A Numerical Study of the Fire Resistance of Square Steel Tube Columns Embedded in Walls

Abstract

1. Introduction

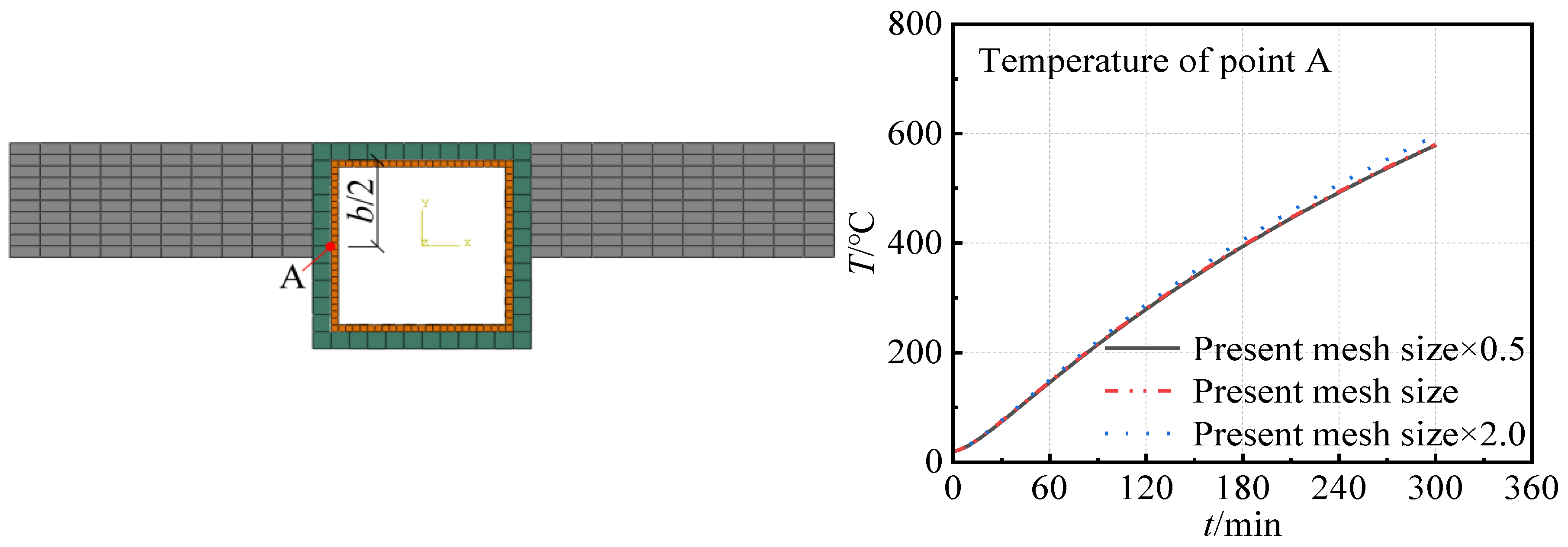

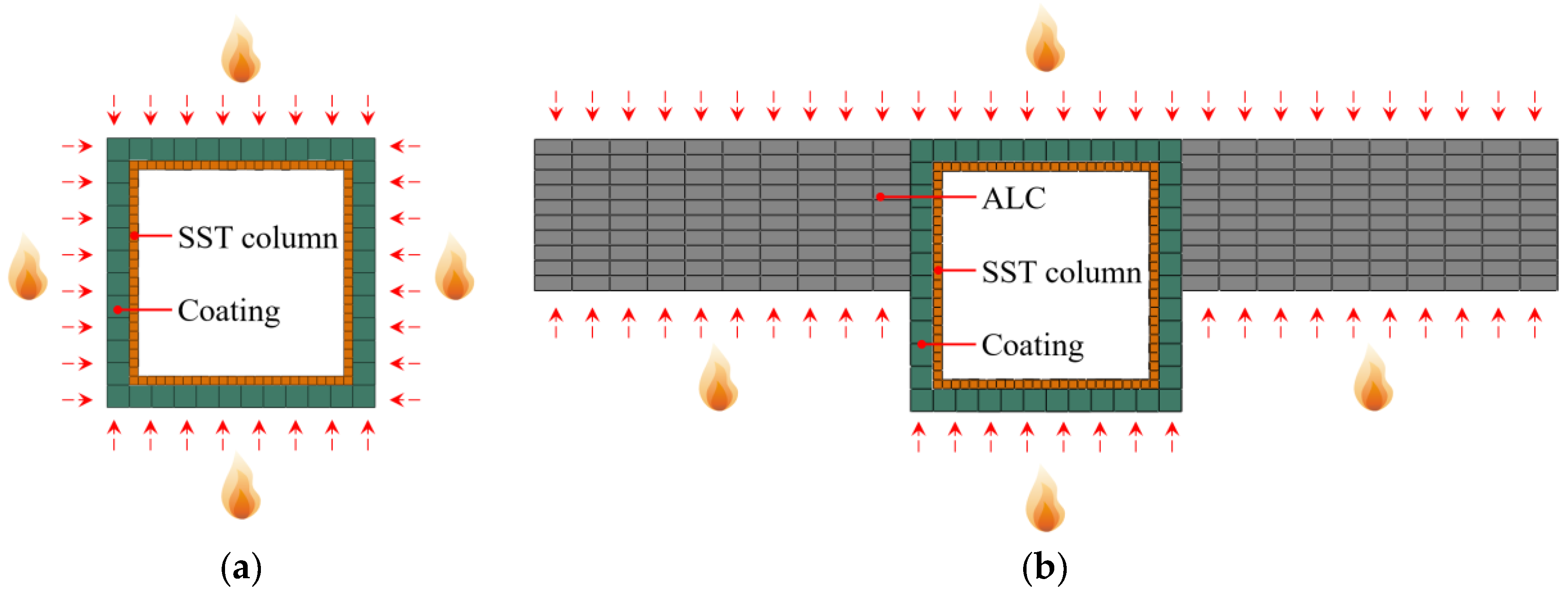

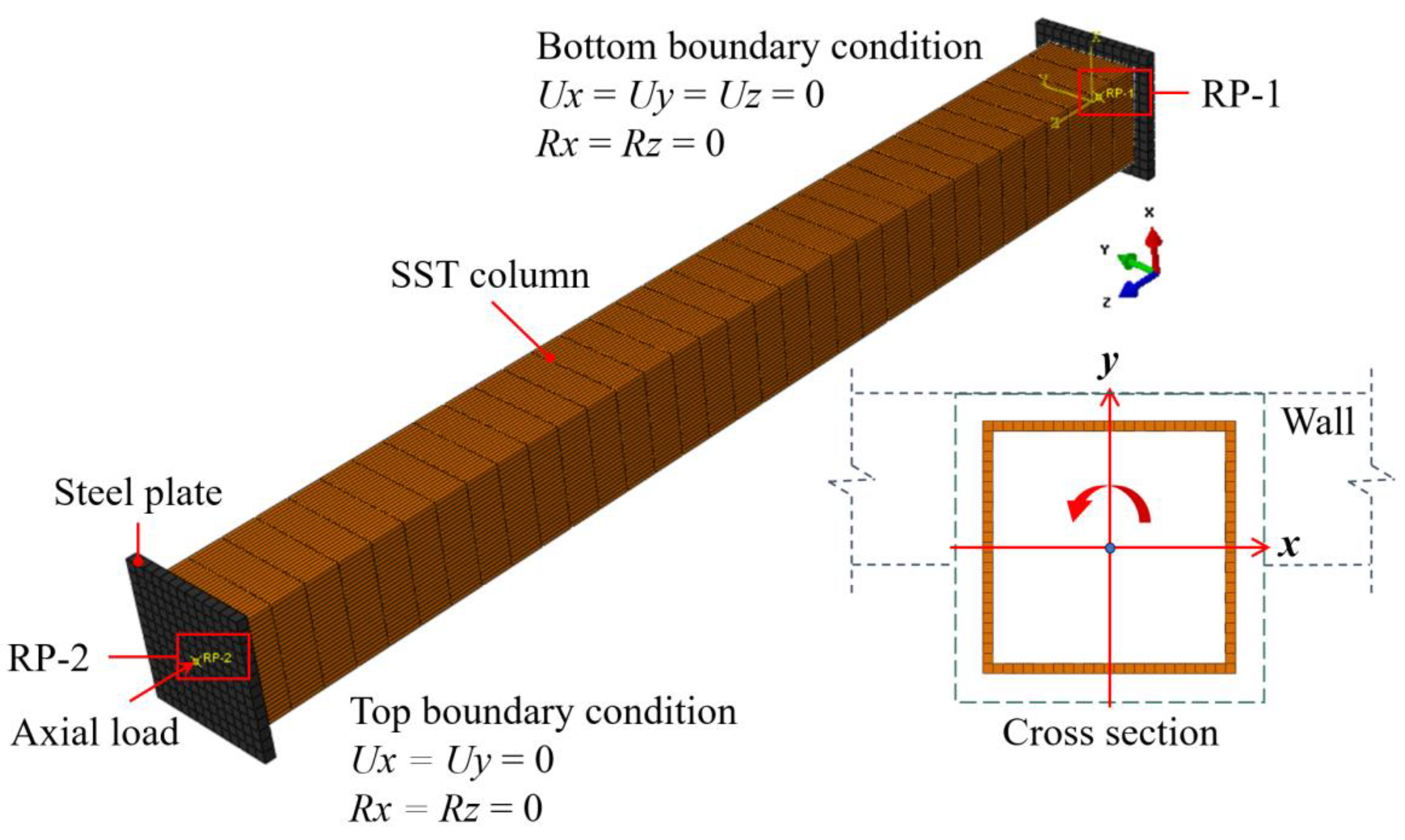

2. FEM Building and Validation

2.1. FEM Building

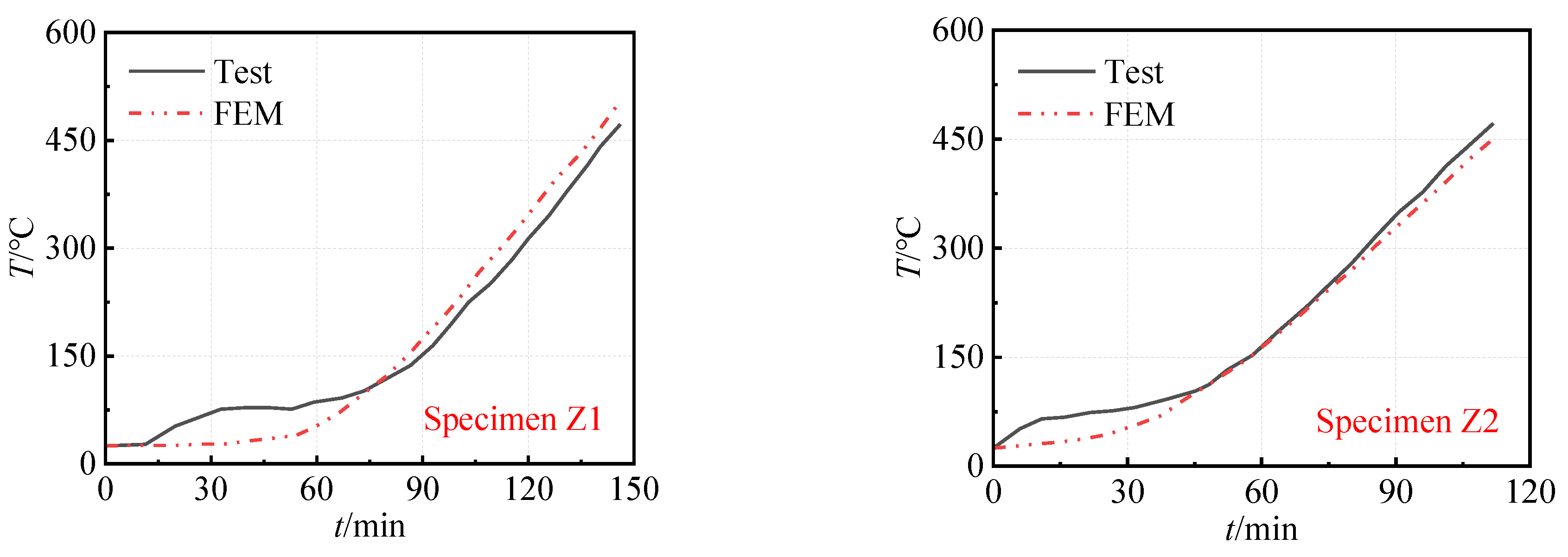

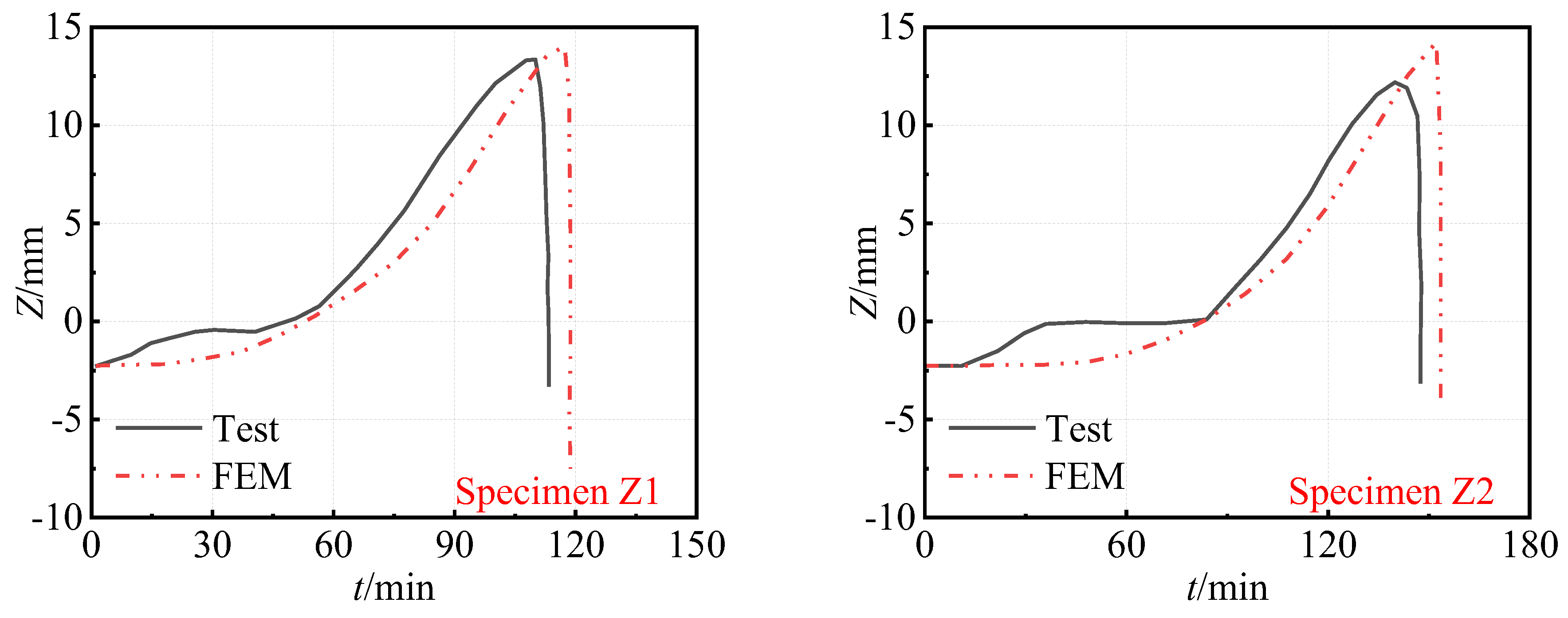

2.2. FEM Validation

3. Simulation Results Analysis

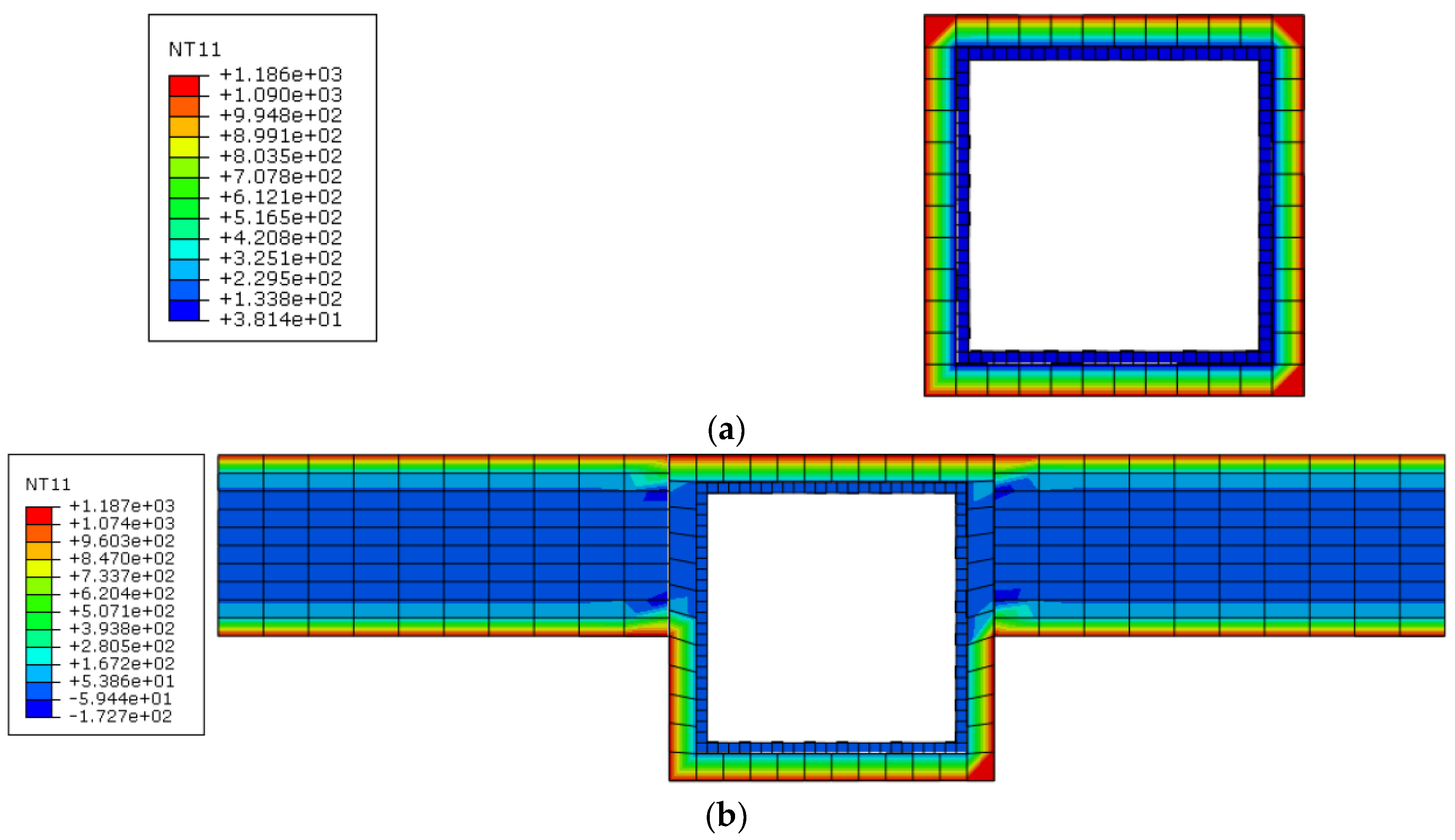

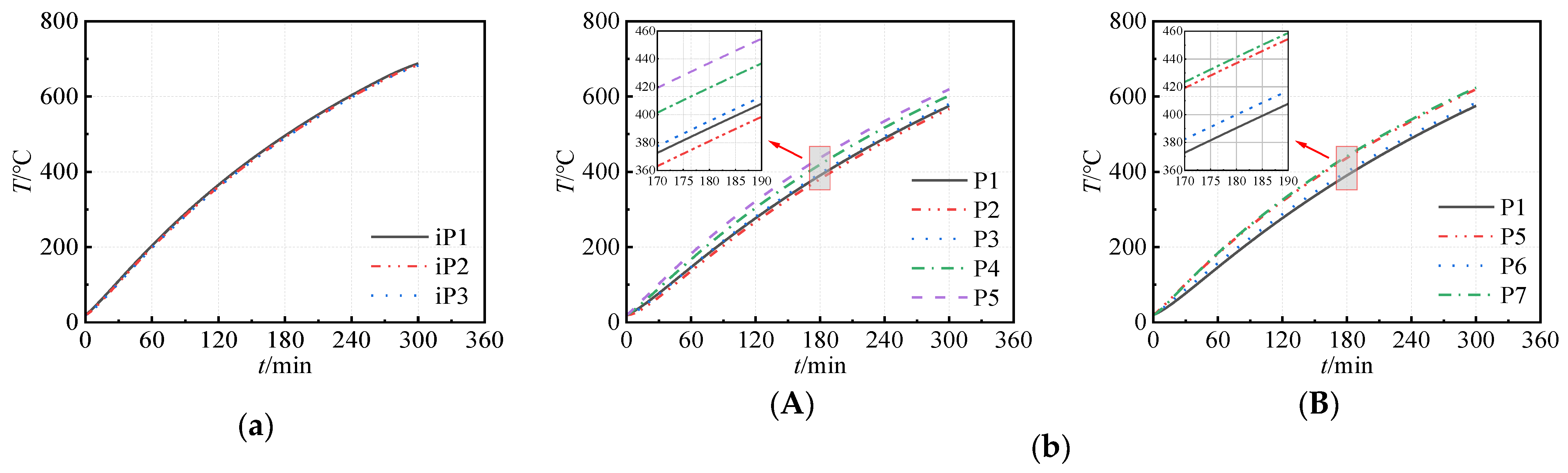

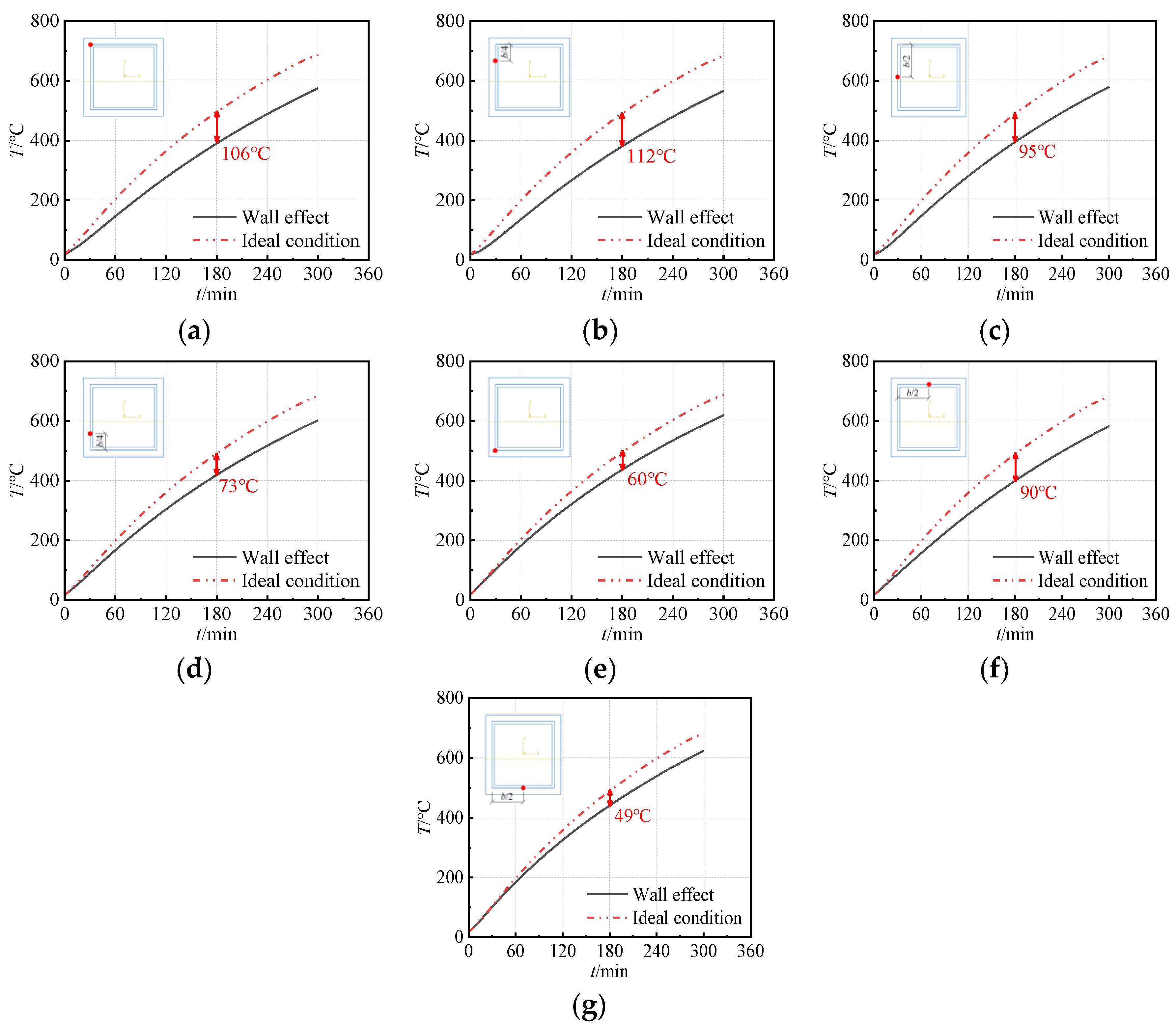

3.1. Heat-Transfer Model

- (1)

- Along the wall-thickness direction, the non-embedded region of the SST column experiences a higher heating rate than that of the embedded region, i.e., points P4/P5 > points P1/P2/P3, and the temperature of point P5 is 14.7% higher than that of point P2 after 3 h of heating. The temperature variation trend is mainly due to the different heat-transfer mechanisms, with the non-embedded region of the SST column being directly affected by the heat radiation from the fire source, while the temperature rise of the embedded region is mainly through the heat conduction between the SST column and the walls. For the measurement points located on the embedded region of the SST column, the temperature of the measurement point near the middle of the wall (P3) is lowest, and as the measurement point approaches the wall edges, the temperature increases gradually, i.e., point P3 < points P1/P4, while for the measurement points located outside the walls, the pattern is reversed, i.e., point P5 > point P4. This is mainly due to the high thickness and relatively high thermal conductivity of the walls, which results in heat dispersion in the walls, and the measurement points near the walls are subject to the “cooling effect” by the walls.

- (2)

- Along the wall-length direction, the temperature of the measurement point near the wall is relatively low, as evidenced by the fact that point P1 < point P6, point P5 < point P7, and the temperature difference between point P1 and point P6 is greater than that between point P5 and point P7; this is attributable to the same underlying reasons previously discussed.

- (3)

- The wall effect results in a non-uniform temperature distribution along the SST column, and the degradation of the material’s properties varies across different positions within the column cross-section, resulting in material strength eccentricities. In practical engineering, considering the economic aspects and standard fire-protection requirements, it may be advantageous to reduce the fire-resistive coating thickness on the embedded region of the SST column.

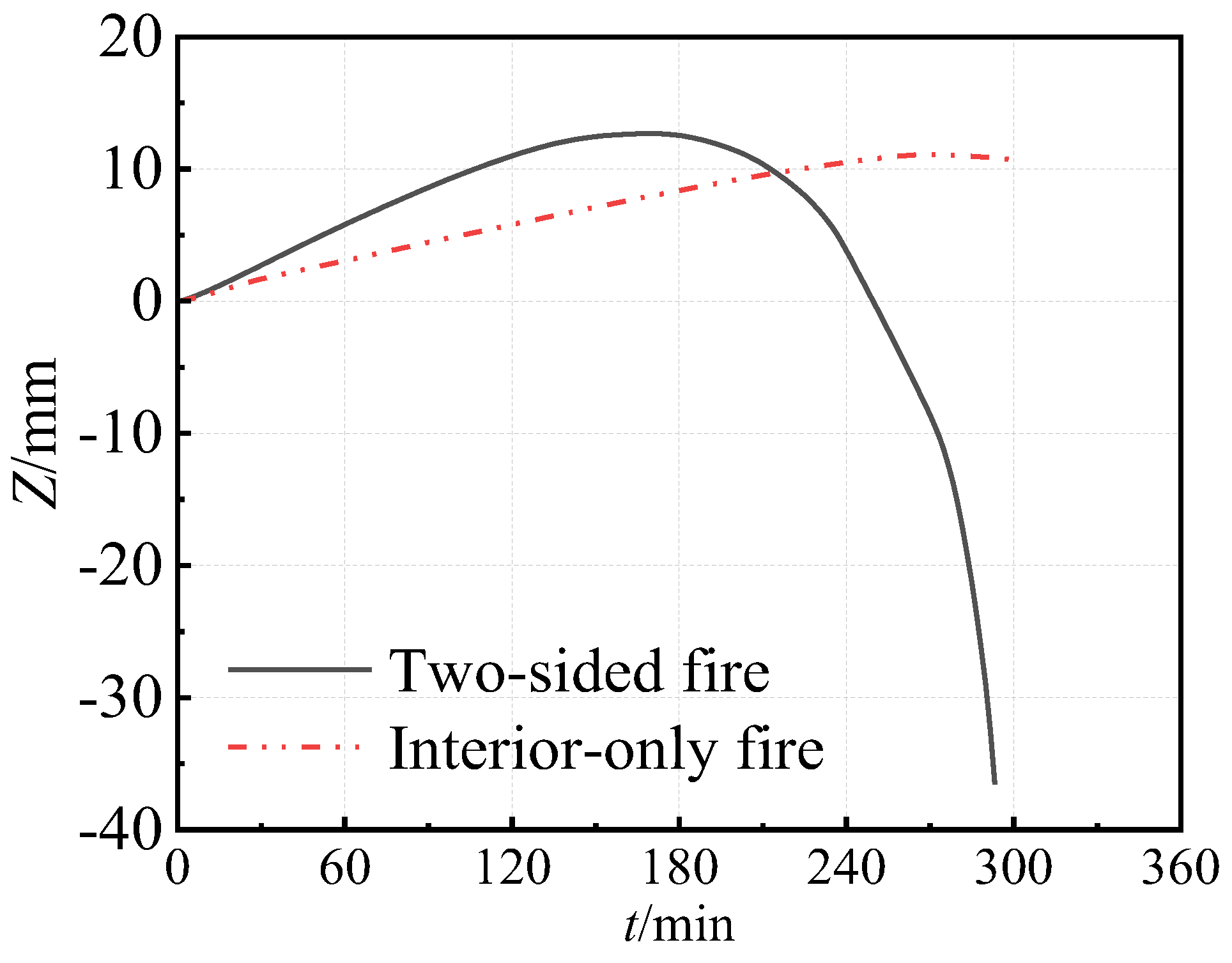

3.2. Mechanical Model

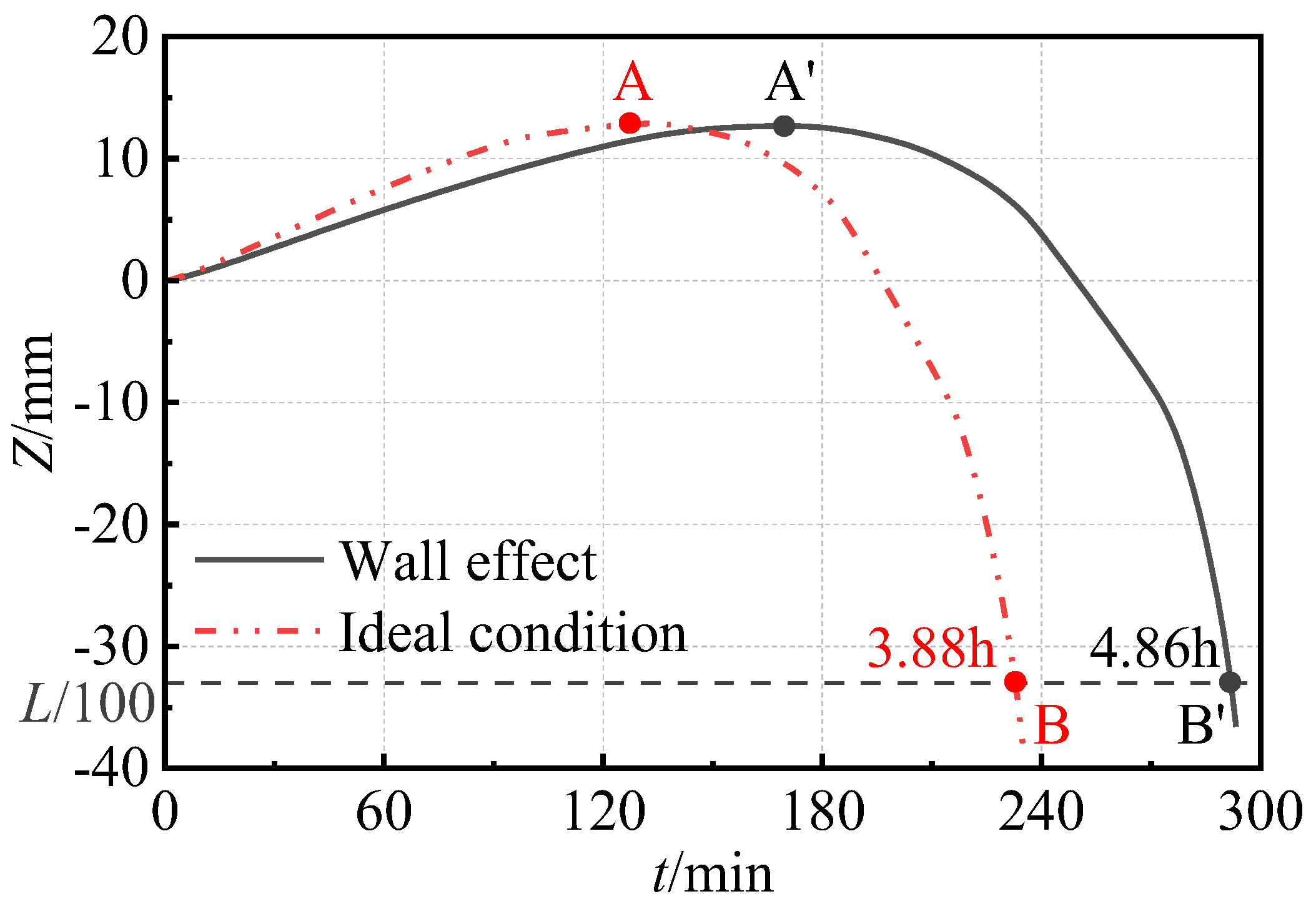

3.2.1. Axial Deformation

- (1)

- Expansion phase (OA/OA’): At the initial heating, the overall temperature of the SST columns remains relatively low, which leads to minimal degradation of the material’s properties. Due to the high thermal-expansion coefficient of the steel, the columns undergo pronounced thermal expansion. During this phase, the deformation due to thermal expansion exceeds that of compressive deformation, resulting in an upward axial displacement of the columns. Under ideal fire conditions, the column experiences a more rapid temperature increase, resulting in a steeper slope of the axial deformation curve compared with that observed under actual fire conditions at this phase. As the columns temperature rises, the steel strength progressively deteriorates, accelerating the compressive deformation rate under axial loading, which is reflected in a gradual decrease in the slope of the Z-t curves. When the overall compressive deformation rate coincides with the thermal-expansion deformation rate, the Z-t curves attain their peak points (A/A’).

- (2)

- Compression failure phase (AB/A’B’): With the increasing temperature of the columns, degradation of the material’s properties becomes markedly pronounced. Concurrently, due to the initial defects and the stress redistribution induced by the thermal expansion, localized buckling or plastic deformation may manifest, resulting in a substantial reduction in the load-bearing capacity of the columns. During this phase, the overall compressive deformation rate significantly exceeds that of thermal expansion. According to the criteria for determining fire resistance outlined in Fire-Resistance Tests-Elements of Building Construction-Part 7: Specific Requirements for Columns GB/T 9978.1-2008 [39], for axial load bearing components, when the axial compressive deformation reaches 1/100 of its length, it is considered that the components undergo failure (B/B’).

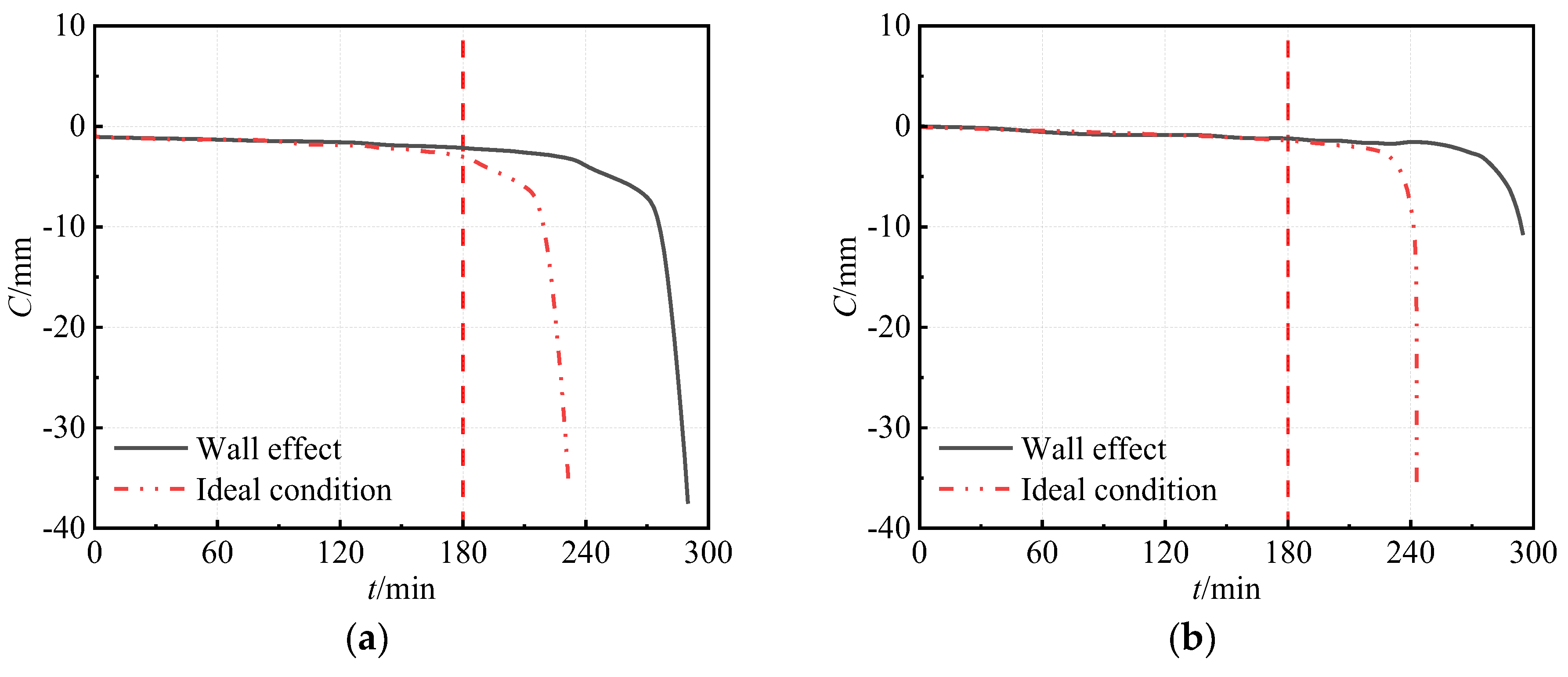

3.2.2. Lateral Deformation

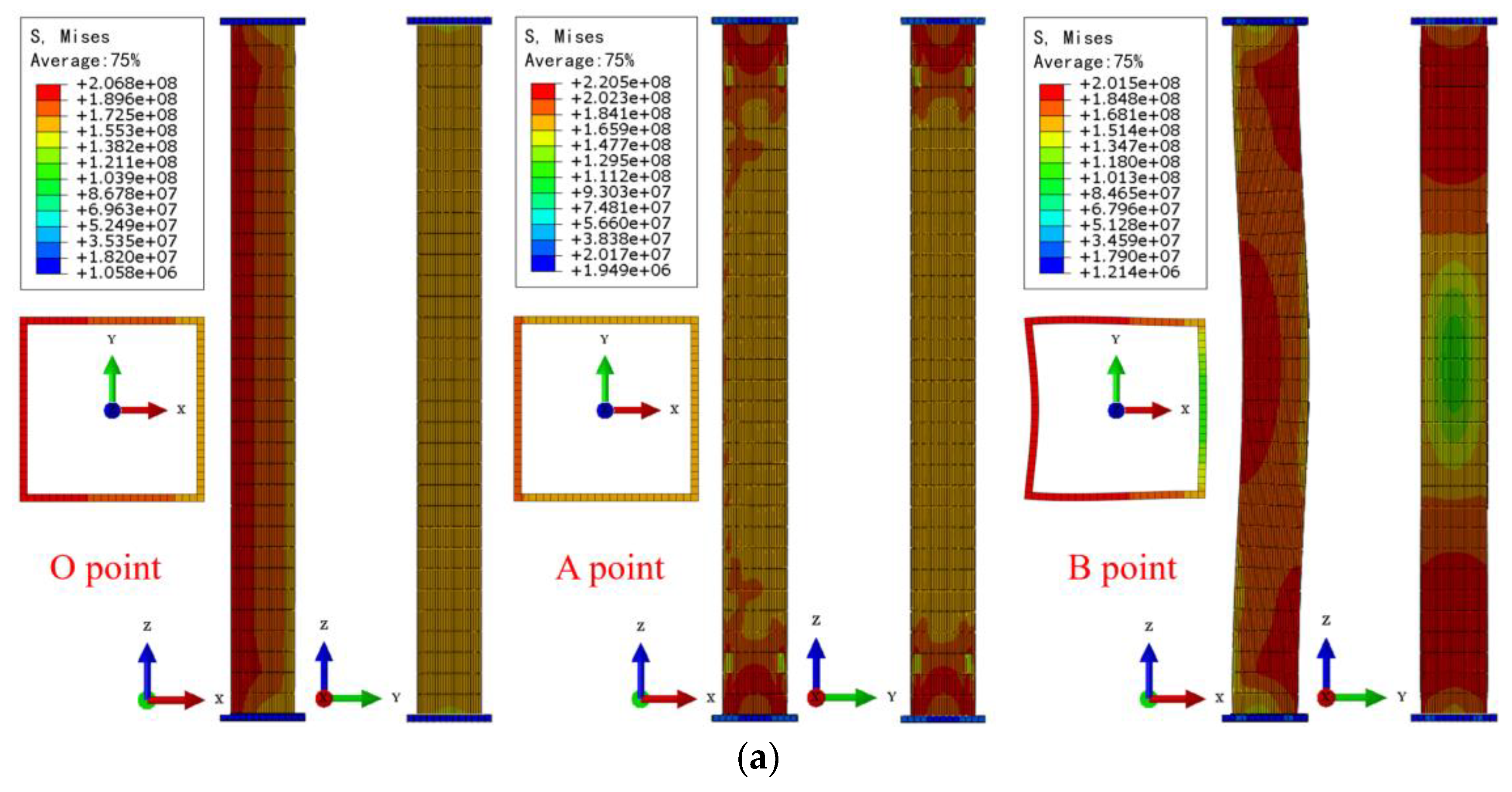

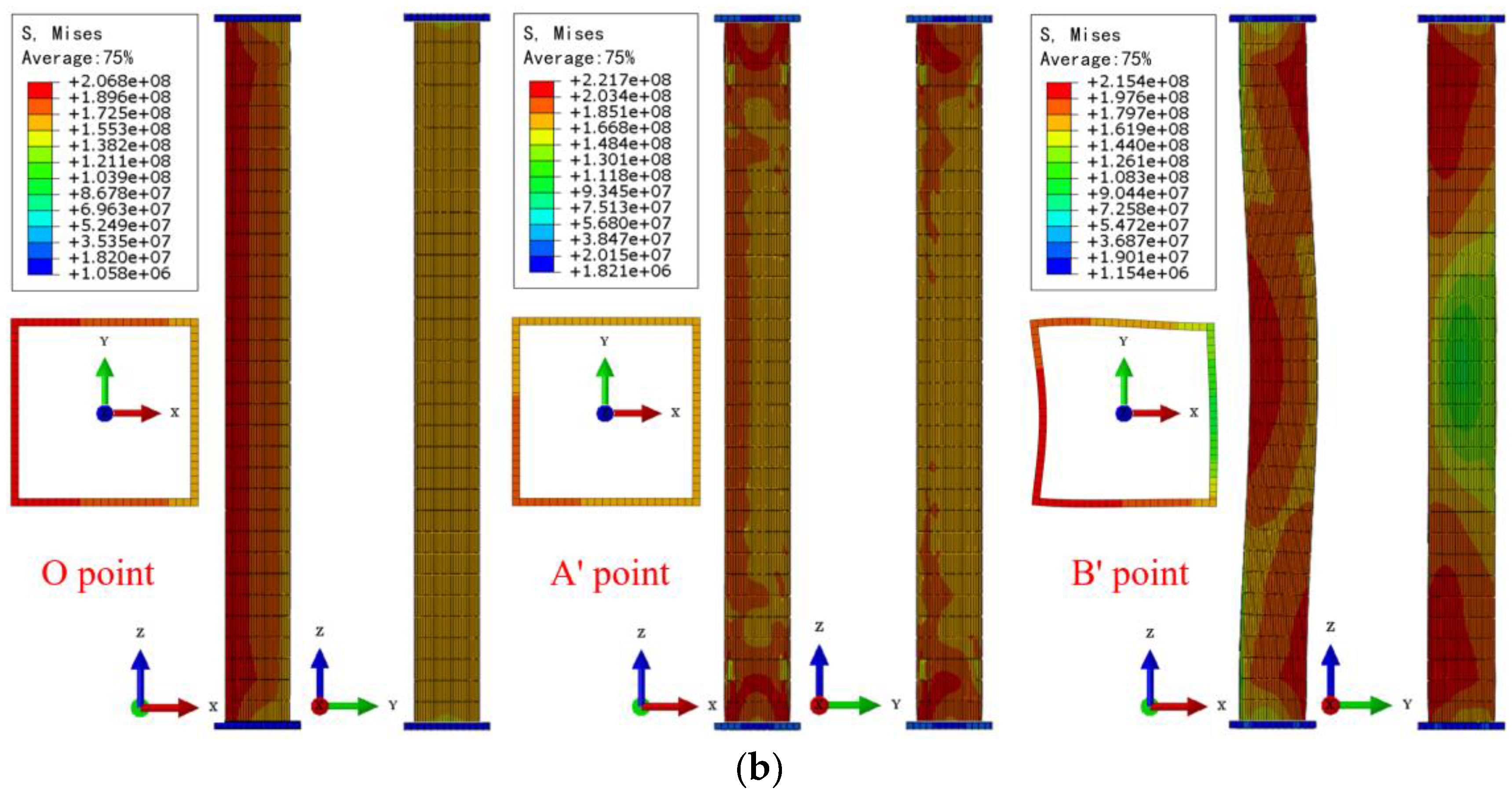

3.2.3. Stress Distribution

4. Parametric Analyses

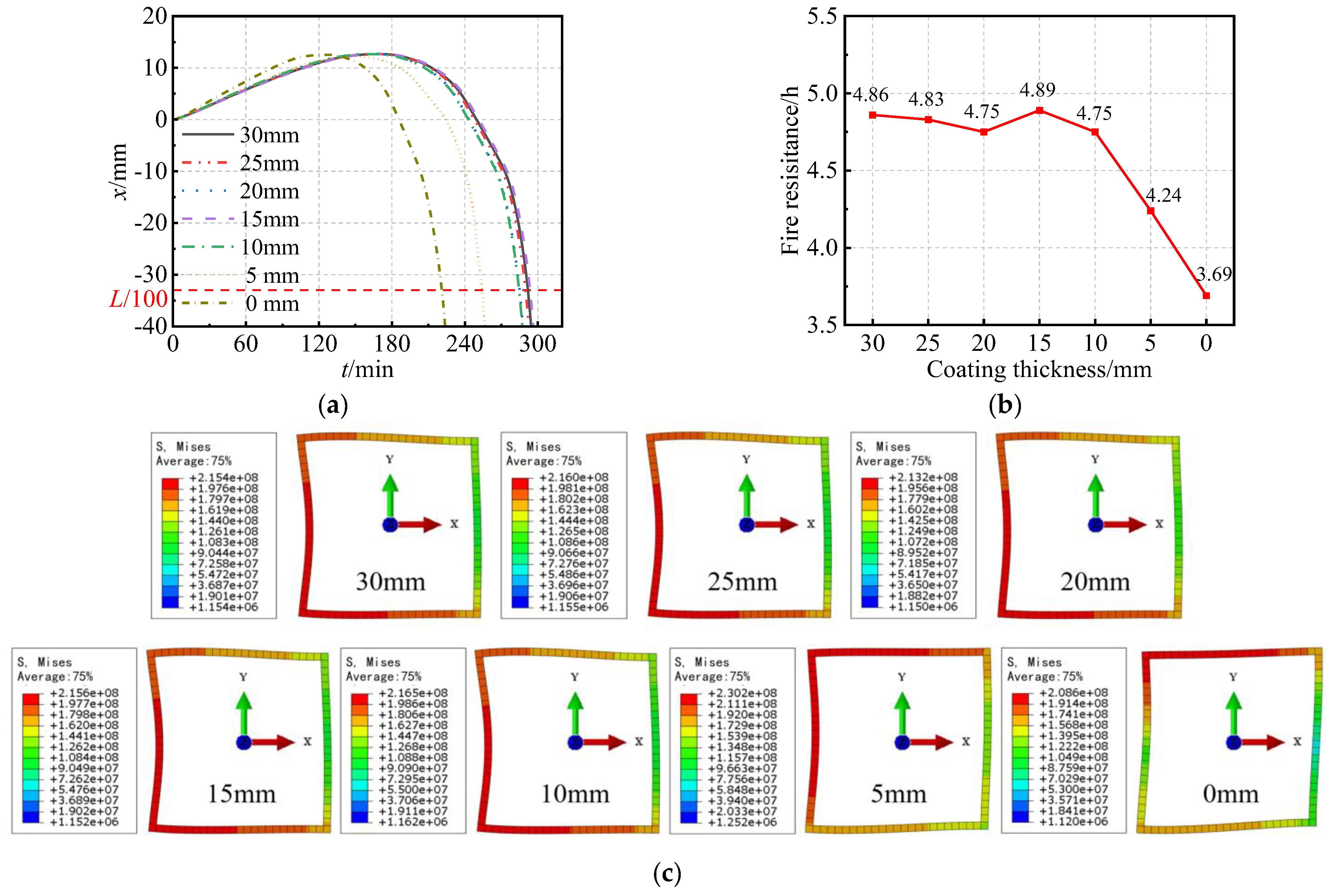

4.1. Fire-Resistive Coating Thickness

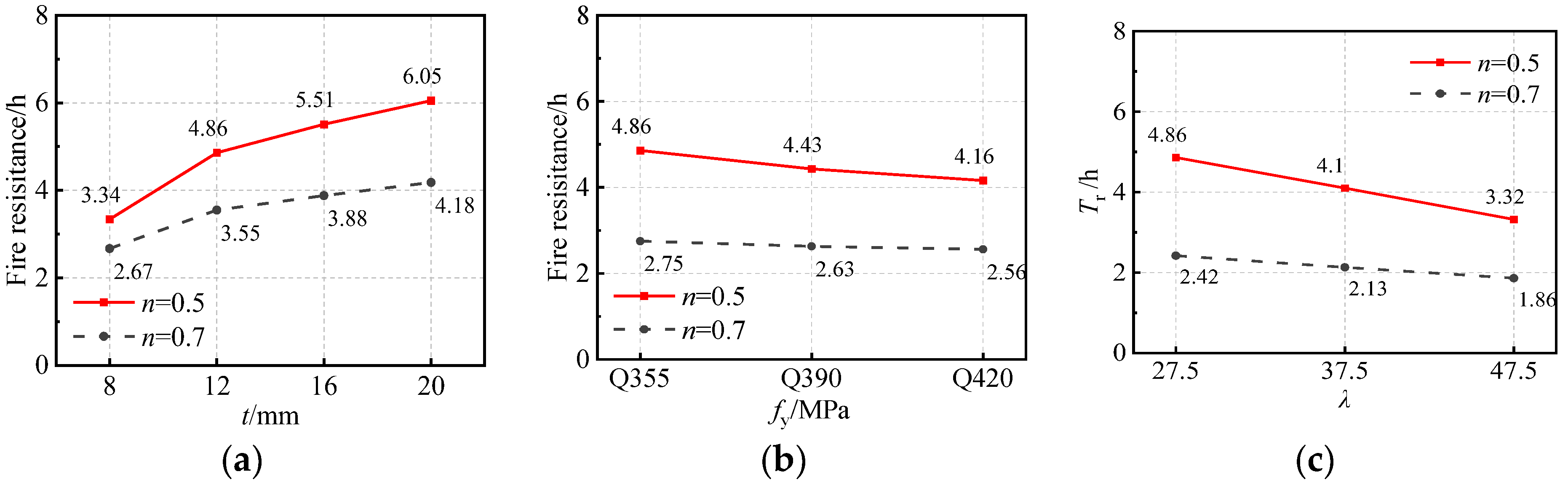

4.2. Steel Tube Thickness

4.3. Steel Strength

4.4. Slenderness Ratio

5. Conclusions

- (1)

- Under ideal fire conditions, the temperature distribution across the whole cross-section of the SST column is uniform. However, when considering the wall effect, the temperature rise rate of the embedded region is considerably lower than that of the non-embedded region. Consequently, degradation of the material’s properties varies at different locations, resulting in eccentricity in the material’s strength.

- (2)

- The axial deformation trends of the SST column under ideal and actual fire conditions are consistent. In the initial heating, the temperature of the columns remains low, and the material’s properties exhibit minimal deterioration, resulting in significant thermal expansion. As the temperature escalates, the degradation of the material’s properties occurs, leading to an increased rate of compressive deformation and local buckling, which ultimately leads to the column’s failure. When considering the wall effect, the fire resistance of the SST column is enhanced by 25.3% compared with that under ideal fire conditions.

- (3)

- Under ideal fire conditions, the buckling direction of the SST column under failure is in the direction of the initial defect setting, whereas when considering the wall effect, the buckling direction of the SST column deviates toward the wall-thickness direction due to the eccentricity of the material strength induced by the non-uniform temperature distribution.

- (4)

- In a practical assembled steel-structure design, the thermal insulation effect of the wall should be considered. By reducing the fire-resistive coating thickness on the embedded region, the uniformity of stress distribution within the column can be ameliorated, which can ensure the fire resistance of the column members and reduce the cost at the same time. When a high load-bearing capacity is required, prioritizing an increase in the steel tube thickness over enhancing steel strength is advisable. Components with high slenderness ratios are more susceptible to local buckling and overall instability in fire conditions.

- (5)

- For the fire-resistance design of SST columns embedded in walls, when the demand for the fire-resistance level is Class I, it is recommended that the fire-resistive coating thickness on the embedded region be reduced to 10 mm, the steel tube thickness be no less than 8 mm and the load ratio and slenderness ratio not exceed 0.5 and 47.5, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, J.P.; Sun, X.L.; Xue, Q.; Fan, C.L. Research and applications of prefabricated steel structure building systems. Eng. Mech. 2017, 34, 1–13. [Google Scholar]

- Hou, J.W.; Wang, X.D.; Liu, J.D.; Chen, Z.; Zhong, X. Study on the stability bearing capacity of multi-column wall in modular steel building. Eng. Struct. 2020, 214, 110648. [Google Scholar] [CrossRef]

- Seyedabadi, M.R.; Karrabi, M.; Shariati, M.; Karimi, S.; Maghrebi, M.; Eicker, U. Global building life cycle assessment: Comparative study of steel and concrete frames across European union, USA, Canada, and Australia building codes. Energy Build. 2024, 304, 113875. [Google Scholar] [CrossRef]

- Li, J.W.; Wang, X.Y.; Chen, L.; Lu, W.B. Bearing capacity of light-steel compound section and steel columns under axial compression. Adv. Civ. Eng. 2022, 2022, 8061015. [Google Scholar] [CrossRef]

- Cai, K.H.; Wang, H.X.; Wang, J.S.; Bai, J.; Zuo, J.; Chan, K.; Lai, K.; Song, Q. Mitigating lifecycle GHG emissions of building sector through prefabricated light-steel buildings in comparison with traditional cast-in-place buildings. Resour. Conserv. Recycl. 2023, 194, 107007. [Google Scholar] [CrossRef]

- Zhang, C.T.; Hu, S.H.; An, R.B.; Wang, Z.S. Seismic performance of a newly assembled joint between shaped steel beams and square steel tubular columns. J. Build. Eng. 2025, 100, 111748. [Google Scholar] [CrossRef]

- Xu, J.H.; Zhou, T.; Chen, Z.H.; Liu, X.S.; Qiao, W.T. Experimental research on H-section beam-square steel column joints connected by self-tapping screws. Thin-Walled Struct. 2024, 200, 111923. [Google Scholar] [CrossRef]

- Liu, J.F.; Cheng, X.; Lei, H.Q.; An, Y. An experimental study on seismic behavior of square hollow section column-truss beam connections. J. Vib. Shock 2023, 42, 237–244. [Google Scholar]

- Chang, H.F.; Li, Z.W.; Qian, Y.L.; Xia, J.W. Experimental and parametric study on flexural performance of transverse reverse channel connections between square hollow section column and H-beam. J. Build. Struct. 2021, 42, 92–102. [Google Scholar]

- Yamada, S.; Ishida, T. Collapse behavior of weak column type steel moment resisting frames built with square hollow section columns subjected to bi-directional horizontal ground motion. J. Build. Eng. 2022, 48, 103960. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, Y.; Takeuchi, T.; Zhao, S. Comprehensive stress-strain model of square steel tube stub columns under compression. Eng. Struct. 2017, 131, 503–512. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, Q.Y.; Xue, H.; Liu, X.K. Low cycle fatigue behavior and damage model analysis of bolted endplate connections to square hollow section columns. J. Build. Struct. 2016, 37, 151–159+173. [Google Scholar]

- Liu, H.; Yao, Y.; Deng, Y.J.; Chu, Y.P. Study on influence of width-to-thickness ratios on static performance of the thin-wall square steel tube columns to axial loads. Build. Sci. 2013, 29, 88–94. [Google Scholar]

- GB 50017-2017; Standard for Design of Steel Structures. National Standard of the People’s Republic of China: Beijing, China, 2017.

- Yang, J.J.; Wang, W.Y.; Shi, Y.; Xu, L. Experimental study on fire resistance of cold-formed steel built-up box columns. Thin-Walled Struct. 2020, 147, 106564. [Google Scholar] [CrossRef]

- ElSabbagh, A.; Nassef, W.; El-Ghandour, M.; Sharaf, T. Inelastic buckling analysis of steel columns at different fire scenarios. Eng. Struct. 2023, 291, 116464. [Google Scholar] [CrossRef]

- Qi, H.-H.; Hou, J.; Lou, G.-B.; Jiang, Y.; Zhong, B.; Li, G.-Q. Experimental and numerical study on fire-induced collapse of unprotected steel framed structures. J. Constr. Steel Res. 2024, 218, 108730. [Google Scholar] [CrossRef]

- Shan, S.D.; Pan, W. Collapse mechanisms of multi-story steel-framed modular structures under fire scenarios. J. Constr. Steel Res. 2022, 196, 107419. [Google Scholar] [CrossRef]

- Ruan, S.P.; Zhao, J.C.; Song, Z.S.; Duan, L.P. Experimental investigation of the structural response of a steel-framed building subjected to traveling fire. J. Struct. Eng. 2022, 148, 4021269. [Google Scholar] [CrossRef]

- GB 51249-2017; Code for Fire Safety of Steel Structures in Buildings. National Standard of the People’s Republic of China: Beijing, China, 2018.

- Li, R.; Chen, W.; Ye, J.H.; Jiang, W. Fire resistance test and simplified theoretical model of square steel tubular columns with composite fire protection. Eng. Mech. 2025, 1–12. [Google Scholar] [CrossRef]

- Zong, J.H.; Li, H.C.; Yu, F.Z.; Huang, Y.L. Numerical analysis of the fire-resistance capacity for mouth-section steel columns with external cladding. J. Hebei Agric. Univ. 2016, 39, 126–130. [Google Scholar]

- Dashdemberel, N.; Han, S.-G.; Kim, S.-H.; Chung, K.-S.; Choi, S.-M. Experimental and analytical study on fire resistance performance of mid-high rise modular rectangular steel tube columns using a 3 h fireproof cladding method. Int. J. Steel Struct. 2024, 24, 1178–1188. [Google Scholar] [CrossRef]

- Agarwal, A.; Choe, L.; Varma, A.H. Fire design of steel columns: Effects of thermal gradients. J. Constr. Steel Res. 2014, 93, 107–118. [Google Scholar] [CrossRef]

- Quiel, S.E.; Garlock, M.E.M.; Dwaikat, M.M.S.; Kodur, V.K.R. Predicting the demand and plastic capacity of axially loaded steel beam–columns with thermal gradients. Eng. Struct. 2014, 58, 49–62. [Google Scholar] [CrossRef]

- Moura Correia, A.J.P.; Rodrigues, J.P.C.; Real, P.V. Thermal bowing on steel columns embedded on walls under fire conditions. Fire Saf. J. 2014, 67, 53–69. [Google Scholar] [CrossRef]

- Rocha, F.M.; Rodrigues, J.P.C.; Neto, J.M. Fire behavior of steel and partially encased composite columns embedded on walls. J. Constr. Steel Res. 2018, 149, 105–118. [Google Scholar] [CrossRef]

- Liu, X.-C.; Feng, X.-Z.; Chen, X.; Zhou, W.; Xu, B.; Yin, Z. Fire resistance performance of L-section fireproof board and thin concrete encased skeleton steel column. Eng. Struct. 2025, 327, 119629. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, S.; Ahmed, M.; Liang, Q.Q. Experimental and numerical investigations of circular concrete filled steel double-skin and double-tube columns exposed to fire. Thin-Walled Struct. 2024, 198, 111766. [Google Scholar] [CrossRef]

- Lie, T.T. Fire resistance of circular steel columns filled with bar-reinforced concrete. J. Struct. Eng. 1994, 120. [Google Scholar] [CrossRef]

- Othuman, M.A.; Wang, Y.C. Elevated-temperature thermal properties of lightweight foamed concrete. Constr. Build. Mater. 2011, 25, 705–716. [Google Scholar] [CrossRef]

- GB 50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. National Standard of the People’s Republic of China: Beijing, China, 2014.

- Duan, B.C.; Yang, D.D.; Liu, F.Q.; Yang, H. Analysis and design on fire performance of circular steel tube confined reinforced concrete columns with fire protection. Eng. Mech. 2024, 41, 118–129. [Google Scholar]

- ISO 834-11: 2014; Fire Resistance Tests-Elements of Building Construction-Part 11: Specific Requirements for the Assessment of Fire Protection to Structural Steel Elements. British Standards Institution: London, UK, 2014.

- Eurocede 3; Design of Steel Structures. McGraw Hill: New York, NY, USA, 1993.

- Mao, W.-J.; Wang, W.-D.; Zhou, K. Fire performance on steel-reinforced concrete-filled steel tubular columns with fire protection. J. Constr. Steel Res. 2022, 199, 107580. [Google Scholar] [CrossRef]

- Wang, Z.; Zhong, Y.; Su, A.; Su, M.; Zhao, O. Post-fire flexural buckling and resistances of square recycled aggregate concrete-filled stainless steel tube (RACFSST) columns. Thin Walled Struct. 2024, 205, 112490. [Google Scholar] [CrossRef]

- GB 14907-2018; Fire Resistive Coating for Steel Structure. National Standard of the People’s Republic of China: Beijing, China, 2019.

- GB/T 9978.1-2008; Fire-Resistance Tests-Elements of Building Construction-Part 7: Specific Requirements for Columns. National Standard of the People’s Republic of China: Beijing, China, 2009.

- GB 50016-2014 (2018 edition); Code for Fire Protection Design of Building. National Standard of the People’s Republic of China: Beijing, China, 2018.

- Liu, F.Q.; Yang, H.; Yang, D.D.; Zhang, S.M. Fire safety design method of circular steel tube confined reinforced concrete columns. J. Build. Struct. 2017, 38, 150–156. [Google Scholar]

| T/°C | Yield Strength | Proportionality Limit | Elastic Modulus |

|---|---|---|---|

| 20 | 1.000 | 1.000 | 1.000 |

| 100 | 1.000 | 1.000 | 1.000 |

| 200 | 1.000 | 0.807 | 0.900 |

| 300 | 1.000 | 0.613 | 0.800 |

| 400 | 1.000 | 0.420 | 0.700 |

| 500 | 0.780 | 0.360 | 0.600 |

| 600 | 0.470 | 0.180 | 0.310 |

| 700 | 0.230 | 0.075 | 0.130 |

| 800 | 0.110 | 0.050 | 0.090 |

| 900 | 0.060 | 0.0375 | 0.0675 |

| 1000 | 0.040 | 0.025 | 0.045 |

| 1100 | 0.020 | 0.0125 | 0.0225 |

| 1200 | 0.000 | 0.000 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, W.; Wang, J.; Tan, S.; Wang, X.; Wang, T. A Numerical Study of the Fire Resistance of Square Steel Tube Columns Embedded in Walls. Fire 2025, 8, 122. https://doi.org/10.3390/fire8040122

Shen W, Wang J, Tan S, Wang X, Wang T. A Numerical Study of the Fire Resistance of Square Steel Tube Columns Embedded in Walls. Fire. 2025; 8(4):122. https://doi.org/10.3390/fire8040122

Chicago/Turabian StyleShen, Wanyu, Jian Wang, Siyong Tan, Xuehui Wang, and Tao Wang. 2025. "A Numerical Study of the Fire Resistance of Square Steel Tube Columns Embedded in Walls" Fire 8, no. 4: 122. https://doi.org/10.3390/fire8040122

APA StyleShen, W., Wang, J., Tan, S., Wang, X., & Wang, T. (2025). A Numerical Study of the Fire Resistance of Square Steel Tube Columns Embedded in Walls. Fire, 8(4), 122. https://doi.org/10.3390/fire8040122