Abstract

Awkward hand-arm posture and overhead work increase the risk of musculoskeletal symptoms. These adverse health effects can also be caused by additional workloads such as hand-arm vibration exposure while carrying or holding a power tool. This pilot trial investigated posture and muscle activity of 11 subjects while using an impact wrench for three working directions: upwards, forwards and downwards. Although the vibration exposure did not show notable differences in the magnitude (4.8 m/s2 upwards, 4.4 m/s2 forwards and 4.7 m/s2 downwards), postural behavior and the muscle activity showed significantly higher workloads for working upwards compared to forwards direction. The muscle activity results for working downwards also showed elevated levels of muscle activity due to the awkward wrist posture. The results demonstrate that not only the working direction but also more importantly the arm, wrist and head posture need to be considered while investigating hand-arm vibration exposure.

1. Introduction

It is well known that long-term exposure to hand-arm vibration (HAV) leads to chronic complaints or diseases. In Germany, approximately 1600 occupational diseases related to HAV are reported annually; approximately 350 are recognized as occupational diseases [1]. While working with vibrating tools, occupants are forced to adopt various postures, such as working overhead or bending forwards. However, to evaluate the workload for most occupational diseases caused by vibrating tools, only the magnitude of the HAV exposure according to ISO 5349-1 [2] is considered. Consequently, adverse health effects of HAV while adopting an awkward posture can be underestimated by investigating the exposure of the device only. For example, the elevated prevalence of musculoskeletal diseases observed by workers with vibrating tools can be caused by combined effects of many risk factors, such as hard physical effort, constrained postures and strong grip force [3,4]. Recent studies [5] have also shown that operators suffer from HAV syndrome as well as neck and back pain when exposed to prolonged vibration and constantly adopting an awkward posture. In contrast to the combined effects of whole-body and awkward posture, which have been quantified in several studies [6,7,8] and even presented in a Technical report ISO/TR 10687 [9], nothing quantifiable has yet been investigated in case of the combined effects of HAV and awkward hand-arm posture.

To show the influence of posture during hand-arm vibration exposure, different approaches such as magnitude of the vibration and feed and gripping forces for different working directions are applied [10,11,12,13]. While significant lower vibration magnitude was measured for working horizontally compared to vertical directions [12], significant influence of the body posture on the acceleration of the main handle was shown by means of feed and gripping forces [13].

Another approach to investigate the impact of posture during HAV exposure is considering power absorption. Thus, awkward wrist and elbow posture can yield higher power absorption into the hand-arm system compared to neutral posture [14,15]. For example, under an extended arm posture, the magnitudes of transmitted vibration were observed to be nearly twice as many as those for the bent-arm posture in the low-frequency region [10].

Also, physiological investigations such as electromyographic measurements have been used to show the effect of combined exposures of vibration and posture on the human body [16]. While the reaction of the flexor carpi ulnaris is primarily determined by the grip pressure, electrical activity of the biceps and triceps brachii muscles is increased during exposure to vibration. The authors suggest that segmental vibration can give rise to intense musculoskeletal strain in the upper extremities of the exposed workers. Thus, pathological changes in the musculoskeletal structures of the hand-arm system are caused by long-term use of portable vibrating tools, followed by musculoskeletal disorders such as upper limb pain, joint stiffness, and movement limitation. These musculoskeletal disorders could also be caused by awkward posture [17], which is not considered quantitively yet.

Finally, the hypothesis here is that only measuring the HAV on the vibrating tool does not describe the impact on the body of the operating people. Thus, there is an underestimation of risk assessment if there is no consideration of the posture. As it is still unknown to what extent awkward posture can modulate the impact of vibrations on the hand-arm system, other investigations, such as muscle activity, can provide an overview about the impacts on the body, accompanying standard vibration measurements on the device. Thus, the aim of this project was to investigate the impact on the muscle load in the shoulder, upper arm, and forearm by using electromyographic data and subjective perception of the subjects using a hand-held power tool in three different positions.

2. Materials and Methods

2.1. Trial Population

Eleven (11) healthy, right-handed volunteers (seven males and four females, mean age ± standard deviation (SD) = 36 ± 11 year; mean height ± SD = 178 ± 8 cm; mean weight ± SD = 76 ± 15 kg) participated in this project. All subjects were not professional users. However, they were well-trained in using the tool.

At the time of the experiment, all subjects were in good health and were not suffering from noteworthy physical complaints. Also, participants should not have had any musculoskeletal problems or disease in the last twelve months. Written informed consent was obtained from the participants to participate in the experiments and allow for data analysis and the publication of results. The Ethics Committee of Luebeck University, Medical Faculty, approved of the study design with a positive vote.

2.2. Experimental Procedure

To investigate the influence of the working direction while using an impact wrench, three directions were chosen: upwards, forwards and downwards. Considering anthropometric differences, a height-adjustable experimental setup was designed to enable starting conditions that were as equal as possible in each working direction for each test person. The test persons were asked to adopt a standing posture with a 90-degree forearm angle perpendicular to the wooden plank of the test rack. Figure 1 shows an example of the test setup with a test person and the examined impact wrench.

Figure 1.

(left): Setup of the test for examining the three working directions while using an impact wrench; (right): Impact wrench with accelerometer.

As a specimen for the tests, oak planks with a thickness of at least 100 mm and a size of approximately 800 mm300 mm were used. To enable a long screw-in time, 100 mm-long wood screws were used.

These screws were screwed in 12 times for each direction. A pilot hole was provided for each of the 12 screwing tasks. The power tool chosen for these tests was the Bosch Professional GDX 18V-LI impact wrench (Robert Bosch, Gerlingen, Germany), since this impact wrench delivers a high torque and is also safe and easy to use, even for inexperienced individuals. The working order (e.g., up/front/down) was randomly allocated, thus, six permutations were executed for three directions. After working in each working direction, 10 min pauses were executed.

2.3. Hand-Arm Vibration Measurements

In accordance with ISO 5349 [2,18], the tool handle vibration was measured for a period of 12 screwdriving operations. Accelerometers were glued on the tool handle (Figure 1) in accordance with ISO 28927-5 [19]. Accelerometer mounting and the application of necessary frequency weightings were undertaken in compliance with ISO 5349-1 and ISO 5349-2 standards [2,18].

The vibration magnitudes were expressed as root-mean-square (r.m.s.) acceleration, which was frequency-weighted and band-limited using the Wh filter in accordance with ISO 5349-1. The root-sum-of-squares (vibration total value, ) of the frequency-weighted acceleration values for the x, y and z axes were calculated using:

Only the screwing-in processes with no pauses were included for the evaluations. When the screwing-in process was not completed in a single step, these instances were not included in the calculation of the mean value.

2.4. Body Posture

A Xsens Awinda (Movella Holdings Inc, Henderson, NV, USA) wireless measurement system (18 inertial measurement units) with 60 Hz measurement frequency was used to assess body posture (Figure 2).

Figure 2.

Positioning of the sensors on the body to measure the angle of the body.

These measurement units comprise accelerometers, gyroscopes, magnetometers and a barometer. Recording of body posture data takes place in combination with the associated MVN 2022.0 Analyze software from Xsens. After the data was recorded, it was imported into CUELA (‘computer-assisted recording and long-term analysis of musculoskeletal loads’), an analyzing software developed by the Institute for Occupational Safety and Health of the German Social Accident Insurance [20]. Hereby, the angle of the body is analyzed in accordance with ISO TR 10687 [9]. Positive values denote flexion and radial deviation, while negative values denote extension and ulnar deviation. Table 1 depicts the angles which will be presented in this paper along with the associated categories for neutral, moderate, and awkward movement ranges. The results are shown as a boxplot distribution of all detected data with respect to these color-coded risk categories (5th, 25th, 50th, 75th and 95th percentile).

Table 1.

Investigated body angles with associated categories for movement ranges in accordance with ISO TR 10687.

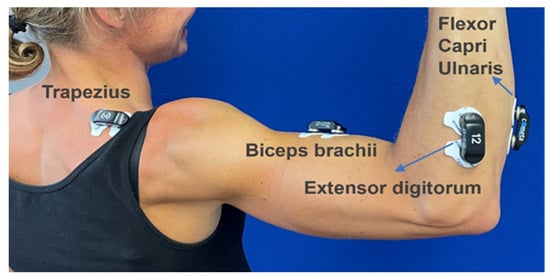

2.5. Electromyography

A wireless bipolar surface Electromyography (sEMG) measuring system, Cometa Wave Plus was used to analyze muscle activity. Surface electrode placement (Ambu®, BlueSensor, Ballerup, Denmark) and skin preparation followed the SENIAM guidelines [21]. The measurements were performed with Ag/AgCL electrodes (Kendall H 124 SG, Dublin, OH, USA). Since all subjects were right-handed, four transducers were placed on the right-hand side of the hand-arm system. Two pairs of adhesive circular surface electrodes were applied with a diameter of 24 mm (Figure 3).

Figure 3.

Location of the electromyography sensors on the skin.

For M. trapezius descendens, electrodes were placed at 50% on the line from the acromion to the spine on vertebra C7. For M. biceps brachii, electrodes were placed on the line between the medial acromion and the fossa cubit at 1/3 from the fossa cubit [21].

M. flexor carpi ulnaris and M. extensor digitorum were chosen as indicators for muscle activity during the chosen task. The electrodes for forearm muscles were applied to the most prominent part of the muscles, approximately one-third of the distance from the lateral epicondyle to the ulnar styloid [17].

All sEMG signals were sampled at a frequency of 2000 Hz. Following the recommendations for the processing of the EMG data of Hansson et al. 1997 [22], a bandpass filtering of 30–400 Hz and a RMS calculation was carried out with a rectangular window (window width of 0.125 s).

The percentage value (MVCP) was calculated from the RMS channels based on the maximum voluntary contraction (MVC values) of the individual muscles.

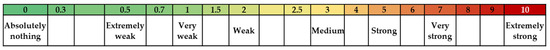

2.6. Subjective Perception of the Exposures

To assess the perceived exertion for the individual test sections, the modified Borg CR10 scale was used [23]. In Figure 4, the classification of the perception after being questioned: “how was the effort felt” is depicted, ranging from 0 for “absolutely nothing” to 10 for “extremely strong” is demonstrated.

Figure 4.

Borg scale for subjective perception of the test subjects.

2.7. Data Analysis and Statistics

Both, EMG and HAV measurement data were exported to the CUELA software (2022/V8) for the evaluation of vibration exposure and assessment of body posture following synchronization with body angles and video data [20]. The statistical analysis of the data was performed with IBM SPSS Statistics 26 software.

This experiment was designed as a counter -balanced trial. A priori case calculations were not conducted.

As a measure of the central tendency, mean values were calculated for continuous variables and the SD as a measure of dispersion. Boxplots are used to describe the dispersion of the data. The Shapiro-Wilk test and additional histogram tests were used for all data to analyze the normal distribution. For normally distributed data, the influences of the posture on the vibration, EMG data and subjective perception are tested via one-way analysis of variance. A subsequent Tukey post hoc test is used for finding significant differences between groups with equal variance, while the Games-Howell post hoc test is used for groups with no equal variance. In the case of no normal distribution, the Kruskall-Wallis test is used for finding stochastic differences between groups, followed by a Dunn-Bonferroni post hoc test.

3. Results

3.1. Duration of the Experimental Task

The average duration for driving a 10 cm screw in the oak test plank is specified in Table 2. On average, 6.3 s were required for the forwards direction, while the upwards and downwards directions required 6.0 and 5.8 s, respectively.

Table 2.

Duration and vibration exposure for one screwdriving operation.

3.2. Hand-Arm Vibration

Table 2 also shows the frequency weighted acceleration for each axis and the total vibration value for the three different working directions. The total vibration values for the upwards (4.8 m/s2) and downwards (4.7 m/s2) direction are comparable. The lowest total vibration value of 4.4 m/s2 was recorded for the forwards working direction. No statistically significant difference was found between the three working directions (p = 0.12).

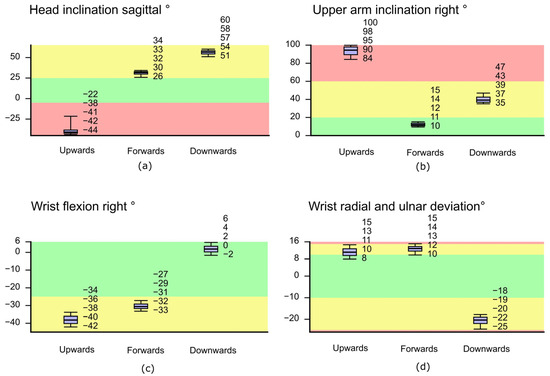

Figure 5 shows the recorded body angles while using the impact wrench as a box plot (5th, 25th, 50th, 75th and 95th percentile). In Figure 5, color scaling based on risk categories defined by Table 1 was also used to indicate the participation of the measured body angles in the three range of movement categories (neutral (green), moderate (yellow) and awkward (red)).

Figure 5.

Posture analysis for three working directions while using an impact wrench; angles are given as boxplots (5th, 25th, 50th, 75th, 95th). The range of movements for each angle is given by the categories with respect to ISO TR 10,687 (green = neutral, yellow = moderate and red = awkward). (a): head inclination sagittal; (b): upper arm inclination right; (c): wrist flexion right; (d): wrist radial and ulnar deviation.

While the head (Figure 5a) was completely extended when working upwards (awkward category), it was flexed working forwards (moderate category) and more flexed in the downwards position compared to the forward position.

When working in the upwards direction, the sagittal upper arm flexion (Figure 5b) was completely in the awkward range. When working in the forwards direction, the work could be completed entirely in the neutral range and in the downwards direction it could be completed entirely in the moderate range.

With regard to wrist extension (Figure 5c), the upwards and forwards working directions showed very similar results and were both in the moderate range. On the contrary, workings downwards resulted in wrist flexion which was entirely in the neutral range.

For wrist radial deviation (Figure 5d), the data was in a neutral to moderate range when working in the upwards and forwards working directions. When working in the downwards direction, however, the data differs significantly. In this direction, the wrist movement was entirely in the moderate risk category, whereby the direction changed completely to ulnar deviation.

3.3. Electromyography

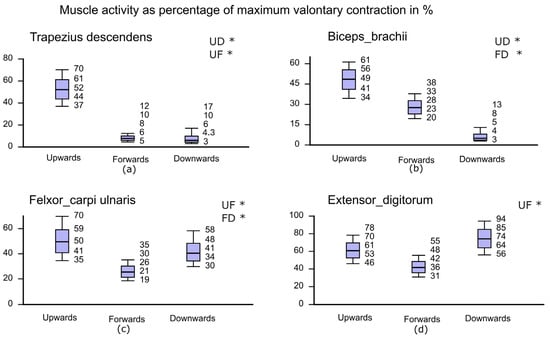

In Figure 6, the MVCP values for the EMG data for all measurements are grouped according to muscles and working directions.

Figure 6.

Electro muscle activity in three working directions; UF* = significance value <0.05 between upwards and forwards, UD* = significance value <0.05 between upwards and downwards and FD* = significance value <0.05 between forwards and downwards. (a): trapezius descendens; (b): biceps brachii; (c): flexor carpi ulnaris; (d): extensor digitorum.

For the M. trapezius descendens (Figure 6a), the muscle activity was the highest when working in the upwards direction with an MVCP median value of almost 52%. When working in the forwards direction, the muscle activity is much smaller than when working in the upwards direction, with a median value of 8 to 6%.

For the M. biceps brachii (Figure 6b), the figure shows that the direction with the biggest median value for muscle activity is again the upwards direction (49%), followed by the forwards direction (28%) and then the downwards direction (5%).

For the M. flexor carpi ulnaris (Figure 6c), the highest level of muscle activity was seen when working in the upwards direction (50%), followed by the downwards direction (41%) and then the forwards direction (26%).

In contrast to the M. flexor carpi ulnaris, for the M. extensor digitorum (Figure 6d), the highest level of muscle activity was in the downwards working direction (74%). The lowest level of muscle activity was measured in the forwards working direction (42%). When working in the upwards direction, the level of muscle activity was somewhat higher than in the forwards direction with a value of 61%.

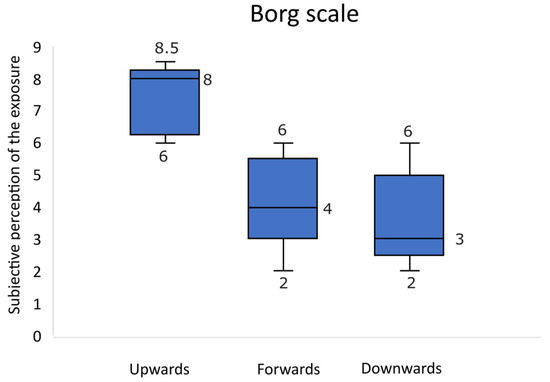

3.4. The Borg Scale Results

Figure 7 shows the results of the test subjects’ rating of the perceived exertion as maximum, minimum and median according to the Borg scale survey.

Figure 7.

Subjective perception for the exposure of vibration and posture in three working directions.

While the test subjects rated the exertion of combined exposures in the forwards (median 4) and downwards direction (median 3) as medium, combined exposures were rated as “very strong”, when working in the upwards direction (median 8).

4. Discussion

With an average exposure duration of 5.8 to 6.3 s for each experimental screwing task, there was also no statistically significant difference between HAV exposures along the measurement axis (x, y and z).

According to the manufacturer technical specifications, the vibration exposure of the wrench for tightening of bolts and nuts of maximum allowable size is about 11.5 m/s2. In comparison to this information, the measured total vibration exposures for the used power tool were much lower, while driving screws into wood (4.4–4.8 m/s2), which is probably due to the material (wood instead of metal).

In contrast to the study by Taylor et. al. [12] in which tool vibrations differed significantly for the various working directions, no significant difference was seen for vibration exposure while working in three directions in this trial. This could also be due to the different type of substrate provided in the experiments. In this study, we used a pre-cast wood plank, whereas the screwing tasks were mainly conducted by rotatory drive. In the study by Taylor et al. [12], a pre-cast concrete paving slab was used to analyze drilling tasks which might mainly require hammer action. The aspects of substrate and the mode of the operation such as rotating, hammering, or oscillating need to be considered in more detail in future studies. Thus, a greater range of tools with different specifications are needed to analyze the impact of the posture on the HAV. In a similar designed experiment however, Liljelind et al. 2011 [4] found that different working posture during grinding operations does not appear to affect the level of HAV. In a subsequent study, significant determinants for HAV were defined by anthropometric measures, such as volume of the hands, maximum grip force and weight of the operator [24]. These findings are consistent with our data in which HAV remained the same at different muscle loads.

For the posture data, there is generally a very small distribution of data within the measurements, which is probably due to the individual adjustment of the test setup in relation to body height of test subjects.

When looking at the risk categories, it is evident that the test subjects frequently adopted an awkward posture when working in the upwards direction. The observed body angles show that the upwards working direction particularly impacts head inclination, due to extension of the neck resulting from the need to look up, and the shoulders, due to the high level of shoulder flexion.

When looking at wrist flexion, the results show that the angles of flexion when working in the forwards and upwards directions are similar and lie in the moderate (yellow) range of motion. This hand position is adopted automatically when gripping the handle of the power tool. When using the tool to drive in screws, this leads to extension of the forearm in the direction of the back of the hand. When working in the downwards direction, the level of wrist flexion is improved, while a high level of ulnar deviation is seen, since the wrist needs to be in a highly angled position for the downwards screwdriving motion. These results are in good agreement with those of the studies by Besa et al. [14], who also emphasized that the transfer of energy to the hand-arm system is dependent on the position of the wrist.

In relation to the MVCP values, the upwards working direction showed the highest level of muscle activity for the M. trapezius descendens, by far. This is due to the fact that the M. trapezius descendens plays a very important role in lifting the arms, since it must compensate for the weight of the arm and the machine and must provide a proportion of the feed force. When working in the forwards direction and downwards direction, the muscle activity in the M. trapezius descendens is very low, since lifting of the arms is not required, particularly in the case of downwards tests. When considering the data for upper arm inclination, a similar pattern can be seen. Therefore, in connection with the posture, a high level of work load for muscles of the shoulder girdle can be assumed when working in the upwards direction in particular.

For the M. biceps brachii, the results show that working in the upwards direction requires the highest level of muscle activity and that the level of muscle activity decreases in the forwards and downwards working directions. As a result, it can be assumed that, particularly when working in the upwards directions, the highest level of muscular force is provided by the M. biceps. The muscle activity in this muscle is lowest when working in the downwards direction, which corresponds to a lower level of muscular force provided.

Both the M. extensor digitorum and M. flexor carpi ulnaris show lower levels of activity in the forwards working direction compared to the upwards and downwards directions. This pattern was also observed for upper arm inclination.

With the M. flexor carpi ulnaris, the highest level of muscle activity was seen in the downwards working directions. This could be caused by the high level of radial deviation. These findings line up with the data from Besa et al. [14] in that the resonance frequencies obtained for extreme wrist positions are higher than for the neutral position. Also, Dupuis et al. 1976 [16] found that the reaction of the flexor carpi ulnaris is primarily determined by the grip pressure. Due to the lack of grip force measurements, it is not possible to interpret these forces in relation to EMG data and wrist postures. This should be considered in future studies.

In contrast to vibration data, the subjective data from the test participants regarding the levels of vibration exposure in three working directions showed high variance. While the levels of perceived vibration exposure were rated as medium for the forwards and downwards working directions, the vibration exposure when working in the upwards direction was rated as very strong. These findings align very well with the measured impacts especially of posture and muscular activity.

When thinking about workplace exposure assessments of combined exposures (as in our case, HAV and posture) by questioning employees, one should keep in mind that these efforts probably are more apt to assess awkward postures than exposures to vibration.

A good example for that is carpal tunnel syndrome, which is thought to arise from a combination of factors, such as vibration, mechanical stresses to tissues from forceful gripping, awkward postures, and repetitive movements [25]. Therefore, to assess the risk of HAV exposure, musculoskeletal disorders of upper extremities among others, quantitative investigations of accompanying factors such as posture and coupling forces are needed [26].

5. Conclusions

Muscle activity and posture analysis of eleven subjects in three working directions (upwards, forwards and downwards), while exposed to HAV showed high workloads, especially in muscles of the shoulder girdle, but also in muscles of the forearm for working upwards. In comparison, working downwards also led to a high workload in the wrist. These results were found while HAV exposure did not show a noticeable difference along the three directions (4.8 m/s2 upwards, 4.4 m/s2 forwards and 4.7 m/s2 downwards).

This highlights the importance of considering posture in general, and especially wrist posture for EMG-studies on HAV.

Subjective perception of the test subjects confirmed that the workload in the upwards direction is extremely high. This is a very important aspect for compensating the actual workload and evaluating the exposure of vibrating tools. Further investigations are also needed to understand the influence of grip force to provide preventive actions to reduce the workloads of hand-arm vibration exposure.

Author Contributions

Conceptualization, N.R. and T.W.; methodology, N.R. and T.W.; software, T.W.; validation, N.R., T.W. and C.F.; formal analysis, N.R. and T.W.; investigation N.R. and T.W.; resources, N.R. and T.W.; data curation, N.R. and T.W.; writing—original draft preparation, N.R., T.W. and E.O.; writing—review and editing, N.R. and T.W.; visualization, N.R. and T.W.; supervision, C.F. and E.O.; project administration, C.F. and E.O.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to (specify the reason for the restriction).

Conflicts of Interest

The authors report no conflict of interest.

References

- Deutsche Gesetzliche Unfallversicherung e.V. DGUV-Statistiken für Die Praxis 2019; DGUV: Berlin, Germany, 2019. [Google Scholar]

- ISO 5349-1:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2001.

- Bovenzi, M.; Zadini, A.; Franzinelli, A.; Borgogni, F. Occupational musculoskeletal disorders in the neck and upper limbs of forestry workers exposed to hand-arm vibration. Ergonomics 1991, 34, 547–562. [Google Scholar] [CrossRef] [PubMed]

- Liljelind, I.; Wahlstrom, J.; Nilsson, L.; Toomingas, A.; Burstrom, L. Variability in hand-arm vibration during grinding operations. Ann. Occup. Hyg. 2011, 55, 296–304. [Google Scholar] [CrossRef] [PubMed]

- Roggio, F.; Vitale, E.; Filetti, V.; Rapisarda, V.; Musumeci, G.; Romano, E. Ergonomic Evaluation of Young Agricultural Operators Using Handle Equipment Through Electromyography and Vibrations Analysis Between the Fingers. Saf. Health Work 2022, 13, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Roeder, S.K.; Wilder, D.G.; Fethke, N.B. Novel methods to detect impacts within whole-body vibration time series data. Ergonomics 2022, 65, 1609–1620. [Google Scholar] [CrossRef] [PubMed]

- Raffler, N.; Rissler, J.; Ellegast, R.; Schikowsky, C.; Kraus, T.; Ochsmann, E. Combined exposures of whole-body vibration and awkward posture: A cross sectional investigation among occupational drivers by means of simultaneous field measurements. Ergonomics 2017, 60, 1564–1575. [Google Scholar] [CrossRef] [PubMed]

- Amari, M.; Perrin, N. Whole-body vibration exposure in unfavourable seated postures: Apparent mass and seat-to-head transmissibility measurements in the fore-and-aft, lateral, and vertical directions. Ergonomics 2023, 66, 136–151. [Google Scholar] [CrossRef] [PubMed]

- ISO/TR 10687:2022; Mechanical Vibration—Description and Determination of Seated Posture with Reference to Whole-Body Vibration. International Organization for Standardization: Geneva, Switzerland, 2022.

- Adewusi, S.A.; Rakheja, S.; Marcotte, P.; Boutin, J. Vibration transmissibility characteristics of the human hand–arm system under different postures, hand forces and excitation levels. J. Sound Vib. 2010, 329, 2953–2971. [Google Scholar] [CrossRef]

- Panariello, D.; Grazioso, S.; Caporaso, T.; Palomba, A.; Di Gironimo, G.; Lanzotti, A. Biomechanical analysis of the upper body during overhead industrial tasks using electromyography and motion capture integrated with digital human models. Int. J. Interact. Des. Manuf. IJIDeM 2022, 16, 733–752. [Google Scholar] [CrossRef]

- Taylor, M.; Maeda, S.; Miyashita, K. An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold. Vibration 2021, 4, 395–405. [Google Scholar] [CrossRef]

- Lindenmann, A.; Uhl, M.; Gwosch, T.; Matthiesen, S. The influence of human interaction on the vibration of hand-held human-machine systems—The effect of body posture, feed force, and gripping forces on the vibration of hammer drills. Appl. Ergon. 2021, 95, 103430. [Google Scholar] [CrossRef] [PubMed]

- Besa, A.J.; Valero, F.J.; Suñer, J.L.; Carballeira, J. Characterisation of the mechanical impedance of the human hand–arm system: The influence of vibration direction, hand–arm posture and muscle tension. Int. J. Ind. Ergon. 2007, 37, 225–231. [Google Scholar] [CrossRef]

- Aldien, Y.; Marcotte, P.; Rakheja, S.; Boileau, P.E. Influence of hand–arm posture on biodynamic response of the human hand–arm exposed to zh-axis vibration. Int. J. Ind. Ergon. 2006, 36, 45–59. [Google Scholar] [CrossRef]

- Dupuis, H.; Hartung, E.; Hammer, W. Biomechanisches Verhalten, Muskelreaktion und subjective Wahrnehmung bei Schwingungserregung der oberen Extremitäten zwischen 8 und 80 Hz. Int. Arch. Occup. Environemental Health 1976, 37, 9–34. [Google Scholar] [CrossRef]

- Simonsen, J.G.; Dahlqvist, C.; Enquist, H.; Nordander, C.; Axmon, A.; Arvidsson, I. Assessments of Physical Workload in Sonography Tasks Using Inclinometry, Goniometry, and Electromyography. Saf. Health Work 2018, 9, 326–333. [Google Scholar] [CrossRef] [PubMed]

- ISO 28927-5:2009; Hand-Held Portable Power Tools Test Methods for Evaluation of Vibration Emission Part 5: Drills and Impact Drills. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 5349-2:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration Part 2: Practical Guidance for Measurement at the Workplace. International Organization for Standardization: Geneva, Switzerland, 2001.

- Hermanns, I.; Raffler, N.; Ellegast, R.; Fischer, S.; Göres, B. Simultaneous field measuring method of vibration and body posture for assessment of seated occupational driving tasks. Int. J. Ind. Ergon. 2008, 38, 255–263. [Google Scholar] [CrossRef]

- Freriks, B.; Hermens, H.J.; Merletti, R.; Stegeman, D.; Blok, J.; Rau, G.; Disselhorst-Klug, C.; Hägg, G. European recommendations for surface electromyography: Results of the SENIAM Project. Roessingh Res. Dev. 1999, 8, 13–54. [Google Scholar]

- Asterland, P.; Hansson, G.Å.; Skerfving, S. Acquisition and analysis of whole-day electromyographic field recordings. In Proceedings of the Second General SENIAM (Surface EMG for Non Invasive Assessment of Muscles) Workshop, Stockholm, Sweden, 13–14 June 1997; pp. 19–27. [Google Scholar]

- Borg, G. Borg’s Perceived Exertion and Pain Scales; Human Kinetics: Champaign, IL, USA, 1998. [Google Scholar]

- Liljelind, I.; Pettersson, H.; Nilsson, L.; Wahlstrom, J.; Toomingas, A.; Lundstrom, R.; Burstrom, L. Determinants explaining the variability of hand-transmitted vibration emissions from two different work tasks: Grinding and cutting using angle grinders. Ann. Occup. Hyg. 2013, 57, 1065–1077. [Google Scholar] [CrossRef]

- Stromberg, T.; Dahlin, L.B.; Brun, A.; Lundborg, G. Structural nerve changes at wrist level in workers exposed to vibration. Occup. Env. Med 1997, 54, 307–311. [Google Scholar] [CrossRef]

- Palmer, K.T.; Bovenzi, M. Rheumatic effects of vibration at work. Best Pract. Res. Clin. Rheumatol. 2015, 29, 424–439. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).