1. Introduction

Pollution prevention (P2) is the process of reducing or eliminating the use of hazardous or toxic materials at the source instead of managing the waste at the end of the product life cycle [

1,

2]. P2 has several advantages over recycling and reuse as it will prevent pollution from being created and emitted to the environment [

1,

2].

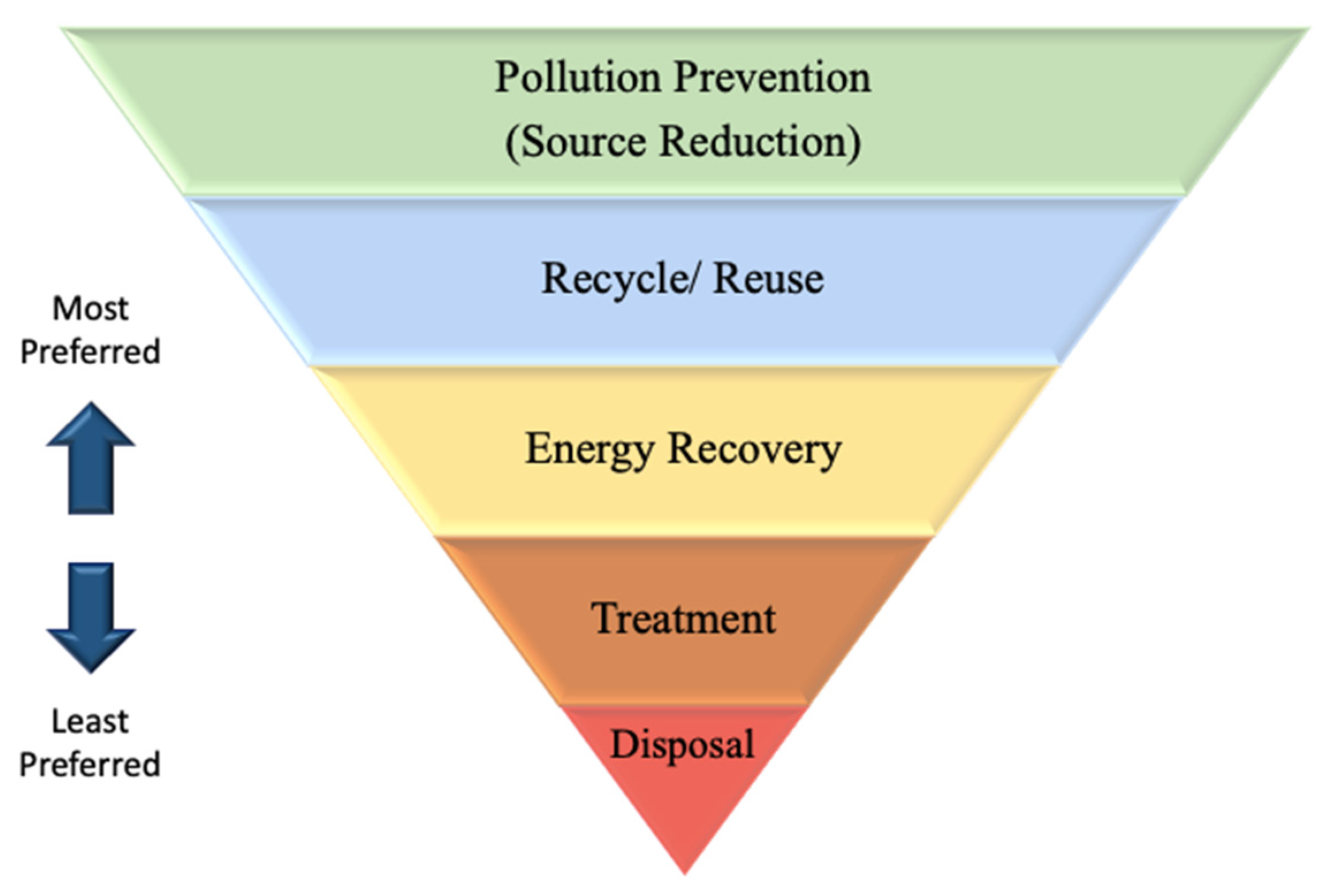

Figure 1 illustrates the waste management hierarchy showing the most preferable (top) and the least preferable (bottom) approaches to managing waste [

3]. Historically, most waste management attempts are focused on the middle of this hierarchy, ranging from treatment to recycling, even though source reduction, also termed P2 [

4], can be seen as the most preferred option.

In 1990, the US Congress passed the Pollution Prevention Act which changed the emphasis of waste management regulation from end-of-the-pipe treatment to eliminating or reducing waste at the source. P2 measures also help industries consider efficient use of resources including energy and water. When companies examine their operational practices, they can cut waste from over-purchasing input materials [

4] and identify less harmful chemicals to use, which can provide among other advantages a healthier environment for workers [

5]. The P2 approach can be accomplished by instituting process modifications that result in reductions in wastes, costs, and use of energy and water. If a long-term life-cycle view is used, changing the nature of the product or reducing the amount of material used in the product can provide P2 results as well [

6].

After the passage of the P2 Act, many manufacturers initiated programs to examine their processes and facilities to identify and implement changes leading to cleaner production and comply with the Act. Many states and local government entities organized technical assistance programs to help smaller manufacturers locate prevention opportunities within their operations and to make similar changes. While substantial reductions were achieved, not all manufacturers, particularly smaller facilities, and service providers who also used hazardous materials were able or motivated to alter their operations. Most frequently the lack of participation was due to lack of time, resources of personnel or funding, or simply because any possible benefit was not seen to be worth the effort due to the presumed small quantity of materials being used and disposed. Frequently that disparity between P2 progress for larger entities and lack of P2 initiatives for smaller manufacturers and service providers continues to this day. The objective of this project was to take steps by collaboratively working with existing community groups to raise awareness of the potential benefits of source reduction to the community at large in terms of reduced health risks and increased economic benefits in order to motivate reduction of chemical and energy use within the commercial sectors of the community, while maintaining productivity. A guiding principle was that greater knowledge and desire for community improvement would serve to motivate source reduction changes.

The overriding approach in this research was to work with clients to help them develop an understanding of the economic and environmental values of obtaining maximum utility from each molecule of chemicals used. The primary focus was to reduce chemical consumption and move to non-toxic (or less toxic when necessary) chemical choices. Typically, when the P2 designs were implemented the decision for companies to accept the proposed designs most often was motivated primarily on a reduction in their operating costs.

Implementation of P2 is known to not only help businesses and industries improve their processes, but also improve the health and well-being of individuals and families living close to those industries. According to Landrigan et al., [

7] air, water, soil, and chemical pollution in 2016 was responsible for the worldwide deaths of approximately 950,000 children, the majority of whom were very young, ranging from 0 to 5 years old. A recent study by Lygia et al, [

8] summarized several other studies that relate the health impact on children and the elderly caused by the pollution from nearby industries. The work presented by Lygia et al, [

9] highlighted the respiratory issues of children living near oil shale industries in Estonia. Guilbert et al., [

10] discussed the respiratory and oxidative stress caused by pollution in Belgium. Budnik and Casteleyn [

11] discussed consequences of mercury contamination on health of children, including chronic obstructive pulmonary disease, cardiovascular disease, stroke and cancer. Pollution not only has a direct impact, but also has indirect consequences such as climate change causing cardiovascular and respiratory mortality risks [

12]. A study by Kouis et al., [

12] showed that mortality risk increased significantly at temperatures above 33 °C, demonstrating the direct relationship between ambient air temperature and adverse health effects.

Unquestionably, pollution has significant impacts on human lives. Urban environments have shown progressive increases in chronic diseases over the past decades. The majority of pollution-related deaths in children and the elderly occurred in low- and middle-income regions similar to the study area described in this research. Most were due to respiratory and gastrointestinal diseases caused by polluted air and water [

7,

8]. The threats posed by pollution to our society have led to initiatives such as the United States Environmental Protection Agency (USEPA) P2 program that has been developed over the past three decades to reduce pollution and to reduce and/or mitigate its adverse effects.

In the past, programs to encourage the adoption of P2 have primarily focused on a single industry sector or have provided services to a large geographical area. The USEPA published a summary of 20 successful P2 projects, which cover 10 industries, including metals fabrication, machinery, lumber products, electronics, textiles, petroleum products, chemical products, printing, and transportation [

13]. The USEPA also maintains a web site that provides P2 case studies conducted in past years [

14].

The toxics release inventory (TRI) database, maintained and updated by the USEPA, is list of publicly available information on all industries working with more than minimal quantities of hazardous chemicals [

15]. Each year, such facilities are required to report to the TRI any new source reduction activities that they initiated or implemented fully. The source reduction information collected by the TRI program can help facilities learn from each other’s best practices and potentially reduce their own chemical releases. Based on this inventory, it is possible to track each business and evaluate whether they have been working towards source reduction. In 2018, 1270 facilities implemented a total of 3120 new source reduction activities among many others including process modification, spill and leak prevention, surface preparation and finishing, and inventory control [

16].

Several technologies have been developed in order to address the environmental issues of our planet [

17]. The USEPA has devoted significant efforts to support businesses in applying source reduction techniques to their daily operations. A USEPA study from 2014 to 2018 reported barriers to source reduction [

18]. Frequently, these impediments are related to the lack of known substitutes or alternative technologies to replace undesirable chemicals, materials or processes. But, sometimes, the major impediment is lack of realization by management of the potential benefit of making such changes. For example, manganese is used in steel production to comply with American Society for Testing and Materials (ASTM) standards, rendering the producers unable to reduce their use of this chemical while still meeting the expected specification [

18]. The worldwide phenomenon of single-use plastic in the packaging industry is another challenge. Development of a biodegradable and less harmful material could help reduce the environmental impacts [

19]. Landfills can negatively impact society (ground/surface water contamination due to leachate; toxic gases release, odor and etc.) [

20]. One possible solution for landfill issues would be to minimize food waste generation and divert that to biodigesters and composters instead of landfilling. Such minimization would significantly reduce/eliminate food waste disposal at landfills (source reduction) and, therefore protect the environment and communities [

20].

Although P2 has been extensively studied, there is still room for improvement because not all businesses, particularly smaller operations, have implemented source reduction changes. In 2021, the USEPA will award several million USD as grants towards source reduction assistance programs [

21]. These grants aim to reduce or eliminate pollutants from entering waste streams.

The main objective of this study was to determine whether a community-based source reduction effort in urban areas in partnership with established group efforts aimed toward neighborhood improvement could accelerate the rate of adoption of source reduction techniques by local businesses. Another goal was to tie P2 efforts to improving the health and well-being of the neighborhood so that everyone would feel part of the P2 effort. There are many economically disadvantaged communities such as Newark and Jersey City in the USA as well as in other nations where industrial/manufacturing centers are located next to residential areas, and hence workers as well as residential neighbors are impacted by industrial/manufacturing activities causing many health and quality-of-life issues.

2. Methodology

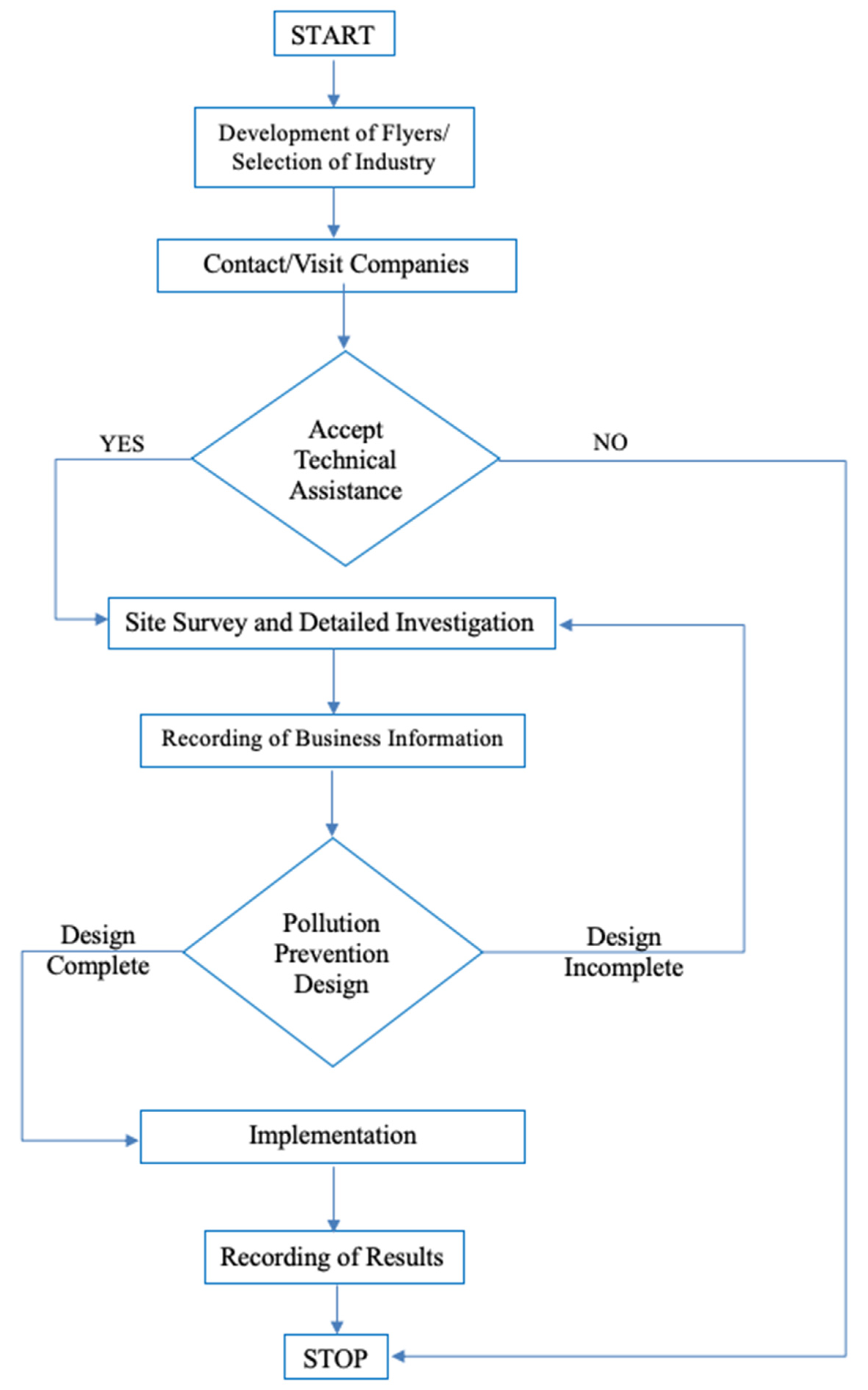

The methodology adopted for this study can be best understood by examining

Figure 2, which describes each step taken toward the completion of the program. This section provides detailed descriptions of how each of the steps in

Figure 2 were developed and the challenges faced when working on their implementation. Additional details about the method of investigation, including how to approach businesses, to be duplicated by other investigators, are provided in

Appendix A.

Prior to defining the methodology, it was necessary to establish understanding of the regions to be studied, in particular, the historical aspect of each site, and its significance to this study. The cities of Newark and Jersey City, New Jersey were chosen because they are industrial cities with high population densities. Both cities were founded in the 1600–1700s, and the physical layouts reflect an interconnection between residential, commercial, and manufacturing areas [

22,

23,

24] that was common at that time. In newer cities, urban planners are able to place residential buildings and industrial activities in different special zones, however, in older cities such as Newark and Jersey City, this was not the case. In these cities, manufacturing and service businesses are located nearby or immediately adjacent to residential areas. When fumes and waste are released from these industries, residents and the general public are easily exposed [

22,

23,

24]. Another salient feature of small businesses in the selected areas was the age of the industry. Most of the small businesses have been in operation for over 50 years and have not adopted recent industrial innovations such as green chemistry and green technology.

In 2012, Hurricane Sandy had an enormous impact on the East Coast of the United States. Both Newark and Jersey City were significantly impacted compared to many other local communities in NJ. Many businesses were flooded because of their proximity to the Hudson and Passaic Rivers [

25]. Not only were the buildings and machines exposed to the intrusive saltwater and highly polluted river water in the industrial area, but many harmful chemicals stored at business locations were also released to the community. During this study, it was found that many companies lost weeks of production, and auto repair facilities were faced with vehicles badly damaged beyond repair. Many of the businesses have recovered since that event, however, an opportunity is present for them to apply P2 concepts to lessen the likelihood of these types of negative impacts in the future by limiting or eliminating or securing the storage of production chemicals. It is to be emphasized that reduction in use of hazardous chemicals by reduced storage or secure storage of chemicals results in reduced risk of community exposure due to accidental spills, fires, or future flooding. This is another way that community-wide improvement in health and economic benefit can be achieved.

Businesses can have a different categorization based on their size. The number of employees in the business is widely used to categorize the business size. In small and medium-sized businesses fewer than 250 people work in the operations (all levels and functions are counted under this definition). Large enterprises usually have more than 250 workers [

26]. Large businesses frequently have environmental compliance officers who usually perform P2 and source reduction to comply with regulations and reduce liabilities. In this study, it was decided to work with small to medium sized businesses in different sectors without dedicated in-house environmental staff to provide the proposed assistance. In addition, these smaller operations are likely to have closer direct ties to the residents of the community around them, and therefore, are more likely to be responsive to calls for enhancements in community health.

2.1. Accessing Two Communinites

In order to build upon close ties within the communities, the New Jersey Institute of Technology (NJIT) P2 program partnered with two local community groups, Greater Newark Enterprises Corporation (GNEC) and Sustainable Jersey City (SJC). The Greater Newark Enterprises Corporation is a community development corporation in Newark that provides financial assistance and training to small and medium size businesses. Sustainable Jersey City is a collaborative network of green community groups and individuals in Jersey City. These partnerships helped the NJIT P2 team with community events, allowing for residents and business owners to understand P2 goals and the connections to area-wide improvements. There were other networking opportunities as well, where locals were able to voice their opinions and mention who may benefit from help with their businesses. Since many residents and business owners speak Spanish and Portuguese in the two cities, connecting with GNEC and SJC created an environment where community members could speak comfortably. The P2 program had team members fluent in Spanish or Portuguese who were able to answer their questions. Communicating with people at the community events helped spread the word about the benefits of P2 to the community.

As stated before, a key feature of businesses in Newark and Jersey City was that owners, workers and customers live in the same neighborhood. So, generating a sense of mutual benefit and responsibility was relatively easy. This was a focus of the initial public community meetings. As the people of the community continue to use P2 recommendations, businesses will save on the cost of chemical supplies, energy and water, while reducing use of toxins and hazardous materials to improve the health of owners, workers and customers who live in the same neighborhood. In addition, a case can be made that improvements in the economics of the business will help improve the overall economic well-being of the community through multiplying spending outcomes.

2.2. Industries Studied

In this program, many different industry segments were approached, however, the only ones that responded positively to the opportunity were auto repair, auto body, printing, beauty care, dry cleaning, and the metal finishing industry. In most cases, these were also the ones with the stronger community roots and connections (owners, workers and customers were from the same community), illustrating the anticipated value of the approach. Additionally, they were among the surviving industries in Newark and Jersey City after the migration of much manufacturing out of the USA.

In these businesses, the materials used have potential to impact community health and wellbeing through air emissions and direct contact, as well as through accidents involving storage and transport. In auto repair and auto body shops, many of the materials and products used for their service include chemicals that may be carcinogens [

27,

28]. These facilities use degreasers, paints, solvents, and lacquer thinners, which contain many problematic substances such as acetone and some aromatic solvents impacting owners, workers and customers [

29]. When people are exposed to high levels of these substances for even short periods, these substances can cause nose, throat, lung, and eye irritation as well as increased pulse rate, nausea, vomiting, and possibly comas [

30,

31]. Formaldehyde, a common chemical that is a carcinogen, can be found associated with solvents that are used in beauty salons and printing shops [

32]. Both industries also use acetone to remove nail polish or ink. While acetone is not a carcinogen, it can still cause harmful health effects. In dry cleaning operations, a wet solvent is used instead of water. Currently, the dry-cleaning industry mostly uses PERC (tetrachlorethylene or perchloroethylene), which is a hazardous chemical that needs careful handling. The industry has become more regulated with stricter enforcement or even bans on using PERC. In response, many dry cleaners have already changed their routine or planned to do so. The metal finishing industry, by definition, uses the process of placing some metal coating on the surface of a metallic part. Hazardous chemicals are used for cleaning and polishing the metal surfaces [

33]. According to the USEPA, metal finishing facilities release a variety of toxic compounds [

34]. Chlorinated hydrocarbons are emitted during cleaning (degreasing) of metal parts and volatile organic compounds are emitted during any painting process. These chemicals can cause a variety of adverse health effects such as neurotoxicity (solvents, mercury), chemical burns (acids and alkalis), or dermal, respiratory, or eye irritations (acid vapors, solvents, metals) [

29]. A salient feature of all selected industries is the chemical smell encountered upon first entering the business, this impacts owners, workers and customers as well. Once a business was selected for P2 investigation and design, an initial site survey followed by detailed investigation of the business was performed to record the business information by working with the owner or operator of the business (please see

Appendix A for details).

2.3. Pollution Prevention Designs

Knowledge of the economic activity of the business was needed for the NJIT P2 team to be able to provide suggestions to the business based on what is feasible to implement. While many factors were considered, some of the complexities were not well known at first, and a key concern was always to obtain initial data and to plan for obtaining final data that would provide the information needed to monitor progress toward achieving the goals of the research. For example, in this study, an important criterion was to lower the total amount of pollutants emitted into the community based on the assumption that this would improve the overall community health. Therefore, the focus of this work was on assembling data that would describe progress towards the reduction of local environmental emissions. Other factors included a reduction in the use of energy and resources such as water because of the impacts they would eventually have on the community as well.

The use of best management practices (BMPs) can improve the efficiency of operations and was crucial to each industry. BMPs provide recommendations on how to keep a clean, organized, and healthy work environment. Keeping a clean environment in the workplace can prevent spills and accidents. Furthermore, in case a spill or accident should occur, BMPs suggest ways to handle such situations. Although the documents describing BMPs cannot make suggestions based on individual company-specific needs, they do provide general suggestions on products that can be used as replacements for those currently in use.

P2 also covers water and energy conservation, as shown in the USEPA Schedule C (see

Appendix B). Hence, lighting information was also recorded in order to determine if businesses were using the best possible products to balance illumination needs with efficiency of energy use. By adopting suggestions to replace incandescent light bulbs with LED light bulbs, owners were able to save both money and energy. LED bulbs do have a higher initial cost than the incandescent bulbs, but over time, the LED choice can make a difference in usage cost. According to the US Department of Energy, Residential LEDs, especially ENERGY STAR rated products, use at least 85% less energy and last 25 times longer than incandescent lighting [

35,

36].

For each business, types of P2 activities recommended included among other things are:

Inventory control

Process modification

Raw material modification

Spill and leak prevention

Good operational practices

Product modifications using green chemicals and green technology

Modification of surface preparation and finishing

Modification of cleaning and degreasing

3. P2 Output and Outcomes

The site and business data were collected and a P2 design was prepared for each site. Then the NJIT team monitored the implementation to account for the reduction of environmental impacts. One crucial aspect of P2 design was determination of the material balance analyses for the operations, followed by recommendations to reduce pollution. The reason for this determination was to be able to quantify material losses through leaks, spills, and fugitive emissions. Then after six months P2 team members visited the business again to evaluate the implementation of P2 designs and estimate the reduction in pollution due to the P2 design. There were 32 case studies and P2 designs. Rather than describing all 32 modifications, the following section summarizes the final outcome based on the business sectors. Additionally, the following section describe the importance of the P2 designs and shares the challenges faced during the implementation in order to assist others to initiate similar studies in different regions. To maintain the proprietary nature from the business studied, no figures or detailed information of their facilities are included here.

3.1. P2 Design Implementation

Once the site survey and discussion with the facility operators were completed, final individual P2 designs were presented as written reports and provided to the companies. Included in these reports were a general BMP for that industry, suggestions for changing chemicals/products and recycling options, upgrading equipment as well as specific P2 recommendations. The P2 team members explained the content to each owner while the details of the report included the possible reduction of emissions and emitting locations and potential cost savings. The measurable results with respect to the USEPA Schedule C was also explained as it was confusing to many without prior introduction or detailed exposure.

There were similarities among all of the facilities investigated throughout the study. One of the most used recommendations was to keep the business uncluttered. Many facilities visited did not exhibit good housekeeping. Supplies, tools, and containers were found throughout the facility, a practice often due to the lack of a designated storage area. This clutter caused or obscured the problem of having excess material in the machinery area. The resulting hazardous conditions could impact workers as well as patrons of the facility. Throughout the program, each business with its own investment had the choice to implement recommendations from the P2 team, which would reduce hazardous chemical use and costs of removal. Furthermore, the recommendations included energy and water savings. When providing suggestions to owners related to energy savings, one common suggestion was to change the lighting fixtures to use LED sources instead of incandescent light bulbs. The following paragraphs describe specific recommendations to six industries investigated.

For auto repair, the NJIT team focused on spill prevention and control of hazardous materials. If storage containers are left open, evaporation can occur, and the risk of spills is increased. Additionally, money and material could be saved when a product control program is put in place by limiting quantities of material from entering the shop that would remain unused at its expiration date. The solvents and cleaners used by auto repair shops contain volatile organic compounds (VOCs). These compounds are mostly composed of acetone and aromatic solvents [

37]. These substances can pose threats such as respiratory health issues for workers over longtime usage. Changing the type of product used can prevent the emission of fumes, which can result in possible cost implications due to not needing secure ventilation. For auto repair shops, ultrasound cleaners were recommended instead of solvents.

For auto body shops, a paint mixing room and a paint booth are typical installations. The main chemicals used are paints and thinner. The NJIT team found that some of the shops did not have enough air exchange for ventilation. When visiting such shops without adequate ventilation, the teams frequently smelled strong chemical odors. Additionally, many had containers, tools, and spare parts scattered around. For auto body shops, the NJIT team recommended low VOC or water-based paint [

38]. In addition, ventilation systems with an adequate air exchange rate were proposed to those who had an enclosed mixing room without any ventilation.

For printing shops, in addition to printing, the companies also do the cutting, folding, binding of materials and products. The type and size of the printing and copy machines depend on their contracts. Large companies make use of a sheet-fed printer as well as web-fed presses. Usually, four inks are used for color printing: cyan, magenta, yellow, and key (black). Solvent is usually used for roller cleaning. Some of the companies visited have already implemented many good P2 practices, such as the use of soy-based inks and changes in the types of solvent-based cleaning solutions. For printing shops, NJIT proposed the use of water-based ink, which can eliminate the need for acetone or other organic solvents for ink removal [

38]. The use of dry ice based techniques was also suggested for cleaning the printer rollers without solvents [

39].

In drying cleaning operations, wet organic solvents are used instead of water. The cleaning process involves tag labeling, pretreatment to remove any stains, washing in a machine filled with PERC or another solvent, drying in the same machine or a separate machine, and finally pressing. Using closed solvent containers, preventing spills and maintaining the equipment to avoid leaks and evaporation would be an example of possible changes that would help to reduce air pollution. The use of petroleum-based solvents in the dry-cleaning operation can release some toxic air pollutants and volatile organic compounds (VOC). Chemicals in these substances has been linked to a number of respiratory effects [

7,

40,

41,

42]. For dry cleaners, the most popular solvent replacement for PERC is Gen X, which does not contain PERC. GEN X is a mixture of propylene glycol ethers and mineral spirits [

43]. However, the best P2 solution is wet cleaning, a process in which the clothes are cleaned using just water that is more environmentally friendly. Therefore, NJIT recommended the use of an environmentally friendly solvent or wet cleaning with water, and the proper disposal of the spent solvent.

For metal finishing companies, the processing includes metal preparation, where strong acids are used for metal cleaning and caustic soda is used for oil or paint removal. Rinsing with water or kittling is a process that involves dipping the metal in a molten metal bath for coating at a very high temperature, followed by cooling, drying, and cleaning by grinding or sanding. Extending bath life and reducing bath contamination could lower the cost of chemical and also decrease the generation of hazardous waste and consequently reduce the cost of disposing those chemicals. For metal finishing companies, the most frequent NJIT recommendations were to implement instruments or tests to inspect the cleanliness of the metal surface, which may help to reduce the amount of chemical use for cleaning and energy reduction during the kittling process.

For beauty shops, the primary chemical use is hair dye and relaxer. A relaxer is a type of lotion or cream. The active agent is usually a strong alkali, although some formulations are based on ammonium thioglycolate. Employees usually use masks, aprons, and gloves when they are performing the hair straightening process. However, the gloves they use often are not appropriate for this chemical. Additionally, most shops do not have hazardous material handling training. For beauty shops, due to the frequent use of a solvent in nail polish removal, the NJIT P2 team recommended proper masks or respirators to use, the replacement of nail polish or other solvent with those that contain fewer toxic materials, proper ventilation, and safety training.

Table 1 summarizes the P2 recommendations. It combines all businesses investigated both from Jersey City and Newark and includes all industry types. The community benefits are also listed in

Table 1 and it can be observed that all P2 interventions reduced air emissions and the chemical smell associated with those businesses.

After six weeks, the team visited each facility and followed up with the owners to check how they had responded to the P2 report. The owners also had opportunities to express what they did and did not like in the report so that revisions could be made to the P2 design. The owners were asked about the P2 suggestions and documented critical steps that they would take in implementation. If they showed some interest in implementing P2 recommendations, they were provided with additional information on the value of making the suggested changes. Towards the end of the program, the team returned and talked with each of the 32 businesses to observe which of the suggestions were implemented. Certain businesses took into account possible savings and followed part of the suggestions which could help their business and community over time. Others decided not to follow recommendations immediately but implement them in the future. This was mainly due to cash flow issues. Since this a voluntary program, businesses need not implement any suggestions, but those who did received economic and environmental benefits. Finally, a certificate of completion was issued to the companies that joined the study.

3.2. Challenges Faced During Implementation

The team faced many obstacles during this research. From the onset, in addition to community meetings, there was a need to visit most of the small and medium sized businesses in the two cities in order to spread the word and find volunteer companies. This was necessary as the USEPA project had a duration of 2 years and the results had to be reported at the end of the project. The entire program was free for small and medium sized businesses. However, as previously stated, many businesses turned down the free assistance. Additionally, because the USEPA funded this P2 study, many potential clients thought that the team members were federal workers sent to inspect their facility directly from the government instead of from NJIT. As a result, many businesses were fearful of having anything to do with the program and refused to allow the NJIT team to walk through their facilities. Additionally, even when the government funding was not disclosed to owners, many still were suspicious of the team. Since environmental related topics were discussed, many assumed the program was from the government and could, therefore, result in harm to the company.

A basic premise of this research was the concept of collaborating with the community expecting that P2 would have an overall benefit to the entire community. Additionally, it would encourage enthusiastic participation by small and medium sized businesses based on recognition of this mutual benefit. A few companies linked to the community responded enthusiastically. However, the majority of the businesses contacted were reluctant to participate, and the community-based efforts seemed to have little or no immediate effect on their participation.

Some businesses in Newark and Jersey City have been around for many years and are family-owned businesses that have been passed on from generation to generation. In many cases, the owners thought that they did not need any assistance with their business, and that each of their current practices was operating at peak efficiency. Many facilities declined participation, while others did not divulge their thoughts to the team. Several businesses did not give reliable, straightforward answers, leaving the team to try to follow up repeatedly.

In the original scope of research, 32 assessments were to be provided to small and medium sized businesses identified as “manufacturing” with an emphasis on solvents and solvent management. The team made its best effort to approach those listed in the TRI database in this category. However, all rejected assistance. Therefore, the focus was placed on consumer-related businesses such as beauty care, dry cleaning, printing, auto repair, auto body, and the metal industry. This is a more diverse set of sectors and captures a range of sector types based on community needs and interests. In some ways, this also reflects the changes in commercial activity in the neighborhoods of Newark and Jersey City.

Table 2 shows a listing of assessments fully completed and sector type.

To continue building support for change, two additional community events were organized in Newark and Jersey City to inform people in the areas about the outcomes from the research, including accounts from businesses that joined the program. It is expected that this type of community feedback, over time, will facilitate additional future participation on the part of those firms that were initially reluctant. This, likely will be the greatest value of working with the community groups—to generate and facilitate sustained interest and recognition of overall community benefit.

4. Discussion of Results

There was a total of 32 P2 interventions, of which 21 were in Newark and 11 in Jersey City. Those 32 P2 interventions included 3 beauty care industries (all in Newark), 4 printing industries (one in Newark), 6 metal industries (five in Newark), 10 auto body shops (seven in Newark), 8 auto care shops (five in Newark) and one dry cleaner in Jersey City.

4.1. P2 Savings

Based on measurements and reporting, the program produced, 932 pounds reduction of hazardous waste, prevented 13.62 metric tons of carbon equivalent (MTCE) of greenhouse gas release, saved

$5335 USD, and decreased 3917 pounds of non-hazardous waste disposal per year in two communities. An important issue to note is that these are recurring savings, year after year, not just one-year impacts. The MTCE calculations were performed using the USEPA Climate Leaders Simplified GHG Emission Calculator [

44] for all 32 P2 interventions.

Table 3 shows the overall public health and environmental reduction resulting from the changes implemented by the businesses. Dollars saved is based on how each business implemented our recommendations.

Appendix C shows details calculations of the

$5335 USD per year saving. Overall, there was an increase in owner profits and a substantial decrease in chemicals used, including volatile chemicals. These results will have a substantial impact on the public health of two communities. The reduction in chemical use tangentially results in reduced storage of chemicals meaning that the community risk level in case of fire, flood or spill is reduced as well.

4.2. Specific Reduction in Use of Hazardous Materials and Associated Community Impacts

Because the main emphasis of P2 is the elimination or reduction of hazardous material use, this section provides details about such elimination and the impact of that elimination on the community. This research contributed to a recurring annual reduction of 932 pounds of hazardous materials from 32 small businesses in the two communities. The reported reduction of 932 pounds of Hazardous Materials resulted from several suggested process changes that are detailed below.

Switching Paint Lacquer thinner to PolyChem Acrastrip and for modifying paint gun cleaning for seven auto body industry interventions resulting in eliminating 254.2 pounds of Methylene Chloride.

- ○

For seven auto body industry interventions seven owners replaced 2542 pounds of Paint Lacquer thinner containing Methylene Chloride with water base PolyChem Acrastrip. Paint lacquer thinner contains 10% methylene chloride. Hence seven interventions eliminated 254.2 pounds of methylene chloride.

Replacing 119 pounds of acetone with nail polish remover with no acetone in three beauty care industry interventions.

Replacing 76 gallons of Meter Roller Cleaner Fast (MRCF), thereby eliminating 509 pounds of hazardous waste by using dry ice blasting to clean printer rollers in one printing industry intervention. MRCF is the solvent mixture frequently used in the cleaning of printer rollers.

Use of ultrasonic parts cleaner to replace 46 pounds of parts washer solvent in one auto care industry intervention.

Replacing the ordinary engine and brake degreaser with a green chemical and saving 4.8 pounds of hazardous waste from one auto care industry intervention.

With the visits six weeks after submitting the final P2 recommendations to 32 small businesses, the research team was able to document, as shown above, the reduction in the use of hazardous chemicals purely motivated by cost savings. The above reduction of hazardous chemical use also resulted in substantial reduction in chemical odor in the facility, which was appreciated by both owners as well as workers. The business was reluctant to share information about the improvements with their competitors. However, the improvement in the working environment was shared by workers with their friends and relatives. This result also illustrates another aspect of such a community-based approach—that word about beneficial changes gets around informally within the community.

Based on these interactions and results, all 32 companies reported that they would be delighted to work with NJIT again and to date none have reverted back to their former practices as they see the economic advantages of what was proposed and implemented. With additional state or federal. funding, the NJIT P2 team plans to follow up with all impacted small businesses to provide continued support and to evaluate longer-term benefits to the community.

4.3. Impacts Beyond the Investigated Communities

Analysis of the results suggests that the recommendations in this study may benefit future studies. It seems that businesses will be more likely to participate, if they are more aware of the potential quantifiable benefits. For example, the first round of meetings or reports about successes and benefits from the first group of community businesses participating did encourage more businesses to take part based on credibility gained for the program and because of word-of-mouth on the part of community residents. It may be that the owners and managers of businesses do not feel that they are a fully accepted part of the community and therefore are reluctant to take part. If this is the case, additional outreach on the part of the community group, as well as the pollution-prevention assistance provider, might be necessary. This, in turn, suggests that a sustained program will be more effective than a short-term effort. It may be that the societal dynamics of communities are different in urban settings than in suburban or more rural settings. If this is true, and likely it is, further consideration of how relationships work and how businesses can best be encouraged by community groups in each type of environment to participate in a P2 program could have a positive impact. This may be particularly true in urban areas where even neighborhoods in close proximity may be composed of people from different cultural and ethnic backgrounds so that the social dynamics and motivational factors may be different. Carefully planned approaches and outreach opportunities likely will be required for success in different neighborhoods. There were some obvious benefits from the community-based approach, hence, additional focus on deepening the partnerships with community groups could enhance the impact of the program in future interactions. An objective of this publication is to share the results so that other environmental justice cities can institute P2 programs to improve their community health based on community group participation.

New Jersey is a very dense state, with a population of nearly 9 million inhabitants, its proximity to New York City makes the state economically active, attracting small and medium size entrepreneurs to explore commercial potential [

45,

46]. According to US 2018 census data, in the state of New Jersey there are 792,088 businesses that pay more than

$1000 USD in federal taxes based on yearly income [

46]. Although the study described in this research was implemented in a narrower area, Newark and Jersey City, with a combined population of 550,000 inhabitants, making a parallel comparison with the entire state and the number of business evaluated in this study, the results show the powerful potential impact on this region. For example, as shown in

Table 3, nearly 17,000 Kwhrs were saved due to P2 implementation in 32 small-medium enterprises. Proportionally expanding this study to approximately 1% of the total number of small-medium enterprises operating in the state (~8000 firms), potentially 4,250,000 kWhrs could be saved yearly on a state-wide basis. Similarly, the state-wide potential for reduced hazardous materials and dollars saved would be 233,000 lbs. and

$1,250,000 USD respectively, exhibiting the environmental and economic impacts of this P2 implementation to additional communities.

There are many disadvantaged communities such as Newark and Jersey City in the USA as well as in other nations where industrial/manufacturing centers are located next to residential areas, and where workers as well as residential neighbors are impacted by industrial/manufacturing activities causing many health issues. Additionally, the situation in Newark and Jersey City is quite similar to many major cities in the developing world such as Delhi, Sao Paulo, Manila, Jakarta, Cape Town. etc. The cases reported in the manuscript are the finding of P2 implemented to 32 businesses. So, this study can be considered as a seed project for a bigger initiative that could be implemented globally. By replicating the efforts outlined in this paper other impacted communities in both developed and developing nations can conduct similar programs.

5. Summary and Conclusions

This paper describes the technical assistance program entitled: “A Community Based Pollution Prevention Program for the USEPA Region 2”. Newark and Jersey City were chosen to implement the community-based P2 program. These are two of the most populated cities in the state of New Jersey with intermingled industrial facilities and residential units. A key feature of these businesses in both cities was that owners, workers and customers typically live in the same neighborhood. To facilitate the implementation, the NJIT P2 Program partnered with two local community groups.

The hypothesis of this study was that a community-based approach designed to emphasize the benefits to the health and economic well-being of urban communities after source reduction practices were implemented by businesses in the community would result in enthusiastic agreement to identify source reduction opportunities and to implement them. Using the methodology and results presented in this paper, a direct relationship between the implementation of P2 practices and improved health and economic benefits to the community have been demonstrated.

The recommendations of this study made it possible to reduce 933 pounds of hazardous waste, prevent 13.65 metric tons of carbon equivalent (MTCE) of greenhouse gas release, save $5329 USD, and decrease 3823 pounds of non-hazardous waste disposal per year in two communities. At the end of the study all 32 business owners, expressed their gratitude to the NJIT P2 program. They were delighted to work with the NJIT P2 program and to date none have reverted back to their former practices as they observed the economic advantages. The findings of this study also suggest that a sustained community-based program would have immense potential to overcome the concerns of small-medium business about initiating a source reduction program, through demonstration of benefit to the business and to the community, and through credibility-building achieved by regular community reporting and the absence of official intervention. Publication of this paper in an open access journal facilitates the information dissemination and outreach to other similar businesses.

A few concluding words might be appropriate regarding the impact of a community-based P2 program in contrast to statewide, regional, or industry-specific programs that have been implemented in the past. A basic premise of this research was that partnering with community groups to achieve P2 in the locality would have overall community benefit and encourage wide, rapid participation by small businesses. But this goal was not immediately attained. However, a good foundation has been prepared that points to wider success in the future if the effort is sustained. An important finding about continued distrust on the part of smaller businesses regarding cooperation with government-sponsored environmental programs may be slowly overcome with this type of community-based program. Recurring environmental and economic benefits can serve as a basis for building support for source reduction changes in the any community.

The cases reported in the manuscript are the findings of P2 implemented to 32 businesses. In summary, it can be considered that this study is a seed study for a bigger project/study, which could be implemented globally.