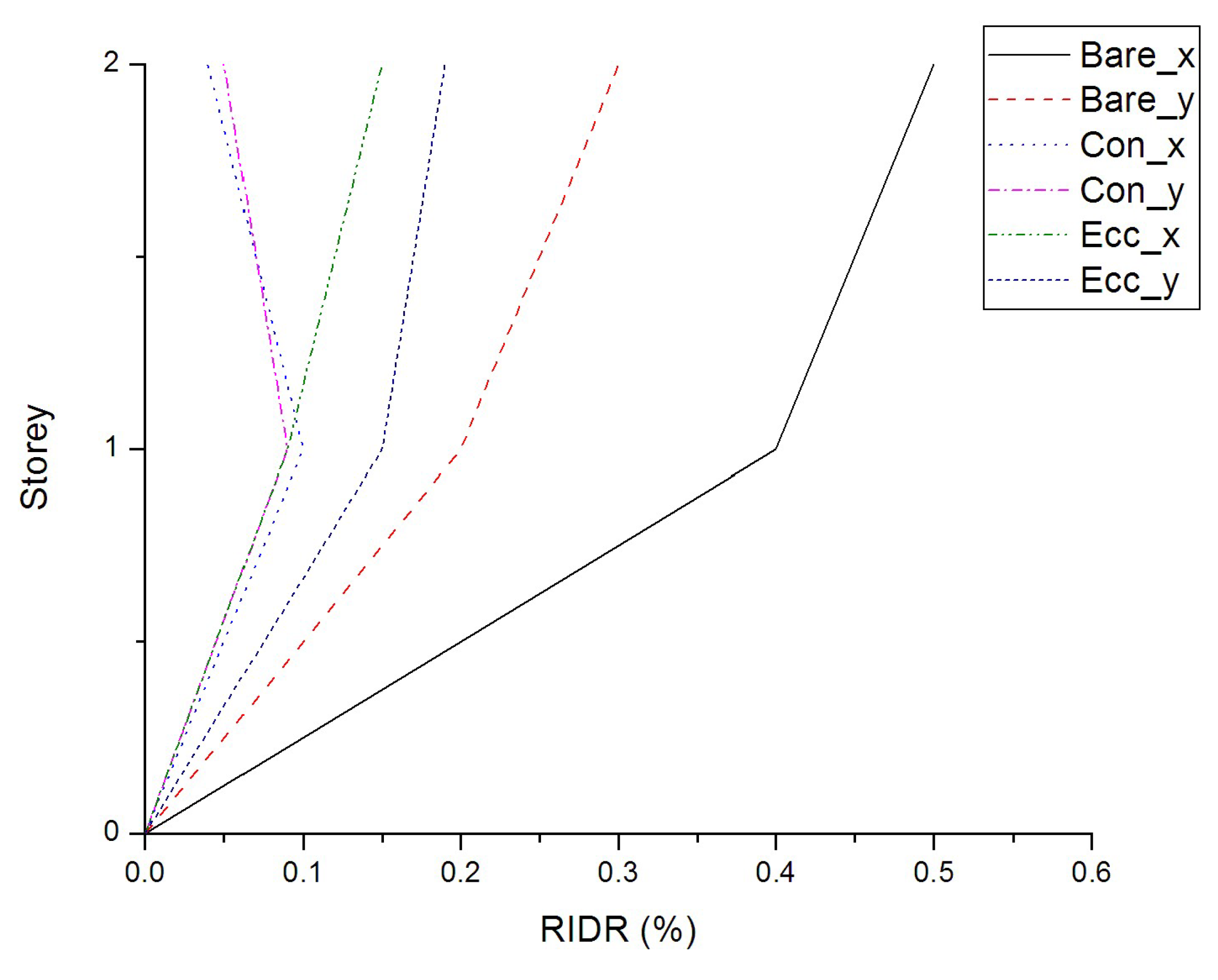

This section presents the RC building under study, the installation type and design of the seesaw system, as well as the seismic motions and modelling assumptions for the purposes of the NLTH analyses.

2.1. The Two-Storey RC Building and Seesaw System Installed

The symmetrical in floor plan and regular in height two-storey RC building equipped with the seesaw system is shown in

Figure 3. Two different configurations of the seesaw system are considered (see

Figure 1 and

Figure 2). According to

Figure 3a, the seesaw system (its cables are highlighted by a green colour) is installed at the middle bay of the perimeter frames and at every floor. The seesaw system is concentrically placed with the respect to the frame where it is installed. The cables emanating from the seesaw are anchored at both ends of the beam of the middle bay. Thus, at each floor of the RC building, four seesaw systems are totally installed.

Referring now to

Figure 3b, four seesaw systems eccentrically placed with respect to the middle bay of the RC frames of the perimeter are totally installed. Unlike steel members, where slotted holes can be easily fabricated in order to let the cables pass through them [

5], this is not an option for the RC members. The seesaw systems are anchored at the outer ends of the beams of the second floor and deviators are used on the intersected beams of the first floor in order to let the cables of the seesaw pass through them [

9,

10]. The perimeter installation of the seesaw systems for the RC buildings shown in

Figure 3 has been deliberately chosen in order to preclude any undesirable torsional effects (due to stiffness and mass distributions), beyond those simulated by means of accidental eccentricity.

For the two-storey RC building shown in

Figure 3, each bay has a 6.0 m span and each storey has a 3.0 m height. Dead (excluding self-weight of the RC) and live loads on the slabs are assumed to be 1.5 kN/m

2 and 2.0 kN/m

2, respectively, whereas the thickness of the slab is 12 cm. The grade of concrete and steel reinforcement is C12/15 and S400 (f

y = 400 MPa), respectively. The dimensions, as well as the steel reinforcement of the RC columns and beams, are presented in

Table 1. The dimensions of all columns of the perimeter frames are 40/40, whereas those of the internal columns are 35/35. The dimensions of all beams are 20/40. The two-storey RC building is assumed to be fixed-base, i.e., soil-structure interaction is absent.

It is then assumed that the two-storey RC building must resist the seismic load that corresponds to the design spectrum of EC8 [

11] for peak ground acceleration (PGA) equal to 0.24 g, soil class B, importance factor γ = 1.0 and behaviour factor q = 1.5. Therefore, response spectrum analysis is conducted and the storey shears in both horizontal directions of the building are computed. These storey shears are then utilised to estimate the diameter (section) of the cables of the seesaw system. The diameter and the design breaking (tensile) strength of the cables are presented in

Table 2. In that table, the numbering of storeys starts from bottom to top.

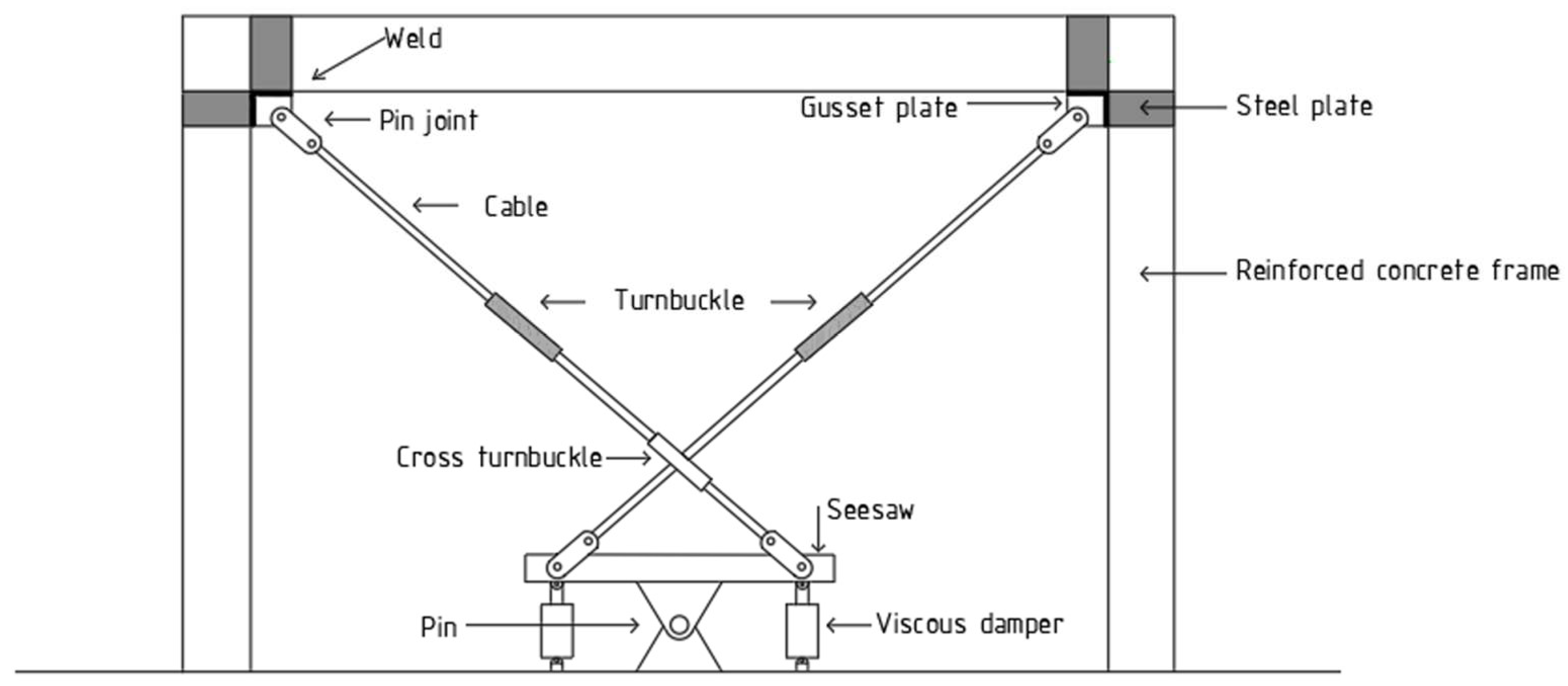

It should be noted that, in the response spectrum analyses, a small initial pre-stressing (2.0 kN) has been taken into account for the cables. It is also assumed that the anchorage type (terminal edge) of the cables is such that the breaking (tensile) strength values of

Table 2 do not need to be reduced according to [

12]. Regarding the rest members of the seesaw (

Figure 1 and

Figure 2), the following assumptions are made: the damping coefficient of the linear viscous dampers is 250 kNs/m [

13], the height of the rigid vertical steel plate (limited by the mid-stroke length of the dampers [

13]) is 870 mm, and the length of the rigid horizontal steel plate is 1600 mm. The steel grade of the seesaw members is S275.

2.2. Seismic Motions and Modelling for NLTH Analyses

The two-storey RC buildings of

Figure 3 are subjected to the two horizontal components of the 11 seismic motions (accelerograms) presented in

Table 3. These accelerograms have been selected so that their 5%-damped response spectrum closely matches the aforementioned design spectrum of EC8 [

11] in the 0.2 T–2.0 T period range, where T is the predominant period of the RC buildings. For the purposes of the seismic analyses, these seismic motions are assumed to be applied in the direction of the two orthogonal structural axes of the RC buildings of

Figure 3, considering three values for the horizontal angle of seismic incidence, i.e., 0°, 45° and 90°, with respect to the geometric centre of the column layout. Some details about these accelerograms, i.e., the earthquake location, date and moment magnitude M

w, as well as the recording station and soil type, can be found in

Table 3. Regarding soil type, the abbreviations HR, SR and SL stand for hard rock, sedimentary and conglomerate rock, and soil/alluvium, respectively.

The seismic response of the RC buildings shown in

Figure 3 is determined through NLTH analysis involving both material and geometrical nonlinearities [

14]. The innate viscous damping of the RC building is assumed to be 5% and follows the Rayleigh formula [

14]. The floor slabs are modelled using thin shell elements. Beam and column members are modelled using standard frame elements, and their inelastic behaviour is taken into account using point plastic hinges at both their ends. An effective (cracked) stiffness for beams, columns and slabs is employed following [

15]. The formation of plastic hinges takes place due to uniaxial bending in beams and due to the interaction between axial force and biaxial moment in columns [

14,

15]. Strength and stiffness deterioration phenomena are modelled according to [

14,

15].

Shear failure is also modelled using shear hinges placed next to the plastic hinges [

14]. The maximum shear force that a shear hinge can sustain is determined by the relevant formulae of EC2 [

16], which is simpler than the one in [

15]. Therefore, when the shear force surpasses the force provided by this formula, shear failure occurs. On the basis of the steel reinforcement shown in

Table 1, the maximum shear and moment capacities are 35 kN and 37 kNm, respectively, for beams; 76.3 kN and 122.1 kNm, respectively, for the 35/35 columns; and 93.5 kN and 150.3 kNm, respectively, for the 40/40 columns.

Since the RC buildings of

Figure 3 do not possess or possess very limited ductility capacity, it is expected that shear failure (especially for columns) precedes flexural failure. The numerical acceptance criteria, i.e., hinge rotations, are those of [

15]. The modelling of non-structural elements is omitted for reasons of future investigation.

Tension (cable) elements, rigid steel elements and discrete viscous dampers are used to model the seesaw system, and elastic behaviour for all elements of the seesaw system is considered. The viscous dampers possess zero stiffness and small mass, and their damping force depends on the velocity in a linear fashion. The properties of the viscous dampers, i.e., the damping coefficient and the mid-stroke length [

13], are mentioned at the end of the previous section.