An Investigation of the Process of Risk Coupling and the Main Elements of Coal-Mine Gas-Explosion Risk

Abstract

1. Introduction

2. Materials and Methods

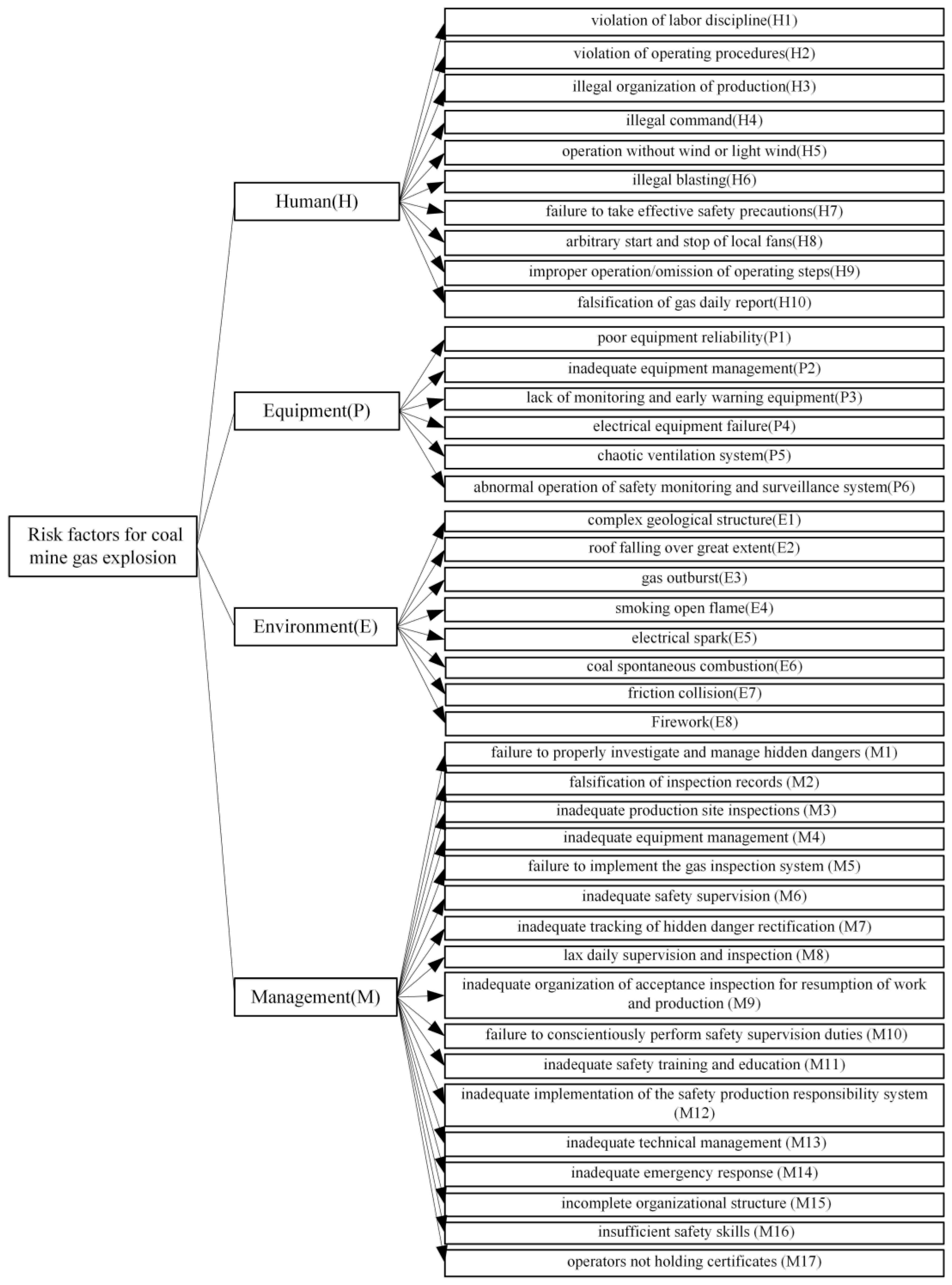

2.1. Identification of Risk Factors for Gas Explosions in Coal Mines

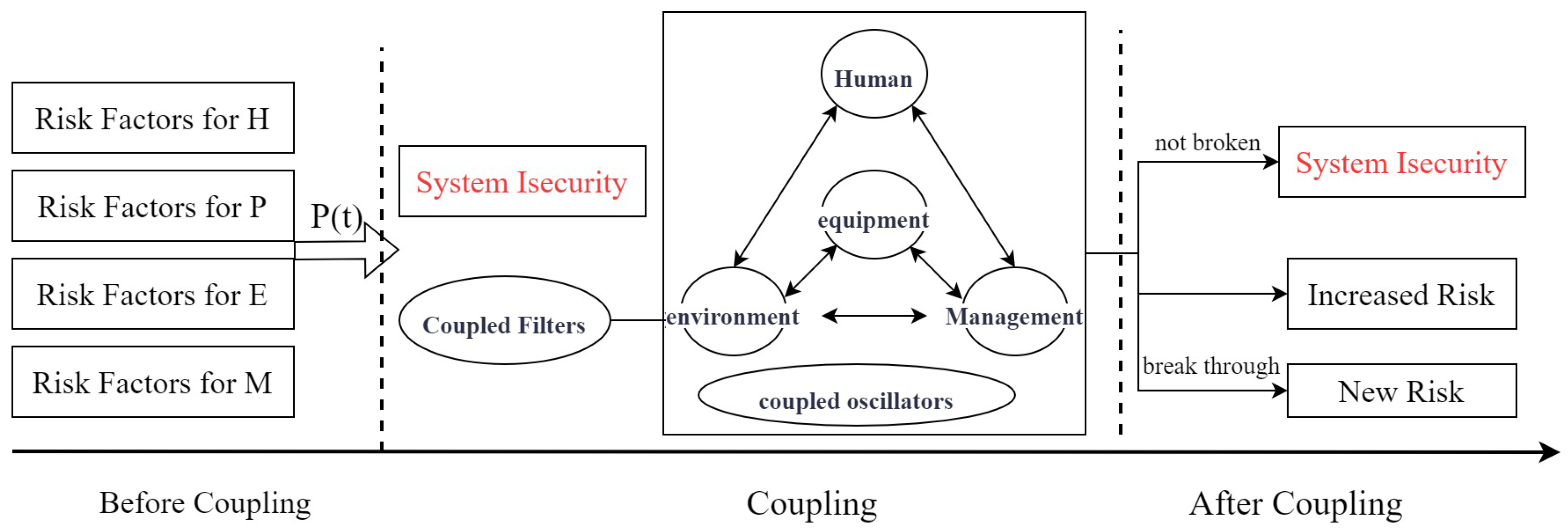

2.2. Coal-Mine Gas-Explosion Risk Elements and Their Coupling Mechanism

2.2.1. Coupling Mechanisms of Coal Mine Gas Explosion Risk Factors

2.2.2. Type of Coal-Mine Gas-Explosion Risk-Factor Pairing

- (1)

- Single-factor coupling: In other words, a risk subsystem’s mutual effect and interaction, including the risk coupling of similar factors like human, equipment, environment, and management, and the associated risk coupling value, are represented as T11, T12, T13, and T14.

- (2)

- Two-factor coupling: The reciprocal influence and interaction between two risk subsystems, which includes six different forms of coupling—human–equipment, human–environment, human–management, equipment–environment, equipment–equipment, and environment–management—is represented by the relevant risk coupling values, which are T21, T22, T23, T24, T25, and T26.

- (3)

- Multi-factor coupling: This study includes three-factor and four-factor risk coupling, which include five different types of coupling: human–equipment–environment, human–equipment–management, human–equipment–environment–management, equipment–environment–management, and human–equipment–environment-management. The corresponding risk coupling values are indicated as T31, T32, T33, T34, and T4.

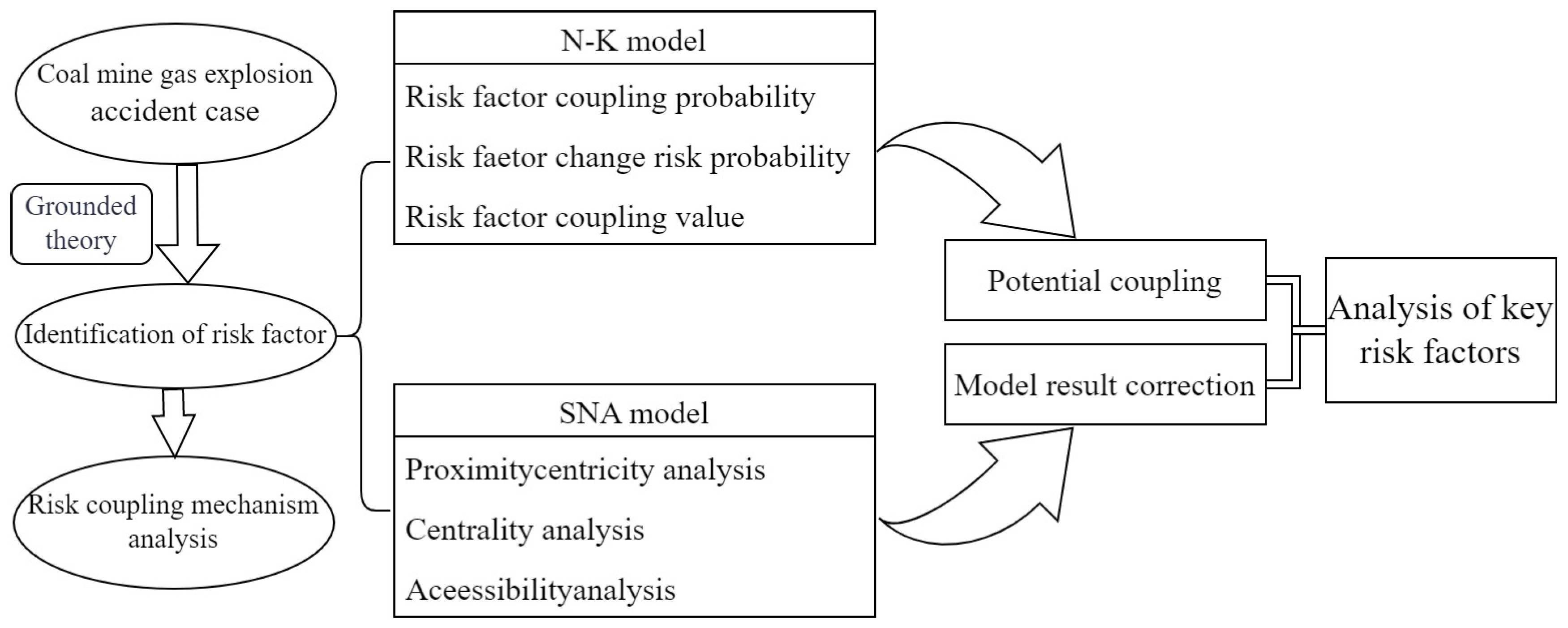

2.3. Method of Key Factor Analysis for Combining N-K and SNA Models

2.3.1. Building the N-K Risk-Coupling Model

2.3.2. Construction of a Model for SNA Risk Evolution Analysis

3. Result

3.1. N-K Model Risk-Coupling Analysis

3.2. Examination of SNA Model Output

3.2.1. Centrality Analysis

3.2.2. Critical Risk Path Accessibility Analysis

4. Model Modification and Discussion

4.1. Combining the N-K and SNA Models to Rectify the Results

4.2. Strategies and Ideas for Risk Prevention

4.3. Future Research Directions

5. Conclusions

- (1)

- The ranking of factor coupling degrees, which is T4 > T32 > T34 > T3(3) > T31 > T22 > T21 > T2(3) > T26 > T24 > T25, was obtained by applying the N-K coupling effect metric model to the study of coal-mine gas-explosion risk evolution. This suggests that as coupling factors rise, so do their hazards. Preventing multi-risk factor coupling is an essential way to reduce accidents. The parameters “human-equipment-environment-management”, “human-equipment-management”, and “human-environment” are more closely associated with the risk of gas explosions among the various heterogeneous multi-risk couplings. The incidence of accidents is directly linked to the danger to personnel, and prevention and control should be the main priorities.

- (2)

- The SNA model’s computation results indicate that the mediator centrality of the entire risk network ranked high for the following: ineffective safety measures (H7), unlawful production organization (H3), falsification of daily gas reports (H10), ventilation system confusion (P5), and insufficient emergency response (M14). For the critical path reachability study, critical risk factors have a positive correlation with the critical risk evolution path. This evidence suggests that managing critical risk factors can successfully prevent accidents by blocking the evolution of the risk propagation path.

- (3)

- The results of the fusion of the N-K and SNA models on the rectification of risk proximity centrality indicate that there is no equipment management in place. M4: Safety monitoring and control systems typically do not operate as expected. P6: No safety instruction or training is available. There is no system for production safety responsibilities in place—M11; there is unauthorized command—H4. M12 and the other five factors are the main components of the risk system for gas explosion. The management factor is the risk system’s weak link, which makes it easy to create a multi-factor risk coupling. By enhancing employee safety education and training, raising employee active safety awareness, bolstering the stability of the monitoring and control system, and combining the safety production responsibility system, the system risk can be effectively avoided and the coal-mine gas-power system safely improved.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Zhou, H.; Xue, D.; Wang, H.; Zhang, R.; Gao, F. Research and consideration on deep coal mining and critical mining depth. J. China Coal Soc. 2012, 37, 535–542. [Google Scholar]

- Yuan, L. Scientific conception of precision coal mining. J. China Coal Soc. 2017, 42, 1–7. [Google Scholar]

- Li, L.; Guo, H.; Cheng, L.; Li, S.; Lin, H. Research on causes of coal mine gas explosion accidents based on association rule. J. Loss Prev. Process Ind. 2022, 80, 104879. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, L.; Li, S. Research on causal factors of coal mine gas explosion based on DEMATEL-ISM-MICMAC. Min. Saf. Environ. Prot. 2023, 50, 114–119. [Google Scholar]

- Nian, Q.F.; Shi, S.L.; Li, R.Q. Research and application of safety assessment method of gas explosion accident in coal mine based on GRA-ANP-FCE. Procedia Eng. 2012, 45, 106–111. [Google Scholar] [CrossRef]

- Lin, Z.; Li, M.; He, S.; Shi, S.; Tian, X.; Wang, D. Risk assessment of gas explosion in coal mines based on game theory and Bayesian network. J. China Coal Soc. 2024, 49, 3484–3497. [Google Scholar]

- Fox, R.F. Review of Stuart Kauffman, the origins of order: Self-organization and selection in evolution. Biophys. J. 1993, 65, 2698–2699. [Google Scholar] [CrossRef]

- Kauffman, S.A. Origins of order in evolution: Self-organization and selection. Underst. Orig. 1992, 130, 153–181. [Google Scholar]

- Wagner, G.P. Final theory in biology. Science 1993, 260, 1531–1533. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, G.; OU, X. Risk Coupling Analysis of Deep Foundation Pits Adjacent to Existing Underpass Tunnels Based on Dynamic Bayesian Network and N-K Model. Appl. Sci. 2022, 12, 10467. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, G.; Meng, X. Coupling risk analysis of deepwater blowout accidents based on N-K model. China Offshore Oil Gas 2020, 32, 182–187. [Google Scholar]

- Deng, J.; Liu, S.; Xie, C.; Liu, K. Risk Coupling Characteristics of Maritime Accidents in Chinese Inland and Coastal Waters Based on N-K Model. J. Mar. Sci. Eng. 2021, 10, 4. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Li, H.; Chen, H.; He, K.; Dai, Z. Study on coupling of subway shield tunneling safety risk based on improved N-K model. China Saf. Sci. J. 2024, 34, 67–75. [Google Scholar]

- Fang, J.; Guo, P.W.; Zhu, K.; Chen, Z.F. Coupled evolutionary analysis of safety risks in underground tunnel construction based on N-K model. China Saf. Sci. J. 2022, 32, 1–9. [Google Scholar]

- Pan, H.W.; Guo, D.S.; Song, Z.P.; Xu, T.; Zhang, Y.W.; Ding, L.B. Multi-risk factor coupling analysis of tunnel construction accidents based on N-K model. Tunn. Constr. (Chin. Engl.) 2022, 42, 1537–1545. [Google Scholar]

- Pan, H.; Gou, J.; Wan, Z.H.; Ren, C.X.; Chen, M.J.; Gou, T.Q.; Luo, Z.H. Research on Coupling Degree Model of Safety Risk System for Tunnel Construction in Subway Shield Zone. Math. Probl. Eng. 2019, 2019, e5783938. [Google Scholar] [CrossRef]

- Guo, D.; Song, Z.P.; Xu, T.; Zhang, Y.W.; Ding, L.B. Coupling Analysis of Tunnel Construction Risk in Complex Geology and Construction Factors. J. Constr. Eng. Manag. 2022, 148, 04022097. [Google Scholar] [CrossRef]

- Brown, R. On social structure. J. R. Anthropol. Inst. Great Br. Irel. 1940, 70, 1–12. [Google Scholar]

- Miao, D.; Wang, W.; Liu, L.; Yao, K.; Sui, X. Coal mine roof accident causation modeling and system reliability research based on directed weighted network. Process Saf. Environ. Prot. 2024, 183, 653–664. [Google Scholar] [CrossRef]

- Chen, W.Q.; Deng, J.J.; Niu, L.C. Identification of core risk factors and risk diffusion effect of urban underground engineering in China: A social network analysis. Saf. Sci. 2022, 147, 105591. [Google Scholar] [CrossRef]

- Yang, J.F.; Wang, P.C.; Liu, X.Y.; Bian, M.C.; Chen, L.C.; Lv, S.Y.; Dou, Z. Analysis on causes of chemical industry accident from 2015 to 2020 in Chinese mainland: A complex network theory approach. J. Loss Prev. Process Ind. 2023, 83, 105061. [Google Scholar] [CrossRef]

- Yuan, L.; Chen, D.; Li, S.; Wang, G.; Li, Y.; Li, B.; Chen, M. Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N-K Model and SNA. Sustainability 2024, 16, 8686. [Google Scholar] [CrossRef]

- Li, Q.; Pang, M.; Zhong, H.; Wang, H.; Zhang, Y. Study on the coupling of explosion risk factors in chemical enterprises using Social Network Analysis integrated with the N-K model. J. Saf. Environ. 2024, 12, 4581–4590. [Google Scholar]

- Luo, M.; Li, H. Coupling analysis of construction and renovation risk of old industrial buildings based on N-K and SNA model. J. Railw. Sci. Eng. 2025, 22, 2293–2302. [Google Scholar]

- Liu, B.; Xu, Z.H.; Hu, H.; Liang, H. Research on the coupling mechanism and evolutionary path of fire risks in underground commercial buildings. J. Saf. Environ. 2025, 25, 1683–1690. [Google Scholar]

- Pan, D.; Li, Y.; Luo, F. Aircraft operational safety risk coupling based on N K model. J. Saf. Environ. 2022, 2, 606–614. [Google Scholar]

- Jiao, J.; Wei, M.W.; Yuan, Y.; Zhao, T.D. Risk Quantification and Analysis of Coupled Factors Based on the DEMATEL Model and a Bayesian Network. Appl. Sci. 2020, 10, 317. [Google Scholar] [CrossRef]

- Wu, X.G.; Wu, K.B.; Shen, M.F.; Chen, Y.Q.; Zhang, L.M. Study on the coupling of underground construction safety risks based on N-K model. China Saf. Sci. J. 2016, 26, 96–101. [Google Scholar]

- Qiao, W.G. Analysis and measurement of multifactor risk in underground coal mine accidents based on coupling theory. Reliab. Eng. Syst. Saf. 2021, 208, 107433. [Google Scholar] [CrossRef]

- Mo, J.W.; Li, J. Analysis of coupling effect of quality risk factors in railway engineering based on improved N-K model. Sci. Technol. Manag. Res. 2022, 42, 202–207. [Google Scholar]

- Hou, G.Y.; Liu, W.; Li, L.; Ma, X.Y.; Mu, X.K.; Liu, Y.J. Vulnerability analysis of underground construction safety system with coupled multiple risk factors. KSCE J. Civ. Eng. 2022, 55, 111–119. [Google Scholar]

- Zhang, W.; Zhang, Y. Research on coupling mechanism of intelligent ship navigation risk factors based on NK model. J. Mar. Sci. Technol. 2023, 28, 195–207. [Google Scholar] [CrossRef]

- Wu, B.J.; Jin, L.H.; Zheng, X.Z.; Chen, S. Coupling analysis of crane accident risks based on Bayesian network and the NK model. Sci. Rep. 2024, 14, 1133. [Google Scholar] [CrossRef]

- Wang, F.; Ding, L.; Love, P.E.; Edwards, D.J. Modeling tunnel construction risk dynamics: Addressing the production versus protection problem. Saf. Sci. 2016, 87, 101–115. [Google Scholar] [CrossRef]

- Liu, J. Network Analysis—A Practical Guide to Ucinet Software, 3rd ed.; Shanghai People’s Publishing House: Shanghai, China, 2019. [Google Scholar]

| Single-Factor Coupling | Number | Frequency | Two-Factor Coupling | Number | Frequency | Multi-Factor Coupling | Number | Frequency |

|---|---|---|---|---|---|---|---|---|

| 0000 | 2 | 0.019 | 1100 | 0 | 0.000 | 1110 | 11 | 0.105 |

| 1000 | 0 | 0.00 | 1010 | 1 | 0.009 | 1101 | 7 | 0.067 |

| 0100 | 0 | 0.00 | 1001 | 5 | 0.048 | 1011 | 12 | 0.114 |

| 0010 | 3 | 0.029 | 0110 | 1 | 0.009 | 0111 | 4 | 0.038 |

| 0001 | 2 | 0.019 | 0101 | 1 | 0.009 | 1111 | 55 | 0.524 |

| 0011 | 1 | 0.009 |

| T2 | T21 | T22 | T23 | T24 | T25 | T26 |

| 0.0394 | 0.0426 | 0.0249 | 0.0174 | 0.0153 | 0.0198 | |

| T3 | T31 | T32 | T33 | T34 | T4 | T4 |

| 0.0634 | 0.1089 | 0.0812 | 0.0985 | 0.2035 |

| Factors | Closeness | Betweenness | Factors | Closeness | Betweenness | ||

|---|---|---|---|---|---|---|---|

| inCloseness | outCloseness | inCloseness | outCloseness | ||||

| H1 | 11.396 | 70.175 | 33.484 | E6 | 11.494 | 62.500 | 14.541 |

| H2 | 11.869 | 37.736 | 44.822 | E7 | 13.423 | 2.439 | 0 |

| H3 | 11.765 | 62.500 | 65.906 | E8 | 12.739 | 2.439 | 0 |

| H4 | 11.236 | 93.023 | 19.086 | M1 | 11.364 | 61.538 | 40.484 |

| H5 | 11.765 | 42.105 | 4.667 | M2 | 11.730 | 55.556 | 35.371 |

| H6 | 11.429 | 88.889 | 50.689 | M3 | 11.331 | 34.783 | 0.25 |

| H7 | 11.834 | 67.797 | 107.839 | M4 | 11.268 | 95.238 | 9.732 |

| H8 | 11.527 | 57.143 | 16.341 | M5 | 11.799 | 63.492 | 36.543 |

| H9 | 11.461 | 48.193 | 0.702 | M6 | 11.332 | 83.333 | 19.408 |

| H10 | 11.730 | 64.516 | 75.833 | M7 | 11.494 | 75.472 | 33.571 |

| P1 | 11.628 | 36.364 | 11.819 | M8 | 11.527 | 39.604 | 5.127 |

| P2 | 11.662 | 46.512 | 43.757 | M9 | 11.662 | 55.556 | 11.516 |

| P3 | 11.461 | 47.059 | 14.794 | M10 | 13.245 | 2.439 | 0 |

| P4 | 11.111 | 39.604 | 0.633 | M11 | 11.331 | 93.023 | 25.075 |

| P5 | 11.696 | 54.795 | 74.172 | M12 | 11.494 | 88.889 | 28.431 |

| P6 | 11.561 | 97.561 | 46.947 | M13 | 11.299 | 80.000 | 18.586 |

| E1 | 11.594 | 95.238 | 45.789 | M14 | 11.594 | 76.923 | 65.288 |

| E2 | 13.201 | 2.439 | 0 | M15 | 11.594 | 42.105 | 32.514 |

| E3 | 11.696 | 28.169 | 8.979 | M16 | 13.158 | 2.439 | 0 |

| E4 | 13.333 | 2.439 | 0 | M17 | 11.834 | 52.632 | 17.305 |

| E5 | 13.468 | 2.4398 | 0 | ||||

| Pathway | Betweenness | Pathway | Betweenness | Pathway | Betweenness |

|---|---|---|---|---|---|

| P5–H2 | 71.326 | P2–M3 | 21.730 | M5–P5 | 16.191 |

| H7–P2 | 65.809 | M7–M2 | 21.639 | M6–H7 | 15.606 |

| H2–E3 | 41.805 | M14–M17 | 20.990 | M11–M9 | 15.372 |

| M1–P4 | 37.226 | P6–H3 | 19.274 | M15–P1 | 14.819 |

| H10–M15 | 34.428 | P2–P1 | 19.257 | M13–H8 | 14.563 |

| H1–P5 | 28.122 | E1–H3 | 18.684 | M15–M3 | 14.186 |

| H3–M15 | 28.208 | P6–H10 | 17.467 | M14–H8 | 13.567 |

| M2–M8 | 26.983 | E1–H10 | 16.877 | H6–H7 | 13.441 |

| Grouping | Factors | Countermeasures |

|---|---|---|

| critical risk factors | M4 | Enhance the equipment archive management system and fortify the construction of equipment management systems. |

| P6 | Bolster monitoring and control system administration and maintenance, and enhance monitoring and control system design. | |

| M11 | To improve staff safety knowledge and skills, and increase safety education and training. | |

| H4 | Boost safety education and training, and when working, adhere to all laws and guidelines. | |

| M12 | Boost the organization’s safety production responsibility framework and make clear what each level of staff is responsible for in terms of safety production management. | |

| critical risk paths | P5-H2 | Optimize ventilation shaft arrangement and tunnel design. |

| H7-P2 | Boost worker safety awareness and strengthen the coal mine safety risk assessment system. | |

| H2-E3 | Boost safety education and training, and when working, adhere to all laws and guidelines. | |

| M1-P4 | Identify and resolve any possible risks by conducting routine safety inspections of the mine. | |

| H10-M15 | Create a structure of accountability and encourage the use of sophisticated monitoring tools. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Gao, L. An Investigation of the Process of Risk Coupling and the Main Elements of Coal-Mine Gas-Explosion Risk. Fire 2025, 8, 294. https://doi.org/10.3390/fire8080294

Li S, Gao L. An Investigation of the Process of Risk Coupling and the Main Elements of Coal-Mine Gas-Explosion Risk. Fire. 2025; 8(8):294. https://doi.org/10.3390/fire8080294

Chicago/Turabian StyleLi, Shugang, and Lu Gao. 2025. "An Investigation of the Process of Risk Coupling and the Main Elements of Coal-Mine Gas-Explosion Risk" Fire 8, no. 8: 294. https://doi.org/10.3390/fire8080294

APA StyleLi, S., & Gao, L. (2025). An Investigation of the Process of Risk Coupling and the Main Elements of Coal-Mine Gas-Explosion Risk. Fire, 8(8), 294. https://doi.org/10.3390/fire8080294