CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles

Abstract

1. Introduction

2. Literature Review

- Different BEVs and FCEVs were considered in the study and were compared to other studies where only one type of vehicle was taken into account, or only one battery vehicle and one hydrogen vehicle were selected, meaning that different fuel consumptions and battery or tank capacities were studied;

- Hydrogen produced from conventional sources (coal and natural gas) and from renewable energy sources (wind, solar, and hydro) was considered;

- Different power generation mixes for BEVs were considered in the study and are compared to those of other studies where the power mix did not change.

3. Materials and Methods

4. Results

5. Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between hydrogen and electric vehicles by life cycle assessment: A case study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Xiong, S.; Wang, Y.; Bai, B.; Ma, X. A hybrid life cycle assessment of the large-scale application of electric vehicles. Energy 2021, 216, 119314. [Google Scholar] [CrossRef]

- Elshurafa, A.M.; Peerbocus, N. Electric vehicle deployment and carbon emissions in Saudi Arabia: A power system perspective. Electr. J. 2020, 33, 106774. [Google Scholar] [CrossRef]

- Küfeoğlu, S.; Hong, D.K.K. Emissions performance of electric vehicles: A case study from the United Kingdom. Appl. Energy 2020, 260, 114241. [Google Scholar] [CrossRef]

- Nuez, I.; Ruiz-García, A.; Osorio, J. A comparative evaluation of CO2 emissions between internal combustion and electric vehicles in small isolated electrical power systems—Case study of the Canary Islands. J. Clean. Prod. 2022, 369, 133252. [Google Scholar] [CrossRef]

- Armenta-Déu, C.; Cattin, E. Real Driving Range in Electric Vehicles: Influence on Fuel Consumption and Carbon Emissions. World Electr. Veh. J. 2021, 12, 166. [Google Scholar] [CrossRef]

- Buberger, J.; Kersten, A.; Kuder, M.; Eckerle, R.; Weyh, T.; Thiringer, T. Total CO2-equivalent life-cycle emissions from commercially available passenger cars. Renew. Sustain. Energy Rev. 2022, 159, 112158. [Google Scholar] [CrossRef]

- Xia, X.; Li, P.; Xia, Z.; Wu, R.; Cheng, Y. Life cycle carbon footprint of electric vehicles in different countries: A review. Sep. Purif. Technol. 2022, 301, 122063. [Google Scholar] [CrossRef]

- Gryparis, E.; Papadopoulos, P.; Leligou, H.C.; Psomopoulos, C.S. Electricity demand and carbon emission in power generation under high penetration of electric vehicles. A European Union perspective. Energy Rep. 2020, 6, 475–486. [Google Scholar] [CrossRef]

- Fuinhas, J.A.; Koengkan, M.; Leitão, N.C.; Nwani, C.; Uzuner, G.; Dehdar, F.; Relva, S.; Peyerl, D. Effect of Battery Electric Vehicles on Greenhouse Gas Emissions in 29 European Union Countries. Sustainability 2021, 13, 13611. [Google Scholar] [CrossRef]

- Koengkan, M.; Fuinhas, J.A.; Teixeira, M.; Kazemzadeh, E.; Auza, A.; Dehdar, F.; Osmani, F. The Capacity of Battery-Electric and Plug-in Hybrid Electric Vehicles to Mitigate CO2 Emissions: Macroeconomic Evidence from European Union Countries. World Electr. Veh. J. 2022, 13, 58. [Google Scholar] [CrossRef]

- Zimakowska-Laskowska, M.; Laskowski, P. Emission from Internal Combustion Engines and Battery Electric Vehicles: Case Study for Poland. Atmosphere 2022, 13, 401. [Google Scholar] [CrossRef]

- Sobol, Ł.; Dyjakon, A. The Influence of Power Sources for Charging the Batteries of Electric Cars on CO2 Emissions during Daily Driving: A Case Study from Poland. Energies 2020, 13, 4267. [Google Scholar] [CrossRef]

- Neugebauer, M.; Żebrowski, A.; Esmer, O. Cumulative Emissions of CO2 for Electric and Combustion Cars: A Case Study on Specific Models. Energies 2022, 15, 2703. [Google Scholar] [CrossRef]

- Boretti, A. Supply of abundant and low-cost total primary energy to a growing world needs nuclear energy and hydrogen energy storage. Int. J. Hydrogen Energy 2022, 46, 20136–20145. [Google Scholar] [CrossRef]

- Savari, G.R.; Sathik, M.J.; Raman, L.A.; El-Shahat, A.; Hasanien, H.M.; Almakhles, D.; Abdel Aleem, S.H.E.; Omar, A.I. Assessment of charging technologies, infrastructure and charging station recommendation schemes of electric vehicles: A review. Ain Shams Eng. J. 2023, 14, 101938. [Google Scholar] [CrossRef]

- Reick, B.; Konzept, A.; Kaufmann, A.; Stetter, R.; Engelmann, D. Influence of Charging Losses on Energy Consumption and CO2 Emissions of Battery-Electric Vehicles. Vehicles 2021, 3, 736–748. [Google Scholar] [CrossRef]

- Kim, I.; Kim, J.; Lee, J. Dynamic analysis of well-to-wheel electric and hydrogen vehicles greenhouse gas emissions: Focusing on consumer preferences and power mix changes in South Korea. Appl. Energy 2020, 260, 114281. [Google Scholar] [CrossRef]

- Kothari, R.; Buddhi, D.; Sawhney, R.L. Comparison of environmental and economic aspects of various hydrogen production methods. Renew. Sustain. Energy Rev. 2008, 12, 553–563. [Google Scholar] [CrossRef]

- Shina, J.; Hwang, W.S.; Choi, H. Can hydrogen fuel vehicles be a sustainable alternative on vehicle market?: Comparison of electric and hydrogen fuel cell vehicles. Technol. Forecast. Soc. Chang. 2019, 143, 239–248. [Google Scholar] [CrossRef]

- Khan, U.; Yamamoto, T.; Sato, H. Consumer preferences for hydrogen fuel cell vehicles in Japan. Transp. Res. Part D Transp. Environ. 2020, 87, 102542. [Google Scholar] [CrossRef]

- Jones, J.; Genovese, A.; Tob-Ogu, A. Hydrogen vehicles in urban logistics: A total cost of ownership analysis and some policy implications. Renew. Sustain. Energy Rev. 2020, 119, 109595. [Google Scholar] [CrossRef]

- Tsuchiya, H. Innovative renewable energy solutions for hydrogen vehicles. Int. J. Energy Res. 2008, 32, 427–435. [Google Scholar] [CrossRef]

- Wanitschke, A.; Hoffmann, S. Are battery electric vehicles the future? An uncertainty comparison with hydrogen and combustion engines. Environ. Innov. Soc. Transit. 2020, 35, 509–523. [Google Scholar] [CrossRef]

- Jorgensen, K. Technologies for electric, hybrid and hydrogen vehicles: Electricity from renewable energy sources in transport. Util. Policy 2008, 16, 72–79. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Ho, D.C.K.; So, S.; Tsang, C.-W.; Chan, E.M.H. Life Cycle Assessment of Electric Vehicles and Hydrogen Fuel Cell Vehicles Using the GREET Model—A Comparative Study. Sustainability 2021, 13, 4872. [Google Scholar] [CrossRef]

- Ahmadi, P.; Khoshnevisan, A. Dynamic simulation and lifecycle assessment of hydrogen fuel cell electric vehicles considering various hydrogen production methods. Int. J. Hydrogen Energy 2022, 47, 26758–26769. [Google Scholar] [CrossRef]

- Ajanovic, A.; Haas, R. Prospects and impediments for hydrogen and fuel cell vehicles in the transport sector. Int. J. Hydrogen Energy 2021, 46, 10049–10058. [Google Scholar] [CrossRef]

- Tollefson, J. Hydrogen vehicles: Fuel of the future? Nature 2010, 464, 1262–1264. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- Nagasawa, K.; Davidson, F.T.; Lloyd, A.C.; Webber, M.E. Impacts of renewable hydrogen production from wind energy in electricity markets on potential hydrogen demand for light-duty vehicles. Appl. Energy 2019, 235, 1001–1016. [Google Scholar] [CrossRef]

- Zhang, C.; Greenblatt, J.B.; Wei, M.; Eichman, J.; Saxena, S.; Muratori, M.; Guerra, O.J. Flexible grid-based electrolysis hydrogen production for fuel cell vehicles reduces costs and greenhouse gas emissions. Appl. Energy 2020, 278, 115651. [Google Scholar] [CrossRef]

- Wen, C.; Rogie, B.; Kærn, R.M.; Rothuizen, E. A first study of the potential of integrating an ejector in hydrogen fuelling stations for fuelling high pressure hydrogen vehicles. Appl. Energy 2020, 260, 113958. [Google Scholar] [CrossRef]

- Bethoux, O. Hydrogen Fuel Cell Road Vehicles and Their Infrastructure: An Option towards an Environmentally Friendly Energy Transition. Energies 2020, 13, 6132. [Google Scholar] [CrossRef]

- Robinius, M.; Linßen, J.; Grube, T.; Reuß, M.; Stenzel, P.; Syranidis, K.; Kuckertz, P.; Stolten, D. Comparative Analysis of Infrastructures: Hydrogen Fueling and Electric Charging of Vehicles. Energy Environ. 2018, 408, 1–108. [Google Scholar]

- Gan, W.; Yan, M.; Yao, W.; Guo, J.; Fang, J.; Ai, X.; Wen, J. Multi-Network Coordinated Hydrogen Supply Infrastructure Planning for the Integration of Hydrogen Vehicles and Renewable Energy. IEEE Trans. Ind. Appl. 2022, 58, 2875–2886. [Google Scholar] [CrossRef]

- Longden, T.; Beck, F.J.; Jotzo, F.; Andrews, R.; Prasad, M. ‘Clean’ hydrogen?—Comparing the emissions and costs of fossil fuel versus renewable electricity based hydrogen. Appl. Energy 2022, 306, 118145. [Google Scholar] [CrossRef]

- Ugurlu, A. An emission analysis study of hydrogen powered vehicles. Int. J. Hydrogen Energy 2020, 45, 26522–26535. [Google Scholar] [CrossRef]

- Bacquart, T.; Moore, N.; Storms, W.; Chramosta, N.; Morris, A.; Murugan, A.; Gozlan, B.; Lescornez, Y.; Férat, S.; Pinte, G.; et al. Hydrogen fuel quality for transport—First sampling and analysis comparison in Europe on hydrogen refuelling station (70 MPa) according to ISO 14687 and EN 17124. Fuel Commun. 2021, 6, 100008. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687. [Google Scholar] [CrossRef]

- Chakraborty, S.; Dash, S.K.; Elavarasan, R.M.; Kaur, A.; Elangovan, D.; Meraj, S.T.; Kasinathan, P.; Said, Z. Hydrogen Energy as Future of Sustainable Mobility. Front. Energy Res. 2022, 10, 893475. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J.R.; Rostrup-Nielsen, T. Large-Scale Hydrogen Production. Cattech 2002, 6, 150–159. [Google Scholar] [CrossRef]

- Hames, Y.; Kaya, K.; Baltacioglu, E.; Turksoy, A. Analysis of the control strategies for fuel saving in the hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2018, 43, 10810–10821. [Google Scholar] [CrossRef]

- Kaya, K.; Hames, Y. Two new control strategies: For hydrogen fuel saving and extend the life cycle in the hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2019, 44, 18967–18980. [Google Scholar] [CrossRef]

- Rothuizen, E.; Rokni, M. Optimization of the overall energy consumption in cascade fueling stations for hydrogen vehicles. Int. J. Hydrogen Energy 2014, 39, 582–592. [Google Scholar] [CrossRef]

- Turoń, K. Hydrogen-powered vehicles in urban transport systems—Current state and development. Transp. Res. Procedia 2020, 45, 835–841. [Google Scholar] [CrossRef]

- Mehrjerdi, H. Off-grid solar powered charging station for electric and hydrogen vehicles including fuel cell and hydrogen storage. Int. J. Hydrogen Energy 2019, 44, 11574–11583. [Google Scholar] [CrossRef]

- Wang, Y.; Kazemi, M.; Nojavan, S.; Jermsittiparsert, K. Robust design of off-grid solar-powered charging station for hydrogen and electric vehicles via robust optimization approach. Int. J. Hydrogen Energy 2020, 45, 18995–19006. [Google Scholar] [CrossRef]

- Nasir, M.; Jordehi, A.R.; Matin, S.A.A.; Tabar, V.S.; Tostado-Véliz, M.; Mansouri, S.A. Optimal operation of energy hubs including parking lots for hydrogen vehicles and responsive demands. J. Energy Storage 2022, 50, 104630. [Google Scholar] [CrossRef]

- Aslani, M.; Imanloozadeh, A.; Hashemi-Dezaki, H.; Hejazi, M.A.; Nazififard, M.; Ketabi, A. Optimal probabilistic reliability-oriented planning of islanded microgrids considering hydrogen-based storage systems, hydrogen vehicles, and electric vehicles under various climatic conditions. J. Power Sources 2022, 52, 231100. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, X.; Sun, Y.; Qiu, J. Carbon Emission Flow Oriented Tri-Level Planning of Integrated Electricity–Hydrogen–Gas System with Hydrogen Vehicles. IEEE Trans. Ind. Appl. 2022, 58, 2607–2618. [Google Scholar] [CrossRef]

- Tao, Y.; Qiu, J.; Lai, S.; Zhang, X.; Wang, G. Collaborative Planning for Electricity Distribution Network and Transportation System Considering Hydrogen Fuel Cell Vehicles. IEEE Trans. Transp. Electrif. 2020, 6, 1211–1225. [Google Scholar] [CrossRef]

- Lakouraj, M.M.; Niaz, H.; Liu, J.J.; Siano, P.; Anvari-Moghaddam, A. Optimal risk-constrained stochastic scheduling of microgrids with hydrogen vehicles in real-time and day-ahead markets. J. Clean. Prod. 2021, 318, 128452. [Google Scholar] [CrossRef]

- AlHajri, I.; Ahmadian, A.; Elkamel, A. Techno-economic-environmental assessment of an integrated electricity and gas network in the presence of electric and hydrogen vehicles: A mixed-integer linear programming approach. J. Clean. Prod. 2021, 319, 128578. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, R.; Zeng, R.; Zhu, R.; Kong, X.; He, Y.; Li, H. Integrated performance optimization of a biomass-based hybrid hydrogen/thermal energy storage system for building and hydrogen vehicles. Renew. Energy 2022, 187, 801–818. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Zhou, Y. Peer-to-peer trading optimizations on net-zero energy communities with energy storage of hydrogen and battery vehicles. Appl. Energy 2021, 302, 117578. [Google Scholar] [CrossRef]

- Kolbe, K. Mitigating urban heat island effect and carbon dioxide emissions through different mobility concepts: Comparison of conventional vehicles with electric vehicles, hydrogen vehicles and public transportation. Transp. Policy 2019, 80, 1–11. [Google Scholar] [CrossRef]

- Mehrjerdi, H.; Bornapour, M.; Hemmati, R.; Ghiasi, S.M.S. Unified energy management and load control in building equipped with wind-solar-battery incorporating electric and hydrogen vehicles under both connected to the grid and islanding modes. Energy 2019, 168, 919–930. [Google Scholar] [CrossRef]

- Kinnon, M.M.; Shaffer, B.; Carreras-Sospedra, M.; Dabdub, D.; Samuelsen, G.S.; Brouwer, J. Air quality impacts of fuel cell electric hydrogen vehicles with high levels of renewable power generation. Int. J. Hydrogen Energy 2016, 41, 16592–16603. [Google Scholar] [CrossRef]

- Murugan, A.; de Huu, M.; Bacquart, T.; van Wijk, J.; Arrhenius, K.; Ronde, I.; Hemfrey, D. Measurement challenges for hydrogen vehicles. Int. J. Hydrogen Energy 2019, 44, 19326–19333. [Google Scholar] [CrossRef]

- Faria, R.; Moura, P.; Delgado, J.; de Almeida, A.T. A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Ramachandran, S.; Stimming, U. Well to wheel analysis of low carbon alternatives for road traffic. Energy Environ. Sci. 2015, 8, 3313–3324. [Google Scholar] [CrossRef]

- Report on the Installed Capacity of the Power Plants in Romania. Available online: https://www.transelectrica.ro/ro/web/tel/productie (accessed on 19 December 2022).

- Production Reports for Romania. Available online: https://www.transelectrica.ro/widget/web/tel/sen-grafic/-/SENGrafic_WAR_SENGraficportlet?display=APE (accessed on 19 December 2022).

- Best-Selling BEV Models in Europe. Available online: https://www.statista.com/statistics/972845/electric-vehicles-leading-models-europe/ (accessed on 19 December 2022).

- Best-Selling BEV Models in USA. Available online: https://www.greencars.com/expert-insights/best-selling-electric-vehicles (accessed on 19 December 2022).

- Statistical Bulletin of the Romanian Automotive Manufacturers and Importers Association. Available online: https://www.apia.ro/en/statistical-bulletin/ (accessed on 19 January 2023).

- Battery Capacity, Range, Fuel Consumption and Charging Time of BEVs. Available online: https://ev-database.org (accessed on 19 January 2023).

- Tong, F.; Michalek, J.; Azevedo, I.L. A review of hydrogen production pathways, cost and decarbonization potential. In Proceedings of the 35th USAEE/IAEE North American Conference, Houston, TX, USA, 12–15 November 2017. [Google Scholar]

- Tenhumberg, N.; Büker, K. Ecological and Economic Evaluation of Hydrogen Production by Different Water Electrolysis Technologies. Chem. Ing. Tech. 2020, 92, 1586–1595. [Google Scholar] [CrossRef]

- Tank Capacity, Range, Fuel Consumption and Charging Time of FCEVs. Available online: https://h2.live/en/fcev (accessed on 19 January 2023).

- MATLAB R2022b. Available online: https://www.mathworks.com/products/matlab.html (accessed on 20 January 2023).

- CO2 Emission Standards for New Cars and Vans. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2022/698920/EPRS_BRI(2022)698920_EN.pdf (accessed on 19 January 2023).

| Power Plant Type | Carbon Dioxide Emissions (gCO2/kWh) |

|---|---|

| Biomass | 340 |

| Coal | 916 |

| Gas | 354 |

| Hydro | 12 |

| Nuclear | 12 |

| Solar | 50 |

| Wind | 10 |

| Power Plant Type | Installed Capacity (MW) | Percentage (%) |

|---|---|---|

| Biomass | 124.23 | 0.75 |

| Coal | 2673.15 | 16.04 |

| Gas | 1981.35 | 11.89 |

| Hydro | 6310.95 | 37.87 |

| Nuclear | 1300 | 7.80 |

| Solar | 1308 | 7.85 |

| Wind | 2965.43 | 17.80 |

| Power Plant Type | Percentage on 4 March 2022 (%) | Percentage on 29 April 2022 (%) | Percentage on 11 August 2022 (%) | Percentage on 16 November 2022 (%) | Percentage on 5 December 2022 (%) |

|---|---|---|---|---|---|

| Biomass | 1.37 | 0.77 | 0.96 | 1.18 | 1.08 |

| Coal | 25.72 | 19.26 | 17.76 | 24.12 | 19.71 |

| Gas | 15.75 | 16.68 | 18.78 | 23.37 | 23.91 |

| Hydro | 29.49 | 34.3 | 14.53 | 22.15 | 21.05 |

| Nuclear | 23.55 | 20.13 | 18.05 | 21.64 | 19.42 |

| Solar | 1.92 | 2.48 | 3.12 | 0.69 | 0.34 |

| Wind | 2.2 | 6.38 | 26.8 | 6.85 | 14.49 |

| Battery Electric Vehicle | Battery Capacity (kWh) | Range (km) | Fuel Consumption (kWh/km) | Charging Time at 2.3 kW (h) | Charging Time at Regular 22 kW Charging Station (h) | Charging Time at Fast 50 kW DC Charging Station (h) |

|---|---|---|---|---|---|---|

| Dacia Spring | 26.8 | 165 | 0.152 | 13 | 4.5 | 0.633 |

| Fiat 500 electric | 23.8 | 135 | 0.158 | 11 | 2.5 | 0.4 |

| Ford Mustang Mach-E RWD | 75.7 | 355 | 0.197 | 36 | 7.5 | 1.28 |

| Hyundai Kona | 42 | 250 | 0.157 | 20.25 | 6.5 | 0.783 |

| Kia Niro EV (e-Niro) | 68 | 380 | 0.171 | 33.25 | 7 | 1.066 |

| Peugeot e-208 | 50 | 285 | 0.158 | 23.25 | 7.25 | 0.683 |

| Skoda Enyaq iV | 62 | 330 | 0.176 | 29.75 | 6.25 | 0.85 |

| Tesla Model S | 100 | 550 | 0.173 | 48.75 | 7 | 1.4 |

| Tesla Model Y | 57.5 | 345 | 0.167 | 29.5 | 6.25 | 0.933 |

| Volkswagen ID.4 | 55 | 285 | 0.182 | 26.75 | 8.5 | 0.95 |

| Hydrogen Production Method | Carbon Dioxide Emissions (gCO2/kg) |

|---|---|

| Biomass gasification | 5000 |

| Gasification of coal | 19,000 |

| Grid-powered electrolysis | 14,000 |

| Hydro-powered electrolysis | 300 |

| Nuclear-powered electrolysis | 600 |

| Solar-powered electrolysis | 1800 |

| Wind-powered electrolysis | 700 |

| Steam reforming of natural gas | 9000 |

| Fuel Cell Electric Vehicle | Hydrogen Tank Capacity (kg) | Range (km) | Fuel Consumption (kg/km) | Charging Time at 70 MPa H2 Fueling Station (h) |

|---|---|---|---|---|

| Hyundai Nexo | 6.33 | 756 | 0.0084 | 0.0833 |

| Toyota Mirai | 5.6 | 650 | 0.0076 | 0.0833 |

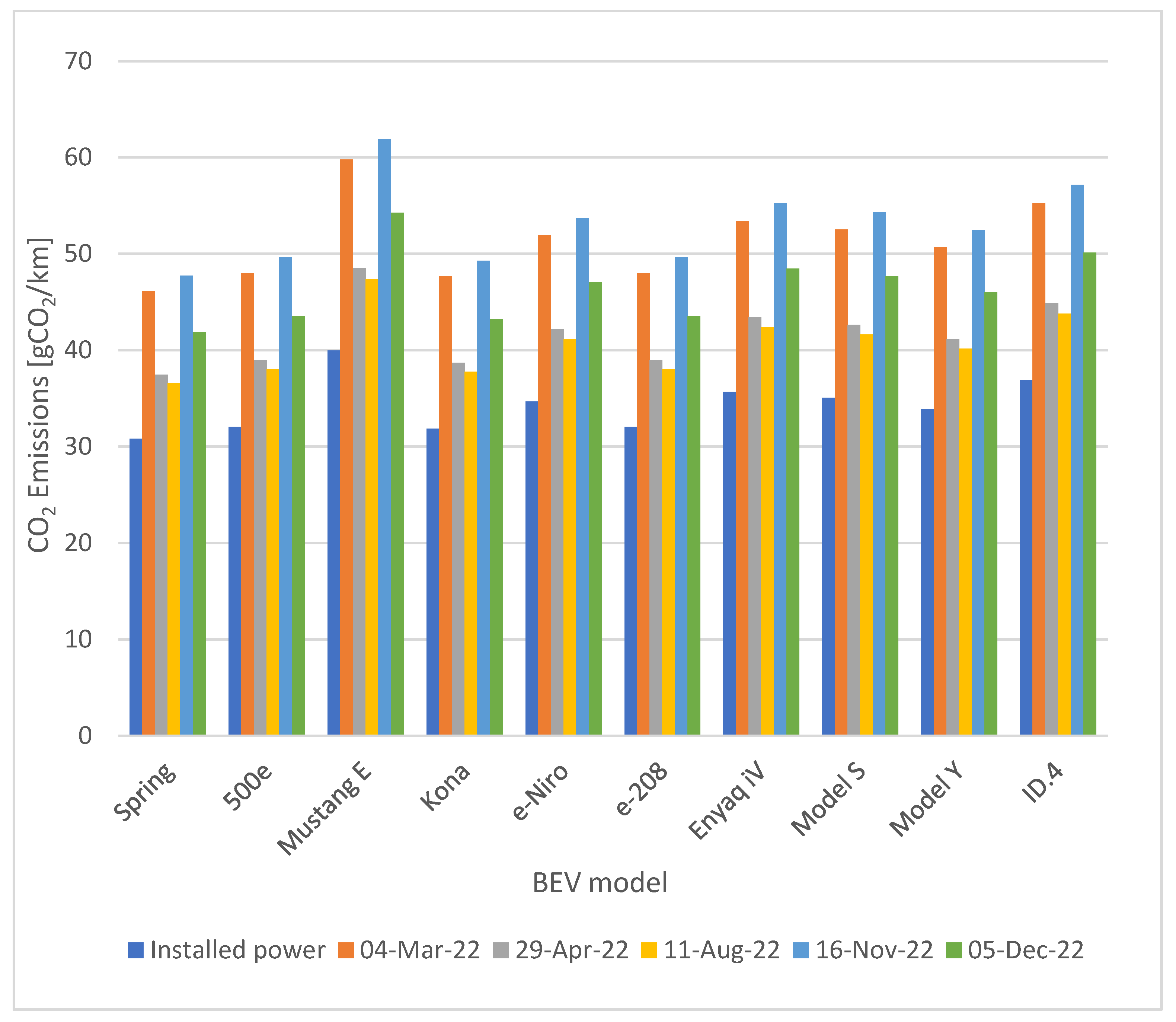

| BEV | Emissions Considering the Installed Power (gCO2/km) | Emissions Considering the Power Supplied on 4 March 2022 (gCO2/km) | Emissions Considering the Power Supplied on 29 April 2022 (gCO2/km) | Emissions Considering the Power Supplied on 11 August 2022 (gCO2/km) | Emissions Considering the Power Supplied on 16 November 2022 (gCO2/km) | Emissions Considering the Power Supplied on 5 December 2022 (gCO2/km) |

|---|---|---|---|---|---|---|

| Dacia Spring | 30.81 | 46.14 | 37.46 | 36.56 | 47.72 | 41.85 |

| Fiat 500 electric | 32.03 | 47.96 | 38.94 | 38.01 | 49.60 | 43.50 |

| Ford Mustang Mach-E RWD | 39.94 | 59.79 | 48.55 | 47.39 | 61.85 | 54.24 |

| Hyundai Kona | 31.83 | 47.65 | 38.69 | 37.77 | 49.29 | 43.22 |

| Kia Niro EV (e-Niro) | 34.67 | 51.90 | 42.15 | 41.13 | 53.68 | 47.08 |

| Peugeot e-208 | 32.03 | 47.96 | 38.94 | 38.01 | 49.60 | 43.50 |

| Skoda Enyaq iV | 35.68 | 53.42 | 43.38 | 42.34 | 55.25 | 48.45 |

| Tesla Model S | 35.07 | 52.51 | 42.64 | 41.61 | 54.31 | 47.63 |

| Tesla Model Y | 33.85 | 50.69 | 41.16 | 40.17 | 52.43 | 45.98 |

| Volkswagen ID.4 | 36.90 | 55.24 | 44.86 | 43.78 | 57.14 | 50.11 |

| BEV | Emissions Considering the Installed Power (gCO2) | Emissions Considering the Power Supplied on 4 March 2022 (gCO2) | Emissions Considering the Power Supplied on 29 April 2022 (gCO2) | Emissions Considering the Power Supplied on 11 August 2022 (gCO2) | Emissions Considering the Power Supplied on 16 November 2022 (gCO2) | Emissions Considering the Power Supplied on 5 December 2022 (gCO2) |

|---|---|---|---|---|---|---|

| Dacia Spring | 369,820.37 | 553,680.67 | 449,609.43 | 438,811.35 | 572,673.61 | 502,206.29 |

| Fiat 500 electric | 384,418.55 | 575,536.48 | 467,357.17 | 456,132.85 | 595,279.15 | 522,030.23 |

| Ford Mustang Mach-E RWD | 479,306.67 | 717,599.29 | 582,717.48 | 568,722.60 | 742,215.15 | 650,885.79 |

| Hyundai Kona | 381,985.52 | 571,893.85 | 464,399.21 | 453,245.93 | 591,511.56 | 518,726.24 |

| Kia Niro EV (e-Niro) | 416,047.92 | 622,890.75 | 505,810.61 | 493,662.77 | 644,257.82 | 564,982.08 |

| Peugeot e-208 | 384,418.55 | 575,536.48 | 467,357.17 | 456,132.85 | 595,279.15 | 522,030.23 |

| Skoda Enyaq iV | 428,213.06 | 641,103.93 | 520,600.39 | 508,097.35 | 663,095.76 | 581,502.02 |

| Tesla Model S | 420,913.98 | 630,176.02 | 511,726.52 | 499,436.60 | 651,793.00 | 571,590.06 |

| Tesla Model Y | 406,315.80 | 608,320.21 | 493,978.78 | 482,115.10 | 629,187.46 | 551,766.12 |

| Volkswagen ID.4 | 442,811.24 | 662,959.75 | 538,348.13 | 525,418.85 | 685,701.30 | 601,325.96 |

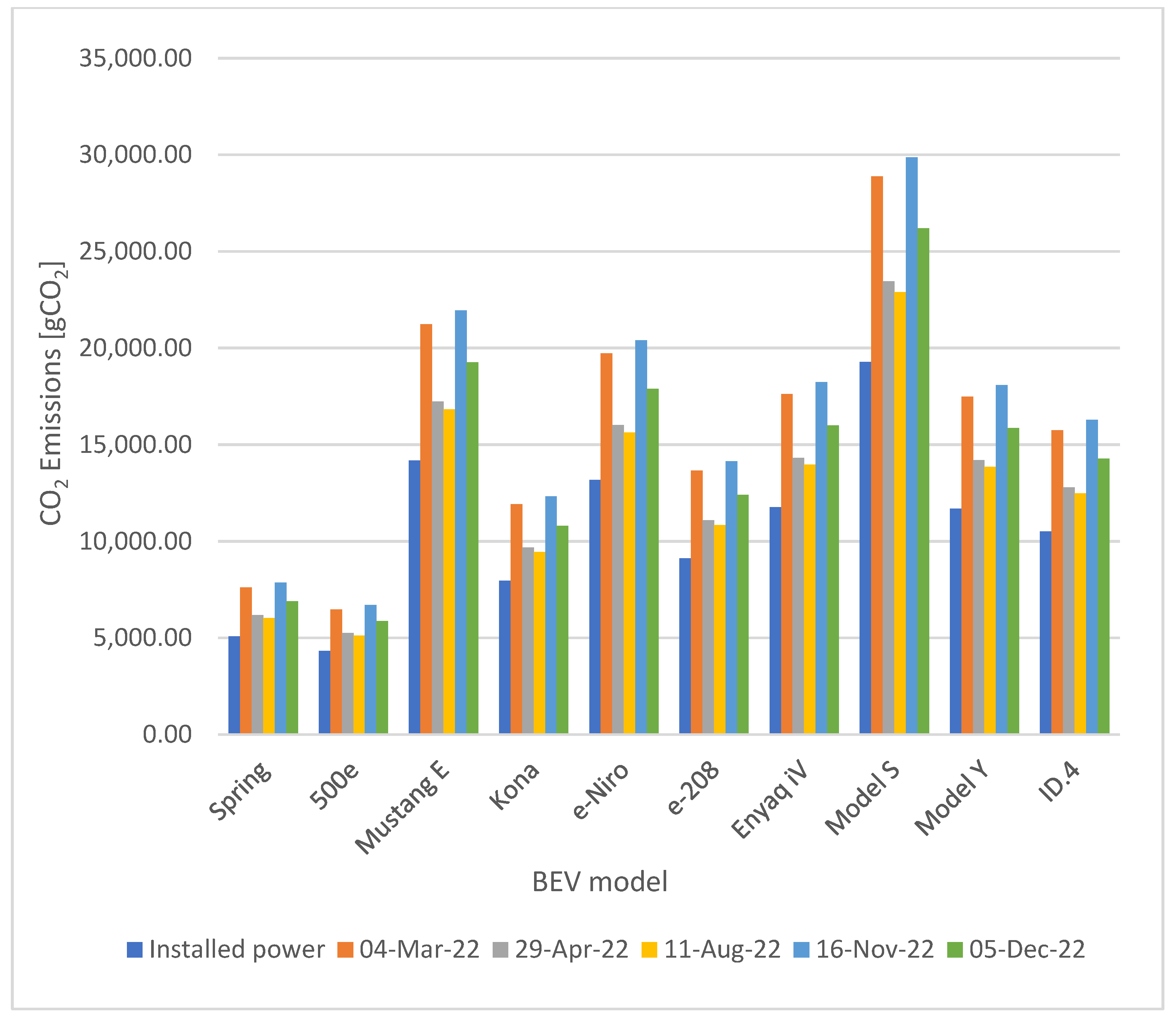

| BEV | Emission Considering the Installed Power (gCO2) | Emissions Considering the Power Supplied on 4 March 2022 (gCO2) | Emissions Considering the Power Supplied on 29 April 2022 (gCO2) | Emissions Considering the Power Supplied on 11 August 2022 (gCO2) | Emissions Considering the Power Supplied on 16 November 2022 (gCO2) | Emissions Considering the Power Supplied on 5 December 2022 (gCO2) |

|---|---|---|---|---|---|---|

| Dacia Spring | 5085.03 | 7613.10 | 6182.12 | 6033.65 | 7874.26 | 6905.33 |

| Fiat 500 electric | 4324.70 | 6474.78 | 5257.76 | 5131.49 | 6696.89 | 5872.84 |

| Ford Mustang Mach-E RWD | 14,179.48 | 21,228.97 | 17,238.72 | 16,824.71 | 21,957.19 | 19,255.37 |

| Hyundai Kona | 7958.03 | 11,914.45 | 9674.98 | 9442.62 | 12,323.15 | 10,806.79 |

| Kia Niro EV (e-Niro) | 13,174.85 | 19,724.87 | 16,017.33 | 15,632.65 | 20,401.49 | 17,891.09 |

| Peugeot e-208 | 9129.94 | 13,668.99 | 11,099.73 | 10,833.15 | 14,137.87 | 12,398.21 |

| Skoda Enyaq iV | 11,775.85 | 17,630.35 | 14,316.51 | 13,972.67 | 18,235.13 | 15,991.30 |

| Tesla Model S | 19,291.89 | 28,883.06 | 23,454.13 | 22,890.84 | 29,873.84 | 26,197.87 |

| Tesla Model Y | 11,681.57 | 17,489.20 | 14,201.89 | 13,860.80 | 18,089.13 | 15,863.27 |

| Volkswagen ID.4 | 10,516.76 | 15,745.29 | 12,785.76 | 12,478.69 | 16,285.40 | 14,281.49 |

| FCEV | Biomass Gasification (gCO2/km) | Gasification of Coal (gCO2/km) | Grid-Powered Electrolysis (gCO2/km) | Hydro-Powered Electrolysis (gCO2/km) | Nuclear-Powered Electrolysis (gCO2/km) | Solar-Powered Electrolysis (gCO2/km) | Wind-Powered Electrolysis (gCO2/km) | Steam Reforming of Natural Gas (gCO2/km) |

|---|---|---|---|---|---|---|---|---|

| Hyundai Nexo | 42 | 159.60 | 117.60 | 2.52 | 5.04 | 15.11 | 5.88 | 75.59 |

| Toyota Mirai | 38 | 144.40 | 106.40 | 2.28 | 4.56 | 13.68 | 5.32 | 68.40 |

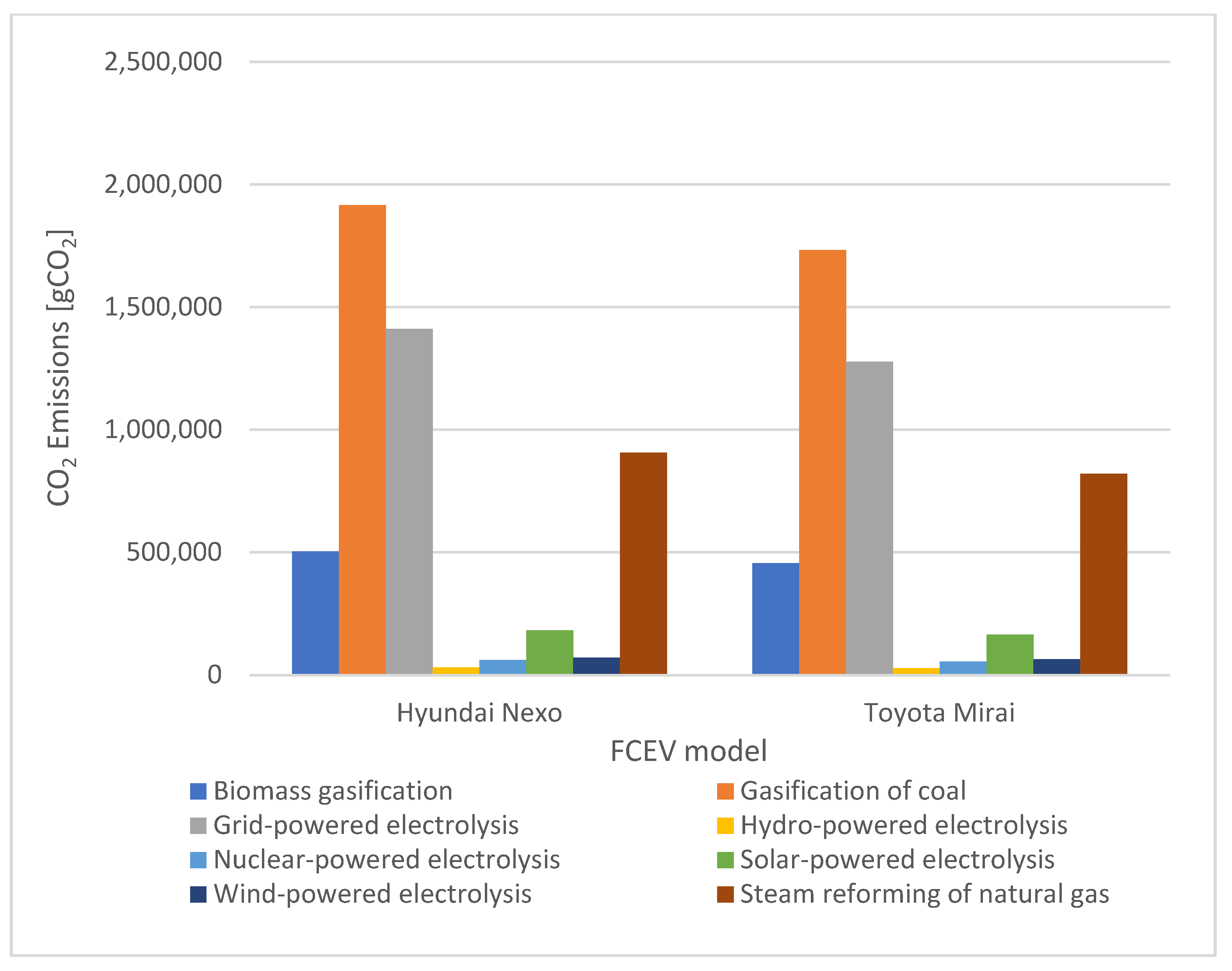

| FCEV | Biomass Gasification (gCO2) | Gasification of Coal (gCO2) | Grid-Powered Electrolysis (gCO2) | Hydro-Powered Electrolysis (gCO2) | Nuclear-Powered Electrolysis (gCO2) | Solar-Powered Electrolysis (gCO2) | Wind-Powered Electrolysis (gCO2) | Steam Reforming of Natural Gas (gCO2) |

|---|---|---|---|---|---|---|---|---|

| Hyundai Nexo | 504,000 | 1,915,200 | 1,411,200 | 30,240 | 60,480 | 181,440 | 70,560 | 907,199.99 |

| Toyota Mirai | 456,000 | 1,732,800 | 1,276,800 | 27,360 | 54,719.99 | 164,160 | 63,840 | 820,800 |

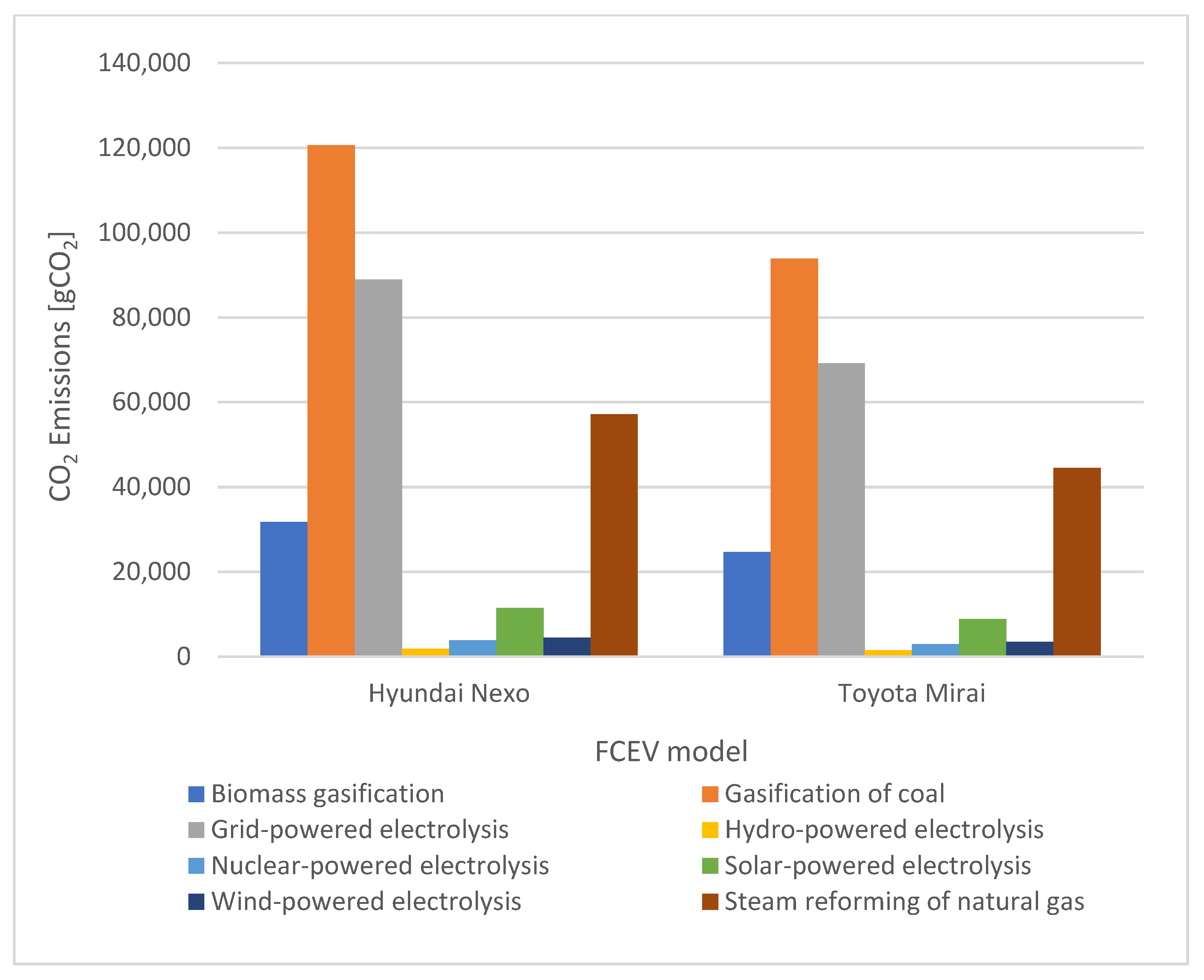

| FCEV | Biomass Gasification (gCO2) | Gasification of Coal (gCO2) | Grid-Powered Electrolysis (gCO2) | Hydro-Powered Electrolysis (gCO2) | Nuclear-Powered Electrolysis (gCO2) | Solar-Powered Electrolysis (gCO2) | Wind-Powered Electrolysis (gCO2) | Steam Reforming of Natural Gas (gCO2) |

|---|---|---|---|---|---|---|---|---|

| Hyundai Nexo | 31,752 | 120,657.6 | 88,905.59 | 1905.12 | 3810.24 | 11,430.72 | 4445.28 | 57,153.60 |

| Toyota Mirai | 24,700 | 93,860 | 69,160 | 1482 | 2964 | 8892 | 3458 | 44,460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dulău, L.-I. CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles. Clean Technol. 2023, 5, 696-712. https://doi.org/10.3390/cleantechnol5020035

Dulău L-I. CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles. Clean Technologies. 2023; 5(2):696-712. https://doi.org/10.3390/cleantechnol5020035

Chicago/Turabian StyleDulău, Lucian-Ioan. 2023. "CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles" Clean Technologies 5, no. 2: 696-712. https://doi.org/10.3390/cleantechnol5020035

APA StyleDulău, L.-I. (2023). CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles. Clean Technologies, 5(2), 696-712. https://doi.org/10.3390/cleantechnol5020035