Damage Identification in Beams via Contourlet Transform of Shearography Modal Data

Abstract

1. Introduction

2. Materials and Methods

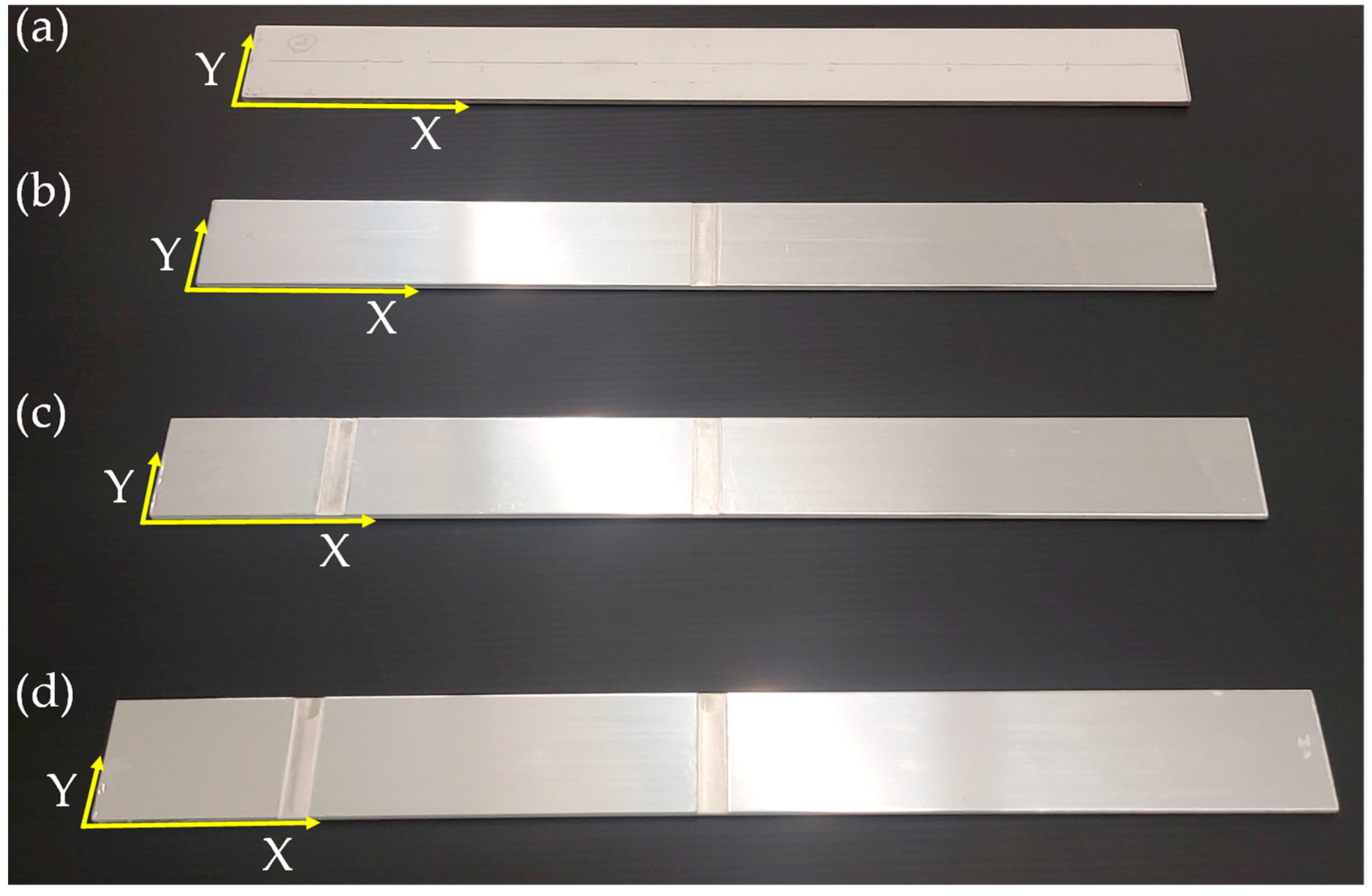

2.1. Tested Aluminum Beams

2.2. Digital Shearography

2.2.1. Introduction

2.2.2. Modal Data

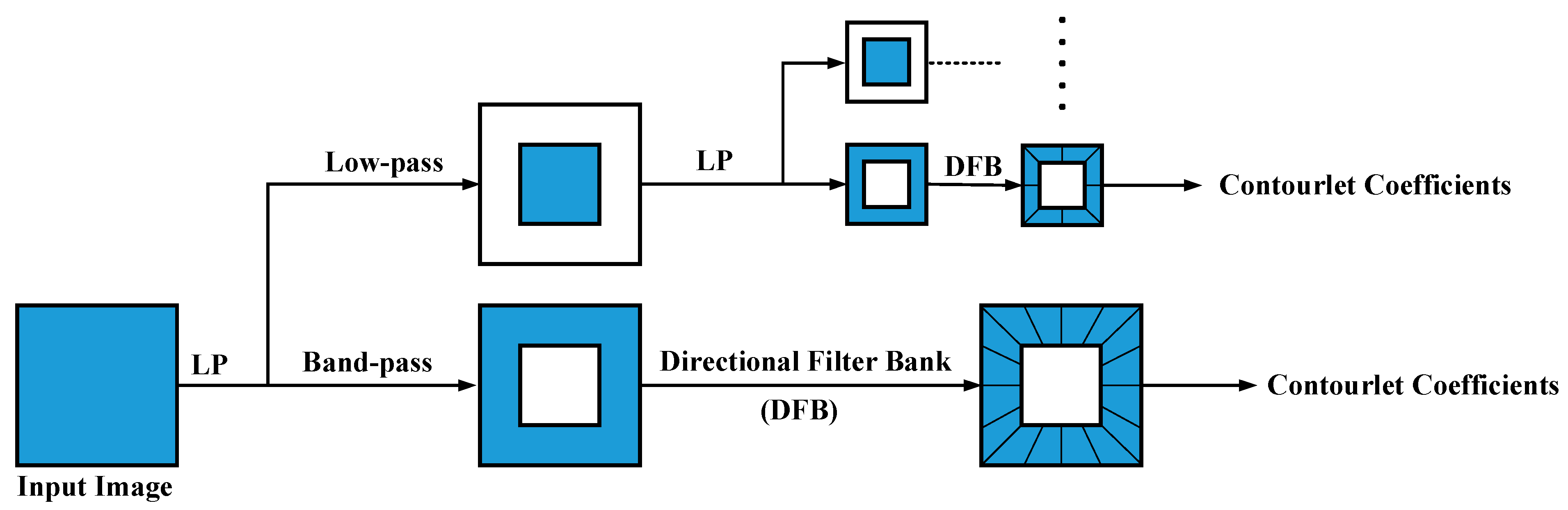

2.3. Contourlet Transform

2.4. Proposed Damage Indices

3. Results and Discussion

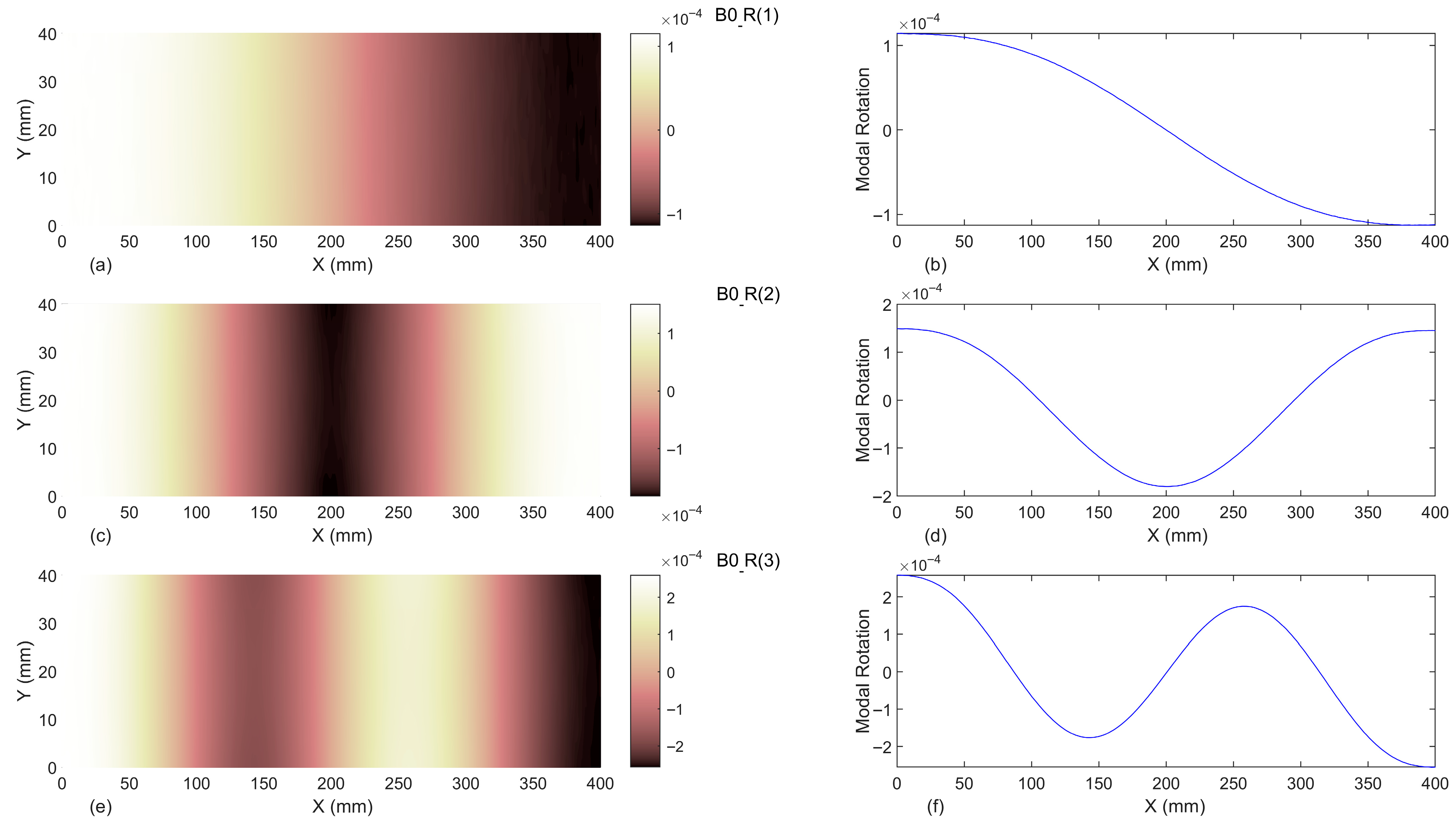

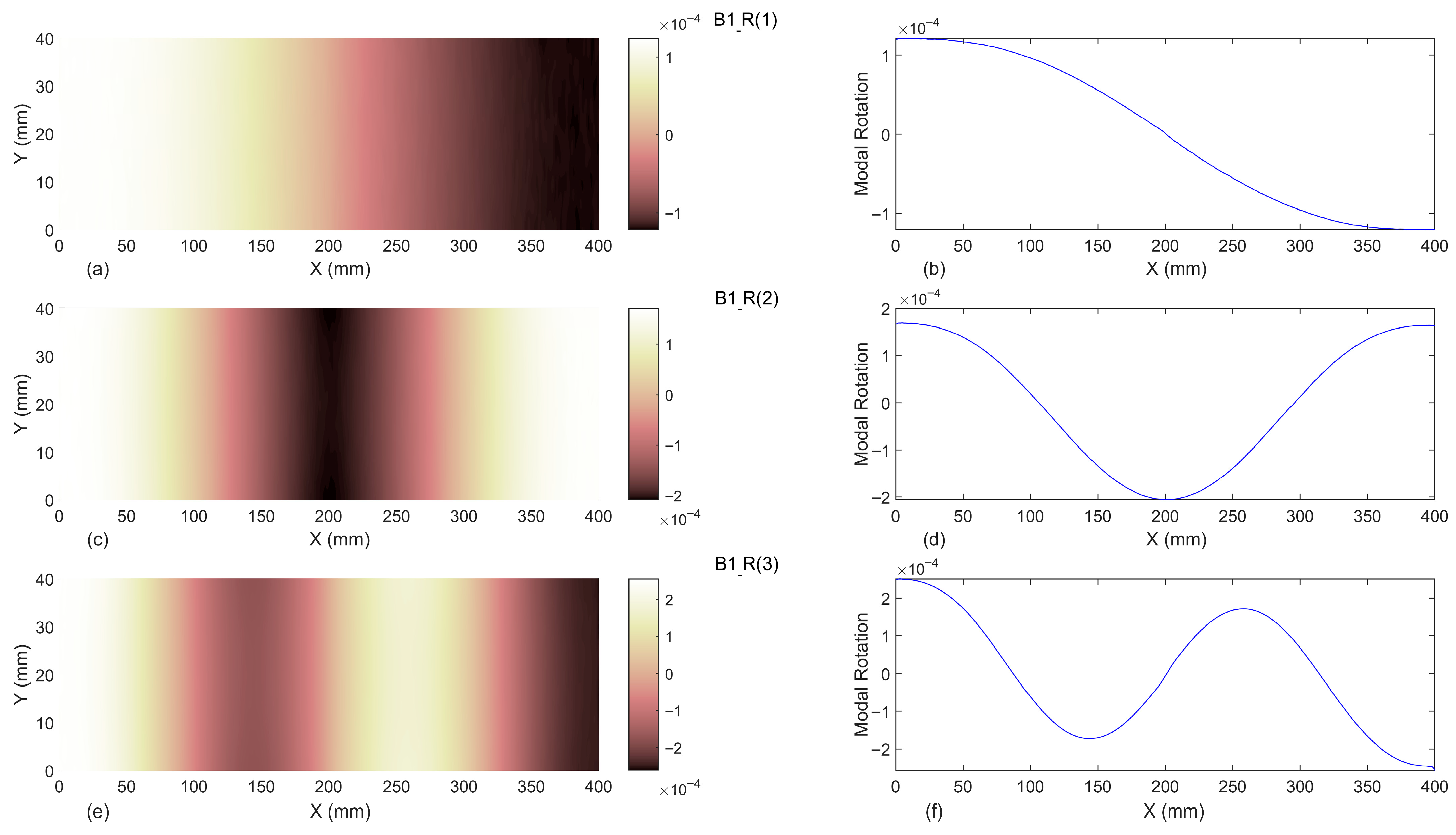

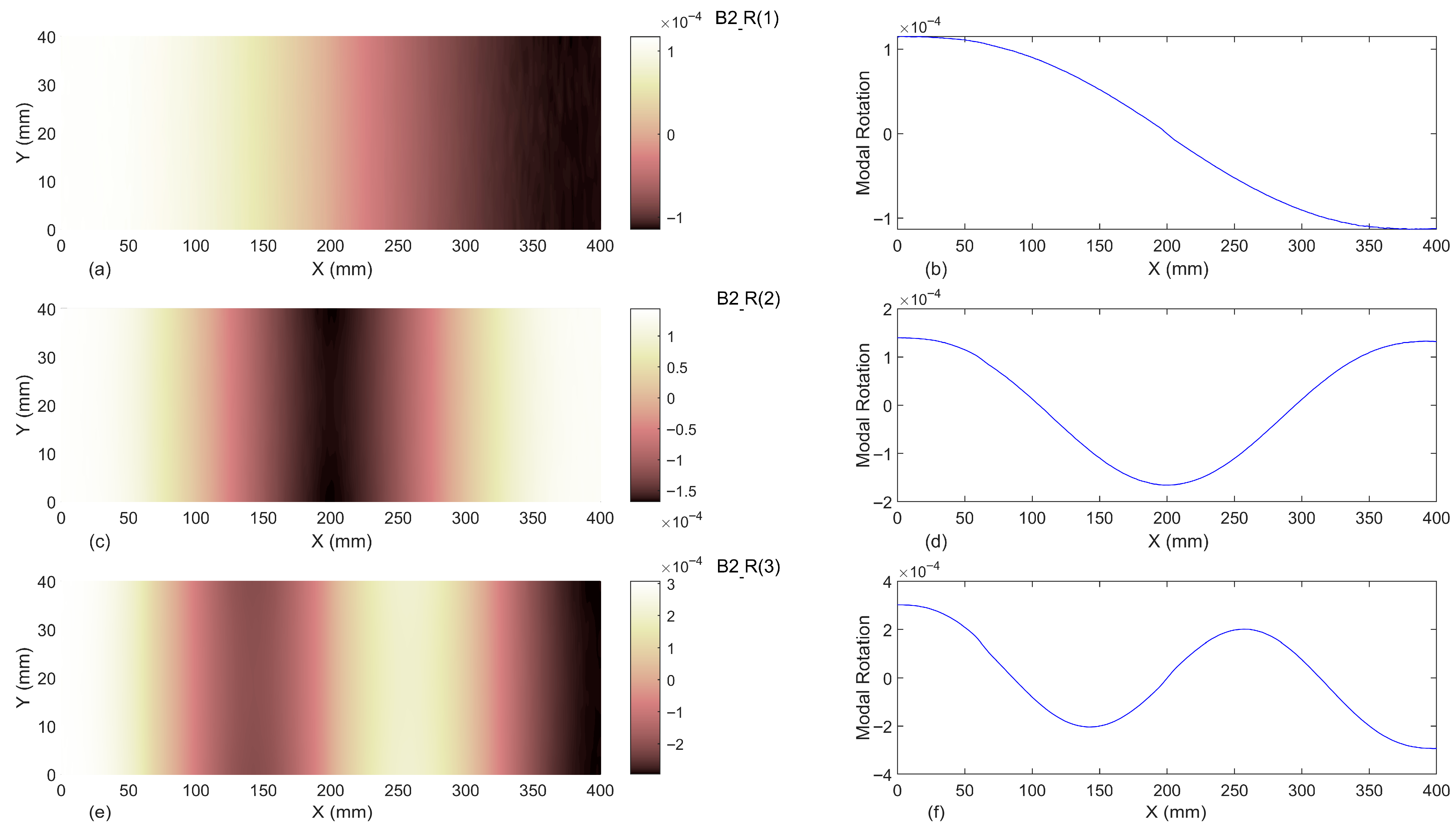

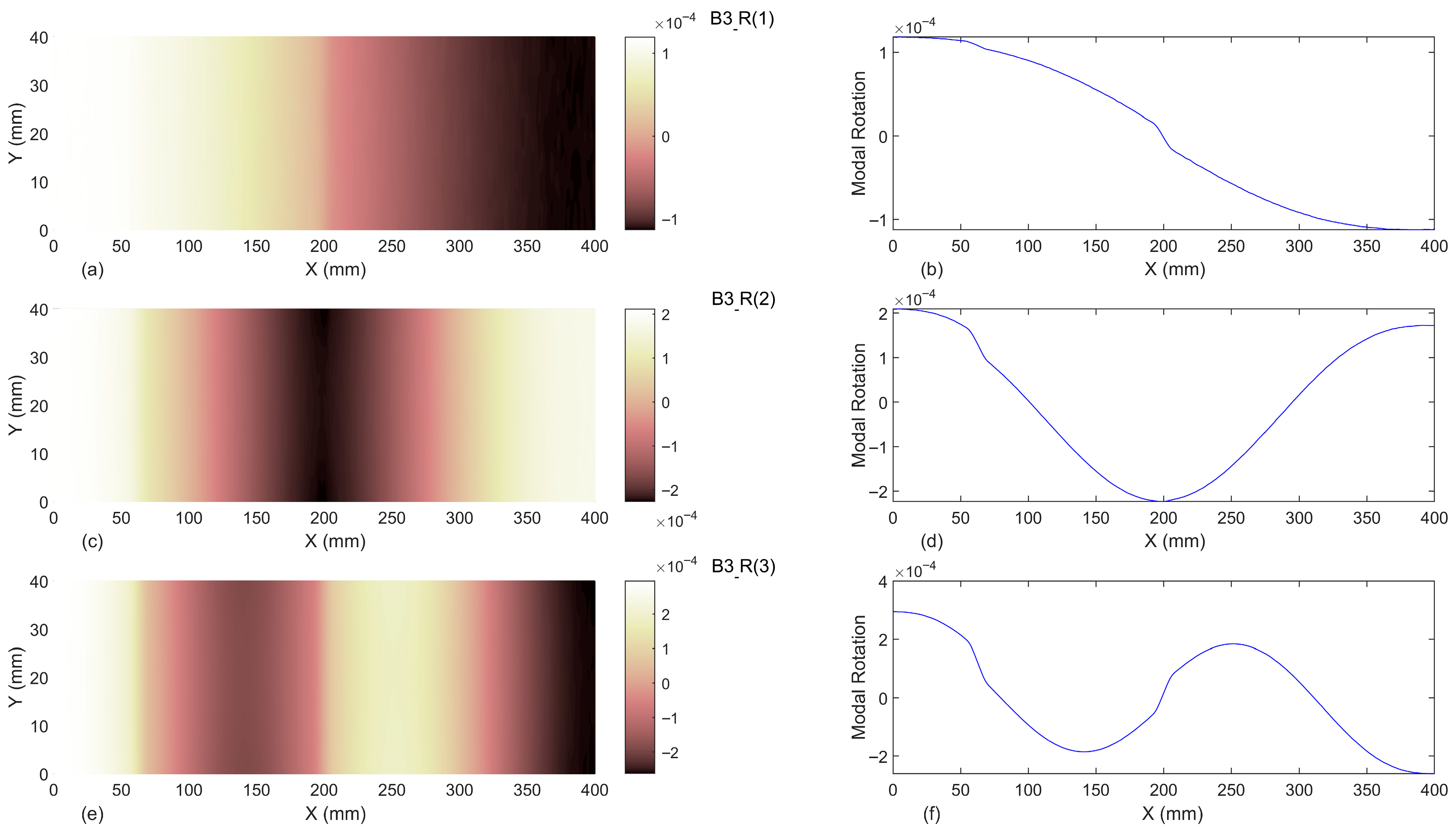

3.1. Modal Rotations

3.1.1. Baseline-Free

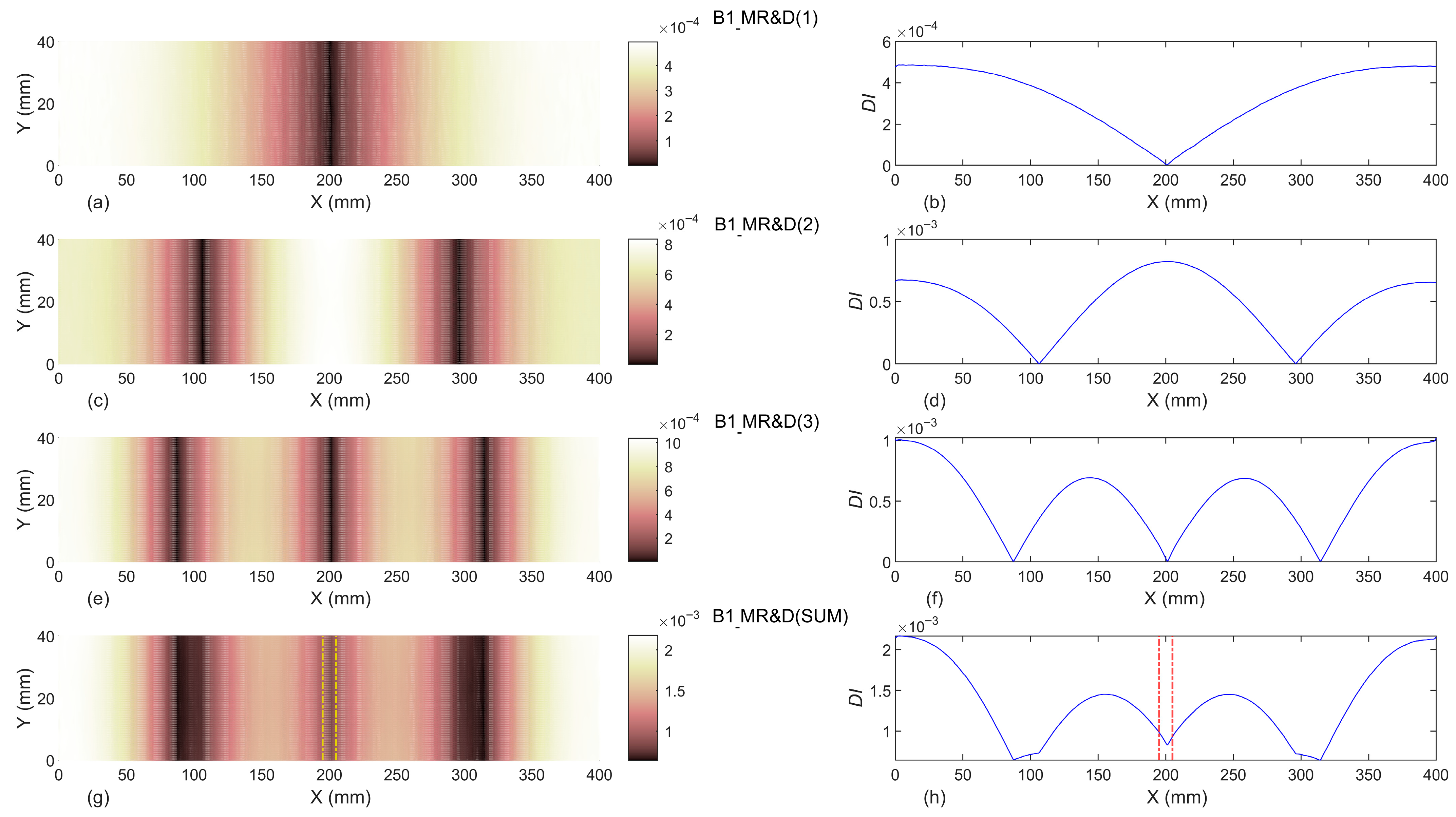

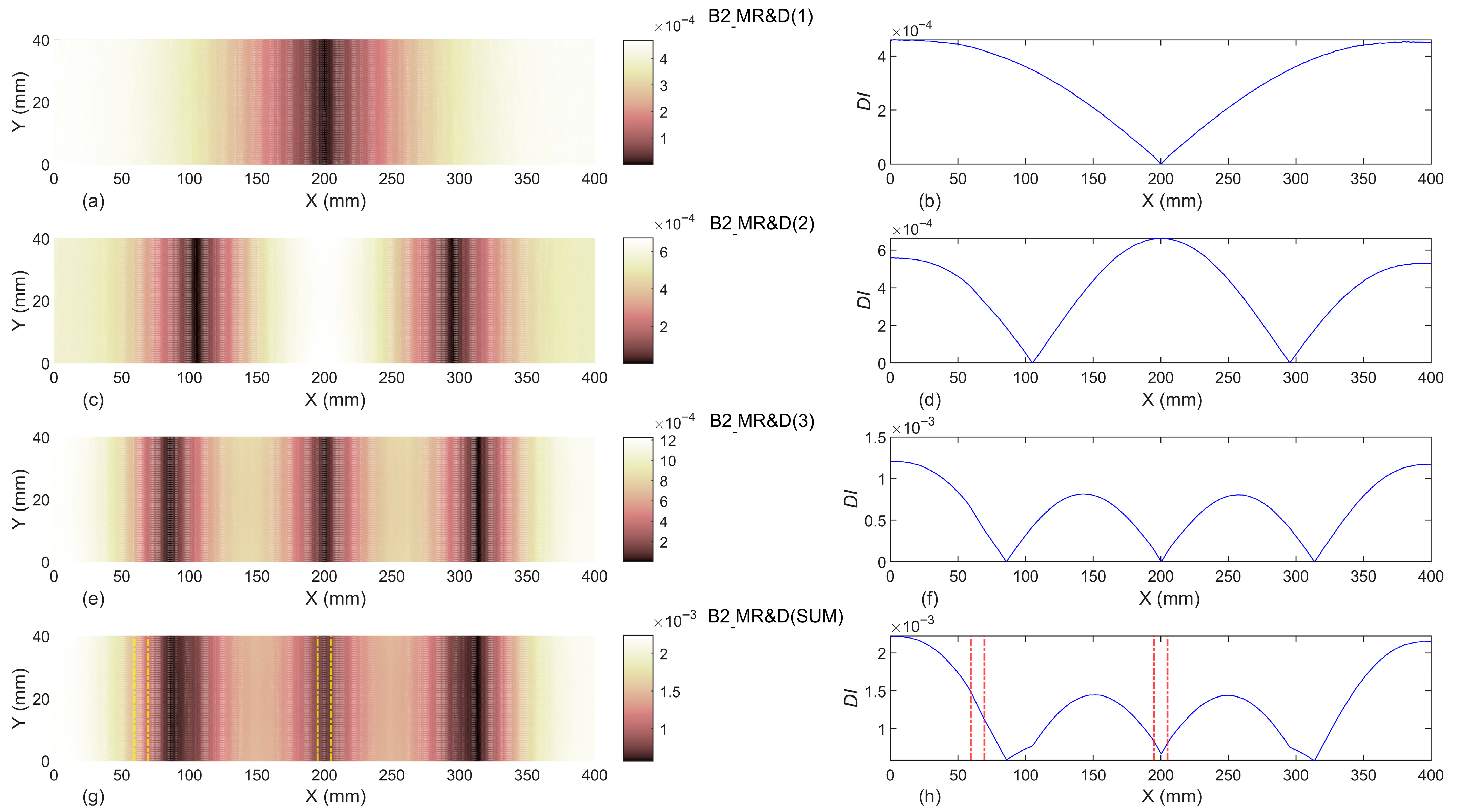

3.1.2. Baseline-Included

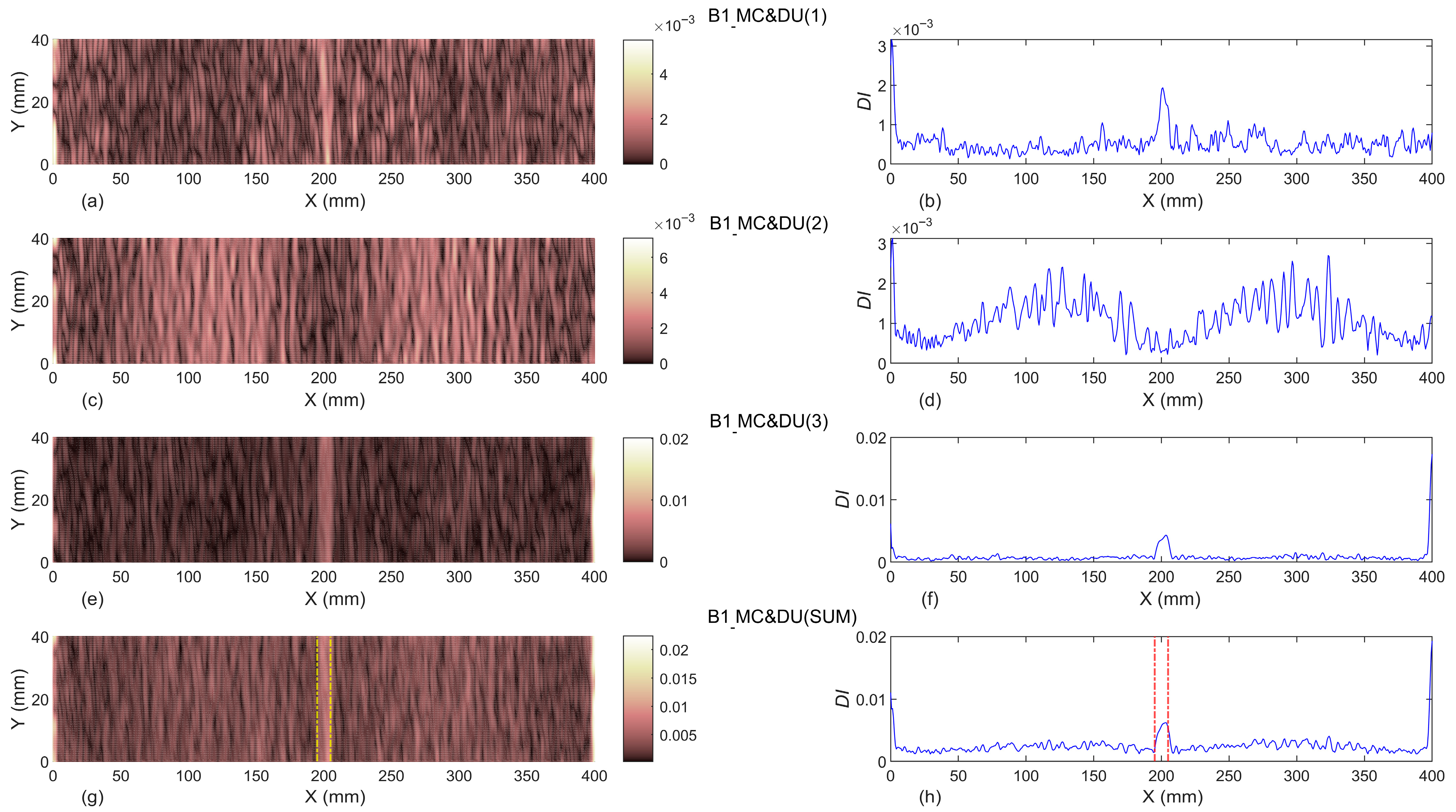

3.2. Modal Curvatures

3.2.1. Baseline-Free

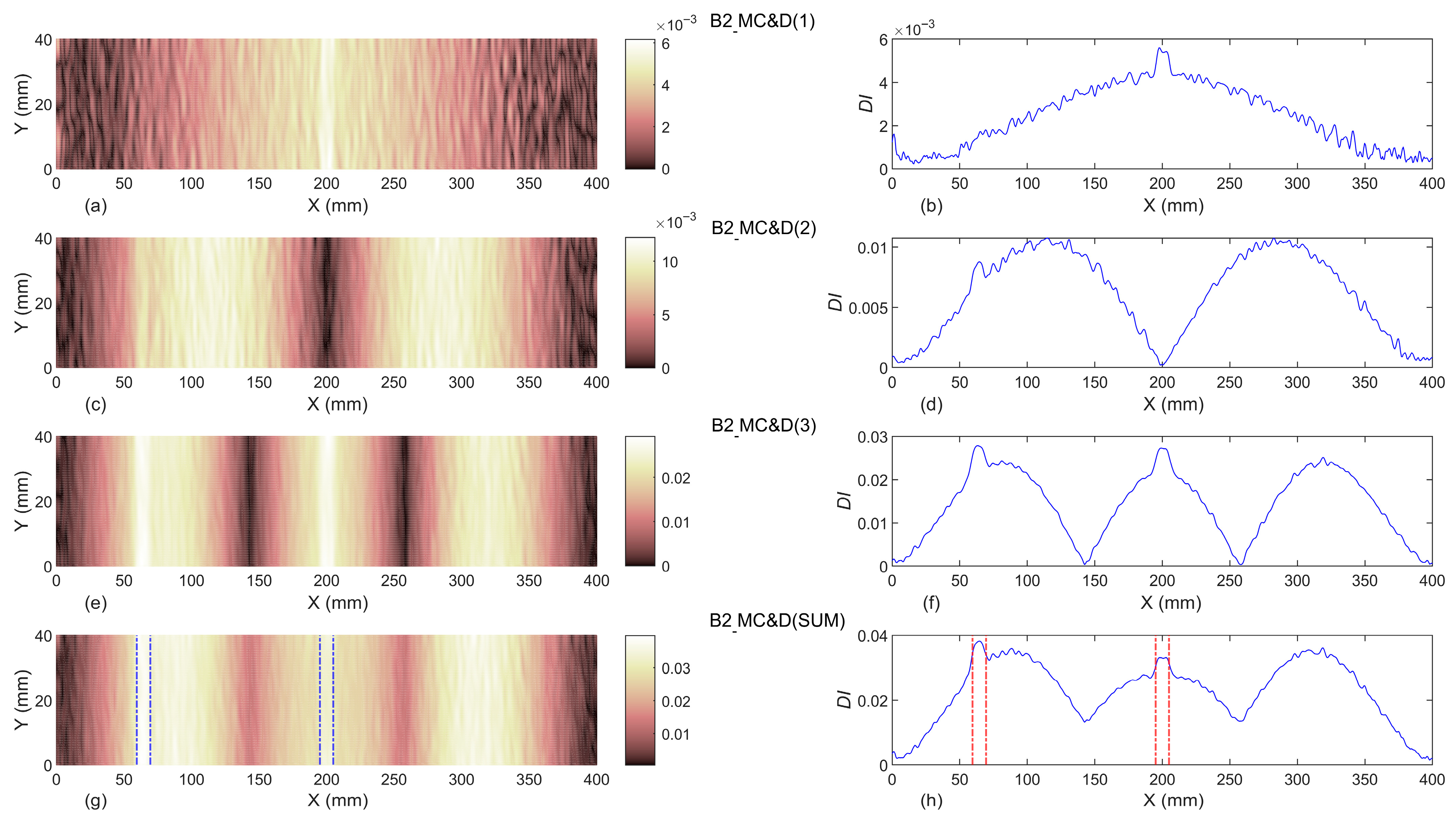

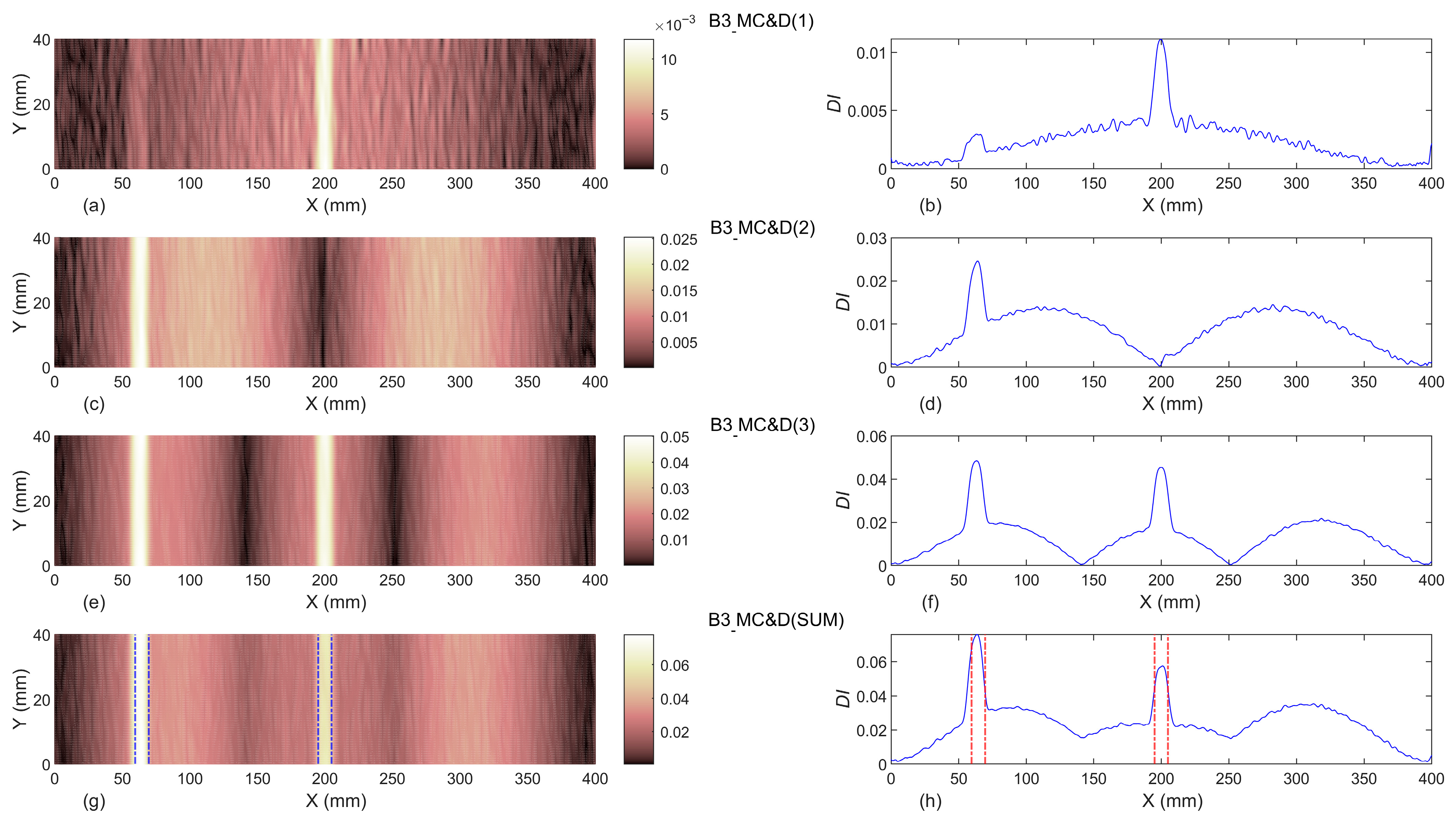

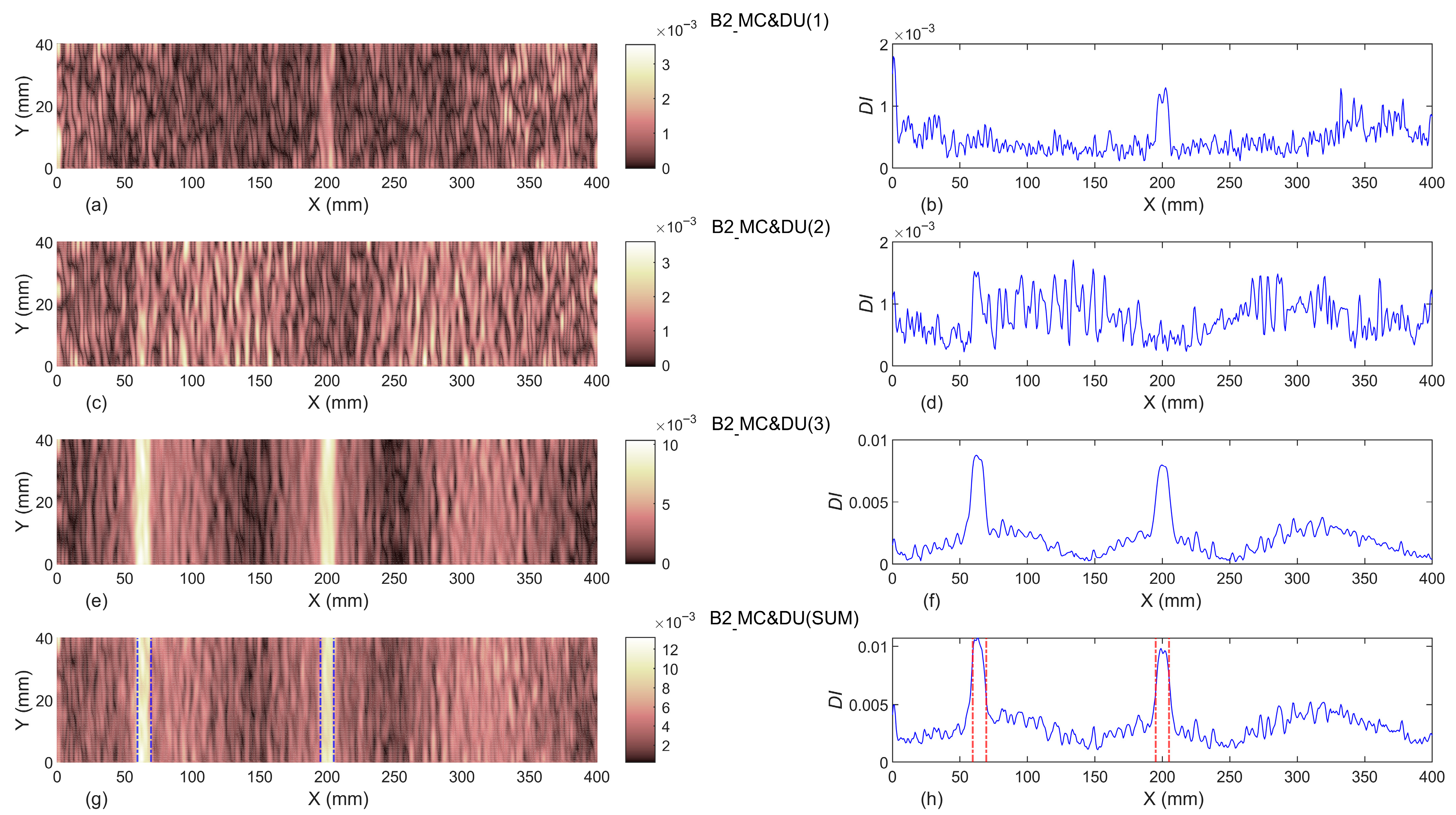

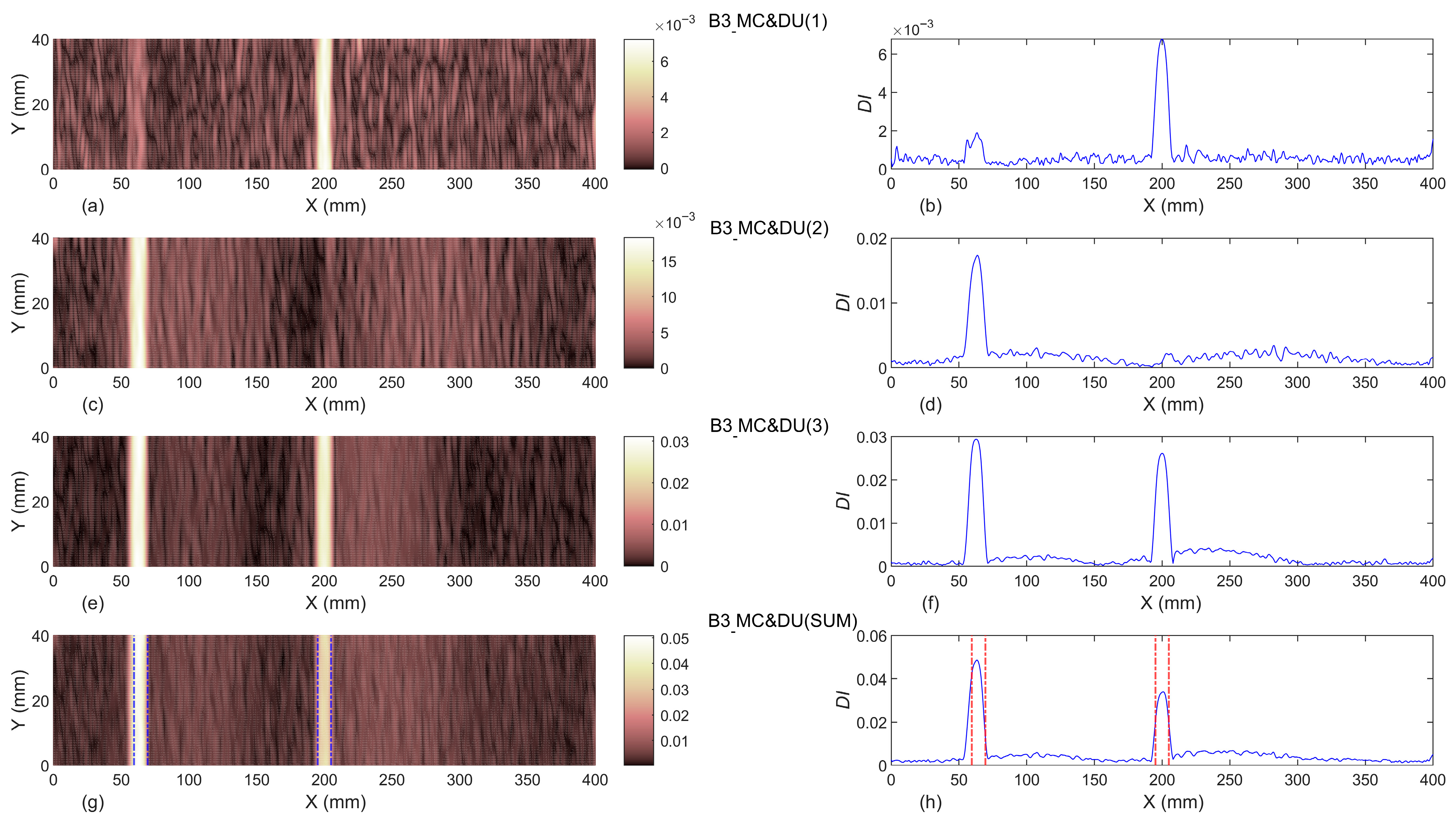

3.2.2. Baseline-Included

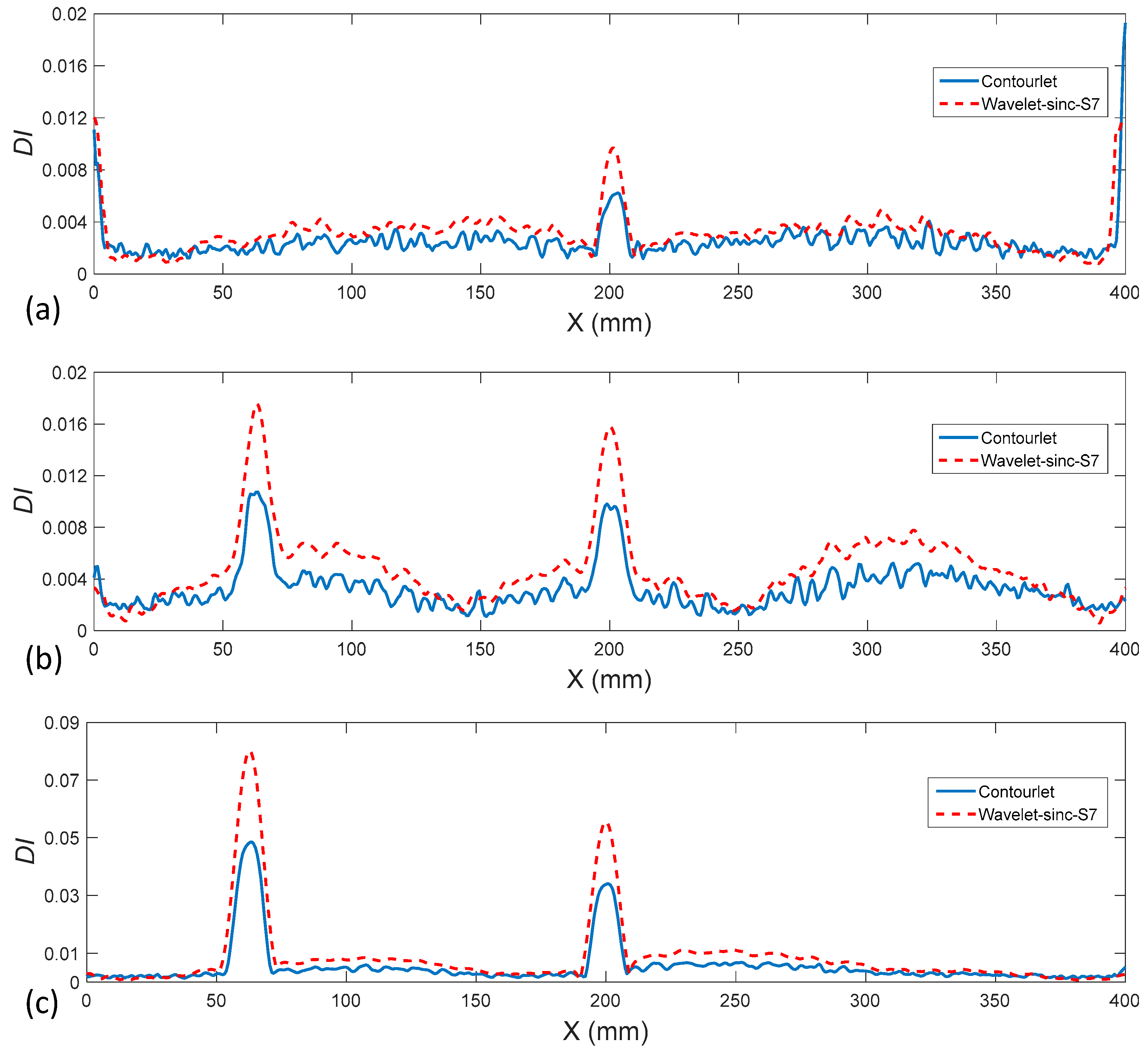

3.3. Contourlet and Wavelet Comparison

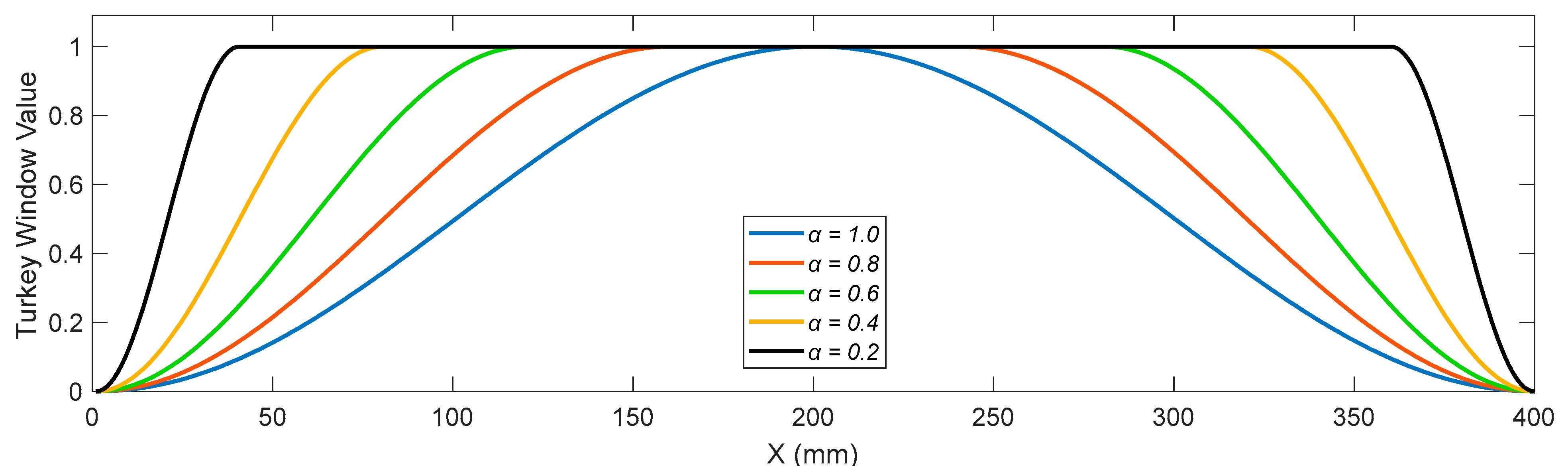

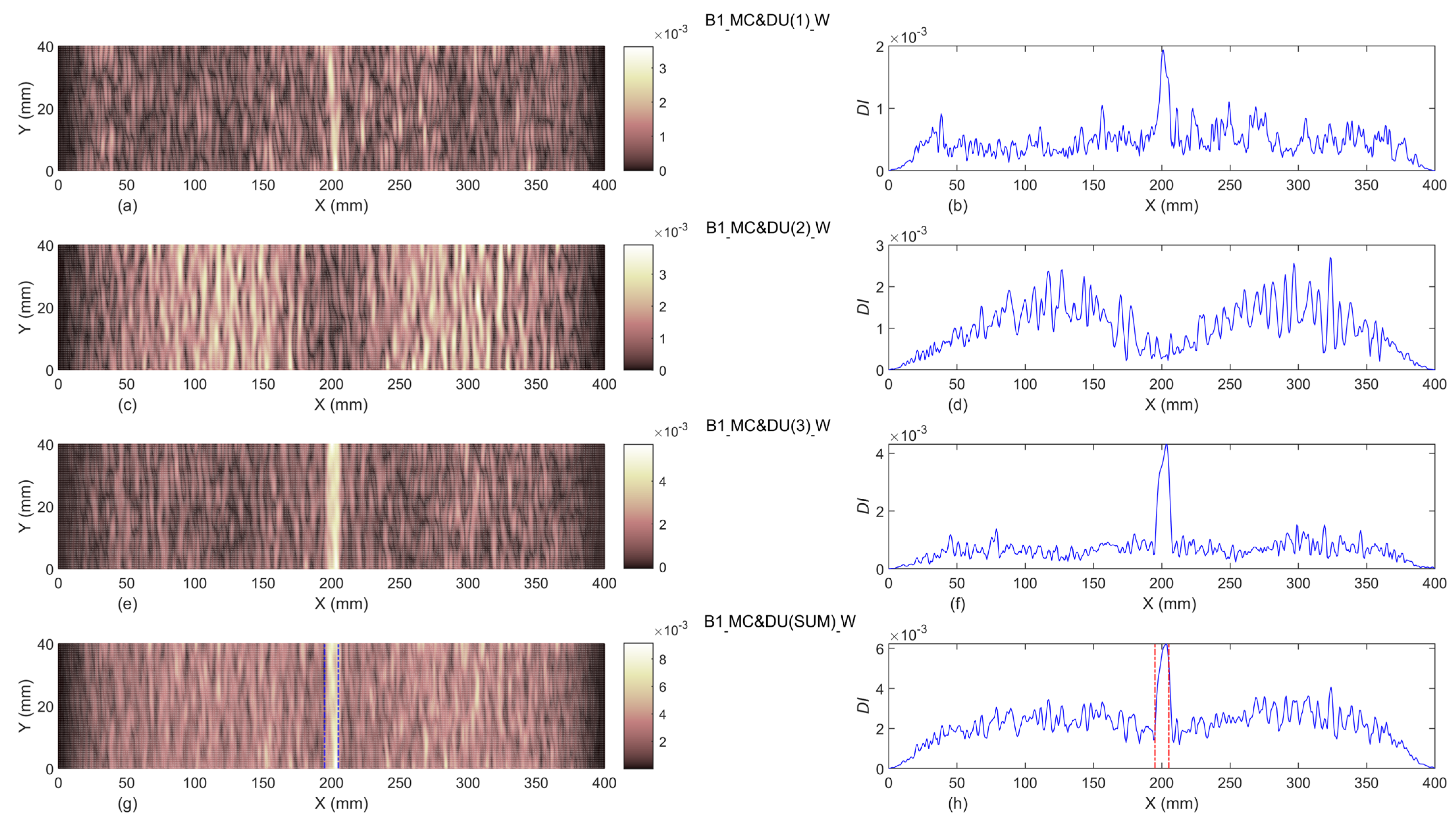

3.4. Windowing Process

3.5. Limitations and Future Work

4. Conclusions

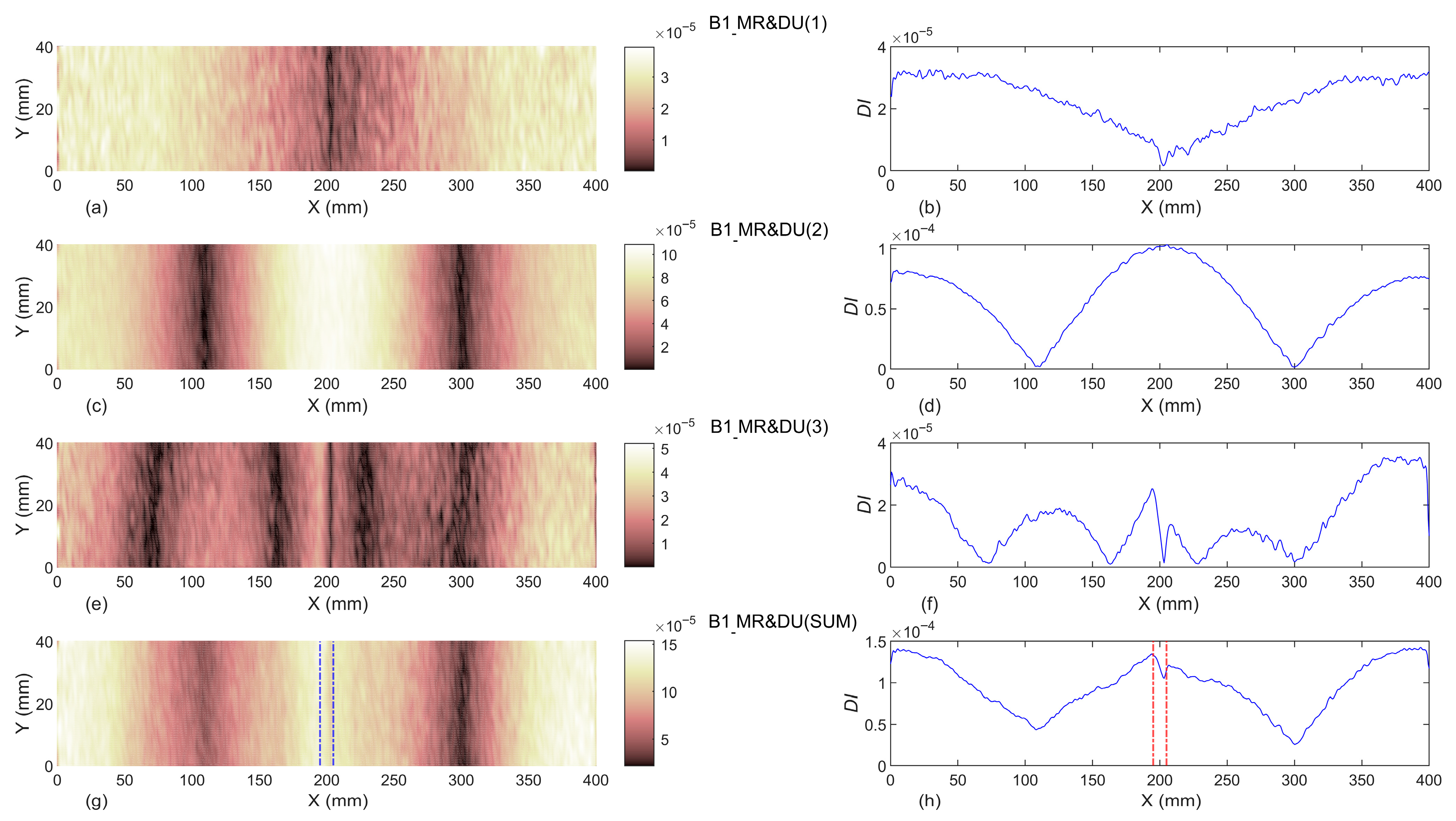

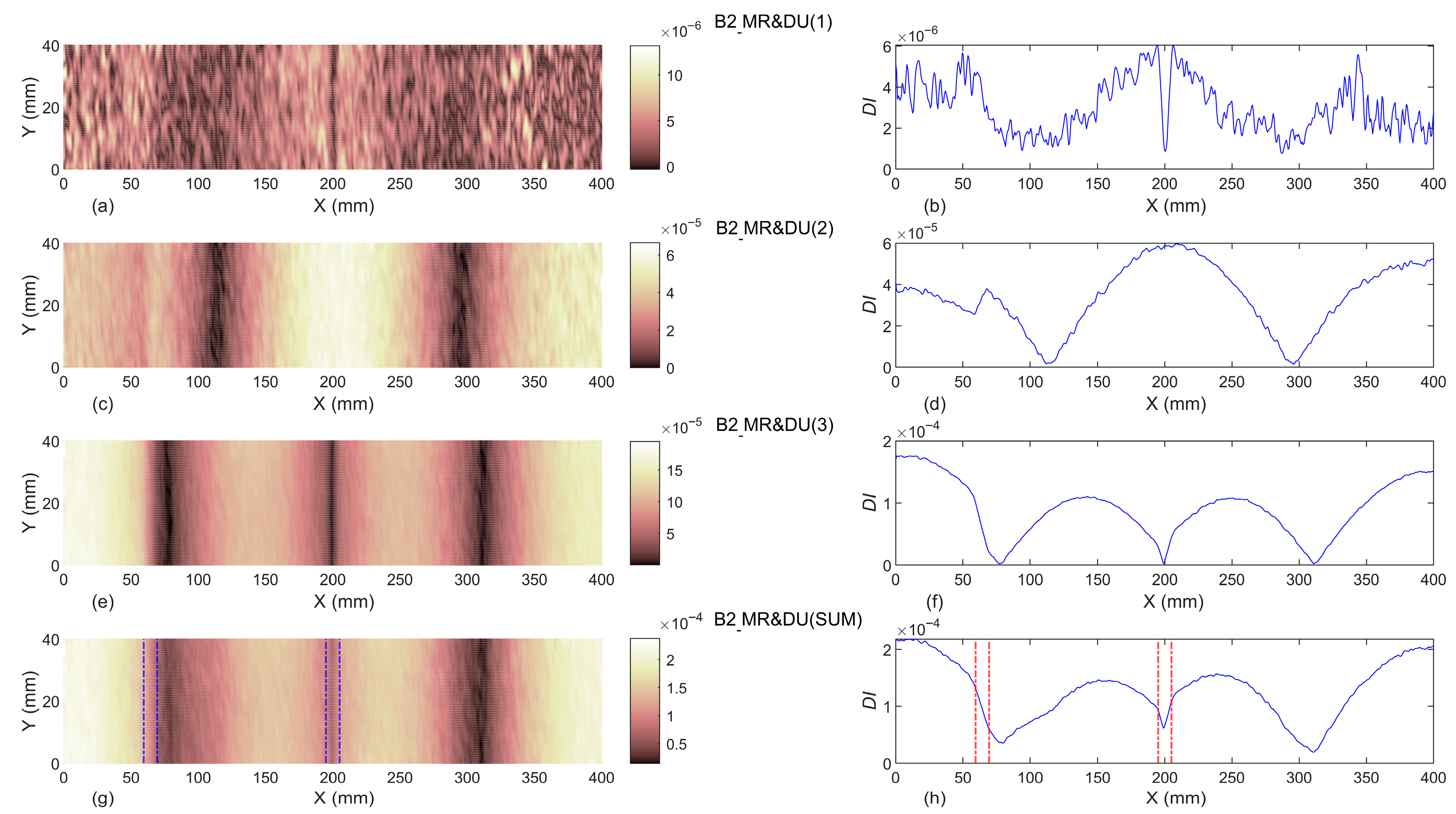

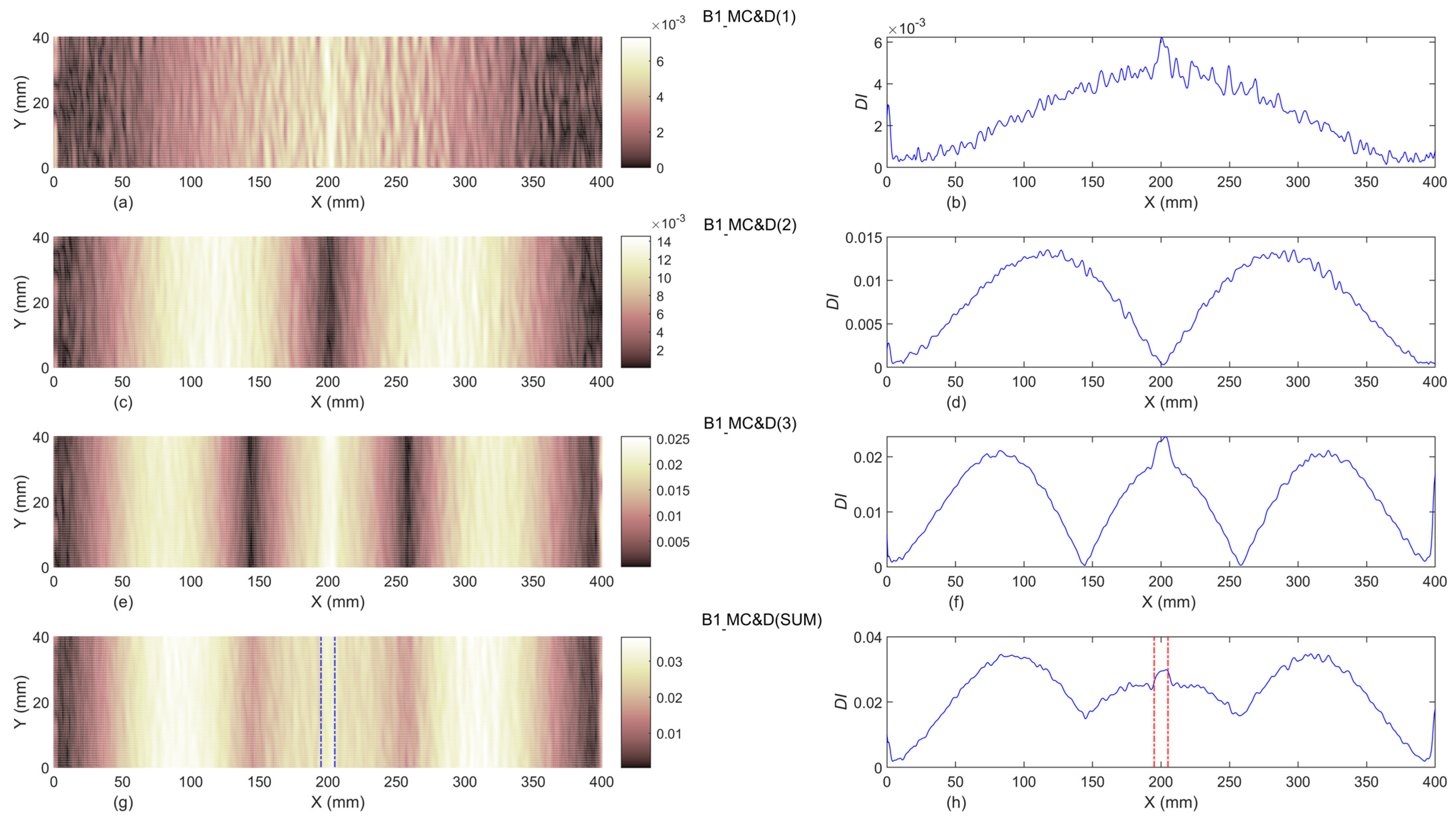

- The results indicated that introducing the first three modal rotations to the proposed damage indices in baseline-free format is not a proper damage identification process. Moreover, even considering the undamaged beam as the baseline, utilizing the first three modal rotations cannot reveal the location of damage.

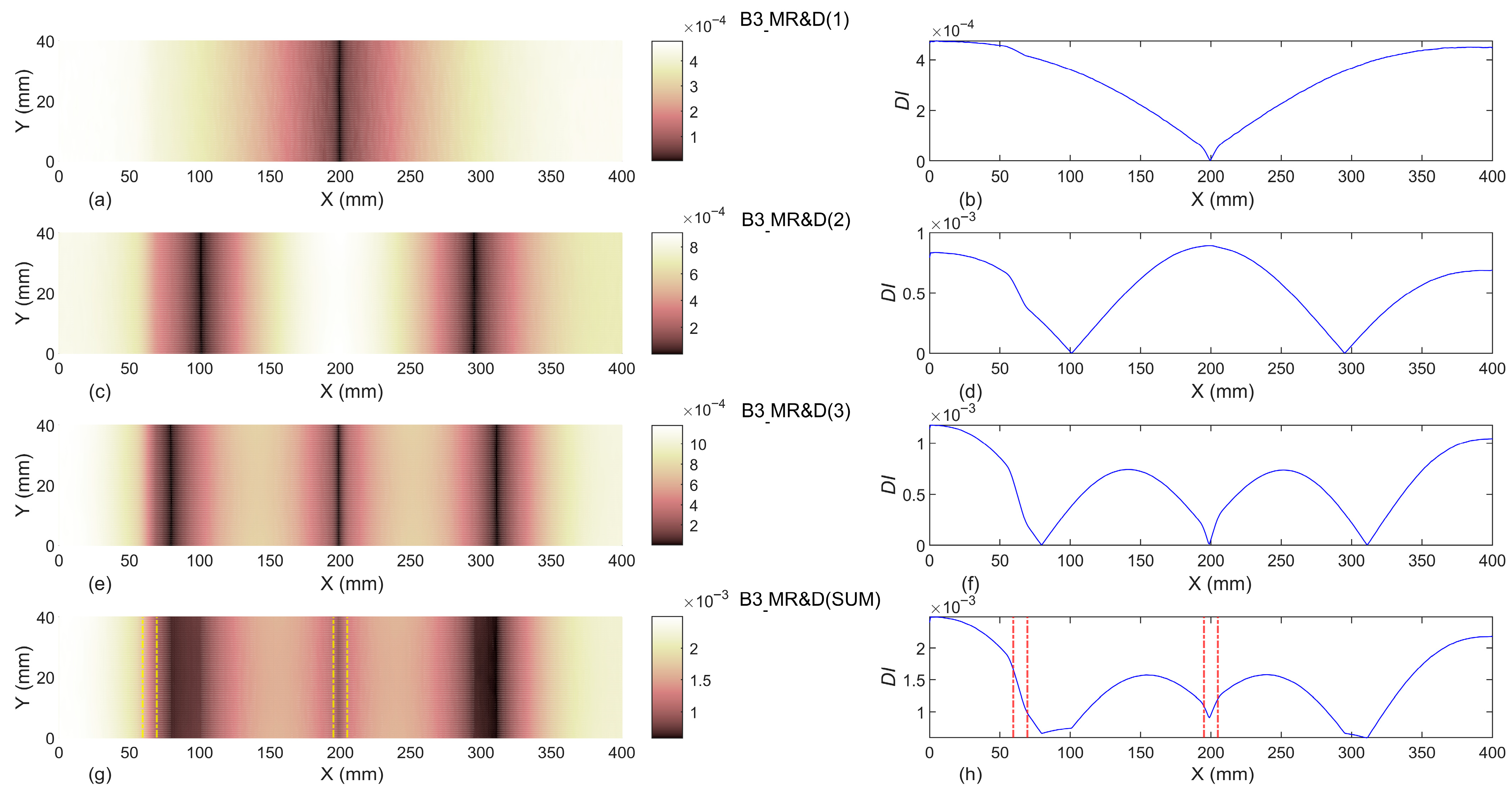

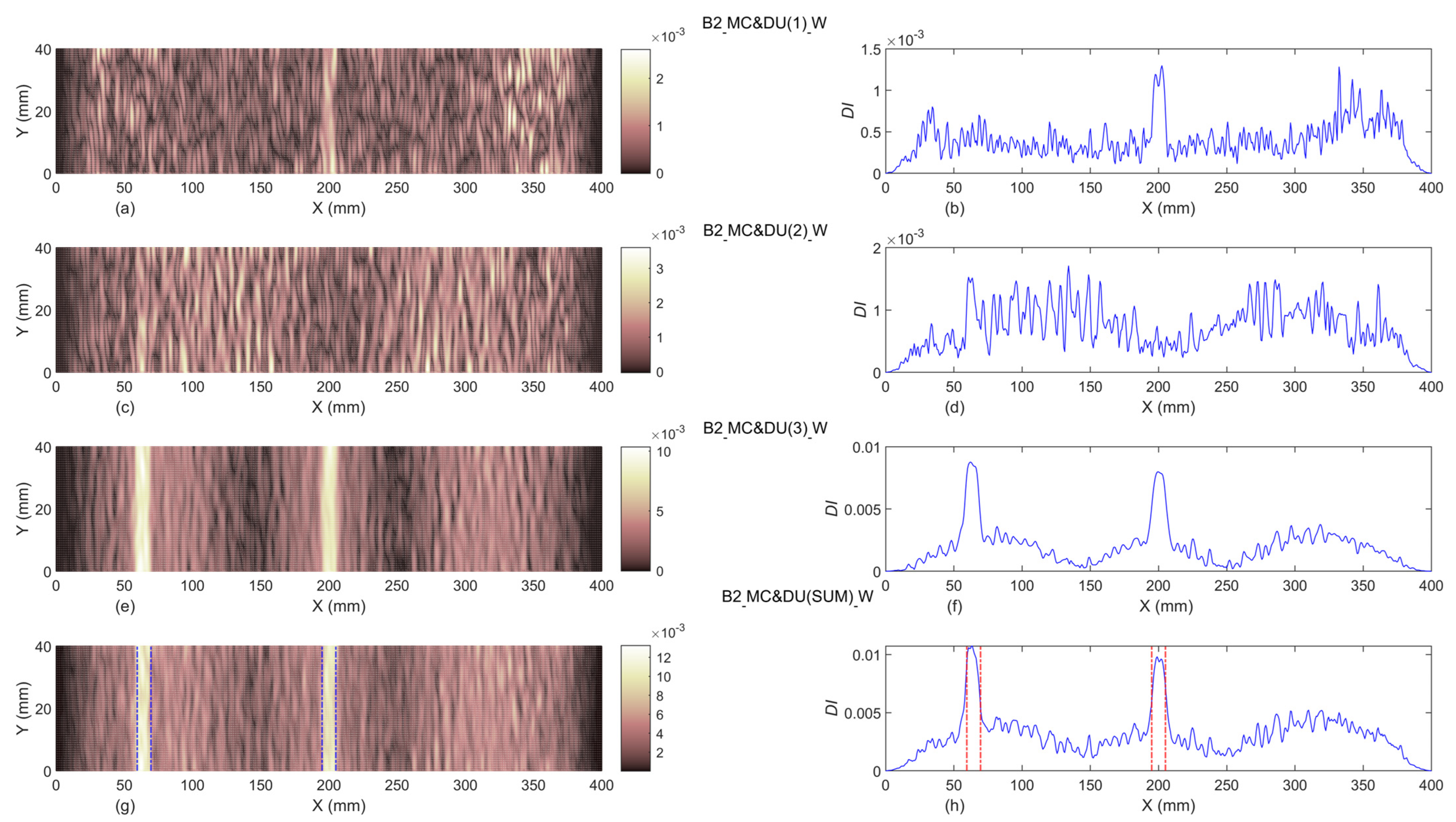

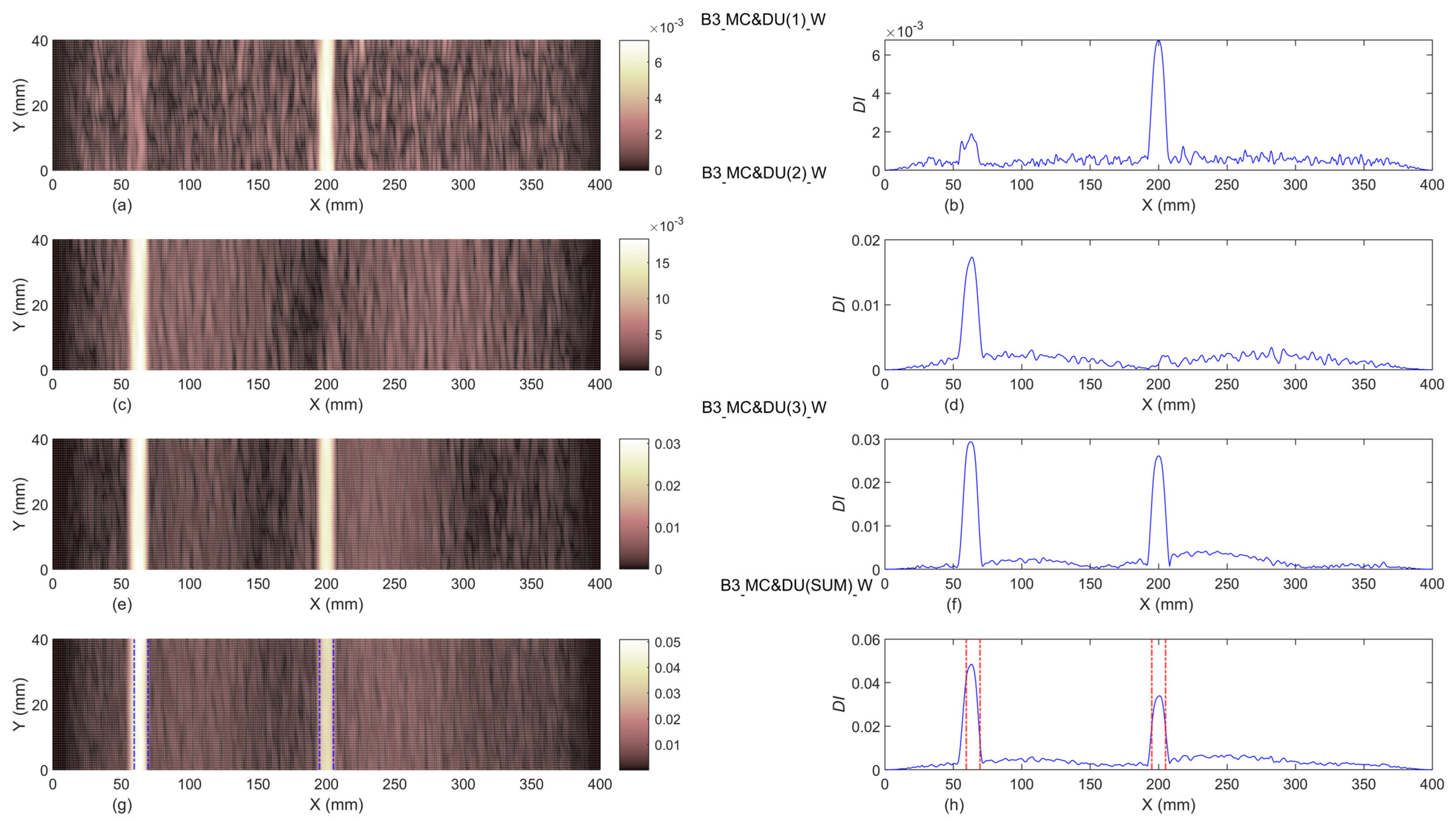

- It can also be concluded that in the current study, the baseline-free damage indices using the first three modal curvatures are not capable of identifying the damage in beams B1 and B2, but can detect the location of damage in beam B3.

- The baseline-included proposed damage indices can successfully identify the exact location of single and double damage, even in beams B1 and B2. In addition, the width of identified damage scenarios in all damaged beams are totally compatible with the exact experimental width of slot(s). Moreover, it can be concluded that the proposed damage indices are capable of detecting damage localization and reveal damage severities with an increase of the slot’s depths.

- The comparison of contourlet-based damage index in the current study and the corresponding previously published wavelet-based damage index with 2D sinc wavelet family and scale of 7, showed that both damage indices can identify the exact locations of damage scenarios. Regarding the damage varieties, although the wavelet-based damage index (sinc-S7) was more sensitive to damage severities and obtained higher values in damage locations, its noise values in undamaged locations were also higher in comparison to the contourlet-based damage index in the current study.

- The boundary effects of proposed damage indices were removed by applying the Tukey window, and the resulting post-windowing damage indices can identify damage locations and severities very well in all damaged beams.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons: Hoboken, NJ, USA, 2012; ISBN 9781119994336. [Google Scholar]

- Sohn, H.; Farrar, C.R.; Hemez, F.M.; Shunk, D.D.; Stinemates, D.W.; Nadler, B.R.; Czarnecki, J.J. A Review of Structural Health Monitoring Literature: 1996–2001; Los Alamos National Laboratory: Los Alamos, NM, USA, 2003; Volume 1, pp. 10–12989.

- Doebling, S.W.; Farrar, C.R.; Prime, M.B.; Shevitz, D.W. Damage Identification and Health Monitoring of Structural and Mechanical Systems from Changes in Their Vibration Characteristics: A Literature Review; Los Alamos National Laboratory: Los Alamos, NM, USA, 1996.

- Rashid, S.M.P.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Detection of Damages in Concrete Structures by Signal Processing and Image Processing Techniques: A Critical Review. In Damage Detection and Structural Health Monitoring of Concrete and Masonry Structures; Springer: Singapore, 2025; pp. 249–270. ISBN 978-981-97-8975-7. [Google Scholar]

- Ewins, D.J. Modal Testing: Theory, Practice and Application; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Daneshvar, M.H.; Saffarian, M.; Jahangir, H.; Sarmadi, H. Damage Identification of Structural Systems by Modal Strain Energy and an Optimization-Based Iterative Regularization Method. Eng. Comput. 2023, 39, 2067–2087. [Google Scholar] [CrossRef]

- Salawu, O.S. Detection of Structural Damage through Changes in Frequency: A Review. Eng. Struct. 1997, 19, 718–723. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage Detection from Changes in Curvature Mode Shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Hamidi, S.; Soleymani, A.; Rashidi, M. A Review of Structural Health Monitoring and Damage Detection Techniques in Frames and Bridges. In Damage Detection and Structural Health Monitoring of Concrete and Masonry Structures; Springer: Singapore, 2025; pp. 295–311. ISBN 978-981-97-8975-7. [Google Scholar]

- Jahangir, H.; Hasani, H.; Esfahani, M.R. Wavelet-Based Damage Localization and Severity Estimation of Experimental RC Beams Subjected to Gradual Static Bending Tests. Structures 2021, 34, 3055–3069. [Google Scholar] [CrossRef]

- Ying, Z.-G.; Ni, Y.-Q. Optimal Parameter Estimation for Uncertain Structural Systems under Unknown Random Excitations. J. Vib. Control 2025, 31, 2058–2074. [Google Scholar] [CrossRef]

- Lei, H.; Ying, Z.-Z.; Ying, Z.-G. Stochastic Optimal Control for Uncertain Structural Systems Under Random Excitations Based on Bayes Optimal Estimation. Buildings 2025, 15, 1579. [Google Scholar] [CrossRef]

- Ubertini, F.; D’Alessandro, A.; Downey, A.; García-Macías, E.; Laflamme, S.; Castro-Triguero, R. Recent Advances on SHM of Reinforced Concrete and Masonry Structures Enabled by Self-Sensing Structural Materials. In Proceedings of the 4th International Electronic Conference on Sensors and Applications, Online, 15–30 November 2017; MDPI: Basel, Switzerland, 2017; p. 119. [Google Scholar]

- Araújo dos Santos, J.V.; Lopes, H. Assessment of Impact Damage of Composite Structures Using Digital Shearography. In Non-destructive Testing of Impact Damage in Fiber-Reinforced Polymer Composites; Elsevier: Oxford, UK, 2024; pp. 87–113. [Google Scholar]

- Abdel-Latif, A.M. An Overview of the Applications of NDI/NDT in Engineering Design for Structural Integrity and Damage Tolerance in Aircraft Structures. In Damage and Fracture Mechanics: Failure Analysis of Engineering Materials and Structures; Springer: Dordrecht, The Netherland, 2009; pp. 93–100. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Computer Vision for SHM of Civil Infrastructure: From Dynamic Response Measurement to Damage Detection—A Review. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- dos Santos, J.V.A.; Lopes, H. Damage Localization Based on Modal Response Measured with Shearography. In Vibration-Based Techniques for Damage Detection and Localization in Engineering Structures; Nobari, A.S., Aliabadi, F.M.H., Eds.; World Scientific Publishing: Hackensack, NJ, USA, 2018; pp. 141–172. [Google Scholar]

- Wang, S.; Shi, P.; Xiong, J.; Feng, Y.; Huang, P.; Dong, B.; Chang, Q.; Wang, J.; Hanson, S.G.; Gao, S. Single-Shot Time-Averaged Shearography for Vibration Strain Mode Shape Visualization. IEEE Sens. J. 2024, 24, 9639–9646. [Google Scholar] [CrossRef]

- Tu, Y.; Liu, L.; Cao, B.; Mei, H.; Wang, L. Infrared-Induced Laser Shearography: Enhanced Multimodal Features Recognition for Interfacial Defects in SIR/GFRP Composite Structures. IEEE Trans. Instrum. Meas. 2024, 73, 1–13. [Google Scholar] [CrossRef]

- Mostafaei, H.; Ghamami, M. State of the Art in Automated Operational Modal Identification: Algorithms, Applications, and Future Perspectives. Machines 2025, 13, 39. [Google Scholar] [CrossRef]

- Mallat, S. A Wavelet Tour of Signal Processing; Academic Press: London, UK, 1999. [Google Scholar]

- Soleymani, A.; Jahangir, H.; Rashidi, M.; Mojtahedi, F.F.; Bahrami, M.; Javanmardi, A. Damage Identification in Reinforced Concrete Beams Using Wavelet Transform of Modal Excitation Responses. Buildings 2023, 13, 1955. [Google Scholar] [CrossRef]

- Douka, E.; Loutridis, S.; Trochidis, A. Crack Identification in Plates Using Wavelet Analysis. J. Sound Vib. 2004, 270, 279–295. [Google Scholar] [CrossRef]

- Douka, E.; Loutridis, S.; Trochidis, A. Crack Identification in Beams Using Wavelet Analysis. Int. J. Solids Struct. 2003, 40, 3557–3569. [Google Scholar] [CrossRef]

- Starck, J.-L.; Candès, E.J.; Donoho, D.L. The Curvelet Transform for Image Denoising. IEEE Trans. Image Process. 2002, 11, 670–684. [Google Scholar] [CrossRef]

- Kingsbury, N. Complex Wavelets for Shift Invariant Analysis and Filtering of Signals. Appl. Comput. Harmon. Anal. 2001, 10, 234–253. [Google Scholar] [CrossRef]

- Katunin, A. Damage Identification in Composite Plates Using Two-Dimensional B-Spline Wavelets. Mech. Syst. Signal Process. 2011, 25, 3153–3167. [Google Scholar] [CrossRef]

- Do, M.N.; Vetterli, M. The Contourlet Transform: An Efficient Directional Multiresolution Image Representation. IEEE Trans. Image Process. 2005, 14, 2091–2106. [Google Scholar] [CrossRef]

- Da Cunha, A.L.; Zhou, J.; Do, M.N. The Nonsubsampled Contourlet Transform: Theory, Design, and Applications. IEEE Trans. Image Process. 2006, 15, 3089–3101. [Google Scholar] [CrossRef]

- Jahangir, H.; Khatibinia, M.; Kavousi, M. Application of Contourlet Transform in Damage Localization and Severity Assessment of Prestressed Concrete Slabs. J. Soft Comput. Civ. Eng. 2021, 5, 39–68. [Google Scholar] [CrossRef]

- Xu, Y.L.; Chen, J. Structural Damage Detection Using Empirical Mode Decomposition and Contourlet Transform. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 27 February–2 March 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6174, p. 61742J. [Google Scholar]

- Zhang, Q.; Chen, S.; Zhao, Y.; Wang, D. Structural Damage Detection Using Contourlet Transform. In Proceedings of the Proceedings of SPIE—Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 9–13 March 2008; SPIE: Bellingham, WA, USA, 2008; Volume 6932, p. 69322D. [Google Scholar]

- Rucka, M. Damage Detection in Beams Using Wavelet Transform on Higher Vibration Modes. J. Theor. Appl. Mech. 2011, 49, 399–417. [Google Scholar]

- Zhou, J.; Cunha, A.L.; Do, M.N. Nonsubsampled contourlet transform: Construction and application in enhancement. In Proceedings of the IEEE International Conference on Image Processing, Genova, Italy, 14 November 2005; Volume 1, p. I-469. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Chen, J.; Zhang, Q. Damage Detection of Structures Using Contourlet Transform and Fractal Dimension. J. Vibroeng. 2014, 16, 3945–3956. [Google Scholar]

- He, Y.; Chen, H.; Liu, D.; Zhang, L. A Framework of Structural Damage Detection for Civil Structures Using Fast Fourier Transform and Deep Convolutional Neural Networks. Appl. Sci. 2021, 11, 9345. [Google Scholar] [CrossRef]

- Hajizadeh, A.R.; Khatibinia, M.; Hamidian, D. Performance Assessment of Contourlet Transform in Damage Detection of Plate Structures. Int. J. Optim. Civ. Eng. 2024, 14, 423–444. [Google Scholar] [CrossRef]

- Jahangir, H.; Hasani, H.; dos Santos, J.V.A.; Lopes, H.M. A Comprehensive Study on the Selection of Mother Wavelets and Mode Shapes for Multiple Damage Identification. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 1313–1327. [Google Scholar] [CrossRef]

- Cinque, D.; dos Santos, J.V.A.; Gabriele, S.; Marfia, S.; Lopes, H. Improvement on Modal Curvatures Methods for Multiple Damage Identification in Beams. Multidiscip. Model. Mater. Struct. 2021, 17, 1061–1080. [Google Scholar] [CrossRef]

- Kreis, T. Handbook of Holographic Interferometry: Optical and Digital Methods; Wiley-VCH: Weinheim, Germany, 2005; ISBN 9783527405466. [Google Scholar]

- Aebischer, H.A.; Waldner, S. A Simple and Effective Method for Filtering Speckle-Interferometric Phase Fringe Patterns. Opt. Commun. 1999, 162, 205–210. [Google Scholar] [CrossRef]

- Ghiglia, D.C.; Pritt, M.D. Two-Dimensional Phase Unwrapping: Theory, Algorithms, and Software; Wiley-Interscience: New York, NY, USA, 1998; ISBN 978-0-471-24935-1. [Google Scholar]

- Zhao, Q.; Dan, X.; Sun, F.; Wang, Y.; Wu, S.; Yang, L. Digital Shearography for NDT: Phase Measurement Technique and Recent Developments. Appl. Sci. 2018, 8, 2662. [Google Scholar] [CrossRef]

- Araújo dos Santos, J.V.; Lopes, H.; Moreno-García, P. Numerical Study on Damage Identification Using Shearography with Different Shearing Amounts. Procedia Struct. Integr. 2017, 5, 1198–1204. [Google Scholar] [CrossRef]

- Lopes, H.M.R.; Guedes, R.M.; Vaz, M.A. An Improved Mixed Numerical-Experimental Method for Stress Field Calculation. Opt. Laser Technol. 2007, 39, 1066–1073. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Liu, Y.; Chauris, H.; Oraintara, S. Implementational Aspects of the Contourlet Filter Bank and Application in Image Coding. EURASIP J. Adv. Signal Process. 2008, 2008, 373487. [Google Scholar] [CrossRef][Green Version]

- Abbasi, A.; Khatibinia, M.; Jahangir, H.; Dos Santos, J.V.A.; Lopes, H.M.R. Shearography-Wavelet-Based Damage Detection Methodology for Aluminum Beams. Rehabil. Civ. Eng. 2023, 11, 22–43. [Google Scholar][Green Version]

- Bloomfield, P. Fourier Analysis of Time Series; Wiley Series in Probability and Statistics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000; ISBN 9780471889489. [Google Scholar][Green Version]

| Tested Beams | Damage Scenario | Slot 1 | Slot 2 | ||||

|---|---|---|---|---|---|---|---|

| Location (X) (mm) | Width (mm) | Depth/Thickness (%) | Location (X) (mm) | Width (mm) | Depth/Thickness (%) | ||

| B0 | undamaged | - - - | - - - | - - - | - - - | - - - | - - - |

| B1 | single damage | 200 | 10 | 7 | - - - | - - - | - - - |

| B2 | double damage | 200 | 10 | 7 | 64.50 | 10 | 7 |

| B3 | double damage | 200 | 10 | 28 | 64.50 | 10 | 28 |

| Frequency Order | B0 (Hz) | B1 (Hz) | B2 (Hz) | B3 (Hz) |

|---|---|---|---|---|

| 1st | 92.00 | 91.25 | 91.25 | 87.00 |

| 2nd | 254.25 | 254.00 | 253.00 | 248.50 |

| 3rd | 449.50 | 496.50 | 493.00 | 465.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, A.M.; Soleymani, A.; Jahangir, H.; Khatibinia, M.; Santos, J.V.A.d.; Lopes, H.M. Damage Identification in Beams via Contourlet Transform of Shearography Modal Data. Vibration 2025, 8, 53. https://doi.org/10.3390/vibration8030053

Mohammadi AM, Soleymani A, Jahangir H, Khatibinia M, Santos JVAd, Lopes HM. Damage Identification in Beams via Contourlet Transform of Shearography Modal Data. Vibration. 2025; 8(3):53. https://doi.org/10.3390/vibration8030053

Chicago/Turabian StyleMohammadi, Ali Mohammad, Atefeh Soleymani, Hashem Jahangir, Mohsen Khatibinia, José Viriato Araújo dos Santos, and Hernâni Miguel Lopes. 2025. "Damage Identification in Beams via Contourlet Transform of Shearography Modal Data" Vibration 8, no. 3: 53. https://doi.org/10.3390/vibration8030053

APA StyleMohammadi, A. M., Soleymani, A., Jahangir, H., Khatibinia, M., Santos, J. V. A. d., & Lopes, H. M. (2025). Damage Identification in Beams via Contourlet Transform of Shearography Modal Data. Vibration, 8(3), 53. https://doi.org/10.3390/vibration8030053