Vibration Signal-Based Fault Diagnosis of Rotary Machinery Through Convolutional Neural Network and Transfer Learning Method

Abstract

1. Introduction

2. Related Work

2.1. Data-Driven Fault Diagnostic Methods

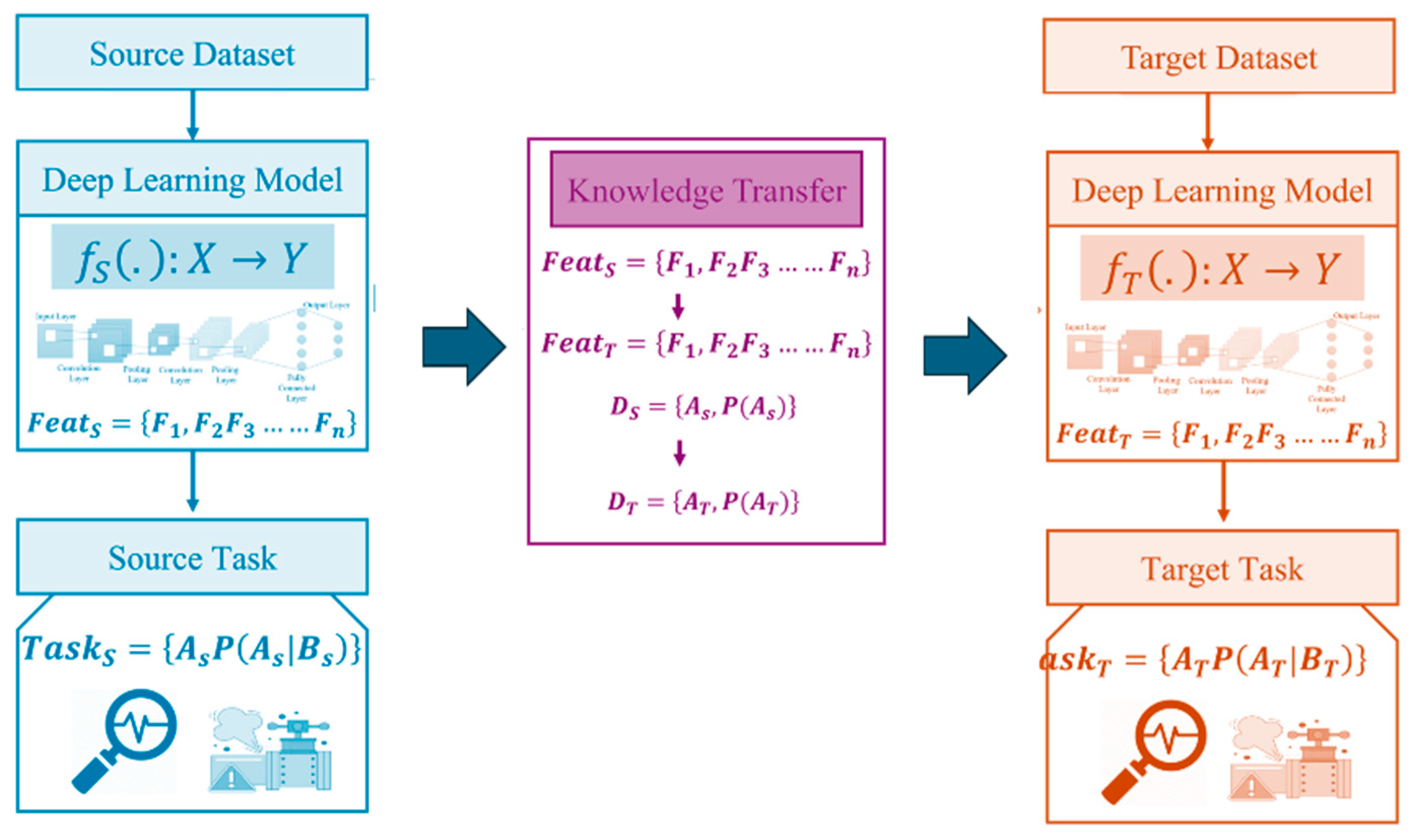

2.2. Transfer Learning

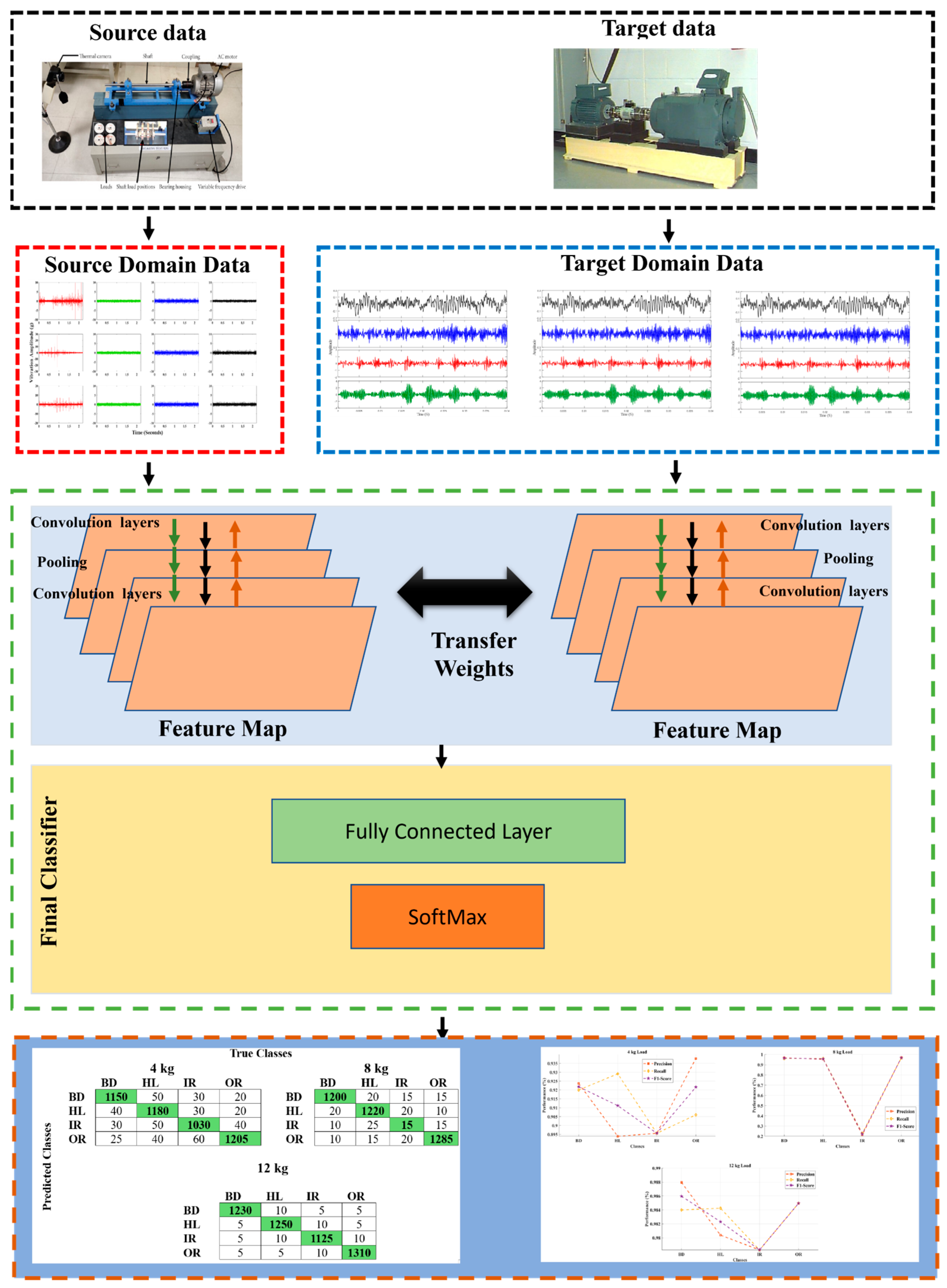

3. Experimental Methodology

- (a)

- The analysis and preprocessing using STFT of an accelerometer sensor dataset obtained from different industrial settings.

- (b)

- The dataset is categorized into source and target domains to facilitate the training and evaluation of the proposed model.

- (c)

- DL model using a CNN is developed using source domain data and its performance is evaluated.

- (d)

- The framework and hyperparameters of the previously trained model based on the source domain dataset have been designed and then fine-tuned to transfer to the targeted domain datasets.

- (e)

- The performance of the proposed TL-based framework has been assessed using the CRWU dataset.

3.1. Conceptual Framework

3.2. TL and Fine-Tuning Strategy

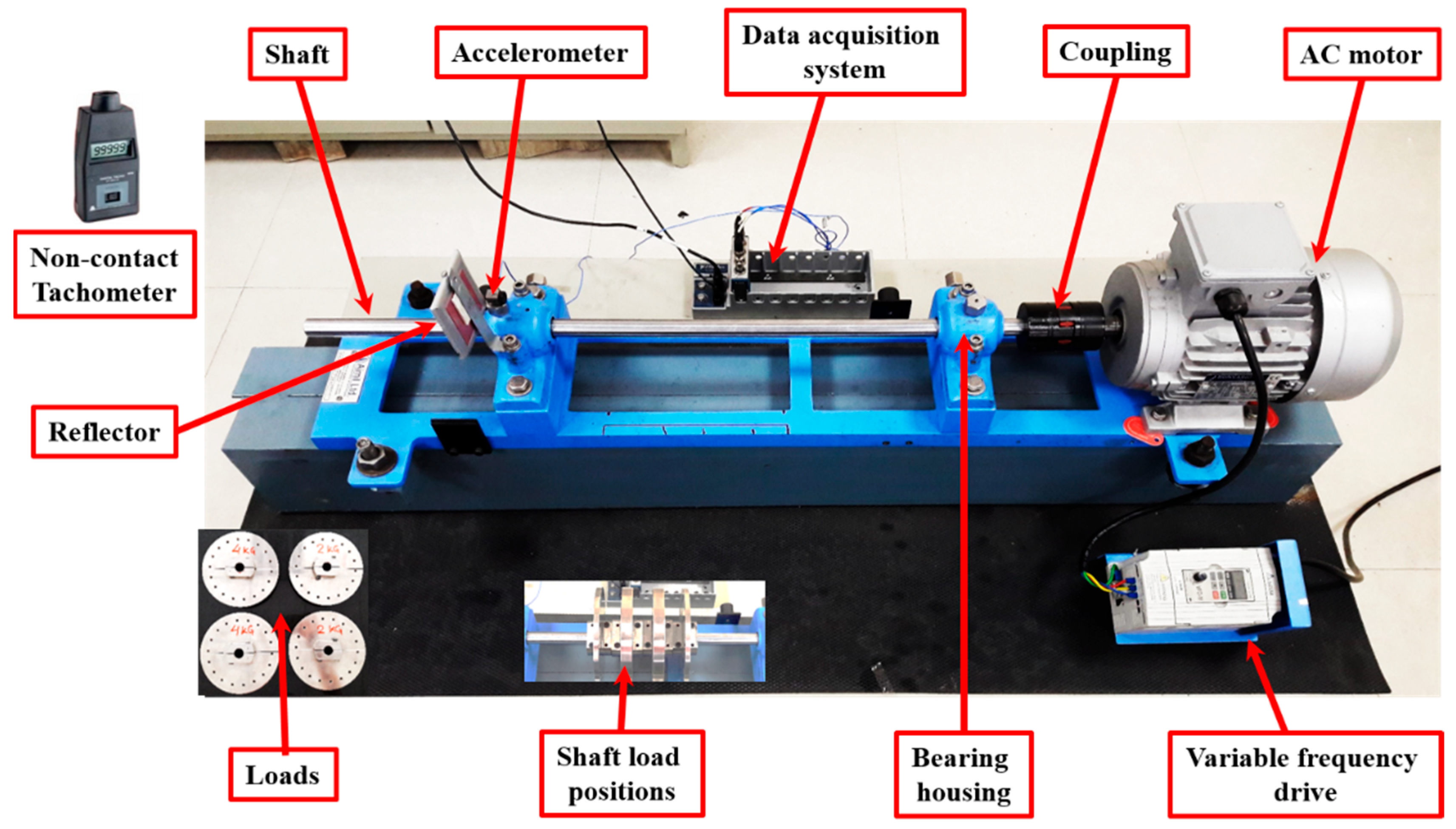

4. Experimental Setup and Data Processing

Data Preprocessing

5. Results and Interpretation

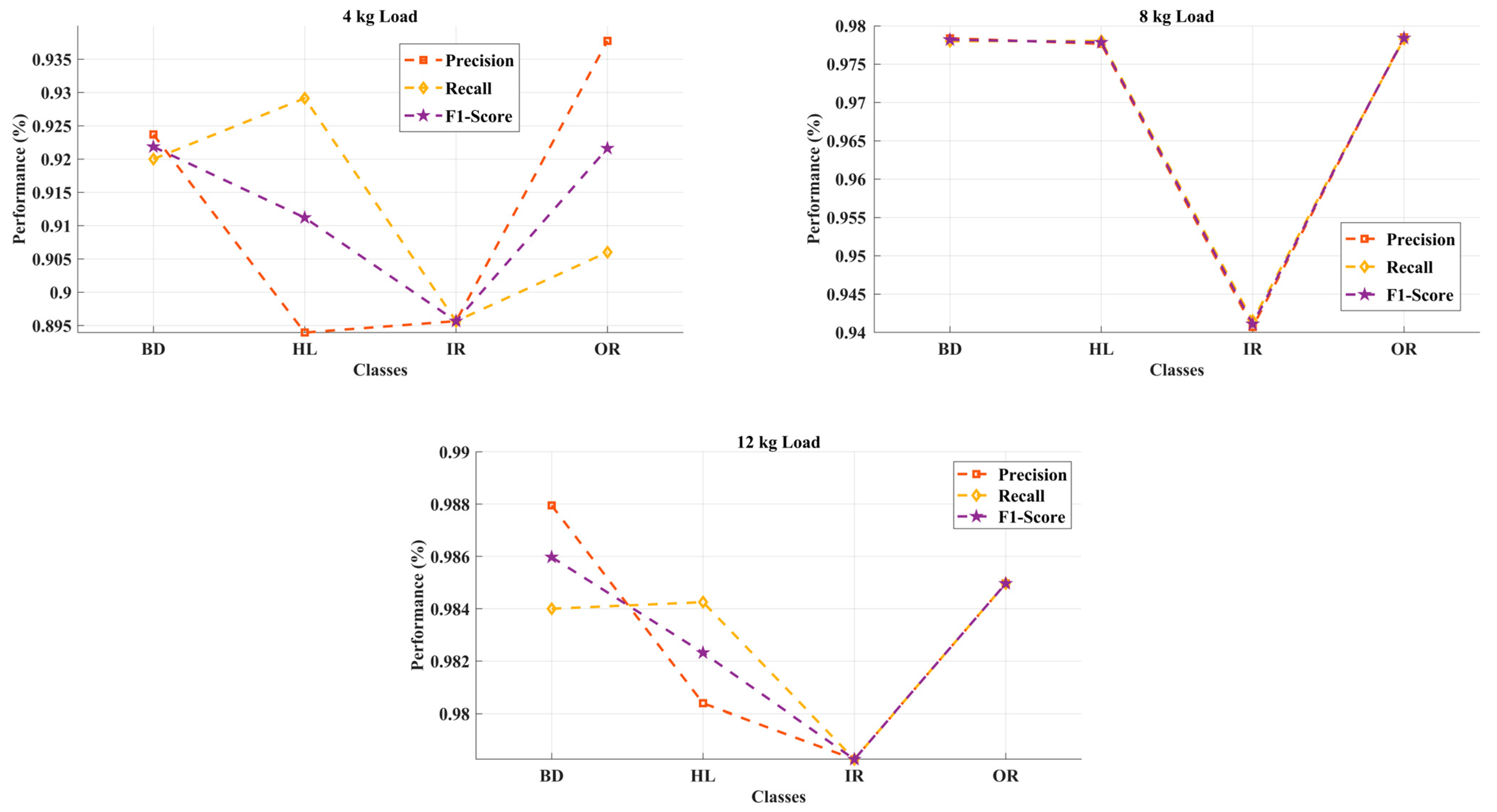

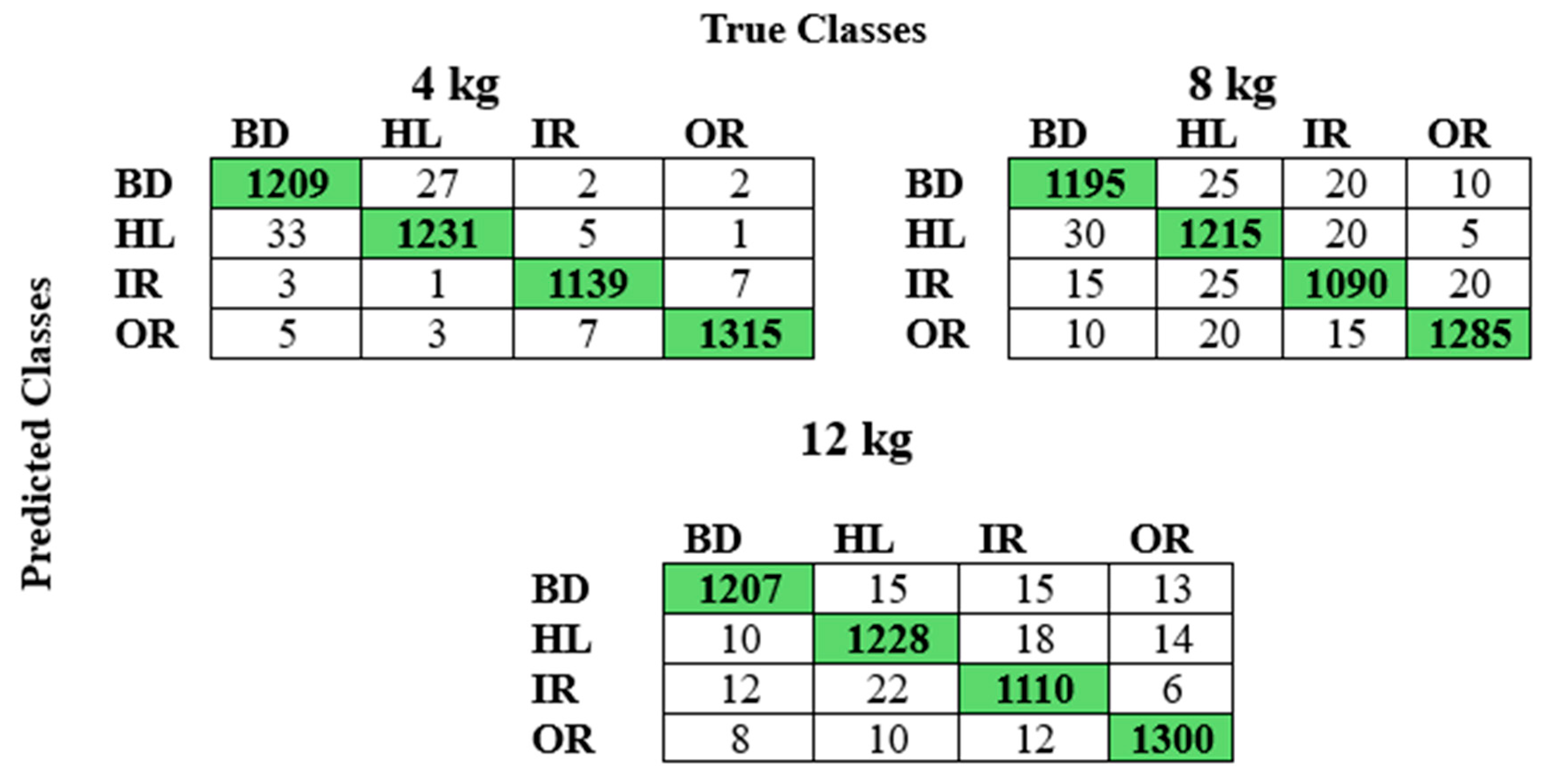

5.1. Results on Source Domain Data

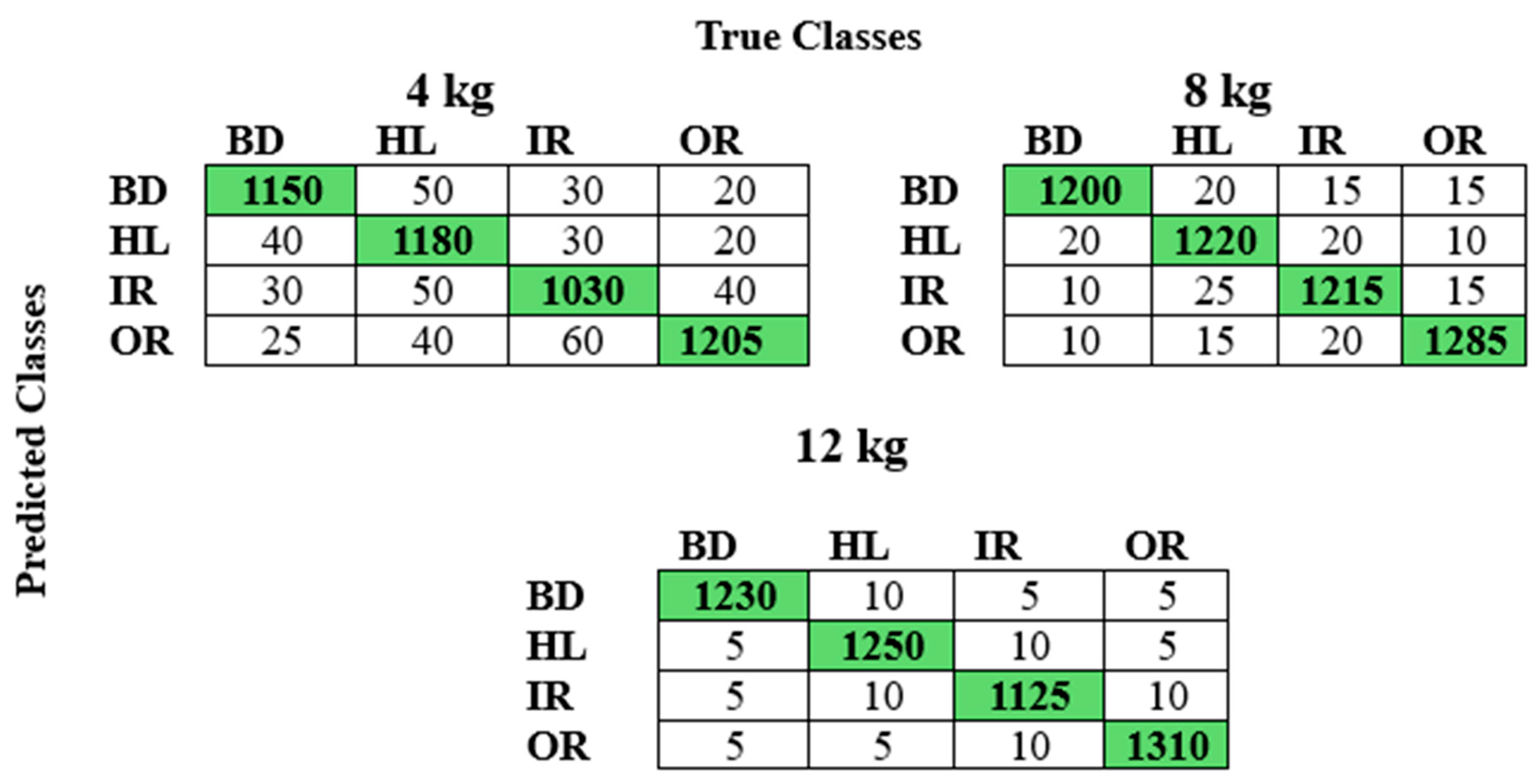

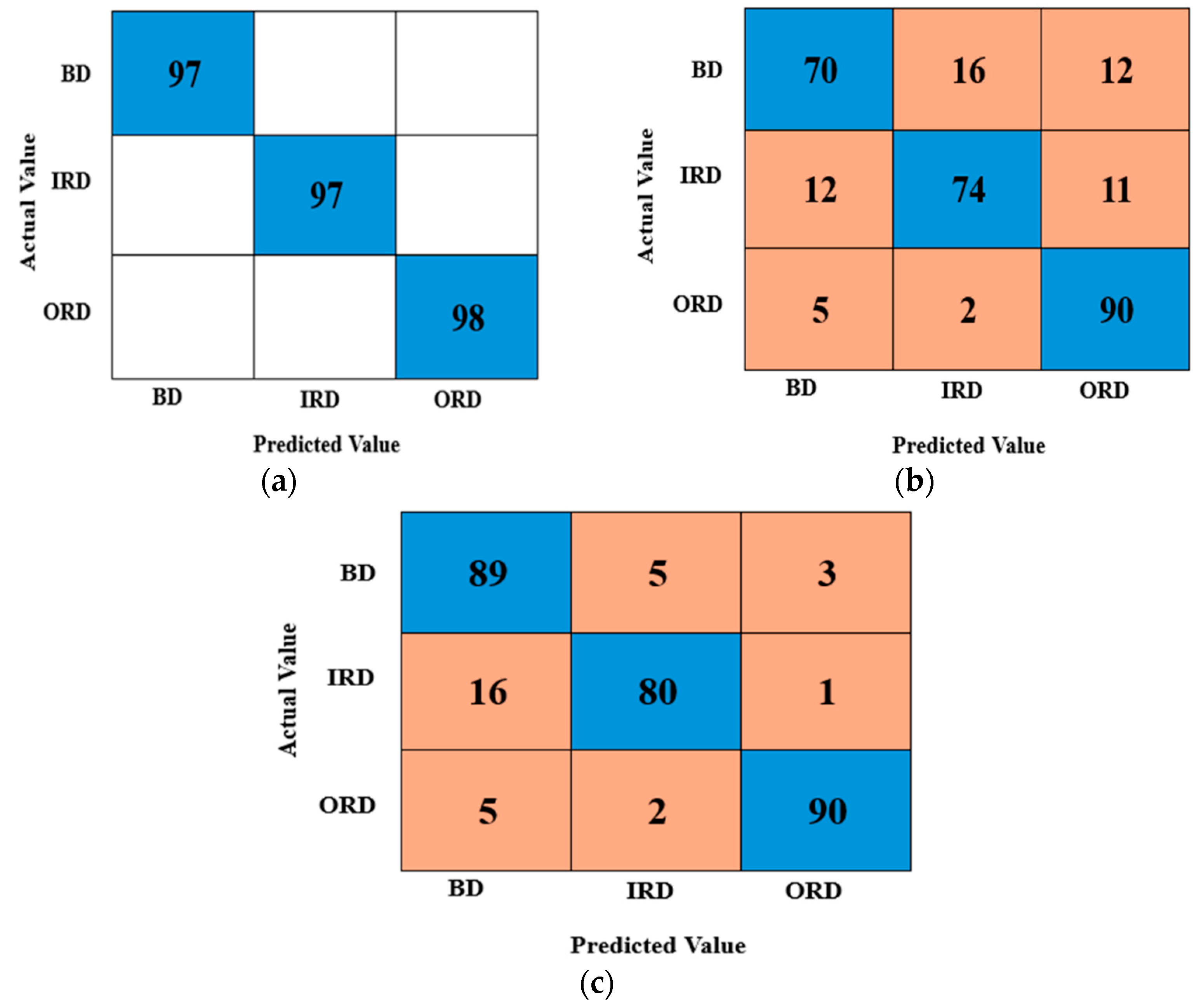

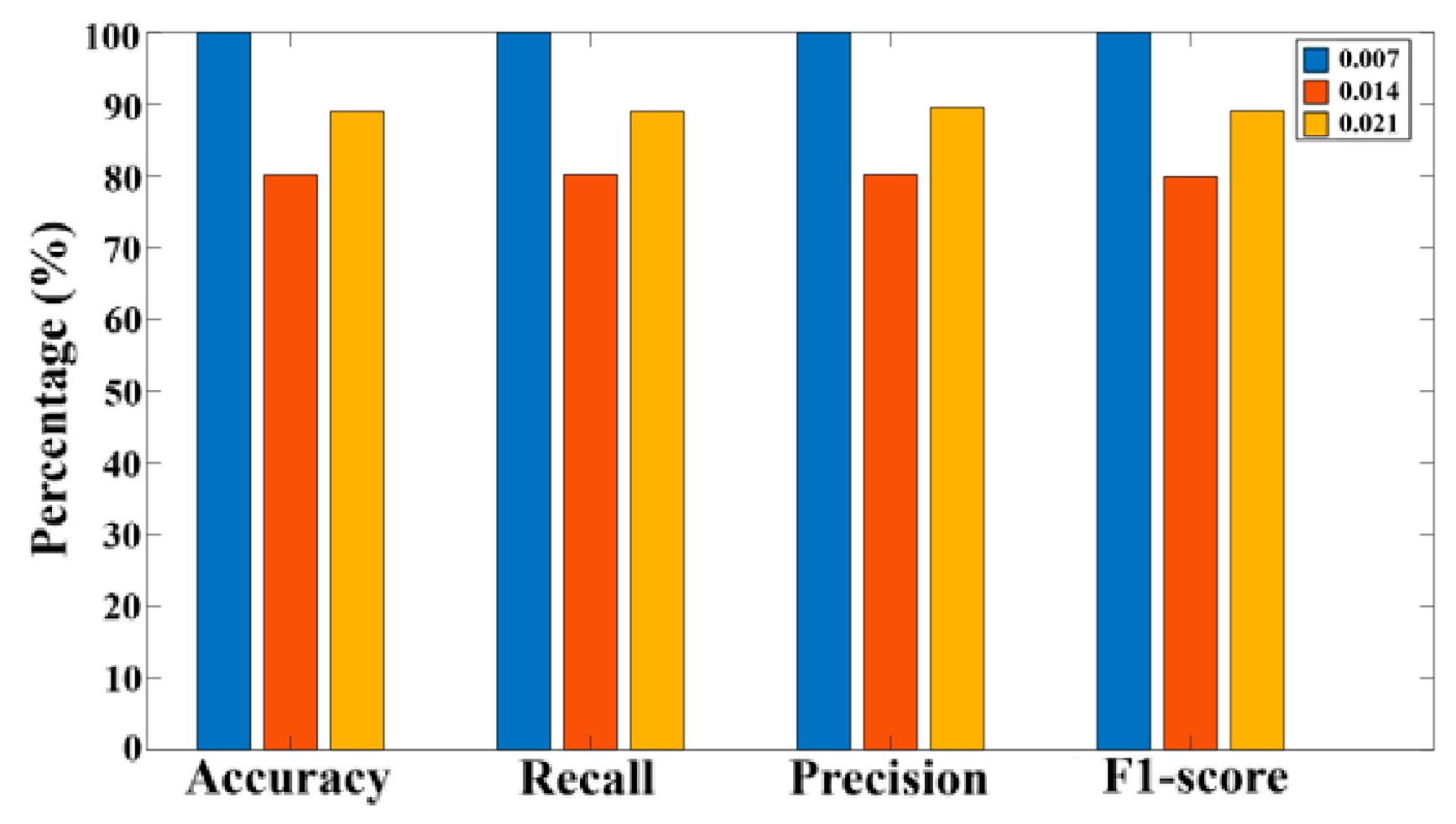

5.2. Results on Target Domain Data

CWRU Dataset

6. Conclusions

- The proposed methodology enhances FD performance with significantly reduced training time.

- The effectiveness of the proposed method has been validated using bearing datasets from rotary machinery that are entirely different from the source data.

- The method demonstrates strong capability in addressing the challenge associated with scarce training data for diagnostic tasks.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviation

| BD | Ball Defect |

| CNN | Convolutional Neural Network |

| CWRU | Case Western Reserve University |

| DBN | Deep Belief Network |

| FD | Fault Diagnosis |

| FL | Federated Learning |

| HL | Healthy (Condition) |

| IRD | Inner Race Defect |

| ORD | Outer Race Defect |

| STFT | Short-time Fourier Transform |

| SVM | Support Vector Machine |

| TL | Transfer Learning |

References

- Nguimfack, R.T.; Bappy, M.M.; Al Mamun, A.; Tian, W. Domain adaptation between heterogeneous time series data: A case study on real-time rotary machinery fault diagnosis. Manuf. Lett. 2024, 41, 1535–1543. [Google Scholar] [CrossRef]

- Goyal, D.; Choudhary, A.; Sandhu, J.K.; Srivastava, P.; Saxena, K.K. An intelligent self-adaptive bearing fault diagnosis approach based on improved local mean decomposition. Int. J. Interact. Des. Manuf. 2022, 1–11. [Google Scholar] [CrossRef]

- Tang, S.; Ma, J.; Yan, Z.; Zhu, Y.; Khoo, B.C. Deep transfer learning Strategy in intelligent fault diagnosis of rotating machinery. Eng. Appl. Artif. Intell. 2024, 134, 108678. [Google Scholar] [CrossRef]

- Choudhary, A.; Mian, T.; Fatima, S.; Panigrahi, B.K. Passive Thermography Based Bearing Fault Diagnosis Using Transfer Learning With Varying Working Conditions. IEEE Sens. J. 2023, 23, 4628–4637. [Google Scholar] [CrossRef]

- Goyal, D.; Dhami, S.S.; Pabla, B.S. Vibration Response-Based Intelligent Non-Contact Fault Diagnosis of Bearings. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 4, 012006. [Google Scholar] [CrossRef]

- Mehta, A.; Goyal, D.; Choudhary, A.; Pabla, B.S.; Belghith, S. Machine Learning-Based Fault Diagnosis of Self-Aligning Bearings for Rotating Machinery Using Infrared Thermography. Math. Probl. Eng. 2021, 2021, 9947300. [Google Scholar] [CrossRef]

- Mi, J.; Chu, M.; Hou, Y.; Jin, J.; Huang, W.; Xiang, T.; Wu, D. A Fault Diagnosis Method for Rolling Bearing Based on Deep Adversarial Transfer Learning With Transferability Measurement. IEEE Sens. J. 2024, 24, 984–994. [Google Scholar] [CrossRef]

- Goyal, D.; Mongia, C.; Sehgal, S. Applications of Digital Signal Processing in Monitoring Machining Processes and Rotary Components: A Review. IEEE Sens. J. 2021, 21, 8780–8804. [Google Scholar] [CrossRef]

- Su, Z.; Zhang, J.; Xu, H.; Zou, J.; Fan, S. Deep semi-supervised transfer learning method on few source data with sensitivity-aware decision boundary adaptation for intelligent fault diagnosis. Expert. Syst. Appl. 2024, 249, 123714. [Google Scholar] [CrossRef]

- Sun, X.; Wang, S.; Jing, J.; Shen, Z.; Zhang, L. Fault diagnosis using transfer learning with dynamic multiscale representation. Cogn. Robot. 2023, 3, 257–264. [Google Scholar] [CrossRef]

- Liang, J.; Liang, Q.; Wu, Z.; Chen, H.; Zhang, S.; Jiang, F. A Novel Unsupervised Deep Transfer Learning Method With Isolation Forest for Machine Fault Diagnosis. IEEE Trans. Industr. Inform. 2024, 20, 235–246. [Google Scholar] [CrossRef]

- Koutsoupakis, J.; Seventekidis, P.; Giagopoulos, D. Machine learning based condition monitoring for gear transmission systems using data generated by optimal multibody dynamics models. Mech. Syst. Signal Process. 2023, 190, 110130. [Google Scholar] [CrossRef]

- Yin, Z.; Hou, J. Recent advances on SVM based fault diagnosis and process monitoring in complicated industrial processes. Neurocomputing 2016, 174, 643–650. [Google Scholar] [CrossRef]

- Goyal, D.; Choudhary, A.; Pabla, B.S.; Dhami, S.S. Support vector machines based non-contact fault diagnosis system for bearings. J. Intell. Manuf. 2020, 31, 1275–1289. [Google Scholar] [CrossRef]

- You, L.; Fan, W.; Li, Z.; Liang, Y.; Fang, M.; Wang, J. A Fault Diagnosis Model for Rotating Machinery Using VWC and MSFLA-SVM Based on Vibration Signal Analysis. Shock. Vib. 2019, 2019, 1908485. [Google Scholar] [CrossRef]

- Goyal, D.; Dhami, S.S.; Pabla, B.S. Non-Contact Fault Diagnosis of Bearings in Machine Learning Environment. IEEE Sens. J. 2020, 20, 4816–4823. [Google Scholar] [CrossRef]

- Martínez-Morales, J.D.; Palacios-Hernández, E.R.; Campos-Delgado, D.U. Multiple-fault diagnosis in induction motors through support vector machine classification at variable operating conditions. Electr. Eng. 2018, 100, 59–73. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Qin, X.; Sun, Y. A two-stage fault diagnosis methodology for rotating machinery combining optimized support vector data description and optimized support vector machine. Measurement 2022, 200, 111651. [Google Scholar] [CrossRef]

- Simon, H.A. The Sciences of the Artificial; MIT Press: Cambridge, MA, USA, 1969. [Google Scholar]

- Zhang, L.; Lin, J.; Liu, B.; Zhang, Z.; Yan, X.; Wei, M.A. Review on Deep Learning Applications in Prognostics and Health Management. IEEE Access 2019, 7, 162415–162438. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Tang, B.; Xiao, K.; Li, J. An integrated approach to planetary gearbox fault diagnosis using deep belief networks. Meas. Sci. Technol. 2016, 28, 025010. [Google Scholar] [CrossRef]

- Pan, T.; Chen, J.; Zhou, Z. Intelligent Fault Diagnosis of Rolling Bearing via Deep-Layerwise Feature Extraction Using Deep Belief Network. In Proceedings of the 2018 International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC 2018), Xi’an, China, 15–17 August 2018; pp. 509–514. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, B.; Luo, W.; Chen, F. Autoencoder-based representation learning and its application in intelligent fault diagnosis: A review. Measurement 2022, 189, 110460. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, J.; Zheng, Y.; Jiang, W.; Zhang, Y. Fault diagnosis of rolling bearings with recurrent neural network-based autoencoders. ISA Trans. 2018, 77, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Tian, X.; Cui, L.; Zheng, F.; Liu, L. WSAFormer-DFFN: A model for rotating machinery fault diagnosis using 1D window-based multi-head self-attention and deep feature fusion network. Eng. Appl. Artif. Intell. 2023, 124, 106633. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, R.; Yang, Y.; Yin, J.; Li, Y.; Li, Y.; Xu, M. Cross-Domain Fault Diagnosis Using Knowledge Transfer Strategy: A Review. IEEE Access 2019, 7, 129260–129290. [Google Scholar] [CrossRef]

- Xiao, D.; Huang, Y.; Zhao, L.; Qin, C.; Shi, H.; Liu, C. Domain Adaptive Motor Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 80937–80949. [Google Scholar] [CrossRef]

- Guo, L.; Lei, Y.; Xing, S.; Yan, T.; Li, N. Deep Convolutional Transfer Learning Network: A New Method for Intelligent Fault Diagnosis of Machines with Unlabeled Data. IEEE Trans. Ind. Electron. 2019, 66, 7316–7325. [Google Scholar] [CrossRef]

- Dong, J.; Su, D.; Gao, Y.; Wu, X.; Jiang, H.; Chen, T. Fine-grained transfer learning based on deep feature decomposition for rotating equipment fault diagnosis. Meas. Sci. Technol. 2023, 34, 065902. [Google Scholar] [CrossRef]

- Wang, B.; Wang, B.; Ning, Y. A novel transfer learning fault diagnosis method for rolling bearing based on feature correlation matching. Meas. Sci. Technol. 2022, 33, 125006. [Google Scholar] [CrossRef]

- Shao, X.; Kim, C.S. Adaptive multi-scale attention convolution neural network for cross-domain fault diagnosis. Expert. Syst. Appl. 2024, 236, 121216. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, X.; Zhao, X.; Wang, L. Federated learning for intelligent fault diagnosis based on similarity collaboration. Meas. Sci. Technol. 2023, 34, 045103. [Google Scholar] [CrossRef]

- Xu, S.; Ma, J.; Song, D. Open-set federated adversarial domain adaptation based cross-domain fault diagnosis. Meas. Sci. Technol. 2023, 34, 115004. [Google Scholar] [CrossRef]

- Ditommaso, R.; Mucciarelli, M.; Ponzo, F.C. Analysis of non-stationary structural systems by using a band-variable filter. Bull. Earthq. Eng. 2012, 10, 895–911. [Google Scholar] [CrossRef]

- Asutkar, S.; Tallur, S. Deep transfer learning strategy for efficient domain generalisation in machine fault diagnosis. Sci. Rep. 2023, 13, 1–9. [Google Scholar] [CrossRef]

| Layer | Type | Activations | Learnable Property |

|---|---|---|---|

| imageinput_1 | Image Input | 100(S) × 100(s) × 3(C) × 1(B) | - |

| conv_1 | 2-D Convolution | 100(S) × 100(s) × 3(C) × 1(B) | Weights: 3 × 3 × 3 × … Bias: 1 × 1 × 8… |

| relu_1 | ReLU | 100(S) × 100(s) × 3(C) × 1(B) | - |

| norm_1 | Cross-channel Normalization | 100(S) × 100(s) × 3(C) × 1(B) | - |

| maxpool_1 | 2-D Max Pooling | 49(S) × 49(s) × 8(C) × 1(B) | - |

| conv2_1 | 2-D Grouped Convolution | 49(S) × 49(s) × 8(C) × 1(B) | Weights: 3 × 3 × 4 × … Bias: 1 × 1 × 16… |

| relu_2 | ReLU | 49(S) × 49(s) × 8(C) × 1(B) | |

| norm_2 | Cross-channel Normalization | 49(S) × 49(s) × 8(C) × 1(B) | - |

| maxpool_2 | 2-D Max Pooling | 24(S) × 24(s) × 32(C) × 1(B) | |

| conv_3 | 2-D Convolution | 24(S) × 24(s) × 16(C) × 1(B) | Weights: 3 × 3 × 32 × ... Bias: 1 × 1 × 16… |

| relu_3 | ReLU | 24(S) × 24(s) × 16(C) × 1(B) | |

| conv2_2 | 2-D Grouped Convolution | 24(S) × 24(s) × 32(C) × 1(B) | Weights: 3 × 3 × 8 × … Bias: 1 × 1 × 16… |

| relu_6 | ReLU | 24(S) × 24(s) × 32(C) × 1(B) | |

| conv2_3 | 2-D Grouped Convolution | 24(S) × 24(s) × 16(C) × 1(B) | Weights: 3 × 3 × 16 × ... Bias: 1 × 1 × 8… |

| relu_7 | ReLU | 24(S) × 24(s) × 16(C) × 1(B) | - |

| maxpool_3 | 2-D Grouped Convolution | 24(S) × 24(s) × 16(C) × 1(B) | - |

| conv_4 | 2-D Convolution | 12(S) × 12(s) × 32(C) × 1(B) | Weights: 3 × 3 × 16 × ... Bias: 1 × 1 × 32… |

| relu_4 | ReLU | 12(S) × 12(s) × 32(C) × 1(B) | - |

| drop_1 | Dropout (50%) | 12(S) × 12(s) × 32(C) × 1(B) | - |

| fc_1 | Fully Connected | 4096(C) × 1(B) | Weights: 4096 × 46 × ... Bias: 4096 × 1… |

| relu_5 | ReLU | 4096(C) × 1(B) | - |

| drop_2 | Dropout (50%) | 4096(C) × 1(B) | |

| fc_2_1 | Fully Connected | 20(C) × 1(B) | Weights: 20 × 4096 Bias: 20 × 1 |

| Output | Fully Connected | 20(C) × 1(B) | Weights: 20 × 40 Bias: 20 × 1 |

| Characteristics | Specification | Characteristics | Specification |

|---|---|---|---|

| Type | SKF 1205 EKTN9 | Contact angle (°) | 10.583 |

| Number of rollers per row | 13 | Pitch diameter (mm) | 38.376 |

| Number of rows | 2 | Ball diameter (mm) | 7.5 |

| Pre-Trained Model | No. of Training Samples | No. of Testing Samples | Training Time (min) | Testing Time (min) | Accuracy |

|---|---|---|---|---|---|

| STFT-GoogleNet | 100,000 | 1225 | 150 | 5 | 97.56 |

| STFT-ImageNet | 100,000 | 1225 | 17 | 6 | 95.45 |

| STFT-ResNet | 100,000 | 1225 | 210 | 6.8 | 97.45 |

| Proposed | 100,000 | 1225 | 75 | 4.3 | 97.56 |

| Ref. | Sensor Modalities | Signal Processing | Computational Method | Accuracy | |

|---|---|---|---|---|---|

| Source Domain | Target Domain | ||||

| [7] | Vibration | Empirical wavelet transform | Deep adversarial TL with transferability measurement (DATLTM) | 97.67% | 98.68% |

| [36] | Continuous wavelet transform | Light-weight CNN | 96.6% | 98% | |

| [9] | Vibration | - | TL + Sa-DBA | 99.7% | 92.48% |

| [4] | Thermal image | Image SNR | TL + CNN | 100% | 95.4% |

| Current study | Vibration | STFT | TL + CNN | 97.56% | 99.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mongia, C.; Sehgal, S. Vibration Signal-Based Fault Diagnosis of Rotary Machinery Through Convolutional Neural Network and Transfer Learning Method. Vibration 2025, 8, 27. https://doi.org/10.3390/vibration8020027

Mongia C, Sehgal S. Vibration Signal-Based Fault Diagnosis of Rotary Machinery Through Convolutional Neural Network and Transfer Learning Method. Vibration. 2025; 8(2):27. https://doi.org/10.3390/vibration8020027

Chicago/Turabian StyleMongia, Chirag, and Shankar Sehgal. 2025. "Vibration Signal-Based Fault Diagnosis of Rotary Machinery Through Convolutional Neural Network and Transfer Learning Method" Vibration 8, no. 2: 27. https://doi.org/10.3390/vibration8020027

APA StyleMongia, C., & Sehgal, S. (2025). Vibration Signal-Based Fault Diagnosis of Rotary Machinery Through Convolutional Neural Network and Transfer Learning Method. Vibration, 8(2), 27. https://doi.org/10.3390/vibration8020027