Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants

Abstract

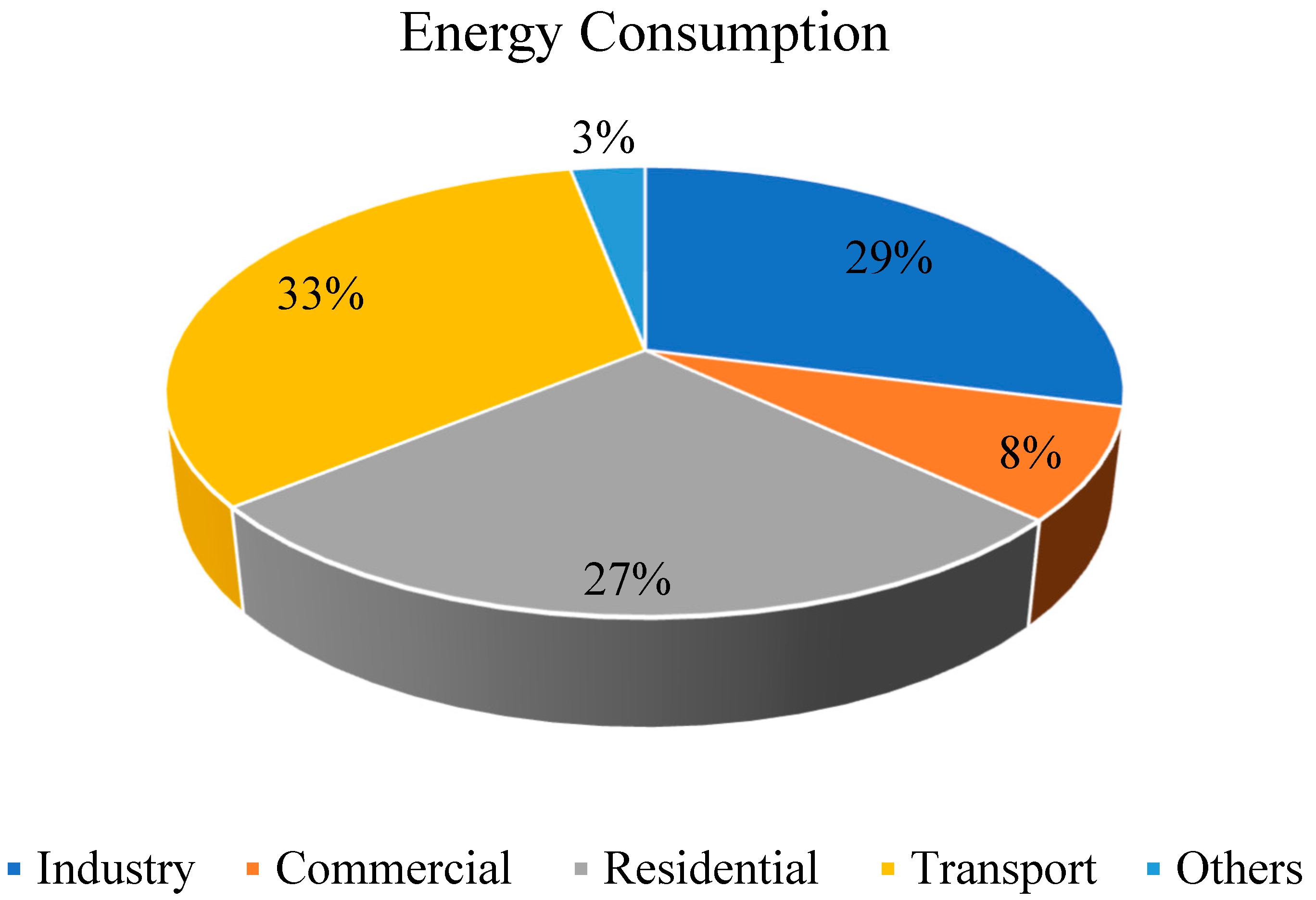

1. Introduction

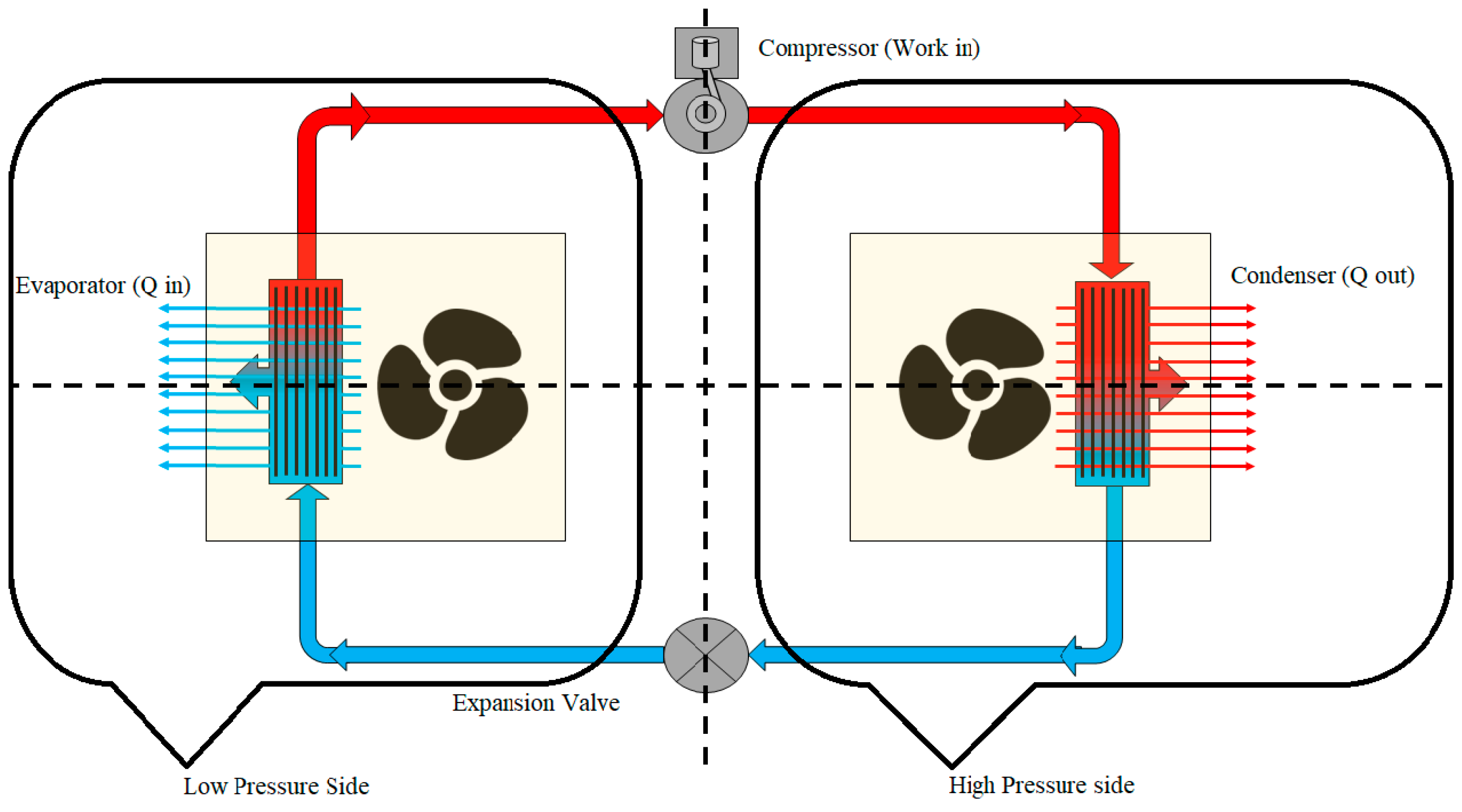

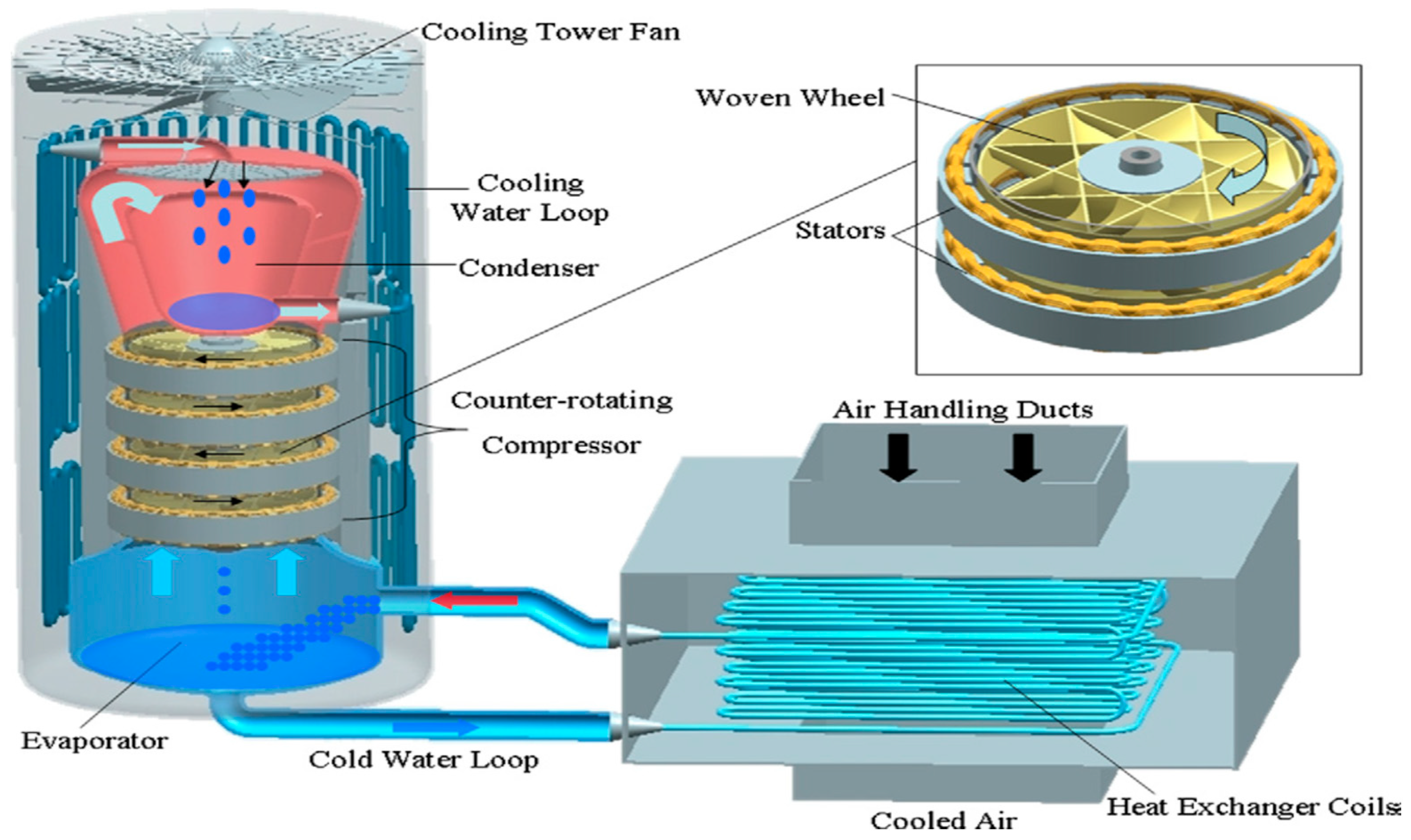

2. Refrigeration Cycle Improvements

- Positive displacement, such as reciprocating and linear compressors

- Rotary, including scroll, screw, root, and rolling compressors

- Kinematic compressors, such as centrifugal and axial compressors

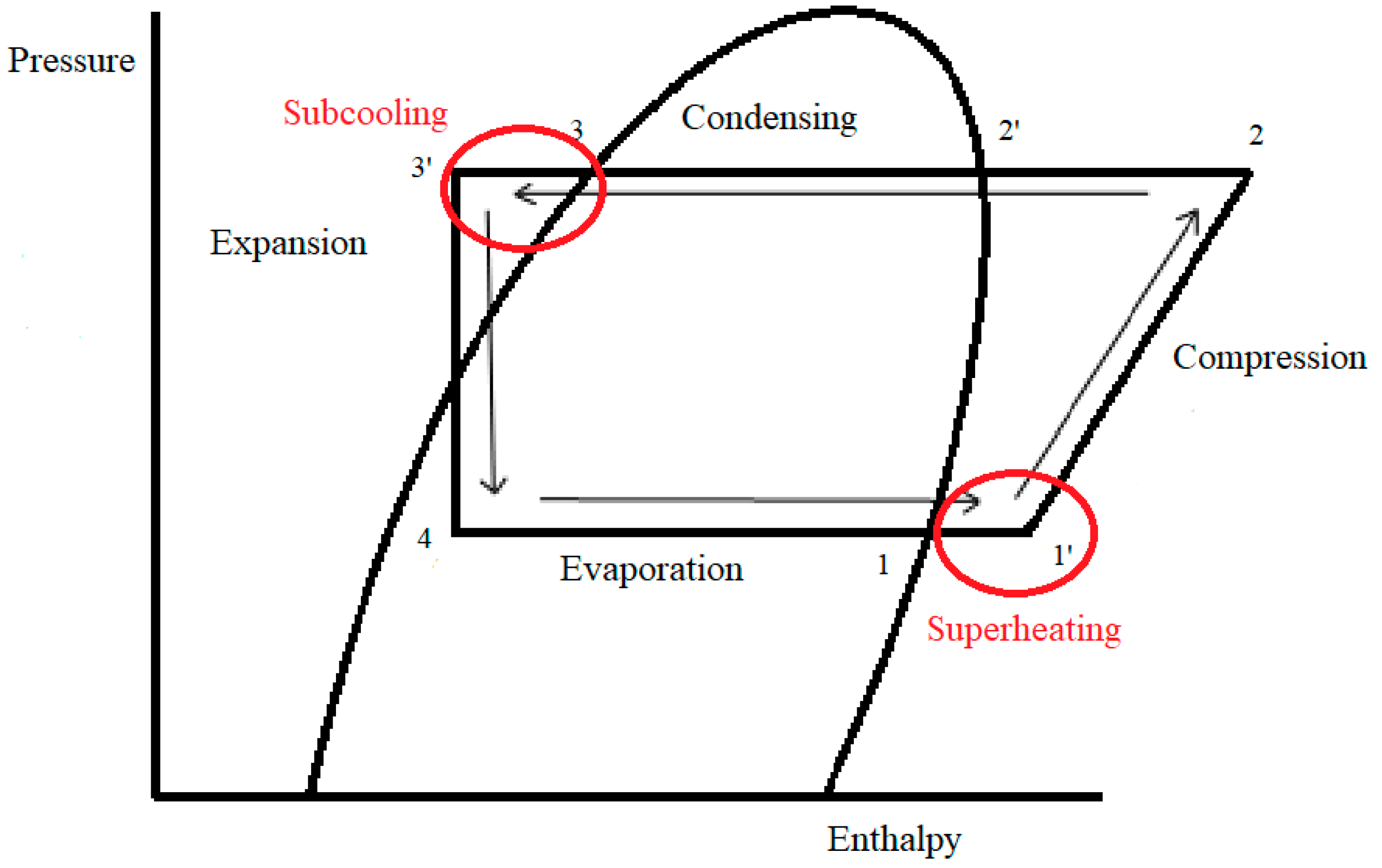

2.1. Cycle Improvement by Increasing Sub-Cooling and Superheating

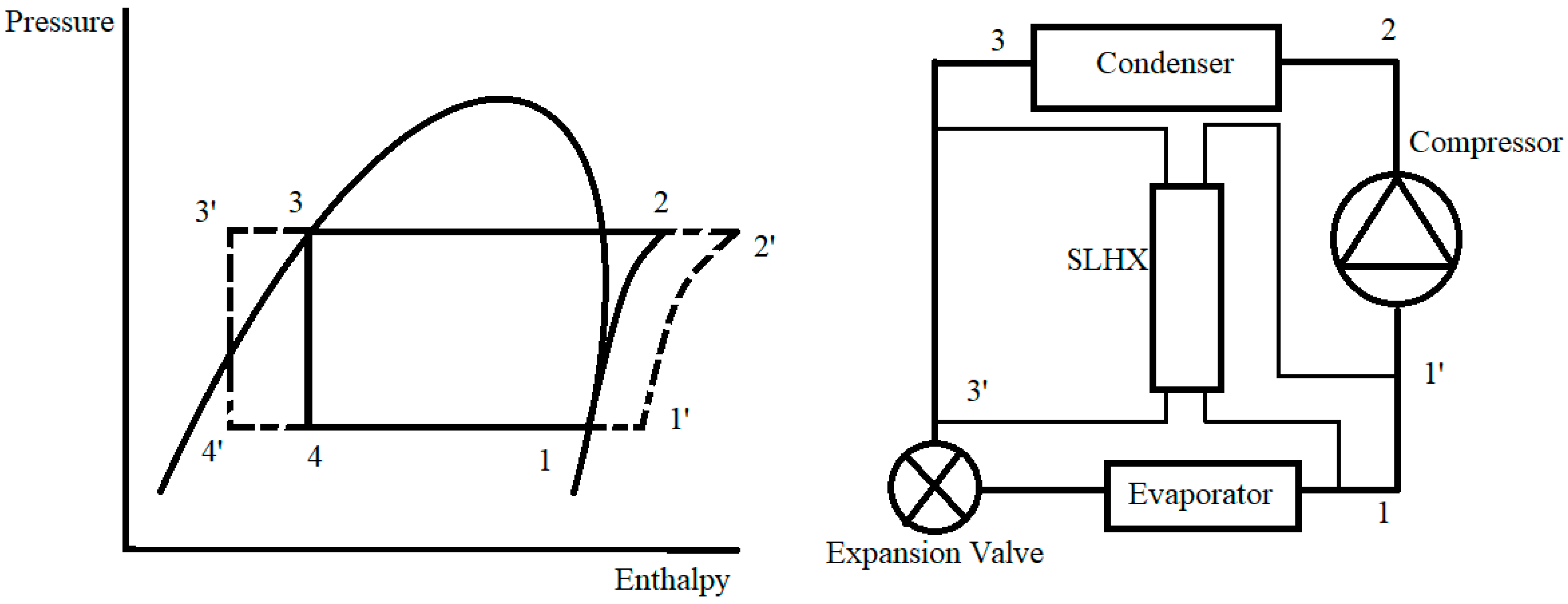

- Suction Line Heat Exchanger (SLHX)

- Mechanical Sub-cooling (MS)

- Thermoelectric Sub-cooling (TS)

2.1.1. Suction Line Heat Exchanger (SLHX)

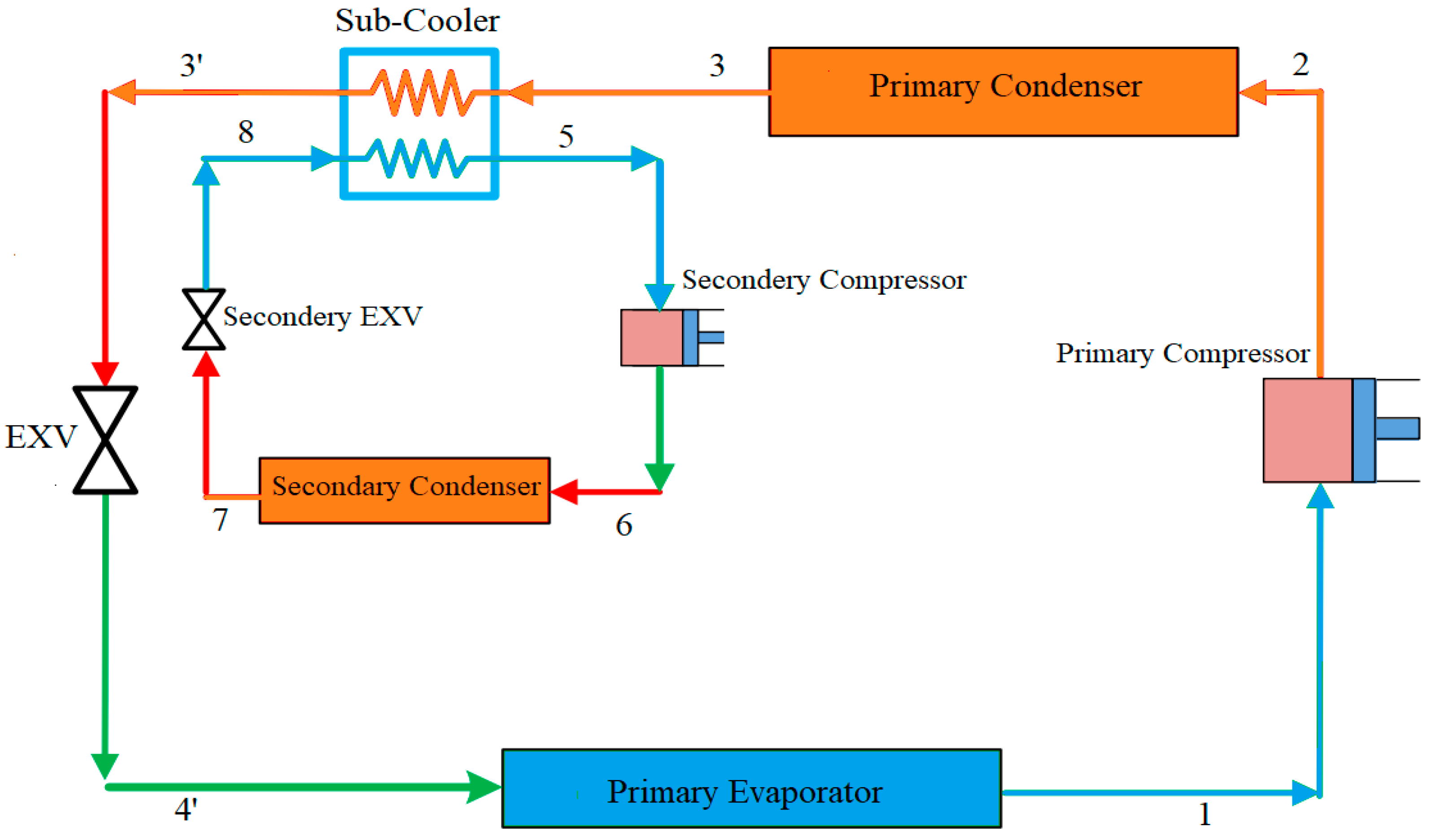

2.1.2. Mechanical Sub-Cooling (MS)

2.1.3. Thermoelectric Sub-Cooling (TS)

2.2. Cycle Improvement by Expansion Loses Recovery

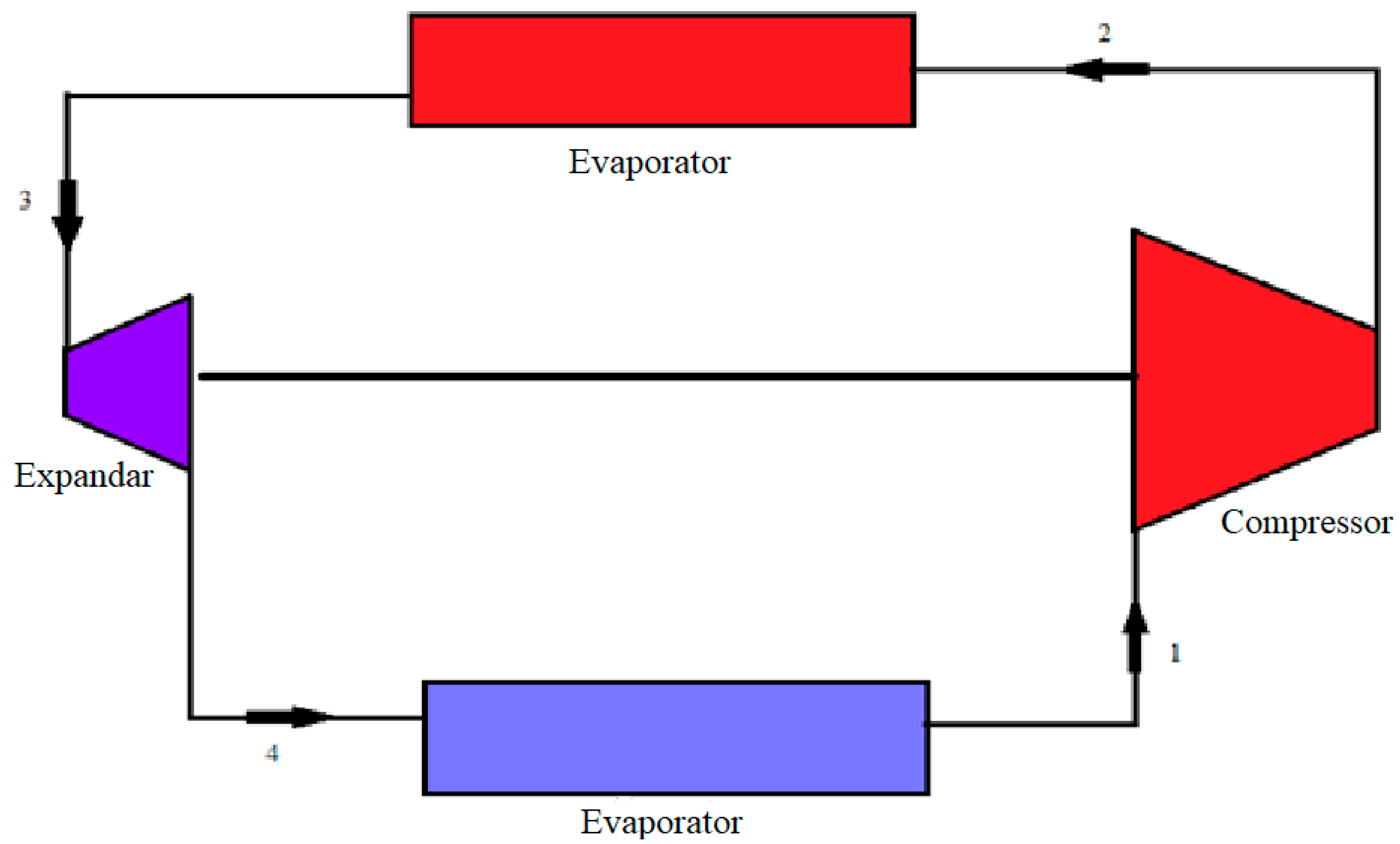

2.2.1. The Expander Cycle

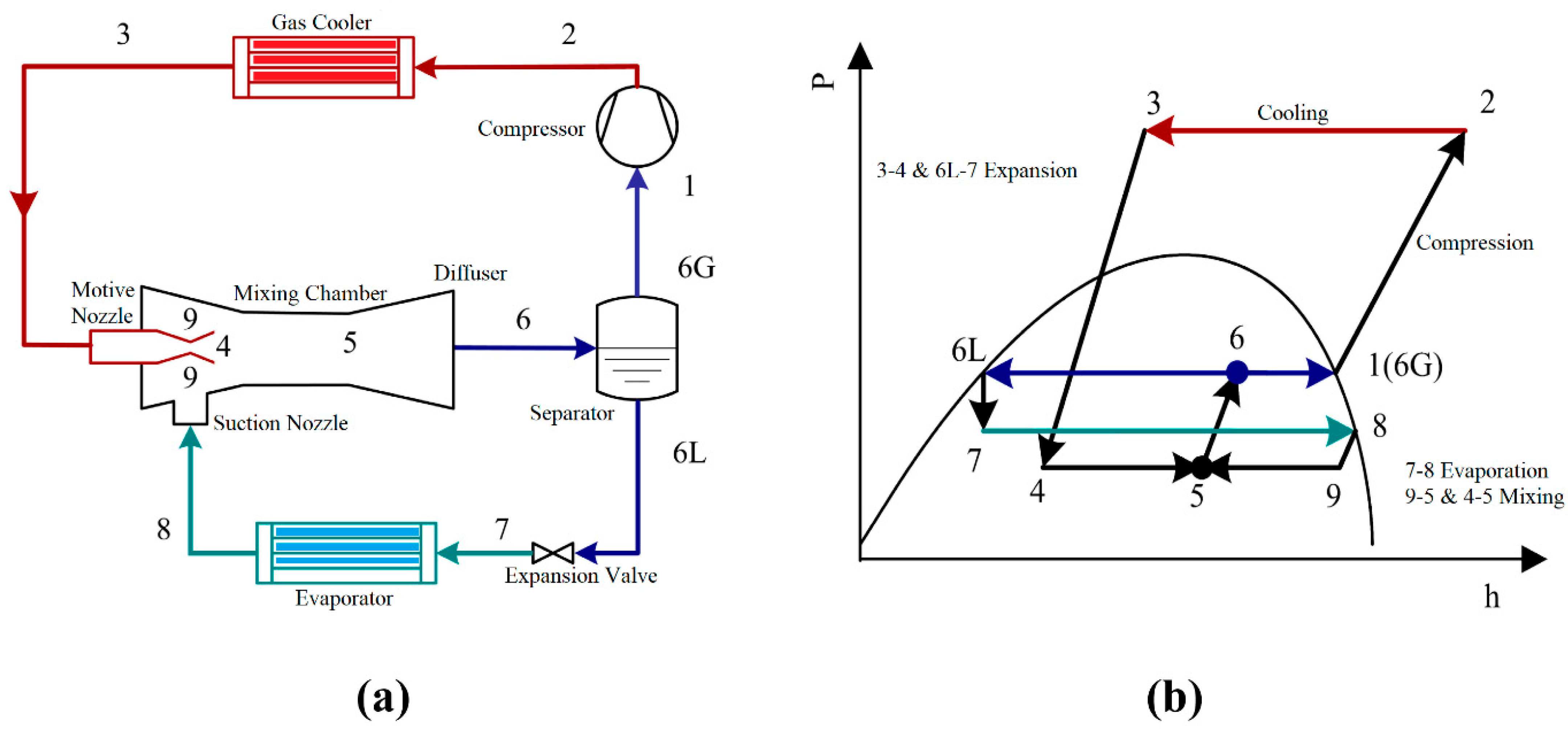

2.2.2. Ejector Cycle

3. Refrigerants Development and Environmental Assessment

3.1. Natural Refrigerants

3.1.1. Air

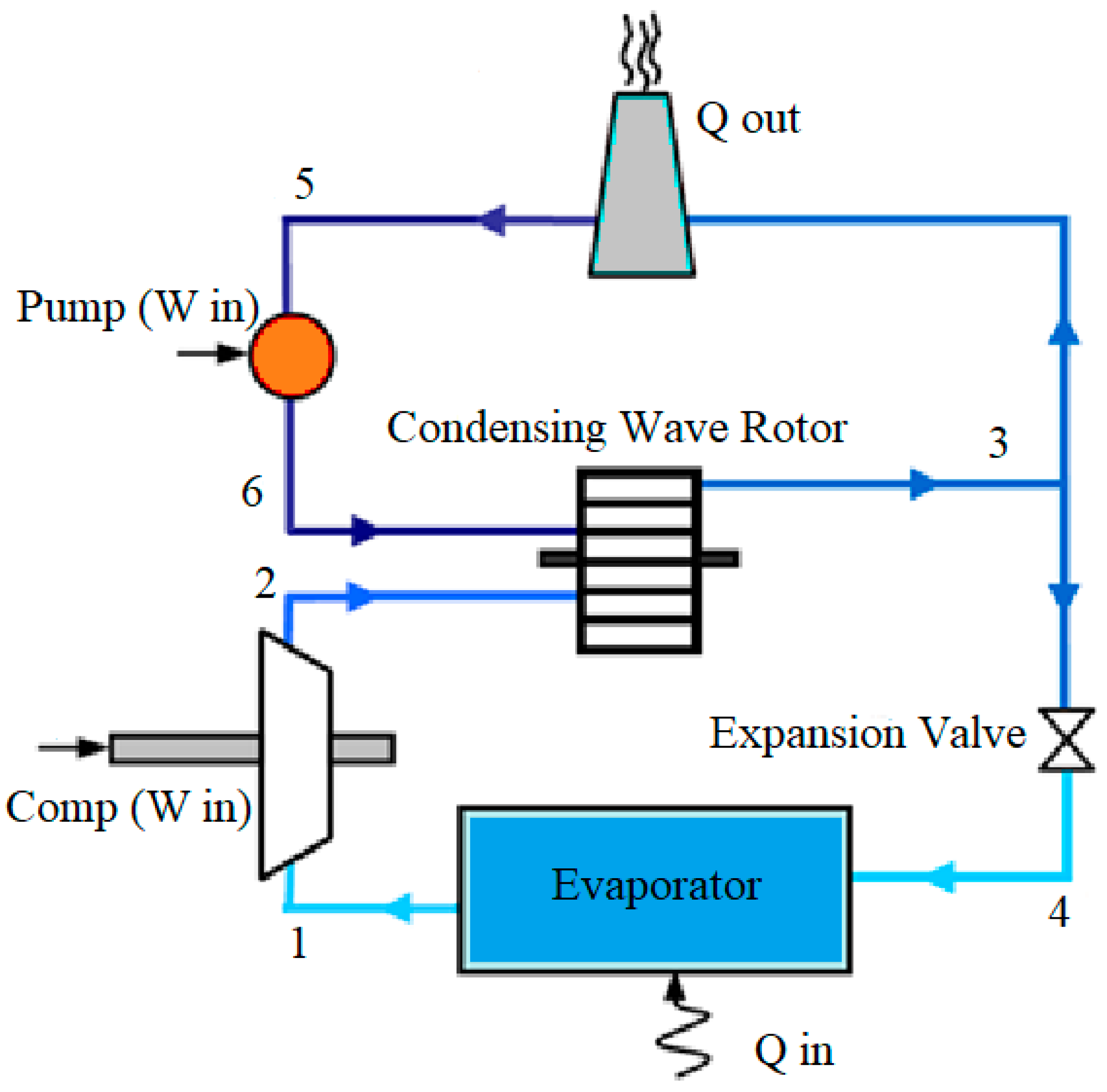

3.1.2. Water (R-718)

3.1.3. Hydrocarbons

3.1.4. Carbon Dioxide (R-744)

3.1.5. Ammonia (R717)

3.2. Water as a Refrigerant

4. Conclusions

- The refrigeration cycle COP can be improved by increasing super-heating and sub-cooling or recovering expansion losses.

- Sub-cooling and super-heating can be increased by using different methods, including suction line heat exchangers, mechanical sub-cooling, and thermo-electric sub-cooling.

- The selection of the most suitable sub-cooling/super-heating method depends on the application and is highly related to the refrigerant properties.

- Natural refrigerants are the ultimate solution for the environmental challenges of the VCC.

- The most promising natural refrigerants are carbon dioxide and water, as they are the safest and most efficient among natural refrigerants.

- Water is a very efficient and safe refrigerant, and could solve most of the environmental challenges related to refrigerants. However, more research is needed to solve the technical challenges associated with using water as a refrigerant.

- The proposed solutions for using water as a refrigerant are as follows: promoting industry collaboration to reduce the cost of water compressors, using direct expansion and condensing techniques.

- Using cascade refrigeration cycle and cycle modifications such as a two-phase ejector or expander could improve the refrigeration cycle performance. However, they are highly dependent on the refrigerant’s thermophysical properties, and detailed research should be performed to choose the most suitable technique.

5. Future Prospects

- The high volumetric flow rate requirement driven by the very high specific volume of water vapor at low temperatures.

- The relatively high pressure ratio that is needed for the system to operate within the evaporation and condensation temperatures commonly used for cooling applications.

- The high compressor discharge temperature that results from the high compression ratio.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CFC | Chlorofluorocarbon |

| COP | Coefficient of performance |

| FIC | Fluoroiodocarbon |

| GHG | Greenhouse gases |

| GW | Global warming |

| GWP | Global warming potential |

| HCFO | Hydrochlorofluoroolefin |

| HFC | Hydrofluorocarbon |

| HFO | Hydroflouroolefin |

| HVAC | Heating ventilation and air conditioning |

| MS | Mechanical sub-cooling |

| OD | Ozone depletion |

| ODP | Ozone depletion potential |

| SLHX | Suction line heat exchanger |

| TS | Thermoelectric sub-cooling |

| VCC | Vapor compression cycle |

| VCR | Vapor compression refrigeration |

References

- World—World Energy Balances: Overview—Analysis. (14 January 2021). IEA. Available online: https://www.iea.org/reports/world-energy-balances-overview/world (accessed on 14 December 2021).

- Energy Efficiency Requirements in Building Codes, Energy Efficiency Policies for New Buildings. (1 July 2008). IEA. Available online: https://www.iea.org/reports/energy-efficiency-requirements-in-building-codes-policies-for-new-buildings (accessed on 10 December 2021).

- Appendix: Compressive Refrigeration and the Heat Pump. In Air-Conditioning in Modern American Architecture, 1890–1970; Penn State University Press: University Park, PA, USA, 2021; pp. 237–240. [CrossRef]

- Heating and Cooling|Energy.gov.au. (13 December 2021). Available online: https://www.energy.gov.au/households/heating-and-cooling (accessed on 14 December 2021).

- Tang, R.; Wang, S.; Sun, S. Impacts of technology-guided occupant behavior on air-conditioning system control and building energy use. Build. Simul. 2020, 14, 209–217. [Google Scholar] [CrossRef]

- Rodriguez, J.; Fumo, N. Zoned heating, ventilation, and air–conditioning residential systems: A systematic review. J. Build. Eng. 2021, 43, 102925. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R. Vapor compression heat pumps with pure Low-GWP refrigerants. Renew. Sustain. Energy Rev. 2021, 138, 110571. [Google Scholar] [CrossRef]

- Savitha, D.; Ranjith, P.; Talawar, B.; Rana Pratap Reddy, N. Refrigerants for sustainable environment—A literature review. Int. J. Sustain. Energy 2022, 41, 235–256. [Google Scholar] [CrossRef]

- Siry, J.M. Air-Conditioning in Modern American Architecture, 1890–1970 (Buildings, Landscapes, and Societies), 1st ed.; Penn State University Press: University Park, PA, USA, 2022. [Google Scholar]

- Zhang, X.; Yang, W.; Shao, Z.; Li, Y.; Su, Y.; Zhang, Q.; Chengyi, H.; Wang, H. A Moisture-Wicking Passive Radiative Cooling Hierarchical Metafabric. ACS Nano 2022, 16, 2188–2197. [Google Scholar] [CrossRef]

- Lu, X.; Xu, P.; Wang, H.; Yang, T.; Hou, J. Cooling potential and applications prospects of passive radiative cooling in buildings: The current state-of-the-art. Renew. Sustain. Energy Rev. 2016, 65, 1079–1097. [Google Scholar] [CrossRef]

- Domanski, P.; Didion, D.; Doyle, J. Evaluation of suction-line/liquid-line heat exchange in the refrigeration cycle. Int. J. Refrig. 1994, 17, 487–493. [Google Scholar] [CrossRef]

- Preissner, M.; Cutler, B.; Radermacher, R.; Zhang, C. Suction line heat exchanger for R134a automotive air conditioning system. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue Conference, Lafayette, IN, USA, 11–14 July 2000; pp. 289–294. [Google Scholar]

- Klein, S.R.; Reindl, D.T.; Brownell, K.A. Refrigeration system performance using liquid-suction heat exchangers. Int. J. Refrig. 2000, 23, 588–596. [Google Scholar] [CrossRef]

- Hwang, Y.; Huff, H.; Preissner, R.; Radermacher, R. CO2 transcritical cycles for high temperature application. In Proceedings of the 2001 ASME International Mechanical Engineering Congress, IMECE2001/AES-23630, New York, NY, USA, 11–16 November 2001. [Google Scholar]

- Cho, H.; Ryu, C.; Kim, Y. Cooling performance of a variable speed CO2 cycle with an electronic expansion valve and internal heat exchanger. Int. J. Refrig. 2007, 30, 664–671. [Google Scholar] [CrossRef]

- Cho, H.; Lee, H.; Park, C. Performance characteristics of a drop-in system for a mobile air conditioner using refrigerant. Korean J. Air Cond. Refrig. Eng. 2012, 24, 823–829. [Google Scholar]

- Navarro-Esbrí, J.; Molés, F.; Barragán-Cervera, Á. Experimental analysis of the internal heat exchanger influence on a vapour compression system performance working with R1234yf as a drop-in replacement for R134a. Appl. Therm. Eng. 2013, 59, 153–161. [Google Scholar] [CrossRef]

- Cho, H.; Lee, H.; Park, C. Performance characteristics of an automobile air conditioning system with internal heat exchanger using refrigerant R1234yf. Appl. Therm. Eng. 2013, 61, 563–569. [Google Scholar] [CrossRef]

- Pottker, G.; Hrnjak, P. Experimental investigation of the effect of condenser subcooling in R134a and R1234yf air-conditioning systems with and without internal heat exchanger. Int. J. Refrig. 2015, 50, 104–113. [Google Scholar] [CrossRef]

- Prabakaran, R.; Narayanaswamy, G.R.; Lal, D.M. Tuning thermostatic expansion valve for implementing suction line heat exchanger in mobile air conditioning system. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 191. [Google Scholar] [CrossRef]

- Mahdi Al-Obaidi, A.S.; Naif, A.; Al-Harthi, T.K. Optimisation of the performance of vapour compression cycle using liquid suction line heat exchanger. J. Therm. Eng. 2020, 6, 201–210. [Google Scholar] [CrossRef]

- Thornton, J.; Klein, S.; Mitchell, J. Dedicated mechanical subcooling design strategies for supermarket applications. Int. J. Refrig. 1994, 17, 508–515. [Google Scholar] [CrossRef]

- Khan, J.U.R.; Zubair, S.M. Design and rating of dedicated mechanical-subcooling vapour compression refrigeration systems. Proc. Inst. Mech. Eng. Part A J. Power Energy 2000, 214, 455–471. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. The effect of refrigerant combinations on performance of a vapor compression refrigeration system with dedicated mechanical sub-cooling. Int. J. Refrig. 2012, 35, 47–57. [Google Scholar] [CrossRef]

- She, X.; Yin, Y.; Zhang, X. A proposed subcooling method for vapor compression refrigeration cycle based on expansion power recovery. Int. J. Refrig. 2014, 43, 50–61. [Google Scholar] [CrossRef]

- Miran, A.Z.; Nemati, A.; Yari, M. Performance analysis and exergoeconomic evaluation of a TRC system enhanced by a dedicated mechanical subcooling. Energy Convers. Manag. 2019, 197, 111890. [Google Scholar] [CrossRef]

- Chen, E.; Li, Z.; Yu, J.; Xu, Y.; Yu, Y. Experimental research of increased cooling output by dedicated subcooling. Appl. Therm. Eng. 2019, 154, 9–17. [Google Scholar] [CrossRef]

- Winkler, J.; Aute, V.; Yang, B.; Radermacher, R. Potential benefits of thermoelectric elements used with air-cooled heat exchangers. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue Conference, R091, West Lafayette, IN, USA, 17–20 July 2006. [Google Scholar]

- Radermacher, R.; Yang, B.; Hwang, Y. Integrating alternative and conventional cooling technologies. ASHRAE J. 2007, 49, 28–35. [Google Scholar]

- Schoenfeld, J.; Hwang, Y.; Radermacher, R. CO2 transcritical vapor compression cycle with thermoelectric subcooler. HVAC&R Res. 2012, 18, 297–311. [Google Scholar]

- Sarkar, J. Exergy analysis of vortex tube expansion vapour compression refrigeration system. Int. J. Exergy 2013, 13, 431. [Google Scholar] [CrossRef]

- Kwan, T.H.; Shen, Y.; Wu, Z. Performance analysis of the thermoelectric device as the internal heat exchanger of the trans-critical carbon dioxide cycle. Energy Convers. Manag. 2020, 208, 112585. [Google Scholar] [CrossRef]

- Liu, X.; Yu, K.; Wan, X.; Li, X. Performance evaluation of CO2 supermarket refrigeration system with multi-ejector and dedicated mechanical subcooling. Energy Reports. 2021, 7, 5214–5227. [Google Scholar] [CrossRef]

- Aranguren, P.; Sánchez, D.; Casi, A.; Cabello, R.; Astrain, D. Experimental assessment of a thermoelectric subcooler included in a transcritical CO2 refrigeration plant. Appl. Therm. Eng. 2021, 190, 116826. [Google Scholar] [CrossRef]

- Sharma, D.; Sachdeva, G.; Saini, D.K. Optimised Refrigerant Flow Rate and Dimensions of the Ejector Employed in a Modified Ejector Vapor Compression System. Int. J. Air-Conditioning Refrig. 2020, 28, 2050038. [Google Scholar] [CrossRef]

- Huff, H.; Linsay, D.; Radermacher, R. Positive displacement compressor and expander simulation. In Proceedings of the International Compressor Engineering Conference at Purdue Conference, C9-2, West Lafayette, IN, USA, 16–19 July 2002. [Google Scholar]

- Nickl, J.; Will, G.; Quack, H.; Kraus, W. Integration of a three-stage expander into a CO2 refrigeration system. Int. J. Refrig. 2005, 28, 1219–1224. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, Y.; Cao, F.; Bu, G.; Wang, Z. Simulation study on a novel vane-type expander with internal two-stage expansion process for R-410A refrigeration system. Int. J. Refrig. 2012, 35, 757–771. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Economic analysis of the application of expanders in medium scale air-conditioners with conventional refrigerants, R1234yf and CO2. Int. J. Refrig. 2013, 36, 1472–1482. [Google Scholar] [CrossRef]

- Hu, J.; Li, M.; Li, H.; Xia, B.; Ma, Y. Improvement and experimental research of CO2 two-rolling piston expander. Energy 2015, 93, 2199–2207. [Google Scholar] [CrossRef]

- Disawas, S.; Wongwises, S. Experimental investigation on refrigeration cycle performance using a two-phase ejector as an expansion device. Int. J. Refrig. 2004, 27, 587–594. [Google Scholar] [CrossRef]

- Li, D.; Groll, E.A. Transcritical CO2 refrigeration cycle with ejector-expansion device. Int. J. Refrig. 2005, 28, 766–773. [Google Scholar] [CrossRef]

- Lawrence, N.; Elbel, S. Theoretical and practical comparison of two-phase ejector refrigeration cycles including First and Second Law analysis. Int. J. Refrig. 2013, 36, 1220–1232. [Google Scholar] [CrossRef]

- Boumaraf, L.; Haberschill, P.; Lallemand, A. Investigation of a novel ejector expansion refrigeration system using the working fluid R134a and its potential substitute R1234yf. Int. J. Refrig. 2014, 45, 148–159. [Google Scholar] [CrossRef]

- Lawrence, N.; Elbel, S. Experimental investigation of a two-phase ejector cycle suitable for use with low-pressure refrigerants R134a and R1234yf. Int. J. Refrig. 2014, 38, 310–322. [Google Scholar] [CrossRef]

- Hafner, A.; Försterling, S.; Banasiak, K. Multi-ejector concept for R-744 supermarket refrigeration. Int. J. Refrig. 2014, 43, 1–13. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, L. Effect of Suction Nozzle Pressure Drop on the Performance of an Ejector-Expansion Transcritical CO2 Refrigeration Cycle. Entropy 2014, 16, 4309–4321. [Google Scholar] [CrossRef]

- Jeon, Y.; Kim, S.; Kim, D.; Chung, H.C.; Kim, Y. Performance characteristics of an R600a household refrigeration cycle with a modified two-phase ejector for various ejector geometries and operating conditions. Appl. Energy 2017, 205, 1059–1067. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Reddy, K.K.S.K. Ozone Layer Depletion and Its Effects: A Review. Int. J. Environ. Sci. Dev. 2011, 2, 30–37. [Google Scholar] [CrossRef]

- Kilicarslan, A.; Muller, N. A comparative study of water as a refrigerant with some current refrigerants. Int. J. Energy Res. 2005, 29, 947–959. [Google Scholar] [CrossRef]

- Ciconkov, R. Refrigerants: There is still no vision for sustainable solutions. Int. J. Refrig. 2018, 86, 441–448. [Google Scholar] [CrossRef]

- Giménez-Prades, P.; Navarro-Esbrí, J.; Arpagaus, C.; Fernández-Moreno, A.; Mota-Babiloni, A. Novel molecules as working fluids for refrigeration, heat pump and organic Rankine cycle systems. Renew. Sustain. Energy Rev. 2022, 167, 112549. [Google Scholar] [CrossRef]

- Uddin, K.; Arakaki, S.; Saha, B.B. Thermodynamic analysis of low-GWP blends to replace R410A for residential building air conditioning applications. Environ. Sci. Pollut. Res. 2021, 28, 2934–2947. [Google Scholar] [CrossRef]

- Bell, I.H.; Domanski, P.A.; McLinden, M.O.; Linteris, G.T. The hunt for nonflammable refrigerant blends to replace R-134a. Int. J. Refrig. 2019, 104, 484–495. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Liu, W.; Chen, J. Evaluation of low-GWP and mildly flammable mixtures as new alternatives for R410A in air-conditioning and heat pump system. Int. J. Refrig. 2021, 121, 95–104. [Google Scholar] [CrossRef]

- Franco, I.G.; Pico, D.F.M.; Santos, D.R.D.; Filho, E.P.B. A review on the performance and environmental assessment of R-410A alternative refrigerants. J. Build. Eng. 2021, 47, 103847. [Google Scholar] [CrossRef]

- Hamza, A.; Khan, T.A. Comparative Performance of Low-GWP Refrigerants as Substitutes for R134a in a Vapor Compression Refrigeration System. Arab. J. Sci. Eng. 2020, 45, 5697–5712. [Google Scholar] [CrossRef]

- Harby, K. Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: An updated overview. Renew. Sustain. Energy Rev. 2017, 73, 1247–1264. [Google Scholar] [CrossRef]

- Ikem, I.; AUbi, P.; IIbeh, M.; EOfem, S.; TAssam, A. Review of refrigerants for steam compression refrigeration machines. Int. J. Eng. Technol. 2018, 10, 1172–1180. [Google Scholar] [CrossRef]

- Antunes, A.V.; Filho, E.P.B. Experimental investigation on the performance and global environmental impact of a refrigeration system retrofitted with alternative refrigerants. Int. J. Refrig.-Rev. Int. 2016, 70, 119–127. [Google Scholar] [CrossRef]

- Saengsikhiao, P.; Taweekun, J.; Maliwan, K.; Sae-ung, S.; Theppaya, T. Development of Environmentally Friendly and Energy Efficient Refrigerants for Refrigeration Systems. Energy Eng. 2021, 118, 411–413. [Google Scholar] [CrossRef]

- Beshr, M.; Aute, V.; Sharma, V.; Abdelaziz, O.; Fricke, B.; Radermacher, R. A comparative study on the environmental impact of supermarket refrigeration systems using low GWP refrigerants. Int. J. Refrig. 2015, 56, 154–164. [Google Scholar] [CrossRef]

- McLinden, M.O.; Brown, J.S.; Brignoli, R.; Kazakov, A.F.; Domanski, P.A. Limited options for low-global-warming-potential refrigerants. Nat. Commun. 2017, 8, 14476. [Google Scholar] [CrossRef]

- Wobst, E.; Kalitzin, N.; Apley, R. Turbo Water Chiller with Water as Refrigerant. In Proceedings of the International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 12–15 July 2004. [Google Scholar]

- De Paula, C.H.; Duarte, W.M.; Rocha TT, M.; de Oliveira, R.N.; Maia, A.A.T. Optimal design and environmental, energy and exergy analysis of a vapor compression refrigeration system using R290, R1234yf, and R744 as alternatives to replace R134a. Int. J. Refrig. 2020, 113, 10–20. [Google Scholar] [CrossRef]

- Orshoven, D.V.; Klein, S.A.; Beckman, W.A. Investigation of water as a refrigerant. J. Energ. Resour. Tech. 1993, 115, 257–263. [Google Scholar] [CrossRef]

- Siddegowda, P.; Sannappagowda, G.; Jain, V.; Gowda, S. Hydrocarbons as Alternate Refrigerants to Replace R134a in Domestic Refrigerators. Rev. Compos. Matériaux Av. 2019, 29, 95–99. [Google Scholar] [CrossRef]

- Shoul, H.; Ameri, M.; Mohammadi, S.M.H. Thermodynamic Investigation of Integrated Air Cycle Refrigeration Systems. Int. J. Air-Cond. Refrig. 2017, 25, 1750016. [Google Scholar] [CrossRef]

- Won, S.P. Performance Analysis of an Air-Cycle Refrigeration System. Korean J. Air-Cond. Refrig. Eng. 2012, 24, 671–678. [Google Scholar] [CrossRef]

- Calm, J.M.; Didion, D.A. Trade-offs in refrigerant selections: Past, present, and future. Int. J. Refrig. 1998, 21, 308–321. [Google Scholar] [CrossRef]

- Bolaji, B.; Huan, Z. Ozone depletion and global warming: Case for the use of natural refrigerant—A review. Renew. Sustain. Energy Rev. 2013, 18, 49–54. [Google Scholar] [CrossRef]

- Nebot-Andrés, L.; Catalán-Gil, J.; Sánchez, D.; Calleja-Anta, D.; Cabello, R. Experimental determination of the optimum working conditions of a transcritical CO2 refrigeration plant with integrated mechanical subcooling. Int. J. Refrig. 2020, 113, 266–275. [Google Scholar] [CrossRef]

- Lachner, B.F.; Nellis, G.F.; Reindl, D.T. The commercial feasibility of the use of water vapor as a refrigerant. Int. J. Refrig. 2007, 30, 699–708. [Google Scholar] [CrossRef]

- Wight, S.E.; Yoshinaka, T.; Le Drew, B.A.; D’Orsi Nicholas, C. The Efficiency Limits of Water Vapor Compressors. In ARTI-21CR/605-10010-01; The Air-Conditioning, Heating and Refrigeration Institute (AHRI): Arlington, VA, USA, 2000. [Google Scholar]

- Yuan, W.; Yuan, X.; Yu, Z. Research on performance of water vapor compression refrigerator. J. Refrig. 2003, 3, 16–19. [Google Scholar]

- Alexis, G. Exergy analysis of ejector-refrigeration cycle using water as working fluid. Int. J. Energy Res. 2005, 29, 95–105. [Google Scholar] [CrossRef]

- Sugawara, A. Research for Air Cooling System Using Vacuum-Cooled Water Refrigerant. J. Environ. Eng. 2008, 3, 135–145. [Google Scholar] [CrossRef]

- Li, Q.; Piechna, J.; Müller, N. Aerodynamic design and CFD analysis of a novel axial compressor. In Proceedings of the 40th AIAA Fluid Dynamics Conference and Exhibit, Chicago, IL, USA, 28 June–1 July 2010. [Google Scholar]

- Sarevski, M.N.; Sarevski, V.N. Preliminary study of a novel compact R718 water chiller with integration of a single stage centrifugal compressor and two-phase ejectors. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue, Lafayette, IN, USA, 16–19 July 2012. [Google Scholar]

- Šarevski, M.N.; Šarevski, V.N. Thermal characteristics of high-temperature R718 heat pumps with turbo compressor thermal vapor recompression. Appl. Therm. Eng. 2017, 117, 355–365. [Google Scholar] [CrossRef]

- Shen, J.; Xing, Z.; Zhang, K.; He, Z.; Wang, X. Development of a water-injected twin-screw compressor for mechanical vapor compression desalination systems. Appl. Therm. Eng. 2016, 95, 125–135. [Google Scholar] [CrossRef]

- Kuhnl-Kinel, J. New Age Water Chillers with Water as Refrigerant; ERN-European Organization for Nuclear Research: Geneva, Switzerland, 1998. [Google Scholar]

- Alkhulaifi, Y.; Mokheimer, E. Thermodynamic Assessment of Using Water as a Refrigerant in Cascade Refrigeration Systems with Other Environmentally Friendly Refrigerants. J. Energy Resour. Technol. 2022, 144, 12. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Progress in ground-source heat pumps using natural refrigerants. Int. J. Refrig. 2018, 92, 70–85. [Google Scholar] [CrossRef]

- Shoyama, T.; Kawano, B.; Ogata, T.; Matsui, M.; Furukawa, M.; Dousti, S. Centrifugal turbo chiller using water as refrigerant and lubricant. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2020, 236, 095440892093819. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R.; Fan, H.; Wang, R. The performance comparison of high temperature heat pump among R718 and other refrigerants. Renew. Energy 2020, 154, 715–722. [Google Scholar] [CrossRef]

- Shoyama, T.; Sun, H.; Kawano, B.; Matsui, M. Continuous Cooling Compressor for water refrigerant heat pump. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1180, 012023. [Google Scholar] [CrossRef]

| Refrigerant Group | Description | Examples | Current Status | Availability | Environmental Impact |

|---|---|---|---|---|---|

| CFCs | Chlorofluorocarbons are very harmful to the environment due to their ODP, GWP, and long atmospheric life | R11, R12 | Phased out in Jan 1996, in accordance with the Montreal protocol. | CFCs are usually produced by halogen exchange initiated by chlorinated ethane and methane. | ODP: High, GWP: Medium, Lifetime: 20–100 Years |

| HCFCs | Hydrochlorofluorocarbons have a relatively low ODP, GWP, and atmospheric life | R22, R123 | Phased out in 2020, in accordance with the Montreal protocol. | Derived from propane, ethane, and methane as a volatile component. | ODP: Medium, GWP: Medium, Lifetime: <20 years |

| HFCs | Hydrofluorocarbons have zero ODP but a relatively high GWP | R-134a, R-245fa, R-125, R-32 | Targeted for a phase-down in 2030. | Derived from propane, ethane, and methane as a volatile component. | ODP: Very Low, GWP: Low, Lifetime: <300 years |

| FICs | Fluoroiodocarbons have a ODP close to zero and a low GWP | Ikon-22A, Ikon-12C | New refrigerants. | Produced in the lab or special manufacturing facilities via chemical reactions. | ODP: Very low, GWP: Low Lifetime: Very short (estimated in days) |

| HFOs | Hydrofluorooelifins are stable, with a short atmospheric life, zero ODP and a very low GWP. However, they have relatively low efficiency | R1234yf, R1234ze, R-1233zd | The industry needs to evaluate the environmental benefits against the efficiency of these refrigerants. | Consist of hydrogen, carbon and fluorine atoms, but should have a minimum of one double bond between the carbon atoms. | ODP: Zero, GWP: Very Low Lifetime: <20 years |

| Natural refrigerants | Naturally available with a negligible effect on the environment | R717, R718, R290, R600, R744 | Used currently for various applications. However, they have not been widely adopted due to unfavourable properties. | Available in nature. | ODP: Zero, GWP: Negligible Lifetime: <20 years |

| Refrigerant | Water | Ammonia | Carbon Dioxide | Isobutane | Propane | Tetrafluoroethane |

|---|---|---|---|---|---|---|

| Code | R-718 | R-717 | R-744 | R-600a | R-290 | R-134a |

| ODP | 0 | 0 | 0 | 0 | 0 | 0 |

| GWP (100 Years) | <1 | <1 | 1 | <5 | 20 | 1430 |

| Critical temperature (°C) | 373.9 | 132.2 | 31 | 134.7 | 96.7 | 101.06 |

| Critical pressure (kPa) | 22.06 | 11.33 | 7.38 | 3.629 | 4.25 | 4.059 |

| Normal boiling temperature (°C) | 100 | −33 | −78.4 | −11.7 | −42.2 | −26.074 |

| Freezing temperature (°C) | 0 | −77.7 | −56.55 | −159.6 | −188 | −103.3 |

| Latent heat of vaporization at 20 °C (kJ/kg) | 2453.8 | 1187.2 | 155.2 | 367 | 344.3 | 180 |

| Safety Classification | A1 | B2 | A1 | A3 | A3 | A1 |

| Refrigerant | Cycle | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Air | Joule (Reverse Brayton) | Airplane cabin air-conditioning | Safety, availability, environmentally Friendly | Relatively low cycle efficiency |

| Water | Absorption and Carnot | Absorption Chillers, evaporative cooling, high-temperature heat pump and VCR | Safety, availability, environmentally friendly, stability, efficiency | High boiling temperature, large specific volume, corrosive |

| Hydrocarbons | Carnot | Small-charge refrigeration systems, truck refrigeration, and small-tonnage chillers | Suitable thermodynamic properties, low environmental impact, availability. | Extremely flammable |

| Carbon Dioxide | Carnot | Large-scale refrigeration, cascade refrigeration | Safety, availability, low cost | Requires a high pressure to condense, high system costs |

| Ammonia | Absorption and Carnot | Large-scale refrigeration, Absorption chillers | Good thermodynamic properties, efficiency, availability, low cost, and low environmental impact | Toxic at high concentration, requires highly trained operators, slightly flammable |

| Advantages of Water as a Refrigerant | |

|---|---|

| Availability | Water is available in nature in large quantities and at a low cost. |

| Environment friendly | Water has no impact on the environment, with ODP = 0 and GWP < 1. |

| Safety | Water is non-toxic and neither flammable nor explosive, and is easy to dispose of after use. |

| Stability | Water is chemically stable and suitable for long-term use. |

| Thermodynamic properties | Water has favourable thermodynamic properties, such as a large latent heat of vaporisation and thermal capacity. Hence, it has a high COP. |

| Strategic Choice | Moving to water as a refrigerant eliminates the uncertainty regarding changes to the regulations and restrictions. |

| Disadvantages of water as a refrigerant | |

| Technical | Water vapor has a very high specific volume, which requires a high volumetric flow rate. In addition, it requires a high compression ratio, which causes a high compressor discharge temperature. |

| Economical | It is very costly to design compressors that enable water to be used as a refrigerant. |

| Space | Due to the high volumetric flow rate required for water, the equipment that uses water as a refrigerant is commonly larger, requiring more space. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsouda, F.; Bennett, N.S.; Saha, S.C.; Salehi, F.; Islam, M.S. Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants. Clean Technol. 2023, 5, 584-608. https://doi.org/10.3390/cleantechnol5020030

Alsouda F, Bennett NS, Saha SC, Salehi F, Islam MS. Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants. Clean Technologies. 2023; 5(2):584-608. https://doi.org/10.3390/cleantechnol5020030

Chicago/Turabian StyleAlsouda, Fadi, Nick S. Bennett, Suvash C. Saha, Fatemeh Salehi, and Mohammad S. Islam. 2023. "Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants" Clean Technologies 5, no. 2: 584-608. https://doi.org/10.3390/cleantechnol5020030

APA StyleAlsouda, F., Bennett, N. S., Saha, S. C., Salehi, F., & Islam, M. S. (2023). Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants. Clean Technologies, 5(2), 584-608. https://doi.org/10.3390/cleantechnol5020030