Waste Recovery through Thermochemical Conversion Technologies: A Case Study with Several Portuguese Agroforestry By-Products

Abstract

:1. Introduction

2. State-of-the-Art

3. Materials and Methods

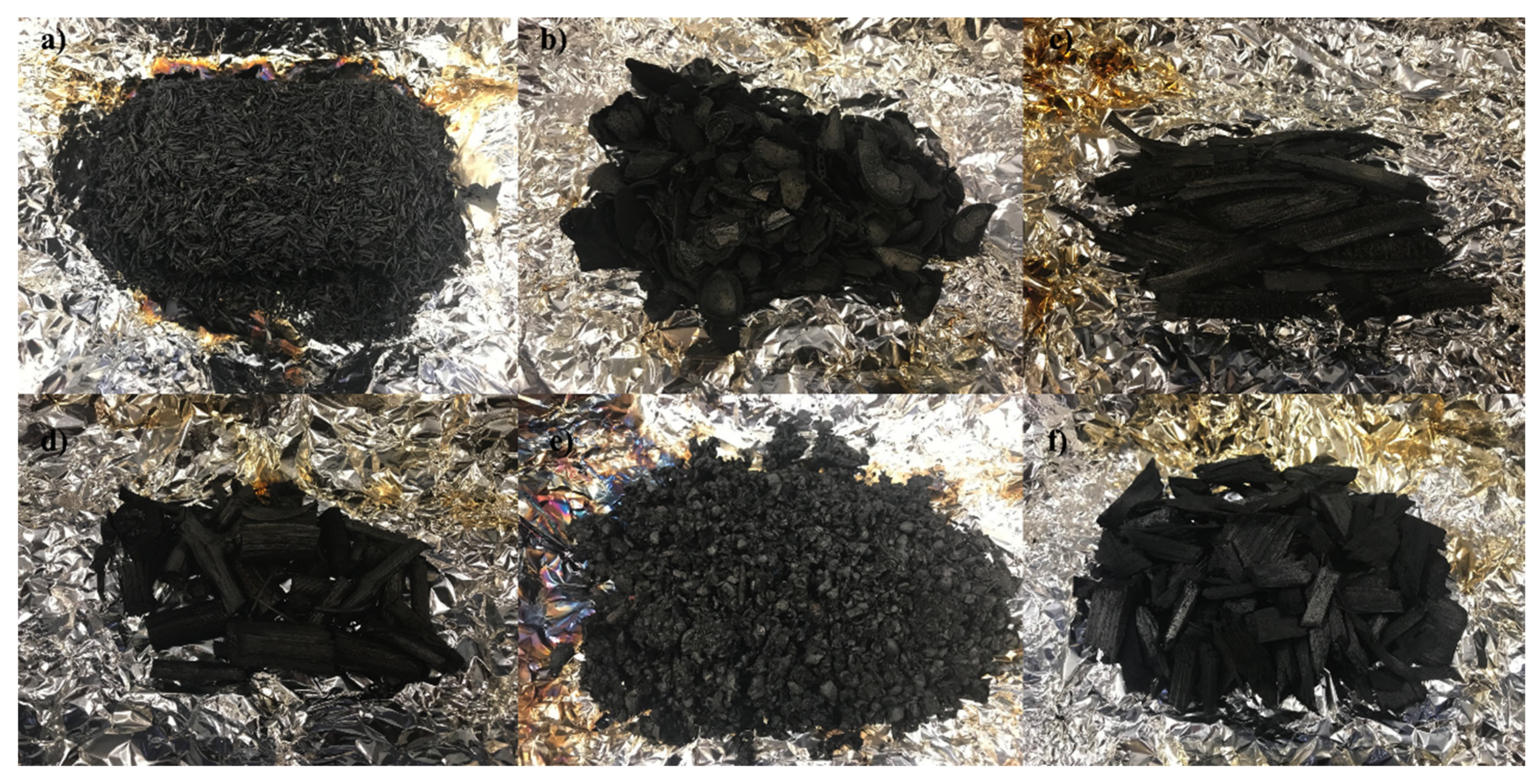

3.1. Sample Collection and Preparation

3.2. Ultimate Analysis

3.3. Proximate Analysis

3.4. Determination of Heating Value

4. Results

4.1. Elemental Analysis

4.2. Thermogravimetric Analysis

4.3. Heating Value

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Madanayake, B.N.; Gan, S.; Eastwick, C.N.; Ng, H.K. Biomass as an energy source in coal co-firing and its feasibility enhancement via pre-treatment techniques. Fuel Process. Technol. 2017, 159, 287–305. [Google Scholar] [CrossRef]

- Bhattacharya, S. State-of-the-art of utilizing residues and other types of biomass as an energy source. Int. Energy J. 2017, 15, 1–21. [Google Scholar]

- Gejguš, M.; Aschbacher, C.; Sablik, J. Potential for the Use of Biomass as a Prospective Renewable Energy Source. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2017, 25, 27–30. [Google Scholar] [CrossRef] [Green Version]

- Abdulrahman, A.O.; Huisingh, D. The role of biomass as a cleaner energy source in Egypt’s energy mix. J. Clean. Prod. 2018, 172, 3918–3930. [Google Scholar] [CrossRef]

- Naik, S.; Goud, V.V.; Rout, P.K.; Jacobson, K.; Dalai, A.K. Characterization of Canadian biomass for alternative renewable biofuel. Renew. Energy 2010, 35, 1624–1631. [Google Scholar] [CrossRef]

- Garcia, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Gumisiriza, R.; Hawumba, J.F.; Okure, M.; Hensel, O. Biomass waste-to-energy valorisation technologies: A review case for banana processing in Uganda. Biotechnol. Biofuels 2017, 10, 11. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. NPJ Clim. Atmos. Sci. 2019, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Toklu, E. Biomass energy potential and utilization in Turkey. Renew. Energy 2017, 107, 235–244. [Google Scholar] [CrossRef]

- Torrisi, S.; Anastasi, E.; Longhitano, S.; Longo, I.C.; Zerbo, A.; Borzì, G. Circular economy and the benefits of biomass as a renewable energy source. Procedia Environ. Sci. Eng. Manag. 2018, 5, 175–181. [Google Scholar]

- Ferreira, S.; Monteiro, E.; Brito, P.S.; Vilarinho, C. Biomass resources in Portugal: Current status and prospects. Renew. Sustain. Energy Rev. 2017, 78, 1221–1235. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. Biomass in the generation of electricity in Portugal: A review. Renew. Sustain. Energy Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Skreiberg, Ø. Upgrading biomass fuels via wet torrefaction: A review and comparison with dry torrefaction. Renew. Sustain. Energy Rev. 2016, 54, 665–677. [Google Scholar] [CrossRef]

- Elum, Z.A.; Modise, D.; Nhamo, G. Climate change mitigation: The potential of agriculture as a renewable energy source in Nigeria. Environ. Sci. Pollut. Res. 2016, 24, 3260–3273. [Google Scholar] [CrossRef] [PubMed]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Pedroli, B.; Elbersen, B.; Frederiksen, P.; Grandin, U.; Heikkilä, R.; Krogh, P.H.; Izakovičová, Z.; Johansen, A.; Meiresonne, L.; Spijker, J. Is energy cropping in Europe compatible with biodiversity?—Opportunities and threats to biodiversity from land-based production of biomass for bioenergy purposes. Biomass Bioenergy 2013, 55, 73–86. [Google Scholar] [CrossRef]

- Mehmood, M.A.; Ibrahim, M.; Rashid, U.; Nawaz, M.; Ali, S.; Hussain, A.; Gull, M. Biomass production for bioenergy using marginal lands. Sustain. Prod. Consum. 2017, 9, 3–21. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: An assessment. GCB Bioenergy 2014, 7, 916–944. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; De Jong, W.; Jansens, P.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Kang, K.; Qiu, L.; Sun, G.; Zhu, M.; Yang, X.; Yao, Y.; Sun, R. Codensification technology as a critical strategy for energy recovery from biomass and other resources—A review. Renew. Sustain. Energy Rev. 2019, 116, 109414. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. REVIEW: A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Wigley, T.; Yip, A.C.; Pang, S. The use of demineralisation and torrefaction to improve the properties of biomass intended as a feedstock for fast pyrolysis. J. Anal. Appl. Pyrolysis 2015, 113, 296–306. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Nunes, L.J. Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms. Clean Technol. 2020, 2, 270–290. [Google Scholar] [CrossRef]

- Bichot, A.; Delgenès, J.-P.; Méchin, V.; Carrere, H.; Bernet, N.; García-Bernet, D. Understanding biomass recalcitrance in grasses for their efficient utilization as biorefinery feedstock. Rev. Environ. Sci. Bio-Technol. 2018, 17, 707–748. [Google Scholar] [CrossRef]

- Proskurina, S.; Sikkema, R.; Heinimö, J.; Vakkilainen, E. Five years left—How are the EU member states contributing to the 20% target for EU’s renewable energy consumption; The role of woody biomass. Biomass Bioenergy 2016, 95, 64–77. [Google Scholar] [CrossRef]

- Sikkema, R.; Steiner, M.; Junginger, M.; Hiegl, W.; Hansen, M.T.; Faaij, A.P.C. The European wood pellet markets: Current status and prospects for 2020. Biofuels Bioprod. Biorefining 2011, 5, 250–278. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. Wood pellets as a sustainable energy alternative in Portugal. Renew. Energy 2016, 85, 1011–1016. [Google Scholar] [CrossRef]

- Nunes, L.J.; Meireles, C.I.R.; Gomes, C.J.P.; Ribeiro, N.M.C.D.A. Socioeconomic Aspects of the Forests in Portugal: Recent Evolution and Perspectives of Sustainability of the Resource. Forests 2019, 10, 361. [Google Scholar] [CrossRef] [Green Version]

- Ericsson, K.; Nilsson, L.J. Assessment of the potential biomass supply in Europe using a resource-focused approach. Biomass Bioenergy 2006, 30, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, A.; Loureiro, L.; Nunes, L.J. Torrefaction of woody biomasses from poplar SRC and Portuguese roundwood: Properties of torrefied products. Biomass Bioenergy 2018, 108, 55–65. [Google Scholar] [CrossRef]

- Nunes, L.J.; Raposo, M.A.M.; Meireles, C.I.R.; Gomes, C.J.P.; Ribeiro, N.M.C.A. Control of Invasive Forest Species through the Creation of a Value Chain: Acacia dealbata Biomass Recovery. Environments 2020, 7, 39. [Google Scholar] [CrossRef]

- Sahu, S.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. Analysis of the use of biomass as an energy alternative for the Portuguese textile dyeing industry. Energy 2015, 84, 503–508. [Google Scholar] [CrossRef]

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar] [CrossRef]

- Amponsah, N.Y.; Troldborg, M.; Kington, B.; Aalders, I.; Hough, R.L. Greenhouse gas emissions from renewable energy sources: A review of lifecycle considerations. Renew. Sustain. Energy Rev. 2014, 39, 461–475. [Google Scholar] [CrossRef]

- Rodrigues, A.; Nunes, L.J. Evaluation of ash composition and deposition tendencies of biomasses and torrefied products from woody and shrubby feedstocks: SRC poplar clones and common broom. Fuel 2020, 269, 117454. [Google Scholar] [CrossRef]

- Sepulveda, N.; Jenkins, J.; De Sisternes, F.J.; Lester, R.K. The Role of Firm Low-Carbon Electricity Resources in Deep Decarbonization of Power Generation. Joule 2018, 2, 2403–2420. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. Biomass waste co-firing with coal applied to the Sines Thermal Power Plant in Portugal. Fuel 2014, 132, 153–157. [Google Scholar] [CrossRef] [Green Version]

- Purkus, A.; Hagemann, N.; Bedtke, N.; Gawel, E. Towards a sustainable innovation system for the German wood-based bioeconomy: Implications for policy design. J. Clean. Prod. 2018, 172, 3955–3968. [Google Scholar] [CrossRef]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, Y.; Tan, H.; Hui, S. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Vicente, E.D.; Gomes, A.P.; Nunes, M.; Alves, C.; Tarelho, L. Effect of industrial and domestic ash from biomass combustion, and spent coffee grounds, on soil fertility and plant growth: Experiments at field conditions. Environ. Sci. Pollut. Res. 2017, 24, 15270–15277. [Google Scholar] [CrossRef]

- Keoleian, G.A.; Volk, T.A. Renewable Energy from Willow Biomass Crops: Life Cycle Energy, Environmental and Economic Performance. Crit. Rev. Plant. Sci. 2005, 24, 385–406. [Google Scholar] [CrossRef]

- Langeveld, J.W.A.; Dixon, J.; Jaworski, J.F. Development Perspectives of the Biobased Economy: A Review. Crop. Sci. 2010, 50, S142–S151. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; López-Ochoa, L.M.; López, L.M.; Las-Heras-Casas, J.; Xiberta-Bernat, J. Evolution and perspectives of the bioenergy applications in Spain. J. Clean. Prod. 2019, 213, 553–568. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Rajagopal, D. Life-cycle energy and climate benefits of energy recovery from wastes and biomass residues in the United States. Nat. Energy 2019, 4, 700–708. [Google Scholar] [CrossRef] [Green Version]

- Pippo, W.A.; Luengo, C.A.; Alberteris, L.A.M.; Garzone, P.; Cornacchia, G. Energy Recovery from Sugarcane-Trash in the Light of 2nd Generation Biofuel. Part 2: Socio-Economic Aspects and Techno-Economic Analysis. Waste Biomass Valorizat. 2011, 2, 257–266. [Google Scholar] [CrossRef]

- Kliopova, I.; Makarskienė, K. Improving material and energy recovery from the sewage sludge and biomass residues. Waste Manag. 2015, 36, 269–276. [Google Scholar] [CrossRef]

- Godina, R.; Godina, R.; Matias, J.C.O.; Nunes, L.J. Future Perspectives of Biomass Torrefaction: Review of the Current State-Of-The-Art and Research Development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef] [Green Version]

- Materazzi, S. Mass Spectrometry Coupled to Thermogravimetry (TG-MS) for Evolved Gas Characterization: A Review. Appl. Spectrosc. Rev. 1998, 33, 189–218. [Google Scholar] [CrossRef]

- Baratieri, M.; Baggio, P.; Fiori, L.; Grigiante, M. Biomass as an energy source: Thermodynamic constraints on the performance of the conversion process. Bioresour. Technol. 2008, 99, 7063–7073. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Yin, C.-Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef] [Green Version]

- Annamalai, K.; Sweeten, J.M.; Ramalingam, S.C. Technical Notes: Estimation of Gross Heating Values of Biomass Fuels. Trans. ASAE 1987, 30, 1205–1208. [Google Scholar] [CrossRef]

- Channiwala, S.; Parikh, P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J. Torrefaction of wood: Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Dos Santos, R.C.; Carneiro, A.d.C.O.; Vital, B.R.; Castro, R.V.O.; Vidaurre, G.B.; Trugilho, P.F.; Castro, A.F.N.M. Effect of properties chemical and siringil/guaiacil relation wood clones of eucalyptus in the production of charcoal. Ciênc. Florest. 2016, 26, 657–669. [Google Scholar]

- Sturion, J.; Pereira, J.; Chemin, M. Wood quality of Eucalyptus viminalis for energy purposes as a function of spacing and felling age. Bol. Pesqui. Florest. 1988, 16, 55–59. [Google Scholar]

- Resquin, F.; Navarro-Cerrillo, R.M.; Carrasco-Letelier, L.; Casnati, C.R. Influence of contrasting stocking densities on the dynamics of above-ground biomass and wood density of Eucalyptus benthamii, Eucalyptus dunnii, and Eucalyptus grandis for bioenergy in Uruguay. For. Ecol. Manag. 2019, 438, 63–74. [Google Scholar] [CrossRef]

- Kalderis, D.; Kotti, M.S.; Mendez, A.; Gascó, G. Characterization of hydrochars produced by hydrothermal carbonization of rice husk. Solid Earth 2014, 5, 477–483. [Google Scholar] [CrossRef] [Green Version]

- Demirbaş, A. Fuel Characteristics of Olive Husk and Walnut, Hazelnut, Sunflower, and Almond Shells. Energy Sources 2002, 24, 215–221. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; Garcia, I.; Peñas, F.J. A novel conical combustor for thermal exploitation of vineyard pruning wastes. Fuel 2013, 110, 178–184. [Google Scholar] [CrossRef]

- Nunes, L.J.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F. Thermochemical Conversion of Olive Oil Industry Waste: Circular Economy through Energy Recovery. Recycling 2020, 5, 12. [Google Scholar] [CrossRef]

- Nunes, L.J.; Godina, R.; Matias, J.C.; Catalão, J. Evaluation of the utilization of woodchips as fuel for industrial boilers. J. Clean. Prod. 2019, 223, 270–277. [Google Scholar] [CrossRef]

- Hasan, M.F.; Shamsuddin, H.S.; Heiree, M.H.M.; Hanaffi, M.F.M.A.; Rahman, M.R.A.; Rahman, M.; Latiff, Z.; Harif, M.H.M. Torrefaction of densified mesocarp fibre and palm kernel shell. Renew. Energy 2018, 122, 419–428. [Google Scholar] [CrossRef]

- Lau, H.S.; Ng, H.K.; Gan, S.; A Jourabchi, S. Torrefaction of oil palm fronds for co-firing in coal power plants. Energy Procedia 2018, 144, 75–81. [Google Scholar] [CrossRef]

- Conag, A.T.; Villahermosa, J.E.R.; Cabatingan, L.K.; Go, A.W. Energy densification of sugarcane bagasse through torrefaction under minimized oxidative atmosphere. J. Environ. Chem. Eng. 2017, 5, 5411–5419. [Google Scholar] [CrossRef]

- Chen, D.; Chen, F.; Cen, K.; Cao, X.; Zhang, J.; Zhou, J. Upgrading rice husk via oxidative torrefaction: Characterization of solid, liquid, gaseous products and a comparison with non-oxidative torrefaction. Fuel 2020, 275, 117936. [Google Scholar] [CrossRef]

- Chiou, B.-S.; Cao, T.; Valenzuela-Medina, D.; Bilbao-Sainz, C.; Avena-Bustillos, R.J.; Milczarek, R.; Du, W.-X.; Glenn, G.M.; Orts, W.J. Torrefaction kinetics of almond and walnut shells. J. Therm. Anal. Calorim. 2017, 131, 3065–3075. [Google Scholar] [CrossRef]

- Margaritis, N.; Grammelis, P.; Karampinis, E.; Kanaveli, I.-P. Impact of Torrefaction on Vine Pruning’s Fuel Characteristics. J. Energy Eng. 2020, 146, 04020006. [Google Scholar] [CrossRef]

- Volpe, R.; Messineo, A.; Millan, M.; Volpe, M.; Kandiyoti, R. Assessment of olive wastes as energy source: Pyrolysis, torrefaction and the key role of H loss in thermal breakdown. Energy 2015, 82, 119–127. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Pode, R. Potential applications of rice husk ash waste from rice husk biomass power plant. Renew. Sustain. Energy Rev. 2016, 53, 1468–1485. [Google Scholar] [CrossRef]

- Prasara-A, J.; Gheewala, S.H. Sustainable utilization of rice husk ash from power plants: A review. J. Clean. Prod. 2017, 167, 1020–1028. [Google Scholar] [CrossRef]

- Raisi, E.M.; Amiri, J.-V.; Davoodi, M.R. Mechanical performance of self-compacting concrete incorporating rice husk ash. Constr. Build. Mater. 2018, 177, 148–157. [Google Scholar] [CrossRef]

- Da Silva, L.R.; de Carvalho Gama, K.N.; Salles, P.V.; Braga, F.C.S. Concrete with rice husk ash and construction and demolition wastes. Res. Soc. Dev. 2019, 8, 2684861. [Google Scholar]

- Dyjakon, A.; Garcia, D. Implementing Agricultural Pruning to Energy in Europe: Technical, Economic and Implementation Potentials. Energies 2019, 12, 1513. [Google Scholar] [CrossRef] [Green Version]

- Boumanchar, I.; Charafeddine, K.; Chhiti, Y.; Alaoui, F.E.M.; Sahibed-Dine, A.; Bentiss, F.; Jama, C.; Bensitel, M. Biomass higher heating value prediction from ultimate analysis using multiple regression and genetic programming. Biomass Convers. Biorefining 2019, 9, 499–509. [Google Scholar] [CrossRef]

- Ren, C.; Guo, D.; Liu, X.; Li, R.; Zhang, Z. Performance of the emerging biochar on the stabilization of potentially toxic metals in smelter- and mining-contaminated soils. Environ. Sci. Pollut. Res. 2020, 1–11. [Google Scholar] [CrossRef]

- Verslype, N.I.; de Souza Caldas, R.M.; Machado, J.; Martins, F.M.G.; Fernandez, H.M.; Rodrigues, J.I. Sustainable agriculture in temporary and permanent crops in Portugal| Agricultura sustentável em culturas temporárias e permanentes em Portugal. Rev. Geama 2016, 2, 211–219. [Google Scholar]

- Pagels, J.; Strand, M.; Rissler, J.; Szpila, A.; Gudmundsson, A.; Bohgard, M.; Lillieblad, L.; Sanati, M.; Swietlicki, E. Characteristics of aerosol particles formed during grate combustion of moist forest residue. J. Aerosol Sci. 2003, 34, 1043–1059. [Google Scholar] [CrossRef] [Green Version]

- Zhao, P.; Shen, Y.; Ge, S.; Chen, Z.; Yoshikawa, K. Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment. Appl. Energy 2014, 131, 345–367. [Google Scholar] [CrossRef] [Green Version]

- Demirbaş, A. Combustion Systems for Biomass Fuel. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 303–312. [Google Scholar] [CrossRef]

- Deboni, T.L.; Simioni, F.J.; Brand, M.A.; Lopes, G.P. Evolution of the quality of forest biomass for energy generation in a cogeneration plant. Renew. Energy 2019, 135, 1291–1302. [Google Scholar] [CrossRef]

- Samadi, S.H.; Ghobadian, B.; Nosrati, M. Prediction and estimation of biomass energy from agricultural residues using air gasification technology in Iran. Renew. Energy 2020, 149, 1077–1091. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Shen, G.; Xue, M.; Wei, S.; Chen, Y.; Zhao, Q.; Li, B.; Wu, H.; Tao, S. Influence of fuel moisture, charge size, feeding rate and air ventilation conditions on the emissions of PM, OC, EC, parent PAHs, and their derivatives from residential wood combustion. J. Environ. Sci. 2013, 25, 1808–1816. [Google Scholar] [CrossRef]

- Tavares, S.R.D.L.; Dos Santos, T.E. Uso De Diferentes Fontes De Biomassa Vegetal Para A Producão De Biocombustíveis Sólidos. HOLOS 2013, 5, 19–27. [Google Scholar] [CrossRef]

- Strzalka, R.; Erhart, T.G.; Eicker, U. Analysis and optimization of a cogeneration system based on biomass combustion. Appl. Therm. Eng. 2013, 50, 1418–1426. [Google Scholar] [CrossRef]

- Bazargan, A.; Gebreegziabher, T.; Hui, C.-W.; McKay, G. The effect of alkali treatment on rice husk moisture content and drying kinetics. Biomass Bioenergy 2014, 70, 468–475. [Google Scholar] [CrossRef]

- Manzone, M.; Gioelli, F.; Balsari, P. Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies 2019, 12, 1044. [Google Scholar] [CrossRef] [Green Version]

- Kalembkiewicz, J.; Chmielarz, U. Ashes from co-combustion of coal and biomass: New industrial wastes. Resour. Conserv. Recycl. 2012, 69, 109–121. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.O.; Catalão, J. Biomass combustion systems: A review on the physical and chemical properties of the ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Van Der Drift, A.; Van Doorn, J.; Vermeulen, J. Ten residual biomass fuels for circulating fluidized-bed gasification. Biomass Bioenergy 2001, 20, 45–56. [Google Scholar] [CrossRef]

- Haykiri-Acma, H.; Yaman, S.; Küçükbayrak, S. Gasification of biomass chars in steam–nitrogen mixture. Energy Convers. Manag. 2006, 47, 1004–1013. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.; Allen, G.C.; Labrincha, J.A.; Ferreira, V. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef] [PubMed]

- Thy, P.; Jenkins, B.; Grundvig, S.; Shiraki, R.; Lesher, C. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, T.; Che, D. Effect of water washing on fuel properties, pyrolysis and combustion characteristics, and ash fusibility of biomass. Fuel Process. Technol. 2013, 106, 712–720. [Google Scholar] [CrossRef]

- Turn, S.Q.; Kinoshita, C.M.; Ishimura, D.M. Removal of inorganic constituents of biomass feedstocks by mechanical dewatering and leaching. Biomass Bioenergy 1997, 12, 241–252. [Google Scholar] [CrossRef]

- Gao, X.; Wu, H. Combustion of Volatiles Producedin Situfrom the Fast Pyrolysis of Woody Biomass: Direct Evidence on Its Substantial Contribution to Submicrometer Particle (PM1) Emission. Energy Fuels 2011, 25, 4172–4181. [Google Scholar] [CrossRef]

- Sun, X.; Shan, R.; Li, X.; Pan, J.; Liu, X.; Deng, R.; Song, J. Characterization of 60 types of Chinese biomass waste and resultant biochars in terms of their candidacy for soil application. GCB Bioenergy 2017, 9, 1423–1435. [Google Scholar] [CrossRef]

- Singh, K.; Zondlo, J. Characterization of Fuel Properties for Coal and Torrefied Biomass Mixtures. J. Energy Inst. 2017, 90, 505–512. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, A.L.; Civitarese, V.; Del Giudice, A.; Suardi, A.; Pari, L. Characterization of Woodchips for Energy from Forestry and Agroforestry Production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- Rosales, E.; Ferreira, L.; Sanromán, M.; Tavares, M.; Pazos, M. Enhanced selective metal adsorption on optimised agroforestry waste mixtures. Bioresour. Technol. 2015, 182, 41–49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Enes, T.; Aranha, J.T.M.; Fonseca, T.F.; Lopes, D.; Alves, A.; Lousada, J.L. Thermal Properties of Residual Agroforestry Biomass of Northern Portugal. Energies 2019, 12, 1418. [Google Scholar] [CrossRef] [Green Version]

- Enes, T.; Aranha, J.T.M.; Fonseca, T.F.; Matos, C.; Barros, A.I.; Lousada, J.L. Residual Agroforestry Biomass—Thermochemical Properties. Forests 2019, 10, 1072. [Google Scholar] [CrossRef] [Green Version]

- Nyakuma, B.B.; Oladokun, O.; Ivase, T.J.; Moveh, S.; Otitolaiye, V.O. Energy Potential of Malaysian Forestry Waste Residues. Pet. Coal 2020, 62, 238–243. [Google Scholar]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A. Trends and Challenges of Brazilian Pellets Industry Originated from Agroforestry. Cerne 2016, 22, 233–240. [Google Scholar] [CrossRef] [Green Version]

- Batidzirai, B.; Mignot, A.; Schakel, W.; Junginger, M.; Faaij, A. Biomass torrefaction technology: Techno-economic status and future prospects. Energy 2013, 62, 196–214. [Google Scholar] [CrossRef]

- Nanou, P.; Carbo, M.C.; Kiel, J.H. Detailed mapping of the mass and energy balance of a continuous biomass torrefaction plant. Biomass Bioenergy 2016, 89, 67–77. [Google Scholar] [CrossRef] [Green Version]

- Viana, H.; Rodrigues, A.; Godina, R.; Matias, J.C.O.; Nunes, L.J. Evaluation of the Physical, Chemical and Thermal Properties of Portuguese Maritime Pine Biomass. Sustainability 2018, 10, 2877. [Google Scholar] [CrossRef] [Green Version]

- Loureiro, L.M.; Nunes, L.J.; Rodrigues, A.M. Woody biomass torrefaction: Fundamentals and potential for Portugal. Silva Lusit. 2017, 25, 35–63. [Google Scholar]

- Nunes, L.J. A Case Study about Biomass Torrefaction on an Industrial Scale: Solutions to Problems Related to Self-Heating, Difficulties in Pelletizing, and Excessive Wear of Production Equipment. Appl. Sci. 2020, 10, 2546. [Google Scholar] [CrossRef] [Green Version]

| Level | Torrefaction Phase | Temperature (°C) | Residence Time (min) |

|---|---|---|---|

| 1 | Heating/Drying | Troom (18 °C) to T1 | Rt1 |

| 2 | Drying/Torrefaction | T1 to T2 | Rt2 |

| 3 | Torrefaction | T2 | Rt3 |

| 4 | Cooling | T2 to 50 °C | Rt4 |

| Temperature (°C) | Residence Time (min) |

|---|---|

| 18–180 | 30 |

| 180–300 | 60 |

| 300 | 90 |

| 300–50 | The time needed to safely collect the material |

| Elements | Rice Husk | Almond Shells | Kiwi Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | |

|---|---|---|---|---|---|---|---|

| C (%) | Dried | 48.60 | 58.40 | 49.40 | 48.30 | 56.20 | 50.20 |

| 300 °C | 52.60 | 79.90 | 75.50 | 73.40 | 81.70 | 80.10 | |

| H (%) | Dried | 4.42 | 5.24 | 5.69 | 5.71 | 6.83 | 5.86 |

| 300 °C | 2.91 | 3.77 | 3.62 | 3.80 | 3.66 | 3.91 | |

| N (%) | Dried | 0.574 | 0.242 | 0.559 | 0.748 | 1.210 | 0.100 |

| 300 °C | 0.833 | 0.470 | 1.600 | 1.320 | 1.560 | 0.227 | |

| O (%) | Dried | 46.41 | 36.12 | 44.35 | 45.24 | 35.76 | 43.84 |

| 300 °C | 43.66 | 15.86 | 19.28 | 21.48 | 13.08 | 15.76 | |

| Properties | Rice Husk | Almond Shells | Kiwi Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | |

|---|---|---|---|---|---|---|---|

| Fixed Carbon (%) | Dried | 17.55 | 20.73 | 19.54 | 20.04 | 18.84 | 17.82 |

| 300 °C | 45.10 | 73.63 | 68.57 | 63.57 | 73.78 | 72.98 | |

| Moisture (%) | Dried | 11.55 | 8.64 | 10.87 | 10.84 | 3.51 | 2.61 |

| 300 °C | 4.37 | 1.26 | 2.98 | 2.68 | 2.26 | 1.87 | |

| Ashes (%) | Dried | 15.86 | 1.60 | 1.32 | 2.89 | 1.31 | 0.27 |

| 300 °C | 33.19 | 4.07 | 5.03 | 7.98 | 4.56 | 0.94 | |

| Volatiles (%) | Dried | 66.59 | 77.67 | 79.14 | 77.06 | 79.85 | 81.91 |

| 300 °C | 21.71 | 22.30 | 26.40 | 28.46 | 21.66 | 26.08 | |

| Properties | Rice Husk | Almond Shells | Kiwi Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | |

|---|---|---|---|---|---|---|---|

| HHV (MJ/kg) | Dried | 17.03 | 22.79 | 19.33 | 18.84 | 23.92 | 19.89 |

| 300 °C | 16.56 | 30.60 | 28.50 | 27.69 | 31.36 | 30.92 | |

| LHV (MJ/kg) | Dried | 15.28 | 20.71 | 17.07 | 16.58 | 21.22 | 17.57 |

| 300 °C | 15.41 | 29.11 | 27.07 | 26.19 | 29.91 | 29.37 | |

| Mass loss (%) | 56.90 | 68.00 | 66.00 | 63.50 | 71.10 | 69.50 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, L.J.R.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F.C. Waste Recovery through Thermochemical Conversion Technologies: A Case Study with Several Portuguese Agroforestry By-Products. Clean Technol. 2020, 2, 377-391. https://doi.org/10.3390/cleantechnol2030023

Nunes LJR, Loureiro LMEF, Sá LCR, Silva HFC. Waste Recovery through Thermochemical Conversion Technologies: A Case Study with Several Portuguese Agroforestry By-Products. Clean Technologies. 2020; 2(3):377-391. https://doi.org/10.3390/cleantechnol2030023

Chicago/Turabian StyleNunes, Leonel J. R., Liliana M. E. F. Loureiro, Letícia C. R. Sá, and Hugo F. C. Silva. 2020. "Waste Recovery through Thermochemical Conversion Technologies: A Case Study with Several Portuguese Agroforestry By-Products" Clean Technologies 2, no. 3: 377-391. https://doi.org/10.3390/cleantechnol2030023

APA StyleNunes, L. J. R., Loureiro, L. M. E. F., Sá, L. C. R., & Silva, H. F. C. (2020). Waste Recovery through Thermochemical Conversion Technologies: A Case Study with Several Portuguese Agroforestry By-Products. Clean Technologies, 2(3), 377-391. https://doi.org/10.3390/cleantechnol2030023