Model-Based Predictive Control of a Solar Hybrid Thermochemical Reactor for High-Temperature Steam Gasification of Biomass

Abstract

1. Introduction

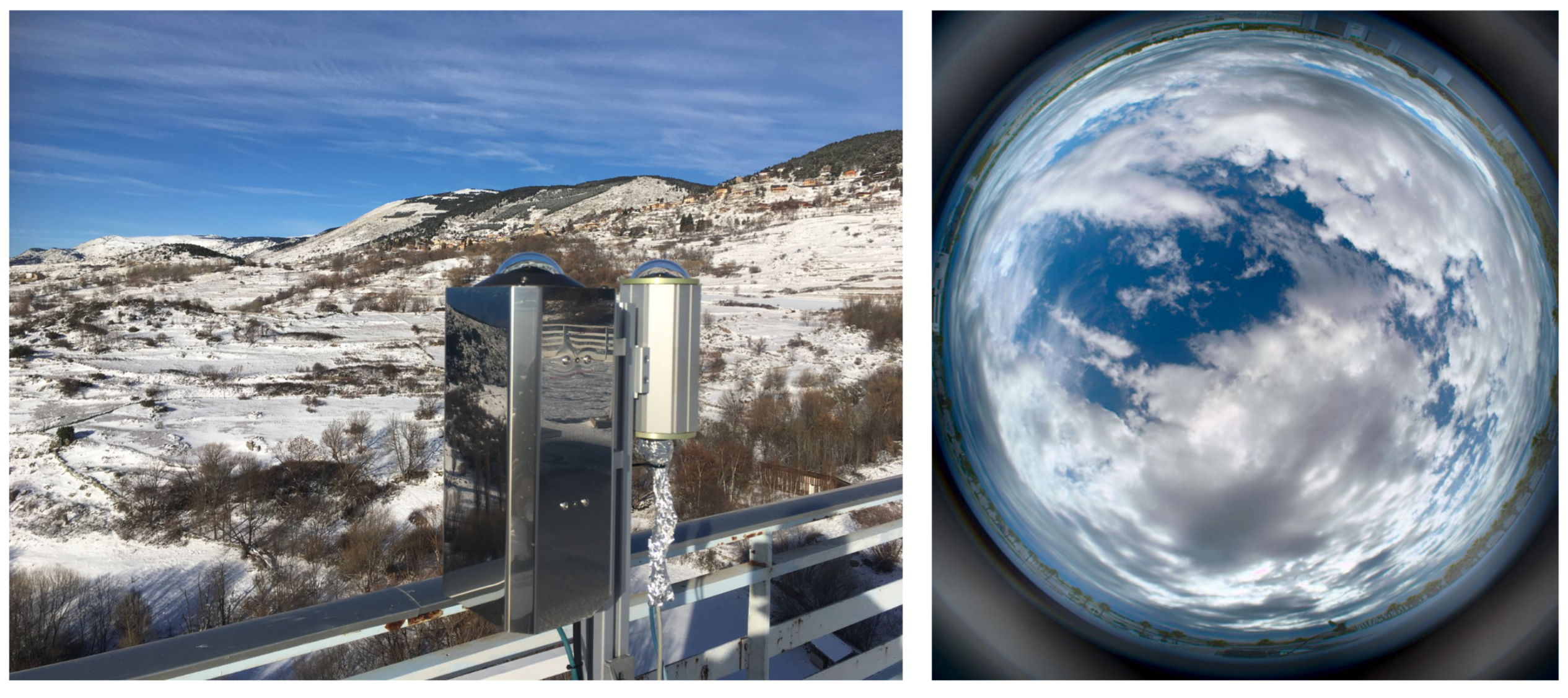

2. Horizon 2020 Project SFERA III

- networking activities to improve the cooperation between the research infrastructures, the scientific community, industries and other stakeholders;

- transnational access activities aiming at providing access to all European researchers from both academia and industry to singular scientific and technological solar research infrastructures;

- joint research activities to improve the infrastructure’s integrated services.

3. Modeling of the Solar Reactor

3.1. Description of the Model

- When no oxygen is injected—DNI is higher than 800 Wm—only the endothermic gasification of biomass occurs, with an enthalpy change kJ mol. This reaction is as follows:

- When oxygen is injected—DNI is lower than 800 —combustion occurs in the cavity along with gasification, with an enthalpy change kJ mol. Combustion of the biomass resource—the reaction is exothermic—can be described as follows:

3.2. Simulation of the Model

3.2.1. Without Oxygen Injection

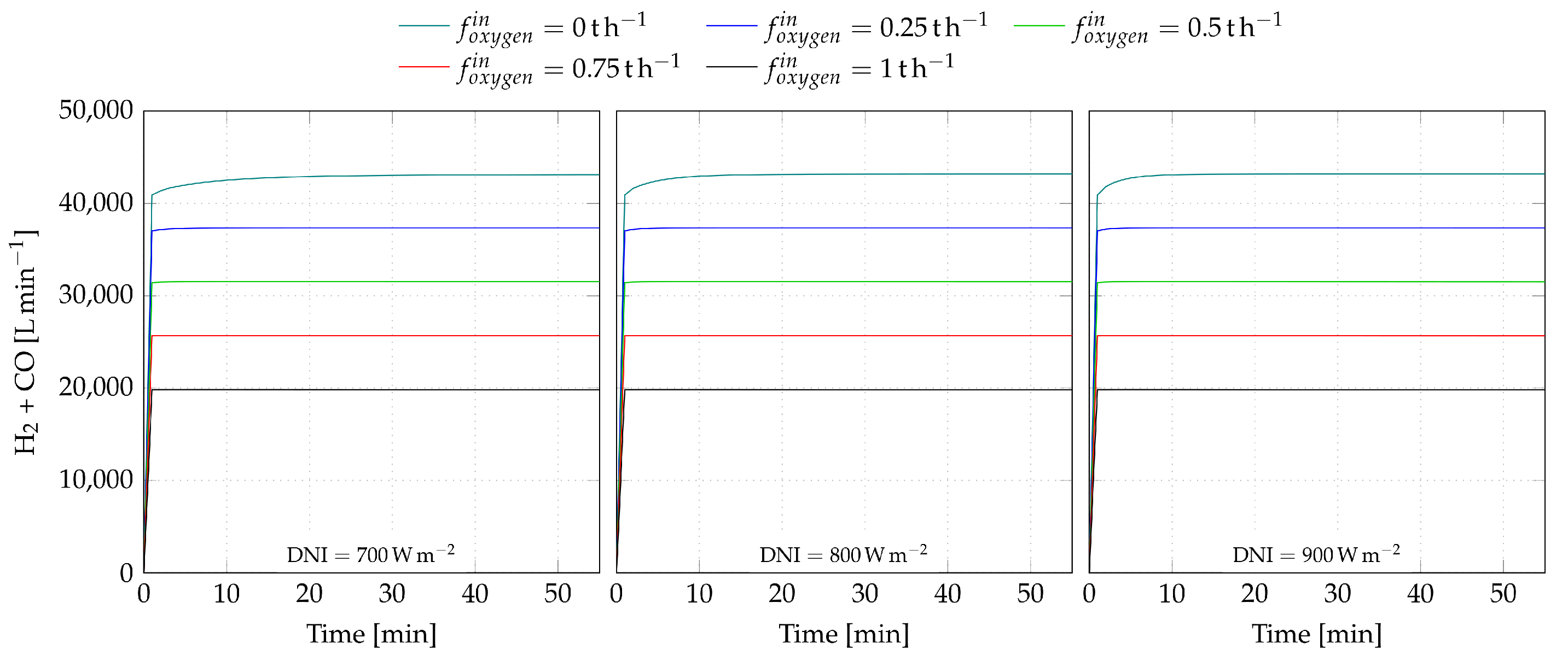

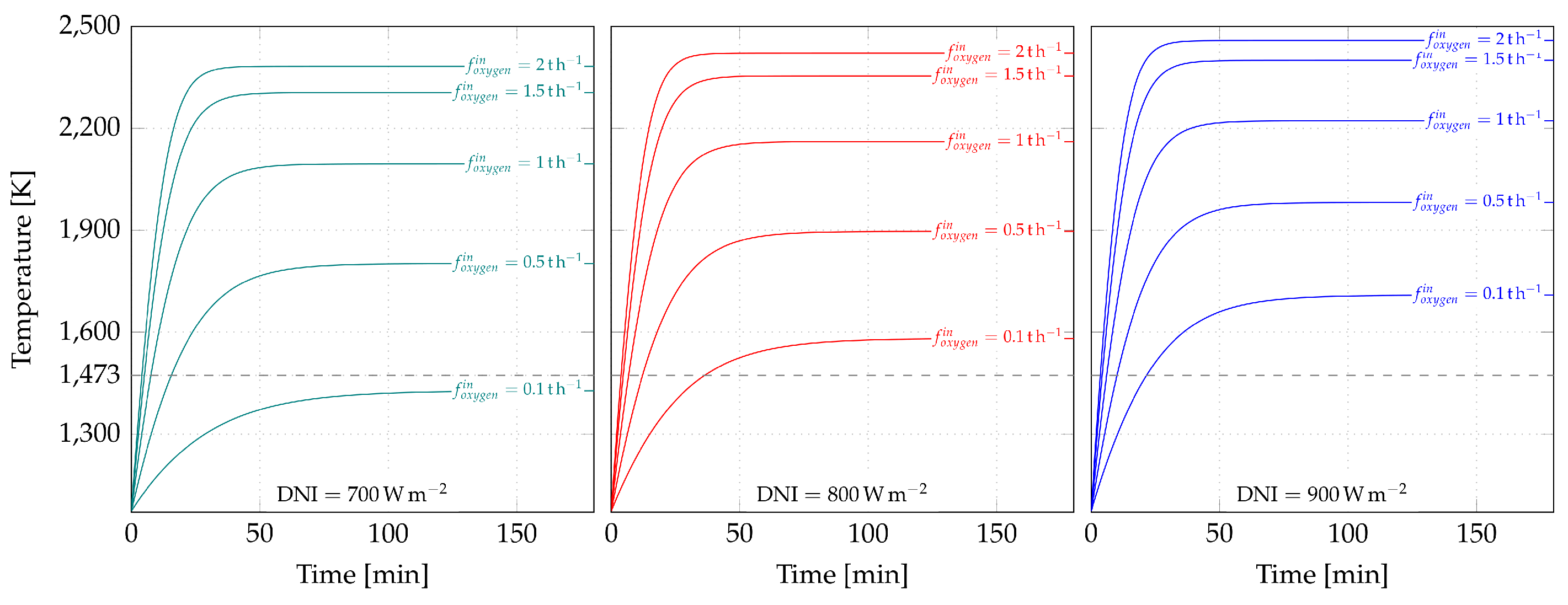

3.2.2. With Oxygen Injection

4. Control of the Solar Reactor

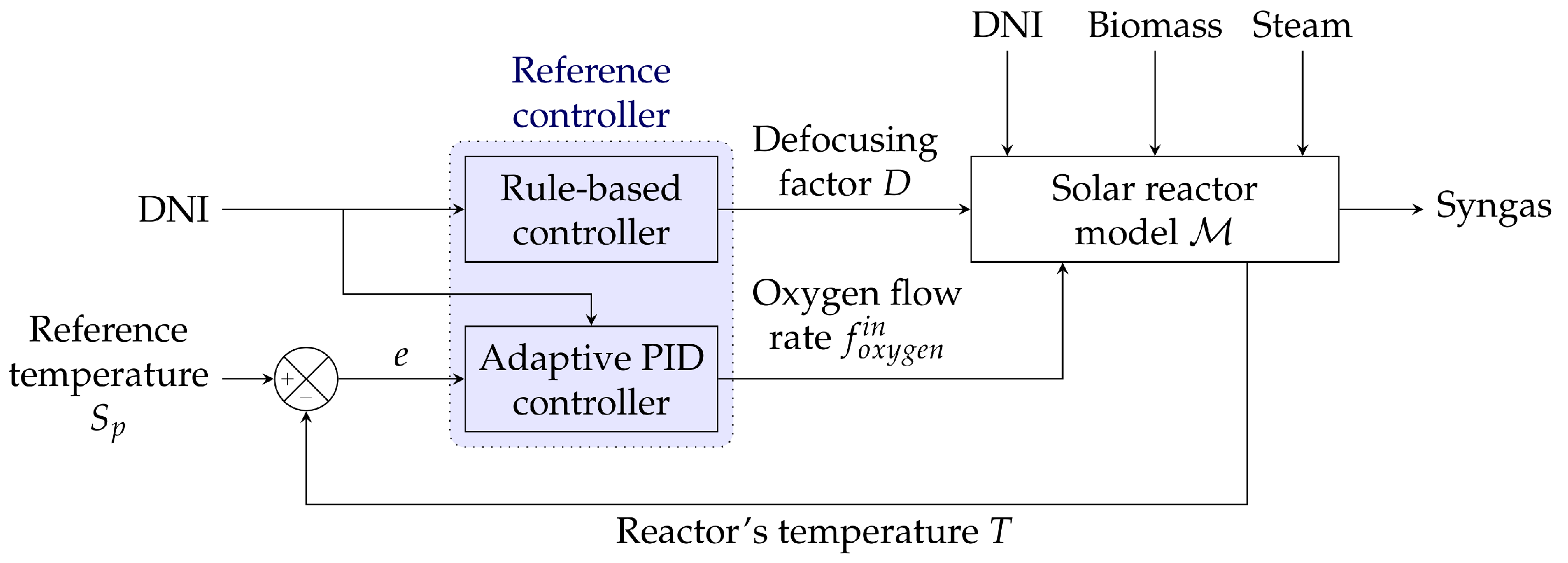

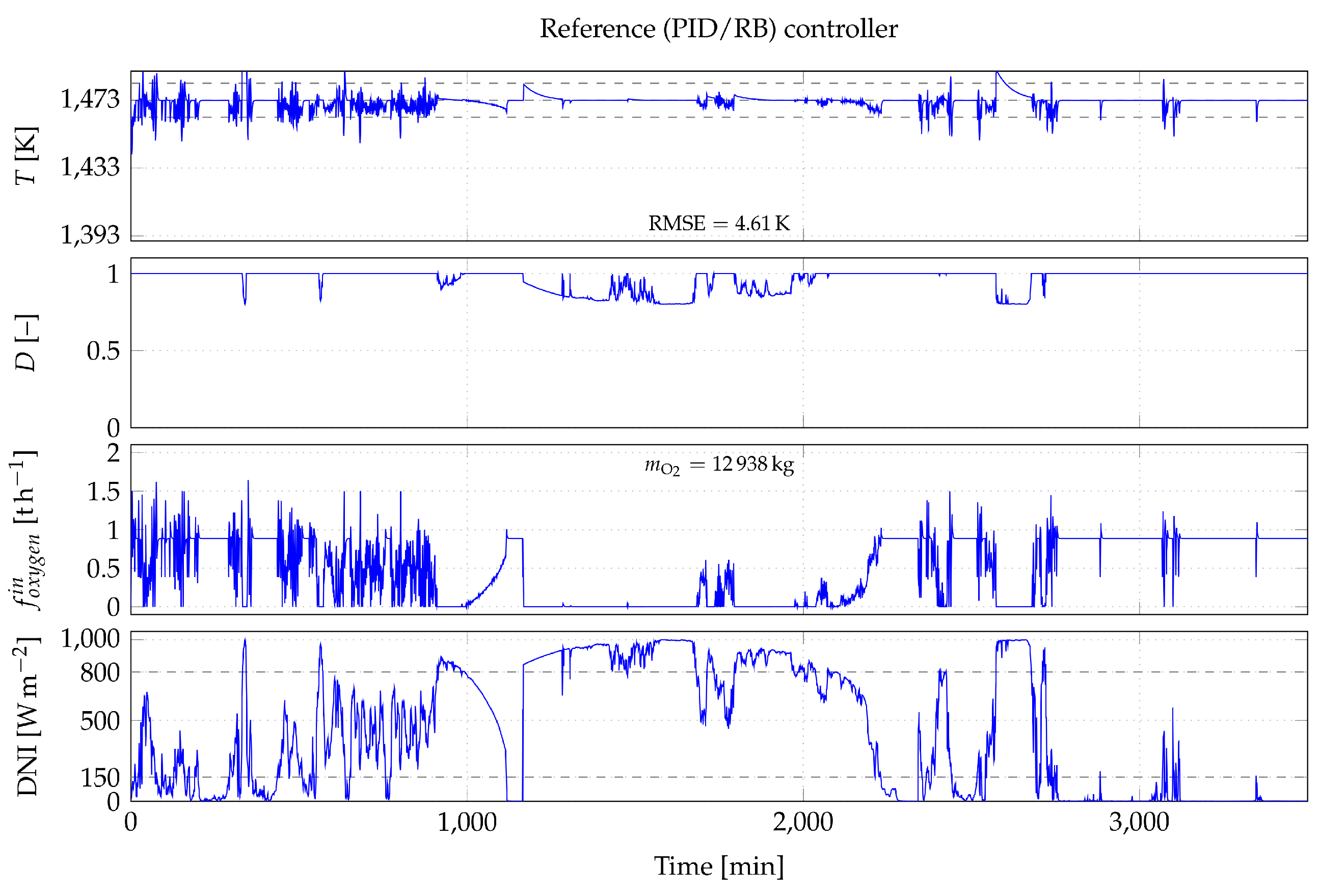

4.1. Reference (PID/RB) Controller

4.1.1. Adaptive PID Controller for the Oxygen Flow Rate

- is the proportional gain, helping the controller reach the setpoint faster, with the risk of overshooting; a small value will result in an important steady-state error;

- is the integral gain, helping to eliminate the steady-state error; a large value can result in a longer settling time and higher oscillations;

- is the derivative gain, generating a fast response and a stabilizing effect in dynamic regime.

- : The reactor’s aperture is closed () to limit radiative losses, which affects the thermal equilibrium of the system. The PID controller manages the system by injecting a minimum of 0.88 th of oxygen.

- : The reactor’s aperture is open, and the amount of DNI received is not sufficient to maintain the reactor’s temperature without oxygen injection. The PID controller determines the oxygen flow rate allowing to minimize the error between the setpoint and the measured temperature.

- : The excess of DNI forces the PID controller to recommend a minimal oxygen flow rate allowing the reactor to cool down and play on defocusing if the reactor’s temperature is higher than the setpoint.

4.1.2. Rule-Based Controller for the Defocusing Factor

- if and K, ;

- if 800 Wm and K, .

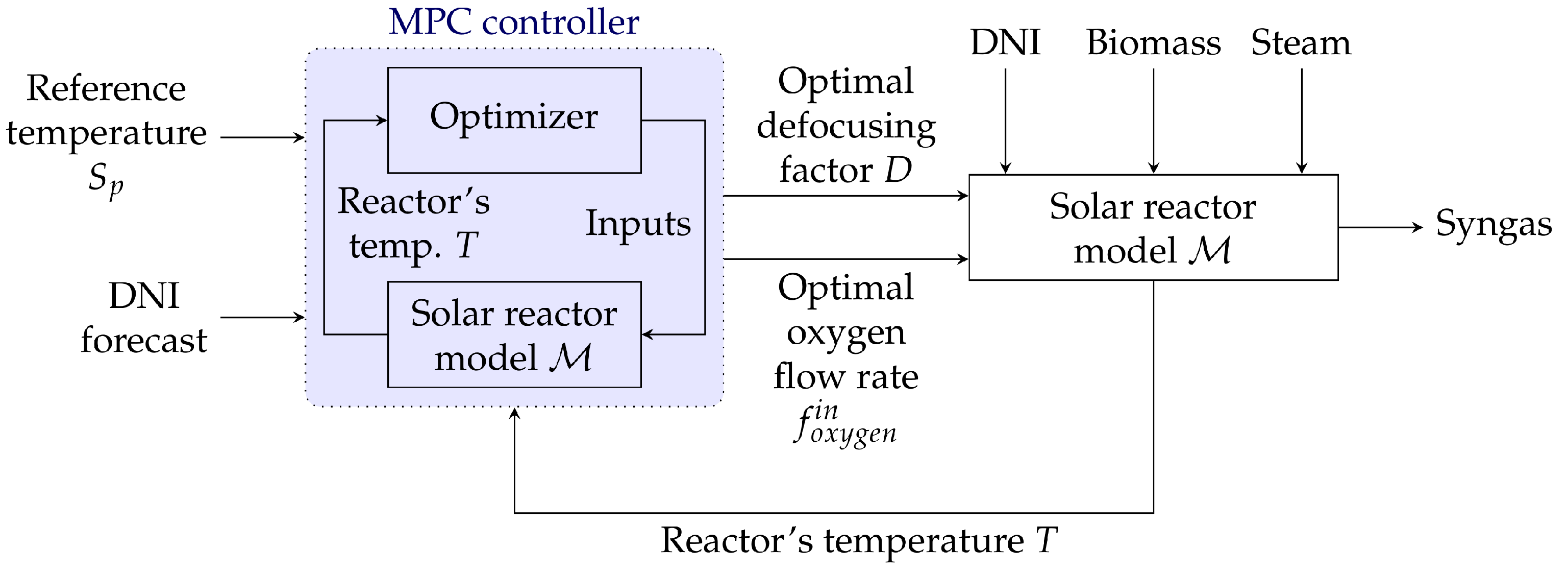

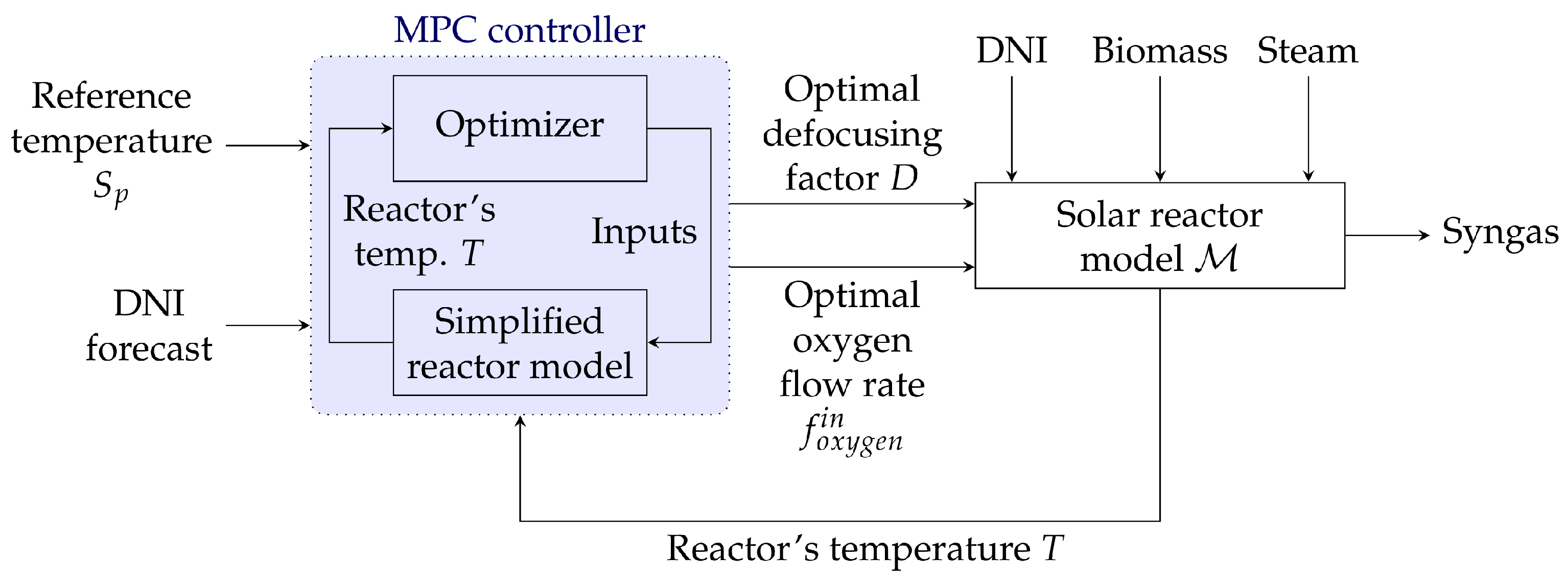

4.2. MPC Controller

4.3. DNI Forecasting

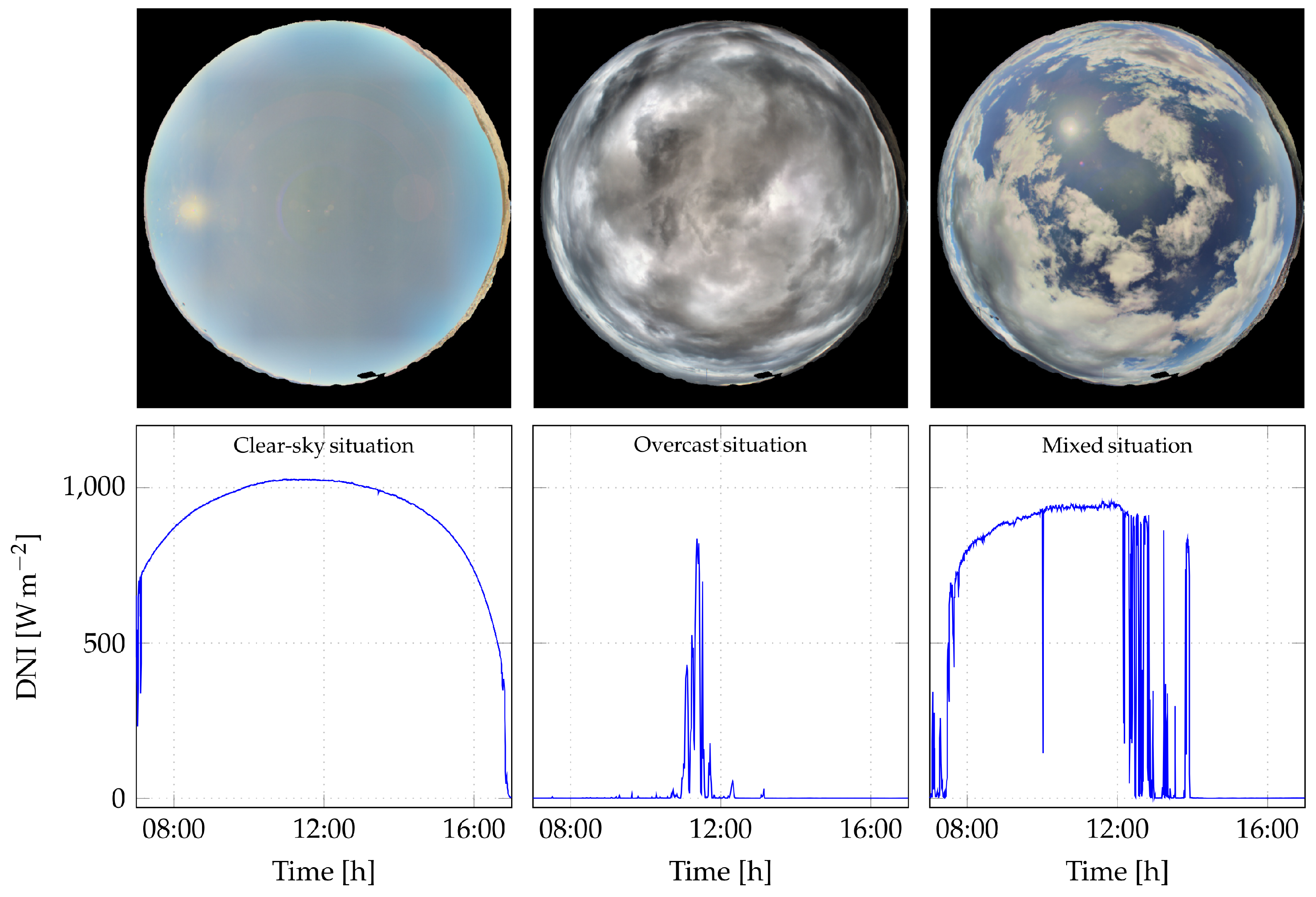

4.3.1. Database

4.3.2. Smart Persistence Forecasts

4.3.3. Image-Based Forecasts

- An HDR image is processed to detect clouds using a segmentation model and estimate their motion with the aim of localizing the part of the image that will interact with the Sun at time . This region is called the region of interest (ROI) in the sequel.

- The cloud fraction (CF) in the ROI () is calculated. is defined as the ratio of the number of cloud pixels to the number of clear-sky pixels in the ROI.

- The model decides if a ramp will occur by analyzing the variation of between two consecutive time steps. If this variation is greater than 3% of the maximum value of , then a ramp is expected. This value is chosen to avoid ramp detection due to noise in the signal. This approach also determines the ramp’s direction, since an increase in indicates a possible decrease in DNI and vice versa.

- The DNI forecast at time is obtained by a persistence (if no ramp is expected) or a persistence to which the ramp magnitude RM is added (if a ramp is expected):where is the measured DNI, is the forecast ramp magnitude and is calculated as follows:with .

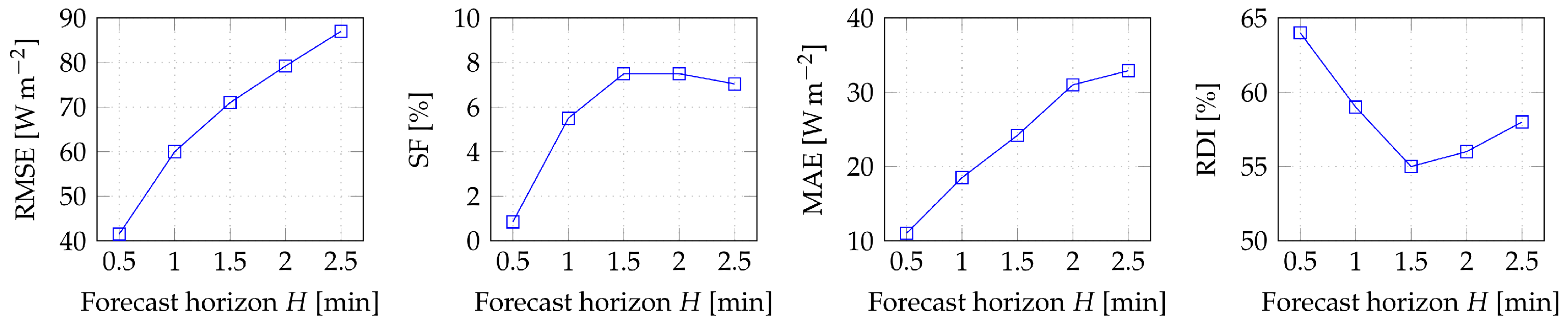

4.3.4. Performance Criteria

- The root mean squared error (RMSE) is calculated as follows:where is the number of observations, is the measured DNI and is the predicted DNI.

- The skill factor (SF) is employed to evaluate the models’ performance versus the smart persistence model (a positive skill factor means that the proposed model outperforms the smart persistence model). It is defined as follows:where and are the nRMSE of the evaluated model and the smart persistence model, respectively.

- The mean average error (MAE) is calculated as follows:where is the number of observations, is the measured DNI and is the forecast DNI.

- Finally, a criteria called ramp detection index (RDI) is used [45]. It is designed to evaluate the ability of the model to predict ramps, which have an important impact on CSP plants: predicting them can thus be helpful in the control process. First, the ramp magnitude (RM) is calculated as:where is the estimated clear-sky DNI.Usually, high-magnitude DNI ramps are defined by and moderate DNI ramps are defined by . A ramp detection (also called a hit) is achieved if the two following conditions are satisfied:where and are the forecast and measured DNI, respectively.The chosen value represents ramps with high occurrence probability, thus increasing the challenge of scoring a high RDI by increasing the number of considered ramps in the RDI calculation. The ramp is not detected (a miss) if Equation (20) is met while Equation () is not. Finally, the ramp detection index is calculated as follows:where and are the numbers of hits and misses, respectively.

4.3.5. Forecasting Results

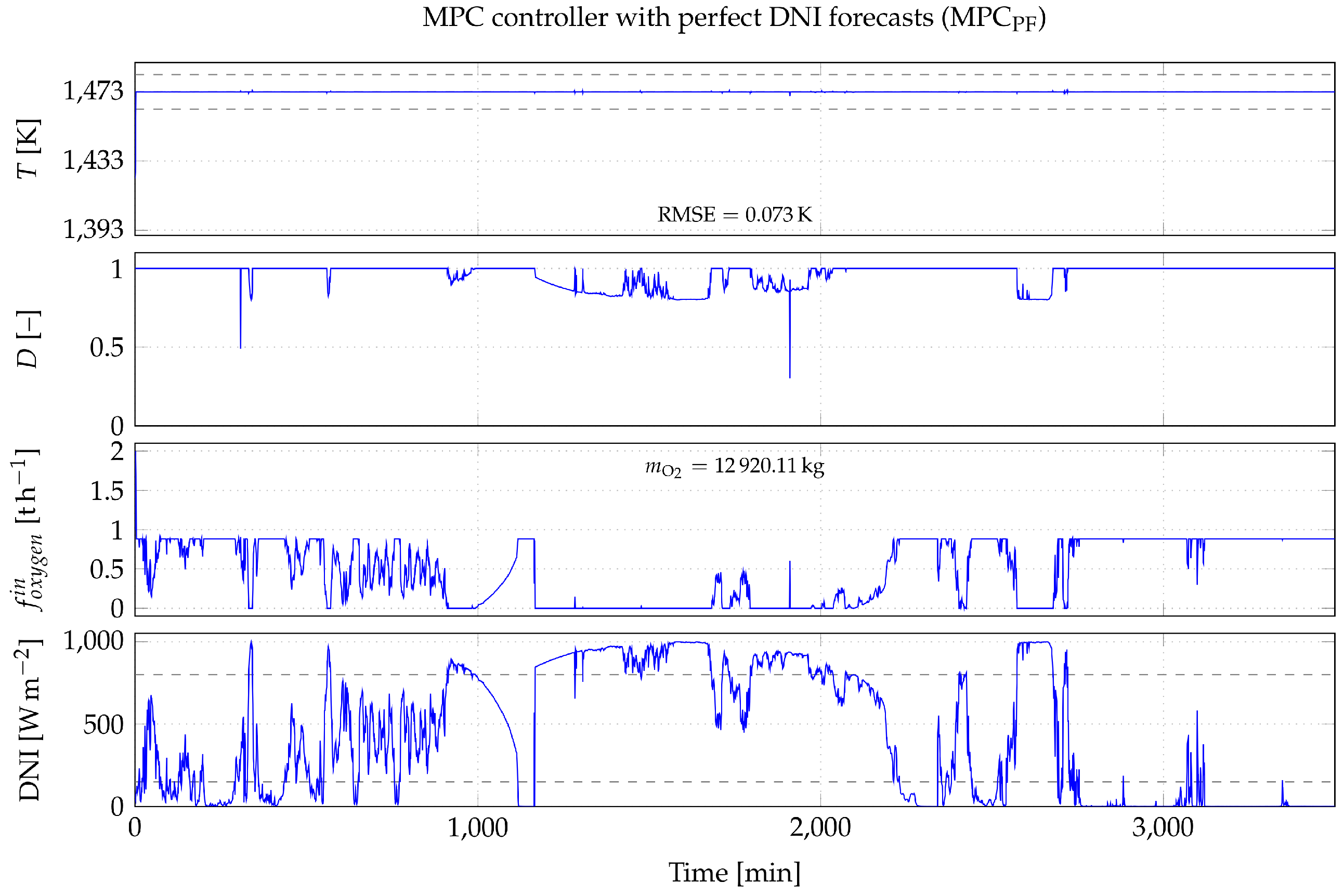

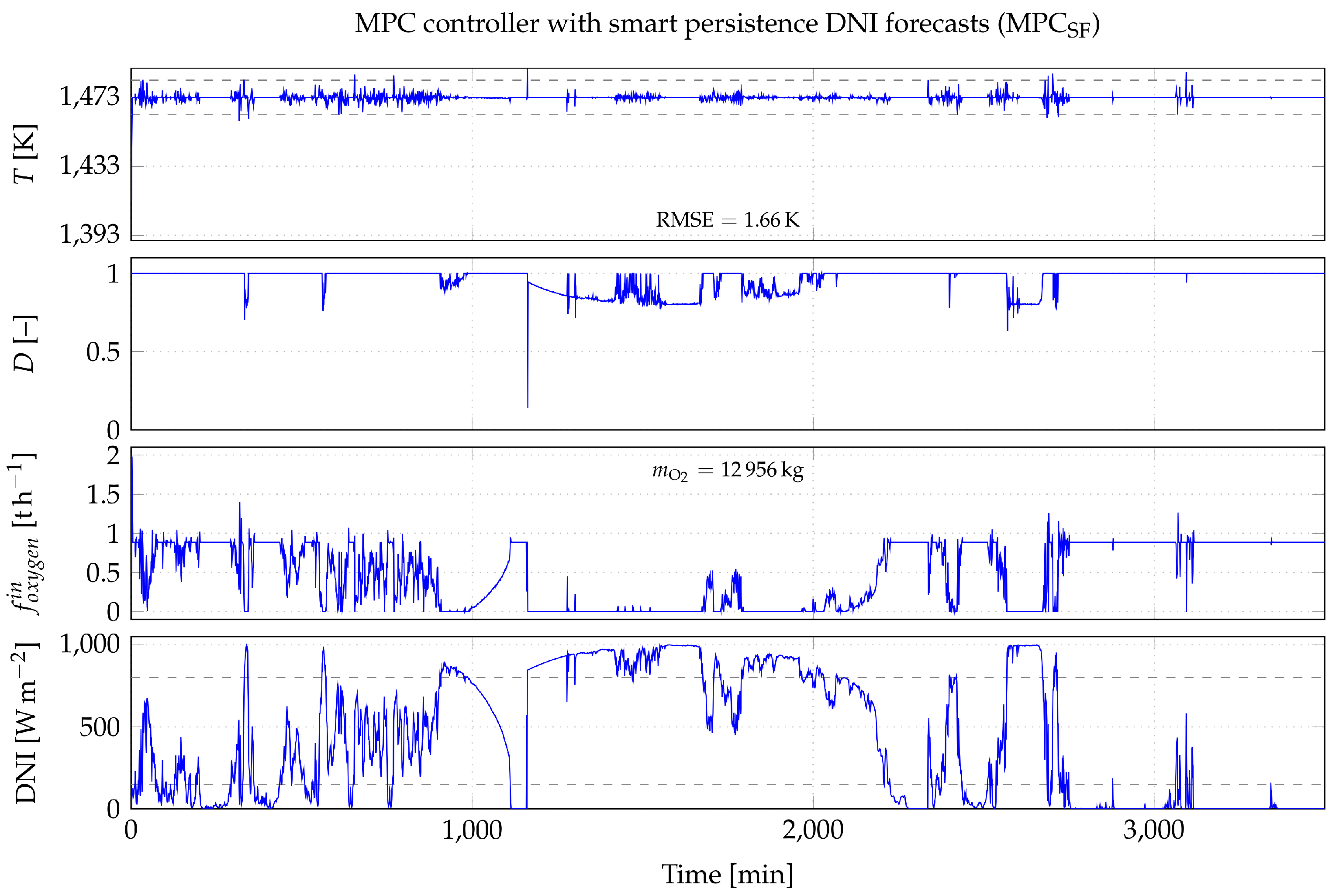

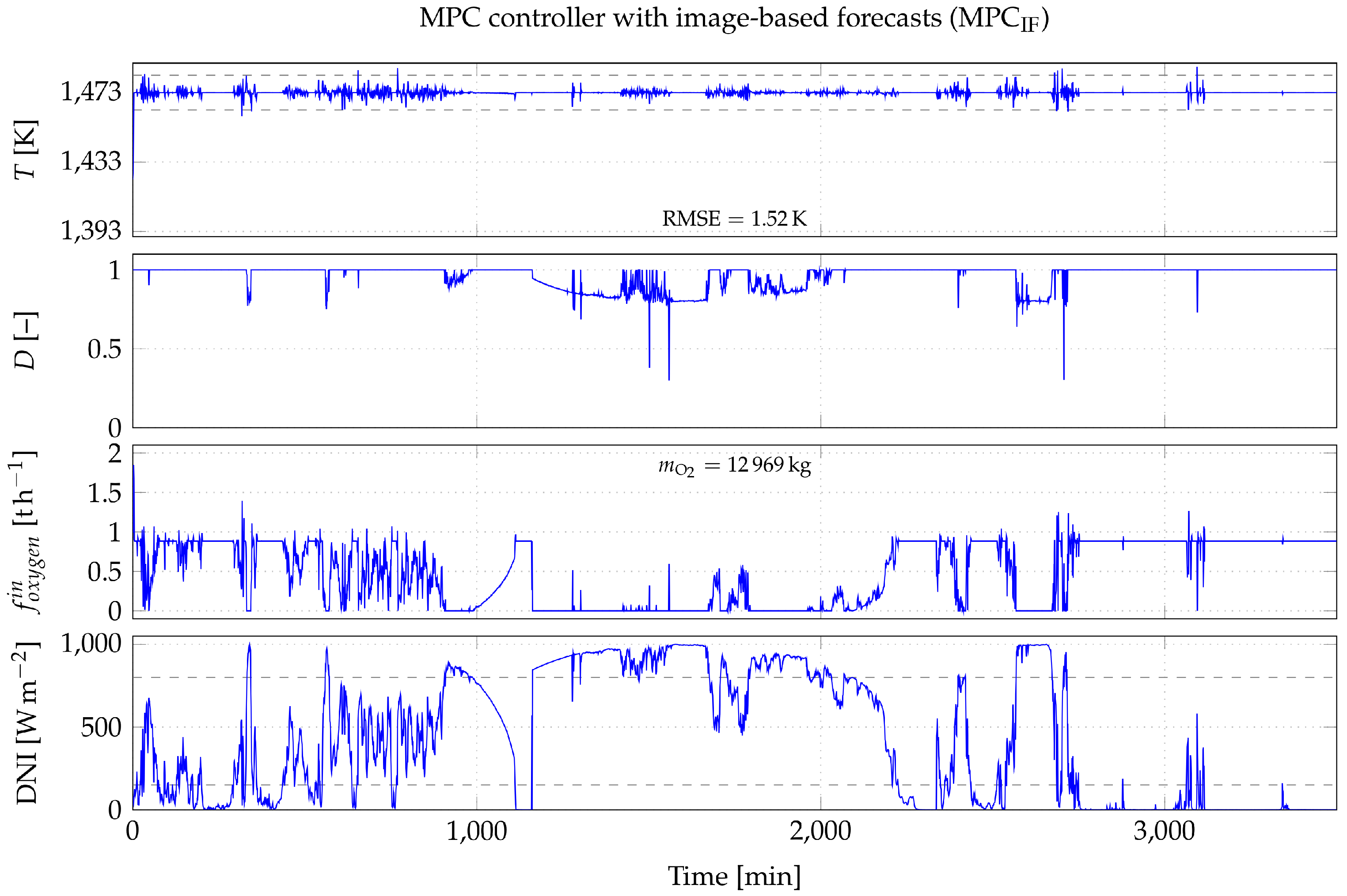

5. Control Results

5.1. Performance Criteria

5.2. Comparative Study

- . This initialization is chosen so that the optimal input found is near 1, which means solar energy is used at its best;

- . This initialization is chosen so that the optimizer converges fast to the optimal solution, which is around . Other initialization values resulted in an increase in computation time and some performance degradation.

5.3. Case Study

6. Computationally-Tractable MPC Controller

6.1. Model Simplification

- for a given reactor’s temperature, is mainly a linear function of the oxygen flow rate (0 th th);

- for a given oxygen flow rate, is a linear function of the reactor’s temperature ().

6.2. MPC Controller with Simplified Reactor Model vs. MPC Controller with Original Reactor Model

6.3. MPC Controller with Simplified Reactor Model vs. Reference Controller

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gregg, D.; Taylor, R.; Campbell, J.; Taylor, J.; Cotton, A. Solar gasification of coal, activated carbon, coke and coal and biomass mixtures. Sol. Energy 1980, 25, 353–364. [Google Scholar] [CrossRef]

- Taylor, R.; Berjoan, R.; Coutures, J. Solar gasification of carbonaceous materials. Sol. Energy 1983, 30, 513–525. [Google Scholar] [CrossRef]

- Yadav, D.; Banerjee, R. A review of solar thermochemical processes. Renew. Sustain. Energy Rev. 2016, 54, 497–532. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Tora, E.; Bruno, J.; Coronas, A. State of the art on reactor designs for solar gasification of carbonaceous feedstock. Sol. Energy 2013, 97, 67–84. [Google Scholar] [CrossRef]

- Milanese, M.; Colangelo, G.; Iacobazzi, F.; de Risi, A. Modeling of double-loop fluidized bed solar reactor for efficient thermochemical fuel production. Sol. Energy Mater. Sol. Cells 2017, 160, 174–181. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Suárez-Almeida, M.; Ghoniem, A. Analysis of fluidized bed gasification of biomass assisted by solar-heated particles. Biomass Convers. Biorefinery 2020, 11, 143–158. [Google Scholar] [CrossRef]

- Bellouard, Q.; Abanades, S.; Rodat, S. Biomass Gasification in an Innovative Spouted-Bed Solar Reactor: Experimental Proof of Concept and Parametric Study. Energy Fuels 2017, 31, 10933–10945. [Google Scholar] [CrossRef]

- Boujjat, H.; Rodat, S.; Chuayboon, S.; Abanades, S. Experimental and numerical study of a directly irradiated hybrid solar/combustion spouted bed reactor for continuous steam gasification of biomass. Energy 2019, 189, 116118. [Google Scholar] [CrossRef]

- Curcio, A.; Rodat, S.; Vuillerme, V.; Abanades, S. Experimental assessment of woody biomass gasification in a hybridized solar powered reactor featuring direct and indirect heating modes. Int. J. Hydrog. Energy 2021, 46, 37192–37207. [Google Scholar] [CrossRef]

- Muroyama, A.P.; Guscetti, I.; Schieber, G.L.; Haussener, S.; Loutzenhiser, P.G. Design and demonstration of a prototype 1.5 kWth hybrid solar/autothermal steam gasifier. Fuel 2018, 211, 331–340. [Google Scholar] [CrossRef]

- Hathaway, B.J.; Davidson, J.H. Autothermal hybridization and controlled production of hydrogen-rich syngas in a molten salt solar gasifier. Int. J. Hydrog. Energy 2021, 46, 15257–15267. [Google Scholar] [CrossRef]

- Blanc, P.; Espinar, B.; Geuder, N.; Gueymard, C.; Meyer, R.; Pitz-Paal, R.; Reinhardt, B.; Renné, D.; Sengupta, M.; Wald, L.; et al. Direct normal irradiance related definitions and applications: The circumsolar issue. Sol. Energy 2014, 110, 561–577. [Google Scholar] [CrossRef]

- Maffezzoni, C.; Parigi, F. Dynamic analysis and control of a solar power plant—II. Control system design and simulation. Sol. Energy 1982, 28, 117–128. [Google Scholar] [CrossRef]

- Camacho, E.; Rubio, F.; Hughes, F. Self-tuning control of a solar power plant with a distributed collector field. IEEE Control. Syst. 1992, 12, 72–78. [Google Scholar] [CrossRef]

- Rubio, F.; Berenguel, M.; Camacho, E. Fuzzy logic control of a solar power plant. IEEE Trans. Fuzzy Syst. 1995, 3, 459–468. [Google Scholar] [CrossRef]

- Pickhardt, R. Nonlinear modelling and adaptive predictive control of a solar power plant. Control. Eng. Pract. 2000, 8, 937–947. [Google Scholar] [CrossRef]

- Arahal, M.; Berenguel, M.; Camacho, E. Neural identification applied to predictive control of a solar plant. Control. Eng. Pract. 1998, 6, 333–344. [Google Scholar] [CrossRef]

- Camacho, E.; Rubio, F.; Berenguel, M.; Valenzuela, L. A survey on control schemes for distributed solar collector fields. Part I: Modeling and basic control approaches. Sol. Energy 2007, 81, 1240–1251. [Google Scholar] [CrossRef]

- Camacho, E.; Rubio, F.; Berenguel, M.; Valenzuela, L. A survey on control schemes for distributed solar collector fields. Part II: Advanced control approaches. Sol. Energy 2007, 81, 1252–1272. [Google Scholar] [CrossRef]

- Petrasch, J.; Osch, P.; Steinfeld, A. Dynamics and control of solar thermochemical reactors. Chem. Eng. J. 2009, 145, 362–370. [Google Scholar] [CrossRef]

- Saade, E.; Clough, D.E.; Weimer, A.W. Model predictive control of a solar-thermal reactor. Sol. Energy 2014, 102, 31–44. [Google Scholar] [CrossRef]

- Muroyama, A.; Shinn, T.; Fales, R.; Loutzenhiser, P.G. Modeling of a Dynamically-Controlled Hybrid Solar/Autothermal Steam Gasification Reactor. Energy Fuels 2014, 28, 6520–6530. [Google Scholar] [CrossRef]

- Boujjat, H.; Yuki Junior, G.M.; Rodat, S.; Abanades, S. Dynamic simulation and control of solar biomass gasification for hydrogen-rich syngas production during allothermal and hybrid solar/autothermal operation. Int. J. Hydrog. Energy 2020, 45, 25827–25837. [Google Scholar] [CrossRef]

- Karout, Y.; Thil, S.; Eynard, J.; Guillot, E.; Grieu, S. Hybrid intrahour DNI forecast model based on DNI measurements and sky-imaging data. Sol. Energy 2023, 249, 541–558. [Google Scholar] [CrossRef]

- Goodwin, D.G.; Speth, R.L.; Moffat, H.K.; Weber, B.W. Cantera: An Object-Oriented Software Toolkit for Chemical Kinetics, Thermodynamics, and Transport Processes. 2021. Available online: https://doi.org/10.5281/ZENODO.4527812 (accessed on 3 March 2021).

- Curcio, A.; Rodat, S.; Vuillerme, V.; Abanades, S. Design and validation of reactant feeding control strategies for the solar-autothermal hybrid gasification of woody biomass. Energy 2022, 254, 124481. [Google Scholar] [CrossRef]

- Dupont, C.; Boissonnet, G.; Seiler, J.M.; Gauthier, P.; Schweich, D. Study about the kinetic processes of biomass steam gasification. Fuel 2007, 86, 32–40. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C.; et al. WHAT’S NEW IN GRI-Mech 3.0. Available online: http://combustion.berkeley.edu/gri-mech/version30/text30.html (accessed on 13 June 2021).

- Ang, K.H.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control. Syst. Technol. 2005, 13, 559–576. [Google Scholar] [CrossRef]

- Liu, G.; Daley, S. Optimal-tuning PID control for industrial systems. Control. Eng. Pract. 2001, 9, 1185–1194. [Google Scholar] [CrossRef]

- García, C.E.; Prett, D.M.; Morari, M. Model predictive control: Theory and practice—A survey. Automatica 1989, 25, 335–348. [Google Scholar] [CrossRef]

- Conn, A.R.; Gould, N.I.M.; Toint, P.L. Trust Region Methods; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2000. [Google Scholar] [CrossRef]

- Martín, L.; Zarzalejo, L.F.; Polo, J.; Navarro, A.; Marchante, R.; Cony, M. Prediction of global solar irradiance based on time series analysis: Application to solar thermal power plants energy production planning. Sol. Energy 2010, 84, 1772–1781. [Google Scholar] [CrossRef]

- Mishra, S.; Palanisamy, P. Multi-time-horizon solar forecasting using recurrent neural network. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 18–24. [Google Scholar] [CrossRef]

- Malakar, S.; Goswami, S.; Ganguli, B.; Chakrabarti, A.; Roy, S.S.; Boopathi, K.; Rangaraj, A.G. Designing a long short-term network for short-term forecasting of global horizontal irradiance. SN Appl. Sci. 2021, 3, 477. [Google Scholar] [CrossRef]

- Brahma, B.; Wadhvani, R. Solar Irradiance Forecasting Based on Deep Learning Methodologies and Multi-Site Data. Symmetry 2020, 12, 1830. [Google Scholar] [CrossRef]

- Du, J.; Min, Q.; Zhang, P.; Guo, J.; Yang, J.; Yin, B. Short-Term Solar Irradiance Forecasts Using Sky Images and Radiative Transfer Model. Energies 2018, 11, 1107. [Google Scholar] [CrossRef]

- Chu, Y.; Pedro, H.T.C.; Coimbra, C.F.M. Hybrid intra-hour DNI forecasts with sky image processing enhanced by stochastic learning. Sol. Energy 2013, 98, 592–603. [Google Scholar] [CrossRef]

- Quesada-Ruiz, S.; Chu, Y.; Tovar-Pescador, J.; Pedro, H.T.C.; Coimbra, C.F.M. Cloud-tracking methodology for intra-hour DNI forecasting. Sol. Energy 2014, 102, 267–275. [Google Scholar] [CrossRef]

- Marquez, R.; Coimbra, C.F.M. Intra-hour DNI forecasting based on cloud tracking image analysis. Sol. Energy 2013, 91, 327–336. [Google Scholar] [CrossRef]

- Caldas, M.; Alonso-Suárez, R. Very short-term solar irradiance forecast using all-sky imaging and real-time irradiance measurements. Renew. Energy 2019, 143, 1643–1658. [Google Scholar] [CrossRef]

- Ineichen, P.; Perez, R. A new airmass independent formulation for the Linke turbidity coefficient. Sol. Energy 2002, 73, 151–157. [Google Scholar] [CrossRef]

- Nou, J.; Chauvin, R.; Thil, S.; Grieu, S. A new approach to the real-time assessment of the clear-sky direct normal irradiance. Appl. Math. Model. 2016, 40, 7245–7264. [Google Scholar] [CrossRef]

- Akiba, T.; Sano, S.; Yanase, T.; Ohta, T.; Koyama, M. Optuna: A Next-generation Hyperparameter Optimization Framework. In Proceedings of the Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining; Anchorage, AK, USA, 4–8 August 2019. [CrossRef]

- Chu, Y.; Pedro, H.T.C.; Li, M.; Coimbra, C.F.M. Real-time forecasting of solar irradiance ramps with smart image processing. Sol. Energy 2015, 114, 91–104. [Google Scholar] [CrossRef]

| DNI [Wm] | Static Gain [-] | [min] | [min] |

|---|---|---|---|

| 700 | 0.3 | 31.5 | 69.3 |

| 800 | 0.5 | 26.3 | 58 |

| 900 | 0.6 | 23 | 50.6 |

| DNI < 150 Wm | 150 Wm ⩽ DNI ⩽ 800 Wm | DNI > 800 Wm | |

|---|---|---|---|

| 1.6 × 10 | 3.4 × 10 | 1.5 × 10 | |

| 0 | 9.0 × 10 | 1.5 × 10 | |

| 1.2 × 10 | 2.5 × 10 | 1.0 × 10 |

| H [min] | Time Support (Observations) | LSTM Layers (Units) | Fully Connected Layers (Units) | |||||

|---|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 1st | 2nd | 3rd | ||

| 0.5 | 8 | 179 | 229 | 204 | 104 | 20 | 5 | 5 |

| 1 | 8 | 254 | 204 | 219 | 229 | 20 | 5 | ⌀ |

| 1.5 | 8 | 229 | 54 | 204 | 179 | 5 | 20 | 20 |

| 2 | 8 | 254 | 104 | 79 | 229 | 5 | 20 | 20 |

| 2.5 | 8 | 154 | 179 | 104 | 4 | 5 | 5 | ⌀ |

| Controller | Performance Criterion | Prediction Horizon of the MPC Controller [min] | ||||

|---|---|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2 | 2.5 | ||

| RMSE [K] | 0.451 | 0.073 | 0.075 | 0.078 | 0.078 | |

| [kg] | 31,945.55 | 31,968.33 | 31,964.17 | 31,988.02 | 31,959.63 | |

| [K] | 0.018 | 0.031 | 0.032 | 0.034 | 0.036 | |

| −42,139.13 | −48,657.01 | −48,653.24 | −48,549.71 | −48,559.12 | ||

| [s] | 1.5 | 5.0 | 10.0 | 15.0 | 30.0 | |

| RMSE [K] | 1.92 | 1.79 | 1.71 | 1.72 | 1.71 | |

| [kg] | 32,080.55 | 32,074.03 | 32,089.23 | 32,075.459 | 32,090 | |

| [K] | 1.50 | 1.47 | 1.542 | 1.58 | 1.47 | |

| 74,260.74 | 56,858.36 | 48,620.45 | 49,702.90 | 48,638.47 | ||

| [s] | 1.0 | 4.6 | 9.7 | 14.5 | 29.0 | |

| RMSE [K] | 1.88 | 1.72 | 1.64 | 1.60 | 1.61 | |

| [kg] | 32,142 | 32,058.87 | 32,063.25 | 32,091.25 | 32,143.56 | |

| [K] | 3.0 | 1.45 | 1.46 | 1.54 | 1.47 | |

| 68,903 | 49,334.44 | 40,786.92 | 36,446.05 | 37,996.54 | ||

| [s] | 1.5 | 5.0 | 10.0 | 15.0 | 30.0 | |

| Controller | Performance Criterion | Prediction Horizon of the MPC Controller (min) | ||||

|---|---|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2 | 2.5 | ||

| with simplified reactor model | RMSE (K) | 0.49 | 0.10 | 0.10 | 0.11 | 0.11 |

| (kg) | 31,956 | 31,961 | 31,965 | 31,972 | 31,979 | |

| (K) | 0.04 | 0.05 | 0.05 | 0.05 | 0.05 | |

| −40,831.19 | −48,508.93 | −48,500.45 | −48,493.56 | −48,487.42 | ||

| (s) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | |

| with original reactor model | RMSE (K) | 0.451 | 0.073 | 0.075 | 0.078 | 0.078 |

| (kg) | 31,945.55 | 31,968.33 | 31,964.17 | 31,988.02 | 31,959.63 | |

| (K) | 0.018 | 0.031 | 0.032 | 0.034 | 0.036 | |

| −42,139.13 | −48,657.01 | −48,653.24 | −48,549.71 | −48,559.12 | ||

| (s) | 1.5 | 5 | 10 | 15 | 30 | |

| with simplified reactor model | RMSE (K) | 2.01 | 1.97 | 1.74 | 1.73 | 1.74 |

| (kg) | 32,043 | 32,093 | 32,137 | 32,152 | 32,106 | |

| (K) | 1.60 | 1.50 | 1.50 | 1.49 | 1.50 | |

| 85,065.71 | 80,101 | 51,807 | 51,350 | 51,652.50 | ||

| (s) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | |

| with original reactor model | RMSE (K) | 1.92 | 1.79 | 1.71 | 1.72 | 1.71 |

| (kg) | 32,080.55 | 32,074.03 | 32,089.23 | 32,075.459 | 32,090 | |

| (K) | 1.50 | 1.47 | 1.542 | 1.58 | 1.47 | |

| 74,260.74 | 56,858.36 | 48,620.45 | 49,702.90 | 48,638.47 | ||

| (s) | 1 | 4.6 | 9.7 | 14.5 | 29 | |

| with simplified reactor model | RMSE (K) | 1.97 | 1.89 | 1.64 | 1.62 | 1.63 |

| (kg) | 32,102 | 32,081 | 32,114 | 32,126 | 32,146 | |

| (K) | 3.10 | 1.47 | 1.47 | 1.47 | 1.47 | |

| 80,943 | 69,440 | 41,032.92 | 38,072 | 40,028 | ||

| (s) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | |

| with original reactor model | RMSE (K) | 1.88 | 1.72 | 1.64 | 1.60 | 1.61 |

| (kg) | 32,142 | 32,058.87 | 32,063.25 | 32,091.25 | 32,143.56 | |

| (K) | 3.00 | 1.45 | 1.46 | 1.47 | 1.47 | |

| 68,903 | 49,334.44 | 40,786.92 | 36,446.05 | 37,996.54 | ||

| (s) | 1.5 | 5 | 10 | 15 | 30 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karout, Y.; Curcio, A.; Eynard, J.; Thil, S.; Rodat, S.; Abanades, S.; Vuillerme, V.; Grieu, S. Model-Based Predictive Control of a Solar Hybrid Thermochemical Reactor for High-Temperature Steam Gasification of Biomass. Clean Technol. 2023, 5, 329-351. https://doi.org/10.3390/cleantechnol5010018

Karout Y, Curcio A, Eynard J, Thil S, Rodat S, Abanades S, Vuillerme V, Grieu S. Model-Based Predictive Control of a Solar Hybrid Thermochemical Reactor for High-Temperature Steam Gasification of Biomass. Clean Technologies. 2023; 5(1):329-351. https://doi.org/10.3390/cleantechnol5010018

Chicago/Turabian StyleKarout, Youssef, Axel Curcio, Julien Eynard, Stéphane Thil, Sylvain Rodat, Stéphane Abanades, Valéry Vuillerme, and Stéphane Grieu. 2023. "Model-Based Predictive Control of a Solar Hybrid Thermochemical Reactor for High-Temperature Steam Gasification of Biomass" Clean Technologies 5, no. 1: 329-351. https://doi.org/10.3390/cleantechnol5010018

APA StyleKarout, Y., Curcio, A., Eynard, J., Thil, S., Rodat, S., Abanades, S., Vuillerme, V., & Grieu, S. (2023). Model-Based Predictive Control of a Solar Hybrid Thermochemical Reactor for High-Temperature Steam Gasification of Biomass. Clean Technologies, 5(1), 329-351. https://doi.org/10.3390/cleantechnol5010018