Abstract

Sugarcane bagasse (SCB), a by-product of the sugar industry, is composed mainly of cellulose, hemicelluloses, and lignin, and can be used to replace petrochemical polymers in various applications. In this work, SCB was treated under mild alkaline conditions with 1.5% NaOH (m:v) and a solid:liquid ratio of 1:20 (m:v) at 60 °C, during 6 h. A 10 kDa polysulfone hollow fiber membrane was used for the purification of the extract in different filtration modes, namely concentration and diafiltration, and a combination of both modes. Permeate fluxes and rejection rates were evaluated at different transmembrane pressure (TMP) at the shear rate of 10,187 s–1, at 40 °C. In concentration mode, increasing the volume reduction factor up to 6.1 led to a significant increase in the retention rates of acid-soluble lignin (ASL) and xylan, and a decrease in inorganic salt content in the retentate. In diafiltration mode, after 2.9 diavolumes, the acid-insoluble lignin (AIL) and xylan rejection rates drastically increased, as did the rejection rates of ash.

1. Introduction

Sugarcane bagasse (SCB) is the solid residue that remains after sugar extraction from sugarcane and is one of the most abundant lignocellulosic biomasses. The main composition of SCB is approximately 32 to 43% cellulose, 19 to 24% hemicelluloses, and 25 to 32% lignin [1,2]. These compounds are considered to have a high potential as alternatives to fossil hydrocarbons to produce second-generation biofuels and bio-based chemicals and materials. Various effective treatment methods to fractionate SCB components have been studied in the literature, including dilute acid pretreatment, liquid hot water extraction, steam explosion, ionic liquids, and alkaline extraction [3,4,5,6]. The choice of extraction method depends on the facilities, target molecules extracted, and the final application. Mild alkaline treatment, as opposed to the drastic conditions employed in the pulp and paper industry, has usually been studied in the frame of a second-generation cellulosic ethanol biorefinery for the recovery of hemicelluloses and lignin in the extract, leading to a cellulosic solid residue [7]. Compared to other methods, the mild alkaline methods have the advantage of removing the lignin without degrading the other components, usually due to milder process conditions. Among several alkalis used, sodium hydroxide is the most popular base catalyst thanks to the high extraction yield of lignin and hemicellulose [6,7,8].

Alkaline extracts are mainly composed of phenolic and sugar oligomers, but also contain ash, acetic acid, monomers of sugars, and phenolic compounds (e.g., para-coumaric acid and ferulic acid) that need to be removed for further valorization of the phenolic oligomers. In order to separate molecules by their size, membrane filtration is known to be an effective process with respect to its low levels of chemical and energy consumption [9,10]. The largest challenge of this technique is membrane fouling which can reduce the permeate flux, as well as the selectivity performances [11]. Hemicelluloses purification from lignocellulosic alkaline extract has been studied through membrane filtration under many different conditions. For example, hollow fiber membranes have been used on wheat bran alkaline extract to purify hemicelluloses from ash and other small molecules [12]. Retention of 69 to 81% of hemicelluloses has been reached by ultrafiltration of black liquor on inorganic membranes [13], and retention of up to 70% of the hemicelluloses has been reached on spiral wound membrane from viscose pulp-steeping [14]. Moreover, smaller molecular weight cut-offs gave a higher retention rate of molecules, and the lignin retention was 46, 70, and 89% for the 100, 10, and 1 kDa membranes, respectively. Similarly, the sugars retention was 42.5, 76 and 86.8% [15]. Overall, membrane filtration has been studied for the purification of hemicelluloses and lignin, mostly from the black liquors obtained in the strongly alkaline conditions used in the pulp and paper industry. Only a few studies have investigated the membrane filtration of lignocellulosic mild alkaline extracts which contain shorter hemicelluloses and lignin oligomers and NaOH salts [12,16].

Aoustin et al. (2001) [17] highlighted the interest in using ultrafiltration as a means to purify biopolymer solutions, but also raised the complexity of the choice of the membrane type and the operating conditions in order to limit clogging. According to the work of Oriez et al. (2019) [18], among seven tested membranes in recycling mode, the 10 kDa polyethersulfone hollow fiber had the highest retention for hemicelluloses and acid-insoluble lignin (AIL). The filtration could be run in concentration mode, where only the retentate is recycled to the tank while the permeate is recovered, to concentrate the target molecules, i.e., hemicelluloses and lignin, and to remove ash, phenolic monomers, and acetate—which is formed during alkaline extraction by the hydrolysis of acetate groups from hemicelluloses. Additionally, the diafiltration mode could improve the removal of small compounds, leading to higher purity of retained compounds [18]. Several successive concentrations by a volume reduction factor (VRF) of 3.6 of wheat bran acid extract were run on the 10 kDa organic membrane and the flux was on average about 10 L.h−1.m−2 showing good reproducibility. Afterward, diafiltration with 2.5 diavolumes was required in order to maximize sugar recovery in the permeate (99% recovery) [19]. Jönsson et al. have presented a promising reflection on the purification of alkaline extracts from bran by a combination of diafiltration and concentration steps [10,13] that inspired this study. However, in this work, the process is applied to an SCB extract containing mostly xylans instead of galactomannan, and ultrafiltration is performed with organic membranes.

Therefore, in continuity with the work of Oriez et al. (2019), the objectives of this study were to perform filtration of sugarcane bagasse milk alkaline extracts in concentration or/and diafiltration mode. The idea was to increase the concentration of larger molecules (acid-insoluble lignin and hemicellulose) and remove the smaller ones in the retentate, then scale up this process. Based on the results of Oriez et al. (2019) [17], the membrane providing the best performances (molecules retention and flux), the 10 kDa hollow fiber membrane, was selected to perform filtration in concentration or/and diafiltration mode in order to scale up this process.

2. Materials and Methods

2.1. Chemicals

For the extraction step, sodium hydroxide (≥98.5%) was used. In order to analyze the total sugars in the extract, 72% sulfuric acid was used for the hydrolysis according to the protocol of the National Renewable Energy Laboratory (NREL) [20]. For the HPLC analyses, the following sugar standards were used: D-(+)-glucose (≥99.5%), D-(+)-galactose (≥99%), L-(+)-arabinose (≥99%), D-(+)-xylose (≥99%). The following phenolic monomers were used: vanillic acid (97%), 4-hydroxybenzaldehyde (4HBA) (98%), vanillin (99%), para-coumaric acid (p-CA) (≥98%), trans-ferulic acid (FA) (≥99%). All of the chemicals were purchased from Sigma Aldrich, St. Louis, MO, USA.

2.2. Extraction

The alkaline extraction was carried out with a solid:liquid ratio of 1:20 (m:v), 1.5% NaOH (m:v), 60 °C, and 6 h. Experiments were performed in a stainless steel-line vessel (De Dietrich, France) with continuous mechanical stirring (200 rpm). The solid residues were removed by a top-discharge vertical basket centrifuge (RC 50 PX R, Rousselet, France) equipped with a 5 μm polypropylene bag. Solid residues were rinsed with distilled water, dried at 50 °C for 48 h, and ground using a microfine grinder (IKA MF 10 basic) on a 1 mm sieve before analysis. The filtered SCB alkaline extract and the water used to rinse the solid residue were mixed, analyzed, and used as the feed for the membrane filtration experiments. This mixture is referred to hereafter as the SCB alkaline extract.

2.3. Filtration Set-Up

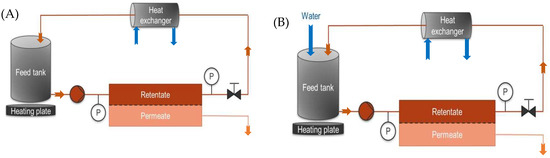

The extract was placed in a 5 L tank. A gear pump (model 10/0005, Johnson Pump, Charlotte, NC, USA) was used to circulate it to the membrane (Figure 1). The feed volumetric flow rate was measured with a flowmeter (Rosemount, Mexico City, Mexico). Permeates were collected on a balance over a given time period to calculate fluxes. Transmembrane pressure (TMP) was set by a valve on the retentate stream and measured with two manometers (Tecsis, Offenbach, Germany) located at the inlet and the outlet of the membrane cartridge, on the retentate stream. The temperature was tuned by a hot plate (Heidolph, Schwabach, Germany) at the bottom of the tank and with a monotube heat exchanger, fed with water at 14 °C, located on the retentate stream. The difference between the inlet and outlet of the membrane (pressure drop) was about 0.2 bar during the whole filtration process.

Figure 1.

Filtration systems: (A) concentration mode and (B) diafiltration mode.

The transmembrane pressure (TMP) is calculated by the Equation (1):

where Ppermeate was equal to atmospheric pressure, and Pinlet and Poutlet were relative pressures.

The shear rate ɣ (s–1) is given from Equation (2):

where Q is the volumetric flow rate through a fiber (m3·s−1), r is the fiber radius (m).

The same conditions used by Oriez et al. [17] were applied including the shear rate of 10,187 s–1, and the TMP of 2.4 bar, at 40 °C.

Concentration experiments were run in semi-batch mode, meaning that the permeate was collected and the retentate was recycled. Concentration was expressed as volume reduction factor (VRF), following Equation (3):

where Vinitial and Vfinal were the volumes of the feed at the beginning and at the end of the concentration experiment, respectively.

For concentration and diafiltration experiments, the yield (Y), also named the recovery rate, of a given compound was determined following Equations (4) and (5), respectively.

where Ci is the concentration of the compound in the feed, the final retentate, or the overall permeate, and V is the volume of feed, final retentate or overall permeate.

The rejection or retention rate R was estimated from Equation (6):

where Ci permeate and Ci retentate are the solute concentrations (g/L) in the permeate and the retentate streams, respectively. The molecules i were measured, including hemicellulose, lignins, p-coumaric acid, acetic acid, and ash.

Diafiltration volume or diavolume was calculated from Equation (7).

The diavolumes are defined as the ratio of the volume of added water to the initial volume of the feed.

No repetition was conducted on the concentration and diafiltration tests, but was conducted during membrane screening with two new 10 kDa membranes. The repeatability was performed in recycling mode where both retentate and permeate return to the feed tank. The results showed that the permeate flux had the same behavior for all shear rates tested, but the second membrane gave lower fluxes with a variation of 30% at 0.8 bars and 7% at 2.8 bars. The retention rates of AIL and xylose were slightly different with a 3% and 5% difference, respectively.

2.4. Membranes Characteristics

SCB extract was filtrated with a 10 kDa polyethersulfone (PES) hollow fiber membrane from GE-Healthcare (Table 1).

Table 1.

Characteristics of the membrane UFP-10-E-4X2MA used for the filtration.

2.5. Analytical Method

2.5.1. Determination of Dry Matter and Ash

Dry solid (DS) content was gravimetrically determined by drying the sample at 100 °C for 12 h and ash content at 500 °C for 12 h.

2.5.2. Carbohydrates and Lignin

Carbohydrates and lignin were analyzed according to the procedure of the NREL [20]. Samples were hydrolyzed by 72% sulfuric acid for 1 h at 121 °C. The resulting monomeric sugars solution was analyzed by high-performance liquid chromatography (HPLC) on a Rezex RPM-monosaccharide Pb2+ (300 × 7.8) mm column (Phenomenex), used together with a Rezex RPM-monosaccharide Pb2+ (50 × 7.8) mm guard column (Phenomenex). Isocratic conditions were applied with 5 mmol/L H2SO4 at 0.6 mL/min, the injection volume was 50 μL, the column was maintained at 65 °C and the RI detector at 50 °C. Acid-insoluble lignin (AIL) was measured gravimetrically as the solid residue obtained after the sulfuric hydrolyses. Acid-soluble lignin (ASL) was determined by UV spectrophotometry on the filtrate at a wavelength of 240 nm. Standard deviation was calculated from two repetitions of the sample hydrolysis and two repetitions of the analysis of each.

2.5.3. Phenolic Monomers

The analysis was carried out on an OmniSpher 3 C18 (100 × 4.6 mm) column (Agilent Technologies). The gradient was as follows: 91% acidified water (1% acetic acid (v:v)) and 9% acetonitrile for 25 min, acetonitrile concentration increasing from 9 to 90% over 5 min, then kept constant for 5 min, before decreasing back to 91% acidified water over 5 min, with column equilibration for 7 min between runs. The flow rate was 0.5 mL/min, the injection volume was 10 µL, and the column temperature was maintained at 25 °C. The wavelength of the UV detector was set to 280 nm since it corresponds to the maximum absorbance of phenolic monomers such as p-CA and FA [21]. Data acquisition was performed using the Chromeleon 6.8 software Chromatography Data System (Dionex). Standard deviation was calculated from two repetitions of the sample analysis.

3. Results and Discussion

3.1. Filtration in Concentration Mode

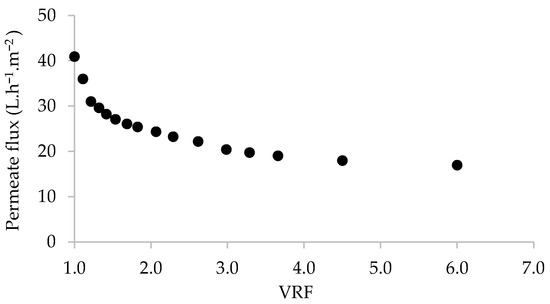

The permeate flux presented a logarithmic decrease with a TMP of 2.4 bar during the concentration experiments of the SCB alkaline extract. At the beginning of the concentration, the flux was 41 L·h−1·m−2, and dropped to 17 L·h−1·m−2 at a VRF of 6.0 (Figure 2). The flux dramatically decreased at the beginning of the concentration due to the apparition of the polarization layer adding a resistance to the membrane resistance. After the stabilization of the layer, the flux progressively decreased. This may be due to the viscosity changes of the solution and/or an increase in the osmotic pressure and/or the progressive fouling of the membrane [10], but these hypotheses would have to be confirmed. Besides, the membrane fouling could be responsible by several mechanisms, such as adsorption of molecules in the pores of the membrane blocking the pores, or cake formation on the surface of the membrane. Moreover, the membrane could be fouled by polysaccharides [22] and lignin [23], and hydrophobic extractives [24]. Jonsson et al., in several publications, also demonstrated the impact of the presence of AIL complexes that form either a layer or a pore fouling during ultrafiltration. A liquid/solid pre-treatment by centrifugation therefore allowed the filtration fluxes to be improved [10,13,25,26].

Figure 2.

Evolution of the permeate flux during the concentration mode.

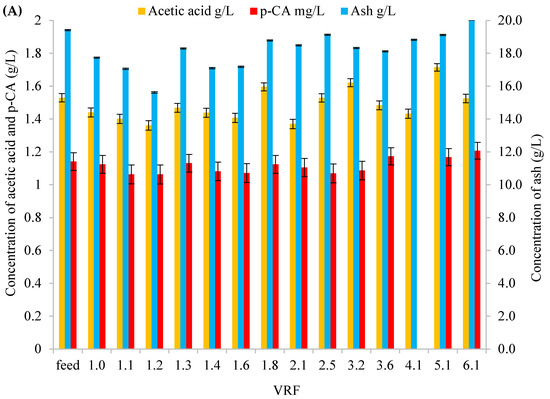

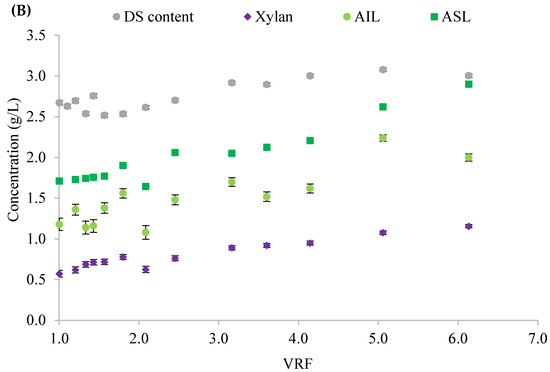

During the concentration experiment, the retention rates of ash, acetic acid, and p-CA were close to 0% (Figure 3A). The same trend was observed with vanillic acid, 4HBA, vanillin, and FA, but since their concentrations were much lower, they were not reported in Figure 3. This low rejection rate combined with the high retention of AIL and xylan led to an increase in the purity of these latter molecules. The concentration of AIL, ASL, and xylan increased in the permeate with increasing VRF (Figure 3B). This observation could be due to the increase in the concentration gradient between the feed stream and the permeate stream, inducing a higher dragging force by diffusion [27].

Figure 3.

(A) Concentration of acetic acid, p-CA, and ash in the feed and in the permeates collected during the concentration; (B) Evolution of the concentration of dry solid (DS) content, xylan, AIL, and ASL in the permeate.

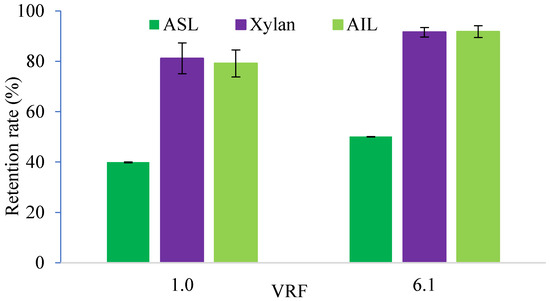

During the concentration experiment, the retention rate of both AIL and xylan increased by about 10% to reach 92% at a VRF of 6.1 (Figure 4). Due to the wide range in the size of these molecules, the small ones were washed out, leading to the increase in the mean molecular size, then increasing the concentration of molecules [26]. The retention rates of ash, acetic acid, and p-CA remained stable as their concentration did not significantly change from the beginning to the end of the experiment in both the permeate and the retentate.

Figure 4.

Retention rate of ASL, xylan, and AIL at the beginning (VRF = 1.0) and at the end of the concentration (VRF = 6.1).

The composition of the overall permeate and final retentate, and the yield of the different components of the feed in these two fractions, are reported in Table 2. At a VRF of 6.1, the ash, acetic acid, and p-CA were mainly recovered in the permeate with values of 78, 81, and 84%, respectively. On the contrary, glucan (55%), xylan (82%), arabinan (74%), and AIL (72%) were recovered in the retentate. Therefore, the purity of glucan, xylan, arabinan, and AIL was increased in the retentate compared to the feed from 1.4 to 2.0%, 8.8 to 18.2%, 2.2 to 4.0%, and 17.9 to 32.4%, respectively. The inorganic ash content in the retentate was drastically decreased but still accounted for 27.8% of the DS content of the final retentate. After the filtration of SCB mild alkaline extract in concentration mode by a VRF of 6.1, the concentrations of glucan, xylan, arabinan, and AIL were multiplied by 3.0, 4.5, 4.0, and 4.0, respectively.

Table 2.

Feed, overall permeate, final retentate composition and yields of the various components after concentration by a VRF of 6.1.

The concentration step enabled us to concentrate the retained species and also to purify them by removing a fraction of the small molecules from the SCB alkaline extract. However, as the ash content was initially high in the alkaline extract, it still accounted for 27.8% of the DS content of the retentate. A diafiltration step could be run afterward on the retentate to further remove the ash.

3.2. Diafiltration Mode

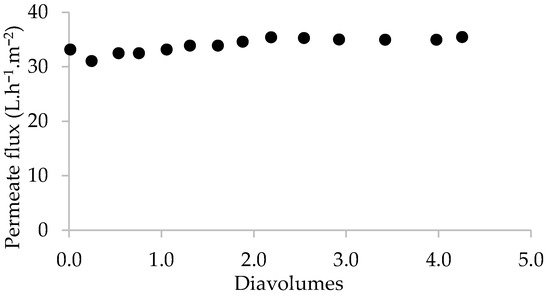

Diafiltration was directly run on another batch of SCB alkaline extract (5 L) on the same extraction conditions and not on the concentrated SCB alkaline extract in order to study the effect of running it potentially before the concentration mode. After a small decrease down to 31 L.h−1.m−2 at the beginning, the permeate flux slightly increased during the diafiltration, from 33 to 35 L.h−1.m−2 after 4.25 diavolumes of water were added (Figure 5). The flux increase could be a result of the viscosity decrease when the concentration of small molecules was reduced. In the research of J. Thuvander et al. (2020), the same trend of flux and the impact of viscosity were also indicated [27].

Figure 5.

Evolution of the permeate flux in the diafiltration mode.

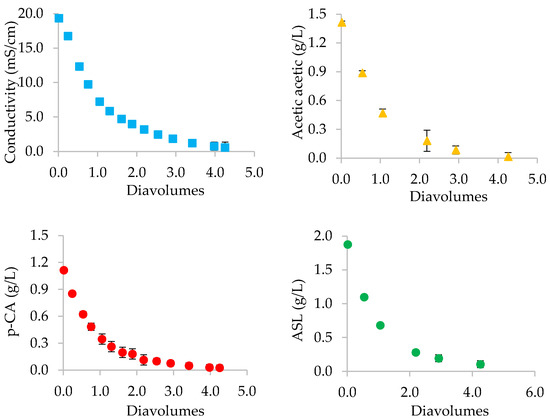

On average, the flux during diafiltration mode was higher than during the concentration mode. As the concentration of the small molecules, (ash, acetic acid, and phenolic monomers) decreased in the retentate, the osmotic pressure decreased as well, leading to a higher effective TMP and a higher flux, compensating for the drop of flux usually observed over time during filtration experiments. The small molecules concentration rapidly decreased in the permeate during the diafiltration (Figure 6).

Figure 6.

Evolution of the conductivity (reflecting the ash concentration) and the concentrations of acetic acid, p-CA, and ASL in the permeate during the continuous diafiltration vs. added diavolumes.

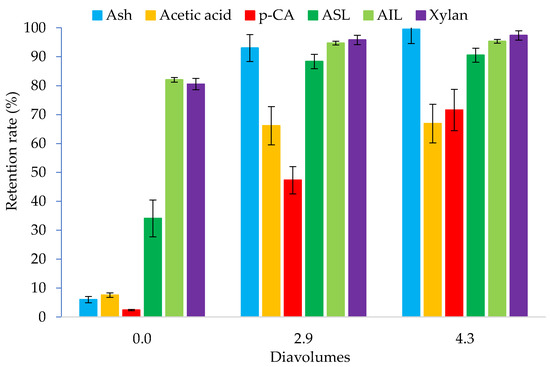

As for the concentration mode, the retention rates of large molecules increased with the diavolumes (Figure 7). After 2.9 diavolumes, the rejection rates of AIL and xylan reached 95% and 96%, respectively. However, unlike the concentration mode experiment, the rejection rates of the small molecules drastically increased. Ash rejection was over 90% after 2.9 diavolumes and reached a quasi-total rejection (over 99%) after 4.3 diavolumes. This result is similar to the work of J. Thuvander et al., (2020) when the ash was removed completely from the feed solution after 4 h of filtration [15]. At the end of the diafiltration, the retention rates of p-CA and acetic acid increased to a lower extent, by 72% and 67%, respectively. At 2.9 diavolumes, the concentrations of the small molecules in the retentate were already drastically reduced compared to their initial concentration, for instance for acetic acid and p-CA, from 1.4 to 0.1 g/L and 1.1 to 0.1 g/L, respectively (Figure 7). Therefore, in an integrated process, diafiltration should be stopped at 3 diavolumes or before, to optimize the water consumption.

Figure 7.

Retention rates of the SCB extract components during the diafiltration.

The ash retention rate increased from 6% at the beginning of the diafiltration to 93% after 2.9 diavolumes, thus limiting ash elimination in the permeate (Figure 7). Acetic acid and phenolic monomers, with purities of 0.5% and 1.3% of the DS, respectively, were almost totally removed from the retentate (Table 3), since their rejection did not increase to the same extent as the ash rejection rate (Figure 7). The high ash rejection rate could be due to the formation of bonds between the ash and the large retained molecules [28,29]. In diafiltration mode, the increase in purity of lignin and xylan was limited with respect to the concentration mode, since the ash was poorly eliminated with diafiltration.

Table 3.

Feed, overall permeate, final retentate composition, and components yield after diafiltration with 4.3 diavolumes.

Diafiltration with 4.3 diavolumes of water led to higher purity of xylan (20.2%) and AIL (42.3%) than concentration with a VRF of 6.1. Surprisingly, the retention of xylan and AIL differed between the experiment in concentration mode and the experiment in diafiltration mode with AIL being more retained than xylan in diafiltration mode, 75% and 66%, respectively; and xylan being more retained than AIL in concentration mode, 82% and 72%, respectively.

For both the concentration and diafiltration mode experiments, the recovery rates of xylan and arabinan in the retentate were close, whereas the recovery of glucan was about 20%, lower than those of the two previous sugars. The molar mass of the glucans is usually described as lower than the molar of the xylans and arabinans.

3.3. Combination of Concentration and Diafiltration Modes

In order to increase the purity of the retained molecules and increase the yield of the molecules passing through the membrane, diafiltration was tested with 2.9 diavolumes after the concentration step.

From the Table 4, it can be seen that after successive concentration and diafiltration, the recovery rates of AIL and xylan reached 71% and 67% in the retentate, respectively. The diafiltration mode increased the purity of retained molecules by removing the small ones, from 32.4% to 48.8% for AIL. Ash was not fully removed, since as for the concentration mode, the retention of the molecules increased during the process, making additional diavolumes inefficient to increase the xylan and AIL purity. However, 90% of the ash was eliminated from the feed, originally containing 56% of ash, leading to a content of 22% in the retentate after the concentration and diafiltration modes. Compared to individual concentration and diafiltration experiments, the combination of the two processes increased the ash removal yield by 18.6 and 29%, respectively.

Table 4.

Composition of the retentate and the permeate streams after combining concentration and diafiltration modes.

4. Conclusions

Membrane filtration could be used for the purification of SCB alkaline extract to separate sugar and lignin oligomers from ash, phenolic monomers, and acetic acid. Filtration in concentration mode enabled to concentrate xylan and AIL in the retentate until a VRF of 6.1 with a recovery rate of 82% for the xylans and 72% for the AIL. However, high ash content remained in the retentate, impacting the purity of hemicelluloses and lignin. Diafiltration was tested to remove the ash to a larger extent, but was found poorly efficient, still accounting for 27.8% of the DS content of the final retentate, since the ash retention increased with the added diavolumes. Diafiltration gave a higher permeate flux, leading to a similar yield for xylan and AIL, and a higher purity than with concentration mode. The main drawback of diafiltration is a lower concentration of xylans and AIL in the retentate, implying an extra step and energy consumption to concentrate it before further treatment. Finally, the choice between concentration and diafiltration of SCB alkaline extract has to be determined according to the objectives of the separation and the cost of the process.

Author Contributions

Conceptualization: V.O. and P.-Y.P.; writing, original draft preparation: V.O., N.T.-T.P.; review and editing: V.O., N.T.-T.P., J.P., P.B. and P.-Y.P. All authors have read and agreed to the published version of the manuscript.

Funding

We would like to thank the ANR (Agence Nationale de la Recherche) for financial support for this research in the framework of the LigNov project (ANR-14-CE06-0025-01).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sakdaronnarong, C.; Jonglertjunya, W. Rice straw and sugarcane bagasse degradation mimicking lignocellulose decay in nature: An alternative approach to biorefinery. ScienceAsia 2012, 38, 364–372. [Google Scholar] [CrossRef]

- Thite, V.S.; Nerurkar, A.S. Valorization of sugarcane bagasse by chemical pretreatment and enzyme mediated deconstruction. Sci. Rep. 2019, 9, 15904. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.-H.; Chen, H.-Z. Xylose production from corn stover biomass by steam explosion combined with enzymatic digestibility. Bioresour. Technol. 2015, 193, 345–356. [Google Scholar] [CrossRef]

- Timung, R.; Mohan, M.; Chilukoti, B.; Sasmal, S.; Banerjee, T.; Goud, V.V. Optimization of dilute acid and hot water pretreatment of different lignocellulosic biomass: A comparative study. Biomass Bioenergy 2015, 81, 9–18. [Google Scholar] [CrossRef]

- Choi, W.-I.; Park, J.-Y.; Lee, J.-P.; Oh, Y.-K.; Park, Y.C.; Kim, J.S.; Park, J.M.; Kim, C.H.; Lee, J.-S. Optimization of NaOH-catalyzed steam pretreatment of empty fruit bunch. Biotechnol. Biofuels 2013, 6, 170. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- Oriez, V.; Peydecastaing, J.; Pontalier, P.-Y. Lignocellulosic Biomass Mild Alkaline Fractionation and Resulting Extract Purification Processes: Conditions, Yields, and Purities. Clean Technol. 2020, 2, 91–115. [Google Scholar] [CrossRef]

- Peng, F.; Peng, P.; Xu, F.; Sun, R.-C. Fractional purification and bioconversion of hemicelluloses. Biotechnol. Adv. 2012, 30, 879–903. [Google Scholar] [CrossRef]

- He, Y.; Bagley, D.M.; Leung, K.T.; Liss, S.N.; Liao, B.-Q. Recent advances in membrane technologies for biorefining and bioenergy production. Biotechnol. Adv. 2012, 30, 817–858. [Google Scholar] [CrossRef]

- Krawczyk, H.; Arkell, A.; Jönsson, A.-S. Impact of prefiltration on membrane performance during isolation of hemicelluloses extracted from wheat bran. Sep. Purif. Technol. 2013, 116, 192–198. [Google Scholar] [CrossRef]

- Rudolph, G.; Thuvander, J.; Jönsson, A.-S.; Lipnizki, F. Fouling and cleaning of membranes in biorefineries. In Proceedings of the 7th Nordic Wood Biorefinery Conference, Stockholm, Sweden, 28–30 March 2017; pp. 196–197. [Google Scholar]

- Zeitoun, R.; Pontalier, P.Y.; Marechal, P.; Rigal, L. Twin-screw extrusion for hemicellulose recovery: Influence on extract purity and purification performance. Bioresour. Technol. 2010, 101, 9348–9354. [Google Scholar] [CrossRef]

- Wallberg, O.; Jönsson, A.-S. Separation of lignin in kraft cooking liquor from a continuous digester by ultrafiltration at temperatures above 100 °C. Desalination 2006, 195, 187–200. [Google Scholar] [CrossRef]

- Singh, S.C.; Murthy, Z.V.P. Hemicelluloses separation from caustic-containing process stream by ultrafiltration. Sep. Sci. Technol. 2017, 52, 2252–2261. [Google Scholar] [CrossRef]

- Mazar, A.; Jemaa, N.; Al Dajani, W.W.; Marinova, M.; Perrier, M. Influence of membrane filtration on extraction and characteristics of lignin from a kraft dissolving pulp mill pre-hydrolysate. Ind. Crops Prod. 2018, 124, 726–734. [Google Scholar] [CrossRef]

- Toledano, A.; García, A.; Mondragon, I.; Labidi, J. Lignin separation and fractionation by ultrafiltration. Sep. Purif. Technol. 2010, 71, 38–43. [Google Scholar] [CrossRef]

- Aoustin, E.; Schäfer, A.I.; Fane, A.G.; Waite, T.D. Ultrafiltration of natural organic matter. Sep. Purif. Technol. 2001, 22–23, 63–78. [Google Scholar] [CrossRef]

- Oriez, V.; Peydecastaing, J.; Pontalier, P.-Y. Separation of sugarcane bagasse mild alkaline extract components by ultrafiltration—Membrane screening and effect of filtration parameters. Process Biochem. 2019, 78, 91–99. [Google Scholar] [CrossRef]

- Blanc, C.-L.; Lemaire, J.; Duval, F.; Théoleyre, M.-A.; Pareau, D. Purification of pentoses from hemicellulosic hydrolysates without neutralization for sulfuric acid recovery. Sep. Purif. Technol. 2017, 174, 513–519. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure (LAP), National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Holser, R. Near-Infrared Analysis of Peanut Seed Skins for Catechins. Am. J. Anal. Chem. 2014, 5, 378–383. [Google Scholar] [CrossRef]

- Puro, L. Identification of Extractives and Polysaccharides as Foulants in Membrane Filtration of Pulp and paper Mill Effluents; Lappeenranta University of Technology: Lappeenranta, Finland, 2011; ISBN 978-952-265-199-0. Available online: https://lutpub.lut.fi/handle/10024/72637 (accessed on 26 January 2023).

- Carlsson, D.J.; Dal-Cin, M.M.; Black, P.; Lick, C.N. A surface spectroscopic study of membranes fouled by pulp mill effluent1Issued as NRC #41964.1. J. Membr. Sci. 1998, 142, 1–11. [Google Scholar] [CrossRef]

- Puro, L.; Kallioinen, M.; Mänttäri, M.; Nyström, M. Evaluation of behavior and fouling potential of wood extractives in ultrafiltration of pulp and paper mill process water. J. Membr. Sci. 2011, 368, 150–158. [Google Scholar] [CrossRef]

- Thuvander, J.; Jönsson, A.-S. Extraction of galactoglucomannan from thermomechanical pulp mill process water by microfiltration and ultrafiltration—Influence of microfiltration membrane pore size on ultrafiltration performance. Chem. Eng. Res. Des. 2016, 105, 171–176. [Google Scholar] [CrossRef]

- Thuvander, J.; Jönsson, A.-S. Techno-economic impact of air sparging prior to purification of alkaline extracted wheat bran hemicelluloses by membrane filtration. Sep. Purif. Technol. 2020, 253, 117498. [Google Scholar] [CrossRef]

- Pontalier, P.-Y.; Ismail, A.; Ghoul, M. Mechanisms for the selective rejection of solutes in nanofiltration membranes. Sep. Purif. Technol. 1997, 12, 175–181. [Google Scholar] [CrossRef]

- Silalahi, J. Hemicellulose: Isolation and Its Application in Pharmacy. In Handbook of Sustainable Polymers: Processing and Applications; Pan Stanford Publishing: Redwood City, CA, USA, 2016; pp. 305–339. ISBN 978-981-4613-53-8. [Google Scholar]

- Sen, S.; Martin, J.D.; Argyropoulos, D.S. Review of Cellulose Non-Derivatizing Solvent Interactions with Emphasis on Activity in Inorganic Molten Salt Hydrates. ACS Sustain. Chem. Eng. 2013, 1, 858–870. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).