3.1. Judgment of Limit Parameter Conditions for Coal Spontaneous Combustion Dangerous Zone

A limit parameter is an external condition that causes coal spontaneous combustion. Parameters characterizing the external conditions of coal spontaneous combustion include minimal floating coal thickness, lower limit of oxygen concentration, and upper limit of air leakage intensity [

16].

(1) Minimal floating coal thickness

In an ideal state, residual coal is regarded as a boundaryless plane, and the heat is transmitted through the coal rock to dissipate heat. The air leakage intensity is very low, meaning it can be considered in a single dimension, and the temperature in the coal is basically the same. Then, the spontaneous combustion conditions and temperature rise of coal are simplified as Equation (1) [

17]:

That is, when it cannot cause loose coal spontaneous combustion, while represents the minimal floating coal thickness.

(2) Limit of oxygen concentration

In the simplified one-dimensional heat transfer model of an infinite plane in the goaf, the expression of the limit of oxygen concentration is [

18]:

From the above formula, when C << Cmin, the coal and oxygen compound reaction amounts decrease relative to the heat emitted amount, meaning coal cannot spontaneously combust. Thus, Cmin is called the lower limit of oxygen concentration.

(3) Ultimate air leakage intensity

When the floating coal thickness is greater than

hmin, the oxygen concentration is sufficient, and the air leakage speed remains constant, with a single direction, the expression of the ultimate air leakage intensity is [

19]:

According to the field observation, the floating coal porosity inside the goaf is 0.38, the loose coal thermal conductivity is 0.0008681 J/(cm·s·°C), the air leakage intensity is 0.05 cm

−3·s

−1·cm

−2, and the rock temperature is 23.42 °C.

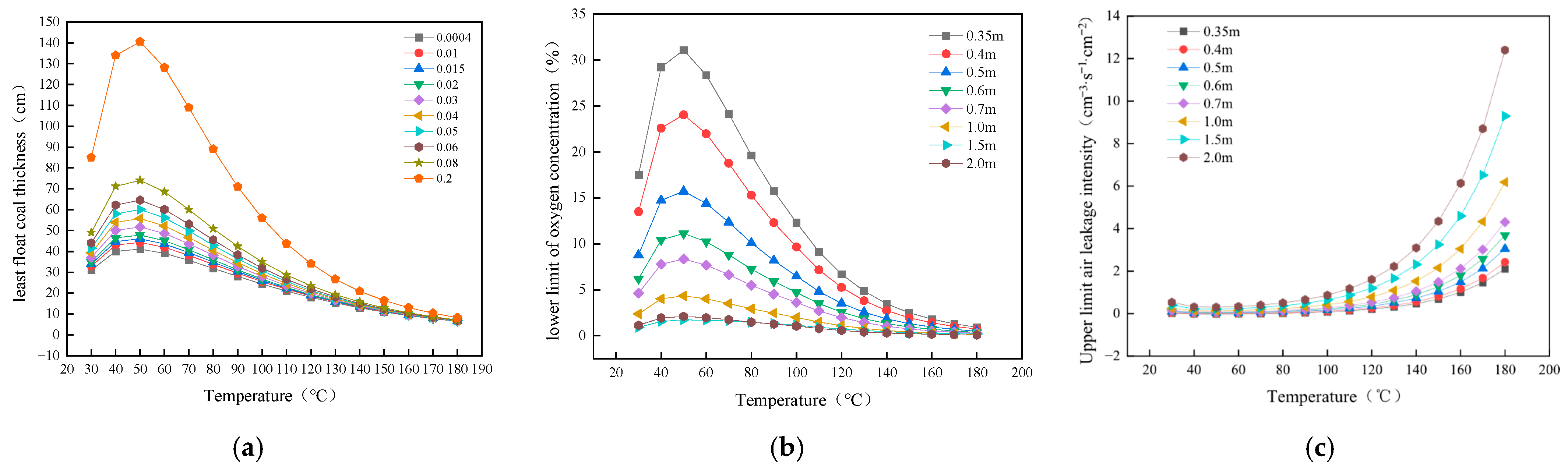

Figure 3a presents the variation law for minimal floating coal thickness obtained through the coal spontaneous combustion experiment at an air leakage intensity of 0~0.2 cm

−3·s

−1·cm

−2. Based on the diagram, at 30–50 °C, the minimal floating coal thickness increases as temperature increases, while at >50 °C, the minimal floating coal thickness decreases as temperature increases.

Figure 3b,c present the lower limit of oxygen concentration and the upper limit of air leakage intensity at a floating coal thickness of 0.35~2 m and a coal temperature of 30 °C~180 °C determined based on experimental results. Clearly, the lower limit of oxygen concentration required for spontaneous combustion for 0.35 m thick floating coal is 31.08%, which is impossible inside loose floating coal, so spontaneous combustion will not occur. At a floating coal thickness of 0.35 m, a coal temperature of 50 °C induces the smallest upper limit of air leakage intensity.

The spontaneous combustion experiment of No.5 coal seam in Chenjiagou Coal Mine was carried out by using XK-8 type coal spontaneous combustion experimental platform (from China Shenmu Chuangyou Company, Shenzhen, China). The experimental test device consisted of an adiabatic oxidation device, a gas supply system, a temperature detection and control system, an oxidation gas product analysis system, and a quality change detection system. The average particle size of the coal sample was 0.86 mm, and the experimental test temperature ranged from room temperature to 190 °C. The spontaneous combustion process of residual coal in goaf was simulated, and the spontaneous combustion period and oxidation characteristic parameters of coal were measured. Based on the experimental test and theoretical analysis of five layers (average particle size of 0.86 mm) of mine coal, the lowest spontaneous combustion duration was 30 days at an underground starting temperature of 23.42 °C, and while a value of 26 days was obtained in our laboratory, with a starting temperature of 30 °C. According to the calculation formula for coal spontaneous combustion limits, the floating coal thickness and coal sample temperature are 0.35 m and 50 °C, respectively, after the calculation of the lower limit of oxygen concentration C

min = 31.08%. The oxygen concentration of fresh air flow is far less than 31.08%, and thus this does not conform to real site conditions. At this time, floating coal cannot spontaneously combust. At a coal sample temperature of about 50 °C, the upper limit of air leakage intensity has its minimum value, being lower than the air leakage intensity required for floating coal to spontaneously combust.

Table 1 displays the upper limit of air leakage intensity at different floating coal thicknesses. At 50 °C, the floating coal has its maximum thickness. When the floating coal thickness is lower than this limit for thickness at this temperature, the floating coal does not combust spontaneously. A higher air leakage intensity leads to more heat being removed via airflow.

Table 2 shows the limit for floating coal thickness under diverse air leakage intensities.

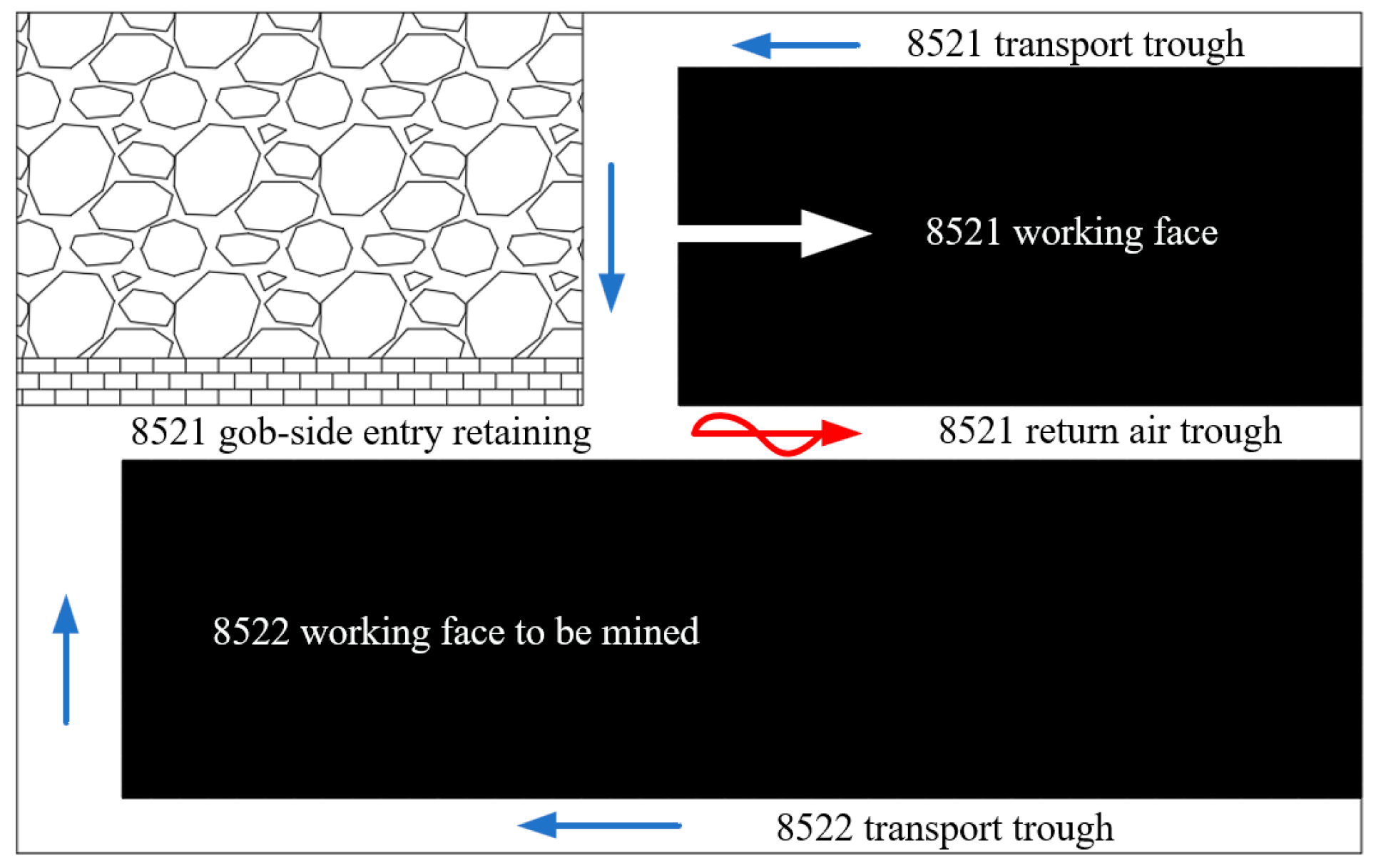

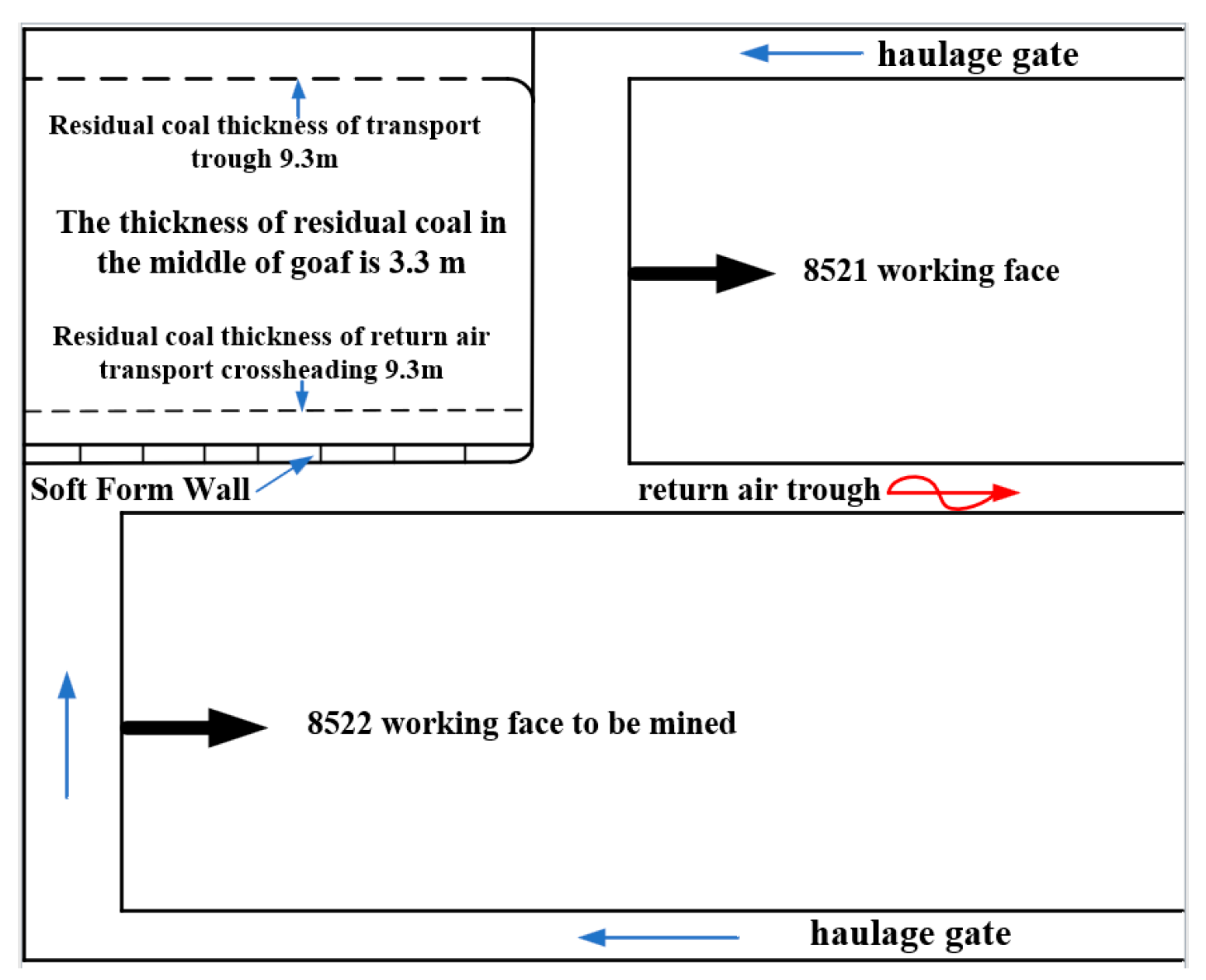

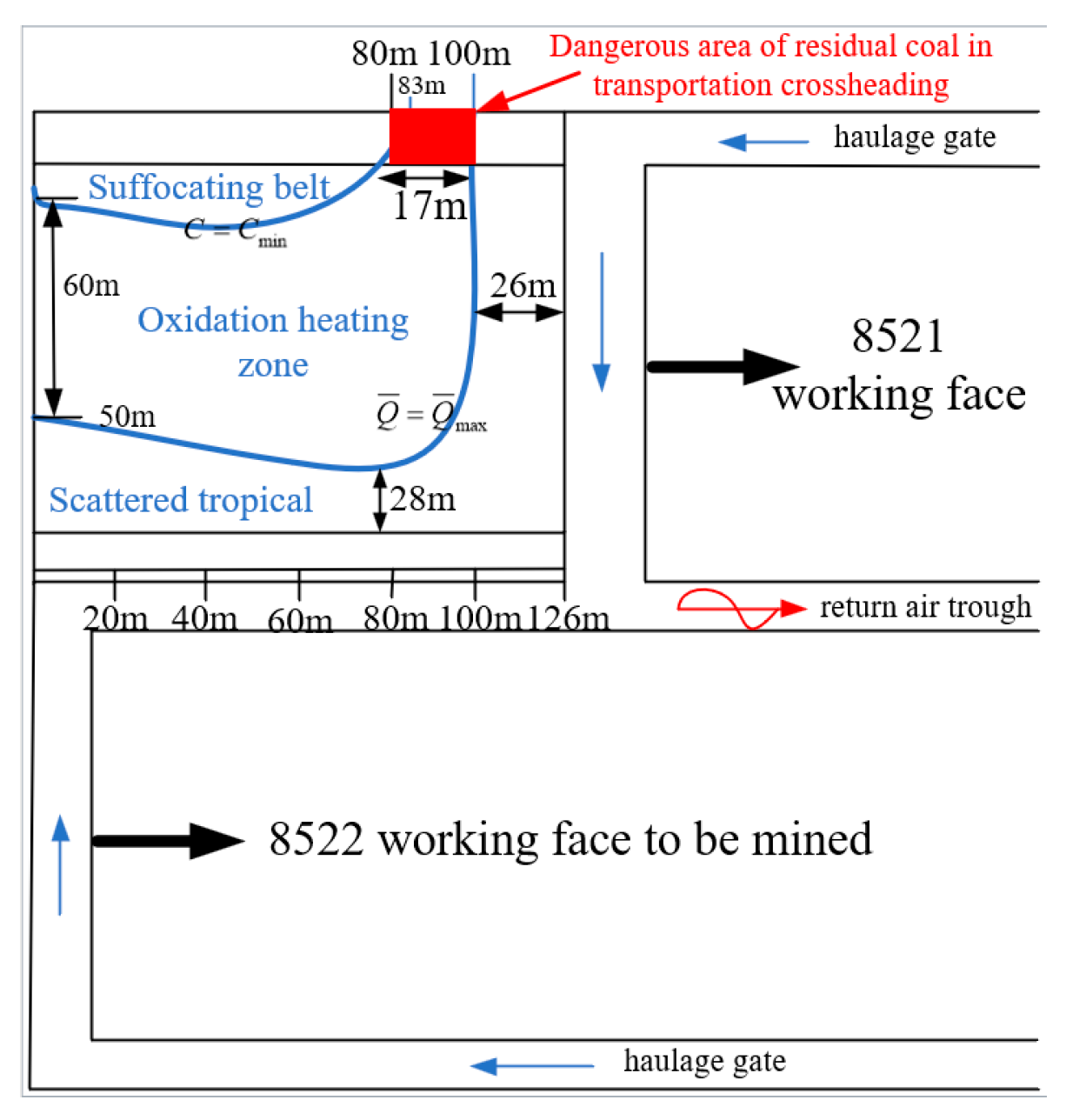

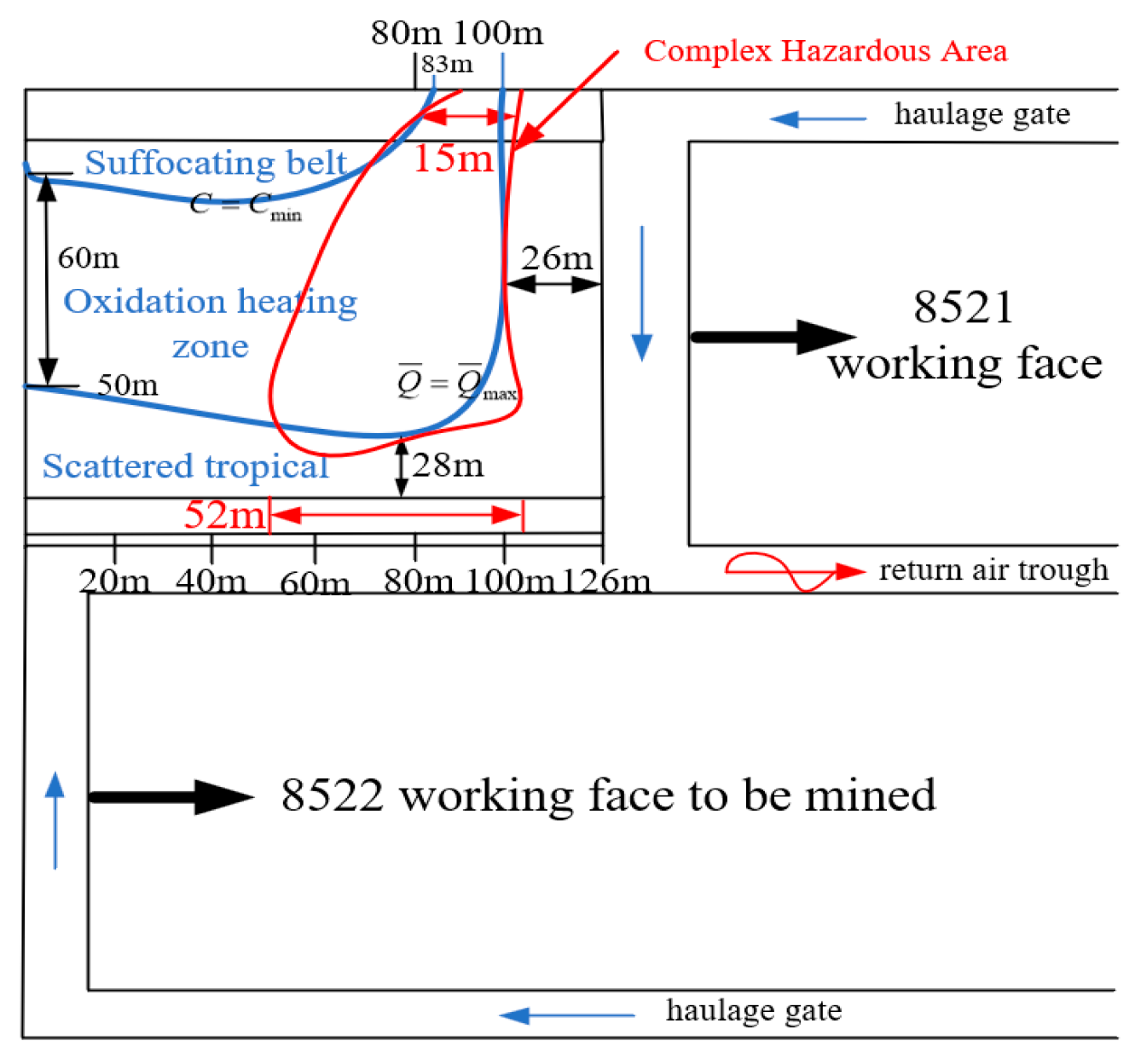

3.2. Study on the Oxidation Temperature Rise Zone Range

Floating coal thickness and the width of the upper layer 8511 goaf and the lower layer 8521 goaf are calculated. The upper layer 8511 working face is mined out, and there is a certain thickness of residual coal and a 6.5 m thick coal pillar amid the upper layer goaf and two roadways. The thickness of the upper layer 8511 working face is 11.9 m, of which the thickness of the machine cutting is 3 m, while that of the top coal is 8.9 m. The lower layer 8521 working face is being mined, and there are two residual coals with a thickness of 4 m within the goaf inside the fully mechanized caving face. Affected by caving during the mining process, both the upper and lower layered goafs will be connected, forming the composite goaf, thereby increasing floating coal thickness inside this composite goaf. Simultaneously, the residual coal in two roadways of the upper layer and the coal pillar with a width of 6 m also fall into the goaf of the fully mechanized caving face inside the goaf-side entry retaining in lower layer 8521. The thickness of this fully mechanized caving face within the goaf-side entry retaining of the lower layer is 10.5 m, of which the thickness of the machine cutting is 4 m. According to the observed top coal thickness and the recovery rate on the working face, the mean floating coal thickness and width are determined.

(1) The floating coal thickness amid upper layered goaf:

(2) The coal and rock mass thickness at lower layered inlet and return air trough and the support at both ends:

(3) The floating coal thickness amid lower layered goaf:

According to the above formulas,

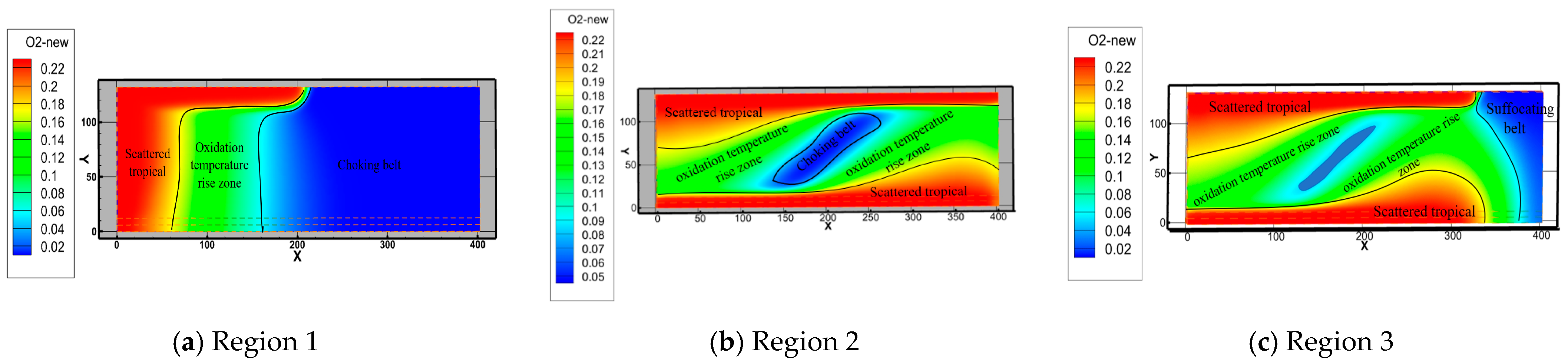

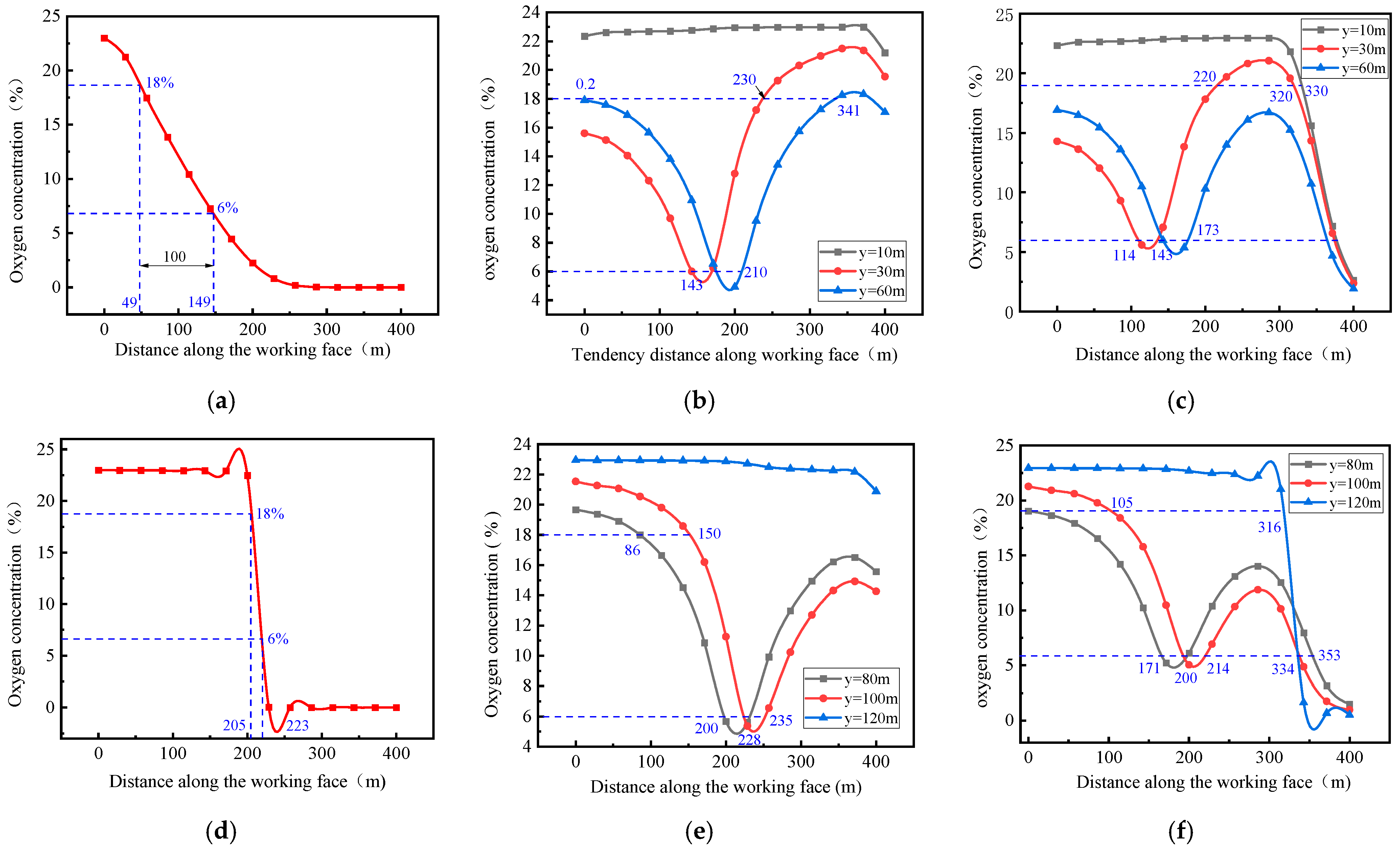

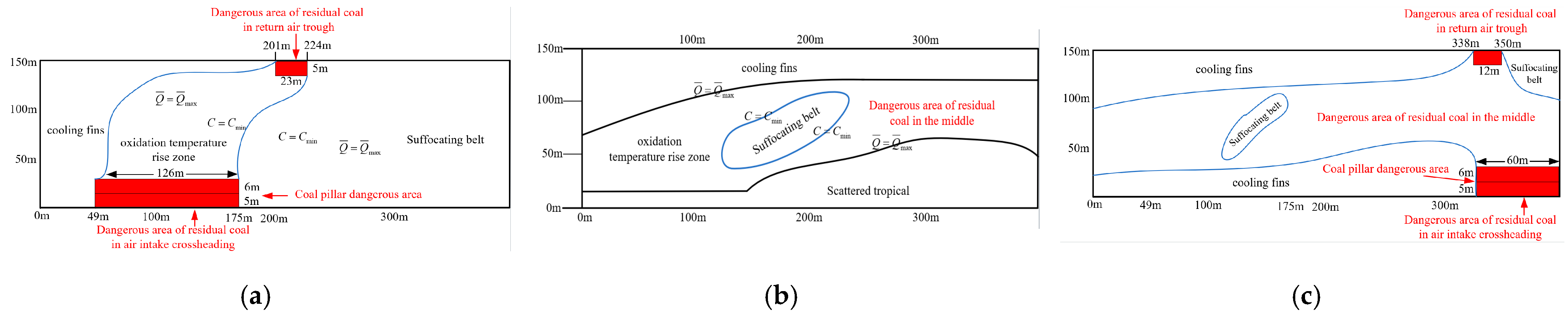

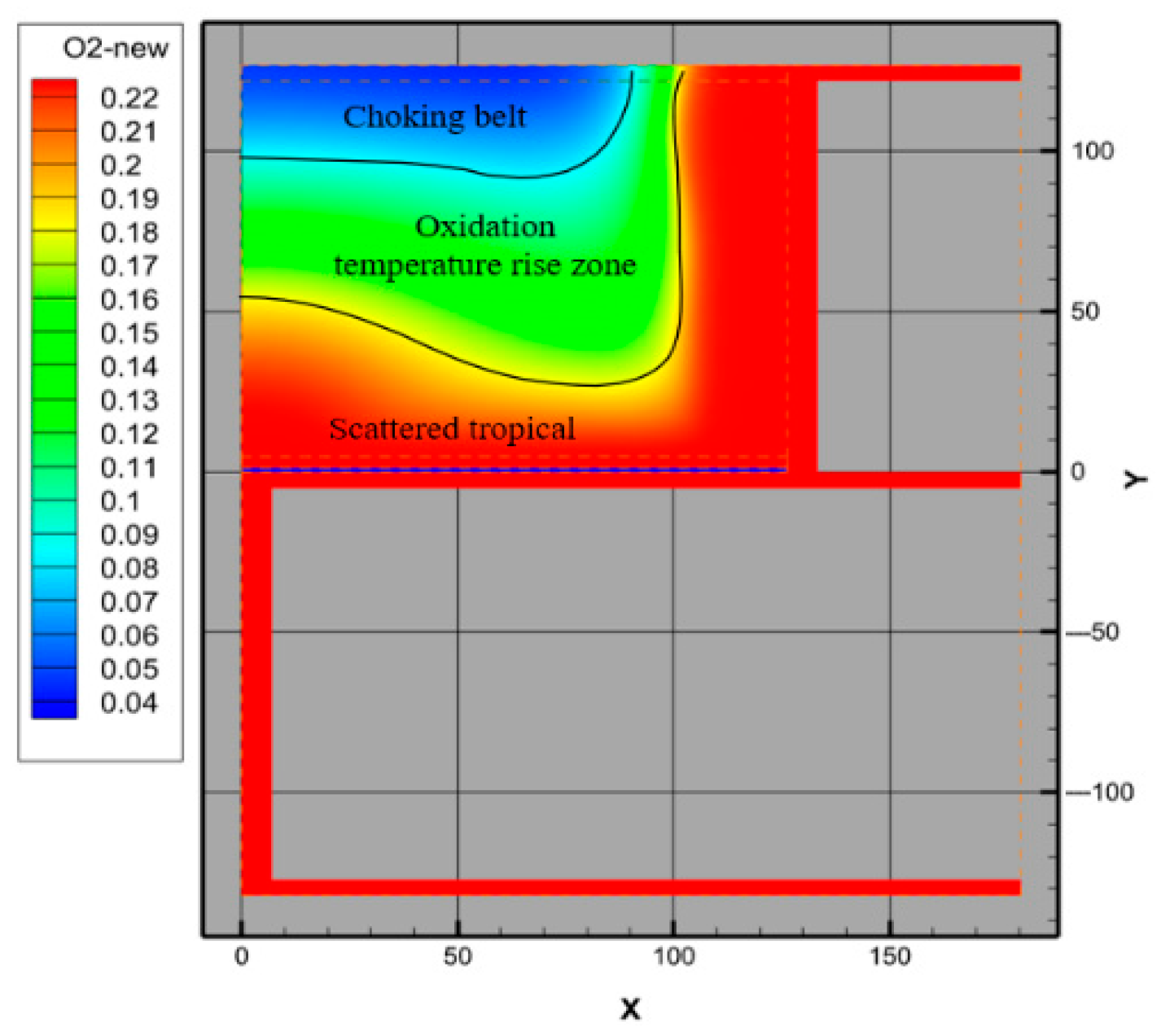

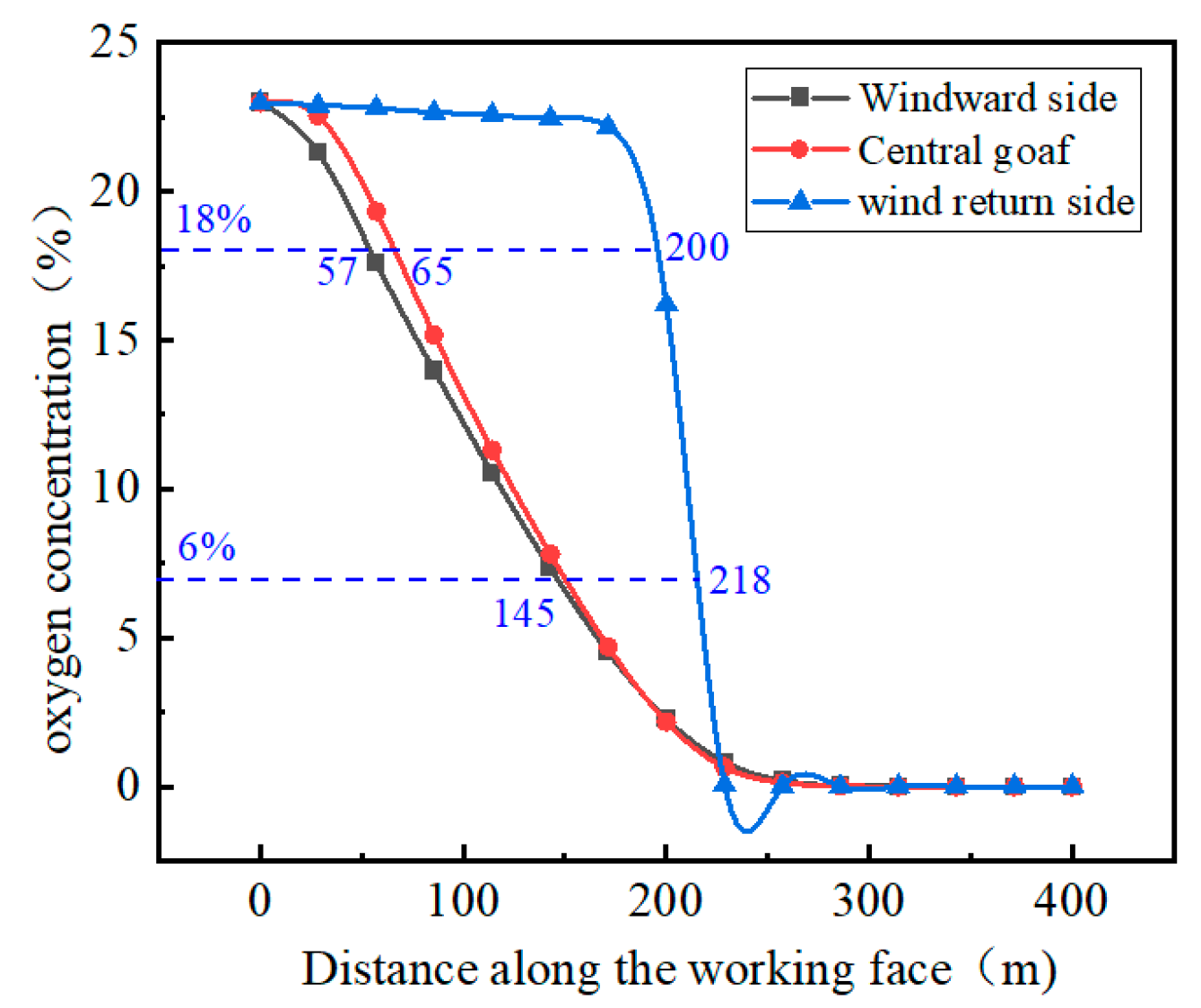

Figure 4 displays the contour map of floating coal thickness in this composite goaf within goaf-side entry retaining in lower layer of Chenjiagou Coal Mine. Based on our experimental data for coal spontaneous combustion, at floating coal thickness of 1.9 m, lower limit oxygen concentration C

min = 6%, upper limit air leakage intensity is 0.282 cm

−3·s

−1·cm

−2, the corresponding seepage velocity is 11.28 × 10

−3 m/s, and the oxidation heating zone is ranges from 6% to 18%.