Abstract

The study concerns promising coal-fired power plants that can gain an advantage over traditional options in the context of decarbonization. The calculations show that combined-cycle plants with integrated coal gasification and carbon dioxide recirculation may have better technical and economic characteristics compared to existing gasification processes (one- and two-stage). The recirculation of carbon dioxide improves the efficiency of the gasification process (the combustible gases yield and the fuel carbon conversion degree) and reduces the energy costs of the flue gas cleaning and carbon capture unit, thereby improving the economic performance of the plant. The estimates show that the decrease in the efficiency of electricity production associated with the removal of carbon dioxide is approximately 8% for the recirculation of combustion products and 15–16% for traditional processes, and the increase in the cost of electricity is 20–25% versus 35–40%, respectively.

1. Introduction

Fossil fuels are likely to be the primary energy source in the global energy mix for a long time to come. In this regard, a reduction in CO2 emissions requires, first of all, not so only increase in the share of renewable energy sources (which is not always rational both technically and in connection with systemic effects []), but also the introduction of methods for capturing CO2 at fossil fuels thermal power plants (carbon capture and storage (CCS) []). With any modernization options, CCS decreases net efficiency and increases the cost of produced energy. The main issue is reducing the losses associated with CCS []. According to the review [], there is no long-term operational experience for thermal power plants using CCS. In this regard, we do not have enough data to determine the reliability of CCS technologies. Another important problem is the use of CO2: the level of CO2 consumption in industry is orders of magnitude lower than the emission level [], and so it must be buried (for example, in suitable geological formations []).

CCS technologies for thermal power plants with fuel combustion are based on the extraction of CO2 from flue gases. Typically, they are based on selective absorption and are associated with high energy costs (primarily related to the regeneration of the absorbent) []. Simplification of the CO2 capture process is possible if inexpensive mineral sorbents are used, such as minerals and slags containing alkaline and alkaline-earth metal elements []. The air separation significantly increases the efficiency of CCS systems: if the oxidation agent is a mixture of oxygen and combustion products instead of air, then the flue gases consist nearly entirely of CO2 and H2O, and so cleaning and removing CO2 becomes much cheaper. In this case, however, there are costs associated with technical oxygen production. The efficiency of an oxyfuel power plant is determined by the difference between the gain in the CCS system and the air separation costs [].

Integrated gasification combined-cycle (IGCC) technology has made it possible to capture CO2 before gas combustion; for this, a “water shift” reaction is carried out in a catalytic reactor where, under the excess water vapor, CO is converted into CO2 with the production of additional hydrogen []. The estimated efficiency of coal-fired IGCC plants is higher than that of traditional thermal power plants, which is especially important when switching to CCS. Promising schemes for IGCC plants with high-temperature air preheating were proposed in []. A combined-cycle methodology with supercritical CO2 serving as the working fluid was proposed in [,], and according to the authors’ estimates, the efficiency of such a cycle can be up to 50%. Similar cycles were also considered in [,].

A new version of a coal-fired oxyfuel IGCC plant with a CCS system was proposed in [,]. In this case, the fuel conversion degree was increased (with a slight decrease in the content of combustible components in the produced gas) []. According to the authors of [], the net efficiency of such a plant with CCS may achieve 43–44%.

Typically, to increase the efficiency of gasification processes, steam is added [,,]. The thermodynamic analysis of the gasification processes of various fuels (coke, coal, and biomass) in O2/CO2 mixtures in [] showed that the CO2 addition was justified only for high-carbon fuels. The effect of CO2 on coal gasification kinetics was considered in [,,], and this effect for staged gasification processes was studied in [,].

The aim of present work was to determine the technical and economic characteristics of coal-fired IGCCs with CO2 capture and recycling, along with the efficiency of electricity production and the cost for such options. For comparison, calculations were made for stations without CCS systems. Data on the fuel conversion efficiency are taken from previous work on modelling the pulverized coal gasification processes with single-stage and two-stage reactors.

2. A Brief Review of Coal-Fired IGCC Plants

Gasification is typically considered to be a clean coal technology due to its low specific emissions and low gas cleaning costs as producer gas obtained from coal conversion contains strong reducing agents (CO and H2), and so the yield of nitrogen and sulfur oxides is lower compared to that of coal combustion. Instead, there are easily removable compounds such as hydrogen sulfide and ammonia []. Producer gas has a lower heating value compared to natural gas. Therefore, special combustion chambers are being developed for its combustion [,]. Coal-fired IGCC plants (as well as other clean coal technologies) have the potential to develop in Russia where there are circumstances suitable for this, namely, the obsolescence of existing power equipment and a noticeable trend towards a decrease in the average quality of energy coals []. However, low gas prices and current environmental standards are holding back this development. The possibility of combining energy and chemical production (primarily, the synthesis of liquid hydrocarbons, oxygenates, and hydrogen) based on one thermochemical process opens up prospects for the creation of environmentally friendly multi-purpose plants with the storage and export of chemical energy [,,].

Among the other ways to improve the technical and environmental efficiency of using solid fuels, one can list fuel mixing [,], thermal preparation [,], the mechanical activation of fuel particles [], special combustion methods (vortex and staged) [,,], the use of chemical oxidation cycles [], the use of reagents and catalysts [,], etc. Gasification as a thermochemical process can also be used to store excess thermal energy (for example, at nuclear power plants) [,,].

The generally accepted value characterizing the efficiency of the gasification process is cold gas efficiency (CGE, ηG), which is the ratio of the chemical energy of combustible gases to the chemical energy of solid fuels [], which is calculated as follows:

where G is the flow rate, Q is the heating value, and the indices g and f refer to producer gas and solid fuel, respectively. The heating value of the generator gas is the sum of the heating values of its components. Therefore, to assess the efficiency of cold gas, it is sufficient to determine the gas composition and the specific gas productivity of the gasifier. Depending on the specific configuration of the gasifier, the numerator and denominator may include additional terms (for example, those associated with the recirculation of heat and matter, the use of additional fuel, etc.). Cold gas efficiency is a convenient process characteristic when using producer gas for energy production. If producer gas is a raw material for chemical syntheses, then the gasification process efficiency depends on many other factors (CO/H2 ratio, content of sulfur and nitrogen compounds, methane content, etc.).

It is possible to classify industrial coal gasification processes according to different criteria, such as conversion stages, fuel supply method, blast composition, ash removal method, etc. Some gasifiers used in coal-fired power production are shown in Table 1. Over the past 10 years, the gasification capacities in the world have grown from 100 to 285 GW(th) [], primarily due to the petrochemical industry. Gasification-produced hydrogen is inexpensive, albeit “grey”. The leader in the use of gasification technologies is China, where more than 30% of all gasification capacities are located.

Table 1.

Industrial entrained flow gasification processes (CWS—coal-water slurry; PC—pulverized coal).

Modern entrained flow gasifiers are the descendants of the Koppers-Totzeck gasifier and heavy oil gasification reactors. Industrial processes are carried out, as a rule, using oxygen to improve the kinetic and thermodynamic conditions of fuel conversion. Therefore, the resulting gas typically has a temperature in the order of 1500 °C, and its cooling before cleaning is associated with significant thermodynamic losses. One of the ways to reduce these losses is “chemical quenching”, where the heat of hot gases is utilized to convert secondary fuel (as in the E-Gas and MHI/MHPS processes) while the temperature of the producer gas can be reduced by 300–500 °C, though this leads to under-burning and additional gas cleaning.

Common problems with coal-fired IGCC plants include low availability, which, even for the best plants, does not exceed 0.8 and is, on average, at the level of 0.6 []. This is due to the failures and equipment repair due to corrosion (nozzles and lining), the condensation of acidic products, slagging, and ash transport. Gas storage is needed to balance a plant’s load.

After several gasification projects in the 1980s and 1990s, a rather optimistic view of the coal energy future has emerged. For example, in a 2001 study [], a forecast was proposed wherein, by 2004, the total gasification capacity in the world would be 60 GW (in actuality, it was 40 GW), and specific capital investments in coal-fired IGCC plants would decrease due to learning effects and would amount to 800–1000 USD/kW by 2012. The review in [] predicted that by 2020, the efficiency of coal-fired IGCC plants would reach 53–56% at specific capital costs of 1200–1400 USD/kW. A graph approach to the analysis of the development of coal-fired IGCC plants was proposed in [], showing the possibility of achieving an efficiency of approximately 55%, a capacity commissioning rate of 7.5 GW per year in the 2020s, and the possibility of replacing traditional coal blocks with IGCC plants by 2035. Even in later studies [,], coal-fired IGCC plants were considered as an option to replace nuclear power in Europe, and the improvement rate was estimated at a 1–3% increase in efficiency and a 2–9% reduction in specific capital costs over 10 years. These high expectations were not fulfilled. According to [], the specific capital investments in coal-fired IGCC plants were estimated at USD 1500 per kW, and the review in [] showed examples of unpredictable growth in capital investments. The available data has shown that specific capital costs can even reach USD 3000–4000 per kW (even without CCS systems). The maximum net efficiency of the implemented coal-fired IGCC plants did not even reach the expected level of 50% [], while coal combustion power plants with supercritical steam parameters can achieve efficiency ratings of approximately 44–48% due to progress in heat-resistant materials [,,,]. Gas turbines for operation on generator gas are, as a rule, more expensive than those developed for the combustion of hydrocarbons. Finally, coal-fired IGCC plants cost nearly twice as much to operate as traditional coal-fired thermal power plants. As noted in [], a significant cost reduction due to learning effects requires an installed capacity of approximately 100 GW of coal-fired IGCC plants, and this threshold has not yet been reached.

The efficiency of electricity generation at IGCC plants is largely determined by their coal conversion efficiency. Therefore, long-term trends in the development of gasification technology were associated with increases in reaction temperature and capacity. Oxygen is a typical gasifying agent in large-scale coal gasification; therefore, such plants require an air separation unit (ASU), and the corresponding increase in the station’s own needs should be compensated by an increase in the efficiency of the fuel gasification. For chemical production, this circumstance is not always significant since nitrogen is a diluent that increases the cost of gaseous product separation, and nitrogen may be used, for example, for the production of ammonia. In the energy use of gasification, it may be expedient to refuse air separation or use a weakly enriched blast [], though on the other hand, this may cause the volumes of the gases to increase and problems to arise with ash removal. In addition to the cryogenic method of air separation, less-expensive methods are being actively studied, for example, membrane and sorption separation, as well as chemical looping cycles [] (though these methods do not yet allow the achievement of high oxygen purity and capacity []).

Another way to achieve a high reaction temperature is high-temperature air gasification (HiTAG []). High-temperature gasification processes were proposed in [,], where the calculated efficiency of the power plants reached 37–45% when the air was heated up to 1000 °C (depending on the fuel type). Different methods for air heating were considered in [,], including convective heating in a channel and non-stationary heating in heat exchangers with ceramic packing.

Producer gas contains particulate matter, sulfur, and nitrogen compounds, and therefore, it requires cleaning before combustion. Cleaning, in turn, requires deep cooling. As a result, a gas conditioning unit is responsible for a significant portion of the thermodynamic losses []. High-temperature gas cleaning is much more technologically complicated since it requires the use of chemical cycles for trapping sulfur compounds (for example, with calcium or zinc compounds [,]), but it allows for increasing the efficiency of the power plant []. The gas-cleaning temperature is limited, however, by the volatility of the components in the mineral portion [].

In addition to the power cycle, there are options for the producer gas conversion in fuel cells, including hybrid schemes with the thermal integration of fuel cells in IGCC plant [,,,,]. In China, power plants with the electrochemical conversion of coal gasification products are being developed, but the declared capacities do not yet exceed 1 MW [,].

In staged gasification processes (e.g., an MHI/MHPS staged gasifier) the mechanical under-burning is returned to the oxidation zone to achieve the desired conversion efficiency. In [,,], IGCC plants with incomplete coal gasification were considered, where the char-ash residue is burned in a separate furnace and used to heat air or to produce additional steam. Schemes for combined cycle plants with integrated pyrolysis were proposed in [].

As mentioned above, coal gasification is widely used in the chemical industry, and so it is natural to expect attempts to combine the production of electricity and chemical products within a single plant. Among such products, special attention is paid to hydrogen [,,] and synthetic liquid fuels (such as dimethyl ether, methanol, and Fischer–Tropsch hydrocarbons [,]). Hydrogen production, in some cases, can improve the economic performance of gasification plants []. In general, an energy-technological installation can operate in different modes, depending on the economic conditions, and focus on the prices of different products (although it was concluded in [] that multi-purpose installations lose out to energy-only producing power plants). In changing the operating conditions of a plant, the operating conditions of its gasifier also change [].

Carbon emissions restrictions lead to a decrease in the production of fossil-based energy. The replacement of coal with plant biomass and waste is often considered []. At some IGCC plants (primarily, Nuon and Elcogas [,]), experiments have been carried out to replace part of the coal with biomass. A simulation of such power plants showed the possibility of a deep replacement (up to 60–70% in terms of heating value [,,]). At the same time, however, the efficiency of the power generation decreases [], and low-melting ash can lead to issues with slag removal. The performance of energy-technological plants with the co-gasification of coal and biomass (including waste) was studied in [,], where the calculations showed that the biomass addition made it possible to obtain a gas that was richer in hydrogen, with lower specific carbon dioxide emissions (since the hydrogen content of biomass is higher than that of coal). In [], an exotic option was considered for integrating a gasifier operating on a mixture of coal and biomass into a natural gas-fired IGCC plant. In this case, it was possible to reduce gas consumption and save on the construction of a solid fuel power plant.

One of the competitive advantages of IGCC (in terms of technological prospects) may be the relatively low cost of CO2 removal, although, at high specific costs, it is difficult to expect that an inexpensive CCS unit will make such a plant more attractive than a conventional coal-fired power plant. The cost of capturing and burying CO2 is currently approximately USD 40–60 per t (i.e., the LCOE increases by 50–100% due to CSS []), and so the implementation of CCS requires either high carbon taxes or technology that is several times cheaper []. The drop in the net efficiency due to a CCS system is 10–12 percentage points, but for promising IGCC plants, even with such a decrease in net efficiency, it may remain at the level of 38–42% [,,,]. In general, the reduction in net efficiency depends on the degree of CO2 removal []. Roughly speaking, a CCS system reduces the net efficiency of coal-fired IGCC plants to that of the average level of conventional coal-fired thermal power plants [,,]. The feasibility studies carried out in [] showed that a coal-fired IGCC plant is the most expensive coal option without CCS, but will be the least expensive option if CCS becomes mandatory. Among the developing projects of coal-fired IGCC-CCS plants, GreenGen (China) [] and CoolGen (Japan) [] can be listed.

The Allam cycle, using CO2 as a working fluid, theoretically allows for obtaining an efficiency of 49–51% when operating on coal at a high degree of CO2 capture []. Work on such a pilot plant has been underway for a long time []. Similar cycles for coal combustion technologies were proposed in [] (Brighton CO2-cycle: net efficiency varies from 38 to 44–45%) and [] (combined CO2-cycle: net efficiency of 37–40%).

Existing CCS systems continue to have a largely demonstration status; nevertheless, according to [], in 2020, the installed capacity of CCS in the world was 40 million tons of CO2 per year. It is important to note that CO2 can only be buried in suitable locations, such as depleted oil or gas fields. For example, the Boundary Dam coal plant partially offsets the costs associated with the extraction of CO2 from flue gases due to the interest of oil companies that use CO2 to increase oil recovery []. In this regard, underground coal gasification with the simultaneous burial of CO2 in mined-out seams is of interest []. According to the available volumes of depleted fields, Russia could become one of the world’s leading countries in CO2 storage.

One of the developed methods for removing CO2 from combustion products is absorption (for example, with methanol or ethanolamines []). This method is quite energy-intensive as the regeneration of the absorbent, as a rule, requires significant heat inputs. IGCC allows for reduction through the use of absorption systems in gas conditioning units. Compressing and transporting concentrated CO2 also requires significant energy consumption, but this stage varies little in different CCS systems. The authors of [] reported on the possibility of an acceptable cost of CO2 removal using the Selexol process (USD 10–20 per t). The mineral sorbents used without regeneration can reduce the cost of the process, especially if CO2 mineralization makes it possible to obtain, for example, construction materials []. Adsorbent regeneration has less energy consumption, but it also has lower capacity [,]. Chemical looping cycles’ energy consumption is comparable to that of absorption processes [].

Another way to extract CO2 from combustion or gasification products is membrane separation, which includes those used for separating H2/CO2 mixtures obtained by the steam conversion of produced gas (water shift) []. This process is exothermic, and it can be used to generate additional steam. Depending on a reactor’s configuration, different strategies may be implemented to integrate carbon capture and power production using a water-shift reactor []. Due to the significant differences in the diffusivity and molecular masses of components, H2 and CO2 mixtures may be separated using relatively inexpensive membrane technology. In [], a combination of water-shift technology with the absorption removal of CO2 was considered, and the calculated efficiency of the electricity generation was 34–36%).

Combustion products primarily consist of N2, H2O, and CO2. It is possible to reduce the cost of the CO2 separation stage if we exclude nitrogen, and water vapor is easily removed by condensation, leaving highly concentrated CO2 as the output. This method is the basis of oxyfuel combustion []. One of the issues with oxyfuel combustion technologies is the need for costly air separation (the combustion temperature is moderated by diluting oxygen with combustion products). In coal gasification, an air separation is a standard option, and so it is possible, for example, to use the oxyfuel combustion of producer gas in a turbine, thus reducing CCS costs []. The recirculation of combustion products makes it possible to increase the fuel conversion efficiency because the flue gases are a mixture with a high concentration of CO2. Such IGCC schemes were proposed for fluidized bed reactors in [,], with an estimated net efficiency of 40–48%, and the entrained flow reactors in [,,,] demonstrated an estimated net efficiency of 42%.

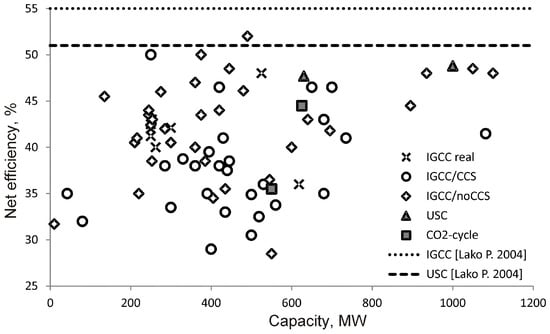

An overview of the data on the net efficiency of coal-fired IGCC plants (operating, dismissed, and promising) and their comparison with traditional coal-fired thermal power plants is presented in Figure 1. The dotted lines limit the forecast indicators given in [] for the year 2020. Coal plants with ultra-supercritical steam parameters are quite close to the predicted boundary. Most of the real coal-fired IGCC plants lie in a rather narrow range of capacities and net efficiency. We concluded that the potential of gasification plants is still far from being realized. The maximum net efficiency of coal-fired IGCC plants is close to 50%, and in rare cases, plants exceed this value, which, according to [], corresponds to the expected progress level of the 2000s.

Figure 1.

Distribution of coal power plants net efficiency according to the literature. Crosses—real IGCC plants; diamonds—calculated IGCC plants without CCS; circles—calculated IGCC plants with CCS; triangles—high-efficiency coal power plants with ultra-supercritical steam parameters; squares—calculated coal power plants using CO2 as working fluid; lines—forecast [].

When using CCS systems, as mentioned above, efficiency decreases, although estimates of some carbon dioxide cycles provide quite high values for net efficiency (for example, the estimated net efficiency of the Allam cycle is approximately 50%). In general, the lack of an experimental basis for the verification of the mathematical models of IGCC power plants leads to the fact that calculated characteristics have no determined accuracy interval, with rare exceptions (see, for example, [,,], where operating stations data were used). Most of the plants shown in Figure 1 correspond to the theoretically calculated efficiency estimates for advanced power plant schemes, and all these schemes differ from each other in a combination of elements (cleaning systems, the degree of integration, methods of CO2 extraction, etc.). Moreover, schemes are typically optimized for different fuels and conditions (for example, prices for fuel and electricity, specific capital costs, and operating conditions of power units), and so their comparison is not always correct. Even within a small power range, the net efficiencies of different coal-fired IGCC plants may differ by a factor of 1.5–2.

3. Calculation of Technical and Economic Characteristics of Coal-Fired IGCC Plants with CO2 Capture

Economic calculations for coal-fired IGCC power plants were carried out according to the method described in []. The energy cost is given by the formula []:

where CPP is the total capital cost of the plant, Mf represents the fixed repair costs, t is the average number of hours per year that the installation produces electricity, P0 is the rated power (500 MW), Mv represents the current costs for the production of 1 MWh of electricity, B is the specific fuel consumption per 1 MWh of electricity, and Cf is the cost of 1 ton of coal. Parameter f takes into account an inflation rate of 8% per year at 30 years of a plant’s operation. The values of all the listed quantities are provided in Table 2.

Table 2.

Initial data for economic calculations (Data from []).

A detailed consideration of a coal-fired IGCC plants with a description of the individual elements of the equipment is not the purpose of this work. Instead, stations are considered as the following lumped units: a gasification and gas conditioning unit; a power unit (gas turbine and steam turbine part); and a CO2 capture unit. The primary characteristic of the units is their energy efficiency (or their specific energy consumption).

The availability factor is 0.7, and as reliability estimates show, such a factor most accurately reflects the operational features of coal-fired IGCC plants [,]. The specific fuel consumption depends on the efficiency of the station, which can be calculated as follows:

where Qc is the calorific value of the fuel. The station’s efficiency (ηPP) depends on the efficiency of individual nodes according to the following simplified formula []:

where ηG is the cold gas efficiency, ηGTU is the efficiency of the gas turbine plant, and ηSTU is the efficiency of the steam turbine plant. This formula shows that the cold gas efficiency is the determining factor in assessing the efficiency of electricity generation. Losses (Δη) primarily consist of the needs of the process associated with air separation (O2 production) and CO2 utilization. In this work, losses are estimated most simply as follows:

where is the work required to obtain the stoichiometric amount of oxygen required to burn 1 kg of coal and is the work required to compress and purify CO2 from the combustion products (estimated based on data from [,,,]).

The detailed modelling of coal conversion is computationally expensive because it requires CFD codes with extended chemical kinetic mechanisms [,]. In this work, cold gas efficiency is estimated using simplified mathematical models of coal gasification processes developed in our previous works [,], which showed good agreement with the available experimental data.

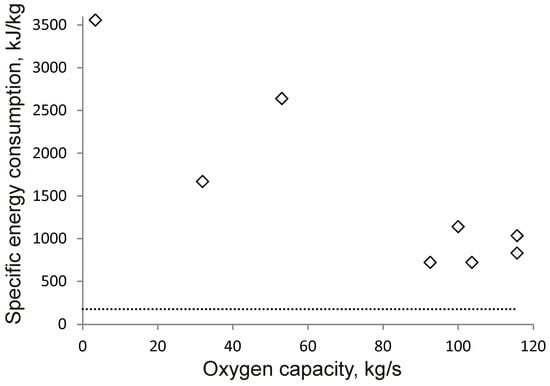

The specific energy consumption of oxygen production was estimated by analyzing the literature data on air separation plants [,,,,,,] (Figure 2). The most mature installations in the industry are cryogenic. They require more energy per unit mass of oxygen produced, but they have better performances and oxygen purity levels. Most of the existing large coal gasification plants operate for the needs of the chemical industry (hydrogen, methanol, or fertilizer production), and so the nitrogen obtained during air separation is a valuable product. The combination of power plants with chemical production (including the utilization of captured CO2), in some cases, can improve the economic performance of coal-fired thermal power plants [,], but such possibilities are not considered in this work.

Figure 2.

Dependence of the unit cost of oxygen production on plant capacity (the dotted line is the thermodynamic estimate of the minimum energy of air separation).

4. Initial Data and Calculation Results

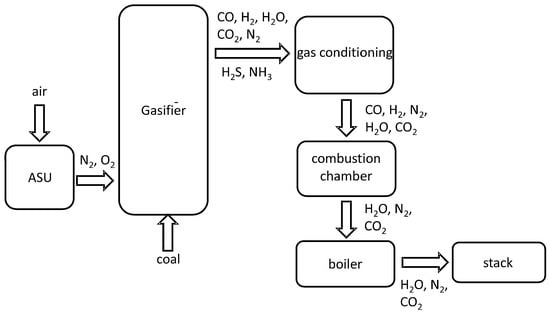

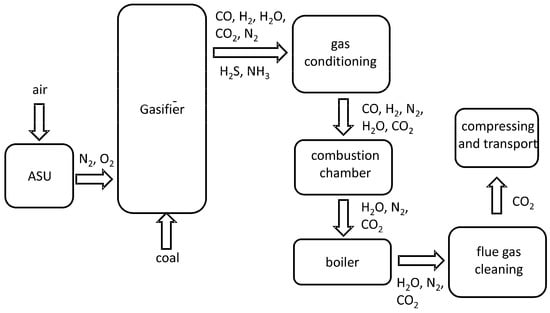

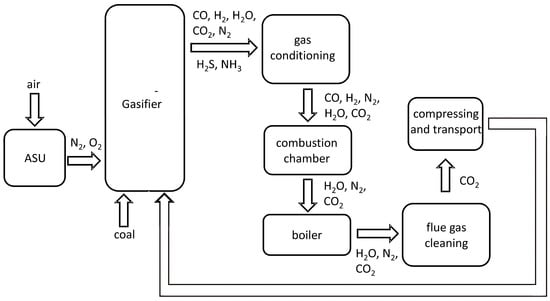

Several options for a coal-fired IGCC plant are being considered. The first option (Figure 3) does not include a CO2 removal unit, and due to the use of a combined cycle, the efficiency of electricity generation in such a scheme can be much higher than that of traditional coal-fired thermal power plants. The second option (Figure 4) includes a CO2 removal scheme that uses the methyldiethanolamine absorption method. As indicated in [,], the total energy costs for removing CO2, in this case, are approximately 4 MJ/kg CO2 (in [], a range of 5–9 MJ/kg corresponded to high capture rates). Finally, the third option (Figure 5) is the oxyfuel gasification process [] in which the flue gases consist of a mixture of CO2 and H2O (with small impurities), and so additional purification before compression and disposal is not required. In this case, the energy consumption in the CCS unit is 0.4 MJ/kg of CO2. The removal of CO2 from producer gas at an intermediate stage between gasification and combustion is not considered. Optimization of the removed fraction of CO2 is also not considered in this work, but we assume that this fraction is 90% for all cases [].

Figure 3.

The basic scheme of a coal-fired IGCC plant.

Figure 4.

Scheme of a coal-fired IGCC plant with the removal of CO2 from flue gases.

Figure 5.

Scheme of a coal-fired IGCC in oxyfuel mode.

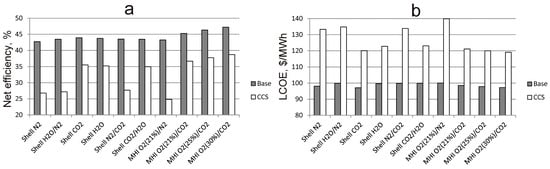

Table 3 shows the gasification processes studied in previous works and the conditions under which they were carried out. The Shell process (according to data from []) is a single-stage gasification using pulverized coal as a gasification agent with an O2 concentration of approximately 80%. The MHI/MHPS process (according the data from []) is a two-stage gasification using pulverized coal as a gasification agent with an O2 concentration that is close to atmospheric (with solid residue recirculation to reduce under-burning). Using the previously developed mathematical models [,,], the limiting values of the cold gas efficiency were estimated. Then, the efficiency of electricity production was calculated both without CO2 removal and with CO2 removal. Even without CO2 removal, electricity production efficiency is higher for the oxyfuel gasification option. Table 3 shows that a CCS leads to a significant reduction in the efficiency of a coal-fired IGCC plant, where the drop is from 8 to 16 percentage points, depending on the composition of the gasifying agent. A higher decrease is observed for gasification processes in O2/N2 mixtures since, in this case, an energy-intensive absorption method for CO2 removal is required (Figure 2). The decrease in efficiency due to the CCS unit for the oxyfuel gasification option is approximately 2 times lower than those of schemes without the recirculation of combustion products. The literature data has shown that the decrease in the efficiency of coal-fired IGCC plants with CCS units lies in the range of 6 to 23 percentage points [,,,,,,]. Estimates of the efficiency of coal-fired IGCC plants operating in oxyfuel mode are 34–39% [,], and our calculations showed similar values.

Table 3.

Dependence of efficiency on the chosen scheme of a coal-fired IGCC plant and gasification processes.

Two-stage gasification processes demonstrate the highest levels of cold gas efficiency, which are associated with its better thermodynamic characteristics []. The CO2 addition to the gasifying agent (as mentioned above) leads to an improvement in fuel conversion and a decrease in specific oxygen consumption. Therefore, the calculated performance of a coal-fired IGCC plant based on a two-stage gasification process reached 36–38%, even with a CCS. Coal-fired IGCC plants using a single-stage gasification process with O2/CO2/H2O mixtures show efficiency limits of approximately 35%.

Figure 6 shows a comparison of the technical and economic indicators of coal-fired IGCC plants. Without CO2 removal, the cost of electricity for all cases was approximately USD 100 per MWh. A CCS leads to a significant increase in the cost of electricity (by 20–40%). At the same time, the oxyfuel gasification process again demonstrated a better performance, where the increase in energy costs was approximately 20–25%. For traditional processes, this increase reached 35–40%. We note that the economic efficiency of different methods will be determined, among other things, by the level of carbon penalties [].

Figure 6.

Dependence of the technical and economic indicators of coal-fired IGCC plants on the fuel gasification process: net efficiency (a) and cost of energy (b). The columns for the basic scheme are grey, and the columns for the CCS schemes are white.

The cost of energy produced by coal-fired IGCC plants is high even for the base case (without CO2 removal) due to higher capital costs (compared to conventional coal-fired thermal power plants with steam cycles) and lower reliability. The values obtained in this section can be compared with the data of other works listed above.

Comparison with traditional coal-fired thermal power plants has not been carried out. It was shown in [,] that the CCS unit increased the costs for coal-fired IGCC plants, to a lesser extent, when compared to coal-fired thermal power plants. The estimated increase in the cost of energy when using CCS in a traditional thermal power plant scheme is at a level of 50% or more [], which is lower than the above estimates for coal-fired IGCC plants.

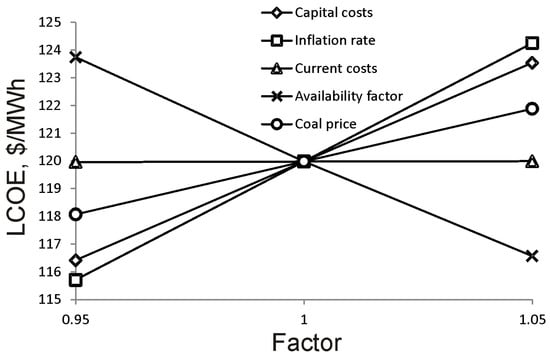

Sensitivity was estimated by a change in economic parameters of 5% both up and down. Calculations were carried out for two-stage gasifiers due to their higher efficiency levels. The results are presented in Figure 7. The most sensitive parameters are capital costs, inflation rates, and availability, which illustrate the crucial drawbacks of IGCC power plants. Lower availability and higher investments have been the major barriers for IGCC technology for many years, as mentioned above. Fuel price and current costs are less influential.

Figure 7.

Sensitivity analysis of a two-stage gasifier-based IGCC.

5. Conclusions

Several promising schemes for coal-fired IGCC plants with CO2 capture have been studied. The estimated decrease in power plant efficiency associated with a CCS depends on the scheme option and the gasification process used (in this work, the efficiency decreased from 43–47% to 25–39%). Our calculations showed that the use of gasification processes with flue gas recirculation makes it possible to reduce losses for CO2 emissions by up to two times (approximately 8.5% instead of 16–18%), and the increase in the cost of energy, respectively, turned out to be 1.5–2 times less (22–23% instead of 35–40%). The two-stage gasification process is more promising for coal-fired IGCC plants with CCSs due to the higher efficiency of the thermochemical conversion of fuel into combustible gas.

Funding

The research was carried out under a State Assignment Project (number FWEU-2021-0005) of the Fundamental Research Program of Russian Federation 2021–2030 (Siberian Branch of Russian Academy of Sciences) using the resources of the High-Temperature Circuit Multi-Access Research Center (Ministry of Science and Higher Education of the Russian Federation, project number 13.CKP.21.0038).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data is available on request from the author.

Conflicts of Interest

The author declares no conflict of interest.

References

- Filippov, S.P.; Dil’man, M.D. Renewable Energy: System Effects. In Proceedings of the 12th International Conference “Modeling of Large Systems Development MLSD’2019”, Moscow, Russia, 1–3 October 2019; pp. 558–567. (In Russian). [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Caramanna, G.; Maroto-Valer, M.M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 2014, 39, 426–443. [Google Scholar] [CrossRef]

- Cau, G.; Tola, V.; Ferrara, F.; Porcu, A.; Pettinau, A. CO2-free coal-fired power generation by partial oxy-fuel and post-combustion CO2 capture: Techno-economic analysis. Fuel 2018, 214, 423–435. [Google Scholar] [CrossRef]

- Yadav, S.; Mondal, S.S. A review on the progress and prospects of oxy-fuel carbon capture and sequestration (CCS) technology. Fuel 2022, 308, 122057. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Bogatova, T.F.; Maslennikov, G.E.; Osipov, P.V.; Nizov, V.A. Creation of energy-efficient and environmentally friendly energy sources on fossil fuels to address global climate issues. J. Phys. Conf. Ser. 2020, 1677, 012115. [Google Scholar] [CrossRef]

- Ringrose, P. How to Store CO2 Underground: Insights from Early-Mover CCS Projects; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Feron, P.H.M.; Cousins, A.; Jiang, K.; Zhai, R.; Garcia, M. An update of the benchmark post-combustion CO2-capture technology. Fuel 2020, 273, 117776. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Bogatova, T.F.; Maslennikov, G.E.; Osipov, P.V. A new approach to the development of zero-emission power generation system. J. Phys. Conf. Ser. 2020, 1675, 012121. [Google Scholar] [CrossRef]

- Chen, W.-H.; Tsai, C.-W.; Lin, Y.-L.; Chein, R.-Y.; Yu, C.-T. Reaction phenomena of high-temperature water gas shift reaction in a membrane reactor. Fuel 2017, 199, 358–371. [Google Scholar] [CrossRef]

- Ryzhkov, A.; Bogatova, T.; Gordeev, S. Technological solutions for an advanced IGCC plant. Fuel 2018, 214, 63–72. [Google Scholar] [CrossRef]

- Allam, R.; Palmer, M.R.; Brown, G.W., Jr.; Fetvedt, J.; Freed, D.; Nomoto, H.; Itoh, M.; Okita, N.; Jones, C., Jr. High Efficiency and Low Cost of Electricity Generation from Fossil Fuels While Eliminating Atmospheric Emissions, Including Carbon Dioxide. Energy Proc. 2013, 37, 1135–1149. [Google Scholar] [CrossRef]

- Allam, R.; Martin, S.; Forrest, B.; Fetvedt, J.; Lu, X.; Freed, D.; Brown Jr., G. W.; Sasaki, T.; Itoh, M.; Manning, J. Demonstration of the Allam Cycle: An Update on the Development Status of a High Efficiency Supercritical Carbon Dioxide Power Process Employing Full Carbon Capture. Energy Proc. 2017, 114, 5948–5966. [Google Scholar] [CrossRef]

- Kosoi, A.S.; Zeigarnik, Y.A.; Popel, O.S.; Sinkevich, M.V.; Filippov, S.P.; Shterenberg, V.Y. The Conceptual Process Arrangement of a Steam–Gas Power Plant with Fully Capturing Carbon Dioxide from Combustion Products. Therm. Eng. 2018, 65, 597–605. [Google Scholar] [CrossRef]

- Shchinnikov, P.A.; Sadkin, I.S.; Shchinnikov, A.P.; Cheganova, N.F.; Vorogushina, N.I. Influence of the initial parameters on the thermodynamic efficiency of carbon dioxide power cycles. J. Phys. Conf. Ser. 2022, 2150, 012011. [Google Scholar] [CrossRef]

- Oki, Y.; Hara, S.; Umemoto, S.; Kidoguchi, K.; Hamada, H.; Kobayashi, M.; Nakao, Y. Development of high-efficiency oxy-fuel IGCC system. Energy Proc. 2014, 63, 471–475. [Google Scholar] [CrossRef]

- Ishi, H.; Hayashi, T.; Tada, H.; Yokohama, K.; Takashima, R.; Hayashi, J. Critical assessment of oxy-fuel integrated coal gasification combined cycles. Appl. Energy 2019, 233, 156–169. [Google Scholar] [CrossRef]

- Oki, Y.; Hamada, H.; Kobayashi, M.; Nakao, Y.; Hara, S. Development of high-efficiency oxy-fuel IGCC system. Mech. Eng. J. 2016, 3, 16-00351. [Google Scholar] [CrossRef]

- Oki, Y.; Hamada, H.; Kobayashi, M.; Yuri, I.; Hara, S. Development of High-Efficiency Oxy-Fuel IGCC System. In Proceedings of the ASME 2017 Power Conference Joint with ICOPE-17, Charlotte, CA, USA, 26–30 June 2017; p. 3024. [Google Scholar] [CrossRef]

- Svishchev, D.A.; Keiko, A.V. A thermodynamic analysis of operating conditions under which coal-water fuel is gasified in flow. Therm. Eng. 2010, 57, 490–494. [Google Scholar] [CrossRef]

- Nikitin, A.D. Influence of Water Vapours on Physico-Chemical Processes in IGCC. Ph.D. Thesis, Ural Federal Univ., Ekaterinburg, Russia, 2021. (In Russian). [Google Scholar]

- Donskoy, I.G. How water vapor and carbon dioxide additives affect oxygen gasification of pulverized coal fuel. Bull. South Ural. St. Univ. Ser. Power Eng. 2021, 21, 21–28. [Google Scholar] [CrossRef]

- Donskoy, I.G. Influence of coal-biomass fuel composition on the efficiency of its conversion in entrained-flow gasifiers. Solid. Fuel Chem. 2019, 53, 113–119. [Google Scholar] [CrossRef]

- Chen, Y.; Sheng, C. Modeling of a single char particle burning in oxygen-enriched O2/N2 and O2/CO2 environment with single film model. Fuel 2016, 184, 905–914. [Google Scholar] [CrossRef]

- Liu, S.; Wen, L.; Niu, Y.; Yan, B.; Lei, Y.; Wang, D.; Hui, S. Separate physicochemical effects of CO2 on the coal char combustion: An experimental and kinetic study. Combust. Flame 2022, 235, 111717. [Google Scholar] [CrossRef]

- Botero, C.; Field, R.P.; Herzog, H.J.; Ghoniem, A.F. Impact of finite-rate kinetics on carbon conversion in a high-pressure, single-stage entrained flow gasifier with coal-CO2 slurry feed. Appl. Energy 2013, 104, 408–417. [Google Scholar] [CrossRef]

- Watanabe, H.; Ahn, S.; Tanno, K. Numerical investigation of effects of CO2 recirculation in an oxy-fuel IGCC on gasification characteristics of a two-stage entrained flow coal gasifier. Energy 2017, 118, 181–189. [Google Scholar] [CrossRef]

- Donskoy, I. A Numerical Study of the Influence of Process Parameters on the Efficiency of Staged Coal Gasification Using Mixtures of Oxygen and Carbon Dioxide. Energy Syst. Res. 2021, 4, 27–34. [Google Scholar] [CrossRef]

- Higman, C.; Tam, S. Advances in Coal Gasification, Hydrogenation, and Gas Treating for the Production of Chemicals and Fuels. Chem. Rev. 2014, 114, 1673–1708. [Google Scholar] [CrossRef] [PubMed]

- Taamallah, S.; Vogiatzaki, K.; Alzahrani, F.M.; Mokheimer, E.M.A.; Habib, M.A.; Ghoniem, A.F. Fuel flexibility, stability and emissions in premixed hydrogen-rich gas turbine combustion: Technology, fundamentals, and numerical simulations. Appl. Energy 2015, 154, 1020–1047. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Bogatova, T.F.; Levin, E.I. Solid Fuel Combined Cycle Technologies; Ural Federal Univ.: Ekaterinburg, Russia, 2018. (In Russian) [Google Scholar]

- Tumanovskii, A.G. Prospects for the development of coal-steam plants in Russia. Therm. Eng. 2017, 64, 399–407. [Google Scholar] [CrossRef]

- Cormos, A.-M.; Dinca, C.; Cormos, C.-C. Multi-fuel multi-product operation of IGCC power plants with carbon capture and storage (CCS). Appl. Therm. Eng. 2015, 74, 20–27. [Google Scholar] [CrossRef]

- Nozdrenko, G.V. Efficiency of Environmentally Promising Energo-Technology Power Plants with New Coal Technologies Use in Kansko-Achinsk Fuel Energy Complex; Novosibirsk Electro-Technical Institute: Novosibirsk, Russia, 1992. (In Russian) [Google Scholar]

- Kler, A.M.; Tyurina, E.A.; Mednikov, A.S. A plant for methanol and electricity production: Technical-economic analysis. Energy 2018, 165B, 890–899. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, Y.; Zhang, Z.; Li, H.; Li, X.; Egorov, R.I.; Strizhak, P.A.; Gao, X. Recent advances in co-thermochemical conversions of biomass with fossil fuels focusing on the synergistic effects. Renew. Sustain. Energy Rev. 2019, 103, 384–398. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Strizhak, P.A.; Chernetskii, M.Y. Organic coal-water fuel: Problems and advances (Review). Therm. Eng. 2016, 63, 707–717. [Google Scholar] [CrossRef]

- Ouyang, Z.; Ding, H.; Liu, W.; Li, S.; Cao, X. Effect of the staged secondary air on NOx emission of pulverized semi-coke flameless combustion with coal preheating technology. Fuel 2021, 291, 120137. [Google Scholar] [CrossRef]

- Messerle, V.E.; Ustimenko, A.B.; Lavrischev, O.A. Comparative study of coal plasma gasification: Simulation and experiment. Fuel 2016, 164, 172–179. [Google Scholar] [CrossRef]

- Burdukov, A.P.; Popov, V.I.; Chernetskiy, M.Y.; Dekterev, A.A.; Hanjalic, K. Mechanical activation of micronized coal: Prospects for new combustion applications. Appl. Therm. Eng. 2015, 74, 174–181. [Google Scholar] [CrossRef]

- Chernetskiy, M.; Dekterev, A.; Chernetskaya, N.; Hanjalic, K. Effects of reburning mechanically-activated micronized coal on reduction of NOx: Computational study of a real-scale tangentially-fired boiler. Fuel 2018, 214, 215–229. [Google Scholar] [CrossRef]

- Kuznetsov, V.; Chernetskiy, M.; Abaimov, N.; Ryzhkov, A. Study of the two-stage gasification process of pulverized coal with a combined countercurrent and concurrent flow system. MATEC Web Conf. 2017, 115, 03008. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Strizhak, P.A.; Chernetskii, M.Y.; Shadrin, E.Y.; Sharypov, O.V. Aerodynamics of a promising vortex furnace design. Tech. Phys. Lett. 2015, 41, 727–730. [Google Scholar] [CrossRef]

- Di Giuliano, A.; Capone, S.; Anatone, M.; Galluchi, K. Chemical Looping Combustion and Gasification: A Review and a Focus on European Research Projects. Ind. Eng. Chem. Res. 2022, 61, 14403–14432. [Google Scholar] [CrossRef]

- Kuznetsov, B.N. Catalysis of Chemical Reactions of Coal and Biomass; Nauka: Novosibirsk, Russia, 1990. (In Russian) [Google Scholar]

- Zhou, H.; Guo, X.; Zhou, M.; Ma, W.; Dahri, M.W.; Cen, K. Optimization of ammonia injection grid in hybrid selective non-catalyst reduction and selective catalyst reduction system to achieve ultra-low NOx emissions. J. Energy Inst. 2018, 91, 984–996. [Google Scholar] [CrossRef]

- Nitskevich, E.A. Use of high-temperature nuclear reactors for technological aims. Teploenergetika 1984, 31, 71–72. (In Russian) [Google Scholar]

- Inaba, Y.; Fumizava, M.; Tonogouchi, M.; Takenaka, Y. Coal gasification system using nuclear heat for ammonia production. Appl. Energy 2000, 67, 395–406. [Google Scholar] [CrossRef]

- Wheeler, V.M.; Bader, R.; Kreider, P.B.; Hangi, M.; Haussener, S.; Lipinski, W. Modelling of solar thermochemical reaction systems. Sol. Energy 2017, 156, 149–168. [Google Scholar] [CrossRef]

- Duan, T.; Lu, C.; Xiong, S.; Fu, Z.; Zhang, B. Evaluation method of the energy conversion efficiency of coal gasification and related applications. Int. J. Energy Res. 2016, 40, 168–180. [Google Scholar] [CrossRef]

- thyssenkrupp Industrial Solutions AG. Gasification Technologies; thyssenkrupp Industrial Solutions AG: Essen, Germany, 2019. [Google Scholar]

- Laugwitz, A.; Grabner, M.; Meyer, B. Availability analysis of integrated gasification combined cycle (IGCC) power plants. In Power Plant Life Management and Performance Improvement; Woodhead Publ.: Cambridge, UK, 2011; pp. 110–142. [Google Scholar] [CrossRef]

- Stiegel, G.J.; Maxwell, R.C. Gasification technologies: The path to clean, affordable energy in the 21st century. Fuel Proc. Technol. 2001, 71, 79–97. [Google Scholar] [CrossRef]

- Lako, P. Coal-Fired Power Technologies. Coal-Fired Power Options on The Brink of Climate Policies (ECN-C-04-076); ECN: Petten, The Netherlands, 2004. [Google Scholar]

- Akimoto, K.; Tomoda, T.; Fujii, Y. Development of a mixed integer programming for technology development strategy and its application to IGCC technologies. Energy 2005, 30, 1176–1191. [Google Scholar] [CrossRef]

- Melchior, T.; Madlener, R. Economic evaluation of IGCC plants with hot gas cleaning. Appl. Energy 2012, 97, 170–184. [Google Scholar] [CrossRef]

- Brouwer, A.S.; van der Broek, M.; Seebregts, A.; Faaij, A. Operational flexibility and economics of power plants in future low-carbon power systems. Appl. Energy 2015, 156, 107–128. [Google Scholar] [CrossRef]

- Olkhovskii, G.G. New projects for CCGTs with coal gasification (Review). Therm. Eng. 2016, 63, 679–689. [Google Scholar] [CrossRef]

- Phillips, J.N.; Booras, G.S.; Marasigan, J. The History of Integrated Gasification Combined-Cycle Power Plants. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition GT 2017, Charlotte, NC, USA, 26–30 June 2017; p. V003T03A007. [Google Scholar] [CrossRef]

- Campbell, P.E.; Mcmullan, J.T.; Williams, B.C. Concept of a competitive coal fired integrated gasification combined cycle power plant. Fuel 2000, 79, 1031–1040. [Google Scholar] [CrossRef]

- Feng, W. China’s national demonstration project achieves around 50% net efficiency with 600 °C class materials. Fuel 2018, 223, 344–353. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsartsaronis, G. Multi-objective optimization of coal-fired power plants using differential evolution. Appl. Energy 2014, 115, 254–264. [Google Scholar] [CrossRef]

- Kler, A.M.; Zharkov, P.V.; Epishkin, N.O. Parametric optimization of supercritical power plants using gradient methods. Energy 2019, 189, 116230. [Google Scholar] [CrossRef]

- Lin, X.; Li, Q.; Wang, L.; Guo, Y.; Liu, Y. Thermo-economic analysis of typical thermal systems and corresponding novel system for a 1000 MW single reheat ultra-supercritical thermal power plant. Energy 2020, 201, 117560. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X.; Gao, L.; Jin, H. Learning rates and future cost curves for fossil fuel energy systems with CO2 capture: Methodology and case studies. Appl. Energy 2012, 93, 348–356. [Google Scholar] [CrossRef]

- Giuffrida, A.; Romano, M.C.; Lozza, G. Thermodynamic analysis of air-blown gasification for IGCC applications. Appl. Energy 2011, 88, 3949–3958. [Google Scholar] [CrossRef]

- Shi, B.; Xu, W.; Wu, E.; Wu, W.; Kuo, P.-C. Novel design of integrated gasification combined cycle (IGCC) power plants with CO2 capture. J. Clean. Prod. 2018, 195, 176–186. [Google Scholar] [CrossRef]

- Wu, F.; Argyle, M.D.; Dellenback, P.A.; Fan, M. Progress in O2 separation for oxy-fuel combustion—A promising way for cost-effective CO2 capture: A review. Prog. Energy Combust. Sci. 2018, 67, 188–205. [Google Scholar] [CrossRef]

- Tsuji, H.; Gupta, A.K.; Hasewaga, T.; Katsuki, M.; Kishimoto, K.; Morita, M. High Temperature Air Combustion. From Energy Conservation to Pollution Reduction; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Kobayashi, H.; Yoshikawa, K.; Tuji, K.; Shioda, S. Analysis of power generation system on gasification of coal and solid wastes using high temperature air. In International Conference on MHD Power Generation and High Temperature Technologies; PRC: Beijing, China, 1999; pp. 12–15. [Google Scholar]

- Yoshikawa, K. High Temperature Gasification of Coal, Biomass, and Solid Wastes. In Proceedings of the 2nd International Seminar on High Temperature Air Combustion, Stockholm, Sweden, 17–18 January 2000. [Google Scholar]

- Kler, A.M.; Marinchenko, A.Y.; Potanina, Y.M. Development of mathematical model of the system of high-temperature ceramic heat exchangers of periodic action. Bull. Tomsk. Polytechnic. Univ. 2019, 329, 26–35. [Google Scholar] [CrossRef]

- Kunze, C.; Riedl, K.; Spliethoff, H. Structured exergy analysis of an integrated gasification combined cycle (IGCC) plant with carbon capture. Energy 2011, 36, 1480–1487. [Google Scholar] [CrossRef]

- Kunze, C.; De, S.; Spliethoff, H. A novel IGCC plant with membrane oxygen separation and carbon capture by carbonation-calcination loop. Int. J. Greenh. Gas Control. 2011, 5, 1176–1183. [Google Scholar] [CrossRef]

- Kagramanov, Y.; Tuponogov, V.; Ryzhkov, A.; Nikitin, A. Multiple Gas-Solid Reactions in a Porous Sorbent Applied to Warm Gas Desulfurization. Ind. Eng. Chem. Res. 2020, 59, 12943–12954. [Google Scholar] [CrossRef]

- Giuffrida, A.; Romano, M.C.; Lozza, G.G. Thermodynamic assessment of IGCC power plants with hot fuel gas desulfurization. Appl. Energy 2010, 87, 3374–3383. [Google Scholar] [CrossRef]

- Muller, M. Integration of hot gas cleaning at temperatures above the ash melting point in IGCC. Fuel 2013, 108, 37–41. [Google Scholar] [CrossRef]

- Lykova, S.A. Highly efficient hydrid power generation based on fuel cells. Therm. Eng. 2002, 49, 54–60. [Google Scholar]

- Ghosh, S.; De, S. Energy analysis of a cogeneration plant using coal gasification and solid oxide fuel cell. Energy 2006, 31, 345–363. [Google Scholar] [CrossRef]

- Grigoruk, D.G.; Kasilova, E.V. Parametric study of hydrid thermal plant schemes with fuel cells fed by coal gasification products and with CO2 capture. Energetik 2012, 12, 39–41. (In Russian) [Google Scholar]

- Thattai, A.T.; Oldenbroek, V.; Schoenmakers, L.; Woudstra, T.; Aravind, P.V. Towards retrofitting integrated gasification combined cycle (IGCC) power plants with solid oxide fuel cells (SOFC) and CO2 capture—A thermodynamic case study. Appl. Therm. Eng. 2017, 114, 170–185. [Google Scholar] [CrossRef]

- Zhang, X. Current status of stationary fuel cells for coal power generation. Clean Energy 2018, 2, 126–139. [Google Scholar] [CrossRef]

- Peng, S. Current status of national integrated gasification fuel cell projects in China. Int. J. Coal Sci. Technol. 2021, 8, 327–334. [Google Scholar] [CrossRef]

- Wei, C.; Liu, Z.; Li, C.; Singh, S.; Lu, H.; Gong, Y.; Li, P.; Wang, H.; Yang, X.; Xu, M.; et al. Status of an MWth integrated gasification fuel cell power-generation system in China. Int. J. Coal Sci. Technol. 2021, 8, 401–411. [Google Scholar] [CrossRef]

- Bogatova, T.F.; Busorgin, V.A.; Ruzhkov, A.F. Solid fuel IGCC with partial gasification. Vopr. Sovrem. Nauk. I Prakt. 2007, 2, 174–180. (In Russian) [Google Scholar]

- Zhang, G.; Yang, Y.; Jin, H.; Xu, G.; Zhang, K. Proposed combined-cycle power system based on oxygen-blown coal partial gasification. Appl. Energy 2013, 102, 735–745. [Google Scholar] [CrossRef]

- Aslanyan, G.S.; Ivanov, P.P.; Medin, S.A. Analysis of efficiency if combined power cycle power plants with two-stage coal combustion. Teploenergetika 1995, 6, 44–47. (In Russian) [Google Scholar]

- Blokhin, A.I.; Karev, A.N.; Keneman, F.E.; Stel’makh, G.P. Internal coal pyrolysis combined cycle mini-power plants. Elektr. Stantsii 2005, 7, 25–33. (In Russian) [Google Scholar]

- Nakoryakov, V.E.; Nozdrenko, G.V.; Kuzmin, A.G. Investigation of coal fired combined-cycle cogeneration plants for power, heat, syngas, and hydrogen. Thermophys. Aeromech. 2009, 16, 515–520. [Google Scholar] [CrossRef]

- Kler, A.M.; Tyurina, E.A.; Mednikov, A.S. Energy-technology installations for combined production of hydrogen and electricity with CO2 removal systems. Int. J. Hydrogen Energy 2011, 36, 1230–1235. [Google Scholar] [CrossRef]

- Cormos, C.-C. Integrated assessment of IGCC power generation technology with carbon capture and storage. Energy 2012, 42, 434–445. [Google Scholar] [CrossRef]

- Tyurina, E.; Mednikov, A.; Zharkov, P. Clean Coal Technologies for Electricity and Synthetic Liquid Fuel Production for Distributed Generation. Environ. Clim. Technol. 2020, 24, 124–135. [Google Scholar] [CrossRef]

- Cormos, A.-M.; Cormos, C.-C. Techno-economic assessment of combined hydrogen & power co-generation with carbon capture: The case of coal gasification. Appl. Therm. Eng. 2019, 147, 29–39. [Google Scholar] [CrossRef]

- Meerman, J.C.; Ramirez, A.; Turkenburg, W.C.; Faaij, A.P.C. Performance of simulated flexible integrated gasification polygeneration facilities, Part B: Economic evaluation. Renew. Sustain. Energy Rev. 2012, 16, 6083–6102. [Google Scholar] [CrossRef]

- Perez-Fortes, M.; Bojarski, A.D.; Puigjuaner, L. Advanced simulation environment for clean power production in IGCC plants. Comp. Chem. Eng. 2011, 35, 1501–1520. [Google Scholar] [CrossRef]

- Syrodoy, S.V.; Kuznetsov, G.V.; Malyshev, D.Y.; Kostoreva, Z.A.; Purin, M.V. Flame Propagation Characteristics in the Boundary Layer of the Bio-Water-Coal Fuel Particle During its Ignition. Combust. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Sofia, D.; Llano, P.C.; Giuliano, A.; Hernandez, M.I.; Pena, F.G.; Barletta, D. Co-gasification of coal-petcoke and biomass in the Puertollano IGCC power plant. Chem. Eng. Res. Des. 2014, 92, 1428–1440. [Google Scholar] [CrossRef]

- van Dongen, A.; Kamaar, M. Co-gasification at the Buggenum IGCC power plant. DGMK-Fachbereichstagung Energetische Nutz. Von Biomassen 2006, 24, 26. [Google Scholar]

- Olivieri, A.; Ravelli, S. Cogasification of Coal and Biomass in an Integrated Gasification Combined Cycle Power Plant: Effects on Thermodynamic Performance and Gas Composition. J. Energy Eng. 2020, 146, 04020071. [Google Scholar] [CrossRef]

- Long III, H.A.; Wang, T. Parametric techno-economic studies of coal/biomass co-gasification for IGCC plants with carbon capture using various coal ranks, fuel-feeding schemes, and syngas cooling methods. Int. J. Energy Res. 2016, 40, 473–496. [Google Scholar] [CrossRef]

- Trop, P.; Agrez, M.; Urbancl, D.; Goricanec, D. Co-gasification of torrefied wood biomass and sewage sludge. Comp. Chem. Eng. 2016, 38, 2229–2234. [Google Scholar] [CrossRef]

- Ali, D.A.; Gadalla, M.A.; Abdelaziz, O.Y.; Hulteberg, C.P.; Ashour, F.H. Co-gasification of coal and biomass wastes in an entrained flow gasifier: Modelling, simulation and integration opportunities. J. Nat. Gas Sci. Eng. 2017, 37, 126–137. [Google Scholar] [CrossRef]

- Kanniche, M.; Le Moullec, Y.; Authier, O.; Hagi, H.; Bontemps, D.; Neveux, T.; Louis-Louisy, M. Up-to-date CO2 Capture in Thermal Power Plants. Energy Proc. 2017, 114, 95–103. [Google Scholar] [CrossRef]

- Clean Coal’ Technologies, Carbon Capture & Sequestration. Available online: https://world-nuclear.org/information-library/energy-and-the-environment/clean-coal-technologies.aspx (accessed on 20 January 2023).

- Kunze. C.; Spliethoff. H. Modelling of an IGGC plant with carbon capture for 2020. Fuel Proc. Technol. 2010, 91, 934–941. [Google Scholar] [CrossRef]

- Majoumerd, M.M.; De, S.; Assadi, M.; Breuhaus, P. An EU initiative for future generation of IGCC power plants using hydrogen-rich syngas: Simulation results for the baseline configuration. Appl. Energy 2012, 99, 280–290. [Google Scholar] [CrossRef]

- Martelli, E.; Kreutz, T.; Consonni, S. Comparison of coal IGCC with and without CO2 capture and storage: Shell gasification with standard vs. partial water quench. Energy Proc. 2009, 1, 607–614. [Google Scholar] [CrossRef]

- Moioli, S.; Giuffrida, A.; Romano, M.C.; Pellegrini, L.A.; Lozza, G. Assessment of MDEA absorption process for sequential H2S removal and CO2 capture in air-blown IGCC plants. Appl. Energy 2016, 183, 1452–1470. [Google Scholar] [CrossRef]

- Descamps, C.; Bouallou, C.; Kanniche, M. Efficiency of an integrated gasification combined cycle (IGCC) power plant including CO2 removal. Energy 2008, 33, 874–881. [Google Scholar] [CrossRef]

- Chen, C.; Rubin, E.S. CO2 control technology effects on IGCC preformance and cost. Energy Policy 2009, 37, 915–924. [Google Scholar] [CrossRef]

- Liszka, M.; Malik, T.; Budnik, M.; Ziebik, A. Comparison of IGCC (integrated gasification combined cycle) and CFB (circulating fluidized bed) cogeneration plants equipped with CO2 removal. Energy 2013, 58, 86–96. [Google Scholar] [CrossRef]

- Supekar, S.D.; Skerlos, S.J. Reassessing the Efficiency Penalty from Carbon Capture in Coal-Fired Power Plants. Environ. Sci. Technol. 2015, 49, 12576–12584. [Google Scholar] [CrossRef] [PubMed]

- Tola, V.; Pettinau, A. Power generation plants with carbon capture and storage: A techno-economic comparison between coal combustion and gasification technologies. Appl. Energy 2014, 113, 1461–1474. [Google Scholar] [CrossRef]

- Xia, C.; Ye, B.; Jiang, J.; Shu, Y. Prospect of near-zero-emission IGCC power plants to decarbonize coal-fired power generation in China: Implications from the GreenGen project. J. Clean. Prod. 2020, 271, 122615. [Google Scholar] [CrossRef]

- Ishida, K. Out Line of the Osaki CoolGen Project. In Proceedings of the ASME 2017 Power Conference, Charlotte, NC, USA, 26–30 June 2017; p. V001T04A031. [Google Scholar] [CrossRef]

- Martins, S.; Forrest, B.; Rafati, N.; Lu, X.; Fetvedt, J.; McGroddy, M.; Brown, B.; Allam, R.; Beauchamp, D.; Freed, D. Progress Update on the Allam Cycle: Commercialization of Net Power and the Net Power Demonstration Facility. In Proceedings of the 14th Greenhouse Gas Control. Technologies Conference GHGT-14, Melbourne, Australia, 21–26 October 2018. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, J.Y.; Yoon, M.K.; Rhim, D.R.; Yeom, C.S. Thermodynamic and economic investigation of coal-fired power plant combined with various supercritical CO2 Brayton power cycle. Appl. Therm. Eng. 2018, 130, 611–623. [Google Scholar] [CrossRef]

- Weiland, N.T.; White, C.W. Techno-economic analysis of an integrated gasification direct-fired supercritical CO2 power cycle. Fuel 2018, 212, 613–625. [Google Scholar] [CrossRef]

- International Energy Agency. Energy Technology Perspectives 2020; International Energy Agency, 2021; Available online: https://www.iea.org/reports/energy-technology-perspectives-2020 (accessed on 19 December 2022).

- Tollefson, J. US government abandons carbon-capture demonstration. Nature 2015. [Google Scholar] [CrossRef]

- Roddy, D.J.; Younger, P.L. Underground coal gasification with CCS: A pathway to decarbonising industry. Energy Environ. Sci. 2010, 3, 400–407. [Google Scholar] [CrossRef]

- Lee, W.-S.; Lee, J.-C.; Oh, H.-T.; Baek, S.-W.; Oh, M.; Lee, C.-H. Performance, economic and exergy analyses of carbon capture processes for a 300 MW class integrated gasification combined cycle power plant. Energy 2017, 134, 731–742. [Google Scholar] [CrossRef]

- Oh, H.-T.; Lee, W.-S.; Ju, Y.; Lee, C.-H. Performance evaluation and carbon assessment of IGCC power plant with coal quality. Energy 2019, 188, 116063. [Google Scholar] [CrossRef]

- Fu, L.; Ren, Z.; Si, W.; Ma, Q.; Huang, W.; Liao, K.; Huang, Z.; Wang, Y.; Li, J.; Xu, P. Research progress on CO2 capture and utilization technology. J. CO2 Util. 2022, 66, 102260. [Google Scholar] [CrossRef]

- Shen, Y. Preparation of renewable porous carbons for CO2 capture—A review. Fuel Proc. Technol. 2022, 236, 107437. [Google Scholar] [CrossRef]

- Rezvani, S.; Huang, Y.; McIlveen-Wright, D.; Hewitt, N.; Mondol, J.D. Comparative assesment of coal fired IGCC systems with CO2 parture using physical absorption, membrane reactors and chemical looping. Fuel 2009, 88, 2463–2472. [Google Scholar] [CrossRef]

- Merkel, T.C.; Zhou, M.; Baker, R.W. Carbon dioxide capture with membranes at an IGCC power plant. J. Memb. Sci. 2012, 389, 441–450. [Google Scholar] [CrossRef]

- Rosner, F.; Chen, Q.; Rao, A.; Samuelsen, S. Thermo-economic analyses of isothermal water gas shift reactor integrations into IGCC power plant. Appl. Energy 2020, 277, 115500. [Google Scholar] [CrossRef]

- Giuffrida, A.; Moioli, S.; Romano, M.C.; Lozza, G. Lignite-fired air-blown IGCC systems with pre-combustion CO2 capture. Int. J. Energy Res. 2016, 40, 831–845. [Google Scholar] [CrossRef]

- Chen, L.; Yong, S.Z.; Ghoniem, A.F. Oxy-fuel combustion of pulverized coal: Characterization, fundamentals, stabilization and CFD-modeling. Prog. Energy Combust. Sci. 2012, 38, 156–214. [Google Scholar] [CrossRef]

- Romano, M.C.; Lozza, G.G. Long-term coal gasification-based power with near-zero emissions. Part B: Zecomag and oxy-fuel IGCC cycles. Int. J. Greenhouse Gas Control. 2010, 4, 469–477. [Google Scholar] [CrossRef]

- Naidu, V.S.; Aghalayam, P.; Jayanti, S. Improving efficiency of CCS-enabled IGCC power plant through the use of recycle flue gas for coal gasification. Clean Technol. Environ. Policy 2018, 20, 1207–1218. [Google Scholar] [CrossRef]

- Ye, C.; Ye, Z.; Zhu, Z.; Wang, Q. Thermodynamic and Economic Analysis of Oxy-Fuel-Integrated Coal Partial Gasification Combined Cycle. ACS Omega 2021, 6, 4262–4272. [Google Scholar] [CrossRef]

- Thattai, A.T.; Oldenboek, V.; Schoenmakers, L.; Woudstra, T.; Aravind, P.V. Experimental model validation and thermodynamic assessment on high percentage (up to 70%) biomass co-gasification at the 253 MWe integrated gasification combined cycle power plant in Buggenum, The Netherlands. Appl. Energy 2016, 168, 381–393. [Google Scholar] [CrossRef]

- Rubin, E.S. Understanding the pitfalls of CCS cost estimates. Int. J. Greenhouse Gas Control. 2012, 10, 181–190. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Filippov, P.S.; Bogatova, T.F. Analysis of Integrated Gasification Combined Cycle Power Units; Ural University Publ.: Ekaterinburg, Russia, 2019. (In Russian) [Google Scholar]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Meyer, L. (Eds.) Carbon Dioxide Capture and Storage. Intergovernment Panel of Climate Chang. Special Report; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Jin, B.; Zhao, H.; Zheng, C. Optimization and control for CO2 compression and purification unit in oxy-combustion power plants. Energy 2015, 83, 416–430. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, H.; Zheng, C. Thermoeconomic cost analysis of CO2 compression and purification unit in oxy-combustion power plants. Energy Conv. Manag. 2015, 106, 53–60. [Google Scholar] [CrossRef]

- Farmer, T.C.; Doherty, M.F. Thermodynamic assessment of carbon dioxide emission reduction during fossil fuel derived energy production. Energy 2019, 177, 565–573. [Google Scholar] [CrossRef]

- Yadav, S.; Mondal, S.S. A complete review based on various aspects of pulverized coal combustion. Int. J. Energy Res. 2019, 43, 3134–3165. [Google Scholar] [CrossRef]

- Mularski, J.; Pawlak-Kruczek, H.; Modlinski, N. A review of recent studies of the CFD modelling of coal gasification in entrained flow gasifiers, covering devolatilization, gas-phase reactions, surface reactions, models and kinetics. Fuel 2020, 271, 117620. [Google Scholar] [CrossRef]

- Donskoi, I.G. Mathematical modeling of the reaction zone of a Shell-Prenflo gasifier with the use of the models of sequential equilibrium. Solid. Fuel Chem. 2016, 50, 191–196. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Abaimov, N.A.; Donskoy, I.G.; Svishchev, D.A. Modernization of Air-Blown Entrained-Flow Gasifier of Integrated Gasification Combined Cycle Plant. Combust. Explos. Shock Waves. 2018, 54, 337–344. [Google Scholar] [CrossRef]

- Alsultannty, Y.A.; Al-Shammari, N.N. Oxygen Specific Power Consumption Comparison for Air Separation Units. Eng. J. 2014, 18, 67. [Google Scholar] [CrossRef]

- Aneke, M.; Wang, M. Potential for improving the energy efficiency of cryogenic air separation unit (ASU) using binary heat recovery cycles. Appl. Therm. Eng. 2015, 81, 223–231. [Google Scholar] [CrossRef]

- Fu, C.; Gundersen, T. Using exergy analysis to reduce power consumption in air separation units for oxy-combustion processes. Energy 2012, 44, 60–68. [Google Scholar] [CrossRef]

- Jones, D.; Bhattacharyya, D.; Turton, R.; Zitney, S.E. Optimal design and integration of an air separation unit (ASU) for an integrated gasification combined cycle (IGCC) power plant with CO2 capture. Fuel Proc. Technol. 2011, 92, 1685–1695. [Google Scholar] [CrossRef]

- Taniguchi, M.; Asoaka, H.; Ayuhara, T. Energy saving air-separation plant based on exergy analysis. Kobelco Technol. Rev. 2015, 33, 34–38. [Google Scholar]

- Tranier, J.-P.; Dubettier, R.; Darde, A.; Perrin, N. Air separation, flue gas compression and purification units for oxy-coal combustion systems. Energy Proc. 2011, 4, 966–971. [Google Scholar] [CrossRef]

- van der Ham, L.V.; Kjelstrup, S. Exergy analysis of two cryogenic separation processes. Energy 2010, 35, 4731–4739. [Google Scholar] [CrossRef]

- Knedsen, J.N.; Jensen, J.N.; Vilhelmsen, P.-J.; Biede, O. Experience with CO2 capture from coal flue gas in pilot-scale: Testing of different amine solvents. Energy Proc. 2009, 1, 783–790. [Google Scholar] [CrossRef]

- Bellotti, D.; Sorce, A.; Rivarolo, M.; Magistru, L. Techno-economic analysis for the integration of a power to fuel system with a CCS coal power plant. J. CO2 Util. 2019, 33, 262–272. [Google Scholar] [CrossRef]

- Keith, D.W.; Holmes, G.; Angelo, D.S.; Heidel, K. A Process for Capturing CO2 from the Atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef]

- Lee, W.-S.; Oh, H.-T.; Lee, J.-C.; Oh, M.; Lee, C.-H. Performance analysis and carbon reduction assessment of an integrated syngas purification process for the co-production of hydrogen and power in an integrated gasification combined cycle plant. Energy 2019, 171, 910–927. [Google Scholar] [CrossRef]

- Falcke, T.J.; Hoadley, A.F.A.; Brennan, D.J.; Sinclair, S.E. The sustainable of clean coal technology: IGCC with/without CCS. Process. Saf. Environ. Protect. 2011, 89, 41–52. [Google Scholar] [CrossRef]

- Hoya, R.; Fushimi, C. Thermal efficiency of advanced integrated coal gasification combined cycle power generation systems with low-temperature gasifier, gas cleaning and CO2 capturing units. Fuel Proc. Technol. 2017, 164, 80–91. [Google Scholar] [CrossRef]

- Prins, M.; van der Berg, R.; van Holthoon, E.; van Dorst, E.; Geuzebroek, F. Technological developments IGCC for carbon capture. Chem. Eng. Technol. 2012, 35, 413–419. [Google Scholar] [CrossRef]

- Svishchev, D. Thermodynamic Analysis of Air-Blown Staged Gasification of Coal in a Flow. Energy Syst. Res. 2021, 4, 38–43. [Google Scholar] [CrossRef]

- Kler, A.; Zharkov, P.; Potanina, Y.; Marinchenko, A.; Epishkin, N. The Effect of the Carbon Tax Value on the Optimal Parameters and Characteristics of Coal Power Plants. Environ. Clim. Technol. 2020, 24, 104–111. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).