1. Introduction

Wood and wood products (including thermally modified wood) are an increasingly important biomass resource for energy generation. When they end their service life, these materials often become waste and they are used as fuel. The chemical composition of wood affects its heating value. Wood is composed of lignin, holocellulose, and extractives. The heating value of lignin is significantly higher than that of polysaccharides. Extractives have the highest heating value. Softwoods have higher HHV than hardwoods because of higher lignin content and resin [

1].

Before wood is used as fuel, it is essential to determine its higher heating value. The higher heating value is typically measured using a calorimeter, a specialized and costly piece of equipment. Alternatively, higher heating values can be estimated using empirical correlations. The usual correlations include elemental composition, proximate analysis, and chemical composition [

2]. Some authors have found a linear relationship between the HHV and the carbon content of fuels [

3,

4] and their chemical composition [

5,

6,

7].

The heat of combustion is the amount of heat released during the complete combustion of a unit amount of fuel [

8]. According to [

9], the heat of combustion ΔHc of a substance is the heat released when the substance reacts completely with oxygen, converting it into its final oxidation products.

Two heats of combustion are associated with fuels. These are known as the gross heat of combustion and the net heat of combustion, or as the high heating value and the low heating value. The gross heat of combustion is based on water in the combustion products being in the liquid phase, while the net heat of combustion is based on water in the combustion products being in the vapor phase. The net heat of combustion is less than the gross heat of combustion by an amount equal to the latent heat of vaporisation of the water produced in the combustion reaction, which is seen to be 44 kJ.mol

−1 or 2.44 kJ.g

−1 of water [

10].

The present study focuses on meranti wood, a tropical hardwood of the genus Shorea. Exotic wood species such as meranti are increasingly imported and utilized in Europe and other regions due to their favourable mechanical properties, availability, and durability. However, unlike common softwoods such as spruce, which are widely studied and well characterized, meranti has a lower lignin content, different extractives, and distinct thermal behavior. These differences can influence both its thermal modification process and its potential energy utilization. Therefore, understanding the effect of thermal treatment on the chemical composition and calorific value of meranti is essential for extending knowledge beyond local species and for supporting the efficient use of exotic woods in energy production.

This work aimed to investigate the effect of the thermal treatment temperature on the chemical composition of meranti wood and the calorimetrically determined heat of combustion, to create a relationship for predicting HHV from the chemical composition of thermally treated wood and the measured HHV.

2. Materials and Methods

2.1. Samples and Thermal Modification

Light red meranti wood (Shorea spp.) used in the work was imported from Indonesia in the requested dimensions (20 mm × 100 mm × 700 mm) by the importer, Wood Store (Prague, Czech Republic), from an unspecified location. The samples of meranti were divided into five groups. To obtain a moisture content level 12%, the samples were conditioned for one year with relative humidity of 65 ± 3% and temperature of 20 ± 2 °C. The moisture content of the samples was determined by gravimetric method. The first group of samples was not subjected to thermal treatment (ρ = 473 kg.m−3). The group was denoted as control samples (conditioned at 20 °C). The other four groups were thermally treated in the chamber (S400/03- LAC Ltd., Rajhrad, Czech Republic) by temperatures of 160 °C, 180 °C, 200 °C, and 220 °C.

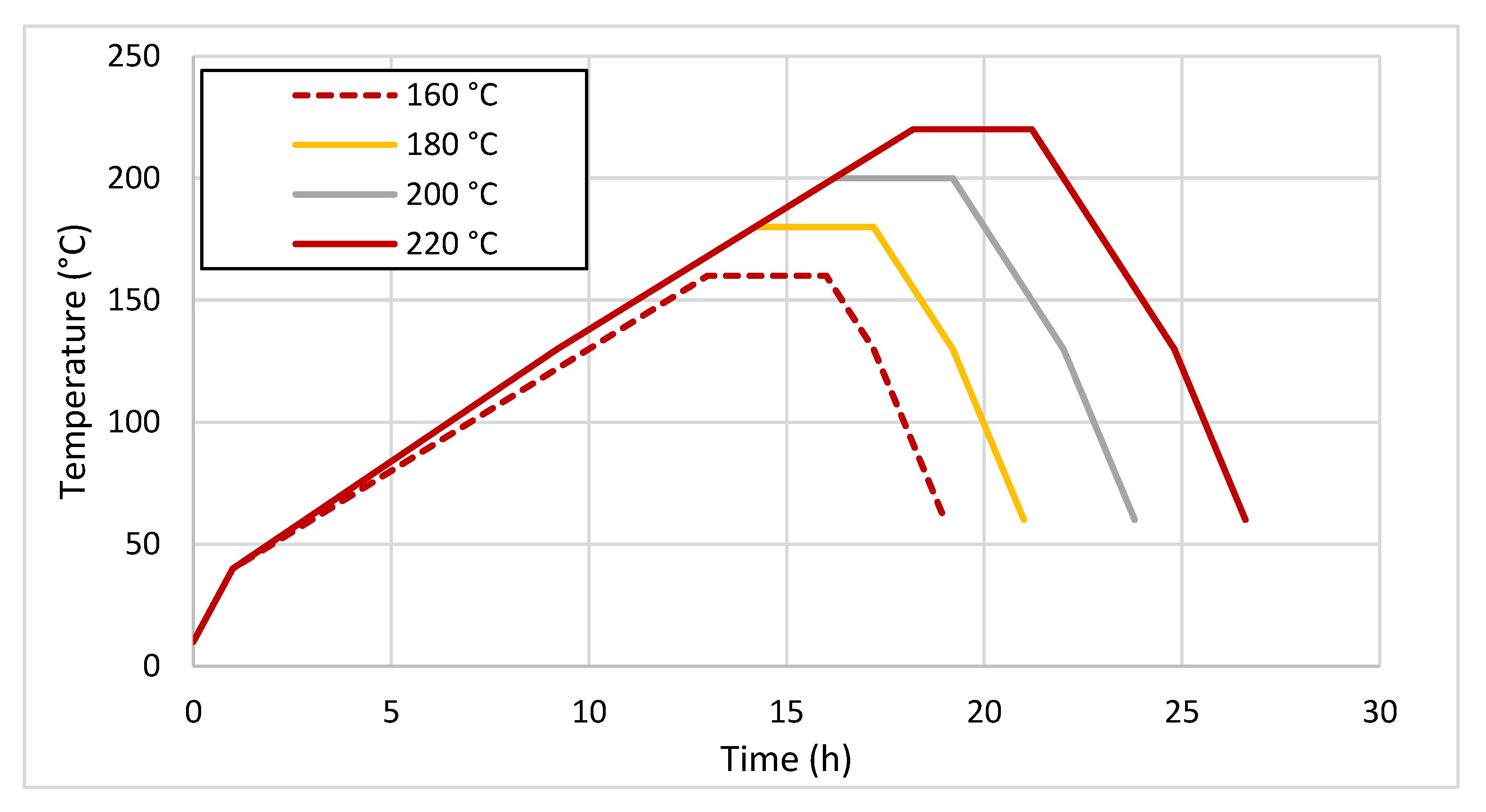

The course of thermal modification at treatment temperatures of 160°, 180°, 200° and 220 °C, in the atmosphere of air:

Phase 1—increase in temperature to 40 °C;

Phase 2—increase in temperature to 130 °C, drying;

Phase 3—thermal modification—heating to working temperature;

Phase 4—thermal modification—exposure to the working temperature for three hours;

Phase 5—cooling to 130 °C;

Phase 6—cooling to 60 °C with moisture content treatment to 4–7% (

Table 1).

Once the 60 °C temperature was achieved, the process was completed.

The temperature of the samples after the thermal treatment was approximately 40 °C. The course of the heating phases, modification and cooling for individual sample groups is illustrated in

Figure 1.

2.2. Chemical Analyses

The control samples (conditioned at 20 °C) and treated samples (160 °C, 180 °C, 200 °C, 220 °C) were first chipped and then milled using a POLYMIX PX-MFC 90D laboratory mill (Kinematica, Luzern, Switzerland). All samples were sieved. Particles from 0.5 to 1.0 mm were extracted in the Soxhlet apparatus by a mixture of ethanol-toluene according to [

11].

The holocellulose was isolated and determined according to the method by [

12], and the cellulose according to [

13]. The content of lignin was determined according to [

14]. Hemicelluloses were calculated as the difference between the holocellulose and cellulose content. Contents of extractives, holocellulose, cellulose and lignin were determined three times each per temperature. The obtained values for holocellulose, cellulose and lignin were recalculated as percentages of oven-dry weight per unextracted wood. The content of extractives was recalculated per oven-dry weight of wood. All results were used to calculate means as weight percentages ± SD.

2.3. Determination of Higher Heating Values

Wood chips from control samples and every treatment temperature samples were oven-dried at 105 ± 2 °C until constant mass before determination of higher heating values. The values of HHV are presented as mean ± SD (n = 5 samples per temperature).

The weight of chips before combustion was approximately 0.5 g, and it was weighed on the analytical scales with an accuracy of 0.0001 g [

15]. The Calorimeter C 200 (IKA

®-WERKE GmbH & Co. KG, Staufen, Germany) was used to measure higher heating values. The evaluation was performed using Cal Win software. In the calorimeter, samples were incinerated entirely in a pure oxygen environment at 30 Bar. Benzoic acid C 723, pelletized, 26.460 kJ.g

−1 (IKA

®-WERKE GmbH & Co. KG, Staufen, Germany) was used as a thermochemical standard for calibration of the calorimeter. Ignition wire type C 5010.3 (IKA

®-WERKE GmbH & Co. KG, Staufen, Germany) was used in the calorimeter.

Calculation of the Higher Heating Value

In addition to experimental determination, Higher Heating Value (HHV) can also be calculated based on the content of lignin (lig) and extractives (ext) in the samples. We calculated the HHVs according to the equations below [

5,

7,

16,

17]. The calculated HHVs were compared with the values determined experimentally. The equations are as follows:

where HHV is the higher heating value of unextracted wood, lig is lignin content (%), and ext is the content of extractives (%).

2.4. Statistical Analysis

The analysis of the selected chemical properties of the examined samples was processed using MatlabR2024b software. A correlation analysis was used to assess the relationship of all properties. The intensity of this relationship was measured by the Pearson correlation coefficient. The statistical significance of the analysis was assessed using the p-value. Given that the degree of dependence between them was significant, a PCA was used to illustrate and evaluate the relationship of these properties. The method converts several correlated variables to two linearly uncorrelated variables. These are then referred to as principal components (PCs). All variables have been standardised to have the same effect on the calculation of the components, regardless of their original measure. The method is a suitable tool for visualising and interpreting multidimensional data.

3. Results and Discussion

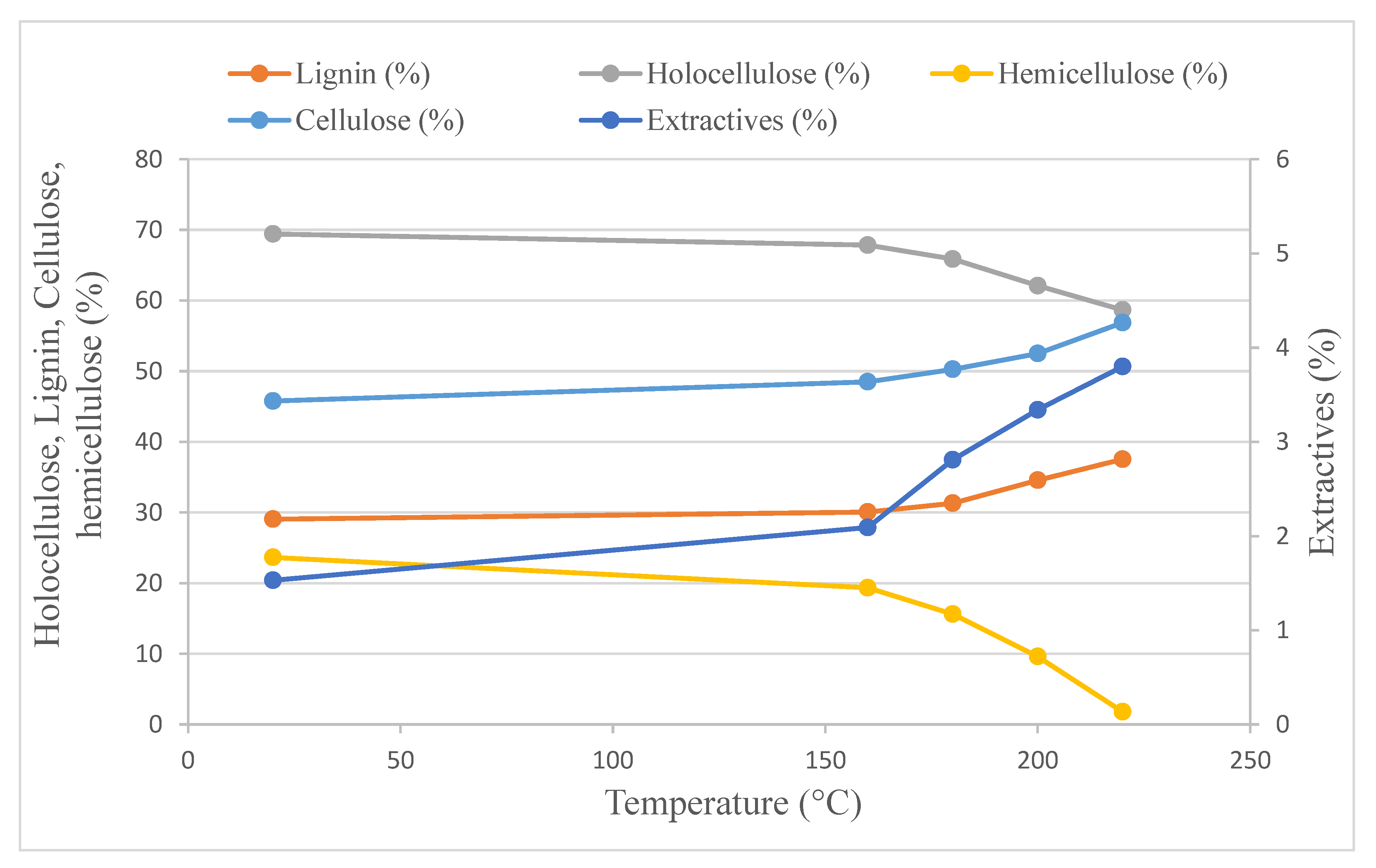

The average values of the chemical components of meranti wood are shown in

Figure 2 and

Table 2. The content of extractives increases during the thermal treatment of meranti wood. Very volatile extractives evaporate or degrade at higher temperatures. In addition to which are formed due to new components as a result of the degradation of wood components, mainly from hemicelluloses. According to [

18], the increase in the content of extractives is due to the degradation of lignin and polysaccharides.

The holocellulose content in meranti wood ranges from 69.42% to 58.66%. The total holocellulose content of wood comprises cellulose and hemicellulose portions. A decrease in holocellulose was mainly due to the degradation of hemicelluloses.

In the studies by [

19,

20], a decrease in the content of holocellulose was also observed after thermal treatment of various types of wood.

Cellulose is the second most stable component of wood after lignin. It has a high crystalline content, approximately 70%. In the thermally treated meranti, the observed increase in cellulose content was by 5.94% at 160 °C, 9.79% at 180 °C, 14.66% at 200 °C, and 24.22% at 220 °C compared to a temperature of 20 °C.

The increase in lignin content by 3.48%, 7.81%, 18.76%, and 29.23% at a temperature of 160 °C, 180 °C, 200 °C, 220 °C compared to a temperature of 20 °C is caused by condensation reactions of lignin with polysaccharide degradation products, which relatively increases the lignin content [

21,

22]. An increase in lignin content in thermally treated wood was also observed in the works [

19,

20].

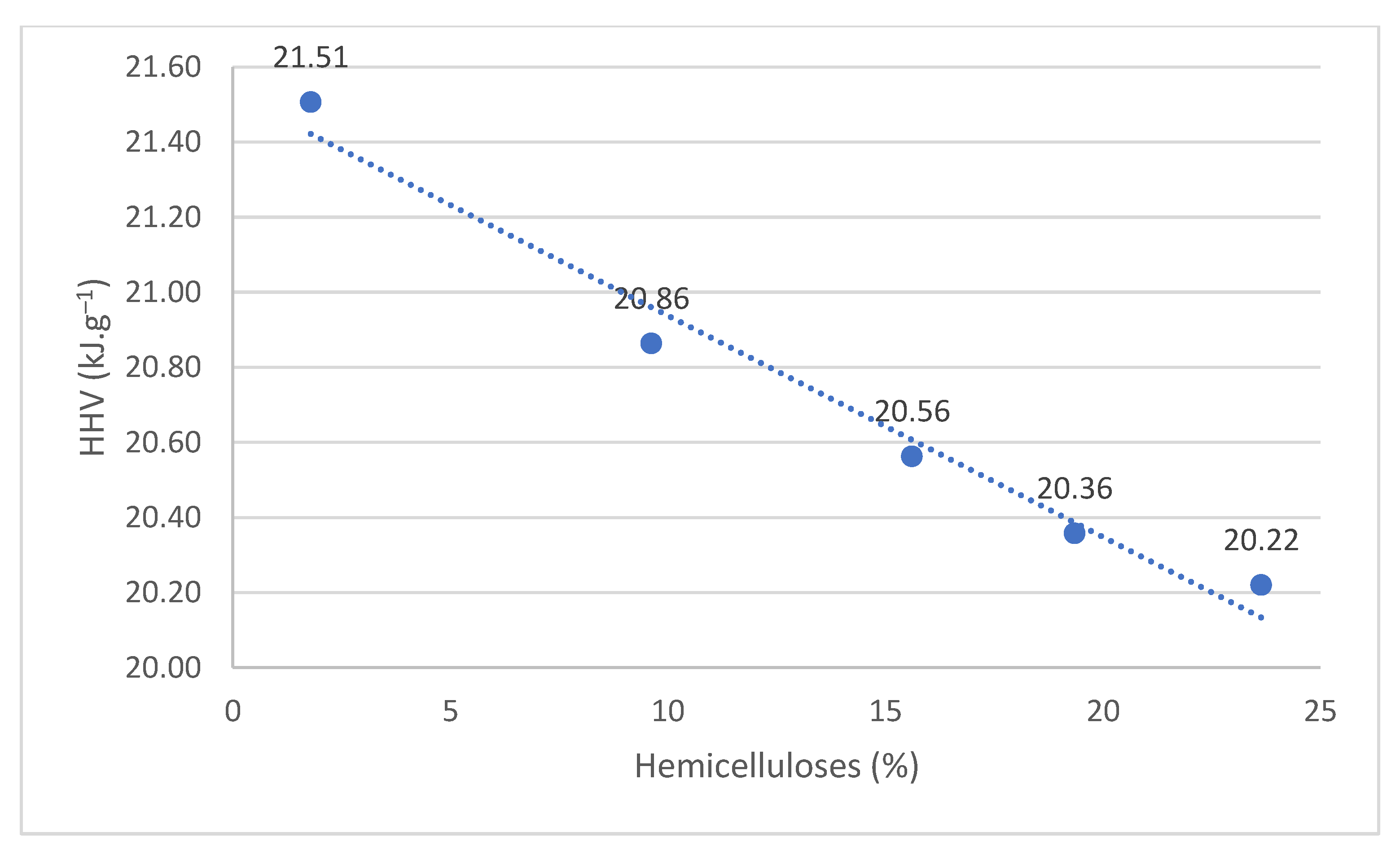

Hemicelluloses are the most affected by higher temperatures, and their content decreases by 92.43% at a temperature of 220 °C when compared to the original samples.

Xylan is the major component of hemicelluloses in meranti wood, and is also the least stable component of hemicelluloses [

23]. Degradation of xylan with dilute acids produces xylose.

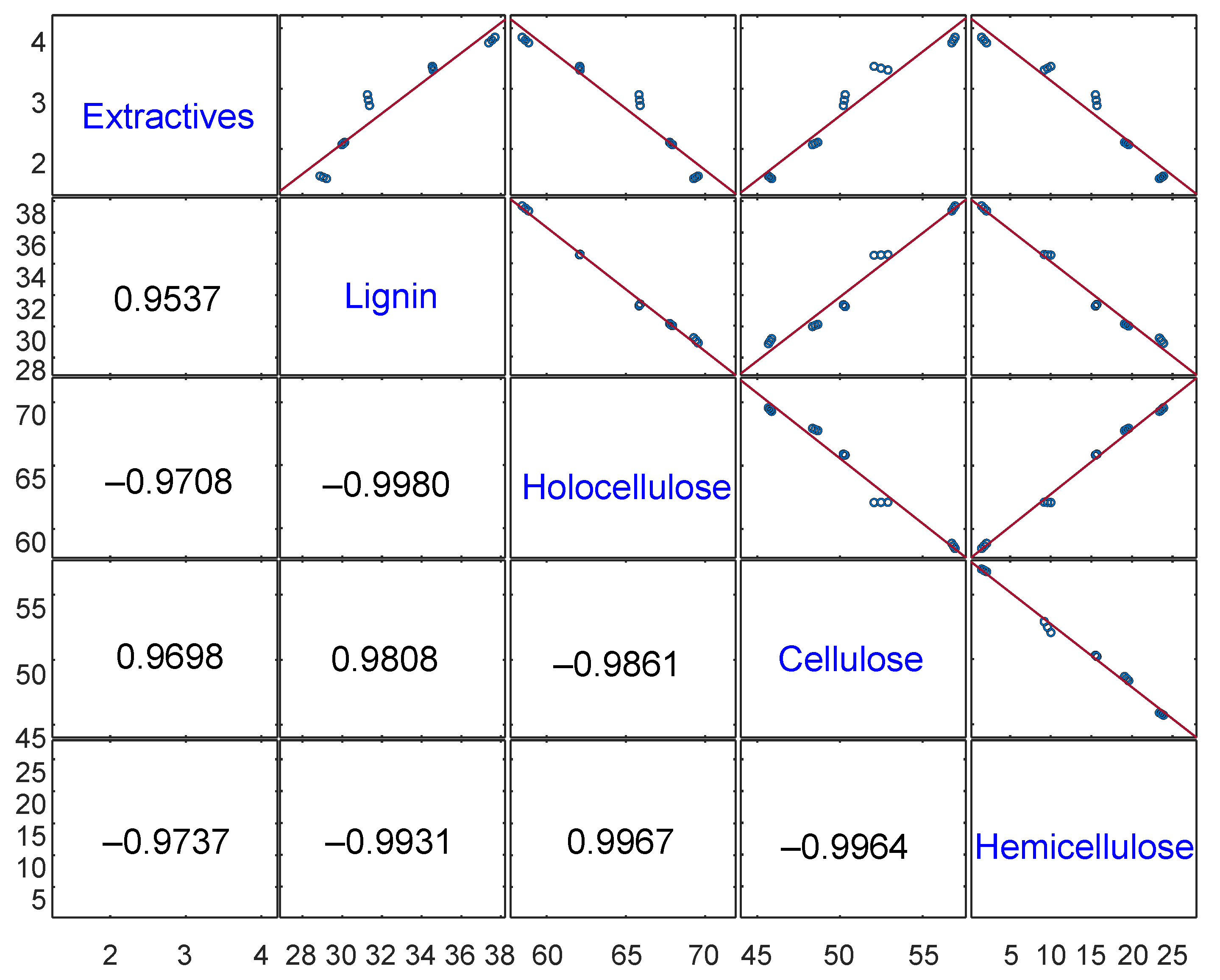

The dependence between the individual chemical components is shown in

Figure 3. Positive values indicate a strong positive correlation between the wood components (extractives and lignin, Pearson r = 0.9537,

p < 0.001, R

2 = 0.9090, n = 15). Conversely, negative values indicate a strong negative correlation between the wood components (extractives and holocellulose, Pearson r = –0.9708,

p < 0.001, R

2 = 0.9425, n = 15).

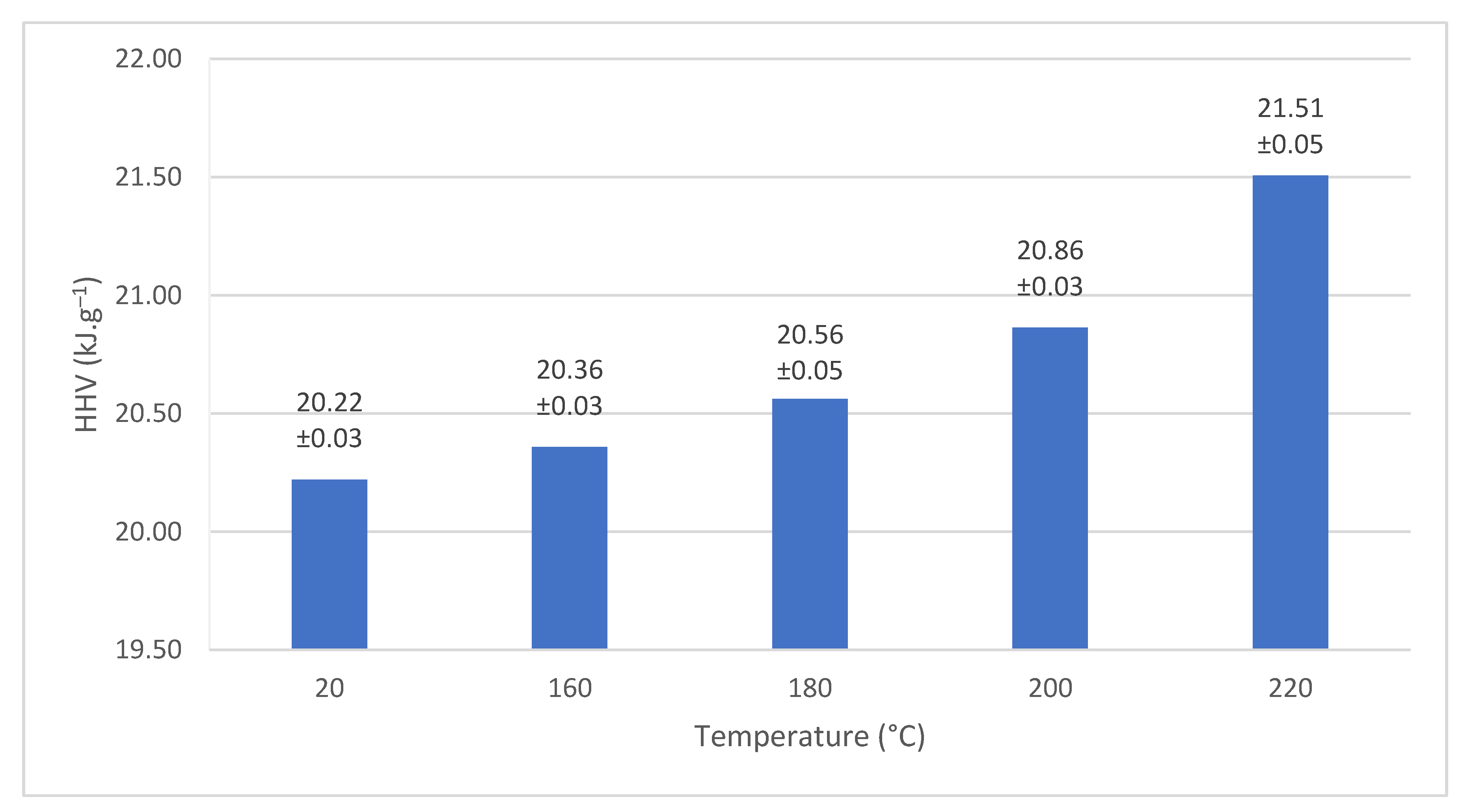

HHVs determined by calorimetry for the control samples and thermally treated meranti wood are shown in

Figure 4. The results show that HHVs increase with wood treatment temperature. The increase in HHV was 6.0% at a temperature of 220 °C compared to a temperature of 20 °C.

If the lignin content or the content of extractives is known, HHV can also be calculated according to the above-mentioned equations given by the authors [

5,

7,

16,

17]. The calculated values are shown in

Table 3.

At the significance level α = 0.05, we tested the experimentally determined HHVs with the calculated values. We found that the values calculated according to Equation (1), converted by 1 Btu. lb−1 = 0.0023 kJ.g−1, corresponded best to our experimental HHV (p = 0.175). The values recalculated by Equation (4) also corresponded to the measured HHVs (p = 0.944). On the contrary, the tests showed statistically significant differences between the HHVs calculated based on Equation (2), p < 0.001 and Equation (3), p < 0.001 and the experimentally determined HHVs.

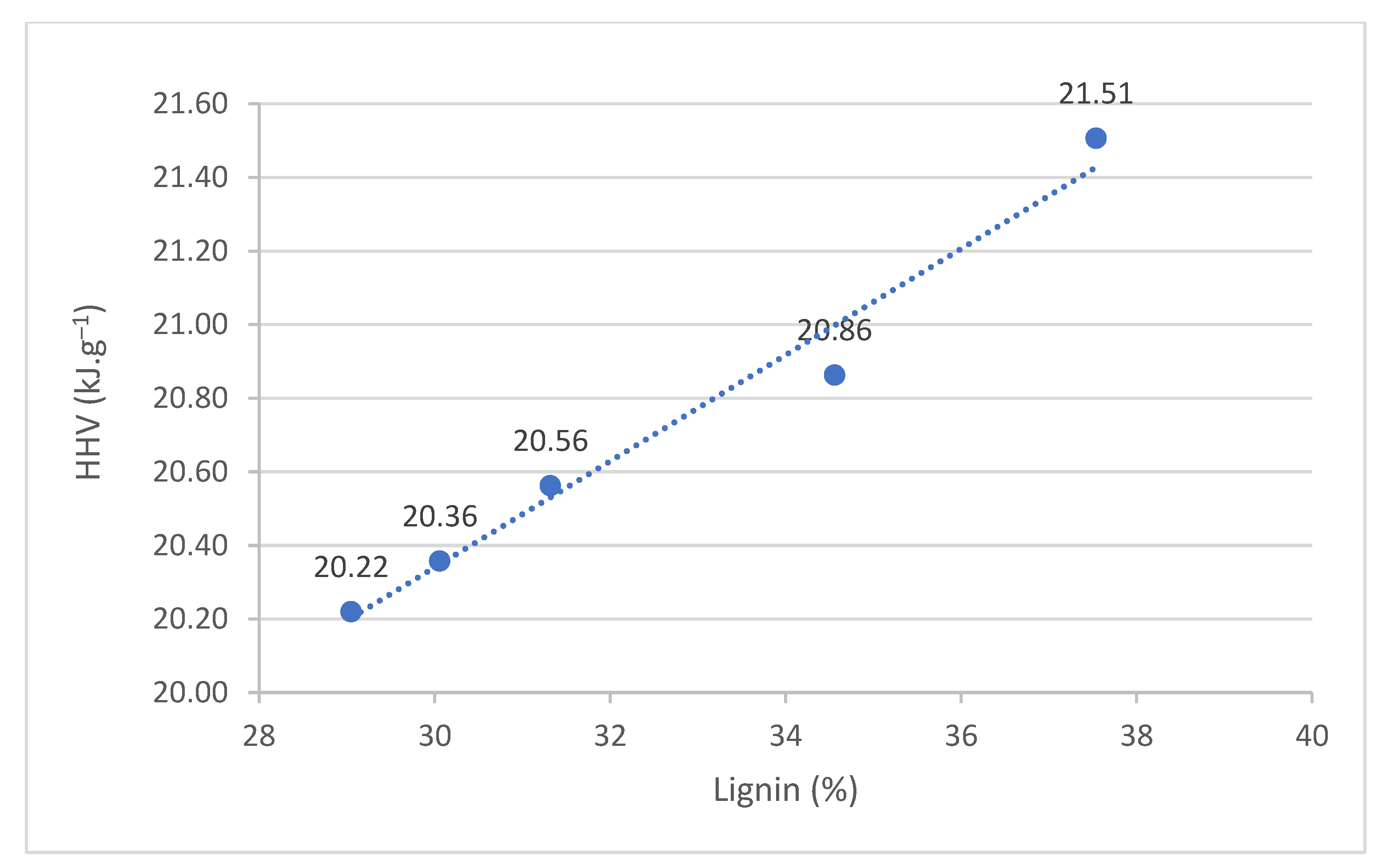

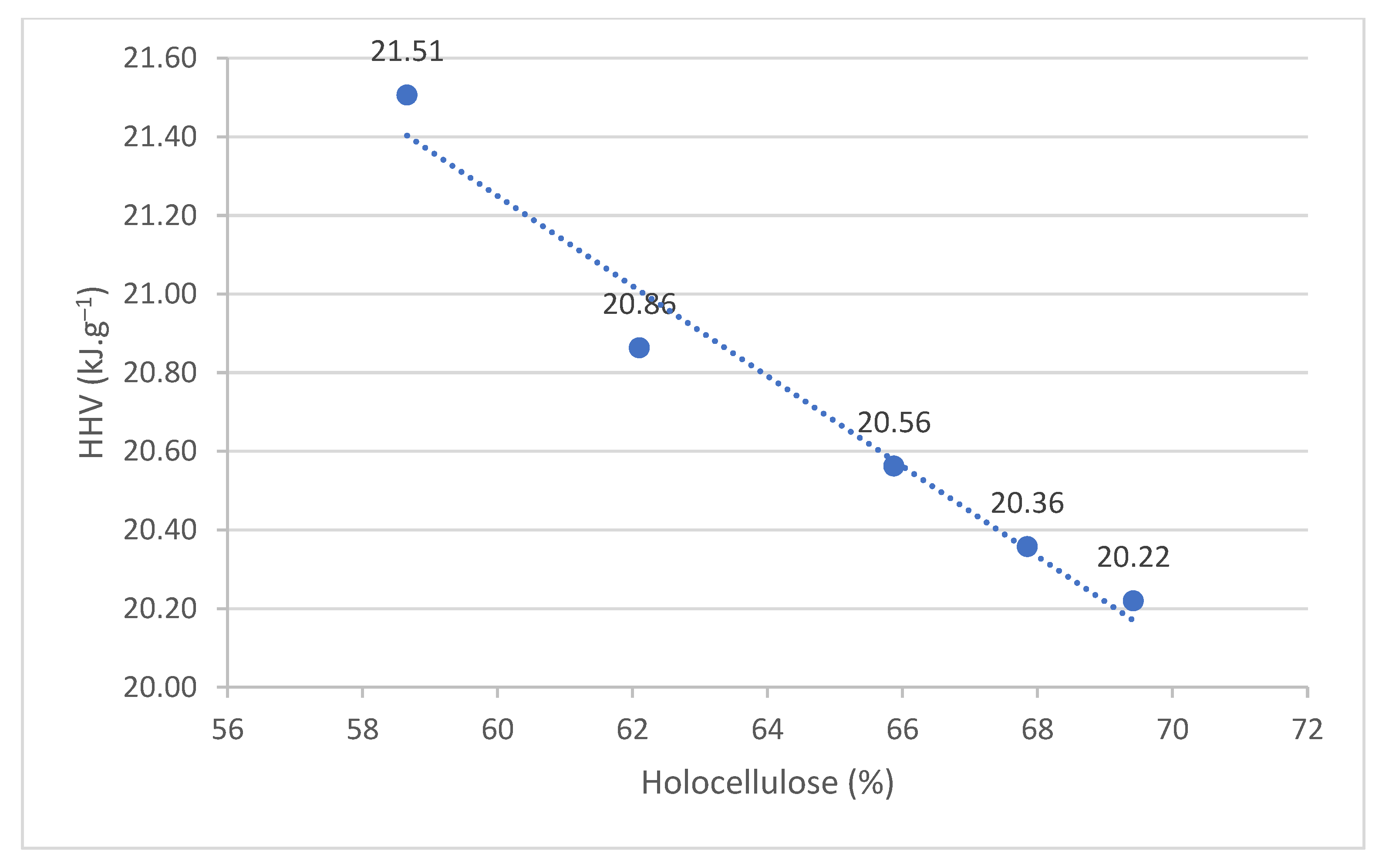

A linear regression has been confirmed between HHV and the content of extractives, holocellulose, cellulose, lignin, and hemicellulose. The coefficients of determination are shown in

Table 4. HHV depends on the chemical composition of the wood [

1,

24]. HHV were positively correlated with the extractives, lignin, and cellulose content (

Figure 5,

Figure 6 and

Figure 7). A negative correlation was found between HHV and holocellulose and hemicelluloses (

Figure 8 and

Figure 9).

The results show that after thermal treatment of wood, the increase in HHV was caused by an increase in the content of lignin, cellulose, and extractives. However, HHV of polysaccharides is lower than HHV of lignin and extractives [

1]. The dependence between HHV and the content of extractives is not as strong as in the case of lignin. At the same time, extractives can be isolated from wood with various solvents. The method used to separate these substances can also affect the regression analysis. In addition, softwood contains resins and terpenes and has a higher lignin content and a different structure than hardwood.

For these reasons, the equation suitable for predicting HHV in thermally treated hardwood is:

For the predicted results to be as reliable as possible, it is necessary to get as close as possible to the thermal treatment conditions. Whether the equation can be used to predict HHV in the case of thermally treated softwood will be the subject of further research.

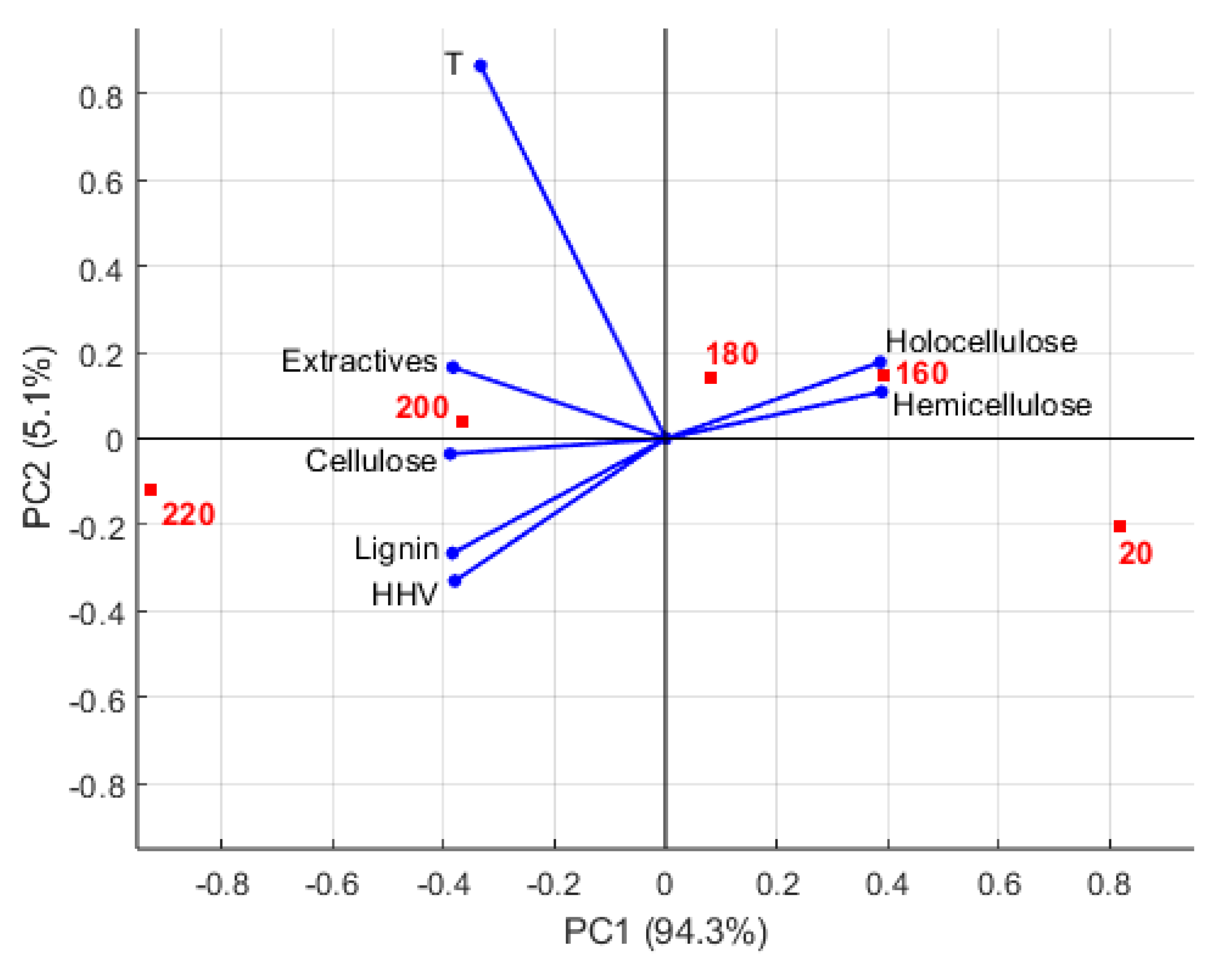

To examine the relationships between individual chemical components and HHV in thermally treated meranti samples in more detail, principal component analysis (PCA) was performed. PCA allows us to reduce all monitored parameters into two principal components, PC1 and PC2 (

Figure 10).

PC1 explains up to 94.3% of the variability which suggests that the data are very well approximated by one component (PC1). Individual samples are divided by temperature (20 °C—control samples, 160 °C, 180 °C, 200 °C, 220 °C).

Figure 10 shows that they are distributed along the PC1 line from right to left. This distribution indicates that the chemical composition of the samples changes systematically with thermal treatment. A larger distance between thermally treated samples indicates substantial differences in chemical composition.

The figure also shows the contribution of each chemical property to each principal component, PC1 and PC2. The most significant influence on PC1 is exerted by hemicelluloses, holocellulose (positive loadings), and cellulose, lignin, and extractives (negative loadings).

Samples with higher PC1 scores treated at lower temperatures (160 °C, 180 °C) show a higher content of hemicelluloses, holocellulose, and less lignin (a lower content of extractives and a lower HHV is also identified). Samples thermally treated at higher temperatures (200°, 220 °C) which contain more lignin, extractives, and cellulose have lower PC1 scores. PC1 therefore monitors the effect of temperature on chemical composition. The result of analysis corresponds to the degradation of wood. PC1 thus represents the degree of degradation of the chemical components of wood.

PC2 explains 5.1% of the total variability. For PC2, the dominant variable is temperature (positive effect).

4. Conclusions

After thermal treatment of meranti wood at temperatures of 160 °C, 180 °C, 200 °C, and 220 °C, the chemical composition of the wood changed in comparison with control samples. The content of extractives, cellulose, and lignin increased. The content of holocellulose, hemicelluloses, on the contrary, decreased. The higher heating values, determined calorimetrically, increased by 6% with the thermal treatment. A linear relationship between HHV and lignin content was confirmed. Regression analysis showed that the model HHV = 0.1443(lig) + 16.012 is suitable for predicting the HHV of thermally treated wood, if the lignin content is known.

PCA separates samples by groups (20 °C—control samples, 160 °C to 220 °C). The first component PC1 captures most of the information in the data and describes the main chemical change in composition related to wood treatment. The results confirm that the chemical components of wood, such as cellulose, lignin, hemicelluloses, and extractives, change significantly with the thermal treatment of wood.

This study provides important insights into the energy potential of thermally treated exotic wood species such as meranti, which differ from common softwoods like spruce in their chemical composition and thermal behaviour. The findings can guide the efficient use of meranti and similar exotic woods for energy applications, informing both industrial practice and sustainable resource management. Limitations of the current study include the focus on a single wood species and specific thermal conditions, suggesting that further research is needed to explore other wood types, treatment regimes, and practical implementation.