1. Introduction

In the early 1990s, there was much interest in the field of photovoltaic (PV) panels, hence the increase in the development and production of solar panels, whose lifespan was assumed to be around 25–30 years [

1]. Nowadays, their lifetime is ending, and this results in a huge amount of solid waste from end-of-life (EoL) solar panels. An international renewable energy agency reported that DSP waste will be produced in large amounts in China. Its weight has been estimated to reach around 1.5 million tons in 2025 and is expected to rise, up to 20 million tons, by the end of 2050, while an approximate 80 million tons of waste will be generated worldwide [

2]. Nowadays, crystalline silicon is a major building block of commercial solar panels, which account for 90% of the world’s solar panel market [

3]. PV modules contain high quantities of silver as the electron-coating metal for the electrical connectors between the cells, gallium, copper, indium, lead, tin, and other HMs, plus a large number of organic compounds such as black sheets, ethylene-vinyl acetate (EVA), aluminum frames, and glass [

4]. EoL solar panels are environmental pollutants as they can release harmful substances such as HMs [

5] if not well disposed of. Moreover, the world is gradually reaching the expected end of life of the first set of produced PV panels; therefore, a sustainable, environmental, and economically feasible technology is required to utilize energy resources and recover valuable materials from spent PV solar panels.

Typically, two layers of EVA act as a binder of the PV cell, covered by tempered glass and a polyvinyl fluoride sheet on the front and on the back, respectively. A large part of a PV panel is glass, which accounts for around 65–75% of the total, while the cell and EVA account for 1–2% and 7–15% of the module, respectively [

6]. According to Parliament et al. (2020) [

7], the European Union recognizes EoL panels as electronic waste. The authors also reported that, at any rate, 80% and 85% of PV panel materials must be recycled or recovered, respectively. Silicon is regarded as a core component of crystalline-Si PV solar panels, and significant amounts of toxic HMs such as Pb, Sn, Cd, and Cu are also present, which will pose serious ecological problems. A study by Su et al. (2019) [

8] examined the environmental pollution of EoL thin-film solar panels (TFSPs). During this experiment, a TFSP was buried in soil, and the acid extract method was used to simulate acid corrosion and metal leaching toxicity to examine if HMs might be released into the soil. The authors found that HMs such as Cu, Pb, Zn, Cr, In, Ga, and Ni were released into the soil. The study by Tammaro et al. (2016) [

5] revealed that the leachate of crystalline-Si PV solar panels releases some hazardous HMs, exceeding the legal limits for water and soil, at which point their presence negatively affects aquatic living things, especially algae. Semenova et al. (2022) [

9] determined the toxicity of the components of a polycrystalline solar panel, such as silicon, glass, Tedlar

®, and polymer EVA. Many tests were conducted using bio-testing techniques. The components were kept in distilled water and some conditions—for example, temperature, exposure time, and fraction size—were considered. The experimental data were analyzed by regression analysis based on the least squares method. The mathematical calculations showed that the toxicity index of all components was α = 0.05, but it depended on the exposure time. They concluded that the landfill is not a suitable route for disposing of EoL solar panels. The sustainable treatment of PV modules can reduce their toxicity to water and human beings by 10–70% compared to untreated spent panels [

10]. Due to DSP being highly regarded as the next electronic waste, successful mitigation measures during PV solar panel development will serve as an option to manage climate change while supporting biodiversity [

11].

Moreover, the presence of EVA in panel modules makes recycling more complex and causes severe environmental degradation when it is not appropriately disposed of, as it accounts for about a quarter of the entire PV module’s mass and is tough to decompose in a natural way. Recently, the most common technique applied has been the use of organic solvents such as acetone, benzene, toluene, hexane, d-limonene, isopropanol, and ethanol, which have been examined to adsorb EVA. These chemical solvents (for instance, toluene) dissolve EVA, but the reaction takes a long period of time. Prasad et al. (2022) [

12], after examining several chemicals, concluded that trichloroethylene is the most suitable solvent for the dissolution of EVA from EoL solar panels. The comparison of three solvents, including toluene, hexane, and benzene, at different time and temperature indicated that toluene showed great efficiency for EVA removal; around 72% can be recovered at 80 °C within 2 h, while hexane was observed to form hazardous compounds based on the gas chromatography and LC50/LD50 [

13]. However, this method has some limitations, such as low removal efficiency, long resident reaction time, and the release of organic liquid waste, which is a complex and expensive treatment process. Fiandra et al. (2023) [

14] proposed a mechanical approach for PV waste treatment, in which some parts of spent panels, such as the aluminum frame, were removed by using a hard plastic hammer, and afterwards, each module was subjected to the treatment process. Therefore, model KP0810C, MAKITA planer, and a blade roller rotated by an electric motor, have been employed. This process allowed the recovery of materials by densimetric separation, grinding, and surface delamination with very low energy consumption and minor ecological impact. On the other hand, it cannot optimize the resource recovery from EoL panel modules and HM contamination is inevitable. Thermal treatment is the mainstream technology to separate the modules in the EoL PV module recycling process. Wang et al. (2019) [

15] conducted two stages of pyrolysis treatment to separate the spent solar panels. This study reported that the TPT backing material was removed at 423.15 K and 300 s, while the EVA binder was recovered at 773.15 K with other products such as acetic acid and other trace hydrocarbons. Wang et al. (2022) [

16] conducted a pyrolysis process of DSP particles by developing reactive discrete element method computational fluid dynamics model to study the physical–thermal characteristics of dense gas–solid reacting flow related to the PV panel particles. Pyrolysis was performed in two different chemical reactors such as bubbling fluidized bed (BFB) and fixed bed (FB). The results showed that FB has a lower efficiency for EVA removal compared to the BFB. It shows better mass and heat transfer performance than the FB, such as larger heat transfer fluxes, higher Reynold and Nusselt numbers, and more steady temperature. The degrees of EVA recovery increased from 91.03% and 94.89% to 99.99%, as the wall temperature increased from 723 K and 773 K to 823 K, respectively. This model has several disadvantages, such as the fact that solar panels are assumed to be a uniform size and spherical shape. Practically, they have irregular size, shapes, and wide-open distribution, which has a considerable effect on bed hydrodynamic and reactor performance. Furthermore, some species of EVA glue solar panel particles have a sandwich structure. Therefore, the results showed no separation of EVA at the end of the process. Furthermore, solar panel particles are considered to be isothermal, and therefore, the thermal gradients inside the particles should be thoroughly examined.

In addition, thermal processes, such as pyrolysis, were conducted to treat EVA from DSP [

15], which led to the production of acetic acid and other several hydrocarbon compounds. Thermal technology seems to be a sustainable treatment to separate crystalline silicon PV modules but also has drawbacks for the recovery of HMs. The solid residue produced at the end of pyrolysis contains all the HMs that were present in the initial waste materials [

17]. Danz et al. (2019) [

18] conducted pyrolysis of back sheets from EoL panels. Polyvinylidene fluoride- and polyvinyl fluoride-based material, including (PVF)Kynar

®/polyethylene terephthalate (PET)/Kynar

®) and Tedlar

®/PET/Tedlar

®, were used, respectively, whereas ethylvinylacetate was used as control. The results showed that a high content of fluorine compounds was released into the gas phase during pyrolysis. A high percentage of fluorine release from Tedlar

®/PET/Tedlar

® was found even at temperatures lower than 573.15 K. This study concluded that experimental investigation and modelling are highly recommended to understand or control the fluorine release phenomena, as it will benefit the treatment of fluorinated polymeric materials for resources, energy, or recycling of spent solar panels.

Therefore, a highly efficient and environmentally friendly treatment process of EoL PV solar panels is urgently needed. Current processing technologies contribute to environmental pollution through the emission of hazardous gases, leaching of HMs that contaminate soil and groundwater, and the underutilization of valuable materials contained in spent solar panels. Additionally, some treatment methods are time-consuming, inefficient in recycling valuable materials, and inadequate for processing the mass of spent solar panels anticipated in the near future. This review proposes plasma pyrolysis as a sustainable technology which will convert EoL PV solar panels into hydrogen-rich syngas and non-leachable slag in an environmental manner. Furthermore, by-products from plasma pyrolysis, such as syngas, can be utilized to generate heat and electricity, while slag can serve as an additive in AD treatment to enhance the production of biogas and promote resource recovery. These applications have the potential to increase net energy production and enhance resource utilization.

2. An Overview of the Treatment Method of Discarded Photovoltaic Solar Panel

The need for alternative renewable energy sources to reduce reliance on environmentally unfriendly energy, such as fossil fuels, has spurred a significant increase in solar panel installations since the early years of the 21st century. The global cumulative capacity of PV panels reached 270 GW in 2015 and is expected to rise to 1630 GW by 2030 and 4500 GW by 2050, with projections indicating further increases over time [

19]. As with any technology, solar panels eventually reach the end of their operational life and require treatment, such as recycling, dismantling, and disposal [

1]. Currently, the leading countries in EoL solar panel production include China, the United States, Japan, India, and Germany. According to a report by International Energy Agency [

20] in 2021, China was responsible for producing approximately 75% of PV modules, with the remaining percentages produced by North America and Europe. The cumulative capacity of China, Europe, and North America accounts for about 35%, 17.7%, and 12%, respectively [

20]. There are considerable PV solar capacities under construction worldwide. For instance, by the end of 2030, the south of Dubai and Seih Al-Dahal are planned to have a production capacity of PV solar panels expected to produce 5 GW [

21]. Many countries classify PV solar panels as industrial or general waste without any restrictions on disposal and recycling. In Australia and South Korea, the disposal of spent solar panels has not yet matured, with only a small percentage of EoL solar panel modules being recycled, while the majority are landfilled. Conversely, some states in the USA have established laws for the management of EoL panel treatment systems.

However, the recycling methods currently applied to PV solar panels face challenges such as the limited recycling capacity and the high cost associated with Si PV recycling [

22]. According to a study by Bošnjaković et al. (2023) [

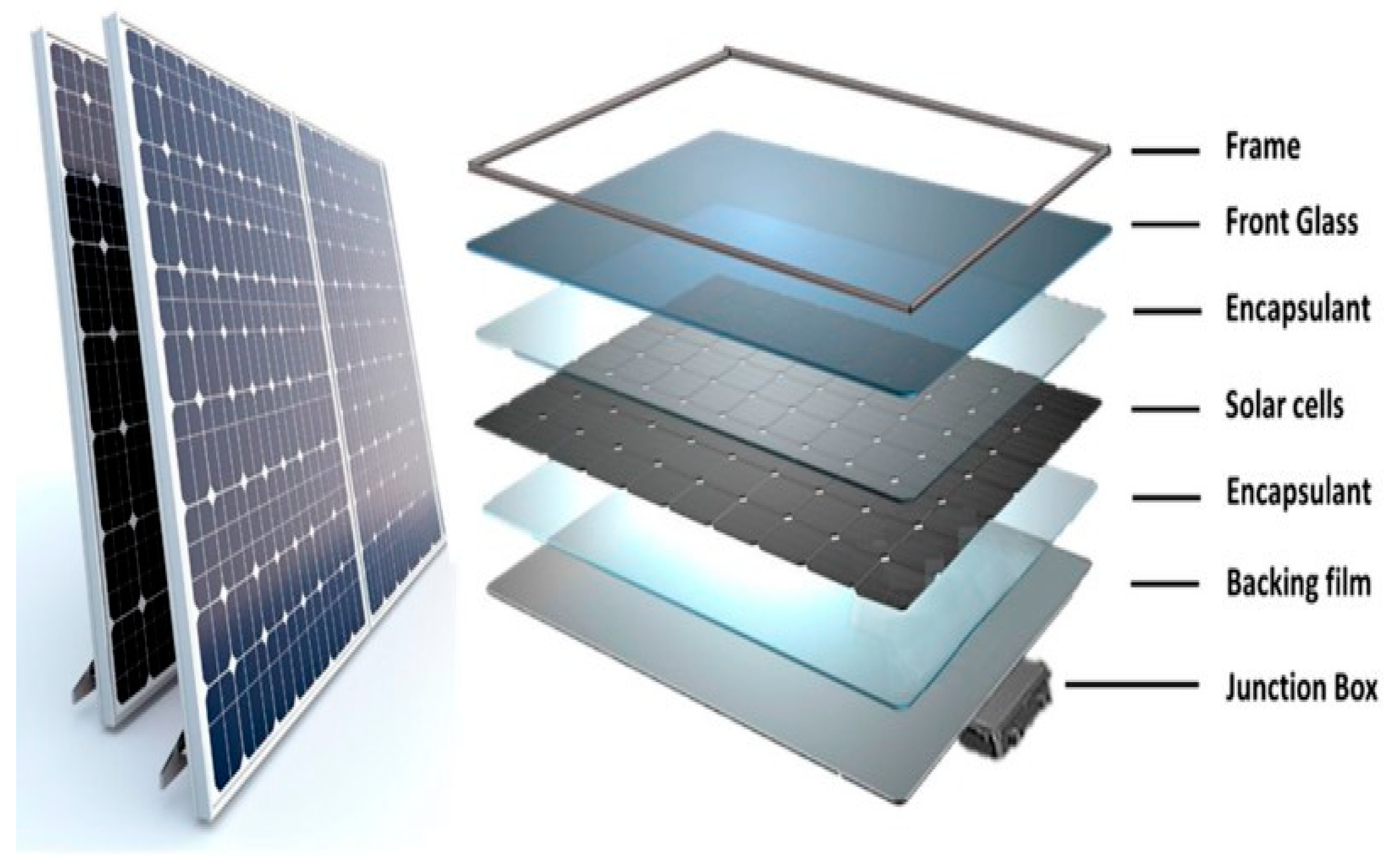

23], legislation and equipment geared towards the treatment of spent solar panels modules are rapidly developing in China, with the first treatment demonstration constructed in 2021. When the solar panels reach their EoL, the issue arises of how to dispose of or recycle the spent solar panel components in a way that simultaneously reduces ecological pollution, recovers energy, and reduces the waste volume. Research has been conducted on recycling EoL of PV solar panels, examining treatment technology, including landfilling, stabilization, mechanical separation, and chemical and thermal methods. The components of a PV solar panel are depicted in

Figure 1.

The demand for PV cells has significantly increased due to the considerable improvements in the efficiency and affordability of PV solar panels. However, the fundamental components of these panels have not changed substantially over the years. Most are composed of silicon crystalline cells [

3], which are sandwiched between tempered glass and a back sheet. The most complex component of the solar panel is the solar cells, which are enclosed by two encapsulant–EVA materials; it generates energy and is composed of two electrodes and a silicon wafer. The overall composition of the solar panel includes an aluminum frame (10%), tempered glass (74%), silicon (3%), polymers (6.3%), and other small constituents, including HMs [

25]. These materials are the primary parts of solar panels. Therefore, plasma pyrolysis of DSP is a sustainable technology, as it allows for the recovery of valuable materials, producing hydrogen-rich syngas. It also generates slag, which can be safely disposed of, used as a construction material, or as an additive in anaerobic treatment, reducing waste volume and immobilizing the HMs.

2.1. Landfilling

The development of PV solar panels has led to the emerging challenge of disposing of DSPs. Landfilling is among the various proposed treatment technologies for these panels and is often considered first [

26]. However, this method was reported to emit of greenhouse gases [

27] and result in HM contamination of ground water and soil [

28]. Currently, PV waste is classified as electronic waste, but in many countries with a high installation rate of solar panels, there is insufficient attention to address the treatment of spent solar panels [

29]. This lack of focus suggests that EoL solar panel waste is typically managed as solid waste. Landfilling remains the most convenient method of disposing of EoL PV solar panels. In Australia, for example, DSPs are transported to landfill sites from their places of operation [

30]. However, measures are taken to mitigate leaching and prevent toxic materials from contaminating the soil or ground water. The study concludes by advising against landfilling as the best disposal method for spent PV panels, as they may break during disposal or transportation. In 2006, the USA incentivized the use of solar panels by providing financial assistance to those who installed them, but lacked a comprehensive strategy for their disposal at the end of their lifetime [

31]. In the USA, landfilling is the most common disposal method, followed by recycling and secondary use. This preference is influenced by the comparatively low cost of landfilling, with fees ranging from USD 30 to 70/ton depending on the geographical location. In contrast, the recycling process can cost between USD 15 and 45 per PV module, while landfill costs are between USD 1 and 5 per PV solar module, excluding transportation fees [

32]. Public and private companies often choose landfilling due to financial considerations among others.

Ramos-Ruiz et al. (2017) [

28] investigated the leaching of HMs from thin-films panels under simulated landfill conditions. Their study reported that within one month, around 21% of the Te and 73% of the Cd were released into the synthetic leachate of a continuous-flow column designed to mimic the acidic phase of a landfill. Nain et al. (2020) [

33] also investigated the contamination from EoL solar panels by exposing the broken and unbroken panels to three synthetic solutions of pH 4, 7, and 10, as well as to real municipal solid waste landfill leachate over a period of 12 months. They discovered that the release of metals into a solution simulating rainwater included up to 13.05% Cr, 17.6% Pb, and 26.9% Ag. In contrast, the release of HMs in the real landfill leachate was lower than the other leaching solutions for all types of PV solar panels tested, indicating that pH levels and the condition of the modules significantly affect HM leaching. Using the Eco-Invent database and life cycle assessment (LCA) methodology, the environmental impacts of disposing of spent solar panels in landfills were evaluated in comparison with two other treatment methods [

34]. The results suggest that the landfilling method poses a substantial ecological risk due to the contamination from metals present in the waste materials of the original solar panels. Proper treatment of EoL solar panels can significantly mitigate the environmental harm that might be caused by improperly treated spend panels.

2.2. Stabilization

The stabilization process is considered as a means to transform DSP into other valuable substances. However, there have been relatively few studies on this treatment technology. Pavlopoulos et al. (2022) [

35] carried out a study on EoL PV solar panels using a stabilization technique involving Portland cement. They processed the discarded first-generation crystalline silicon PV panels, which were cut into 40 × 30 mm pieces and placed in a furnace at 823.15 K to remove EVA and polymer sheets. Afterwards, the resulting mixture consisting of silicon flakes, ash, electrodes, and soda lime glass was separated using a trommel screen. Through this process, the silver electrode was successfully recovered, and the remaining fractions were used in cement mortar as an aggregate. This study revealed that soda lime glass contributed to the mechanical strength of the mortar, achieving results close to the reference. However, the mortar containing the mixed fraction and semiconductor displayed lower final values and slower rates of compressive and flexural strength development compared to the reference mortar. This reduced performance was attributed to the presence of aluminum on the back side of the semiconductor, which led to expansion in the sample and gas generation within the cement paste.

The study by Sandanayake et al. (2022) [

4] proposed the use of different waste materials from solar panels, such as glass, aluminum (Al), silicon (Si), and polymer waste, as potential replacement materials in various types of pavement construction. Although the stabilization treatment method seems effective and sustainable for DSP treatment, this process faces certain limitation. The toxicity of HMs, such as Pb, Ag, Zn, Cu, Al, Sn, Mo, Se, In. and Ga. was found in mortar containing waste from both the first and second generation of crystalline silicon PV panels [

36]. Moreover, secondary pollution may occur through the use of EoL solar panel modules in some processes, such as construction.

2.3. Physical Separation

Materials such as aluminum, copper, and steel can be mechanically removed and sold on the scrap metal markets, while front glass can be reused in the fabrication of secondary products or recycled. However, although the bulk of non-module PV constituent materials can be directed to the scrap metal recycling market, inverters and modules are considered electronic waste, lacking robust handling pathways comparable to those for scrap metal markets or for recycling non-module components [

32]. The physical separation of PV panel modules begins with the removal of the aluminum frame and junction box. Afterward, silicon can be commercialized, and the modules can be shredded into small parts and crushed into fine particles. Subsequently, solar cells, polymers, cell stringing ribbons, and glass can be separated using sifting and eddy current technique. As previously mentioned in

Section 2.1, recycling costs for PV modules are much higher than landfill costs. This is explained by the fact that the costs of the substances obtained, such as cadmium telluride and silicon PV modules, are much cheaper compared to their recycling processes, hence no profit for recyclers. For instance, Al-Aqqad et al. (2023) [

36] report that the cost of virgin materials is USD 46.56/1 m

2 and USD 42.97/1 m

2, while the cost of recovered materials is only USD 6.72/1 m

2 and USD 5.71/1 m

2 for private cost and external cost, respectively.

In China, research on physical treatment for PV recycling was examined, involving the separation and recycling of materials using abrasive machining combined with electrostatic and cryogenic conditions [

37]. However, this process was inefficient for recycling silicon due to the high impurities in the resultant silicon. The study compared this method with advanced recycling technology of PV modules adopted in Europe and concluded that PV recycling techniques in China must be developed to handle the huge amount of PV waste that will be generated in the near future. The study conducted by Bogust et al. (2020) [

38] emphasizes that for successful removal of some materials from DSP, it is essential to integrate the treatment process with other techniques, such as chemical and thermal processes. This method alone cannot remove EVA, as other materials may become mixed with EVA during processing [

39]. Additionally, valuable substances such as silicon and other chemical elements cannot be fully recovered without further treatment. This mechanical process also leads to the production of a considerable amount of glass dust, which is a source of noise pollution, and there is a risk of contamination from HMs when modules are mechanically dismantled. Moreover, during the separation process, the panel components are crushed, making it impossible to recover those components without damage [

40].

2.4. Chemical Treatment

Chemical treatment of DSP refers to the use of chemicals reagents to recover intact module metal fraction materials. A decade ago, Kim et al. (2012) [

41] investigated dissolution of EVA using numerous organic solvents including toluene, benzene, O-dichlorobenzene, and trichloroethylene. After studying different experimental conditions such as temperature, irradiation time, solvent concentration, and ultrasonic powers, the study concluded that EVA can be completely dissolved with 3 M of toluene at 343.15 K and 4.5 × 10

−7 GW of ultrasonic radiation, while under ultrasonic irradiation, PV cells can be recovered using O-dichlorobenzene solvent. In addition, a chemical process to recover silicon wafer using HNO

3 and KOH to extract silver and for removing aluminum metal, respectively, was developed [

42]. A solution of various reagents including ethanoic acid, HNO

3, Br, and HF was successfully used for the removal of the anti-reflective layer. Dias et al. (2016) [

43] reported a technology for recycling silver from silicon PV modules. After mechanical removal of the aluminum frame, the panels were sliced into very small pieces then crushed and sifted to achieve fractions of approximately 0.5 mm. Afterward, the fine fraction was leached in 64% HNO

3 and subsequently treated with NaCl to precipitate AgCl. This technique yields a high concentration of silver, with a recovery rate of 94%. Furthermore, Jung et al. (2016) [

44] focused on the recovery of copper, silicon, lead, and silver from PV panels. By immersing the solar cell in a 5 M HNO

3 solution for metal dissolution, several elements, including lead, silver, copper, and silicon, were recovered with yields of 93%, 90%, 80%, and 79%, respectively.

Silicon and silver were recovered through a leaching and extraction process. The solar cell was leached in 4 M HNO

3 followed by 3 M NaOH, achieving leaching efficiencies of 99.9% for aluminum and 99.7% for silver [

45]. With the aim of separating silver and aluminum, Na-Cyanex 272 in kerosene was used, hydrochloric acid was used to strip aluminum from organic solution, while silver was precipitated from aqueous phase to AgCl. The leaching method allows silicon separation from other metals, and its recovery rate was 99.5%. Despite its ability to extract several valuable elements, chemical treatment often involves long reaction times that increase with module area. The process also has some disadvantages. For instance, if the solvent employed is not reused, it leads to the generation of a huge amount of volatile organic waste liquid, which is challenging to treat [

46]. In terms of waste solvent treatment, in most of cases, it is impossible to achieve the integration recovery, and some extraction processes may take more time and also emit greenhouse gases along with other harmful gases that pose a health risk when inhaled. The use of both inorganic and organic solvents to separate EVA can lead to nitrogen oxide (NO) emissions [

47]. Moreover, the loss of conventional rare materials, such as aluminum and glass, is a concern. Chowdhury et al. (2020) [

48] reported that the EVA can be effectively removed by using nitric acid. However, it will lead to cell damage because of the inorganic acids which reduce the recovery rate of metals from spent PV modules. Chemical treatment is also contingent upon the possible pre-treatment method, such as thermal or physical separation, and it also depends on the use of hazardous reagents. This makes the technology environmentally unfriendly and economically unviable compared to other existing treatment methods.

2.5. Thermal Treatment

A thermal process can be used to remove encapsulant after some other treatment method, such as physical separation; this technology can also be used to recover other EoL solar panel components, such as silicon and silver solar cells and glass, without breaking them [

49]. The study by Frisson et al. (2020) [

50] proposed thermal technology as an acceptable treatment over DSP. The method involves introducing the entire PV solar panel into a conveyer belt furnace under a nitrogen environment to allow the breakdown of EVA. Moreover, this technique was used for the recovery of valuable materials, for example, metal, glass, and silicon, from modified crystalline silicon modules [

51]. This study used two thermal steps; the first and second processes were carried out at 603 K and 673 K to allow the separation of Tedlar

® from PV modules and burn out the EVA to recover intact glass plate, ribbons, and cell ships. The glass plate can be immediately recycled at the end of the treatment process to be used as a component in a new module. Doni et al. (2012) [

52] performed an electrothermal method with very low temperature, which cannot decompose EVA but only heats the core of the PV silicon panel and allows easy removal of the glass chips. Afterwards, the glass fragments can be used as raw materials in glass recycling companies, whereas a minority of the module samples can be treated to recover other valuable materials. Wang et al. (2022) [

16] performed pyrolysis of DSP in two different reactors, including bubbling fluidized bed (BFB) and fixed bed (FB) reactors. The results show that BFB is more efficient for EVA removal and has a more constant temperature distribution than FB. This research studied key parameters, including superficial gas velocity and wall temperature. The study concluded that the wall temperature has a remarkable effect on the degree of EVA removal and product yield. Due to the increase in temperature from 723 K, 773 K, and 823 K, the EVA removal increased by 91.03%, 94.89%, and 99.99%, respectively.

According to Wang et al.’s (2019) [

15] study, the pyrolysis process is an effective treatment for separating PV modules. EVA binder was removed at 773.15 K, along with the production of acetic acid and other numerous valuable hydrocarbon compounds. However, this process can be regarded as the best treatment and most productive in EVA removal, as it allows around 90% of PV modules to be recycled. However, it has been reported to consume a large amount of energy and impose costly gas processing methods, which hinder its application [

53]. After the pyrolysis process, no energy recovery is anticipated because the generated gases are condensed [

54]. The study of Frisson et al. (2020) [

50] was found to be the only study proposing energy recovery through combustion of pyrolytic products. In addition, Farrell et al. (2019) [

55] suggest that an alternative pathway to promote environmental and economic sustainability of the technology is thermal decomposition of the polymeric materials from PV panels. Application of the pyrolysis process on solar panels is also hindered by fluorine transfer into the gas phase from back sheets during thermal treatments [

18]. The authors concluded that the residues produced from pyrolysis contain fluorinated compounds, which introduce secondary pollution and make it more difficult to the design post-thermal section. Therefore, the back sheet is often removed before the pyrolysis process, and the treatment is subsequently performed. Due to the presence of HMs in PV module panels, pyrolysis was reported as an inefficient process for treating HMs containing waste, as solid residues and gas phases from the process were found to contain hazardous HMs [

56]. In this sense, treatment technology that promotes energy recovery, resolves fluorine formation in the product gas phase, and immobilizes the existence of toxic metals in solid residue is highly required. All the treatments were compared in terms of environmental impact, efficiency, waste mass processing, speed of processing, and state of material recovery. Plasma pyrolysis is the fastest among all methods and promotes recovery of valuable materials such as syngas and slag in an environmentally friendly way compared to other processes.

Plasma pyrolysis technology presents a more environmentally friendly alternative to traditional waste disposal methods such as landfilling and incineration. It has demonstrated greater environmental benefits in terms of global warming potential compared to these conventional methods [

57]. Plasma pyrolysis also yields lower pollutant emissions and higher conversion efficiencies, leading to a lower carbon footprint [

58]. Additionally, plasma pyrolysis facilitates the production of valuable products such as syngas and hydrogen, which can be used for energy generation [

59]. The implementation of plasma technologies in energy production can also help to reduce the emissions of harmful flue gases from thermal power plants, thereby contributing to a cleaner environment [

60]. Overall, plasma pyrolysis technology is a sustainable waste management option with minimal environmental impact and energy consumption [

61]. Furthermore, this technology offers the advantage of being able to handle large quantities of EoL PV solar panels. The treatment methods, along with the merits and demerits of the aforementioned processes, are comprehensively outlined in

Table 1.

3. Toxicity and Environmental Pollution from Discarded Solar Panel

The treatment of PV panels has not been extensively exploited, and consequently, each proposed recycling method has its own merits and demerits. Generally, the treatment of spent PV modules is complex, as some techniques only recover impure materials, produce liquid waste, emit harmful gases, form fluorinated compounds, are insufficient for mobilizing toxic HMs, and extract low concentrations of valuable materials from DSP. Improper disposal of PV panels after EoL not only results in the loss of raw materials that could be reused in some treatment processes and valuable compounds, but also poses environmental problems. Consequently, the recycling of PV modules is highly required to address various related challenges. In this context, the issues regarding contamination of the EoL PV solar panel modules must be scrutinized from different perspectives. Tammaro et al. (2016) [

5] investigated the potential of eco-toxicological pollution from broken or spent PV solar panel modules, comparing crystalline silicon and thin-film solar panels. The results showed that both could release considerable amounts of hazardous HMs including Cr, Ni, Pb, and Cd, exceeding legal limits for water and soil. Moreover, the contamination of water with these metals can have harmful effects on aquatic creatures, especially algae. PV cells are made of different substances that can be classified into carcinogenic and non-carcinogenic materials [

63]. When these substances come into contact with humans or animals via skin adsorption, breathing, or ingestion, they are responsible for tumor formation. They can also badly affect the nervous system, weaken the immune system, reduce growth, and damage the reproductive system.

In addition, Su et al. (2019) [

8] examined the ecological problems associated with the disposal of spent thin-film solar panels as domestic trash. They used acid extract to simulate acid and HM leaching toxicity and buried this panel module in the soil. The results showed that HMs were dissolved into the soil, and the increase in the metal levels correlated with the residence time and amount of spent PV modules added. The cumulative EoL PV solar panel waste (millions of tons) in high-producing countries is presented in

Figure 2.

From

Figure 2, it is projected that by the end of 2030, the countries expected to generate the highest amount of spent solar panels are China, Germany, and Japan [

64]. In the mid-21st century, China will still be the top country, with the greatest volume of PV waste, followed by the USA. This scenario presents high environmental pollution from EoL solar panels if they are not properly treated or disposed of.

Figure 3 shows the potential value creation through the management of spent PV solar modules.

Globally, different policies are made to treat the broken or discarded panels after EoL to reduce pollution; however, the proposed treatment methods have proven to be inefficient. Thus, the proper management of spent PV modules is of great importance, both for energy production and the recovery of valuable materials that would otherwise be wasted if landfilled [

30]. In this context, Tammaro et al. (2015) [

56] studied the release of metals in the solid residue and gas phase during the thermal treatment of panels. The authors found significant amounts of toxic HMs such as Cr and Pb in the gas phase, which may cause ecological issues if released into the environment. It is also recommended that the residues (char) be disposal of properly. As a single solar panel is made of 12.67 g of Pb, this is a high amount, and it must be effectively disposed of. The study reported that between 13% and 90% of the Pb amount that is present in each EoL unit could be released to the environment by factors such as rainwater. Consequently, there is a risk of significant environmental contamination, with a large amount of HMs, such as Cd (2.9 tons) and Pb (30 tons) released by 2050, posing a substantial threat to the ecosystem [

5].

Moreover, due to the use of many solvents in the chemical treatment of DSP, particularly with the aim of recycling wafers or valuable metals, other challenges may arise. Müller et al. (2006) [

54] recovered silicon wafers from Deutsche PV panels. The study finds that the wafer can be recovered by using less energy compared with the energy needed to generate a virgin wafer. However, Klugmann-Radziemska et al. (2010) [

42] reported that the chemical waste liquid used to recover pure silicon from EoL PV cells contains a huge amount of hazardous hydrofluoric acid and nitrogen oxides, which demand expensive and complex treatments. The physical separation produces harmful noise and dust, and the thermal treatment, such as pyrolysis, consumes a lot of energy with a by-product that contains many impurities [

24]. The use of organic solvent to remove EVA from EoL solar panels takes a long period of time, which leads to inefficiency and the additional problem of wastewater treatment. For instance, to dissolve the polymer by using isopropanol and trichloroethylene, the reaction time takes two days and ten days, respectively. Moreover, the spent PV modules not only contaminate the soil but also occupy a large surface area of land, which leads to the improper exploitation of land. The inefficiency of the existing treatment methods and the lack of sustainable solutions and suitable treatment processes, such as plasma pyrolysis, to treat large volumes of the EoL PV waste could lead to complex ecological problems.

Plasma pyrolysis technology has been extensively studied for its environmental impact and sustainability, including evaluation through LCA to measure and assess its environmental benefits. LCA is the prevailing approach used to evaluate the performance of plasma pyrolysis in terms of its impact on various domains such as environmental, technical, economic, and social spheres [

57]. In their report, they highlight that LCA studies have shown that plasma pyrolysis has several environmental advantages over other waste-to-energy (WtE) techniques, such as landfilling and incineration. It has been found to reduce or eliminate toxicity and pollution issues, while also diverting waste from open dumps or landfills and producing renewable energy and/or by-products. Utilizing LCA tools in the evaluation of plasma pyrolysis aligns with the principles of the circular economy and aids the transition towards a more sustainable society. Overall, plasma pyrolysis technology offers a promising future for effective treatment of solid hazardous waste with minimal environmental impact.

4. Assessment of Plasma Pyrolysis Process

Plasma pyrolysis is the breakdown of organic compounds into syngas and non-leachable solid residues in an oxygen-free atmosphere. This process uses ions, excited molecules, high-energy radiation, and a large fraction of electrons to decompose chemical compounds. Furthermore, chemical and physical reactions occur very fast within the plasma chamber. Near the end of the 20th century, plasma pyrolysis appeared as a sustainable technology, which provides a suitable solution to destroy some hazardous waste, including medical waste, plastics, sewage sludge, biomass, and industrial waste, in both an environmental and economic manner. The versatile and intense heat generated by plasma torches allows the treatment of different types of waste materials, such as municipal solid waste [

65], medical waste [

66], polymer waste [

67], sewage sludge [

68], and other hazardous waste materials in a reliable and safe manner. This treatment process has a constant temperature supply because of the plasma equilibrium within temperature ranges around 10

6 to 10

8 K. The strong energy supplied to the plasma carrier gas (including nitrogen, hydrogen, or argon), facilitates the production of electrons and ions. During the ionization phase of the carrier gas, electrons strike with atoms to produce cations, anions, and electrons [

69]. Since gas molecules start to be ionized at 6000 K, the plasma arc should be set above this temperature.

Based on Bhatt et al. (2022) [

57], there are three types of plasma pyrolysis: radiofrequency plasma, DC/AC arc plasma, and microwave plasma, which are produced by capacitive coupled plasma or inductive coupled plasma, generated by two electrodes via plasma carrier gas and magnetron, respectively. This technique is performed by integrating the thermochemical characteristics of pyrolysis and plasma to degrade wastes. Parcon’s transportation plasma environment technology is designed and developed to breakdown the environment’s most challenging wastes, such as chlorinated or fluorinated organic compounds. The destruction and removal efficiency exceeds 99.99%. For example, the Parcon emission of furans and dioxins has been documented at between 0.005 and 0.009 nanograms per cubic meter (ng/m

3), which is significantly below the environmental standard around the world. The plasma pyrolysis technology is effective and utilized to treat numerous waste materials on an industrial scale worldwide with significant economic value [

57]. Comparing plasma pyrolysis with other types of pyrolysis methods has been widely presented and discussed [

70]. Plasma pyrolysis offers several advantages, including high efficiency for HM removal, negligible emission of toxic gases, thermal stability, resource recovery, short reaction time, and a significant decrease in the volume of waste [

68]. The past and recent studies on the valorization of wastes under the plasma pyrolysis process are shown in

Table 2.

As presented in

Table 2, plasma pyrolysis has great efficiency in the production of hydrogen-rich syngas with other value-added combustible gases. In addition, a specific type of plasma pyrolysis is applied according to the type of waste. Thus, suitable and effective plasma techniques for treating DSP must be evaluated in future study. Due to the fact that the demand for hydrogen (H

2) is growing day by day, by the mid-21st century, the H

2 market potential is estimated to reach USD 2.5 trillion in the USA [

83]. Moreover, the design of the plasma reactor is essential, as it may affect heat transfer, collision of molecules, residence time, and by-products. Thus, construction materials need to have sufficient efficiency to endure the high temperature of the process and avoid loss of heat [

57]. Plasma technology demands a high supply of voltage power, which impedes its transition from the laboratory level to industrial-scale application. However, thermal plasma treatment of medical waste is industrially in use [

84]. Therefore, a pilot-scale study must be developed to check the electrode selection, distribution of temperature, and stability of the high-voltage energy source before leveling it up to the industrial scale. This will create safe disposal of broken or EoL solar modules, promote the circular economy, and reduce the environmental burden related to the inappropriate treatment of spent PV solar panels. The solar e-waste glut is coming in the near future.

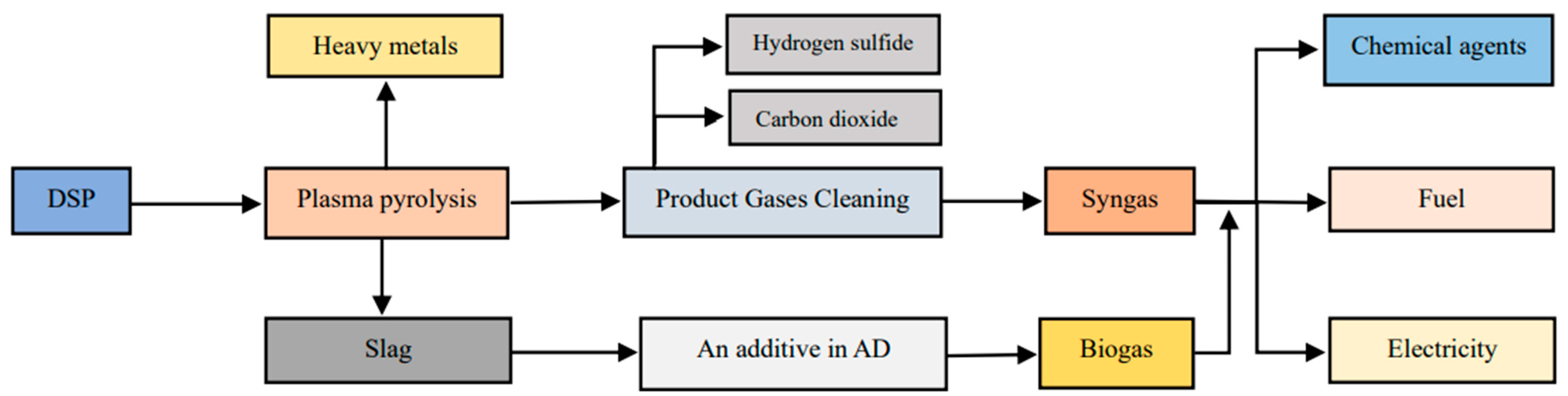

5. Treatment of Discarded Photovoltaic Solar Panels under Plasma Pyrolysis

Thermal plasma pyrolysis is a well-known technique that combines the characteristics of pyrolysis and plasma to break down solid wastes into syngas and slag under oxygen-free conditions [

57]. This technology is more suitable for converting large volumes of DSPs and not only produces the aforementioned products, but also allows for the adsorption of HMs. When plasma pyrolytic products are used as an additive in the anaerobic digestion process, this enhances resource utilization in terms of nutrient recovery and energy production. However, both are thermal processes and performed in an oxygen-free atmosphere, but plasma pyrolysis consumes more energy compared to AD. To fully benefit from EoL PV solar panels, DSPs have to be treated with plasma pyrolysis to produce syngas, which is further upgraded to produce electricity, heat, and fuel. The resulting slag can be used as additive in other treatment processes, such as AD, to mitigate inhibitors, stabilize the reactor, improve microbial performance, regulate of pH, and reduce COD. This will result in the high production of biogas, and the enhancement of nutrient recovery. The digestates from the AD treatment can serve as an organic fertilizer to improve soil properties. In addition, integration of both treatment processes will highly increase the production of energy such as syngas and biogas, which can operate the entire plasma pyrolysis and AD process. This integration may solve the energy source burden of powering the treatment plant as well as addressing the ecological challenges posed by untreated or ineffective treatment of DSP.

EoL PV solar panels consist of an encapsulant, solar cell, HMs, polymer, and other materials [

20]. This makes spent solar panels great feed for plasma pyrolysis to recover HMs and produce syngas with slag. Thereafter, slag must be employed as an additive in AD to improve energy recovery and utilize every resource from DSP. The AD process is well-known to treat organic waste materials; therefore, the direct feed of EoL PV modules is not optional, owing to the fact that DPS is considered electronic waste products. The HMs can be recovered through the plasma pyrolysis process [

68]; therefore, DSP should first be treated with plasma pyrolysis for syngas production and to recover valuable materials, such as HMs and other chemical agents, and for slag generation, which will further be used in the AD process for full resource utilization. By-products from both processes can be cleaned and advanced to produce H

2 and methane, which are great sources of energy, while slag will enhance the overall performance of the AD process and improve the digestates’ properties, which will be applied as soil amendment. The pathway of the plasma pyrolysis process of DSP is shown in

Figure 4.

As shown in

Figure 4, the entire DSP can be introduced into the plasma pyrolysis process. This technology uses high temperatures, not only to decompose DSP but also to break down materials that currently contribute to landfill waste. Moreover, the high temperatures facilitate the vaporization of hazardous HMs from EoL PV panel modules, allowing for their recovery in the gas phase. The HMs which are present in spent solar panels must be identified beforehand, as different models of DSP contain different amounts of HMs, each with a specific vaporizing temperatures [

85]. This will help in the clean production of syngas and slag, as well as avoid the formation of harmful gases such as fluorine. Plasma pyrolysis provides advanced chemical reaction dynamics with the availability of any type of working gas and sufficiently high temperatures [

86]. This promotes destruction and removal of non-degradable toxic gases and suppresses the generation of undesirable by-products. Chen et al. (2019) [

87] reported that fluorinated compounds could be destroyed by high-temperature plasma, with a removal efficiency exceeding 99.99%.

Therefore, plasma pyrolysis of DSP is more profitable, as it allows the recovery of valuable materials such as HMs and fluorine, which can be employed in several industrial fields. Moreover, the produced syngas will be refined to produce electricity, heat, chemicals, and H

2 to be applied in different industrial applications as clean fuel. Previously, slag was used for construction, which underutilizes its resource potential and may cause secondary pollution. Recently, Çalhan et al. (2022) [

88] reported slag as a good additive in AD, as it enhances the production of biogas, stabilizes digesters, reduces COD as well as inhibitors, and improves the digestates’ properties. The produced biogas can be polished to generate methane for electricity and heat, while the digestates will be used as soil conditioner. Therefore, this technology can serve as the best DSP disposal route, as it allows the utilization of resources from EoL solar panels through thermal breakdown of hazardous materials such as fluorine and recovers HMs in an economic and environmentally friendly manner.

Techno-Economic Performance of Discarded Photovoltaic Solar Panel via Plasma Pyrolysis

Plasma pyrolysis is a well-known technology that significantly reduces the high volume of solid waste and allows recovery of the valuable materials. In this review, it was recommended as a suitable and ecological treatment process for DSP. In addition, integrating this process with AD will be more profitable in terms of energy production and recovery of valuable materials. However, spent solar panels are complex and hazardous, as they contain HMs and polymers that are made from fluorinated compounds. Contrary to that, those constituents make DSP a great feed to the recommended technology. Moreover, this method will result in the high production of syngas from the thermal breakdown of the EoL PV modules. The produced syngas is the best source of H2, electricity, fuels, and other high-value-added chemicals that can be commercialized in different targeted markets.

In addition, the breakdown of solid waste and adsorption process of HMs strongly depend on the temperature in the plasma pyrolysis reactor. In Zhao et al.’s (2022) [

85] study, the effect of high-temperature (attapulgite) adsorbents on the migration and transformation mechanisms of HMs was investigated by comparing them to conventional adsorbents (kaolin). The author reported that attapulgite showed higher adsorption than kaolin due to more active sites and smaller crystal distortion, which increased the surface area. It was revealed that Zn and Pb are more volatile, while Cr, Cu, and Ni are low-volatility HMs. The high- and low-volatility HMs were attained from fly ash and bottom slag by Si-Al-based absorbents, respectively. Thus, HMs can be adsorbed through plasma pyrolysis in a chemical-free method, which solves ecological and economic problems, as there is no use for chemical reagents. Adsorbed HMs can also bring additional cash when sold or applied in other industrial processes.

Furthermore, the slag generated from the proposed technology can be employed on farmland to improve soil properties. Slag is a valuable source of Fe, Mg, N, P, and K, which are essential nutrients for agriculture and act as fertilizer [

89]. Producing slag through DSP plasma pyrolysis will increase the supply in the market, potentially reducing costs. Additionally, many researchers have reported the utilization of slag as an additive to stabilize and improve AD treatment [

88]. The slag enhances the production of biogas from AD, with methane and carbon dioxide as major constituent gases, which can be upgraded to generate energy, heat, and electricity. Therefore, slag generated from EoL PV solar panels is another value-added material that could be sold, thereby influencing the reutilization of carbon and mitigating environmental pollution caused by untreated spent PV modules. Moreover, slag increases valuable nutrients of the digestates from AD, which is employed as an inorganic fertilizer to amend soil properties. Despite a large part being decomposed in AD for biogas production, the remaining digestates can be applied as soil conditioning for full utilization of the resources. In addition, the proposed route offers a zero-waste outcome from DSP, where all by-products become high-value products that further encourage a circular economy.

The economic feasibility will highly depend on many factors, for example, the cost of value-added products (such as H

2, CH

4, slag, HMs, and other chemical products), capacity of the plant, and the cost of electricity. Generally, plasma pyrolysis of DSP coupled with AD is an affordable process in terms of value -added products and environmental conservation compared to other existing EoL PV solar module treatment processes. The energy produced from both treatment processes can power the entire plant or be commercialized, which will provide another source of income. Moreover, the slag or oil from plasma pyrolysis can be converted into valuable products to be sold as biochar fuel. Referring to the Galaly et al. (2022) [

90] study, which reported the techno-economic feasibility of medical waste treatment via thermal plasma pyrolysis, in the kingdom of Saudi Arabia, especially in Makkah, the average annual weight of medical waste in hospitals is 2835 × 10

3 tons, with an extracted amount of pyrolysis oil equivalent to 2268 × 10

3 tons and an equivalent energy of 90 × 10

9 M J. Through plasma technology, after distillation, the diesel oil reaches up to 1928 × 10

3 tons, with an estimated sale profit of electricity reaching up to 21 × 106 MW·h. Moreover, in 2022, the sales profits of pyrolysis oil were USD 34.44 million, and the sales profits of electricity extracted by using diesel oil reached up to USD 1445 million for factories and USD 1020 million for households. Therefore, this detailed analysis of the economic feasibility of plasma pyrolysis of medical wastes shows the great income potential of plasma pyrolysis of EoL PV solar panel modules, as a great mass of spent panels will be generated in the near future. Moreover, this review proposed the integration of the plasma pyrolysis process with AD treatment for additional cash streams. Future research is crucial to ascertain the precise financial potential of the proposed technology.

6. Challenges and Recommendations

Recently, several studies have been conducted to evaluate various disposal pathways of EoL PV panels to recycle valuable materials and lower environmental pollution. These proposed methods include the decomposition of EVA [

15], stabilization [

35], physical separation [

37], silicon [

42], and HMs [

45]. Several challenges exist, however, and future recommendations are necessary for the application of plasma pyrolysis in treating DSP. This technology uses extremely high temperatures to decompose spent solar panels, with great waste mass reduction of around 95%, leading to the production of syngas and non-leachable solid residue. The generated syngas can be upgraded to produce H

2, fuel, electricity, and other value-added chemical compounds, while the rich carbon slag can be employed in the AD as an additive or as a soil conditioner. The plasma technology takes full advantage of solid waste by converting it into value-added products. Nevertheless, the implementation and development of plasma technology has not been fully exploited or studied. This review emphasizes the need to improve recycling efficiency, investigate co-plasma pyrolysis to increase H

2 yield in syngas, and develop industrial applications for other value-added products. In addition, the polymer component from DSP was reported to contain hazardous HMs [

91]. Hence, comprehensive adsorption of HMs from plasma pyrolysis technology must be examined to avoid environmental pollution.

Plasma pyrolysis technology offers a promising solution for the effective treatment of solid waste, including hazardous waste, while simultaneously generating valuable products such as syngas and hydrogen [

57]. The design of plasma reactors and the selection of plasma design are important considerations in the implementation of this technology. Optimizing processes, including factors such as current supplied, temperature, and feed flow rate, plays a crucial role in achieving efficient and sustainable waste management [

92]. The invention of plasma pyrolysis devices, with features such as ionization and activation of the processing medium, high-temperature plasma arc processing, and ease of obtaining target products, further enhances the potential of this technology [

57]. However, challenges in scaling up the technology for commercial applications, including system configuration, operating parameters, and the need for efficient solar pyrolysis reactions, need to be addressed. Furthermore, given the complex chemical composition of PV module panels, the characterization of the carbonaceous solid residue is imperative to prevent secondary pollution. Another future task includes the optimization of plasma pyrolysis parameters to maximize recycling, H

2 production in syngas, and the adsorption of HMs. Factors such as temperature, reaction time, and rate are pivotal, affecting the recovery of high-value-added materials, the vaporization of HMs, and the physicochemical properties of the solid residue. In the past decades, PV solar panels have been installed all over the world, especially in developed and developing countries. Thus, it is anticipated that thermal plasma pyrolysis technology will play a significant role in processing the substantial amount of DSP expected in the near future. Consequently, improving treatment efficacy and assessing the exact techno-economic feasibility of this technique are of great importance in advancing sustainable plasma pyrolysis treatment for EoL solar panel modules and promoting a circular economy.