Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms

Abstract

1. Introduction

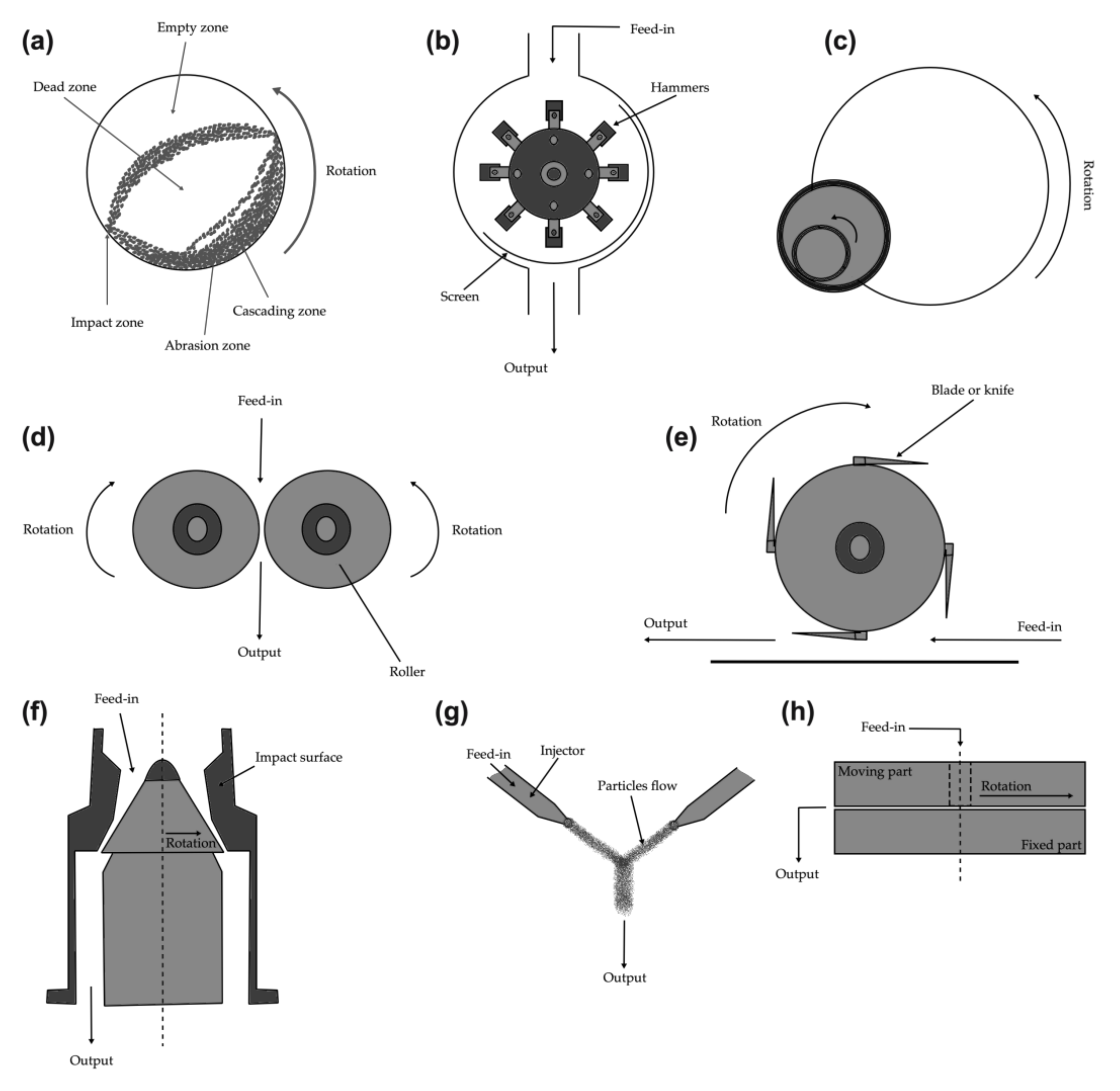

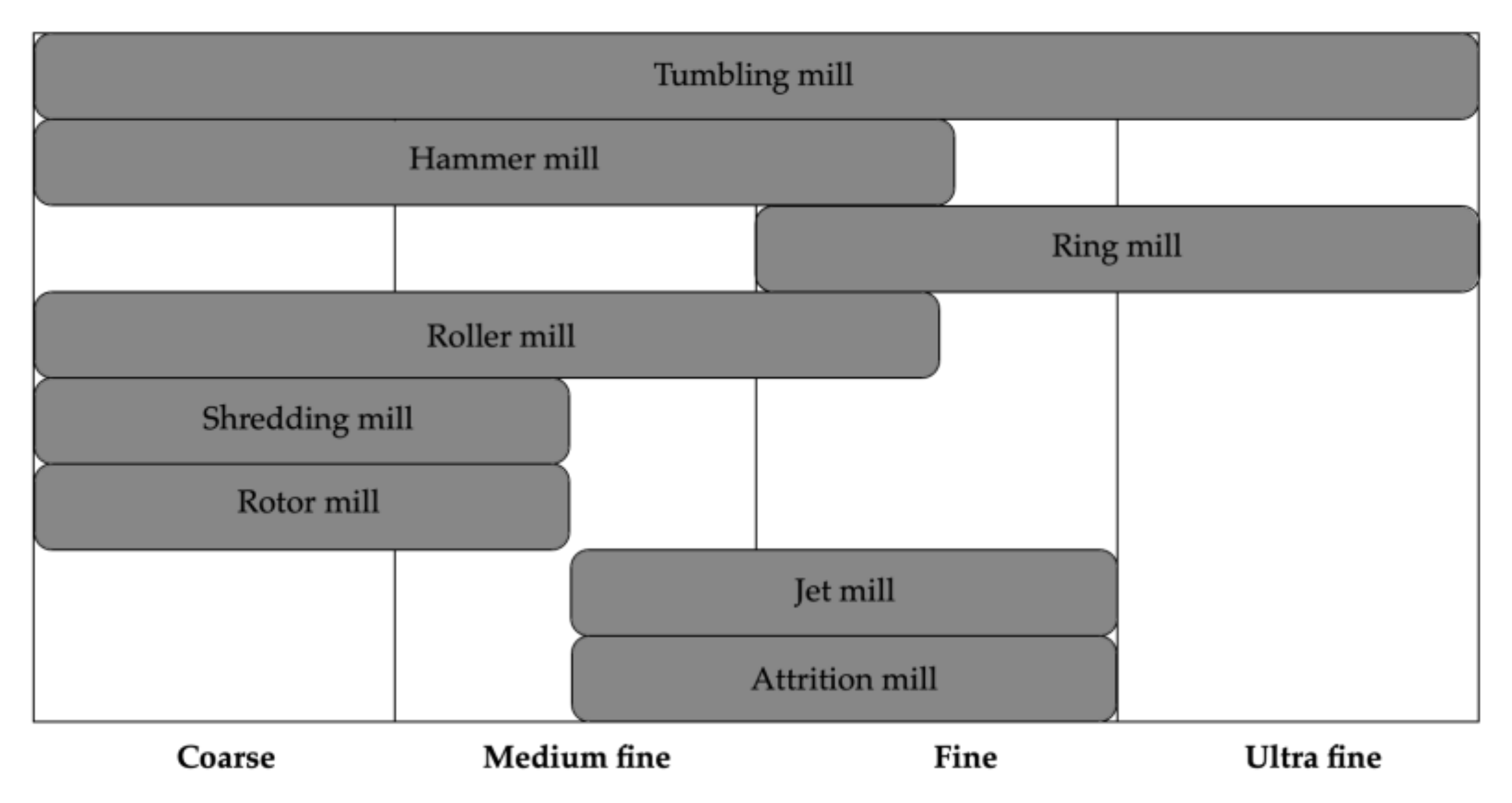

- (a)

- A tumbling mill consists of a rotating deposit, where the loose material inside is set in motion by the rotation of the deposit, causing the collision and breaking of the particles. To facilitate the process, spheres or other similar shapes made up of harder materials are often added to the material to be ground;

- (b)

- Hammer and impact mills use hydraulic steel pistons (or suspended arms) which repeatedly hit the particles to be ground, breaking them until they reach the desired dimension. Normally, sizes are selected by using a graduated sieve or mesh, which the particles pass through when they reach the desired dimension;

- (c)

- Ring or disc mills consist of a rotating ring or disc, using the inner and outer surfaces of the rotating ring or disc to grind the material when it comes into contact with the moving surface. The degree of abrasiveness of the surface of the disk or ring, as well as the speed of rotation, determine the degree of grinding of the material;

- (d)

- High Pressure Grinding Rollers (HPGR), or roller mills, are equipment that pulverize material as it passes between two rollers or between a roll and a flat surface. The rollers may have different types of surfaces, commonly being serrated, toothed, or smooth;

- (e)

- Blade (or knife) granulators and shredders are equipment that use several equally spaced blades to crush the material. These blades (or knives) can be arranged horizontally or vertically;

- (f)

- Central rotor (or universal) mills are equipment in which an impact surface placed on a central axis rotates at high speed, breaking the falling material and projecting it against the mill walls, further increasing the grinding efficiency; that is, grinding is carried out through a combination of the high speed of rotation of the rotor and the action of the generated centrifugal force, which projects the particles;

- (g)

- Jet (or flow) mills are equipment that project a flow of particles against another flow, which is projected in the opposite direction to the first, or against a stationary surface; and

- (h)

- Friction mills (or millstones) are equipment where a stone (or metallic part) rotates on another stone (or metallic part), which is stationary and of similar hardness, grinding material which is introduced through a central hole.

- (a)

- Desired output—with this parameter, it is possible to determine the dimension of the equipment based on the quantity to be processed;

- (b)

- Type of material, particle size when entering the mill, particle shape, presentation mode (e.g., if it comes loose or with some type of baling), and the hardness of the material (or, even better, its ability to resist grinding or grindability); and

- (c)

- Particle size of the output.

2. Materials and Methods

2.1. Samples Collection and Preparation

2.1.1. Torrefaction of the Samples

2.1.2. Ultimate Analysis

2.1.3. Proximate Analysis

2.1.4. Determination of Heating Value

2.2. Grindability Indices

3. Results

3.1. Elemental Analysis

3.2. Thermogravimetric Analysis

3.3. Heating Value

3.4. Grindability Indices

4. Discussion

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Bunn, D.W.; Redondo-Martin, J.; Muñoz-Hernandez, J.I.; Diaz-Cachinero, P. Analysis of coal conversion to biomass as a transitional technology. Renew. Eng. 2019, 132, 752–760. [Google Scholar] [CrossRef]

- Proskurina, S.; Heinimö, J.; Schipfer, F.; Vakkilainen, E. Biomass for industrial applications: The role of torrefaction. Renew. Eng. 2017, 111, 265–274. [Google Scholar] [CrossRef]

- Roni, M.S.; Chowdhury, S.; Mamun, S.; Marufuzzaman, M.; Lein, W.; Johnson, S. Biomass co-firing technology with policies, challenges, and opportunities: A global review. Renew. Sustain. Eng. Rev. 2017, 78, 1089–1101. [Google Scholar] [CrossRef]

- Stirling, R.J.; Snape, C.E.; Meredith, W. The impact of hydrothermal carbonisation on the char reactivity of biomass. Fuel Proc. Technol. 2018, 177, 152–158. [Google Scholar] [CrossRef]

- Melikoglu, M. Vision 2023: Status quo and future of biomass and coal for sustainable energy generation in Turkey. Renew. Sustain. Eng. Rev. 2017, 74, 800–808. [Google Scholar] [CrossRef]

- Gowrisankaran, G.; Reynolds, S.S.; Samano, M. Intermittency and the value of renewable energy. J. Political Econ. 2016, 124, 1187–1234. [Google Scholar] [CrossRef]

- Aflaki, S.; Netessine, S. Strategic investment in renewable energy sources: The effect of supply intermittency. Manuf. Serv. Oper. Manag. 2017, 19, 489–507. [Google Scholar] [CrossRef]

- Engeland, K.; Borga, M.; Creutin, J.-D.; François, B.; Ramos, M.-H.; Vidal, J.-P. Space-time variability of climate variables and intermittent renewable electricity production–A review. Renew. Sustain. Eng. Rev. 2017, 79, 600–617. [Google Scholar] [CrossRef]

- Elum, Z.; Modise, D.; Nhamo, G. Climate change mitigation: The potential of agriculture as a renewable energy source in Nigeria. Environ. Sci. Pollut. Res. 2017, 24, 3260–3273. [Google Scholar] [CrossRef] [PubMed]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A. Bioenergy and climate change mitigation: An assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- Niu, Y.; Lv, Y.; Lei, Y.; Liu, S.; Liang, Y.; Wang, D. Biomass torrefaction: Properties, applications, challenges, and economy. Renew. Sustain. Eng. Rev. 2019, 115, 109395. [Google Scholar] [CrossRef]

- Shankar Tumuluru, J.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Eng. Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. Biomass in the generation of electricity in Portugal: A review. Renew. Sustain. Eng. Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.C.; Catalao, J.P. Wood pellets as a sustainable energy alternative in Portugal. Renew. Eng. 2016, 85, 1011–1016. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Meireles, C.I.R.; Pinto Gomes, C.J.; de Almeida Ribeiro, N.M.C. Socioeconomic Aspects of the Forests in Portugal: Recent Evolution and Perspectives of Sustainability of the Resource. Forests 2019, 10, 361. [Google Scholar] [CrossRef]

- Rodrigues, A.; Loureiro, L.; Nunes, L. Torrefaction of woody biomasses from poplar SRC and Portuguese roundwood: Properties of torrefied products. Biomass Bioenergy 2018, 108, 55–65. [Google Scholar] [CrossRef]

- Nunes, L.J.; Raposo, M.A.; Meireles, C.I.; Pinto Gomes, C.J.; Ribeiro, N.; Almeida, M. Control of Invasive Forest Species through the Creation of a Value Chain: Acacia dealbata Biomass Recovery. Environments 2020, 7, 39. [Google Scholar] [CrossRef]

- Batidzirai, B.; Mignot, A.; Schakel, W.; Junginger, H.; Faaij, A. Biomass torrefaction technology: Techno-economic status and future prospects. Energy 2013, 62, 196–214. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. Analysis of the use of biomass as an energy alternative for the Portuguese textile dyeing industry. Energy 2015, 84, 503–508. [Google Scholar] [CrossRef]

- Rodrigues, A.; Nunes, L. Evaluation of ash composition and deposition tendencies of biomasses and torrefied products from woody and shrubby feedstocks: SRC poplar clones and common broom. Fuel 2020, 269, 117454. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. Biomass waste co-firing with coal applied to the Sines Thermal Power Plant in Portugal. Fuel 2014, 132, 153–157. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Vicente, E.D.; Gomes, A.P.; Nunes, M.I.; Alves, C.; Tarelho, L.A. Effect of industrial and domestic ash from biomass combustion, and spent coffee grounds, on soil fertility and plant growth: Experiments at field conditions. Environ. Sci. Pollut. Res. 2017, 24, 15270–15277. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.; Matias, J.C. Biomass Torrefaction as a Key Driver for the Sustainable Development and Decarbonization of Energy Production. Sustainability 2020, 12, 922. [Google Scholar] [CrossRef]

- Moon, C.; Sung, Y.; Ahn, S.; Kim, T.; Choi, G.; Kim, D. Thermochemical and combustion behaviors of coals of different ranks and their blends for pulverized-coal combustion. Appl. Therm. Engineer. 2013, 54, 111–119. [Google Scholar] [CrossRef]

- Geier, M.; Shaddix, C.R.; Davis, K.A.; Shim, H.-S. On the use of single-film models to describe the oxy-fuel combustion of pulverized coal char. Appl. Energy 2012, 93, 675–679. [Google Scholar] [CrossRef]

- Visona, S.; Stanmore, B. Modelling NO formation in a swirling pulverized coal flame. Chem. Eng. Sci. 1998, 53, 2013–2027. [Google Scholar] [CrossRef]

- Wang, L.; Barta-Rajnai, E.; Skreiberg, Ø.; Khalil, R.; Czégény, Z.; Jakab, E.; Barta, Z.; Grønli, M. Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark. Appl. Energy 2018, 227, 137–148. [Google Scholar] [CrossRef]

- Correia, R.; Gonçalves, M.; Nobre, C.; Mendes, B. Impact of torrefaction and low-temperature carbonization on the properties of biomass wastes from Arundo donax L. and Phoenix canariensis. Bioresour. Technol. 2017, 223, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, J.M.C.; Godina, R.; Matias, J.C.d.O.; Nunes, L.J.R. Future perspectives of biomass torrefaction: Review of the current state-of-the-art and research development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef]

- Tchapda, A.H.; Pisupati, S.V. A review of thermal co-conversion of coal and biomass/waste. Energies 2014, 7, 1098–1148. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Zheng, A.; Jiang, L.; Zhao, Z.; Huang, Z.; Zhao, K.; Wei, G.; Wang, X.; He, F.; Li, H. Impact of torrefaction on the chemical structure and catalytic fast pyrolysis behavior of hemicellulose, lignin, and cellulose. Energy Fuels 2015, 29, 8027–8034. [Google Scholar] [CrossRef]

- Thrän, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S. Moving torrefaction towards market introduction–Technical improvements and economic-environmental assessment along the overall torrefaction supply chain through the SECTOR project. Biomass Bioenergy 2016, 89, 184–200. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- Van der Stelt, M.; Gerhauser, H.; Kiel, J.; Ptasinski, K. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Eng. Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Miao, Z.; Grift, T.E.; Hansen, A.C.; Ting, K.C. Energy requirement for comminution of biomass in relation to particle physical properties. Ind. Crops Prod. 2011, 33, 504–513. [Google Scholar] [CrossRef]

- Bitra, V.S.; Womac, A.R.; Chevanan, N.; Miu, P.I.; Igathinathane, C.; Sokhansanj, S.; Smith, D.R. Direct mechanical energy measures of hammer mill comminution of switchgrass, wheat straw, and corn stover and analysis of their particle size distributions. Powder Technol. 2009, 193, 32–45. [Google Scholar] [CrossRef]

- Temmerman, M.; Jensen, P.D.; Hebert, J. Von Rittinger theory adapted to wood chip and pellet milling, in a laboratory scale hammermill. Biomass Bioenergy 2013, 56, 70–81. [Google Scholar] [CrossRef]

- Bitra, V.S.; Womac, A.R.; Igathinathane, C.; Miu, P.I.; Yang, Y.T.; Smith, D.R.; Chevanan, N.; Sokhansanj, S. Direct measures of mechanical energy for knife mill size reduction of switchgrass, wheat straw, and corn stover. Bioresour. Technol. 2009, 100, 6578–6585. [Google Scholar] [CrossRef] [PubMed]

- Schell, D.J.; Harwood, C. Milling of lignocellulosic biomass. Appl. Biochem. Biotechnol. 1994, 45, 159–168. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Ulusoy, U.; Igathinathane, C. Particle size distribution modeling of milled coals by dynamic image analysis and mechanical sieving. Fuel Proc. Technol. 2016, 143, 100–109. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M.; Vieira, J. Relationship between rheological, textural and melting properties of dark chocolate as influenced by particle size distribution and composition. Eur. Food Rese. Technol. 2008, 227, 1215–1223. [Google Scholar] [CrossRef]

- Burmeister, C.F.; Kwade, A. Process engineering with planetary ball mills. Chem. Soc. Rev. 2013, 42, 7660–7667. [Google Scholar] [CrossRef]

- Hanak, D.; Kolios, A.; Biliyok, C.; Manovic, V. Probabilistic performance assessment of a coal-fired power plant. Appl. Energy 2015, 139, 350–364. [Google Scholar] [CrossRef]

- Goodarzi, F. Assessment of elemental content of milled coal, combustion residues, and stack emitted materials: Possible environmental effects for a Canadian pulverized coal-fired power plant. Int. J. Coal Geol. 2006, 65, 17–25. [Google Scholar] [CrossRef]

- Basu, P.; Butler, J.; Leon, M.A. Biomass co-firing options on the emission reduction and electricity generation costs in coal-fired power plants. Renew. Energy 2011, 36, 282–288. [Google Scholar] [CrossRef]

- Odgaard, P.F.; Lin, B.; Jorgensen, S.B. Observer and data-driven-model-based fault detection in power plant coal mills. IEEE Trans. Energy Conver. 2008, 23, 659–668. [Google Scholar] [CrossRef]

- Hussain, T.; Dudziak, T.; Simms, N.; Nicholls, J. Fireside corrosion behavior of HVOF and plasma-sprayed coatings in advanced coal/biomass co-fired power plants. J. Therm. Spray Technol. 2013, 22, 797–807. [Google Scholar] [CrossRef]

- Qi, H.; Guo, Y.; He, Y.; Wang, D. High temperature corrosion in boilers of coal fired power plants. Corros. Sci. Protect. Technol. 2002, 14, 113–116. [Google Scholar]

- Chao, C.Y.; Kwong, P.C.; Wang, J.; Cheung, C.; Kendall, G. Co-firing coal with rice husk and bamboo and the impact on particulate matters and associated polycyclic aromatic hydrocarbon emissions. Bioresour. Technol. 2008, 99, 83–93. [Google Scholar] [CrossRef]

- Starke, M.; Schulpin, H.J.; Haug, M.; Schreiber, M. Measuring coal particles in the pipe. Power Eng. 2007, 111, 44–49. [Google Scholar]

- Joseph, T.J.; Thapa, D.S.; Patel, M. Review on Combustion Optimization Methods in Pulverised Coal Fired Boiler. Int. J. Eng. Dev. Res. 2017, 5, 70–77. [Google Scholar]

- Bose, D.; Chattopadhyay, S.; Bose, G.; Adhikary, D.; Mitra, S. RAM investigation of coal-fired thermal power plants: A case study. Int. J. Ind. Eng. Comput. 2012, 3, 423–434. [Google Scholar]

- Sligar, J. Component wear in vertical spindle mills grinding coal. Int. J. Miner. Proc. 1996, 44, 569–581. [Google Scholar] [CrossRef]

- Spero, C.; Hargreaves, D.; Kirkcaldie, R.; Flitt, H. Review of test methods for abrasive wear in ore grinding. Wear 1991, 146, 389–408. [Google Scholar] [CrossRef]

- Peatfield, D. Coal and coal preparation in South Africa—A 2002 review. J. S. Afr. Inst. Min. Metall. 2003, 103, 355–372. [Google Scholar]

- Callcott, T. Coal grindability–A standardized procedure for the determination of coal grindability and a survey of the grindabilities of British coals. J. Inst. Fuel 1956, 29, 207–217. [Google Scholar]

- Tiryaki, B. Practical assessment of the grindability of coal using its hardness characteristics. Rock Mech. Rock Eng. 2005, 38, 145–151. [Google Scholar]

- Zuo, W.; Zhao, Y.; He, Y.; Shi, F.; Duan, C. Relationship between coal size reduction and energy input in Hardgrove mill. Int. J. Min. Sci. Technol. 2012, 22, 121–124. [Google Scholar] [CrossRef]

- Snyman, C.; Barclay, J. The coalification of South African coal. Int. J. Coal Geol. 1989, 13, 375–390. [Google Scholar] [CrossRef]

- Snyman, C. The role of coal petrography in understanding the properties of South African coal. Int. J. Coal Geol. 1989, 14, 83–101. [Google Scholar] [CrossRef]

- Materazzi, S. Mass Spectrometry Coupled to Thermogravimetry (TG-MS) for Evolved Gas Characterization: A Review. Appl. Spectrosc. Rev. 1998, 33, 189–218. [Google Scholar] [CrossRef]

- Baratieri, M.; Baggio, P.; Fiori, L.; Grigiante, M. Biomass as an energy source: Thermodynamic constraints on the performance of the conversion process. Bioresour. Technol. 2008, 99, 7063–7073. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Yin, C.-Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef]

- Annamalai, K.; Sweeten, J.; Ramalingam, S. Technical Notes: Estimation of gross heating values of biomass fuels. Trans. ASAE 1987, 30, 1205–1208. [Google Scholar] [CrossRef]

- Channiwala, S.; Parikh, P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Kieseler, S.; Neubauer, Y.; Zobel, N. Ultimate and proximate correlations for estimating the higher heating value of hydrothermal solids. Energy Fuels 2013, 27, 908–918. [Google Scholar] [CrossRef]

- Selvig, W.; Gibson, F. Chemistry of Coal Utilization; John Wiley: New York, NY, USA, 1945; Volume 132, p. 170. [Google Scholar]

- Nhuchhen, D.R.; Afzal, M.T. HHV predicting correlations for torrefied biomass using proximate and ultimate analyses. Bioengineering 2017, 4, 7. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.; Ghosal, G. A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 2005, 84, 487–494. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J. Torrefaction of wood: Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Sengupta, A.N. An assessment of grindability index of coal. Fuel Proc. Technol. 2002, 76, 1–10. [Google Scholar] [CrossRef]

- Mathews, J.P.; Krishnamoorthy, V.; Louw, E.; Tchapda, A.H.; Castro-Marcano, F.; Karri, V.; Alexis, D.A.; Mitchell, G.D. A review of the correlations of coal properties with elemental composition. Fuel Proc. Technol. 2014, 121, 104–113. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, A.L.; Civitarese, V.; Giudice, A.D.; Suardi, A.; Pari, L. Characterization of woodchips for energy from forestry and agroforestry production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- Rosales, E.; Ferreira, L.; Sanromán, M.Á.; Tavares, T.; Pazos, M. Enhanced selective metal adsorption on optimised agroforestry waste mixtures. Bioresour. Technol. 2015, 182, 41–49. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Lopes, D.; Alves, A.; Lousada, J. Thermal Properties of Residual Agroforestry Biomass of Northern Portugal. Energies 2019, 12, 1418. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Matos, C.; Barros, A.; Lousada, J. Residual Agroforestry Biomass–Thermochemical Properties. Forests 2019, 10, 1072. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Oladokun, O.; Ivase, T.J.; Moveh, S.; Otitolaiye, V.O. Energy Potential of Malaysian Forestry Waste Residues. Pet. Coal 2020, 62.1, 238–243. [Google Scholar]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A. Trends and challenges of Brazilian pellets industry originated from agroforestry. Cerne 2016, 22, 233–240. [Google Scholar] [CrossRef]

- dos Santos, R.C.; Carneiro, A.d.C.O.; Vital, B.R.; Castro, R.V.O.; Vidaurre, G.B.; Trugilho, P.F.; Castro, A.F.N.M. Effect of properties chemical and siringil/guaiacil relation wood clones of eucalyptus in the production of charcoal. Ciênc. Florest. 2016, 26, 657–669. [Google Scholar]

- Sturion, J.; Pereira, J.; Chemin, M. Wood quality of Eucalyptus viminalis for energy purposes as a function of spacing and felling age. Bol. Pesqui. Florest. 1988, 16, 55–59. [Google Scholar]

- Resquin, F.; Navarro-Cerrillo, R.M.; Carrasco-Letelier, L.; Casnati, C.R. Influence of contrasting stocking densities on the dynamics of above-ground biomass and wood density of Eucalyptus benthamii, Eucalyptus dunnii, and Eucalyptus grandis for bioenergy in Uruguay. Forest Ecol. Manag. 2019, 438, 63–74. [Google Scholar] [CrossRef]

- Demirbaş, A. Fuel characteristics of olive husk and walnut, hazelnut, sunflower, and almond shells. Energy Sour. 2002, 24, 215–221. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- San José, M.J.; Alvarez, S.; García, I.; Peñas, F.J. A novel conical combustor for thermal exploitation of vineyard pruning wastes. Fuel 2013, 110, 178–184. [Google Scholar] [CrossRef]

- Nunes, L.J.; Loureiro, L.M.; Sá, L.C.; Silva, H.F. Thermochemical Conversion of Olive Oil Industry Waste: Circular Economy through Energy Recovery. Recycling 2020, 5, 12. [Google Scholar] [CrossRef]

- Nunes, L.J.; Godina, R.; Matias, J.C.; Catalão, J.P. Evaluation of the utilization of woodchips as fuel for industrial boilers. J. Clean. Prod. 2019, 223, 270–277. [Google Scholar] [CrossRef]

- Sá, L.C.; Loureiro, L.M.; Nunes, L.J.; Mendes, A.M. Torrefaction as a pretreatment technology for chlorine elimination from biomass: A case study using Eucalyptus globulus Labill. Resources 2020, 9, 54. [Google Scholar] [CrossRef]

- Faizal, H.M.; Shamsuddin, H.S.; Heiree, M.H.M.; Hanaffi, M.F.M.A.; Rahman, M.R.A.; Rahman, M.M.; Latiff, Z. Torrefaction of densified mesocarp fibre and palm kernel shell. Renew. Eng. 2018, 122, 419–428. [Google Scholar] [CrossRef]

- Lau, H.S.; Ng, H.K.; Gan, S.; Jourabchi, S.A. Torrefaction of oil palm fronds for co-firing in coal power plants. Energy Procedia 2018, 144, 75–81. [Google Scholar] [CrossRef]

- Conag, A.T.; Villahermosa, J.E.R.; Cabatingan, L.K.; Go, A.W. Energy densification of sugarcane bagasse through torrefaction under minimized oxidative atmosphere. J. Environ. Chem. Eng. 2017, 5, 5411–5419. [Google Scholar] [CrossRef]

- Chiou, B.-S.; Cao, T.; Valenzuela-Medina, D.; Bilbao-Sainz, C.; Avena-Bustillos, R.J.; Milczarek, R.R.; Du, W.-X.; Glenn, G.M.; Orts, W.J. Torrefaction kinetics of almond and walnut shells. J. Therm. Anal. Calorim. 2018, 131, 3065–3075. [Google Scholar] [CrossRef]

- Margaritis, N.; Grammelis, P.; Karampinis, E.; Kanaveli, I.-P. Impact of Torrefaction on Vine Pruning’s Fuel Characteristics. J. Energy Eng. 2020, 146, 04020006. [Google Scholar] [CrossRef]

- Volpe, R.; Messineo, A.; Millan, M.; Volpe, M.; Kandiyoti, R. Assessment of olive wastes as energy source: Pyrolysis, torrefaction and the key role of H loss in thermal breakdown. Energy 2015, 82, 119–127. [Google Scholar] [CrossRef]

- Dyjakon, A.; García-Galindo, D. Implementing agricultural pruning to energy in europe: Technical, economic and implementation potentials. Energies 2019, 12, 1513. [Google Scholar] [CrossRef]

- Boumanchar, I.; Charafeddine, K.; Chhiti, Y.; Alaoui, F.E.M.H.; Sahibed-dine, A.; Bentiss, F.; Jama, C.; Bensitel, M. Biomass higher heating value prediction from ultimate analysis using multiple regression and genetic programming. Biomass Convers. Biorefinery 2019, 9, 499–509. [Google Scholar] [CrossRef]

- Ren, C.; Guo, D.; Liu, X.; Li, R.; Zhang, Z. Performance of the emerging biochar on the stabilization of potentially toxic metals in smelter-and mining-contaminated soils. Environ. Sci. Pollut. Res. 2020, 27, 1–11. [Google Scholar] [CrossRef]

- Verslype, N.I.; de Souza Caldas, R.M.; Machado, J.; Martins, F.M.G.; Fernandez, H.M.; Rodrigues, J.I. Sustainable agriculture in temporary and permanent crops in Portugal| Agricultura sustentável em culturas temporárias e permanentes em Portugal. Rev. Geama 2016, 2, 211–219. [Google Scholar]

- Pagels, J.; Strand, M.; Rissler, J.; Szpila, A.; Gudmundsson, A.; Bohgard, M.; Lillieblad, L.; Sanati, M.; Swietlicki, E. Characteristics of aerosol particles formed during grate combustion of moist forest residue. J. Aerosol Sci. 2003, 34, 1043–1059. [Google Scholar] [CrossRef]

- Zhao, P.; Shen, Y.; Ge, S.; Chen, Z.; Yoshikawa, K. Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment. Appl. Energy 2014, 131, 345–367. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion systems for biomass fuel. Energy Sour. Part A 2007, 29, 303–312. [Google Scholar] [CrossRef]

- Deboni, T.L.; Simioni, F.J.; Brand, M.A.; Lopes, G.P. Evolution of the quality of forest biomass for energy generation in a cogeneration plant. Renew. Energy 2019, 135, 1291–1302. [Google Scholar] [CrossRef]

- Samadi, S.H.; Ghobadian, B.; Nosrati, M. Prediction and estimation of biomass energy from agricultural residues using air gasification technology in Iran. Renew. Eng. 2020, 149, 1077–1091. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Shen, G.; Xue, M.; Wei, S.; Chen, Y.; Zhao, Q.; Li, B.; Wu, H.; Tao, S. Influence of fuel moisture, charge size, feeding rate and air ventilation conditions on the emissions of PM, OC, EC, parent PAHs, and their derivatives from residential wood combustion. J. Environ. Sci. 2013, 25, 1808–1816. [Google Scholar] [CrossRef]

- De Lucena Tavares, S.R.; dos Santos, T.E. Uso de diferentes fontes de biomassa vegetal para a produção de biocombustíveis sólidos. Holos 2013, 5, 19–27. [Google Scholar] [CrossRef]

- Strzalka, R.; Erhart, T.G.; Eicker, U. Analysis and optimization of a cogeneration system based on biomass combustion. Appl. Therm. Engineer. 2013, 50, 1418–1426. [Google Scholar] [CrossRef]

- Bazargan, A.; Gebreegziabher, T.; Hui, C.-W.; McKay, G. The effect of alkali treatment on rice husk moisture content and drying kinetics. Biomass Bioenergy 2014, 70, 468–475. [Google Scholar] [CrossRef]

- Manzone, M.; Gioelli, F.; Balsari, P. Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies 2019, 12, 1044. [Google Scholar] [CrossRef]

- Kalembkiewicz, J.; Chmielarz, U. Ashes from co-combustion of coal and biomass: New industrial wastes. Resour. Conserv. Recycl. 2012, 69, 109–121. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. Biomass combustion systems: A review on the physical and chemical properties of the ashes. Renew. Sustain. Eng. Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Van der Drift, A.; Van Doorn, J.; Vermeulen, J.W. Ten residual biomass fuels for circulating fluidized-bed gasification. Biomass Bioenergy 2001, 20, 45–56. [Google Scholar] [CrossRef]

- Haykiri-Acma, H.; Yaman, S.; Kucukbayrak, S. Gasification of biomass chars in steam–nitrogen mixture. Energy Convers. Manag. 2006, 47, 1004–1013. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Thy, P.; Jenkins, B.; Grundvig, S.; Shiraki, R.; Lesher, C. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, T.; Che, D. Effect of water washing on fuel properties, pyrolysis and combustion characteristics, and ash fusibility of biomass. Fuel Proc. Technol. 2013, 106, 712–720. [Google Scholar] [CrossRef]

- Turn, S.Q.; Kinoshita, C.M.; Ishimura, D.M. Removal of inorganic constituents of biomass feedstocks by mechanical dewatering and leaching. Biomass Bioenergy 1997, 12, 241–252. [Google Scholar] [CrossRef]

- Gao, X.; Wu, H. Combustion of volatiles produced in situ from the fast pyrolysis of woody biomass: Direct evidence on its substantial contribution to submicrometer particle (PM1) emission. Energy Fuels 2011, 25, 4172–4181. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef]

- Sun, X.; Shan, R.; Li, X.; Pan, J.; Liu, X.; Deng, R.; Song, J. Characterization of 60 types of Chinese biomass waste and resultant biochars in terms of their candidacy for soil application. Gcb Bioenergy 2017, 9, 1423–1435. [Google Scholar] [CrossRef]

- Singh, K.; Zondlo, J. Characterization of fuel properties for coal and torrefied biomass mixtures. J. Energy Inst. 2017, 90, 505–512. [Google Scholar] [CrossRef]

- Nanou, P.; Carbo, M.C.; Kiel, J.H. Detailed mapping of the mass and energy balance of a continuous biomass torrefaction plant. Biomass Bioenergy 2016, 89, 67–77. [Google Scholar] [CrossRef]

- Dos Santos Viana, H.F.; Martins Rodrigues, A.; Godina, R.; de Oliveira Matias, J.C.; Jorge Ribeiro Nunes, L. Evaluation of the physical, chemical and thermal properties of Portuguese maritime pine biomass. Sustainability 2018, 10, 2877. [Google Scholar] [CrossRef]

- Loureiro, L.M.; Nunes, L.J.; Rodrigues, A.M. Woody biomass torrefaction: Fundamentals and potential for Portugal. Silva Lusit. 2017, 25, 35–63. [Google Scholar]

- Nunes, L.J. A Case Study about Biomass Torrefaction on an Industrial Scale: Solutions to Problems Related to Self-Heating, Difficulties in Pelletizing, and Excessive Wear of Production Equipment. Appl. Sci. 2020, 10, 2546. [Google Scholar] [CrossRef]

| Temperature (°C) | Residence Time (Minutes) |

|---|---|

| 18–180 | 30 |

| 180–300 | 60 |

| 300 | 90 |

| 300–50 | The time required to safely collect the material |

| Elements | Almond Shells | Kiwifruit Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | Eucalyptus Woodchips | |

|---|---|---|---|---|---|---|---|

| C (%) | Dried | 58.40 | 49.40 | 48.30 | 56.20 | 50.20 | 57.44 |

| 300 °C | 79.90 | 75.50 | 73.40 | 81.70 | 80.10 | 63.67 | |

| H (%) | Dried | 5.24 | 5.69 | 5.71 | 6.83 | 5.86 | 5.83 |

| 300 °C | 3.77 | 3.62 | 3.80 | 3.66 | 3.91 | 5.23 | |

| N (%) | Dried | 0.242 | 0.559 | 0.748 | 1.210 | 0.100 | 0.236 |

| 300 °C | 0.470 | 1.600 | 1.320 | 1.560 | 0.227 | 0.174 | |

| O (%) | Dried | 36.12 | 44.35 | 45.24 | 35.76 | 43.84 | 36.49 |

| 300 °C | 15.86 | 19.28 | 21.48 | 13.08 | 15.76 | 30.93 | |

| Properties | Almond Shells | Kiwifruit Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | Eucalyptus Woodchips | |

|---|---|---|---|---|---|---|---|

| Fixed Carbon (%) | Dried | 20.73 | 19.54 | 20.04 | 18.84 | 17.82 | 17.30 |

| 300 °C | 73.63 | 68.57 | 63.57 | 73.78 | 72.98 | 68.67 | |

| Moisture (%) | Dried | 8.64 | 10.87 | 10.84 | 3.51 | 2.61 | 6.98 |

| 300 °C | 1.26 | 2.98 | 2.68 | 2.26 | 1.87 | 2.89 | |

| Ashes (%) | Dried | 1.60 | 1.32 | 2.89 | 1.31 | 0.27 | 0.67 |

| 300 °C | 4.07 | 5.03 | 7.98 | 4.56 | 0.94 | 1.67 | |

| Volatiles (%) | Dried | 77.67 | 79.14 | 77.06 | 79.85 | 81.91 | 82.02 |

| 300 °C | 22.30 | 26.40 | 28.46 | 21.66 | 26.08 | 29.76 | |

| Properties | Almond Shells | Kiwifruit Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | Eucalyptus Woodchips | |

|---|---|---|---|---|---|---|---|

| HHV (MJ/kg) | Dried | 22.79 | 19.33 | 18.84 | 23.92 | 19.89 | 23.13 |

| 300 °C | 30.60 | 28.50 | 27.69 | 31.36 | 30.92 | 25.15 | |

| LHV (MJ/kg) | Dried | 20.71 | 17.07 | 16.58 | 21.22 | 17.57 | 20.82 |

| 300 °C | 29.11 | 27.07 | 26.19 | 29.91 | 29.37 | 23.08 | |

| Mass loss (%) | 68.00 | 66.00 | 63.50 | 71.10 | 69.50 | 70.04 | |

| Properties | Almond Shells | Kiwifruit Pruning | Vine Pruning | Olive Pomace | Pine Woodchips | Eucalyptus Woodchips |

|---|---|---|---|---|---|---|

| SGI | 80–100 | 80–100 | <80 | 80–100 | 80–100 | 80–100 |

| HGI | 30–55 | 30–55 | 30–55 | 30–55 | 30–55 | 30–55 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, L.J.R. Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms. Clean Technol. 2020, 2, 270-289. https://doi.org/10.3390/cleantechnol2030018

Nunes LJR. Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms. Clean Technologies. 2020; 2(3):270-289. https://doi.org/10.3390/cleantechnol2030018

Chicago/Turabian StyleNunes, Leonel J. R. 2020. "Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms" Clean Technologies 2, no. 3: 270-289. https://doi.org/10.3390/cleantechnol2030018

APA StyleNunes, L. J. R. (2020). Torrefied Biomass as an Alternative in Coal-Fueled Power Plants: A Case Study on Grindability of Agroforestry Waste Forms. Clean Technologies, 2(3), 270-289. https://doi.org/10.3390/cleantechnol2030018