Numerical Study of Fire-Induced Steel Frame Collapse: Validation of Experiments Using Static and Dynamic Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Validation Framework

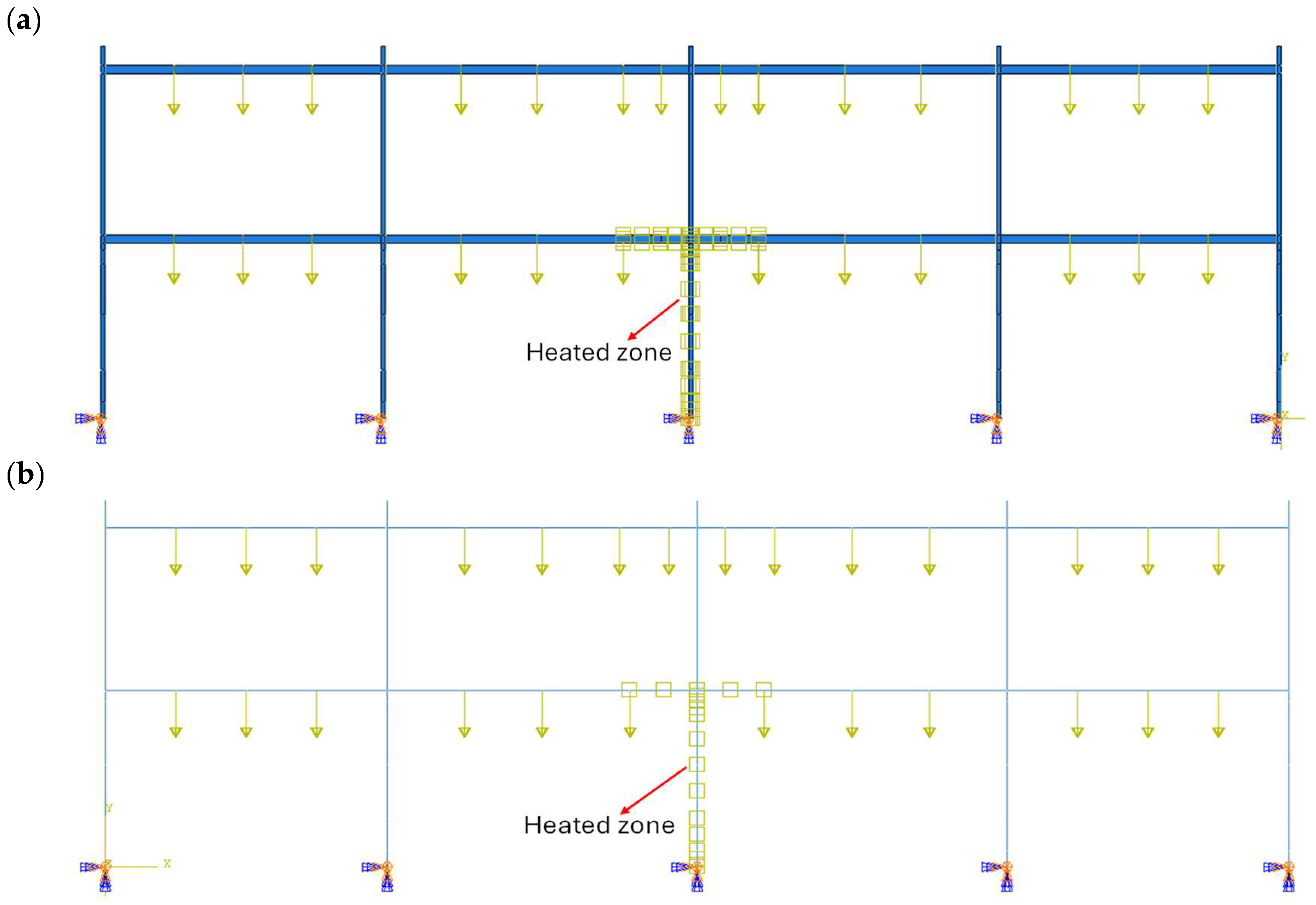

2.2. Numerical Modelling

3. Results and Discussion

3.1. Case Study 1

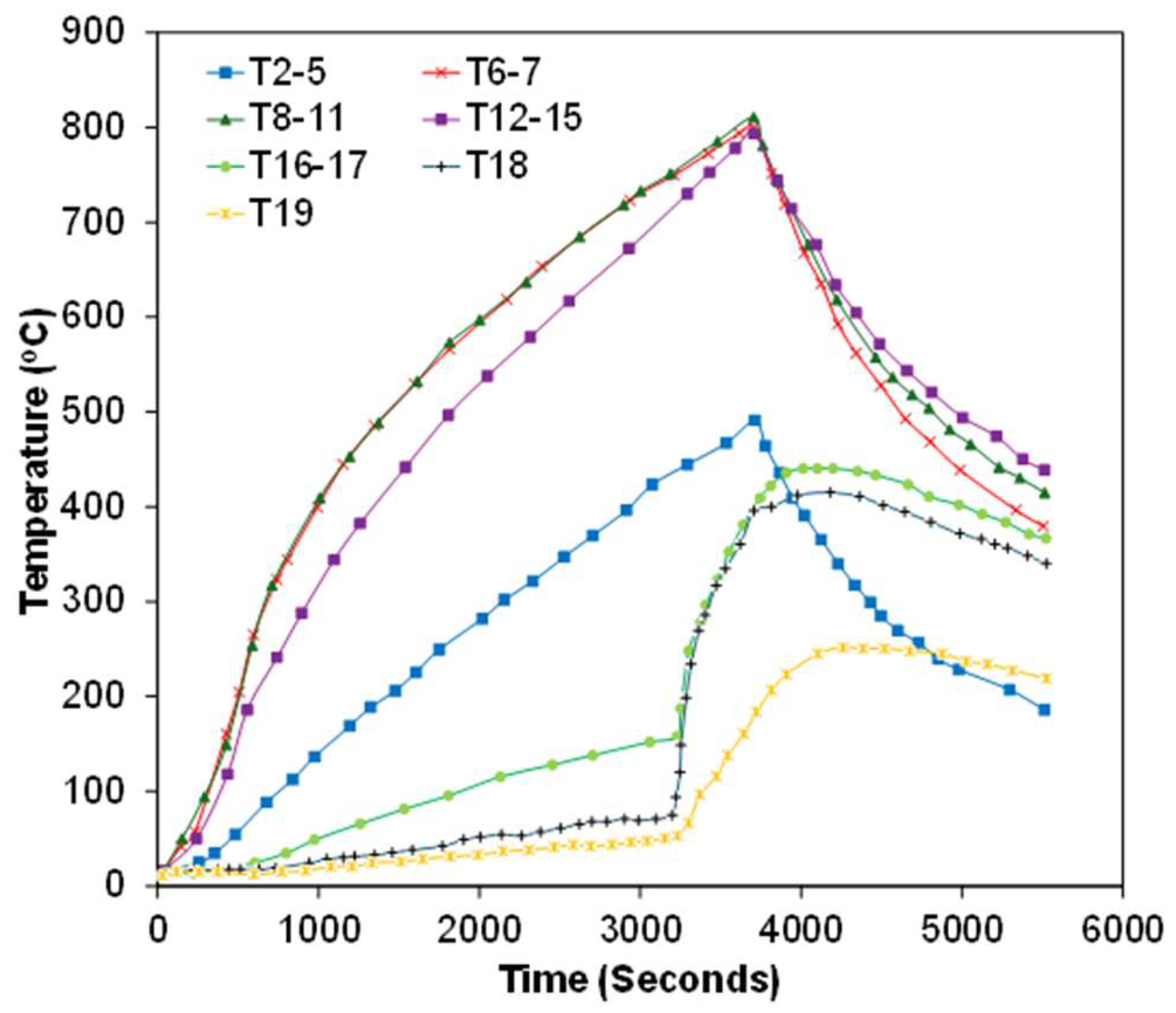

3.1.1. Test Details of Case Study 1

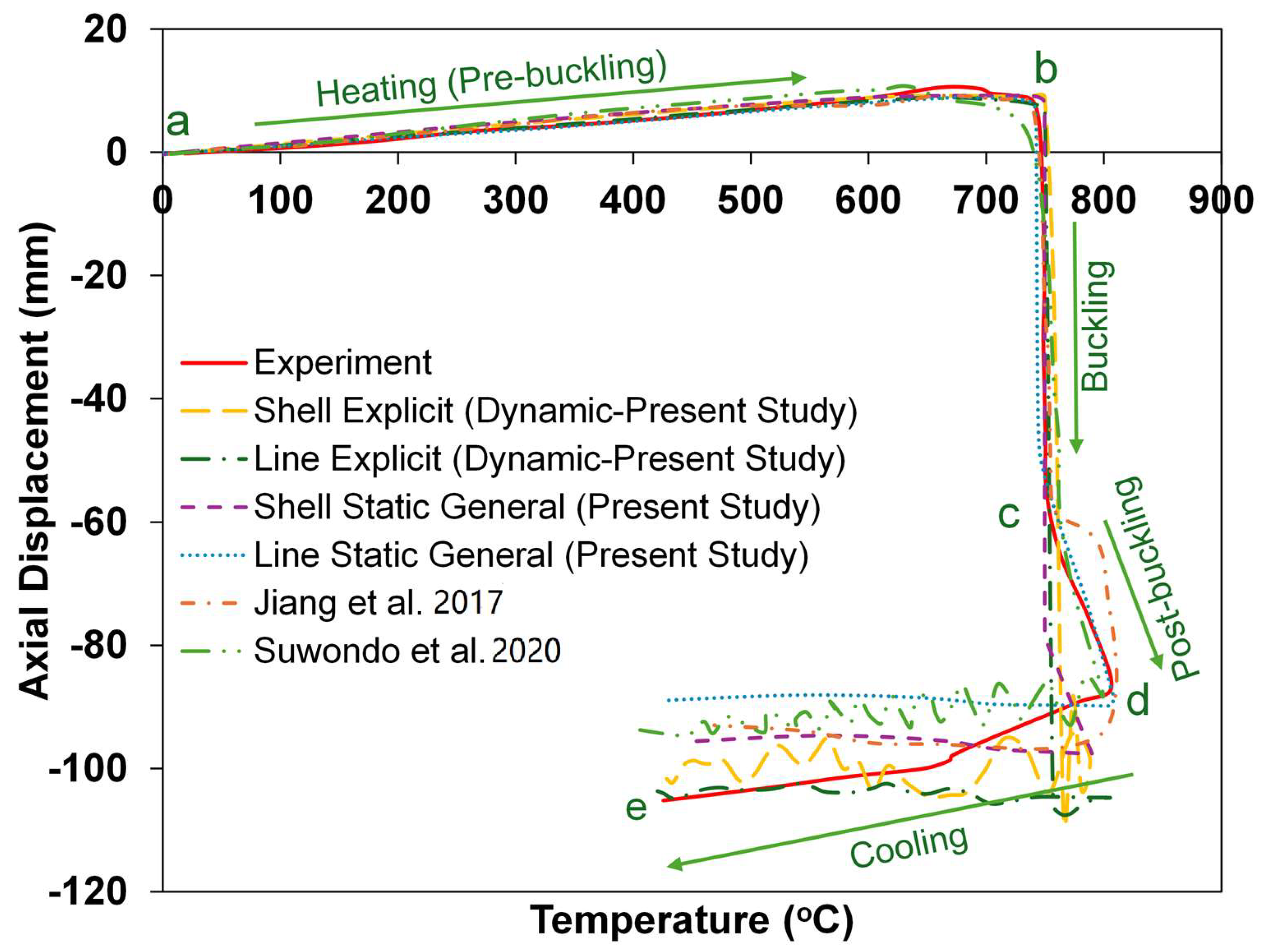

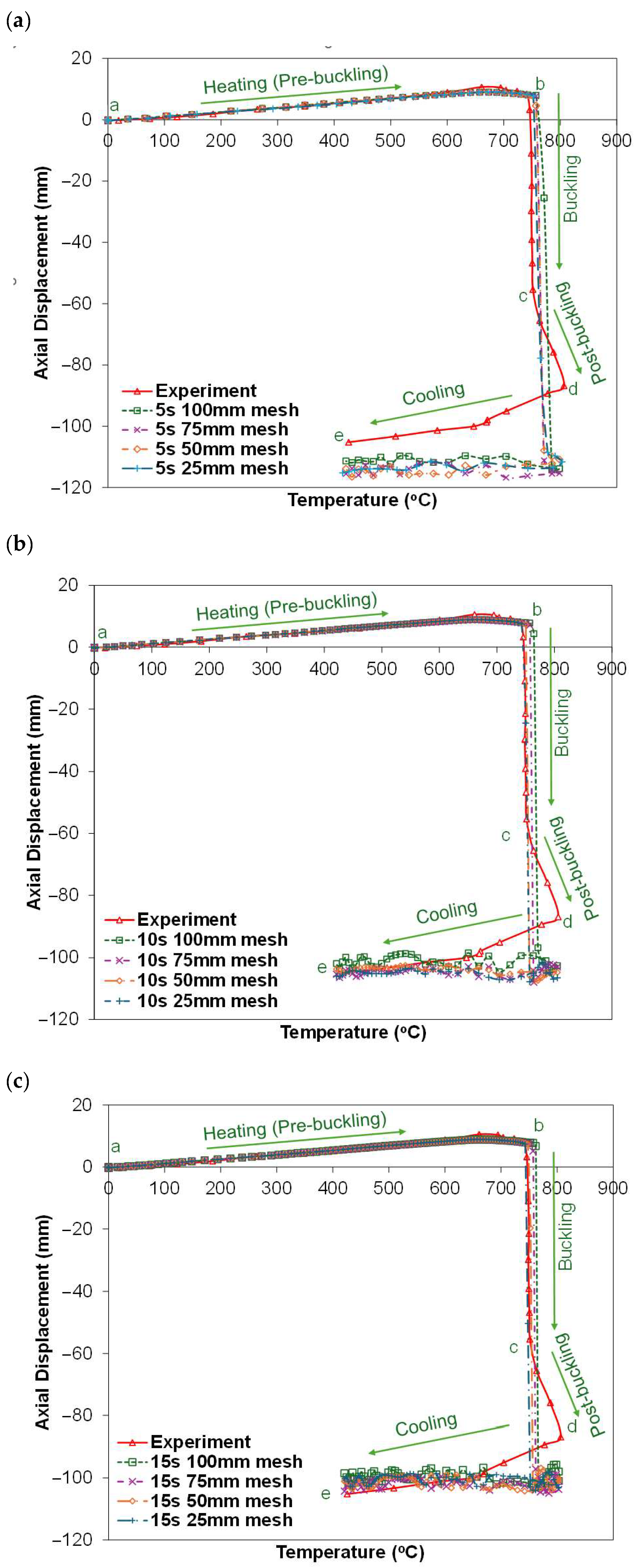

3.1.2. Analysis Using Dynamic Explicit Step

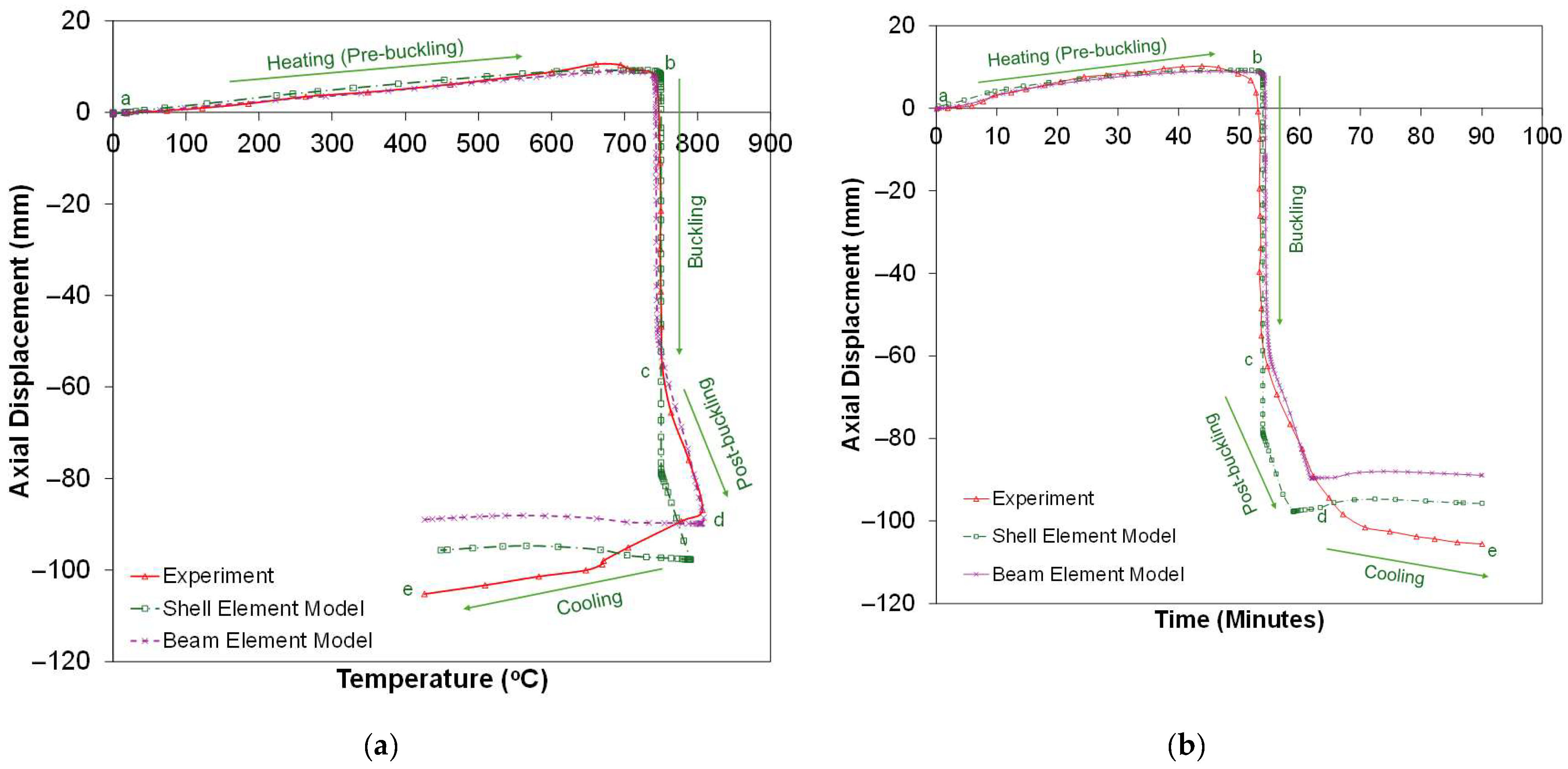

3.1.3. Analysis Using Static General Step

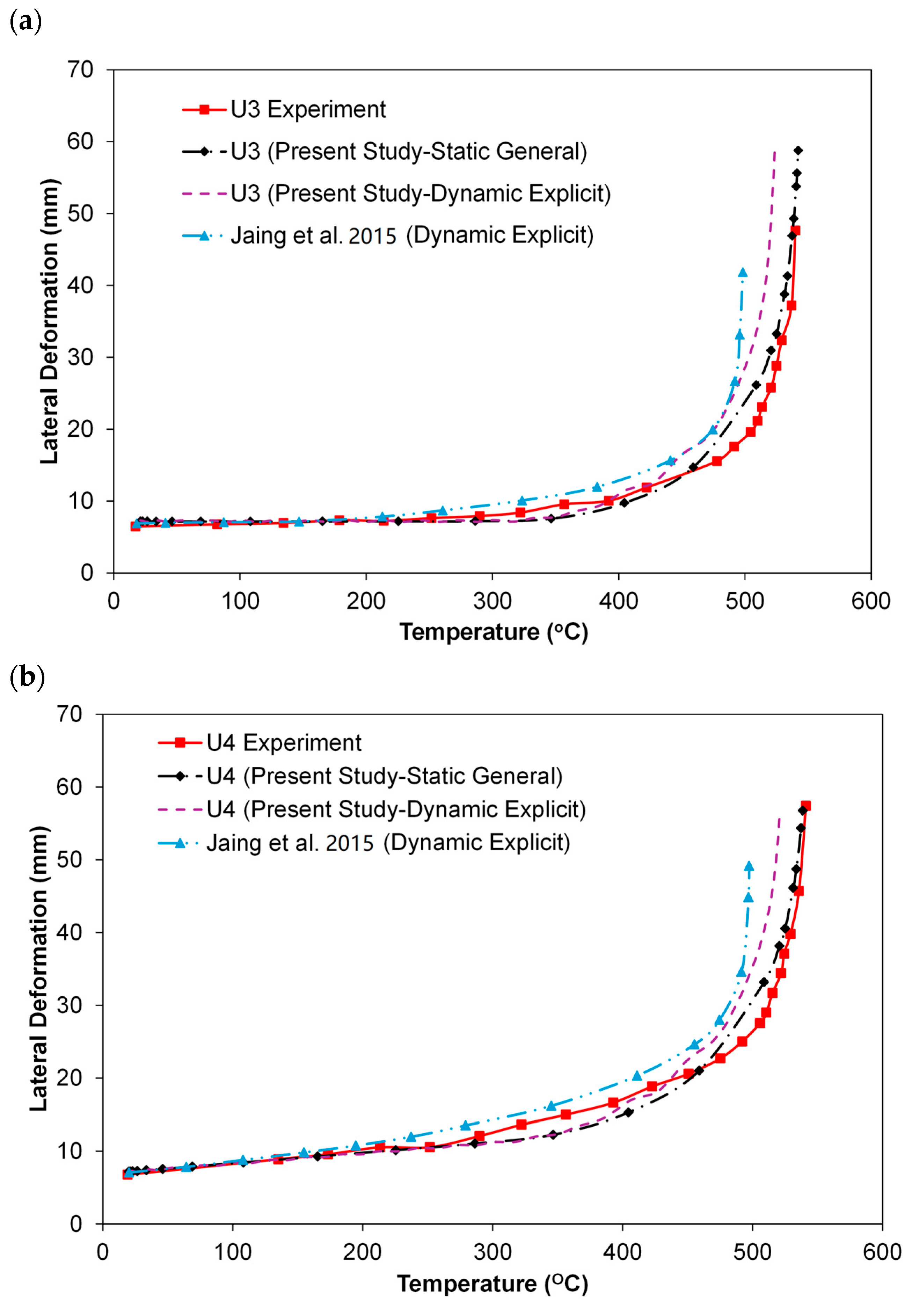

3.1.4. Comparative Analysis

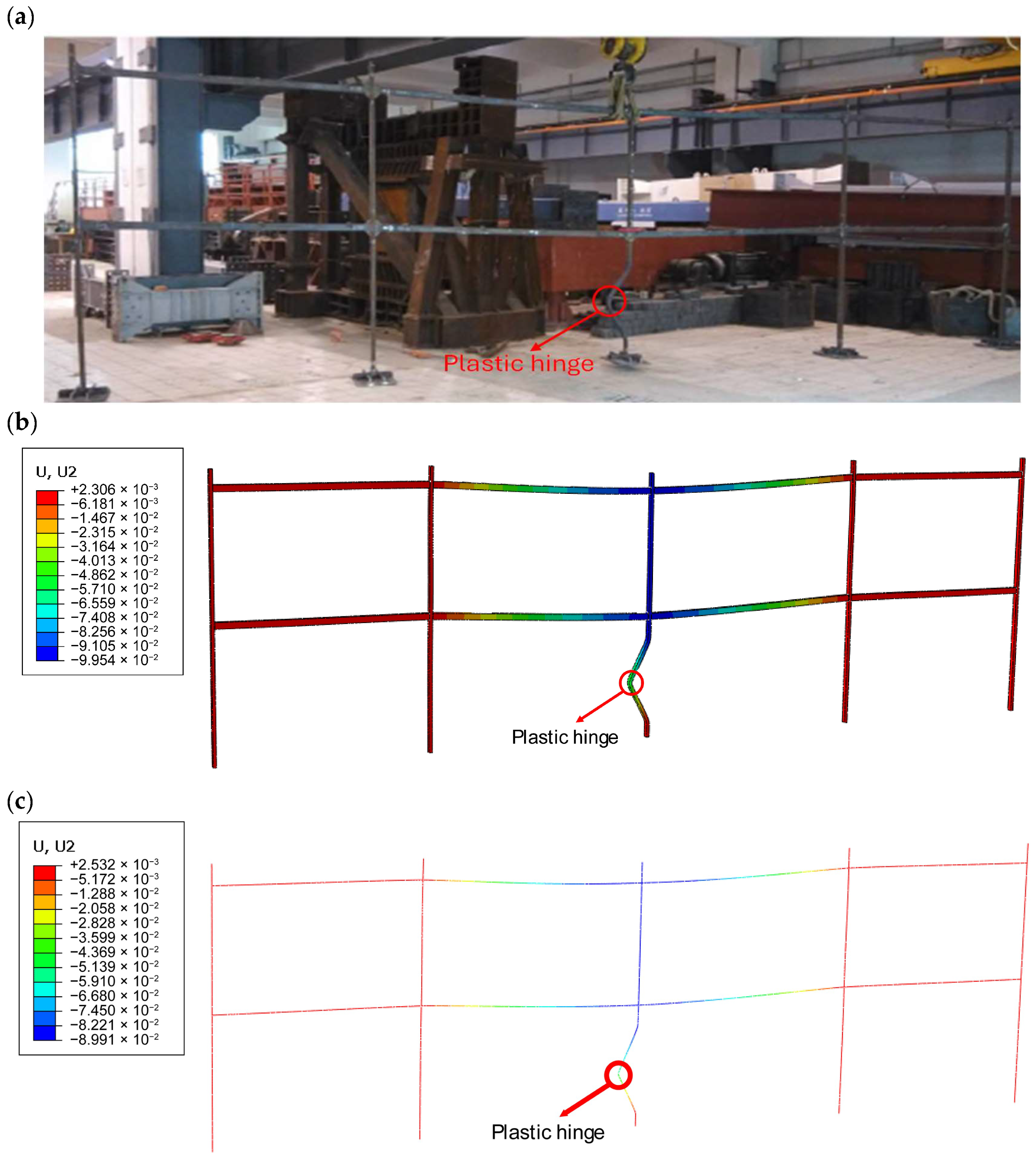

3.2. Case Study 2

4. Conclusions

- Both dynamic explicit and static general analyses accurately captured the critical temperature of collapse, with deviations typically within 2–3% of experimental values, confirming the reliability of both approaches for predicting the start of the failure.

- The dynamic explicit solver successfully reproduced the collapse mechanism and failure mode but exhibited oscillations after buckling due to inertia effects. In contrast, the static general method provided a smoother post-buckling response, better matching the experimental displacement temperature curve.

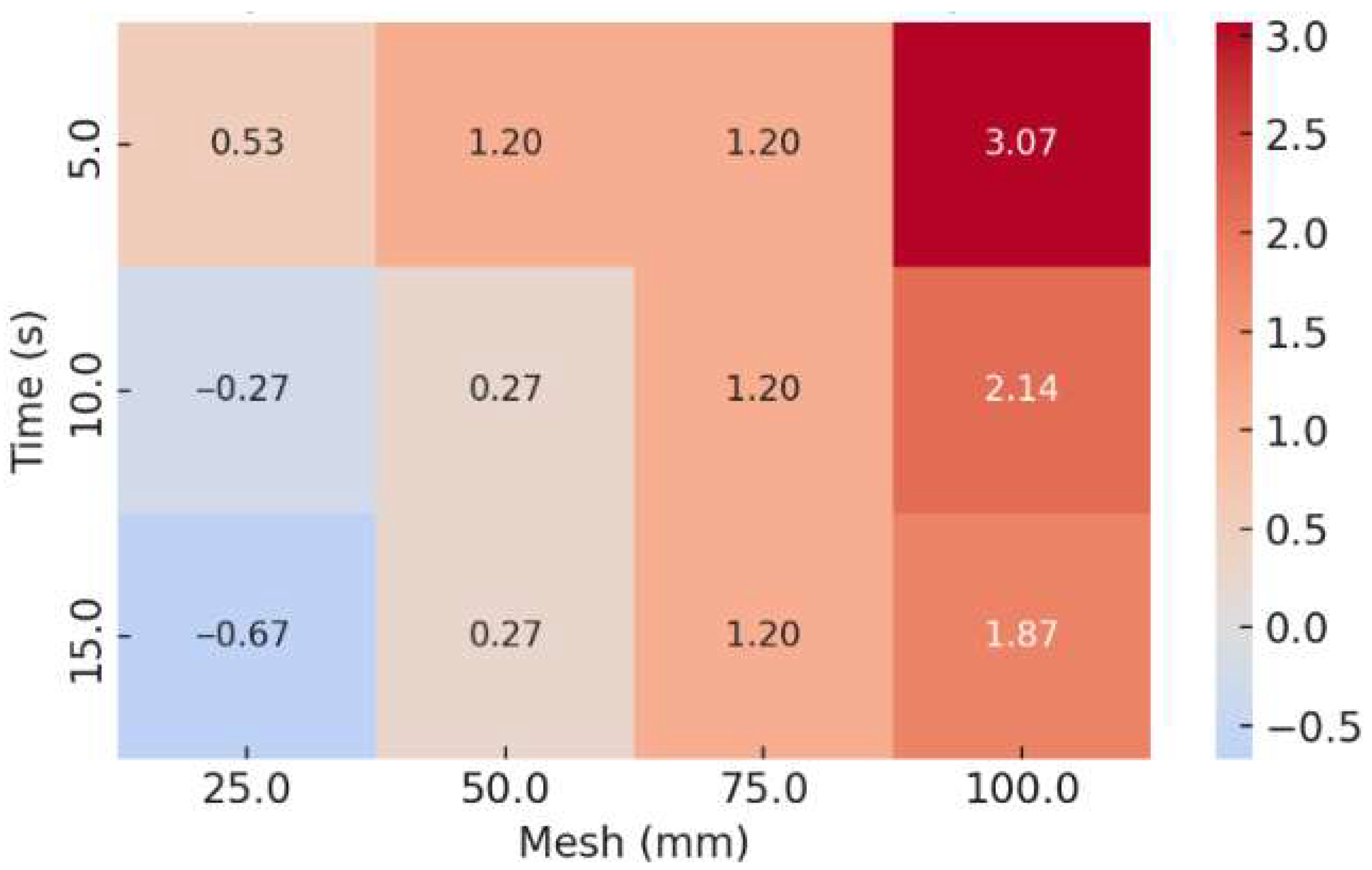

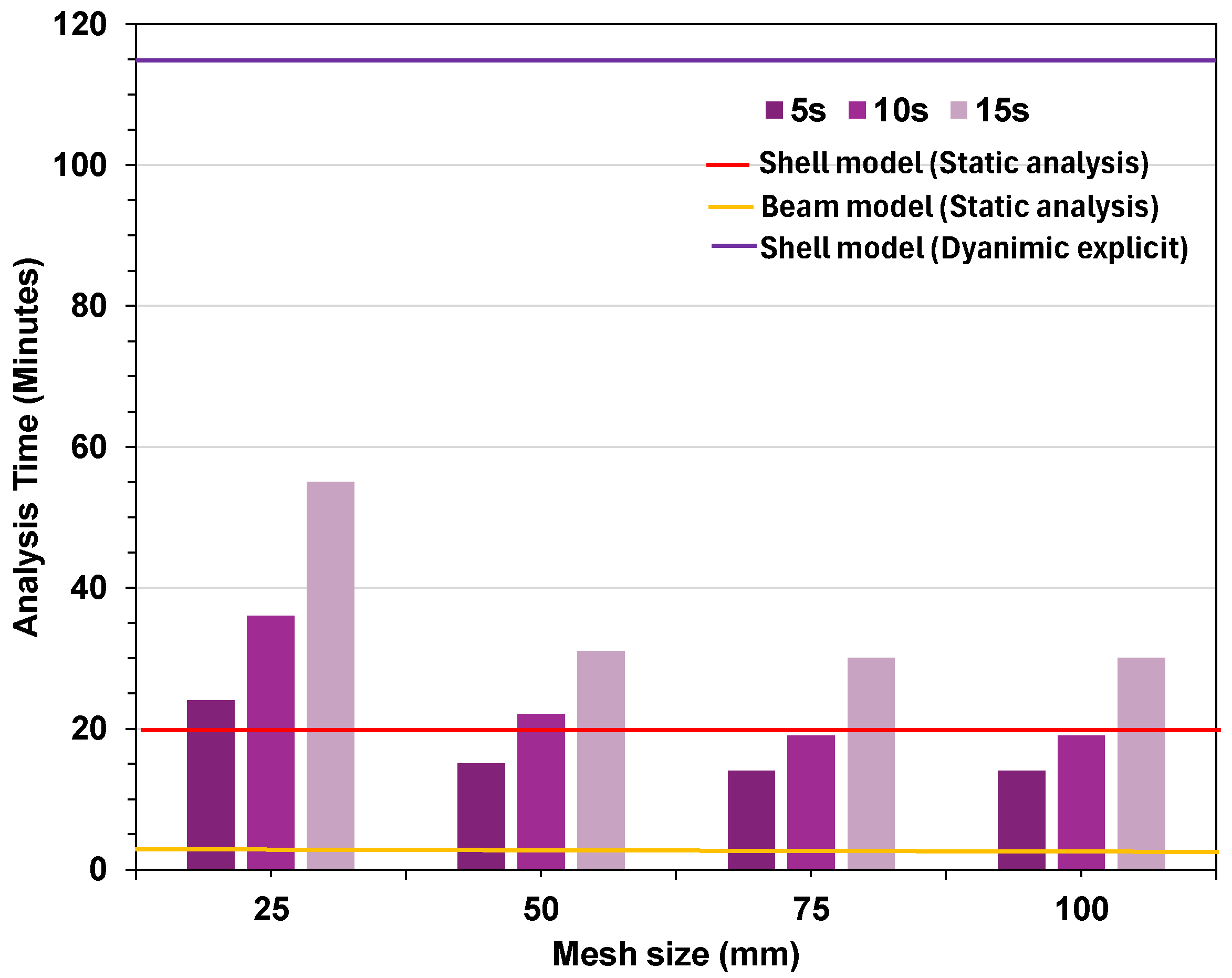

- For dynamic explicit analyses, time scaling and mesh refinement are critical factors in calibrating the model with experimental results. While higher time scales and finer meshes lead to a significant increase in computational cost. The analysis time was observed to increase by nearly six to nine times when using shell elements compared to line elements under similar mesh and time-scale conditions.

- The static general solver can capture collapse in both line and shell element models by introducing geometric imperfections and applying a standard artificial energy dissipation coefficient. This approach maintains quasi-static equilibrium and enables smoother tracing of the post-buckling response. Compared to explicit analysis, the computational time is reduced by approximately six to eighteen times, depending on whether shell or beam elements are used.

- For validation against progressive collapse fire tests, the static general step with shell elements offers the most representative post-buckling response, while the dynamic explicit method with beam elements is more suitable for studying rapid instability and large deformations where inertia effects are critical.

- Since the experimental validation in this study is limited to planar (2D) steel frames, it is recommended that the proposed modelling approaches be further evaluated on three-dimensional frame systems to establish their broader applicability. Future work should also incorporate material fracture and damage models, as well as investigate travelling fire scenarios, to enhance the practicality and extend the use of these methods in performance-based structural fire engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, Y.; Jiang, J.; Lu, Y.; Chen, W.; Ye, J. Progressive collapse of steel structures exposed to fire: A critical review. J. Constr. Steel Res. 2023, 207, 107985. [Google Scholar] [CrossRef]

- Agarwal, A.; Varma, A.H. Fire Induced Progressive Collapse of Steel Building Structures. In Structures Congress; ASCE: Washington, DC, USA, 2012; pp. 235–246. [Google Scholar]

- Agarwal, A.; Varma, A.H. Fire induced progressive collapse of steel building structures: The role of interior gravity columns. Eng. Struct. 2014, 58, 129–140. [Google Scholar] [CrossRef]

- Shakeri, K.; Aval, S.M.M.; Akrami, V.; Khansoltani, E. Progressive Collapse Analysis of Intermediate Moment-Resisting Steel Frame under Fire-Induced Column Failure. J. Perform. Constr. Facil. 2023, 37, 04023034. [Google Scholar] [CrossRef]

- Roy, K.; Lim, J.B.; Lau, H.H.; Yong, P.; Clifton, G.; Johnston, R.P.; Wrzesien, A.; Mei, C.C. Collapse behaviour of a fire engineering designed single-storey cold- formed steel building in severe fires. Thin-Walled Struct. 2019, 142, 340–357. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Y.; Dai, X.; Li, G.-Q.; Chen, W.; Ye, J. Disproportionate collapse of steel-framed gravity buildings under travelling fires. Eng. Struct. 2021, 245, 112799. [Google Scholar] [CrossRef]

- Rackauskaite, E.; Kotsovinos, P.; Jeffers, A.; Rein, G. Structural analysis of multi-storey steel frames exposed to travelling fires and traditional design fires. Eng. Struct. 2017, 150, 271–287. [Google Scholar] [CrossRef]

- Rackauskaite, E.; Kotsovinos, P.; Lange, D.; Rein, G. Collapse Initiation and Mechanisms for a Generic Mul-ti-storeySteel Frame Subjected to Uniform and Travelling Fires. Int. J. High-Rise Build. 2021, 10, 265–283. [Google Scholar] [CrossRef]

- Rubert, A.; Schaumann, P. Structural steel and plane frame assemblies under fire action. Fire Saf. J. 1986, 10, 173–184. [Google Scholar] [CrossRef]

- Li, G.-Q.; Wang, P.; Wang, Y. Behaviour and design of restrained steel column in fire, Part 1: Fire test. J. Constr. Steel Res. 2010, 66, 1138–1147. [Google Scholar] [CrossRef]

- Suwondo, R.; Cunningham, L.; Gillie, M.; Bailey, C. Progressive collapse analysis of composite steel frames subject to fire following earthquake. Fire Saf. J. 2019, 103, 49–58. [Google Scholar] [CrossRef]

- Jiang, B.; Li, G.-Q.; Li, L.; Izzuddin, B.A. Experimental Studies on Progressive Collapse Resistance of Steel Moment Frames under Localized Furnace Loading. J. Struct. Eng. 2018, 144, 04017190. [Google Scholar] [CrossRef]

- Jiang, B.; Li, G.-Q.; Li, L.; Izzuddin, B. Simulations on progressive collapse resistance of steel moment frames under localized fire. J. Constr. Steel Res. 2017, 138, 380–388. [Google Scholar] [CrossRef]

- Abaqus, Finite Element Modelling Programme and Standard User’s Manual; Version 6.14; SIMULIA. Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2016; Available online: http://130.149 89 (2018) v6 (accessed on 1 July 2024).

- Sam, V.S.; Anand, N.; Iswarary, A.; Ananthi, B.G.; Andrushia, D. Influence of heating cooling regime on the buckling capacity of galvanized iron-based cold-formed steel columns with welded connections. J. Infrastruct. Preserv. Resil. 2025, 6, 13. [Google Scholar] [CrossRef]

- EN 1993-1-1:2005 Eurocode 3; Design of Steel Structures–Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium; John Wiley & Sons: Hoboken, NJ, USA, 2005.

- Kumar, R.; Alam, N.; Nadjai, A. Integrated analysis of loading eccentricity on response of a column under travelling fire. In Proceedings of the 13th International Conference on Structures in Fire, Coimbra, Portugal, 19–21 June 2024. [Google Scholar]

- Kumar, R.; Alam, N.; Nadjai, A. Behaviour of steel columns under fire: A review on experimental testing and numerical investigation supplemented with computational case studies validation. J. Struct. Fire Eng. 2025, 16, 427–457. [Google Scholar] [CrossRef]

- Wang, Y.C. Postbuckling Behavior of Axially Restrained and Axially Loaded Steel Columns under Fire Conditions. J. Struct. Eng. 2004, 130, 371–380. [Google Scholar] [CrossRef]

- Yang, J.; Xia, Y.; Wang, W.; Al-Azzani, H. Fire resistance of axially restrained Q690 H-shaped welded steel columns: Test, simulation and design. J. Constr. Steel Res. 2021, 177, 106413. [Google Scholar] [CrossRef]

- Suwondo, R.; Cunningham, L.; Gillie, M. Modelling progressive failure of steel moment frames exposed to localised fire. IOP Conf. Ser. Earth Environ. Sci. 2020, 426, 012046. [Google Scholar] [CrossRef]

- ManojKumara, C.; Sachin, V.; Suresh, N.; Naveen, B. The collapse mechanism of steel framed structure exposed to parametric design fire and travelling fire scenarios. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jiang, B.; Li, G.-Q.; Usmani, A. Progressive collapse mechanisms investigation of planar steel moment frames under localized fire. J. Constr. Steel Res. 2015, 115, 160–168. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, R.; Alam, N.; Nadjai, A. Numerical Study of Fire-Induced Steel Frame Collapse: Validation of Experiments Using Static and Dynamic Methods. Fire 2025, 8, 420. https://doi.org/10.3390/fire8110420

Kumar R, Alam N, Nadjai A. Numerical Study of Fire-Induced Steel Frame Collapse: Validation of Experiments Using Static and Dynamic Methods. Fire. 2025; 8(11):420. https://doi.org/10.3390/fire8110420

Chicago/Turabian StyleKumar, Rabinder, Naveed Alam, and Ali Nadjai. 2025. "Numerical Study of Fire-Induced Steel Frame Collapse: Validation of Experiments Using Static and Dynamic Methods" Fire 8, no. 11: 420. https://doi.org/10.3390/fire8110420

APA StyleKumar, R., Alam, N., & Nadjai, A. (2025). Numerical Study of Fire-Induced Steel Frame Collapse: Validation of Experiments Using Static and Dynamic Methods. Fire, 8(11), 420. https://doi.org/10.3390/fire8110420