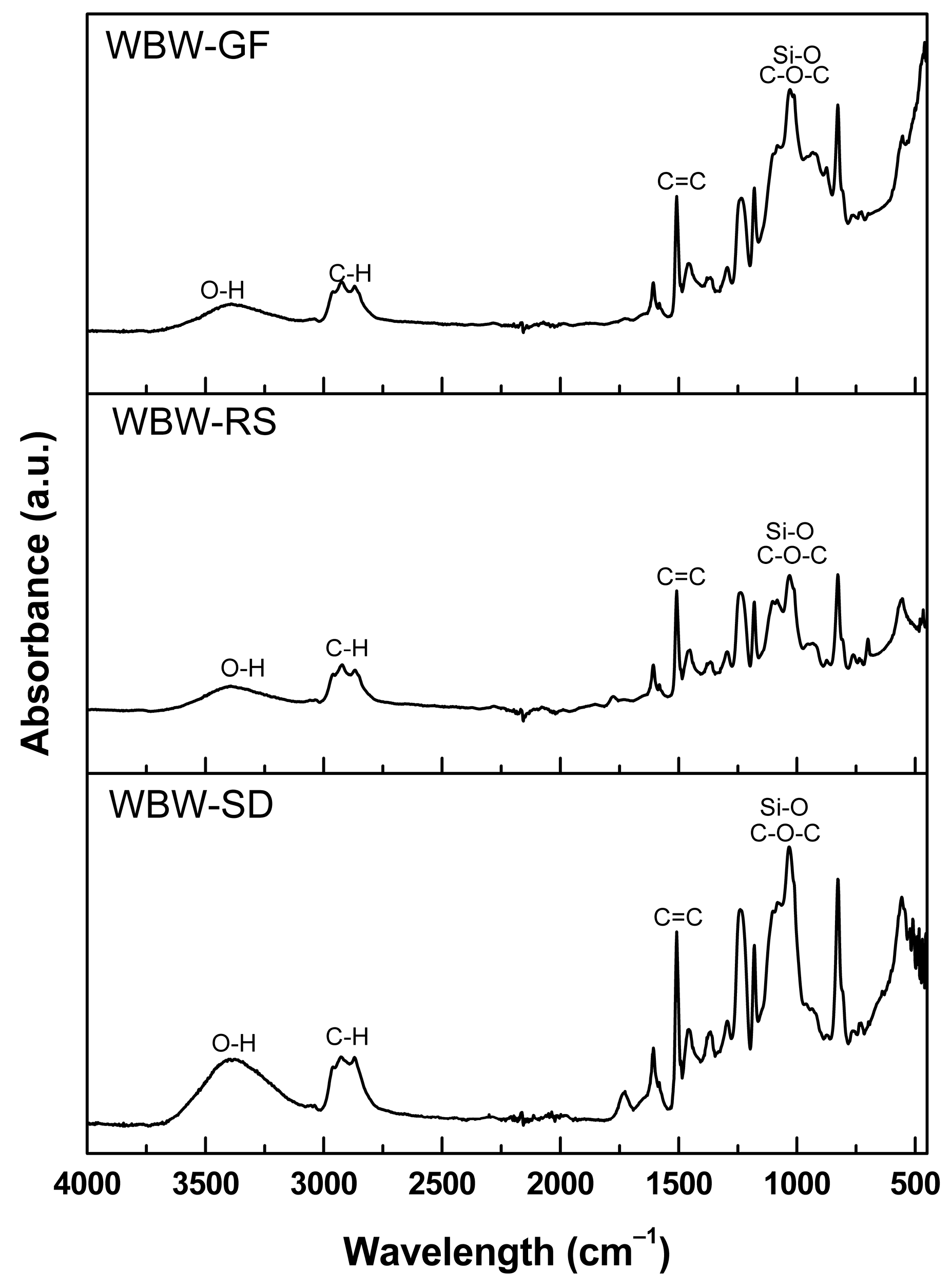

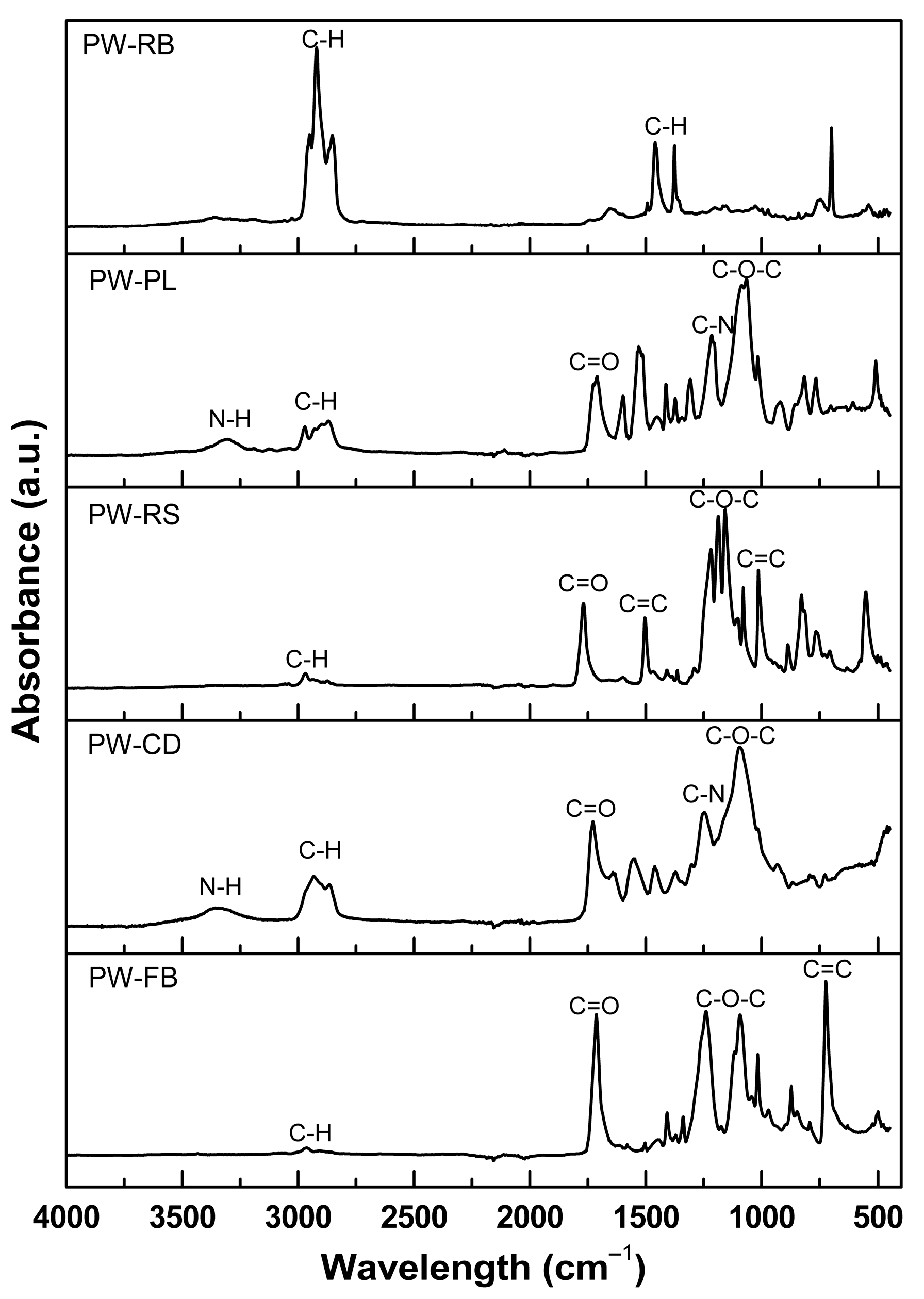

| Peak (cm−1) | Bond |

|---|---|

| 720, 1010, 1500, 1600 | C=C bending |

| 960–1300 | C-O-C stretching |

| 1060 | Si-O stretching |

| 1250 | C-N stretching |

| 1370, 1450, 1550 | C-H bending |

| 1650–1750 | C=O stretching |

| 2800–3000 | C-H stretching |

| 3300 | N-H stretching |

| 3400 | O-H stretching |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera Sasso, O.; Carreño Gallardo, C.; Soto Castillo, D.M.; Ojeda Farias, O.F.; Bojorquez Carrillo, M.; Prieto Gomez, C.; Herrera Ramirez, J.M. Valorization of Biomass and Industrial Wastes as Alternative Fuels for Sustainable Cement Production. Clean Technol. 2024, 6, 814-825. https://doi.org/10.3390/cleantechnol6020042

Rivera Sasso O, Carreño Gallardo C, Soto Castillo DM, Ojeda Farias OF, Bojorquez Carrillo M, Prieto Gomez C, Herrera Ramirez JM. Valorization of Biomass and Industrial Wastes as Alternative Fuels for Sustainable Cement Production. Clean Technologies. 2024; 6(2):814-825. https://doi.org/10.3390/cleantechnol6020042

Chicago/Turabian StyleRivera Sasso, Ofelia, Caleb Carreño Gallardo, David Martin Soto Castillo, Omar Farid Ojeda Farias, Martin Bojorquez Carrillo, Carolina Prieto Gomez, and Jose Martin Herrera Ramirez. 2024. "Valorization of Biomass and Industrial Wastes as Alternative Fuels for Sustainable Cement Production" Clean Technologies 6, no. 2: 814-825. https://doi.org/10.3390/cleantechnol6020042

APA StyleRivera Sasso, O., Carreño Gallardo, C., Soto Castillo, D. M., Ojeda Farias, O. F., Bojorquez Carrillo, M., Prieto Gomez, C., & Herrera Ramirez, J. M. (2024). Valorization of Biomass and Industrial Wastes as Alternative Fuels for Sustainable Cement Production. Clean Technologies, 6(2), 814-825. https://doi.org/10.3390/cleantechnol6020042