Study of an Optimized Mechanical Oscillator for the Forced Vibration of the Soil Cutting Blade

Abstract

1. Introduction

2. Materials and Methods

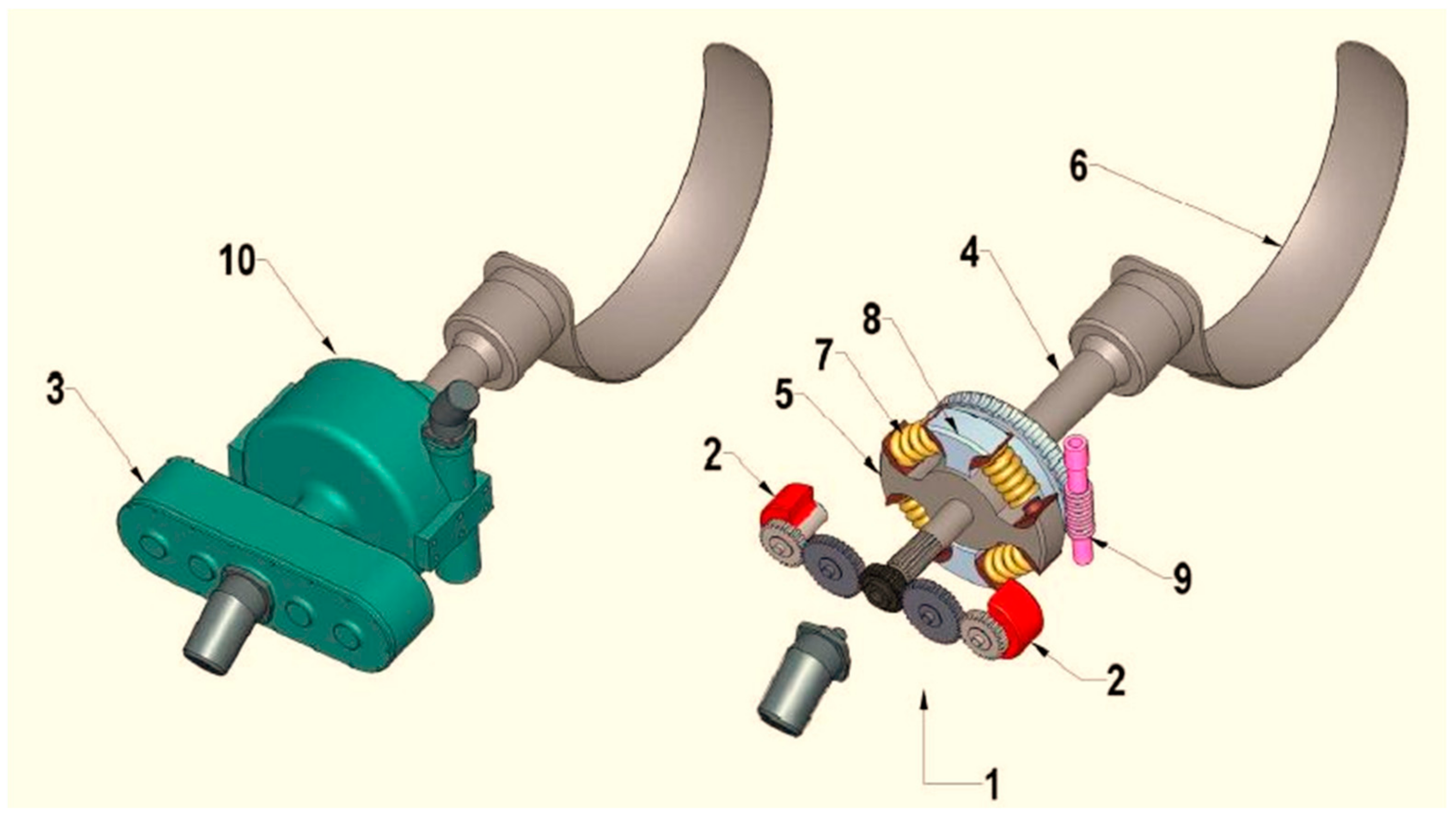

2.1. The Mechanical Oscillator and the Vibrating Blade

2.2. The Differential Equation of the Forced Vibration with Coulomb Friction

2.3. Den Hartog Solution Applied to the Vibrating Blade

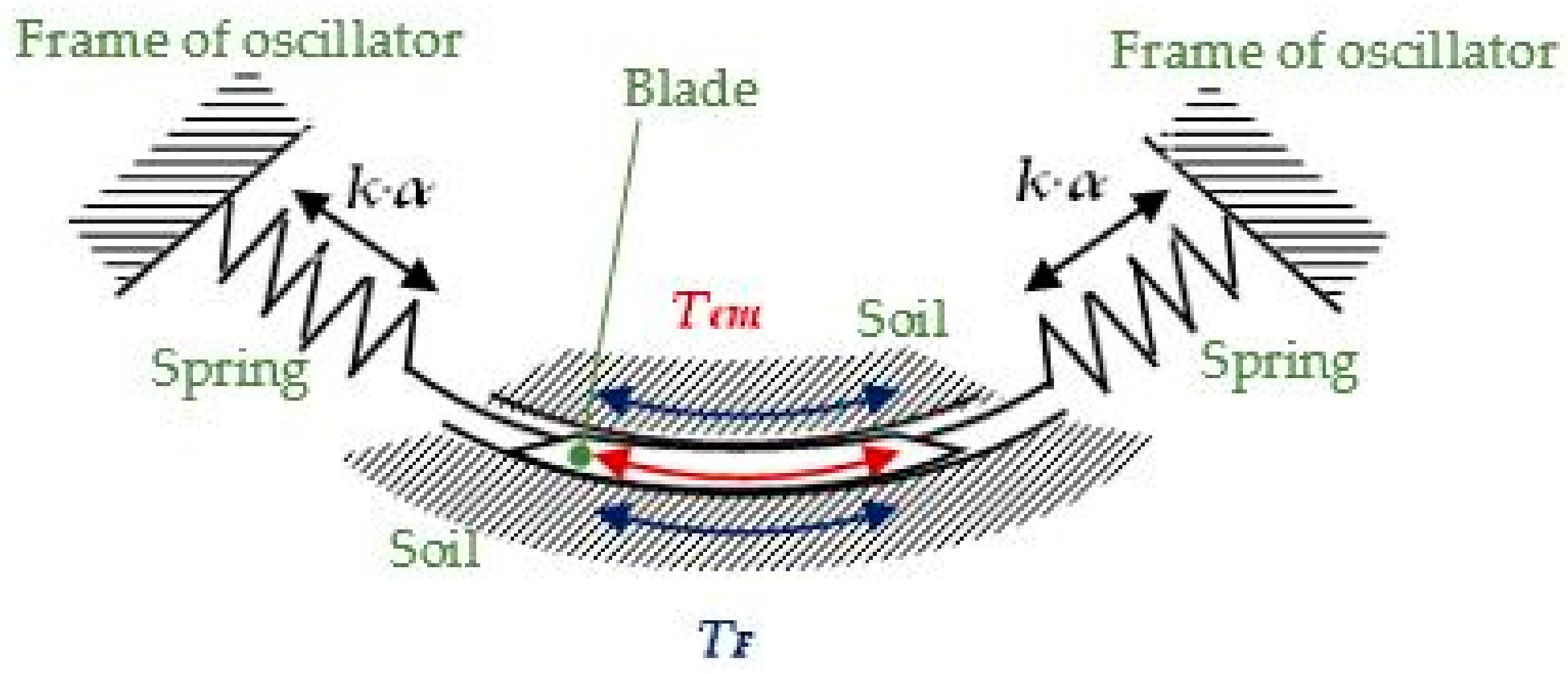

2.4. The Vibrating Blade While Cutting the Soil

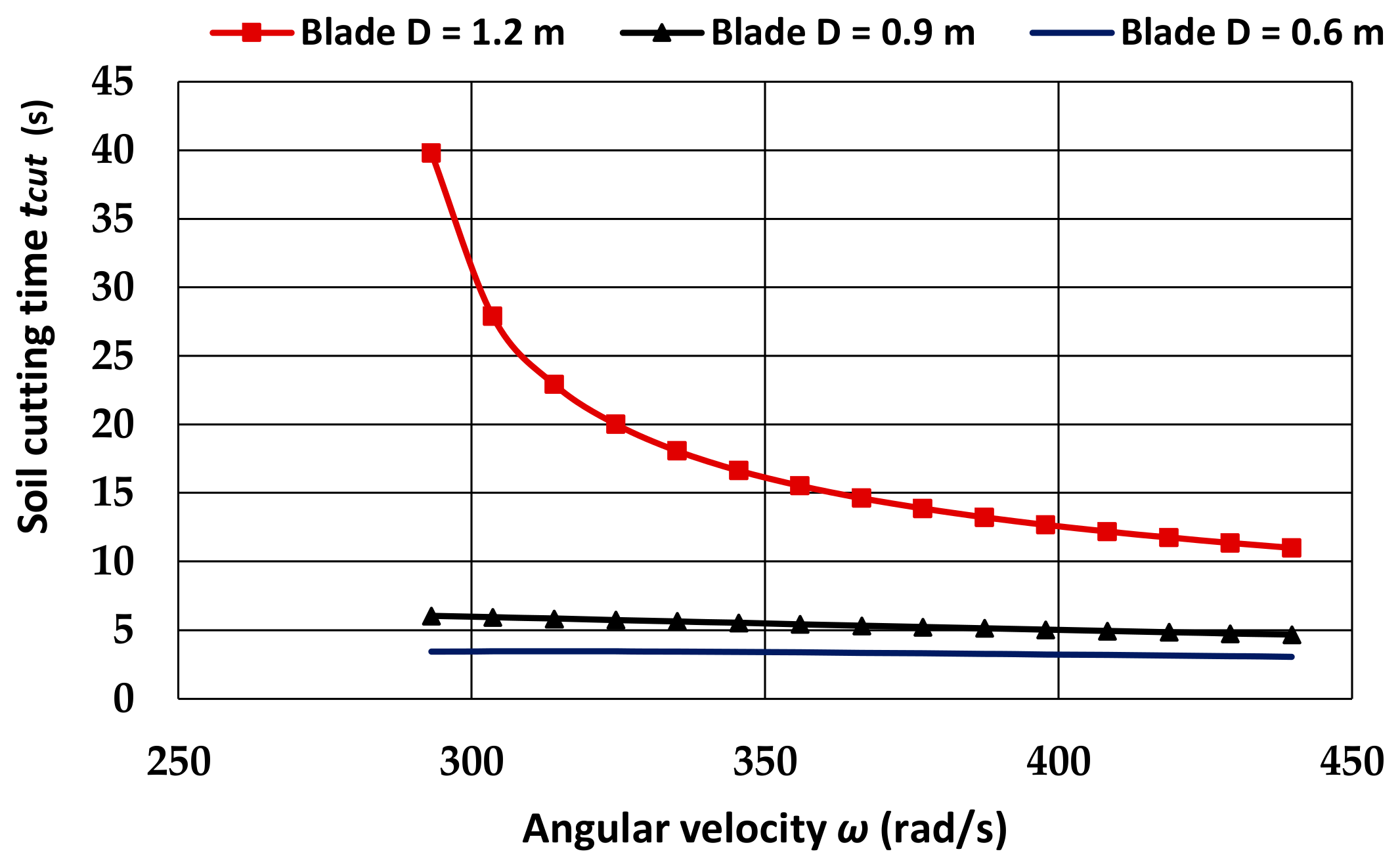

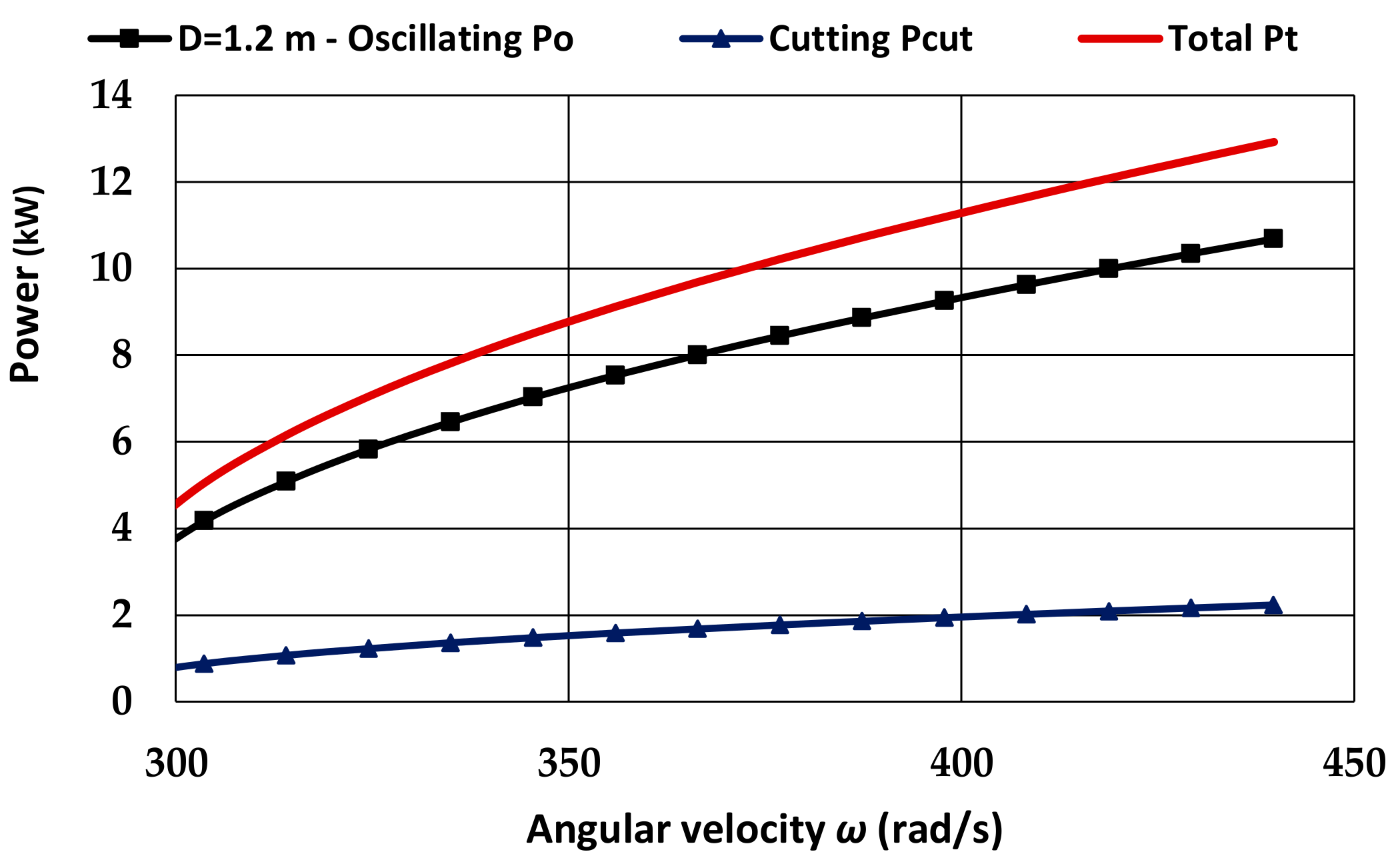

2.5. Soil Cutting Time and Energy Required

2.6. Experimental Evaluation of Cutting Torque and Maximum Displacement

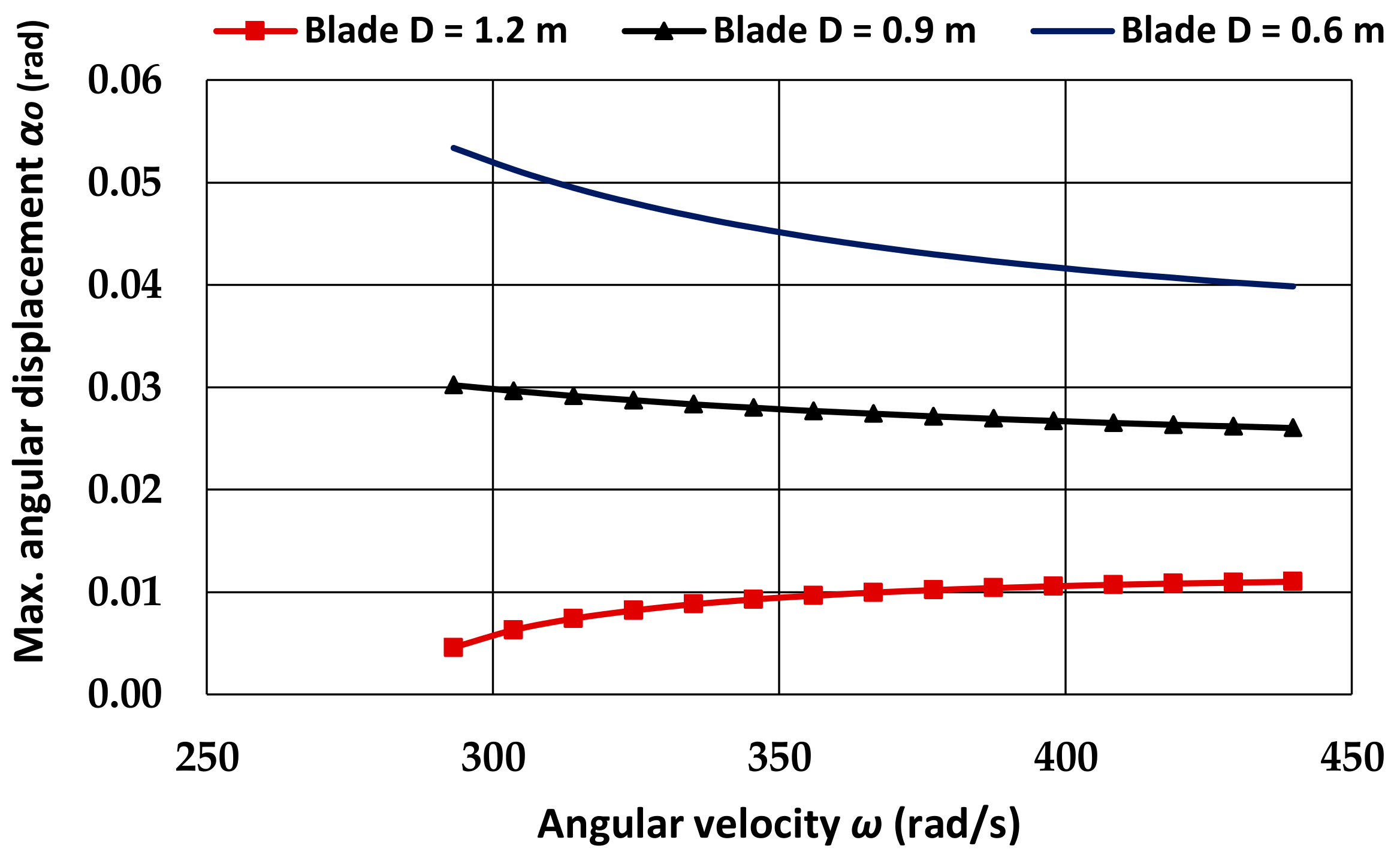

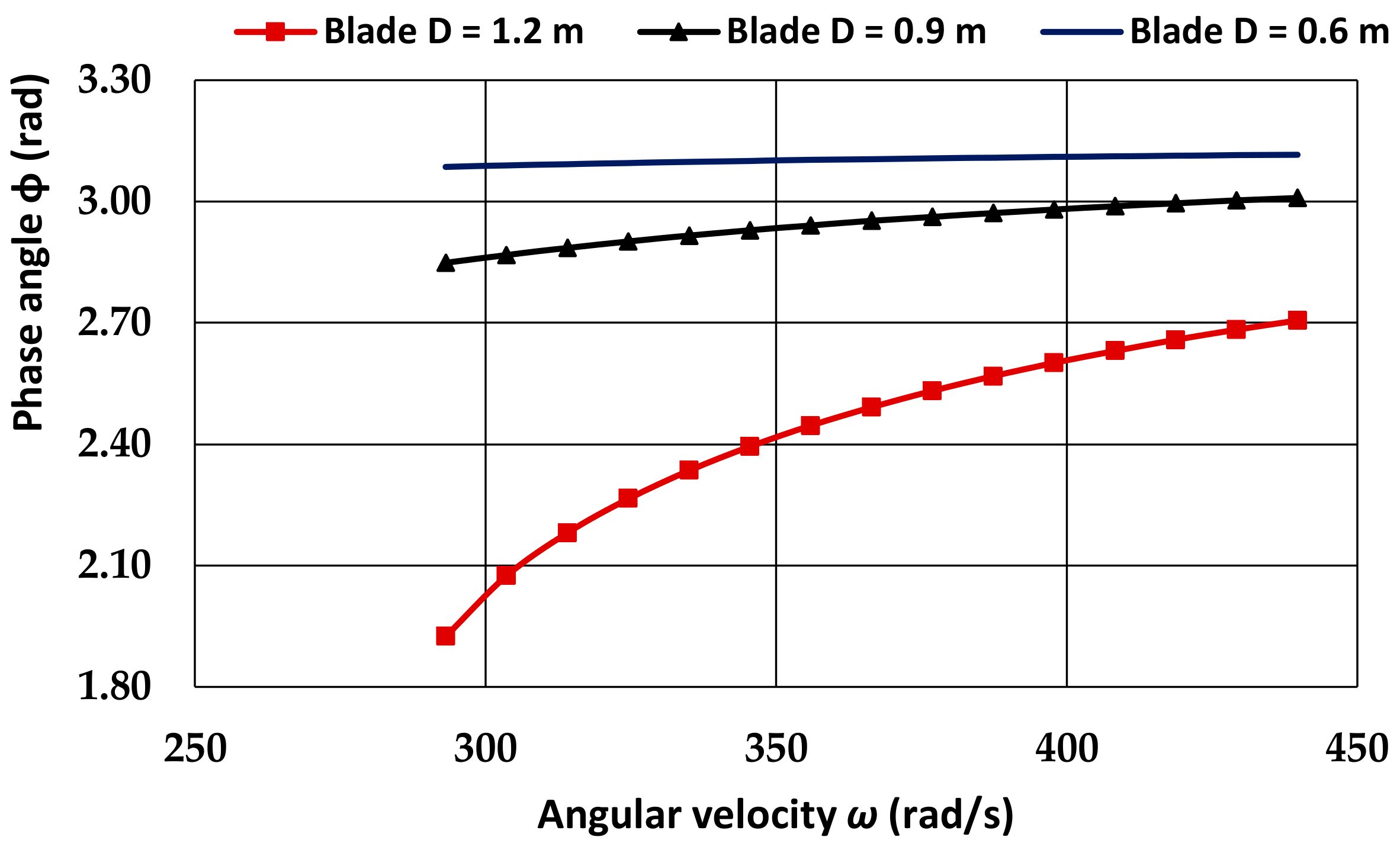

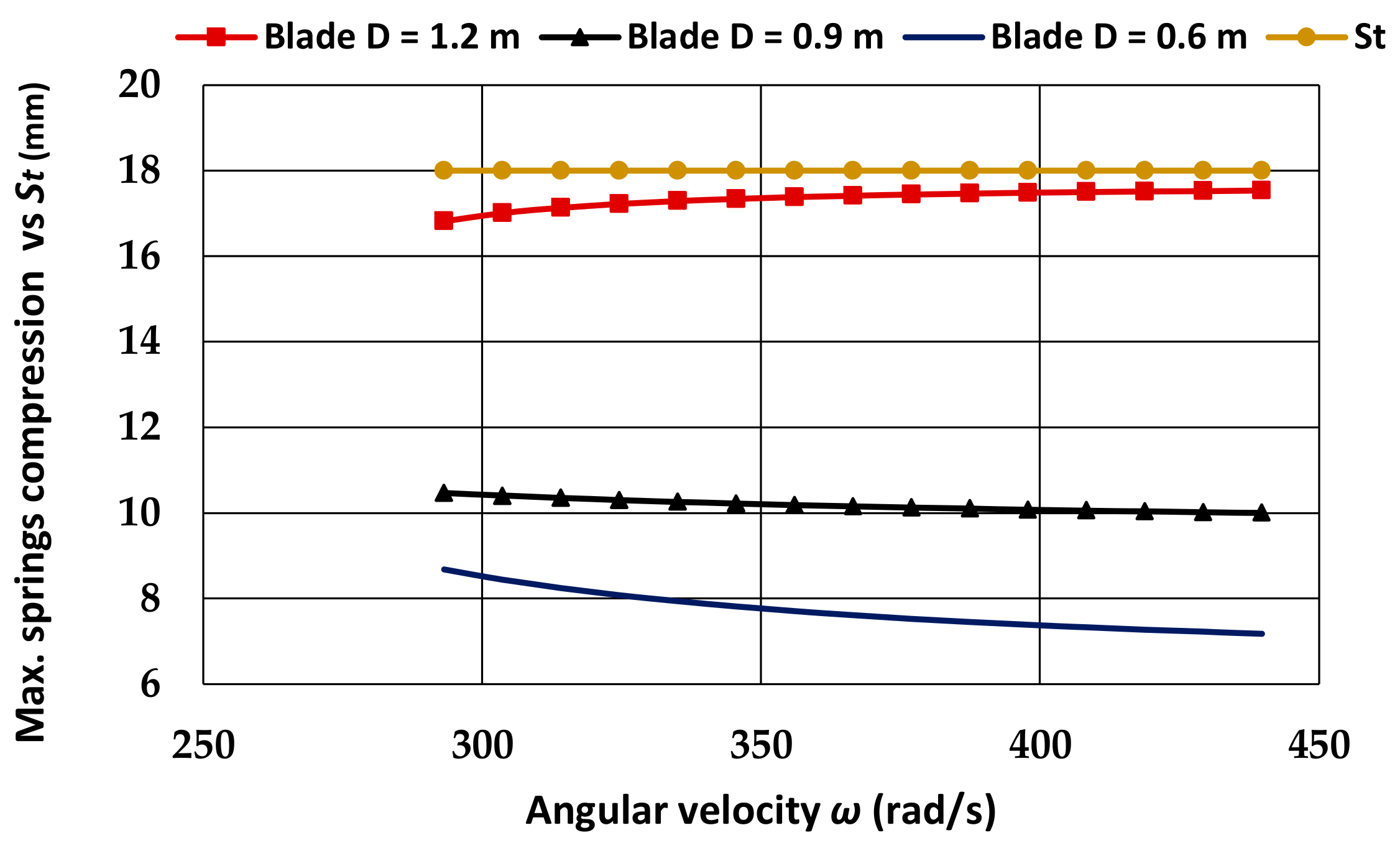

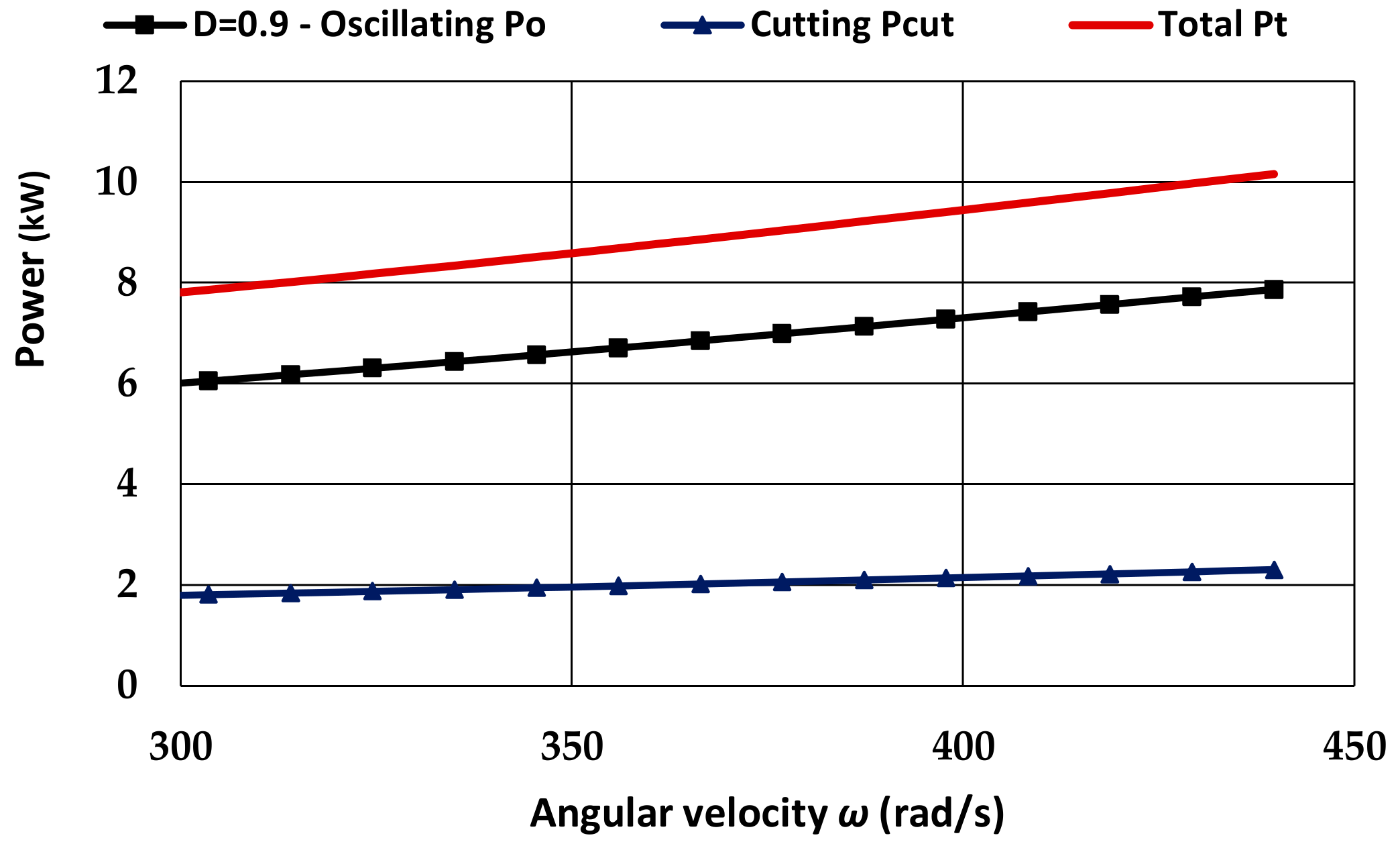

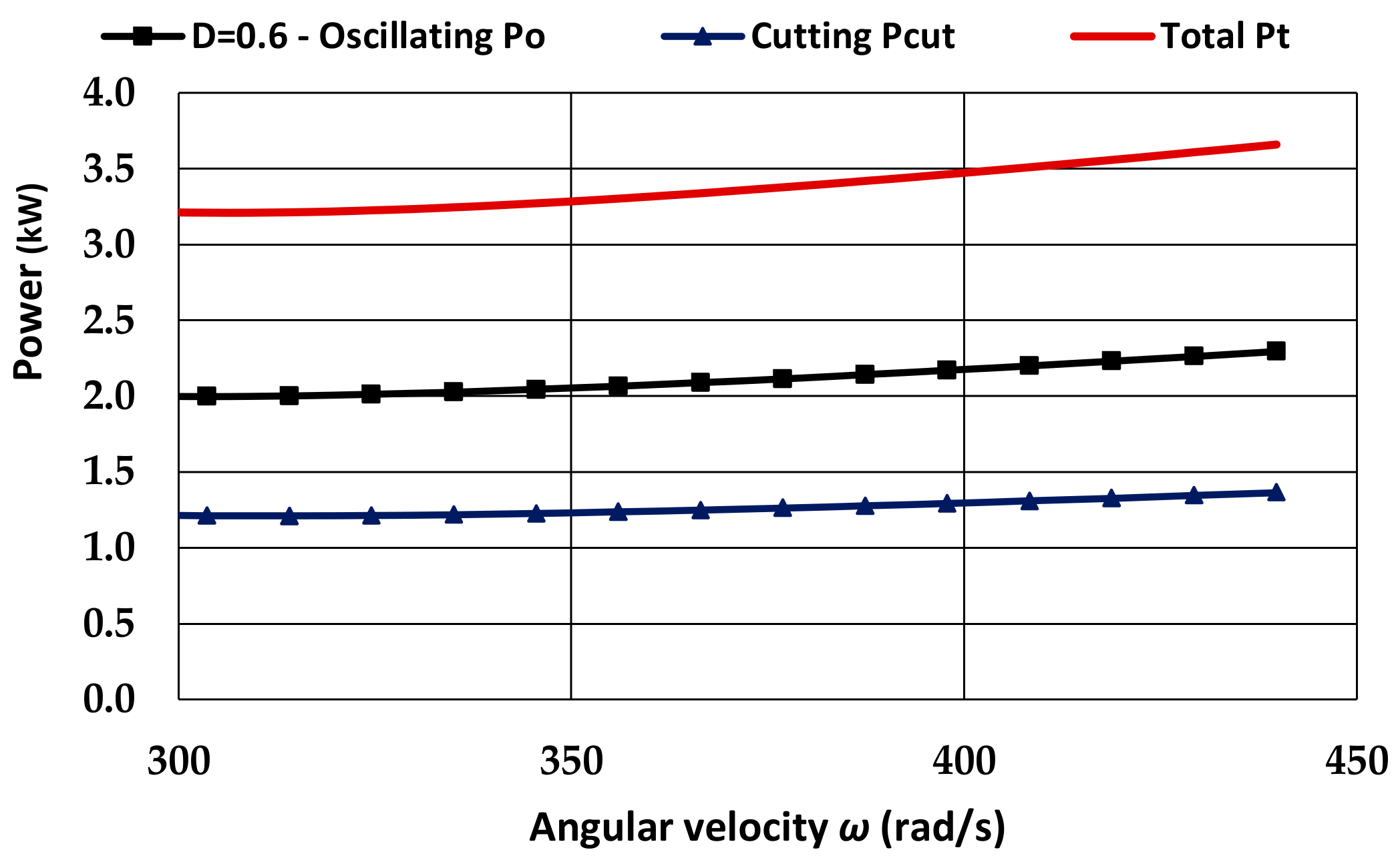

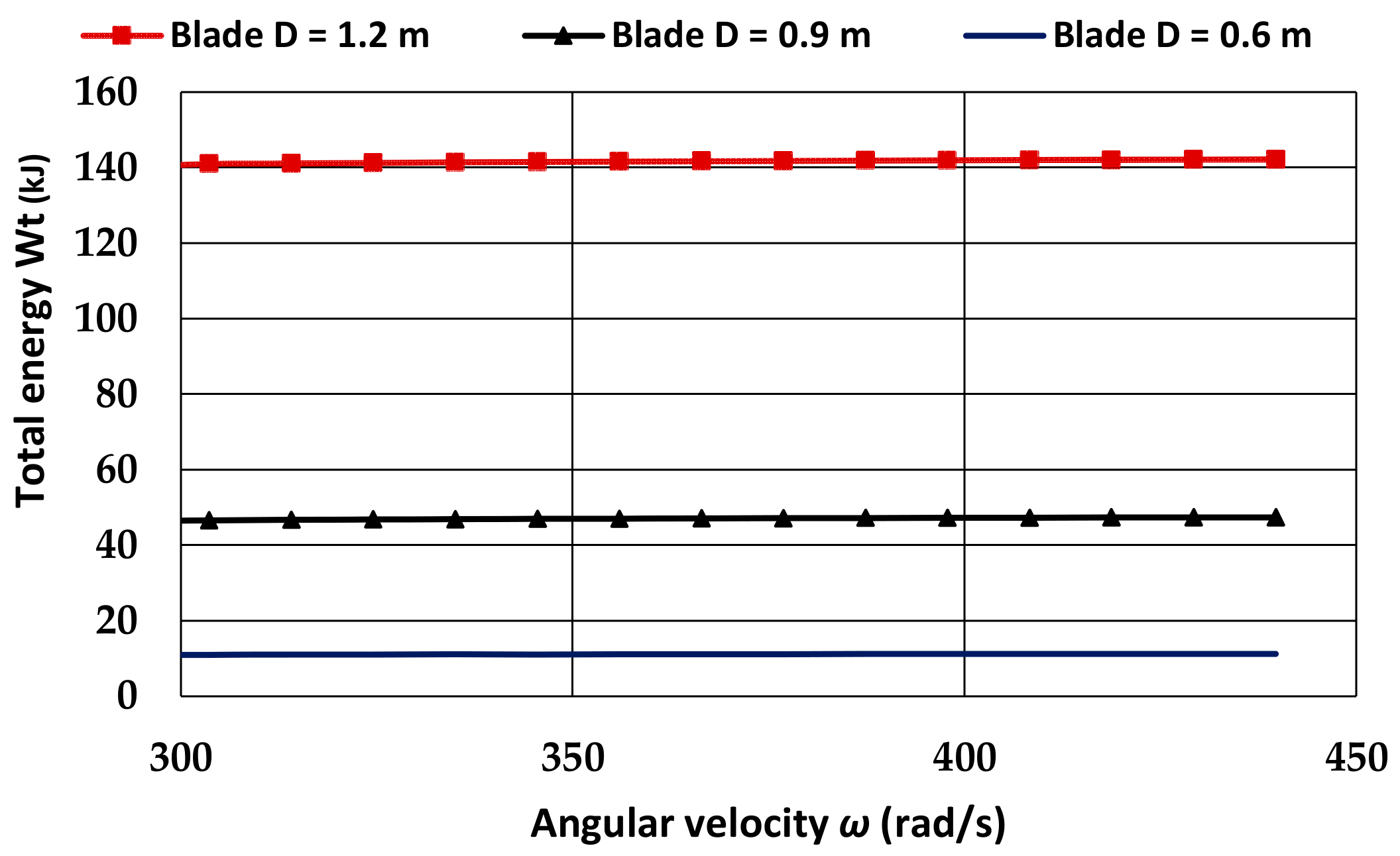

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gunn, J.; Tramontini, V.N. Oscillation of tillage implements. J. Agric. Eng. Res. 1955, 36, 725–729. [Google Scholar]

- Eggenmueller, A. Oscillating implements: Kinematics and experiments with model of the individual tools. Grundl. Landtechnik. 1958, 10, 55–69. [Google Scholar]

- Brixius, W.W.; Weber, J.A. Soil failure characteristics for oscillating tillage tool and bulldozer blade models. Trans. ASAE 1975, 18, 633–637. [Google Scholar] [CrossRef]

- Verma, S.R. Some investigations on oscillating inclined blade for potato harvesting. Ph.D. Thesis, Kharagpur University, Kharagpur, India, 1976. [Google Scholar]

- Butson, M.; MacIntyre, D. Vibratory soil cutting: I. Soil tank studies of draught and power requirements. J. Agric. Eng. Res. 1981, 26, 409–418. [Google Scholar] [CrossRef]

- Butson, M.J.; Rackham, D.H. Vibratory soil cutting: II. An improved mathematical model. J. Agric. Eng. Res. 1981, 26, 419–439. [Google Scholar] [CrossRef]

- Narayanarao, P.V.; Verma, S.R. Effect of the mode of action of an oscillating soil-working tool on draft and power require-ments. A theoretical analysis and an experimental verification. Soil Tillage Res. 1982, 2, 177–197. [Google Scholar] [CrossRef]

- Al-Jubouri, K.; McNulty, P. Potato digging using orbital vibration. J. Agric. Eng. Res. 1984, 29, 73–82. [Google Scholar] [CrossRef]

- Shkurenko, N.S. Experimental data on the effect of oscillation on the cutting resistance of soil. J. Agric. Eng. Res. 1960, 5, 226–232. [Google Scholar]

- Wolf, D.; Shmuelevich, I. Vibrating subsoilers in clod forming soils. In Proceeding of the ASAE Winter Meeting, Chicago, IL, USA, 12–16 December 1977. ASAE Paper No. 77-1010. [Google Scholar]

- Smith, J.L.; Dais, J.L.; Flikke, A.M. Theoretical analysis of vibratory tillage. T ASAE 1972, 15, 831–833. [Google Scholar] [CrossRef]

- Smith, J.L.; Hallmann, K.; Flikke, A.M. Experimental analysis of vibratory tillage. T ASAE 1972, 15, 834–837. [Google Scholar] [CrossRef]

- Niyamapa, T.; Salokhe, V. Soil disturbance and force mechanics of vibrating tillage tool. J. Terramechanics 2000, 37, 151–166. [Google Scholar] [CrossRef]

- Szabo, B.; Barnes, F.; Sture, S.; Ko, H.-Y. Effectiveness of vibrating bulldozer and plow blades on draft force reduction. Trans. ASAE 1998, 41, 283–290. [Google Scholar] [CrossRef]

- Shahgoli, G.; Saunders, C.; Desbiolles, J.; Fielke, J. The effect of oscillation angle on the performance of oscillatory tillage. Soil Tillage Res. 2009, 104, 97–105. [Google Scholar] [CrossRef]

- Shahgoli, G.; Fielke, J.; Saunders, C.; Desbiolles, J. Simulation of the dynamic behaviour of a tractor-oscillating subsoiler system. Biosyst. Eng. 2010, 106, 147–155. [Google Scholar] [CrossRef]

- Shahgoli, G.; Fielke, J.; Desbiolles, J.; Saunders, C. Optimising oscillation frequency in oscillatory tillage. Soil Tillage Res. 2010, 106, 202–210. [Google Scholar] [CrossRef]

- Tang, M.; Li, X.; Zhang, D.; Wang, W. The effects of vibrating subsoiling on tractional resistance and soil properties. In Proceedings of the 2015 ASABE Annual International Meeting, New Orleans, LA, USA, 26–29 July 2015. [Google Scholar] [CrossRef]

- Shchukin, S.G.; Nagajka, M.A.; Golovatyuk, V.A. Investigation of the soil tillage process by vibratory subsoiler. Sib. Her. Agric. Sci. 2015, 3, 83–89. [Google Scholar]

- Razzaghi, E.; Sohrabi, Y. Vibratory soil cutting a new approach for the mathematical analysis. Soil Tillage Res. 2016, 159, 33–40. [Google Scholar] [CrossRef]

- Rao, G.; Chaudhary, H. A review on effect of vibration in tillage application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012030. [Google Scholar] [CrossRef]

- Rao, G.; Chaudhary, H.; Sharma, A. Design and analysis of vibratory mechanism for tillage application. Open Agric. 2018, 3, 437–443. [Google Scholar] [CrossRef]

- Rao, N.R.N.V.G.; Chaudhary, H.; Sharma, A.K. Optimal design and analysis of oscillatory mechanism for agricultural tillage operation. SN Appl. Sci. 2019, 1, 1–5. [Google Scholar] [CrossRef]

- Rao, N.R.N.V.G.; Chaudhary, H.; Sharma, A.K. Design and development of vibratory cultivator using optimization algorithms. SN Appl. Sci. 2019, 1, 1287. [Google Scholar] [CrossRef]

- Rao, N.G.; Kumar, A.; Chaudhary, H.; Sharma, A.K. Design of four-bar mechanism for vibratory tillage cultivator using five precision position method for path generation problem. Int. J. Environ. Sustain. Dev. 2021, 21, 4–20. [Google Scholar] [CrossRef]

- Keppler, I.; Hudoba, Z.; Oldal, I.; Csatar, A.; Fenyvesi, L. Discrete element modeling of vibrating tillage tools. Eng. Comput. 2015, 32, 308–328. [Google Scholar] [CrossRef]

- Biris, S.S.; Ungureanu, N.; Vladut, V. Study on the influence of mechanical vibrations to the energy required for soil tillage. In Proceedings of the 5th International Conference on Thermal Equipment, Renewable Energy and Rural Development, Golden Sands, Bulgaria, 2–4 June 2016; pp. 175–180. [Google Scholar]

- Dzhabborov, N.; Dobrinov, A.; Sergeev, A. Vibration parameters and indicators of a dynamic tillage tool. IOP Conf. Ser. Earth Environ. Sci. 2021, 937, 1–10. [Google Scholar] [CrossRef]

- Wang, D.; Wang, J.; Shang, S. Experimental research on soil digging resistance and energy consumption based on vibration. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2020, 51, 267–272. [Google Scholar] [CrossRef]

- Friso, D.; Bietresato, M. Dynamic analysis and design guidelines of mechanical oscillators for cutting soil through vibrating tools. J. Vibroeng. 2012, 14, 1775–1786. [Google Scholar]

- Cerruto, E.; Balsari, P.; Oggero, G.; Friso, D.; Guarella, A.; Raffaelli, M. Operator safety during pesticide application in greenhouses: A survey on italian situation. Acta Hortic. 2008, 801, 1504–1514. [Google Scholar] [CrossRef]

- Pochi, D.; Fornaciari, L.; Vassalini, G.; Grilli, R.; Fanigliulo, R. Levels of whole-body vibrations transmitted to the driver of a tractor equipped with self-levelling cab during soil primary tillage. Agriengineering 2022, 4, 695–706. [Google Scholar] [CrossRef]

- Singh, A.; Samuel, S.; Singh, H.; Kumar, Y.; Prakash, C. Evaluation and analysis of whole-body vibration exposure during soil tillage operation. Safety 2021, 7, 61. [Google Scholar] [CrossRef]

- Den Hartog, J.P. Forced vibrations with combined Coulomb and viscous friction. T ASME 1931, 53, 107–115. [Google Scholar]

- Mostaghel, N.; Davis, T. Representations of coulomb friction for dynamic analysis. Earthq. Eng. Struct. D 1997, 26, 541–548. [Google Scholar] [CrossRef]

- Friso, D. Energy saving with total energy system for cold storage in Italy: Mathematical modeling and simulation, exergetic and economic analysis. Appl. Math. Sci. 2014, 8, 6529–6546. [Google Scholar] [CrossRef]

| Quantity | Symbol | Oscillator Old | Oscillator New |

|---|---|---|---|

| Linear spring rate | kl (N m−1) | 572,000 | 1,140,000 |

| Number of springs | z | 4 | 4 |

| Lever arm of the springs | bS (m) | 0.087 | 0.108 |

| Torsional springs rate | k (N m rad−1) | 17,318 | 53,227 |

| Number of masses | n | 4 | 4 |

| Mass | m (kg) | 1.27 | 2.41 |

| Eccentricity | yG (m) | 0.0212 | 0.028 |

| Mass lever arm | bG (m) | 0.163 | 0.200 |

| Moment of inertia | JO (kg m2) | 0.38 | 1.30 |

| Quantity | Symbol | Values | ||

|---|---|---|---|---|

| Blade Diameter | D (m) | 0.6 | 0.9 | 1.2 |

| Moment of inertia (blade) | JB (kg m2) | 0.32 | 1.02 | 3.40 |

| Moment of inertia (oscillator) | JO (kg m2) | 1.30 | 1.30 | 1.30 |

| Moment of inertia (system b+o) | J (kg m2) | 1.62 | 2.32 | 4.70 |

| Natural frequency | ωn (rad s−1) | 181.2 | 151.4 | 106.4 |

| Quantity | Symbol | Values | ||

|---|---|---|---|---|

| Blade Diameter | D (m) | 0.6 | 0.9 | 1.2 |

| Cutting torque | Tcut (N m) | 1268 | 3190 | 6324 |

| Standard deviation | S.D. (N m) | 89 | 182 | 286 |

| Friction torque | TF (N m) | 176 | 892 | 2819 |

| Quantity | Symbol | Values | |||

|---|---|---|---|---|---|

| Blade Diameter | D (m) | 0.6 | 0.9 | 1.2 | |

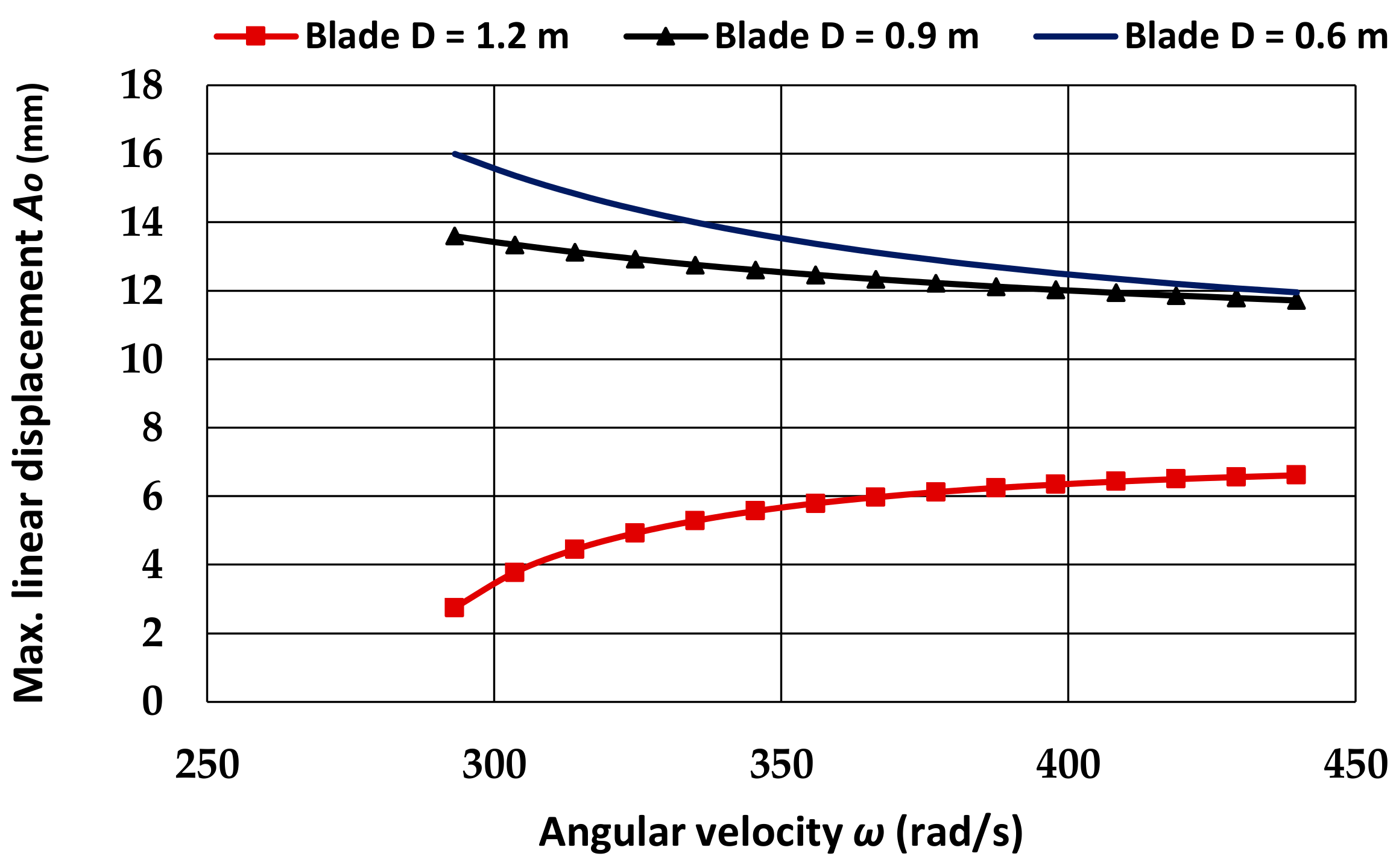

| Calculated | Max. angular displacement | α0 (rad) | 0.0407 | 0.0264 | 0.0108 |

| Max. linear displacement | A0 (mm) | 12.2 | 11.9 | 6.5 | |

| Measured | Max. angular displacement | α0 (rad) | 0.0396 | 0.0253 | 0.0101 |

| Max. linear displacement | A0 (mm) | 11.9 | 11.4 | 6.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friso, D. Study of an Optimized Mechanical Oscillator for the Forced Vibration of the Soil Cutting Blade. Vibration 2023, 6, 239-254. https://doi.org/10.3390/vibration6010015

Friso D. Study of an Optimized Mechanical Oscillator for the Forced Vibration of the Soil Cutting Blade. Vibration. 2023; 6(1):239-254. https://doi.org/10.3390/vibration6010015

Chicago/Turabian StyleFriso, Dario. 2023. "Study of an Optimized Mechanical Oscillator for the Forced Vibration of the Soil Cutting Blade" Vibration 6, no. 1: 239-254. https://doi.org/10.3390/vibration6010015

APA StyleFriso, D. (2023). Study of an Optimized Mechanical Oscillator for the Forced Vibration of the Soil Cutting Blade. Vibration, 6(1), 239-254. https://doi.org/10.3390/vibration6010015