Steam Explosion Pre-Treatment of Sawdust for Biofuel Pellets

Abstract

:1. Introduction

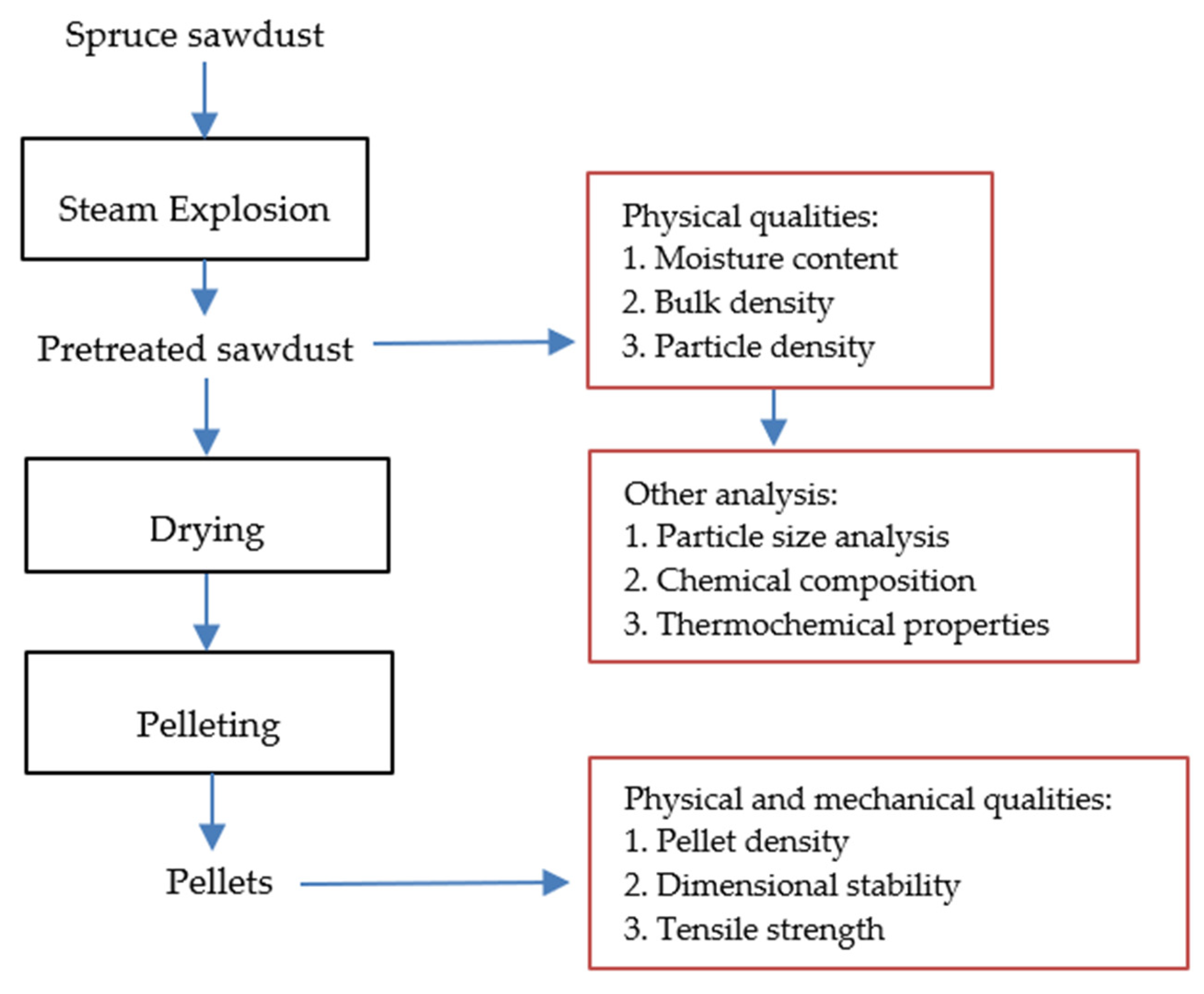

2. Materials and Methods

2.1. Feedstock Preparation

2.2. Steam Explosion Experiment

2.3. Physical and Chemical Properties of Pretreated and Non-Treated Samples

2.4. Densification

2.5. Pellet Density and Dimensional Stability

2.6. Pellet Tensile Strength

2.7. Statistical Analysis

2.8. Thermochemical Analysis of Biomass

2.9. Mass and Energy Yields of Biomass

3. Results and Discussion

3.1. Design Parameters

3.2. Optimization

3.3. Particle Size Analysis

3.4. Chemical Composition

3.5. Thermochemical Analysis of Treated and Non-Treated Biomass

3.6. Mass and Energy Yield

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yue, H.; Worrell, E.; Crijns-Graus, W.; Zhang, S. The Potential of Industrial Electricity Savings to Reduce Air Pollution from Coal-Fired Power Generation in China. J. Clean. Prod. 2021, 301, 126978. [Google Scholar] [CrossRef]

- Cui, L.; Li, Y.; Tang, Y.; Shi, Y.; Wang, Q.; Yuan, X.; Kellett, J. Integrated Assessment of the Environmental and Economic Effects of an Ultra-Clean Flue Gas Treatment Process in Coal-Fired Power Plant. J. Clean. Prod. 2018, 199, 359–368. [Google Scholar] [CrossRef]

- Carlini, E.M.; Schroeder, R.; Birkebæk, J.M.; Massaro, F. EU Transition in Power Sector: How RES Affects the Design and Operations of Transmission Power Systems. Electr. Power Syst. Res. 2019, 169, 74–91. [Google Scholar] [CrossRef]

- Davis, S.J.; Socolow, R.H. Commitment Accounting of CO2 Emissions. Environ. Res. Lett. 2014, 9, 84018. [Google Scholar] [CrossRef] [Green Version]

- DOE. Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billon Ton Annual Supply; Department of Energy (DOE), Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2005. [Google Scholar]

- Lam, P.S. Steam Explosion of Biomass to Produce Durable Wood Pellets. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- FAO. Forestry Production and Trade. Available online: http://www.fao.org/faostat/en/#data/FO/visualize (accessed on 6 October 2022).

- Ghafghazi, S.; Lochhead, K.; Mathey, A.-H.; Forsell, N.; Leduc, S.; Mabee, W.; Bull, G. Estimating Mill Residue Surplus in Canada: A Spatial Forest Fiber Cascade Modeling Approach. For. Prod. J. 2017, 67, 205–218. [Google Scholar] [CrossRef]

- Bradley, D. Estimated Production, Consumption, and Surplus Mill Wood Residues in Canada–2004. A National Report; BW McCloy & Associates Inc. and Climate Change Solutions for the Canadian Forest Service and the Forest Products Association of Canada: Ottawa, ON, Canada, 2005. [Google Scholar]

- Change, O.C. Intergovernmental Panel on Climate Change; World Meteorological Organization: Geneva, Switzerland, 2007. [Google Scholar]

- Lehtikangas, P. Quality Properties of Pelletised Sawdust, Logging Residues and Bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Wright, C.T.; Boardman, R.D.; Yancey, N.A. A Review on Biomass Classification and Composition, Co-Firing Issues and Pretreatment Methods. In Proceedings of the 2011 ASABE Annual International Meeting, Louisville, KY, USA, 7–10 August 2011; Volume 3, pp. 2053–2083. [Google Scholar] [CrossRef]

- Stelte, W. Steam Explosion for Biomass Pre-Treatment; Danish Technological Institute: Taastrup, Denmark, 2013; pp. 1–15. [Google Scholar]

- ALTENER. Biomass Co-Firing—An Efficient Way to Reduce Greenhouse Gas Emissions; EUBION (European Bioenergy Networks): Madrid, Spain, 2021. [Google Scholar]

- Baxter, L. Biomass-Coal Co-Combustion: Opportunity for Affordable Renewable Energy. Fuel 2005, 84, 1295–1302. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Tabil, L.G.; Wang, D.; Li, X.; Mupondwa, E. Comparison of Pretreatment Methods for Wheat Straw Densification by Life Cycle Assessment Study. Trans. ASABE 2015, 58, 453–464. [Google Scholar] [CrossRef]

- Dererie, D.Y.; Trobro, S.; Momeni, M.H.; Hansson, H.; Blomqvist, J.; Passoth, V.; Schnürer, A.; Sandgren, M.; Ståhlberg, J. Improved Bio-Energy Yields via Sequential Ethanol Fermentation and Biogas Digestion of Steam Exploded Oat Straw. Bioresour. Technol. 2011, 102, 4449–4455. [Google Scholar] [CrossRef]

- Maness, P.; Czernik, S.; Smolinski, S. Fermentation Approaches to Hydrogen Production; National Renewable Energy Laboratory: Golden, CO, USA, 2005. [Google Scholar]

- Kobayashi, F.; Take, H.; Asada, C.; Nakamura, Y. Methane Production from Steam-Exploded Bamboo. J. Biosci. Bioeng. 2004, 97, 426–428. [Google Scholar] [CrossRef]

- Liu, H.W.; Walter, H.K.; Vogt, G.M.; Vogt, H.S.; Holbein, B.E. Steam Pressure Disruption of Municipal Solid Waste Enhances Anaerobic Digestion Kinetics and Biogas Yield. Biotechnol. Bioeng. 2002, 77, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Bura, R.; Mansfield, S.D.; Saddler, J.N.; Bothast, R.J. SO2-Catalyzed Steam Explosion of Corn Fiber for Ethanol Production. Appl. Biochem. Biotechnol. 2002, 98–100, 59–72. [Google Scholar] [CrossRef]

- Bura, R.; Bothast, R.J.; Mansfield, S.D.; Saddler, J.N. Optimization of SO2-Catalyzed Steam Pretreatment of Corn Fiber for Ethanol Production. Appl. Biochem. Biotechnol. 2003, 105–108, 319–335. [Google Scholar] [CrossRef]

- Kokta, B.V.; Ahmed, A. Steam Explosion Pulping, Environmentally Friendly Technologies for the Pulp and Paper Industry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1998. [Google Scholar]

- Adapa, P.; Tabil, L.G.; Schoenau, J. Compression Characteristics of Non-Treated and Steam-Exploded Barley, Canola, Oat, and Wheat Straw Grinds. Appl. Eng. Agric. 2010, 26, 617–632. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Physical and Frictional Properties of Non-Treated and Steam Exploded Barley, Canola, Oat and Wheat Straw Grinds. Powder Technol. 2010, 201, 230–241. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G.; Opoku, A. Pelleting Characteristics of Selected Biomass with and without Steam Explosion Pretreatment. IJABE.org 2010, 3, 62–79. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook, the Production and Thermalutilization of Biomass Pellets; IEA Bioenergy: Washington, DC, USA, 2010. [Google Scholar]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical Degradation of Biomass Wood Pellets during Long Term Stockpile Storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Lam, P.S.; Lam, P.Y.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Melin, S. Effect of Steam Explosion Pretreatment on Size Reduction and Pellet Quality of Woody and Agricultural Biomass. In Innovative Solutions in Fluid-Particle Systems and Renewable Energy Management; IGI Global: Hershey, PA, USA, 2015; pp. 27–53. [Google Scholar]

- Emmel, A.; Mathias, A.L.; Wypych, F.; Ramos, L.P. Fractionation of Eucalyptus Grandis Chips by Dilute Acid-Catalysed Steam Explosion. Bioresour. Technol. 2003, 86, 105–115. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A Review on Biomass Torrefaction Process and Product Properties for Energy Applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Overend, R.P.; Chornet, E. Fractionation of Lignocellulosics by Steam-Aqueous Pretreatments. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1987, 321, 523–536. [Google Scholar] [CrossRef]

- Borén, E.; Larsson, S.H.; Thyrel, M.; Averheim, A.; Broström, M. VOC Off-Gassing from Pelletized Steam Exploded Softwood Bark: Emissions at Different Industrial Process Steps. Fuel Process. Technol. 2018, 171, 70–77. [Google Scholar] [CrossRef]

- Borén, E.; Larsson, S.H.; Averheim, A.; Thyrel, M.; Broström, M. Reducing Volatile Organic Compound Off-Gassing during the Production of Pelletized Steam-Exploded Bark: Impact of Storage Time and Controlled Ventilation. Energy Fuels 2018, 32, 5181–5186. [Google Scholar] [CrossRef]

- Shahrukh, H.; Oyedun, A.O.; Kumar, A.; Ghiasi, B.; Kumar, L.; Sokhansanj, S. Net Energy Ratio for the Production of Steam Pretreated Biomass-Based Pellets. Biomass Bioenergy 2015, 80, 286–297. [Google Scholar] [CrossRef]

- Biswas, A.K.; Yang, W.; Blasiak, W. Steam Pretreatment of Salix to Upgrade Biomass Fuel for Wood Pellet Production. Fuel Process. Technol. 2011, 92, 1711–1717. [Google Scholar] [CrossRef]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. Influence of Steam Explosion Processes on the Durability and Enzymatic Digestibility of Wood Pellets. Fuel 2018, 211, 87–94. [Google Scholar] [CrossRef]

- Niemelä, N.P.; Nowak Delgado, R.; de Riese, T.; Tolvanen, H.; Fendt, S.; Spliethoff, H.; Joronen, T. Fuel-Specific Devolatilization Parameters for Detailed Comparison of Pulverized Biomass Fuels. Fuel 2021, 286, 119309. [Google Scholar] [CrossRef]

- Abelha, P.; Cieplik, M.K. Evaluation of Steam-Exploded Wood Pellets Storage and Handling Safety in a Coal-Designed Power Plant. Energy Fuels 2021, 35, 2357–2367. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Compaction Characteristics of Barley, Canola, Oat and Wheat Straw. Biosyst. Eng. 2009, 104, 335–344. [Google Scholar] [CrossRef]

- Adapa, P. Densification of Selected Agricultural Crop Residues as Feedstock for the Biofuel Industry. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2011. [Google Scholar]

- Valdez, E.; Tabil, L.G.; Mupondwa, E.; Cree, D.; Moazed, H. Microwave Torrefaction of Oat Hull: Effect of Temperature and Residence Time. Energies 2021, 14, 4298. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of Compressive Force, Particle Size and Moisture Content on Mechanical Properties of Biomass Pellets from Grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass; Office of Energy Efficiency and Renewable Energy, National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Kaliyan, N.R.; Morey, V. Factors Affecting Strength and Durability of Densified Products. In Proceedings of the 2006 ASABE Annual International Meeting, Portland, OR, USA, 9–12 July 2006. [Google Scholar]

- Li, Y.; Liu, H. High-Pressure Densification of Wood Residues to Form an Upgraded Fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Tabil, L.G. Effect of Microwave-Chemical Pre-Treatment on Compression Characteristics of Biomass Grinds. Biosyst. Eng. 2011, 108, 36–45. [Google Scholar] [CrossRef]

- Tabil, L.G.; Sokhansanj, S. Bulk Properties of Alfalfa Grind In Relation To Its Compaction Characteristics. Appl. Eng. Agric. 1997, 13, 499–505. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Kashaninejad, B.; Tabil, L.G. Effect of Microwave Pretreatment on Densification of Wheat Straw. In Proceedings of the ASABE 2010, Pittsburgh, PA, USA, 20–23 June 2010. [Google Scholar]

- Fell, J.T.; Newton, J.M. The Tensile Strength of Lactose Tablets. J. Pharm. Pharmacol. 1968, 20, 657–659. [Google Scholar] [CrossRef] [PubMed]

- Fell, J.T.; Newton, J.M. Determination of Tablet Strength by the Diametral-Compression Test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef]

- Agu, O.; Tabil, L.; Dumonceaux, T. Microwave-Assisted Alkali Pre-Treatment, Densification and Enzymatic Saccharification of Canola Straw and Oat Hull. Bioengineering 2017, 4, 25. [Google Scholar] [CrossRef] [Green Version]

- Karber, S. Introduction to Response Surface Methods. Part 1. Available online: https://cdn.statease.com/media/public/documents/rsm_part1_intro.pdf (accessed on 6 October 2022).

- Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. Available online: https://www.astm.org/d3175-20.html (accessed on 6 October 2022).

- ASTM Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal 1. Available online: https://www.astm.org/d3174-12r18.html (accessed on 6 October 2022).

- ASTM Standard Test Method for Gross Calorific Value of Coal and Coke. Available online: https://www.astm.org/d5865_d5865m-19.html (accessed on 6 October 2022).

- Gong, C.; Huang, J.; Feng, C.; Wang, G.; Tabil, L.; Wang, D. Effects and Mechanism of Ball Milling on Torrefaction of Pine Sawdust. Bioresour. Technol. 2016, 214, 242–247. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of Reed Canary Grass, Wheat Straw and Willow to Enhance Solid Fuel Qualities and Combustion Properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Shaw, M.D.; Karunakaran, C.; Tabil, L.G. Physicochemical Characteristics of Densified Untreated and Steam Exploded Poplar Wood and Wheat Straw Grinds. Biosyst. Eng. 2009, 103, 198–207. [Google Scholar] [CrossRef]

- Verhoeff, F. TorTech: Torrefaction Technology for the Production of Solid Bioenergy Carriers from Biomass and Waste; ECN: Petten, The Netherlands, 2011; Available online: https://library.wur.nl/WebQuery/titel/2012815 (accessed on 21 September 2022).

- Startsev, O.V.; Salin, B.N. Polycondensation of the Components of the Lignin–Carbohydrate Complex of Steam-Exploded Wood. Dokl. Chem. Technol. 2000, 373, 30–33. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Bi, X.; Zaini, P.; Tabil, L.G. Binderless Pelletization of Biomass. In Proceedings of the 2005 ASAE Annual Meeting, Tampa, FL, USA, 17–20 July 2005. [Google Scholar]

- Franke, M.; Rey, A. Pelleting Quality. World Grain 2006, 24, 78–79. [Google Scholar]

- Grover, P.D.; Mishra, S.K. Biomass Briquetting: Technology and Practices; Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 1996; Volume Field Document. [Google Scholar]

- MacBain, R. Pelleting Animal Feed; American Feed Manufacturing Association: Chicago, IL, USA, 1966. [Google Scholar]

- Payne, J.D. Improving Quality of Pellet Feeds. Milling Feed Fertil. 1978, 162, 34–39. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and Switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Shaw, M.D. Feedstock and Process Variables Influencing Biomass Densification. Master’s Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2008. [Google Scholar]

- Tooyserkani, Z. Hydrothermal Pretreatment of Softwood Biomass and Bark for Pelletization. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2013. [Google Scholar]

- Back, E.L.; Salmen, N.L. Glass Transitions of Wood Components Hold Implications for Molding and Pulping Processes. TAPPI J. 1982, 65, 107–110. [Google Scholar]

- Lam, P.S.; Lam, P.Y.; Sokhansanj, S.; Bi, X.T.; Lim, C.J. Mechanical and Compositional Characteristics of Steam-Treated Douglas Fir (Pseudotsuga menziesii L.) during Pelletization. Biomass Bioenergy 2013, 56, 116–126. [Google Scholar] [CrossRef]

- Öhman, M.; Nordin, A. A New Method for Quantification of Fluidized Bed Agglomeration Tendencies: A Sensitivity Analysis. Energy Fuels 1998, 12, 90–94. [Google Scholar] [CrossRef]

- Mondragón-Valero, A.; Velázquez-Martí, B.; Salazar, D.M.; López-Cortés, I. Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller). Energies 2018, 11, 1189. [Google Scholar] [CrossRef] [Green Version]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- He, X.; Wang, L.; Lau, A. Investigation of Steam Treatment on the Sorption Behavior of Rice Straw Pellets. Energies 2020, 13, 5401. [Google Scholar] [CrossRef]

- Fernández-González, E. Análisis de los Procesos de Producción de Biomasa Residual Procedente del Cultivo de Frutales Mediterráneos. Cuantificación, Cosecha y Caracterización; Universitat Politècnica de València: Valencia, Spain, 2010. [Google Scholar]

- Iroba, K.L.; Tabil, L.G.; Sokhansanj, S.; Dumonceaux, T. Pretreatment and Fractionation of Barley Straw Using Steam Explosion at Low Severity Factor. Biomass Bioenergy 2014, 66, 286–300. [Google Scholar] [CrossRef]

- Tooyserkani, Z.; Sokhansanj, S.; Bi, X.; Lim, J.; Lau, A.; Saddler, J.; Kumar, L.; Lam, P.S.; Melin, S. Steam Treatment of Four Softwood Species and Bark to Produce Torrefied Wood. Appl. Energy 2013, 103, 514–521. [Google Scholar] [CrossRef]

- Demirbaş, A. Relationships between Lignin Contents and Heating Values of Biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial Processes for Biomass Drying and Their Effects on the Quality Properties of Wood Pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Esteves, B.; Graça, J.; Pereira, H. Extractive Composition and Summative Chemical Analysis of Thermally Treated Eucalypt Wood. Holzforschung 2008, 62, 344–351. [Google Scholar] [CrossRef]

- Mazlan, I.; Glasser, W.G. Steam-Assisted Biomass Fractionation. Part III: A Quantitative Evaluation of the “Clean Fractionation” Concept. Bioresour. Technol. 1999, 70, 181–192. [Google Scholar] [CrossRef]

- Kobayashi, N.; Okada, N.; Hirakawa, A.; Sato, T.; Kobayashi, J.; Hatano, S.; Itaya, Y.; Mori, S. Characteristics of Solid Residues Obtained from Hot-Compressed-Water Treatment of Woody Biomass. Ind. Eng. Chem. Res. 2009, 48, 373–379. [Google Scholar] [CrossRef]

- Arteaga-Pérez, L.E.; Grandón, H.; Flores, M.; Segura, C.; Kelley, S.S. Steam Torrefaction of Eucalyptus Globulus for Producing Black Pellets: A Pilot-Scale Experience. Bioresour. Technol. 2017, 238, 194–204. [Google Scholar] [CrossRef]

| Biomass | Pellet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Run | Temperature (°C) | Time (min) | Severity Factor | Bulk Density (kg/m3) | Particle Density (kg/m3) | Ash Content (% d.b.) | HHV 1 (MJ/kg) | M.C. (% d.b.) 2 | Pellet Density (kg/m3) | Tensile Strength (MPa) | Dimensional Stability (%) |

| 0 | - | - | 115.4 | 1420 | 0.23 | 18.44 | 4.40 | 1049.26 | 0.32 | 2.63 | |

| 1 | 180 | 3 | 2.83 | 144.6 | 1450 | 1.22 | 17.26 | 9.47 | 1137.63 | 0.63 | 0.05 |

| 2 | 180 | 6 | 3.13 | 138.8 | 1480 | 1.30 | 17.33 | 12.76 | 1169.03 | 0.65 | 1.56 |

| 3 | 180 | 9 | 3.39 | 137.4 | 1440 | 0.61 | 17.62 | 8.72 | 1149.29 | 1.50 | 1.02 |

| 4 | 200 | 3 | 3.42 | 135.2 | 1440 | 0.43 | 17.67 | 7.89 | 1165.04 | 1.52 | 0.76 |

| 5 | 200 | 6 (1) | 3.72 | 133.6 | 1430 | 0.48 | 18.03 | 3.87 | 1267.91 | 4.91 | 1.56 |

| 6 | 200 | 6 (2) | 3.72 | 138.1 | 1440 | 0.44 | 17.92 | 5.08 | 1269.61 | 2.82 | 2.95 |

| 7 | 200 | 6 (3) | 3.72 | 132.6 | 1460 | 0.41 | 17.99 | 2.33 | 1266.97 | 4.12 | 2.54 |

| 8 | 200 | 6 (4) | 3.72 | 133.5 | 1430 | 0.32 | 17.94 | 3.68 | 1245.28 | 5.59 | 2.18 |

| 9 | 200 | 6 (5) | 3.72 | 137.9 | 1420 | 0.38 | 17.76 | 5.96 | 1241.10 | 3.49 | 2.52 |

| 10 | 200 | 9 | 3.90 | 132.8 | 1450 | 0.43 | 17.99 | 5.24 | 1257.31 | 3.01 | 2.43 |

| 11 | 220 | 3 | 4.01 | 132.3 | 1450 | 0.40 | 17.48 | 21.24 | 1249.58 | 3.66 | 3.51 |

| 12 | 220 | 6 | 4.31 | 150.8 | 1480 | 0.40 | 17.70 | 18.54 | 1263.26 | 3.54 | 2.79 |

| 13 | 220 | 9 | 4.49 | 149.1 | 1500 | 0.40 | 17.93 | 19.65 | 1262.51 | 2.80 | 2.64 |

| Variable | Value/Equation | R2 | Optimized Value |

|---|---|---|---|

| Selected optimal conditions | |||

| (A) Temperature (°C) | 215.13 | ||

| (B) Time (min) | 9 | ||

| Bulk density (kg/m3) | 135.52 + 1.9A + 1.2B + 6AB + 8.30A2 − 2.49B2 | 0.78 | 144.96 ± 3.80 |

| Particle density (kg/m3) | 1440.89 + 7.58A + 10.05B + 15.46AB + 26.02A2 − 2.30B2 | 0.70 | 1480.98 ± 15.54 |

| Pellet density (kg/m3) | 1253.95 + 53.23A + 19.47B + 0.31AB − 27.25A2 − 32.22B2 | 0.88 | 1266.12 ± 22.83 |

| Tensile Strength (MPa) | 3.91 + 1.20A + 0.25B − 0.43AB − 1.13A2 − 0.96B2 | 0.70 | 3.13 ± 1.09 |

| Dimensional stability (% d.b.) | 2.51 + 1.16A + 0.16B − 0.00AB − 0.18A2 − 0.81B2 | 0.78 | 2.5 ± 0.66 |

| Ash content (% d.b.) | 0.43 − 0.32A − 0.10B + 0.15AB + 0.33A2 − 0.08B2 | 0.89 | 0.32 ± 0.13 |

| Higher heating value (MJ/kg) | 19.46 + 0.16A + 0.20B + 0.02AB − 0.36A2 − 0.02B2 | 0.91 | 19.57 ± 0.11 |

| Sample | dgw (mm) | Sgw (mm) |

|---|---|---|

| Pine sawdust | 1.43 | 1.13 |

| Spruce sawdust | 0.92 | 0.94 |

| Sawdust (mix) | 0.33 | 0.20 |

| Steam pretreated (Spruce sawdust) | 0.39 | 0.35 |

| Sample | Skewness | Kurtosis | Shapiro–Wilk | p-Value |

|---|---|---|---|---|

| Pine sawdust | 0.875 | 0.153 | 0.866 | 0.139 |

| Spruce sawdust | 0.128 | −0.898 | 0.95 | 0.709 |

| Sawdust (mix) | 1.494 | 1.622 | 0.795 | 0.025 |

| Steam-treated (Spruce sawdust) | 1.504 | 1.292 | 0.784 | 0.019 |

| Components | Sawdust (Mix) | Spruce Sawdust | Pine Sawdust | Steam Pretreated (Spruce Sawdust) |

|---|---|---|---|---|

| Ash (% d.b.) | 0.230 | 0.101 | 0.047 | 0.400 |

| Lignin (% d.b.) | 25.167 | 25.332 | 25.565 | 20.447 |

| Hemicellulose (% d.b.) | 14.470 | 15.413 | 13.759 | 1.045 |

| Cellulose (% d.b.) | 50.389 | 51.016 | 45.544 | 36.271 |

| Solubles (% d.b.) | 9.74 | 8.14 | 15.08 | 41.84 |

| Sample | HHV 1 (MJ/kg) | M.C. (% d.b.) 2 | Proximate Analysis (% d.b.) | Ultimate Analysis (% d.b.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixed Carbon | Volatile | Ash | N 3 | C 4 | H 5 | S 6 | O 7 | O/C | H/C | |||

| Sawdust (mix) | 17.49 | 4.57 | 17.4 | 77.80 | 0.23 | 0.06 | 49.25 | 6.27 | 0.02 | 44.39 | 0.90 | 0.13 |

| Spruce sawdust | 18.44 | 4.40 | 18.6 | 76.90 | 0.23 | 0.03 | 48.81 | 6.29 | 0.02 | 44.84 | 0.92 | 0.13 |

| Pine sawdust | 18.70 | 4.76 | 19.8 | 75.40 | 0.04 | 0.09 | 51.52 | 6.43 | 0.04 | 41.91 | 0.81 | 0.12 |

| Steam treated (Spruce sawdust) | 17.93 | 5.00 | 22.9 | 71.70 | 0.4 | 0.07 | 50.76 | 6.22 | 0.04 | 42.89 | 0.85 | 0.12 |

| Temperature (°C) | Time (min) | Severity Factor | Mass Loss (%) | HHV 1 (MJ/kg) | Mass Yield (%) | Energy Yield (%) |

|---|---|---|---|---|---|---|

| Non-treated | ||||||

| - | - | - | - | 18.44 | 100 | 100 |

| Steam-treated (Spruce sawdust) | ||||||

| 180 | 3 | 2.83 | 18.90 | 17.26 | 81.10 | 78.70 |

| 180 | 6 | 3.13 | 25.30 | 17.33 | 74.70 | 74.00 |

| 180 | 9 | 3.31 | 28.50 | 17.62 | 71.50 | 72.10 |

| 200 | 3 | 3.42 | 26.00 | 17.67 | 74.00 | 70.88 |

| 200 | 6 | 3.72 | 27.00 | 18.03 | 73.00 | 75.20 |

| 200 | 9 | 3.90 | 22.70 | 17.99 | 77.30 | 75.43 |

| 220 | 3 | 4.01 | 30.30 | 17.48 | 69.70 | 69.60 |

| 220 | 6 | 4.31 | 40.40 | 17.70 | 59.60 | 60.30 |

| 220 | 9 | 4.49 | 31.90 | 17.93 | 68.10 | 69.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alizadeh, P.; Dumonceaux, T.; Tabil, L.G.; Mupondwa, E.; Soleimani, M.; Cree, D. Steam Explosion Pre-Treatment of Sawdust for Biofuel Pellets. Clean Technol. 2022, 4, 1175-1192. https://doi.org/10.3390/cleantechnol4040072

Alizadeh P, Dumonceaux T, Tabil LG, Mupondwa E, Soleimani M, Cree D. Steam Explosion Pre-Treatment of Sawdust for Biofuel Pellets. Clean Technologies. 2022; 4(4):1175-1192. https://doi.org/10.3390/cleantechnol4040072

Chicago/Turabian StyleAlizadeh, Peyman, Tim Dumonceaux, Lope G. Tabil, Edmund Mupondwa, Majid Soleimani, and Duncan Cree. 2022. "Steam Explosion Pre-Treatment of Sawdust for Biofuel Pellets" Clean Technologies 4, no. 4: 1175-1192. https://doi.org/10.3390/cleantechnol4040072

APA StyleAlizadeh, P., Dumonceaux, T., Tabil, L. G., Mupondwa, E., Soleimani, M., & Cree, D. (2022). Steam Explosion Pre-Treatment of Sawdust for Biofuel Pellets. Clean Technologies, 4(4), 1175-1192. https://doi.org/10.3390/cleantechnol4040072