Experimental Study of the Thermoelectric Conversion Characteristics of a Device Combining a TPCT and TGs

Abstract

1. Introduction

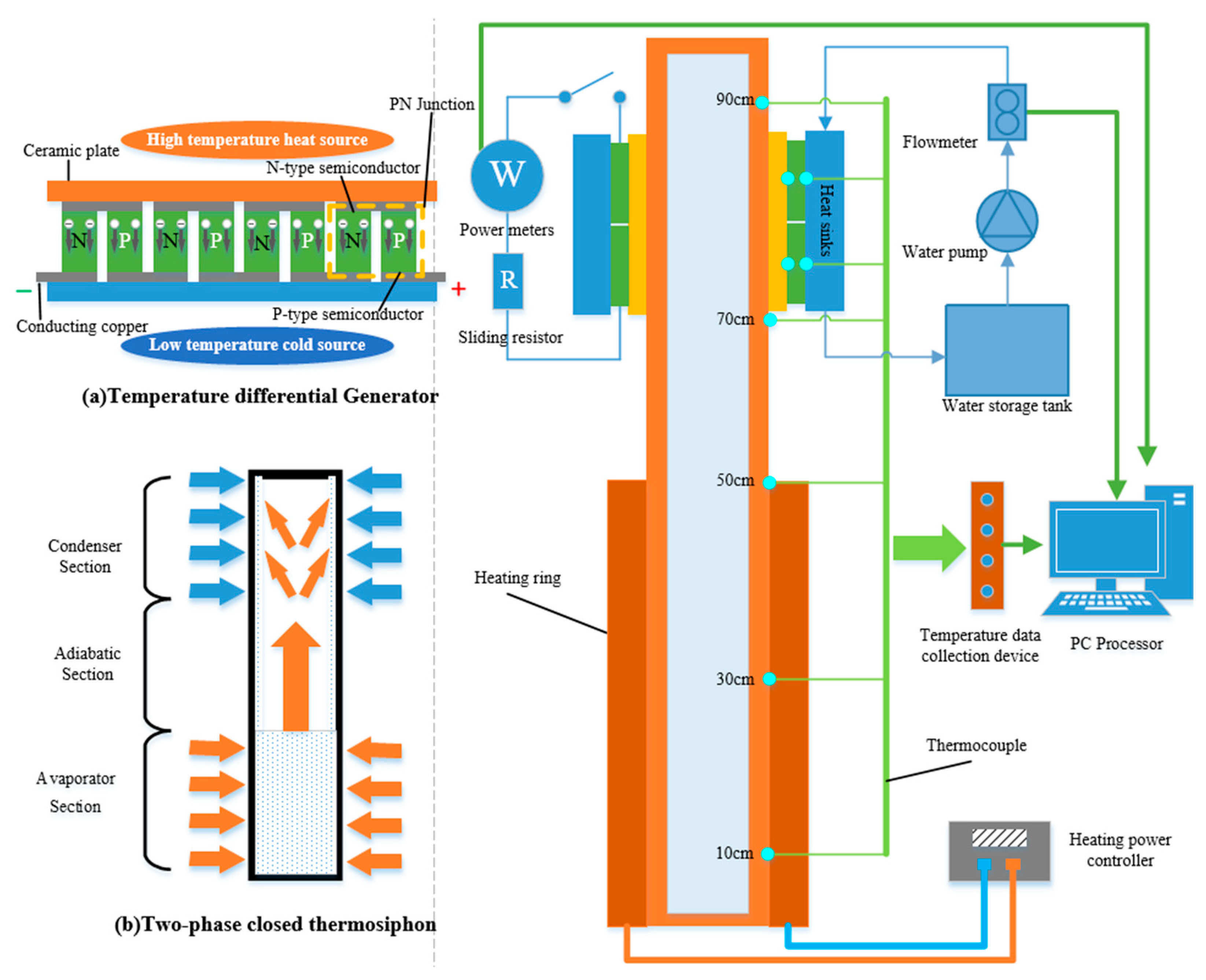

2. Materials and Methods

2.1. Experimental Devices

2.1.1. TPCT Heat Transfer Module

2.1.2. Cooling and Heat Dissipation Module

2.1.3. Thermoelectric Power Generation Module

2.1.4. Data Acquisition Module

2.1.5. Experimental Methods

2.2. Principle and Calculation

2.2.1. Heat Transfer Loss

Radiation Heat Transfer Loss

Convective Heat Transfer Loss

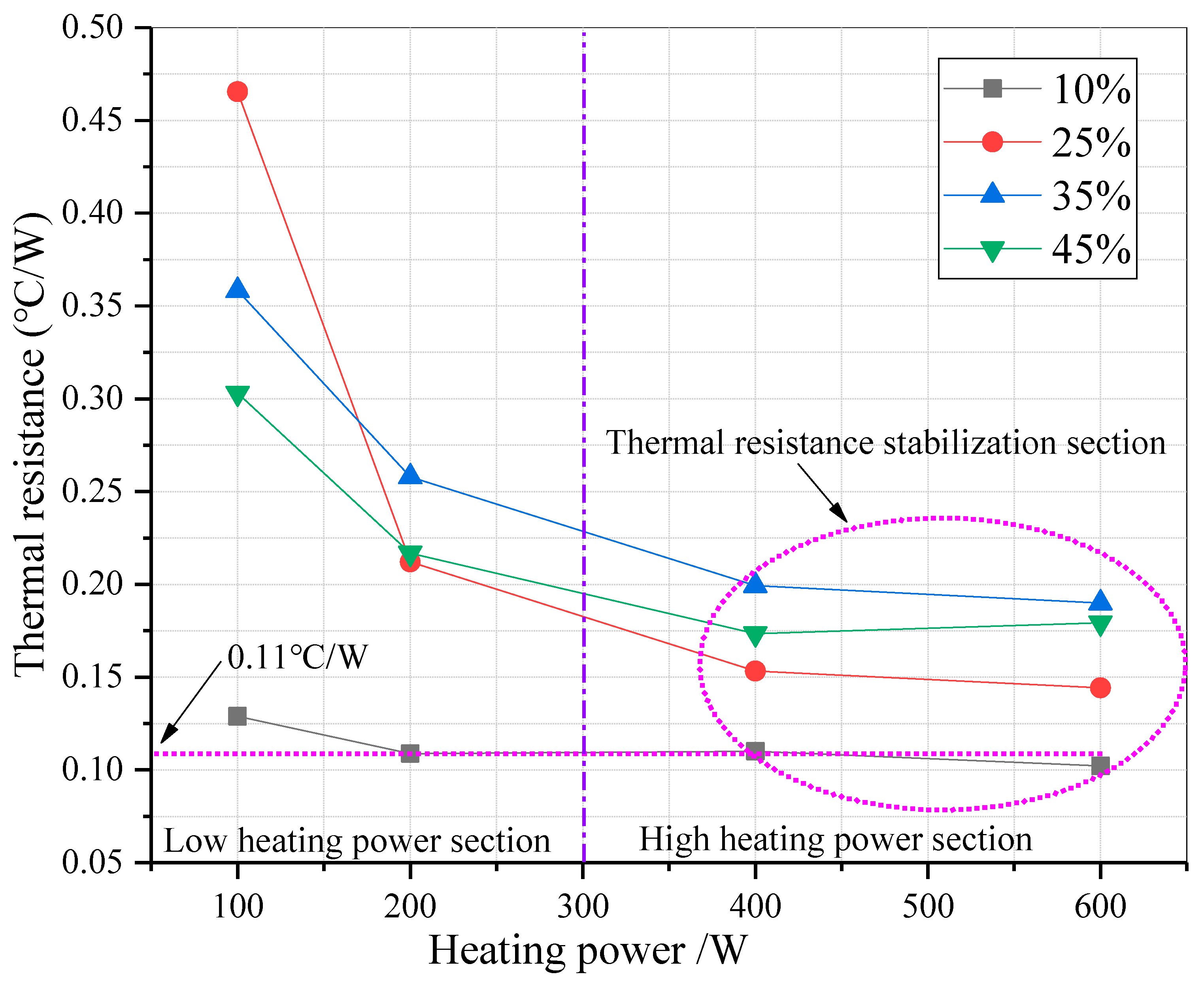

2.2.2. Thermal Resistance of TPCT

- The liquid in the evaporation section is heated to evaporate and absorb heat.

- The evaporated vapor is transferred along the TPCT to the condensing section of the TPCT.

- Vapor in the condensing section of the wall of the tube is exothermic condensation.

- Heat is transferred from the vapor–liquid through the wall of the TPCT to the cold source.

- The liquid condensed in the condensing section wall flows back to the evaporating section due to gravity.

| Definition | Expressions |

|---|---|

| The heat transfer thermal resistance from the heating source to the outer wall of the evaporation section of the TPCT | |

| The thermal conductivity thermal resistance from the outer wall to the inner wall of the evaporation section of the TPCT | |

| The liquid-vapor evaporative heat transfer thermal resistance of the medium inside the evaporation section | |

| The thermal resistance caused by the pressure drop in the vapor flow from the evaporation section to the condensation section of the TPCT | |

| The heat transfer resistance of the condensing section medium vapor–liquid condensation | |

| The thermal conductivity thermal resistance from the inner wall to the outer wall of the condensing section of the TPCT | |

| The heat transfer thermal resistance between the outer wall of the condensing section of the TPCT and the heat sink |

2.2.3. Thermoelectric Power Generation

3. Results and Discussion

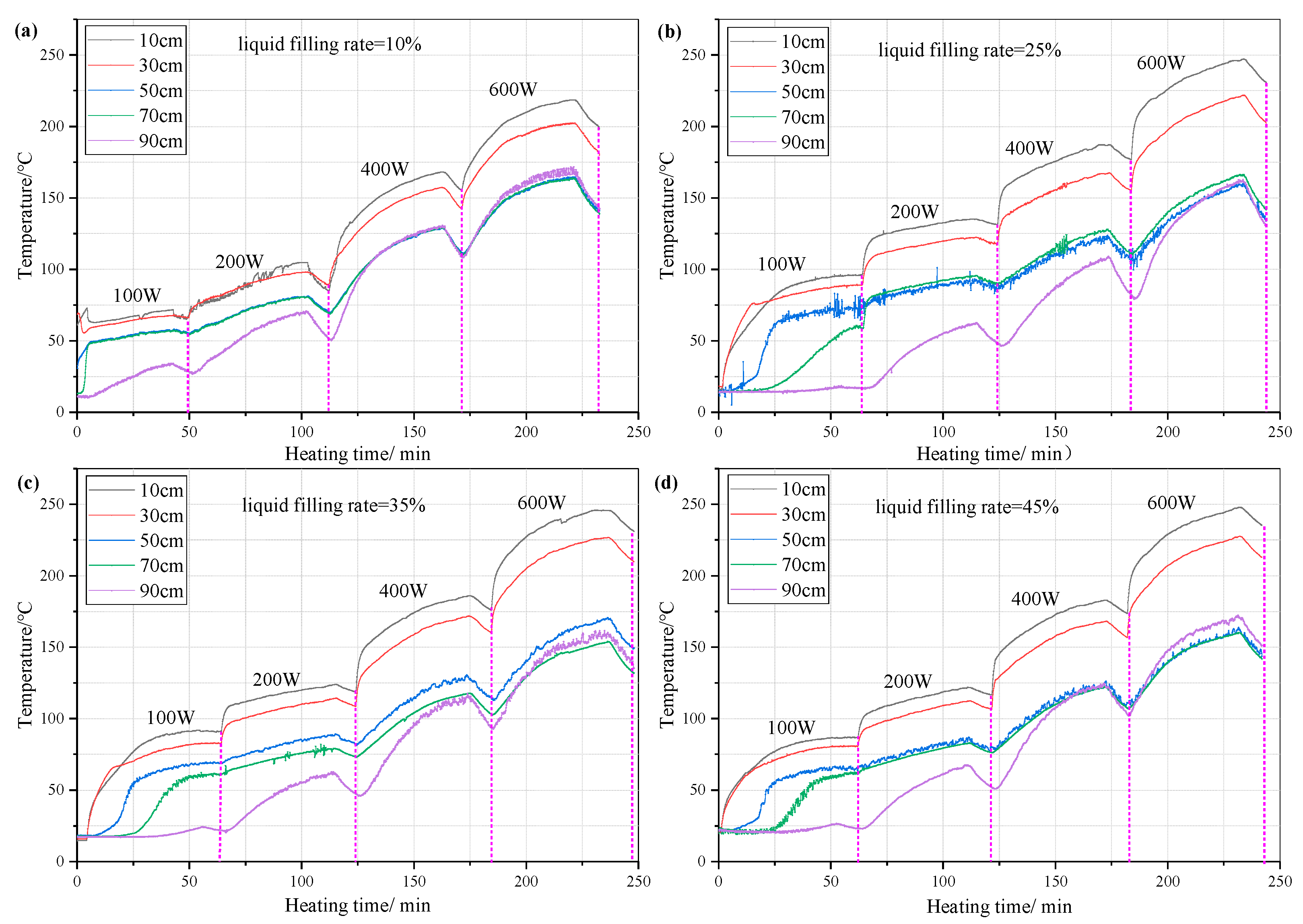

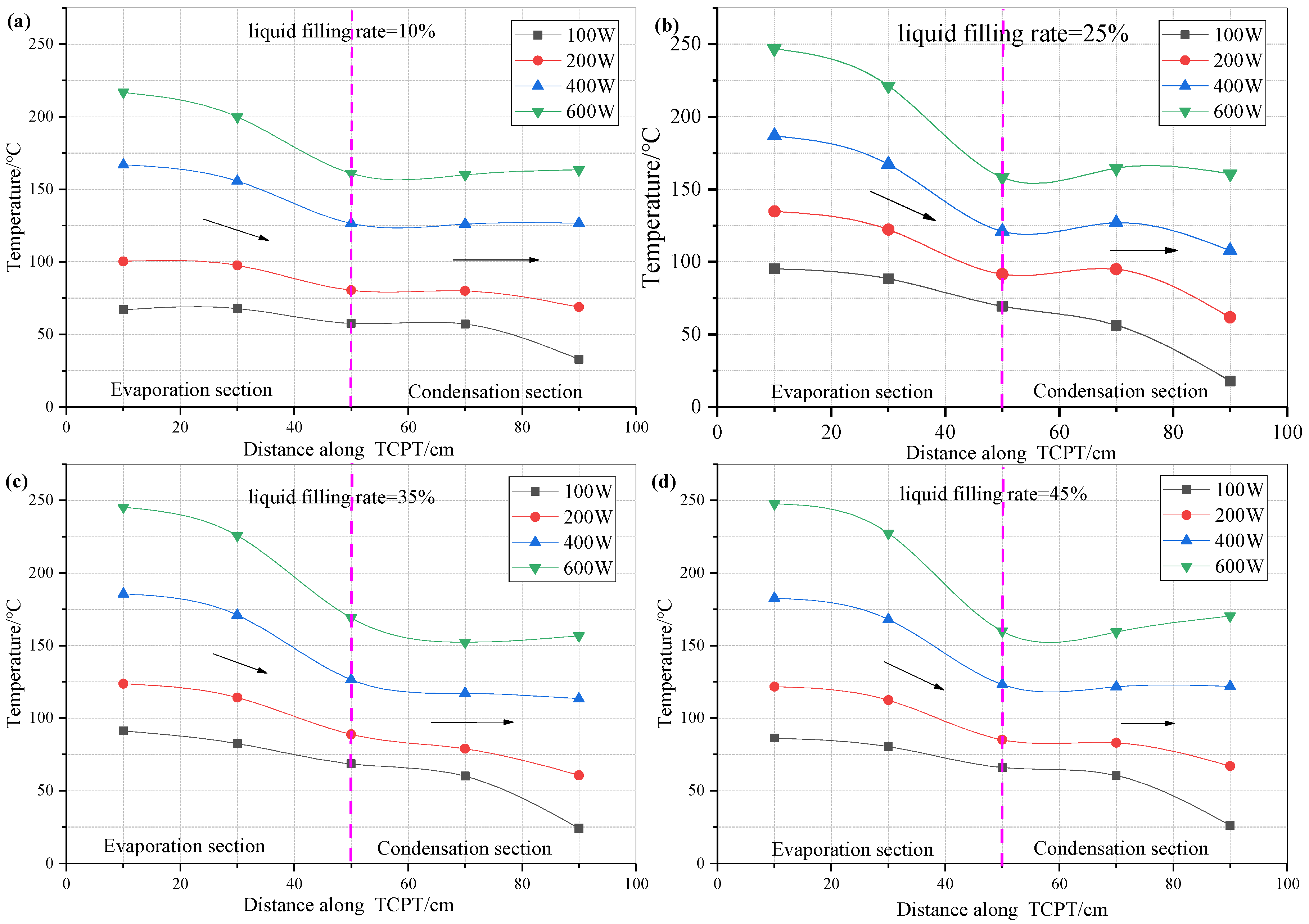

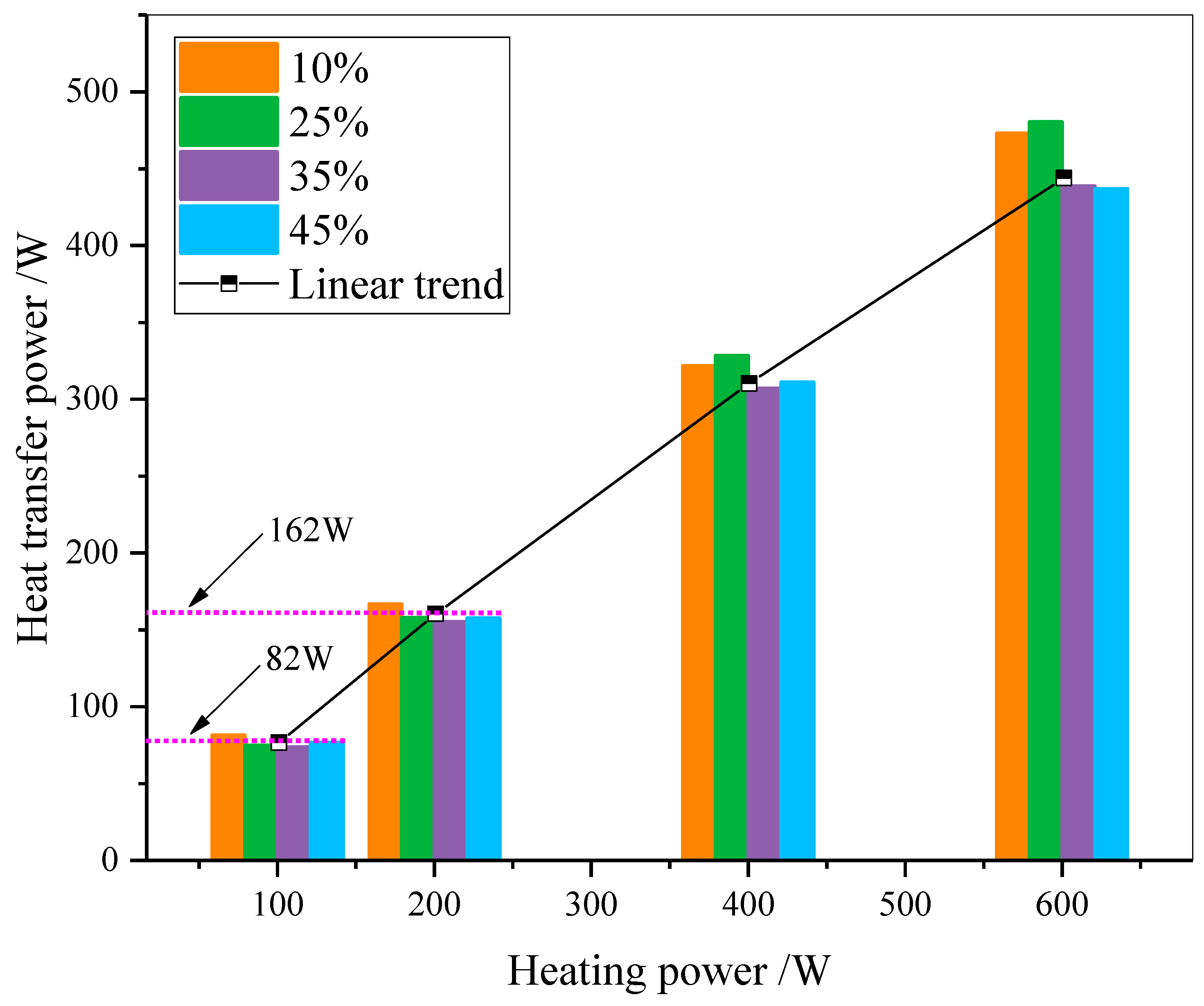

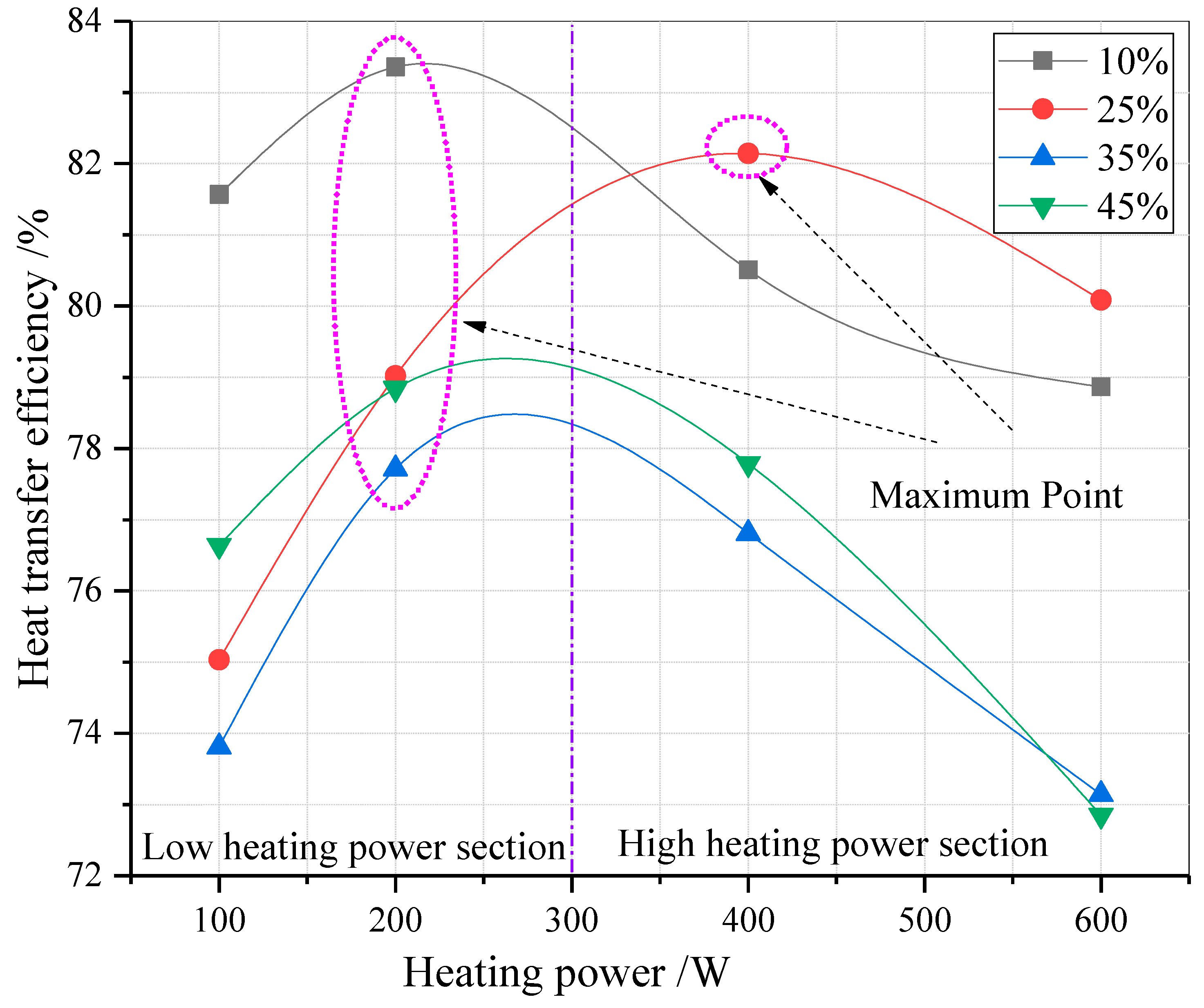

3.1. Heat Transfer Performance

3.1.1. TPCT Heating and Isothermal Characteristics

3.1.2. TPCT Heat Transfer Characteristics Analysis

3.2. Power Generation Performance Analysis

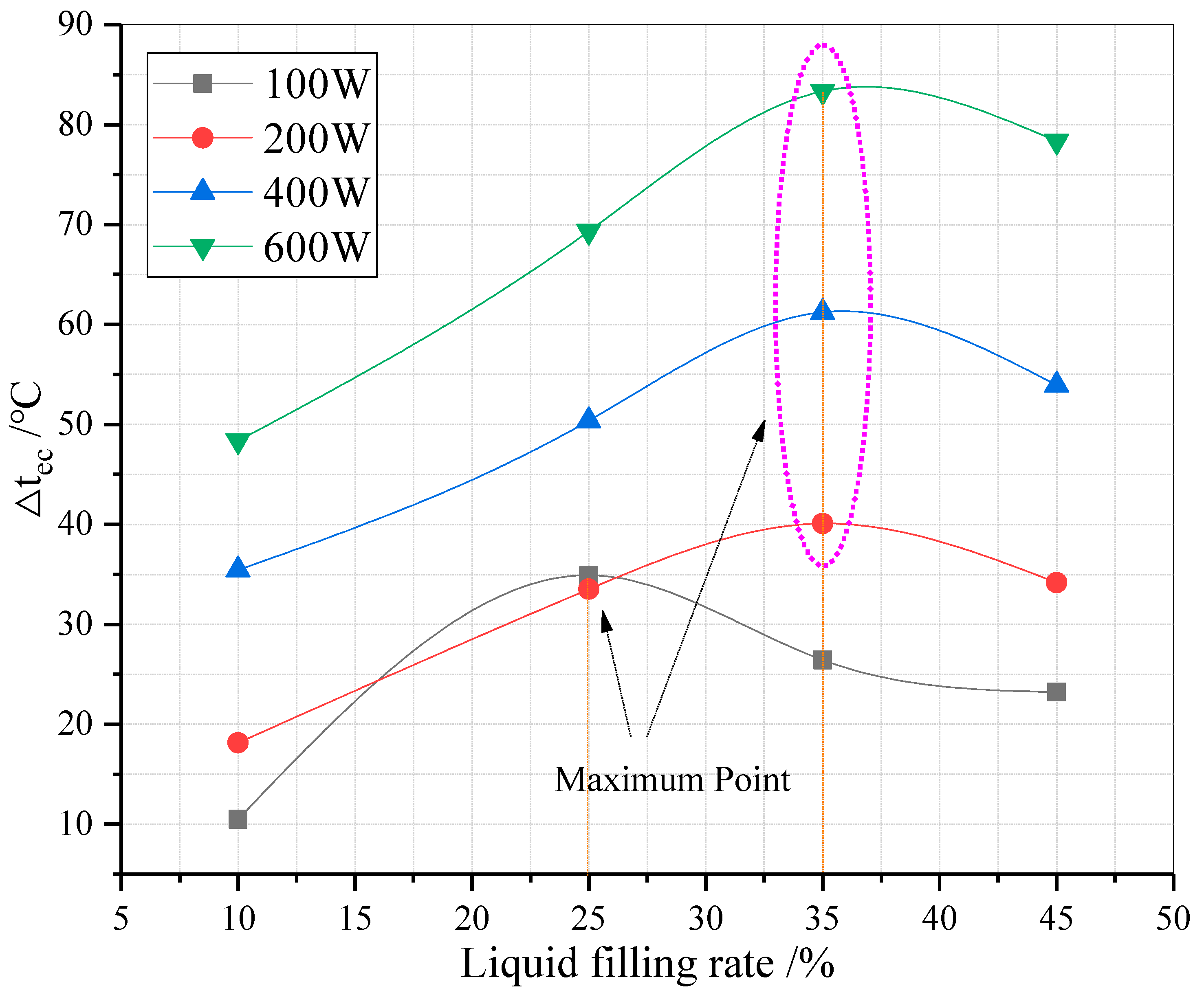

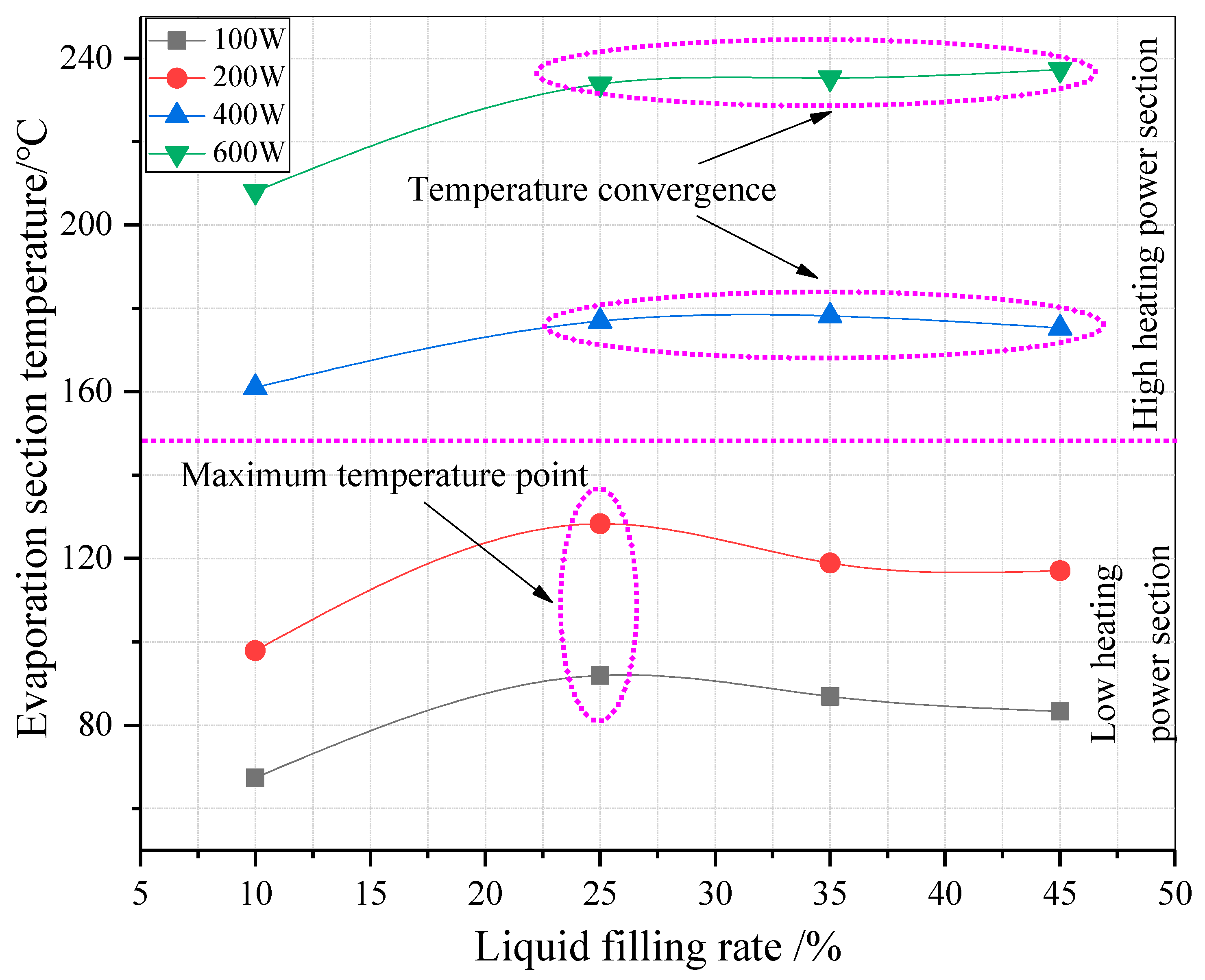

3.2.1. Temperature Parameters Analysis

3.2.2. Power Generation Performance Indicators Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, H.T.; Zhou, F.B.; Shi, B.B.; Qi, H.N.; Deng, J.C. Causes and detection of coalfield fires, control techniques, and heat energy recovery: A review. Int. J. Miner. Metall. Mater. 2020, 27, 3–19. [Google Scholar] [CrossRef]

- Su, H.; Zhou, F.; Qi, H.; Li, J. Design for thermoelectric power generation using subsurface coal fires. Energy 2017, 140, 929–940. [Google Scholar] [CrossRef]

- Shi, B.; Su, H.; Li, J.; Qi, H.; Zhou, F.; Torero, J.L.; Chen, Z. Clean Power Generation from the Intractable Natural Coalfield Fires: Turn Harm into Benefit. Sci. Rep. 2017, 7, 5302. [Google Scholar] [CrossRef] [PubMed]

- Faghri, A. Heat Pipe Science & Technology; Taylor & Francis Group: Abingdon, UK, 1995. [Google Scholar]

- Esen, M.; Esen, H. Experimental investigation of a two-phase closed thermosyphon solar water heater. Sol. Energy 2005, 79, 459–468. [Google Scholar] [CrossRef]

- Fontaine, P.-O.; Marcotte, D.; Pasquier, P.; Thibodeau, D. Modeling of horizontal geoexchange systems for building heating and permafrost stabilization. Geothermics 2011, 40, 211–220. [Google Scholar] [CrossRef]

- Vasilyeva, M.; Stepanov, S.; Sirditov, I. Reduced dimension model for heat transfer of ground heat exchanger in permafrost. J. Phys. Conf. 2017, 937, 012056. [Google Scholar] [CrossRef]

- Zhang, B.; Sheng, Y.; Chen, J.; Li, J. In-Situ Test Study on the Cooling Effect of Two-Phase Closed Thermosyphon in Marshy Permafrost Regions along the Chaidaer–Muli Railway, Qinghai Province, China. Cold Reg. Sci. Technol. 2011, 65, 456–464. [Google Scholar] [CrossRef]

- Song, Y.; Jin, L.; Zhang, J. In-situ study on cooling characteristics of two-phase closed thermosyphon embankment of Qinghai-Tibet Highway in permafrost re gions. Cold Reg. Sci. Technol. 2013, 93, 12–19. [Google Scholar] [CrossRef]

- Zorn, R.; Steger, H.; Kolbel, T. De-Icing and Snow Melting System with Innovative Heat Pipe Technology. In Proceedings of the World Geothermal Congress 2015, Melbourne, VIC, Australia, 19–25 April 2015. [Google Scholar]

- Sakata, Y.; Chishimba, J.; Mochizuki, M.; Nagano, K. Evaluating Groundwater Flow Effects for Enhancement of Ground-Source Heat Pipes in the Case of the Toyohira River Alluvial Fan, Japan. Hydrology 2021, 8, 135. [Google Scholar] [CrossRef]

- Chen, F.; Su, X.; Ye, Q.; Fu, J. Experimental Investigation of Concrete Runway Snow Melting Utilizing Heat Pipe Technology. Sci. World J. 2018, 2018, 4343167. [Google Scholar] [CrossRef]

- Jeong, Y.S.; Kim, K.M.; Kim, I.G.; Bang, I.C. Hybrid heat pipe based passive in-core cooling system for advanced nuclear power plant. Appl. Therm. Eng. 2015, 90, 609–618. [Google Scholar] [CrossRef]

- Shi, S.; Liu, Y.; Yilgor, I.; Sabharwall, P. A two-phase three-field modeling framework for heat pipe application in nuclear reactors. Ann. Nucl. Energy 2022, 165, 108770. [Google Scholar] [CrossRef]

- Kirsch, M.; Castro, S.I.C. Experimental Investigation on the Long-term Operational Behaviour of Two-phase Closed Thermosyphon Bundles for Passive Heat Transfer from Spent Fuel Pools under Normal, Abnormal, and Accident Conditions. Atw-Int. J. Nucl. Power 2022, 67, 74–77. [Google Scholar]

- Lu, Z.; Wang, R. Novel adsorption refrigerators with separate type two phase closed thermosyphon designs. Int. J. Energy Res. 2015, 39, 1681–1688. [Google Scholar] [CrossRef]

- Ma, C.; Wu, X.; Gao, S. Analysis and applications of a two-phase closed thermosyphon for improving the fluid temperature distribution in wellbores. Appl. Therm. Eng. 2013, 55, 1–6. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, L.; Fan, Z.; Wu, X.; Fu, L.; Xu, B.; Kong, F.; Jiang, S. Temperature distribution of fluids in a two-section two-phase closed thermosyphon wellbore. Pet. Sci. 2014, 11, 287–292. [Google Scholar] [CrossRef][Green Version]

- Tyurin, M.P.; Borodina, Y.S.; Osmanov, Z.N. Investigation of Processes of Heat and Mass Exchange in a Closed Two-Phase Thermosiphon for the Development of Energy Conserving Technologies in the Production of Edible Phosphates. Fibre Chem. 2018, 49, 388–393. [Google Scholar] [CrossRef]

- Bolozdynya, A.I.; Efremenko, Y.V.; Khromov, V.A.; Shafigullin, R.R.; Shakirov, A.V.; Sosnovtsev, V.V.; Tolstukhin, I.A. Thermostabilization system based on two-phase closed cryogenic thermosyphon for RED100 detector. Phys. Procedia 2015, 74, 431–434. [Google Scholar] [CrossRef]

- Hassanpour, A.; Borji, M.; Ziapour, B.M.; Kazemi, A. Performance Analysis of a Cascade PCM Heat Exchanger and Two-Phase Closed Thermosiphon: A Case Study of Geothermal District Heating System. Sustain. Energy Technol. Assess. 2020, 40, 100755. [Google Scholar] [CrossRef]

- Abreu, S.L.; Colle, S. An Experimental Study of Two-Phase Closed Thermosyphons for Compact Solar Domestic Hot-Water Systems. Sol. Energy 2004, 76, 141–145. [Google Scholar] [CrossRef]

- Li, B.; Deng, J.; Xiao, Y.; Zhai, X.W.; Shu, C.M.; Gao, W. Heat transfer capacity of heat pipes: An application in coalfield wildfire in China. Heat Mass Transf. 2018, 54, 1755–1766. [Google Scholar] [CrossRef]

- Zhong, K.Q.; Xiao, Y.; Lu, X.; Deng, J.; Yin, L.; Tian, Y.; Shu, C.-M. Nanofluidic two-phase closed thermosyphon-assisted thermoelectric generator for heat recovery from coal spontaneous combustion. Appl. Therm. Eng. 2021, 197, 117397. [Google Scholar] [CrossRef]

- Janak, L.; Ancik, Z.; Vetiska, J.; Hadas, Z. Thermoelectric Generator Based on MEMS Module as an Electric Power Backup in Aerospace Applications. Mater. Today Proc. 2015, 2, 865–870. [Google Scholar]

- Tohidi, F.; Holagh, S.G.; Chitsaz, A. Thermoelectric Generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 2022, 201, 117793. [Google Scholar] [CrossRef]

- Li, K.; Garrison, G.; Moore, M.; Zhu, Y.; Liu, C.; Horne, R.; Petty, S. An Expandable Thermoelectric Power Generator and the Experimental Studies on Power Output. Int. J. Heat Mass Transf. 2020, 160, 120205. [Google Scholar] [CrossRef]

- Nuwayhid, R.; Shihadeh, A.; Ghaddar, N. Development and testing of a domestic woodstove thermoelectric generator with natural convection cooling. Energy Conver. Manag. 2004, 46, 1631–1643. [Google Scholar] [CrossRef]

- O’Shaughnessy, S.; Deasy, M.; Doyle, J.; Robinson, A. Field trial testing of an electricity-producing portable biomass cooking stove in rural Malawi. Energy Sustain. Dev. 2014, 20, 1–10. [Google Scholar] [CrossRef]

- Champier, D.; Bédécarrats, J.; Rivaletto, M.; Strub, F. Thermoelectric power generation from biomass cook stoves. Energy 2010, 35, 935–942. [Google Scholar] [CrossRef]

- Singh, R.; Tundee, S.; Akbarzadeh, A. Electric power generation from solar pond using combined thermosyphon and thermoelectric modules. Solar Energy 2014, 48, 453–463. [Google Scholar] [CrossRef]

- Zhang, M.; Miao, L.; Kang, Y.P.; Tanemura, S.; Fisher, C.A.J.; Xu, G.; Li, C.X.; Fan, G.Z. Efficient, low-cost solar thermoelectric cogenerators comprising evacuated tubular solar collectors and thermoelectric modules. Appl. Energy 2013, 109, 51–59. [Google Scholar] [CrossRef]

- Whalen, S.A.; Dykhuizen, R.C. Thermoelectric energy harvesting from diurnal heat flow in the upper soil layer. Energy Convers. Manag. 2012, 64, 397–402. [Google Scholar] [CrossRef]

- Suter, C.; Jovanovic, Z.R.; Steinfeld, A. A 1 kWe Thermoelectric Stack for Geothermal Power Generation—Modeling and Geometrical Optimization. Appl. Energy 2012, 99, 379–385. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Saber, H.H. Performance analysis of cascaded thermoelectric converters for advanced radioisotope power systems. Energy Convers. Manag. 2005, 46, 1083–1105. [Google Scholar] [CrossRef]

- El-Genk, M.; Saber, H.; Caillat, T. Efficient segmented thermoelectric unicouples for space power applications. Energy Convers. Manag. 2003, 44, 1755–1772. [Google Scholar] [CrossRef]

- Karri, M.; Thacher, E.; Helenbrook, B. Exhaust energy conversion by thermoelectric generator: Two case studies. Energy Convers. Manag. 2011, 52, 1596–1611. [Google Scholar] [CrossRef]

- Ono, K.; Suzuki, R.O. Thermoelectric Power Generation: Converting Low-Grade Heat into Electricity. Energy Resour. 1998, 50, 49–51. [Google Scholar] [CrossRef]

- Crane, D.T.; Jackson, G.S. Optimization of cross flow heat exchangers for thermoelectric waste heat recovery. Energy Convers. Manag. 2004, 45, 1565–1582. [Google Scholar] [CrossRef]

- Hendricks, T.J. Thermal System Interactions in Optimizing Advanced Thermoelectric Energy Recovery Systems. J. Energy Resour. Technol. 2007, 129, 223–231. [Google Scholar] [CrossRef]

- Gould, C.A.; Shammas, N.Y.A.; Grainger, S.; Taylor, I. Thermoelectric Cooling of Microelectronic Circuits and Waste Heat Electrical Power Generation in a Desktop Personal Computer. Mater. Sci. Eng. B 2011, 176, 316–325. [Google Scholar] [CrossRef]

- Putra, N.; Yanuar; Iskandar, F.N. Application of nanofluids to a heat pipe liquid block and the thermoelectric cooling of electronic equipment. Exp. Therm. Fluid Sci. 2011, 35, 1274–1281. [Google Scholar] [CrossRef]

- Su, H.; Qi, H.; Liu, P.; Li, J. Experimental investigation on heat extraction using a two-phase closed thermosyphon for thermoelectric power generation. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 1485–1490. [Google Scholar]

- Deng, J.; Zhou, F.; Shi, B.; Torero, J.L.; Qi, H.; Liu, P.; Ge, S.; Wang, Z.; Chen, P.C. Waste heat recovery, utilization and evaluation of coalfield fire applying heat pipe combined thermoelectric generator in Xinjiang, China. Energy 2020, 207, 118303. [Google Scholar] [CrossRef]

- Yang, S.M.; Zhang, Z.Z. An Experimental Study of Natural Convection Heat Transfer from a Horizontal Cylinder in High Rayleigh Number Laminar and Turbulent Regions. In Institution of Chemical Engineers Symposium Series; Hemisphere Publishing Corporation: London, UK, 1994; Volume 135, p. 185. [Google Scholar]

| Heating Power | Maximum Open-Circuit Voltage/V | Maximum Load Current/A | Maximum Load Power/W |

|---|---|---|---|

| 100 W | 3.51 (10%) | 0.25 (10%) | 0.47 (10%) |

| 200 W | 8.89 (10%) | 0.61 (10%) | 2.68 (10%) |

| 400 W | 16.43 (35%) | 1.06 (25%) | 8.13 (25%) |

| 600 W | 21.93 (35%) | 1.37 (35%) | 13.64 (35%) |

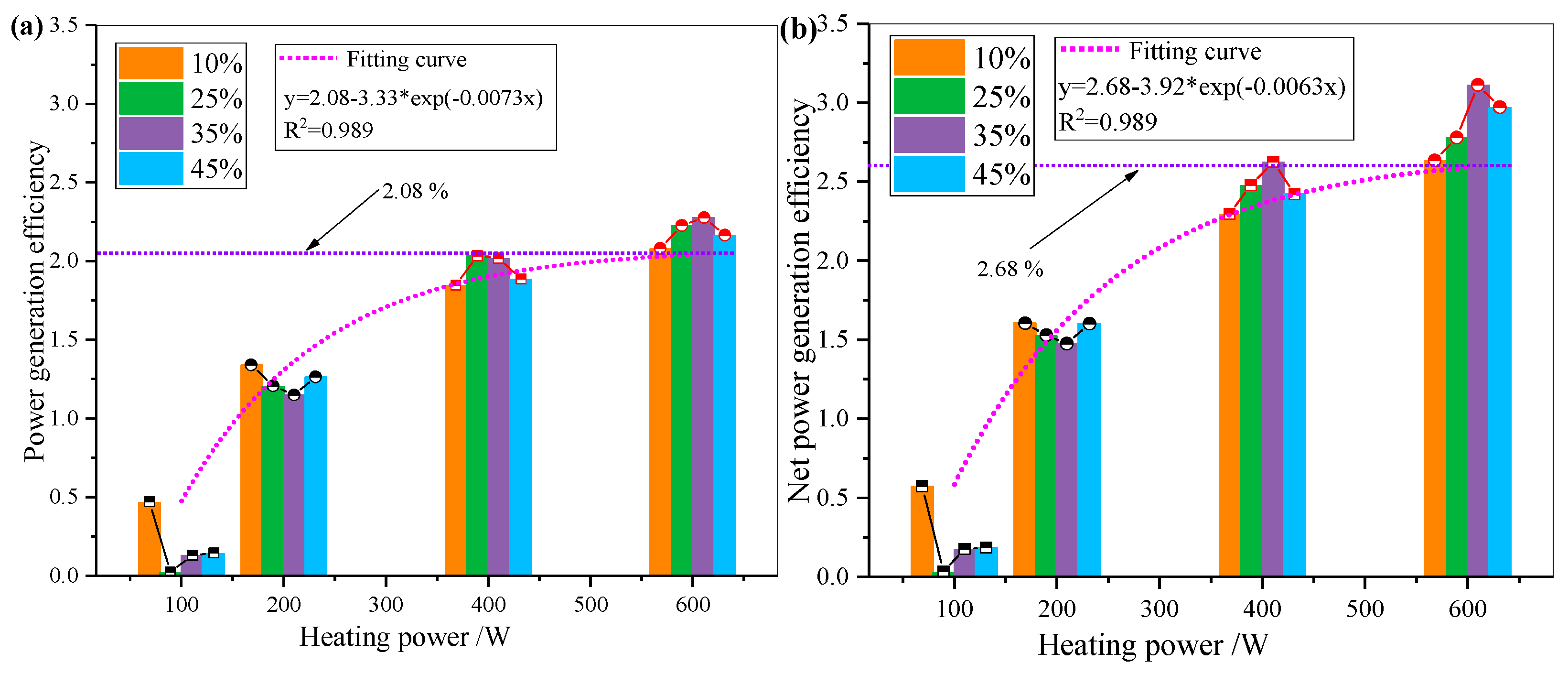

| Heating Power | Maximum Power Generation Efficiency/% | Maximum Net Power Generation Parameters Under/% |

|---|---|---|

| 100 W | 0.4657 (10%) | 0.5709 (10%) |

| 200 W | 1.3375 (10%) | 1.6046 (10%) |

| 400 W | 2.0313 (25%) | 2.6217 (35%) |

| 600 W | 2.2736 (35%) | 3.1086 (35%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, H.; Su, H. Experimental Study of the Thermoelectric Conversion Characteristics of a Device Combining a TPCT and TGs. Fire 2025, 8, 103. https://doi.org/10.3390/fire8030103

Qi H, Su H. Experimental Study of the Thermoelectric Conversion Characteristics of a Device Combining a TPCT and TGs. Fire. 2025; 8(3):103. https://doi.org/10.3390/fire8030103

Chicago/Turabian StyleQi, Haining, and Hetao Su. 2025. "Experimental Study of the Thermoelectric Conversion Characteristics of a Device Combining a TPCT and TGs" Fire 8, no. 3: 103. https://doi.org/10.3390/fire8030103

APA StyleQi, H., & Su, H. (2025). Experimental Study of the Thermoelectric Conversion Characteristics of a Device Combining a TPCT and TGs. Fire, 8(3), 103. https://doi.org/10.3390/fire8030103