Experimental Study on the Melt Dripping Behavior of Flexible Polyurethane Foam in an Oscillating Ship Cabin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

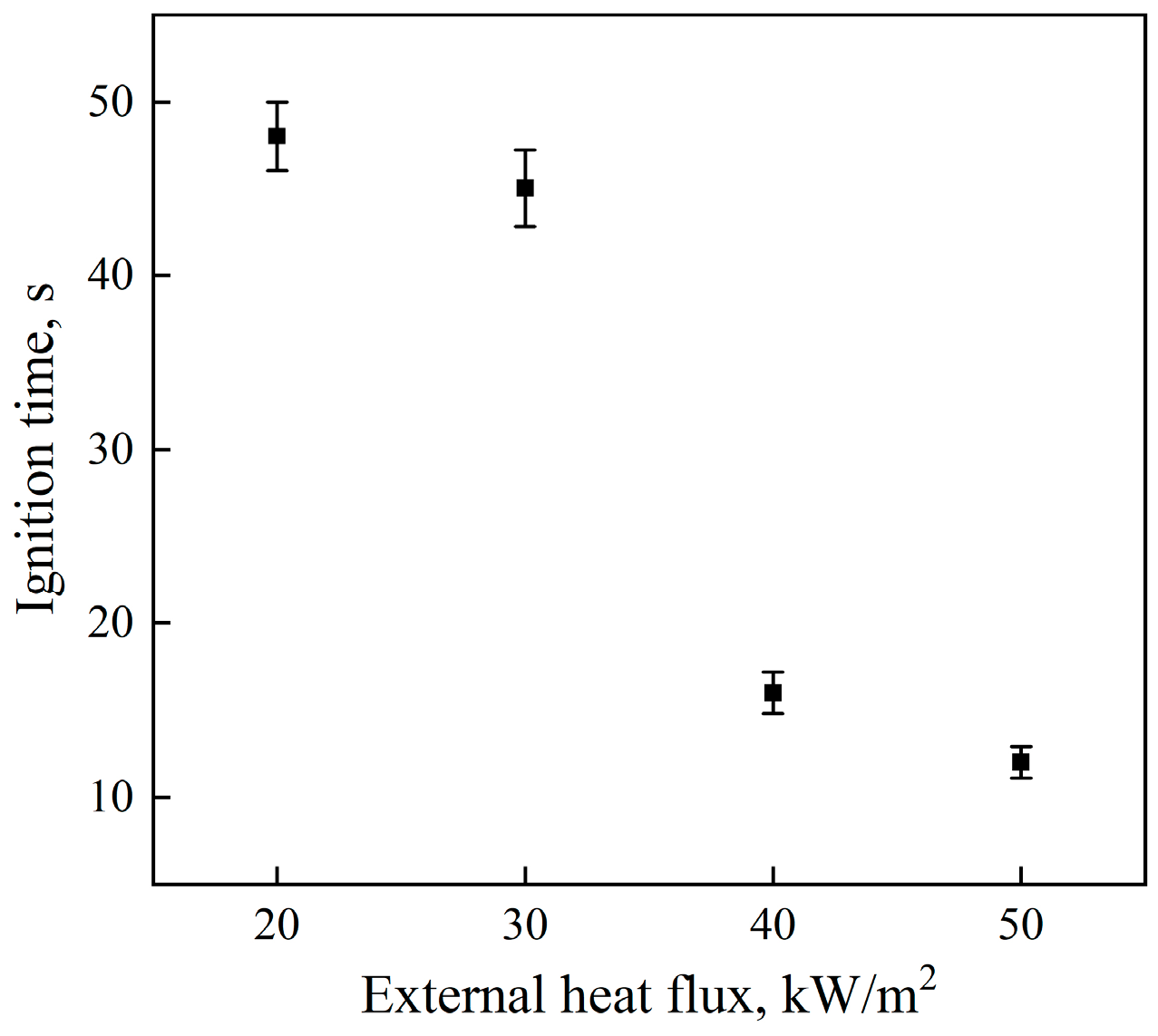

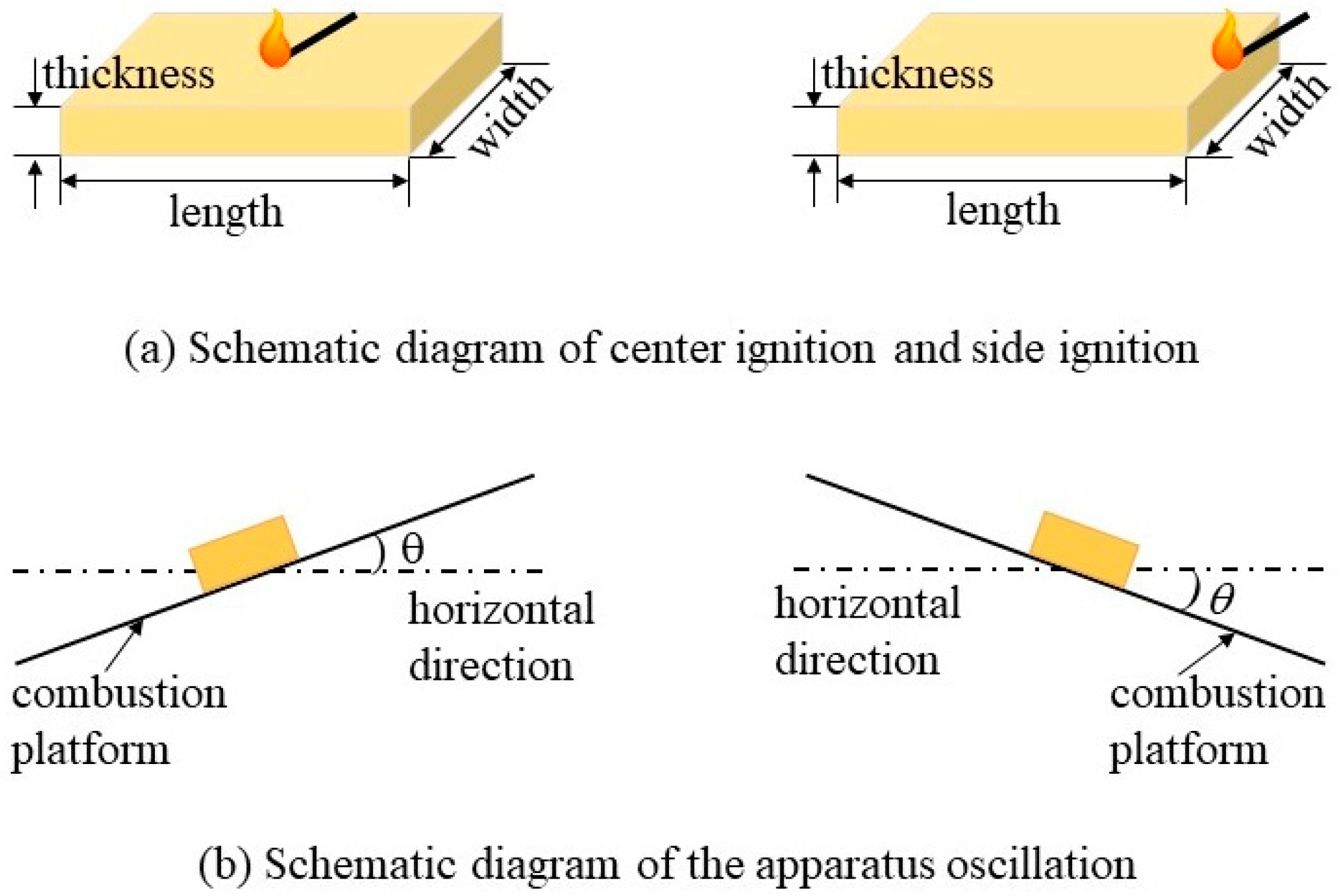

2.2. Experimental Setup and Procedure

3. Results

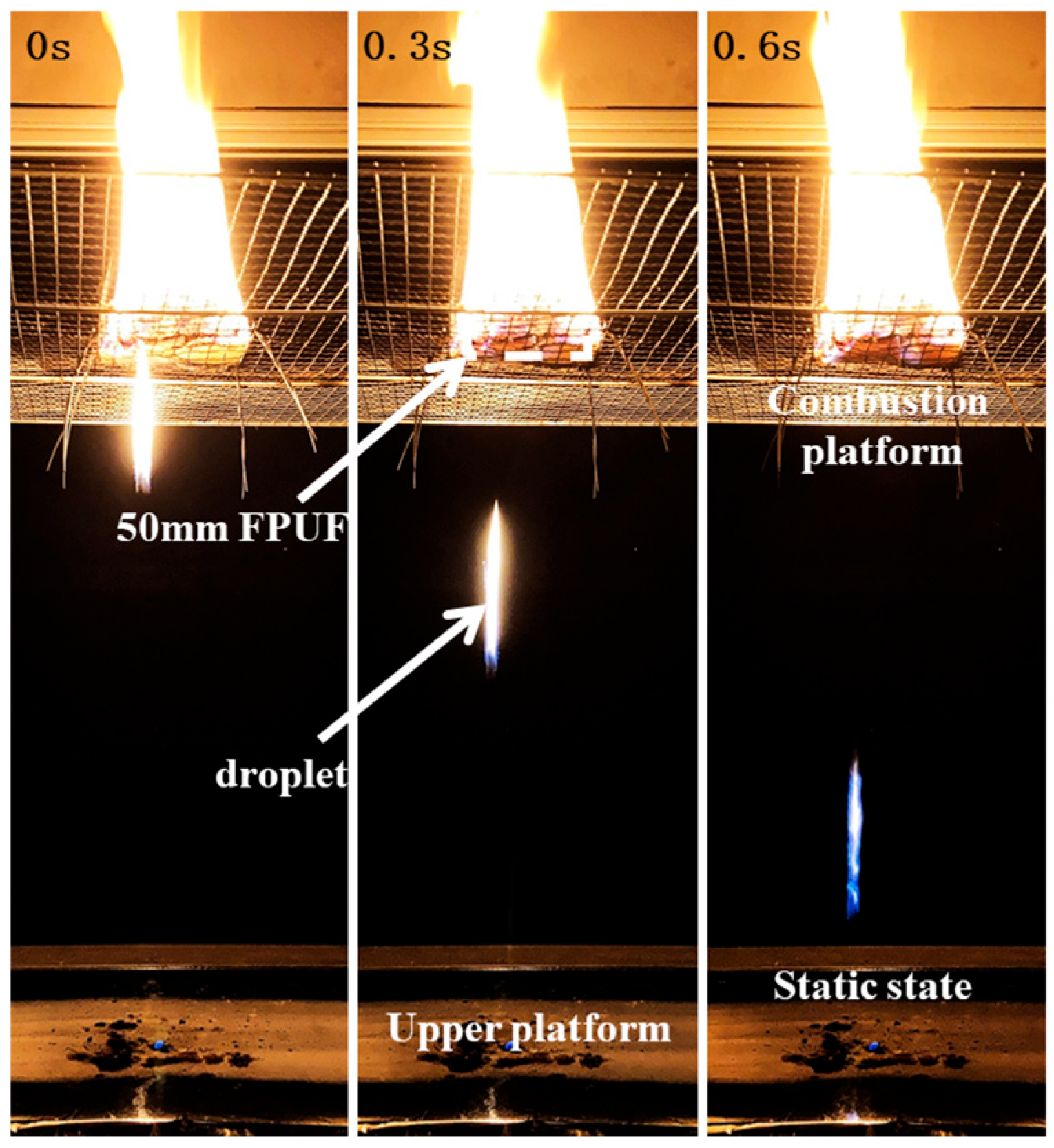

3.1. Effects of Sample Size and Ignition Location on Dripping Behavior Under Static Conditions

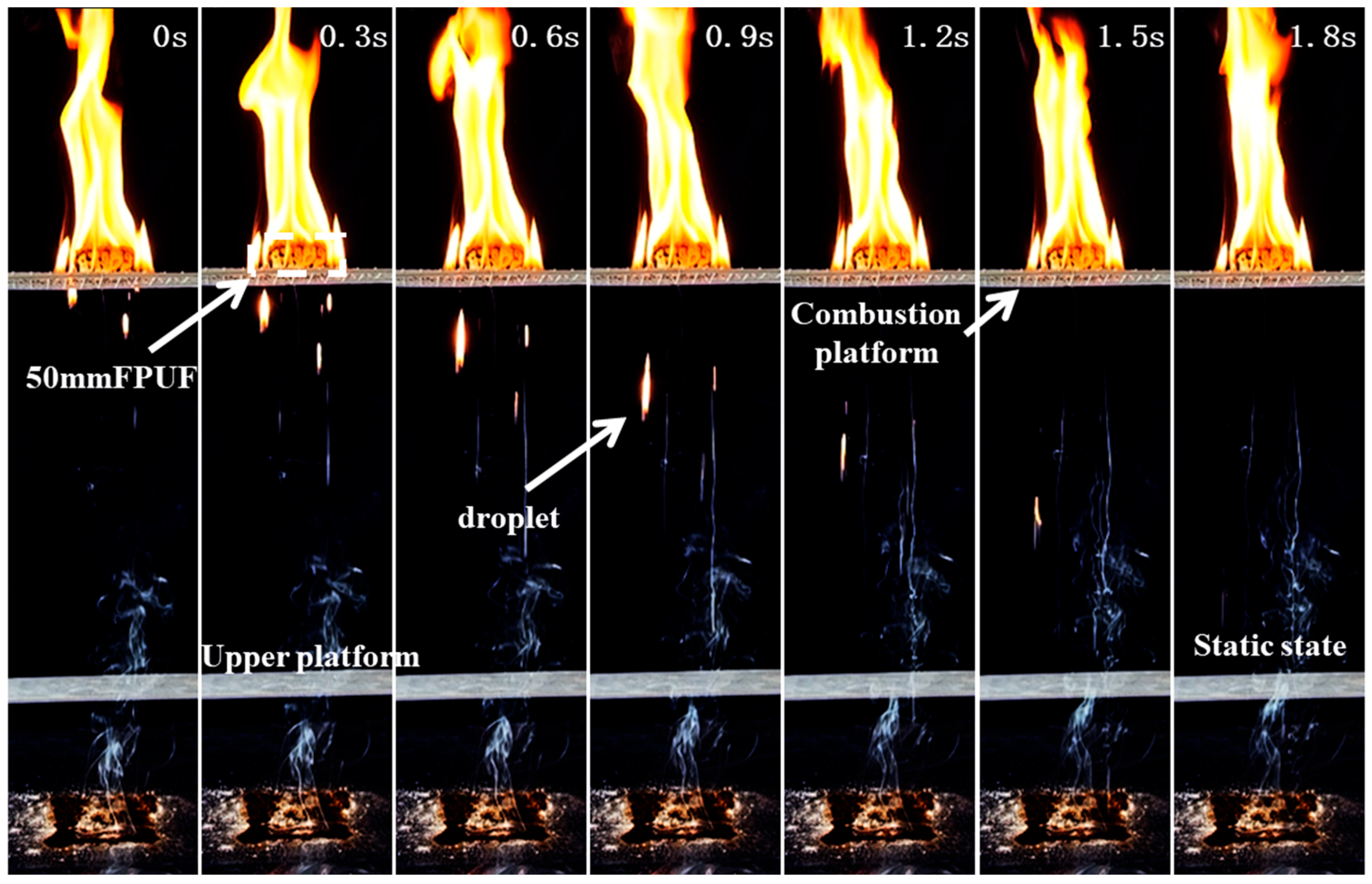

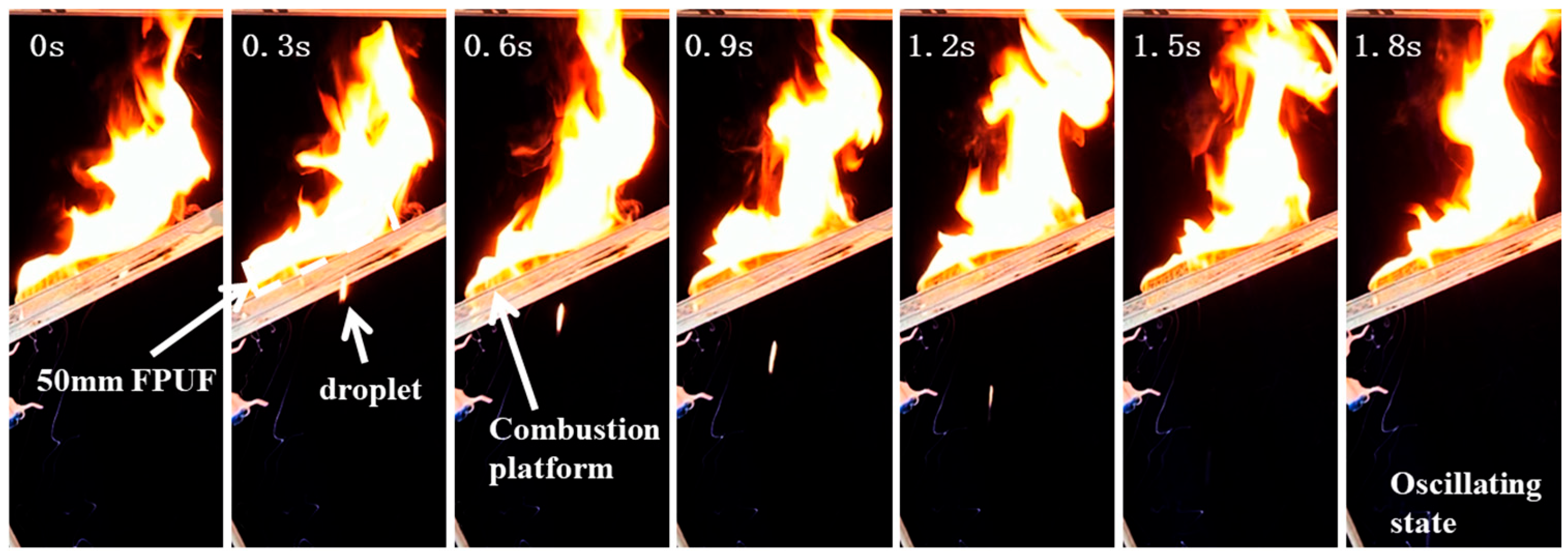

3.2. Dripping Behavior Under Static and Oscillating Conditions with Different Ignition Locations

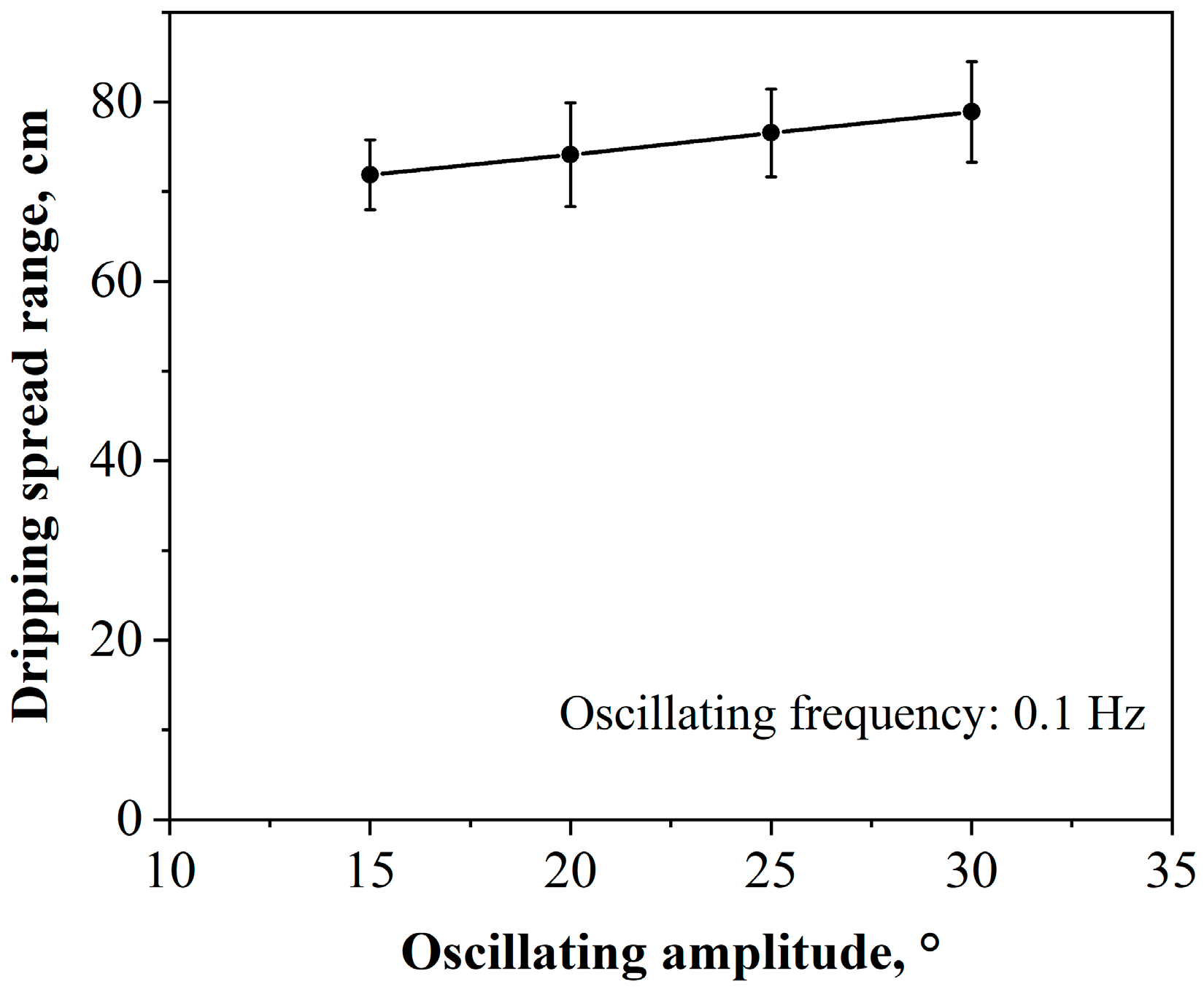

3.3. Effects of Oscillation Frequency and Amplitude on Dripping Behavior

4. Discussion

5. Conclusions

- (1)

- Under static conditions, noticeable differences were observed in the burning and dripping behavior of FPUF samples of different sizes. Under side ignition, the dripping frequency of FPUF samples of the same specification was significantly higher than under central ignition. Under central ignition, molten material from thicker samples (50 mm) dripped primarily from the edges, whereas thinner samples (25 mm) exhibited dripping from both the center and the edges.

- (2)

- Under central ignition, the total amount and frequency of molten dripping from FPUF samples of the same specification were markedly higher under oscillation than under static conditions. Oscillation-induced shear facilitates the breakup of molten material, leading to the formation of smaller droplets. The proportion of large-size flaming drips under oscillation was approximately 43%, lower than that under static conditions (50%). However, due to the increased total number of drips, the absolute number of large-size flaming drips was greater under oscillation, indicating a higher risk of fire spread.

- (3)

- Oscillation frequency and amplitude had minimal impact on the dripping frequency of molten material, but significantly influenced the dripping spread range. Under a constant dripping height of 50 cm, the dripping spread range expanded with increasing oscillation frequency or amplitude. At an oscillation amplitude of 30° and a frequency of 0.1 Hz, the dripping spread range increased by over 300% compared to the static condition, demonstrating that oscillatory motion greatly enhances the dispersal distance of molten material and the associated potential fire risk.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sherratt, J. The Effect of Thermoplastics Melt Flow Behaviour on the Dynamics of Fire Growth. Ph.D. Thesis, University of Edinburgh, Edinburgh, Scotland, 2001. [Google Scholar]

- Ohlemiller, T.J.; Shields, J.R. Aspects of the fire behavior of thermoplastic materials. NIST Tech. Note 2008, 1493, 158. [Google Scholar]

- Wang, Y.; Zhang, J. Thermal stabilities of drops of burning thermoplastics under the ul 94 vertical test conditions. J. Hazard. Mater. 2013, 246, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Yuan, Y.; Wang, W.; Xu, L. Recent advances in flame-retardant flexible polyurethane foams. Fire 2025, 8, 90. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Chen, X.; Jin, Y.; Zhang, J. Burning and dripping behaviors of polymers under the UL94 vertical burning test conditions. Fire Mater. 2010, 34, 203–215. [Google Scholar] [CrossRef]

- Huang, X.; Chen, G.; Liu, W.; Zhang, Y.; Sun, J. Thermal analysis of vertical upward flame spread and dripping behaviors of polystyrene foams at different altitudes. J. Macromol. Sci. Part B 2017, 56, 517–531. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Melt-flow behaviours of thermoplastic materials under fire conditions: Recent experimental studies and some theoretical approaches. Materials 2015, 8, 8793–8803. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, H.; Ye, R. Experimental study on melting and flowing behavior of thermoplastics combustion based on a new setup with a T-shape trough. J. Hazard. Mater. 2009, 166, 1321–1325. [Google Scholar] [CrossRef]

- Luo, S.; Xie, Q.; Tang, X.; Qiu, R.; Yang, Y. A quantitative model and the experimental evaluation of the liquid fuel layer for the downward flame spread of XPS foam. J. Hazard. Mater. 2017, 329, 30–37. [Google Scholar] [CrossRef]

- Sun, P.; Jia, Y.; Zhang, X.; Huang, X. Fire risk of dripping flame: Piloted ignition and soaking effect. Fire Saf. J. 2021, 122, 103360. [Google Scholar] [CrossRef]

- Kandola, B.K.; Price, D.; Milnes, G.J.; Da Silva, A. Development of a novel experimental technique for quantitative study of melt dripping of thermoplastic polymers. Polym. Degrad. Stab. 2013, 98, 52–63. [Google Scholar] [CrossRef]

- Kandola, B.K.; Ndiaye, M.; Price, D. Quantification of polymer degradation during melt dripping of thermoplastic polymers. Polym. Degrad. Stab. 2014, 106, 16–25. [Google Scholar] [CrossRef]

- Zhang, J.; Shields, T.J.; Silcock, G.W.H. Effect of melting behaviour on upward flame spread of thermoplastics. Fire Mater. 1997, 21, 1–6. [Google Scholar] [CrossRef]

- Wang, Y.; Jow, J.; Su, K.; Zhang, J. Dripping behavior of burning polymers under UL94 vertical test conditions. J. Fire Sci. 2012, 30, 477–501. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, W.; Zhang, X.; Chen, C.; Sun, P.; Zhang, F.; Li, S. Development of a pendant experiment using melt indexer for correlation with the large-size dripping in the UL-94 test. Fire Mater. 2018, 42, 436–446. [Google Scholar] [CrossRef]

- Butler, K.M. A model of melting and dripping thermoplastic objects in fire. In Proceedings of the Fire and Materials 11th International Conference, San Francisco, CA, USA, 26–28 January 2009. [Google Scholar]

- Onate, E.; Marti, J.; Ryzhakov, P.; Rossi, R.; Idelsohn, S.R. Analysis of the melting, burning and flame spread of polymers with the particle finite element method. Comput. Assist. Methods Eng. Sci. 2013, 20, 165–184. [Google Scholar]

- Xie, Q.; Tu, R.; Wang, N.; Ma, X.; Jiang, X. Experimental study on flowing burning behaviors of a pool fire with dripping of melted thermoplastics. J. Hazard. Mater. 2014, 267, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Tu, R.; Xie, Q.; Jiang, Y.; Zhao, Y.; Wang, N. Experimental study on the burning behaviors of three typical thermoplastic materials liquid pool fire with different mass feeding rates. J. Therm. Anal. Calorim. 2016, 123, 329–337. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Levendis, Y.A.; Delichatsios, M.A. A method to assess downward flame spread and dripping characteristics of fire-retardant polymer composites. Fire Mater. 2018, 42, 347–357. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Huang, X.; Nakaya, S.; Tsue, M.; Fernandez-Pello, C. Flame spread over horizontal and vertical wires: The role of dripping and core. Fire Saf. J. 2017, 91, 112–122. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, Y.; Huang, X.; Xue, Y.; Wang, J.; Zhao, S.; He, X.; Zhao, L. Dripping and fire extinction limits of thin wire: Effect of pressure and oxygen. Combust. Sci. Technol. 2021, 193, 437–452. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.; Tu, R.; Zhao, L.; Liu, J.; Zhang, Y. Molten thermoplastic dripping behavior induced by flame spread over wire insulation under overload currents. J. Hazard. Mater. 2016, 320, 628–634. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, R.; He, J.; Wang, J. Melt dripping behavior in the process of flame spread over energized electrical wire at different pressures. Fire Mater. 2020, 44, 58–64. [Google Scholar] [CrossRef]

- Zhu, H.; Gao, Y.; Zhu, G. Experimental studies on the effects of spacing on dripping behavior of thin polymethyl-methacrylate slab. Case Stud. Therm. Eng. 2016, 8, 10–18. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, G.; Gao, Y.; Hu, Z. Dripping behavior of vertical burning thermally thin PMMA with different spacings to wall. J. Thermoplast. Compos. Mater. 2018, 31, 616–633. [Google Scholar]

- Luo, S.; Xie, Q.; Qiu, R. Melting and dripping flow behaviors on the downward flame spread of a wide XPS foam. Fire Technol. 2019, 55, 2055–2086. [Google Scholar] [CrossRef]

- Huang, X. Critical drip size and blue flame shedding of dripping ignition in fire. Sci. Rep. 2018, 8, 16528. [Google Scholar] [CrossRef]

- Sun, P.; Lin, S.; Huang, X. Ignition of thin fuel by thermoplastic drips: An experimental study for the dripping ignition theory. Fire Saf. J. 2020, 115, 103006. [Google Scholar] [CrossRef]

- Chen, Y.; He, H.; Liu, Z. Research on the flow and dropping behaviour of droplets generated by burning of flexible polyurethane foam. Combust. Sci. Technol. 2024, 196, 4450–4468. [Google Scholar] [CrossRef]

- McKeen, P.; Liao, Z. A three-layer macro-scale model for simulating the combustion of PPUF in CFD. Build. Simul. 2016, 9, 583–596. [Google Scholar] [CrossRef]

- Chen, Y.; He, H.; Liu, Z. Application of the global search algorithm to analyze the kinetic mechanism of the thermal decomposition of flexible polyurethane foam. Prog. React. Kinet. 2021, 46, 1468678320982185. [Google Scholar] [CrossRef]

- Lefebvre, J.; Bastin, B.; Le Bras, M.; Duquesne, S.; Ritter, C.; Paleja, R.; Poutch, F. Flame spread of flexible polyurethane foam: Comprehensive study. Polym. Test. 2004, 23, 281–290. [Google Scholar] [CrossRef]

- McKenna, S.T.; Hull, T.R. The fire toxicity of polyurethane foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef]

- Pau, D.S.W.; Fleischmann, C.M.; Delichatsios, M.A. Apparatus for investigating the burning and dripping of vertically oriented polyurethane foams. Fire Mater. 2020, 44, 211–229. [Google Scholar] [CrossRef]

- Liu, Z.; He, H.; Zhang, J.; Zheng, J.; Zhuang, H. Experimental investigation and numerical simulation of the combustion of flexible polyurethane foam with larger geometries. Polym. Test. 2020, 81, 106270. [Google Scholar] [CrossRef]

- Chen, Y.; He, H.; Zheng, J.; Liu, Z.; Lai, D. Effects of maritime saline and humid environments on the characteristics of combustion dropping behavior of flexible polyurethane foam. Case Stud. Therm. Eng. 2025, 73, 106683. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, P.; Wang, B.; She, J.-H.; Liu, Y.; Zhu, P. Inorganic-organic hybrid coatings from tea polyphenols and laponite to improve the fire safety of flexible polyurethane foams. Colloids Surf. A Physicochem. Eng. Asp. 2022, 655, 130336. [Google Scholar] [CrossRef]

- Cademartori, G.; Oneto, L.; Valdenazzi, F.; Coraddu, A.; Gambino, A.; Anguita, D. A review on ship motions and quiescent periods prediction models. Ocean Eng. 2023, 280, 114822. [Google Scholar] [CrossRef]

- Robson, L.; Torvi, D.; Obach, M.; Weckman, E. Effects of thickness and ignition location on flame spread rates in furniture calorimeter tests of polyurethane foam. Fire Saf. Sci. 2014, 11, 248–261. [Google Scholar] [CrossRef]

| Elements | Proportion (%) |

|---|---|

| C | 56.8 ± 0.17 |

| H | 9.5 ± 0.03 |

| O | 17.6 ± 0.08 |

| N | 6.2 ± 0.13 |

| S | 0.4 ± 0.17 |

| other | 9.5 ± 0.03 |

| Ignition Position | Sample | Size (mm × mm × mm) | Average Burning Time (s) | Average Drip Number (Drops) | Average Drip Frequency (Drops per Second) |

|---|---|---|---|---|---|

| Center | ① | 100 × 100 × 50 | 145 | 17 | 0.117 |

| Center | ② | 100 × 100 × 25 | 96 | 9 | 0.094 |

| Center | ③ | 200 × 200 × 50 | 171 | 35 | 0.205 |

| Center | ④ | 200 × 200 × 25 | 128 | 15 | 0.117 |

| Side | ① | 100 × 100 × 50 | 140 | 106 | 0.757 |

| Side | ② | 100 × 100 × 25 | 88 | 56 | 0.636 |

| Side | ③ | 200 × 200 × 50 | 175 | 237 | 1.354 |

| Side | ④ | 200 × 200 × 25 | 122 | 144 | 1.180 |

| Ignition Position | Platform State | Average Burning Time (s) | Average Drip Number (Drops) | Average Drip Frequency (Drops per Second) |

|---|---|---|---|---|

| Center | Static | 145 | 17 | 0.117 |

| Center | Oscillating | 152 | 61 | 0.401 |

| Side | Static | 140 | 106 | 0.757 |

| Side | Oscillating | 138 | 153 | 1.109 |

| Oscillating Frequency (Hz) | Average Burning Time (s) | Average Drip Number (Drops) | Average Drip Frequency (Drops per Second) | Proportion of Large-Size Drips (%) |

|---|---|---|---|---|

| 0.125 | 146 | 61 | 0.418 | 42.6 |

| 0.1 | 143 | 60 | 0.419 | 43.3 |

| 0.0833 | 145 | 59 | 0.407 | 44.0 |

| 0.0714 | 144 | 63 | 0.438 | 47.6 |

| 0.0625 | 150 | 58 | 0.387 | 48.3 |

| Oscillating Amplitude | Average Burning Time (s) | Average Drip Number (Drops) | Average Drip Frequency (Drops per Second) | Proportion of Large-Size Drips (%) |

|---|---|---|---|---|

| 15° | 128 | 58 | 0.453 | 44.8% |

| 20° | 127 | 60 | 0.472 | 45.0% |

| 25° | 124 | 59 | 0.476 | 44.0% |

| 30° | 125 | 61 | 0.488 | 44.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, W.; Wang, Z.; Lai, D.; Huang, Y.; Zhuang, H.; Liu, Z.; He, H. Experimental Study on the Melt Dripping Behavior of Flexible Polyurethane Foam in an Oscillating Ship Cabin. Fire 2025, 8, 446. https://doi.org/10.3390/fire8110446

Shen W, Wang Z, Lai D, Huang Y, Zhuang H, Liu Z, He H. Experimental Study on the Melt Dripping Behavior of Flexible Polyurethane Foam in an Oscillating Ship Cabin. Fire. 2025; 8(11):446. https://doi.org/10.3390/fire8110446

Chicago/Turabian StyleShen, Wenfeng, Zhenyu Wang, Dimeng Lai, Yujin Huang, Huanghuang Zhuang, Zhongqin Liu, and Hongzhou He. 2025. "Experimental Study on the Melt Dripping Behavior of Flexible Polyurethane Foam in an Oscillating Ship Cabin" Fire 8, no. 11: 446. https://doi.org/10.3390/fire8110446

APA StyleShen, W., Wang, Z., Lai, D., Huang, Y., Zhuang, H., Liu, Z., & He, H. (2025). Experimental Study on the Melt Dripping Behavior of Flexible Polyurethane Foam in an Oscillating Ship Cabin. Fire, 8(11), 446. https://doi.org/10.3390/fire8110446