1. Introduction

Crosslinked polyethylene (XLPE) is widely used as an insulation material for electrical wires in power systems, building wiring, and rail transit due to its superior electrical insulating properties, enhanced thermal stability, and cost-effectiveness [

1,

2]. However, under extreme conditions such as fire or electrical overload, PE insulation exhibits a series of significant fire hazards—most notably molten dripping, which has become a critical factor in triggering secondary ignition sources and accelerating fire spread [

3,

4]. Unlike conventional flame propagation along the wire, molten dripping facilitates vertical fire expansion in a more concealed and hazardous manner. Dripping thermoplastic material tends to accumulate beneath the wire and ignite nearby combustibles, often resulting in multiple ignition points that greatly increase the complexity of fire suppression. In recent years, with growing insight into the causes of electrical fires, molten dripping has emerged as a frontier issue in fire dynamics research, particularly in areas such as polymer pyrolysis, droplet dynamics, and localized ignition mechanisms [

5,

6,

7]. A comprehensive understanding of the formation mechanism of molten dripping and its coupling with electrical load is of critical theoretical and engineering value for improving early-stage electrical fire risk assessment and enhancing fire-resistant wire design.

In recent years, extensive research has been conducted on the molten dripping behavior during wire combustion, with scholars exploring the phenomenon from perspectives such as material properties, environmental conditions, and electric field effects. Hirschler [

8] and Rodak et al. [

9] reviewed standard flammability test methods for wire insulation materials, highlighting that dripping behavior serves as a critical indicator of fire risk for thermoplastic materials in vertical flame tests (e.g., UL-94). Brabrauskas [

10] discussed the fire hazards and ignition behavior of energized electrical wiring. Hasegawa et al. [

11] experimentally confirmed that molten dripping could act as an ignition source during the early stages of flame propagation. Building on this, Leung et al. [

12] developed a mathematical model that revealed the role of the wire core in the pyrolysis process during combustion. Furthermore, Umemura et al. [

13] constructed a physical model of flame spread under microgravity conditions, for the first time considering how insulation melting alters heat transfer pathways.

Fujita and Nakamura conducted a series of studies analyzing the flame propagation mechanisms along electrical wires under various conditions including oxygen concentration [

14], external airflow [

15], opposing wind [

16], and low-pressure environments [

17]. Their findings indicate that the preheating capability of the internal metal core can intensify the molten dripping behavior of the insulation material. They also examined the influence of alternating electric fields on flame structure and molten dripping [

18] as well as the ignition mechanisms of insulation materials triggered by short-term overload currents [

19]. Building upon this work, Huang et al. [

20] developed a thermal conduction model describing the transition from ignition to flame spread, while Takahashi further investigated the accumulation and morphological evolution of molten material in microgravity conditions [

21]. Additionally, Hu et al. [

22] demonstrated the combined effects of high thermal conductivity metal cores and wire inclination angles on the dripping trajectory.

Regarding the dripping behavior itself, Lim et al. [

23] found that high-frequency alternating current can intensify insulation melting and increase dripping, which may inhibit flame spread by promoting a “drip-induced extinction” phenomenon. Wang et al. [

24] systematically tested the dripping performance of various thermoplastic materials (including PE) under standard combustion conditions. Kandola et al. [

25,

26] developed real-time recording techniques for dripping behavior and proposed a quantitative thermal degradation model, laying the groundwork for future thermal hazard prediction. Wang [

27], along with Xie et al. [

28,

29], investigated the mechanism of molten droplets accumulating on the ground and igniting secondary materials through mesoscale experiments and a T-shaped apparatus. Their findings highlighted that XLPE, due to its rapid melting rate and strong flame-sustaining capability, presents significantly higher fire hazards compared with other thermoplastics such as polystyrene.

In recent years, researchers have increasingly focused on the role of molten dripping in the secondary ignition of materials located beneath the burning wire. Xu et al. [

30] conducted a systematic study on how molten drips—generated by burning wires at varying heights (10–50 cm)—affect the ignition and combustion behavior of typical thermal insulation materials. Their findings revealed that a greater dripping height leads to stronger penetration and ignition capability, and uncovered complex phenomena such as “flame up” and “flame out”. Furthermore, Sun et al. [

31] investigated XLPE molten droplets and quantitatively analyzed the influence of drip mass and dripping frequency on the ignition probability of thin paper. They proposed that the dripping ignition capability is governed by the “drip mass rate”, thereby providing a quantitative criterion for assessing the fire hazard associated with molten dripping.

Meanwhile, researchers have gradually recognized the critical influence of electrical current on molten dripping behavior. He et al. [

32] were among the first to investigate insulation dripping induced by flame spread under overload current conditions and proposed a theoretical relationship between current and dripping frequency. Building upon this, Zhang et al. [

33] systematically analyzed the effects of molten dripping on flame propagation under higher current levels (0–50 A). They observed periodic oscillations in flame height caused by dripping, and for the first time, identified phenomena such as “flaming drip” and pulsating, liquid-like flames. They also proposed and validated a frequency prediction model for dripping. In a 2024 study, the influence of thermal aging on the combustion characteristics of XLPE-insulated wires was examined. It was found that aging led to reduced flame height and spread rate as well as a decrease in dripping frequency, but an increase in individual drip mass [

34]. It is noteworthy that a similar oscillatory dripping behavior has been observed at intermediate gravitational levels under conditions without electrical overload, as reported by Li et al. [

35], who identified cyclic patterns in the downward flame spread over cylindrical samples. Kobayashi et al. [

36] further revealed the dual role of the metal core: acting as a heat source downstream to promote flame spread while serving as a heat sink upstream to delay dripping. This was the first study to clearly elucidate the interaction mechanism between molten dripping and flame propagation.

In addition, Sun et al. [

37] conducted combustion experiments on molten XLPE droplets under microgravity conditions, revealing that the droplets exhibited distinct combustion rate patterns during the “comet-shaped flame” and “spherical flame” phases. Their study quantitatively demonstrated how bubble formation and fuel ejection influence combustion rates. These findings not only broaden the research perspective of molten droplet combustion in space fire environments, but also underscore the increased complexity of fire hazards posed by molten dripping under special environmental conditions.

In summary, existing studies have explored the multifaceted mechanisms of molten dripping from the perspectives of material properties, external environmental factors, and the effects of electric fields and current conditions, gradually establishing the relationship between dripping behavior, flame propagation, and ignition risk. However, a systematic quantification of the dynamic evolution and stable periodicity of the dripping process itself remains lacking. In particular, the response mechanisms of key parameters—such as drip initiation time, frequency, and period—under different levels of electrical load have yet to be clearly elucidated.

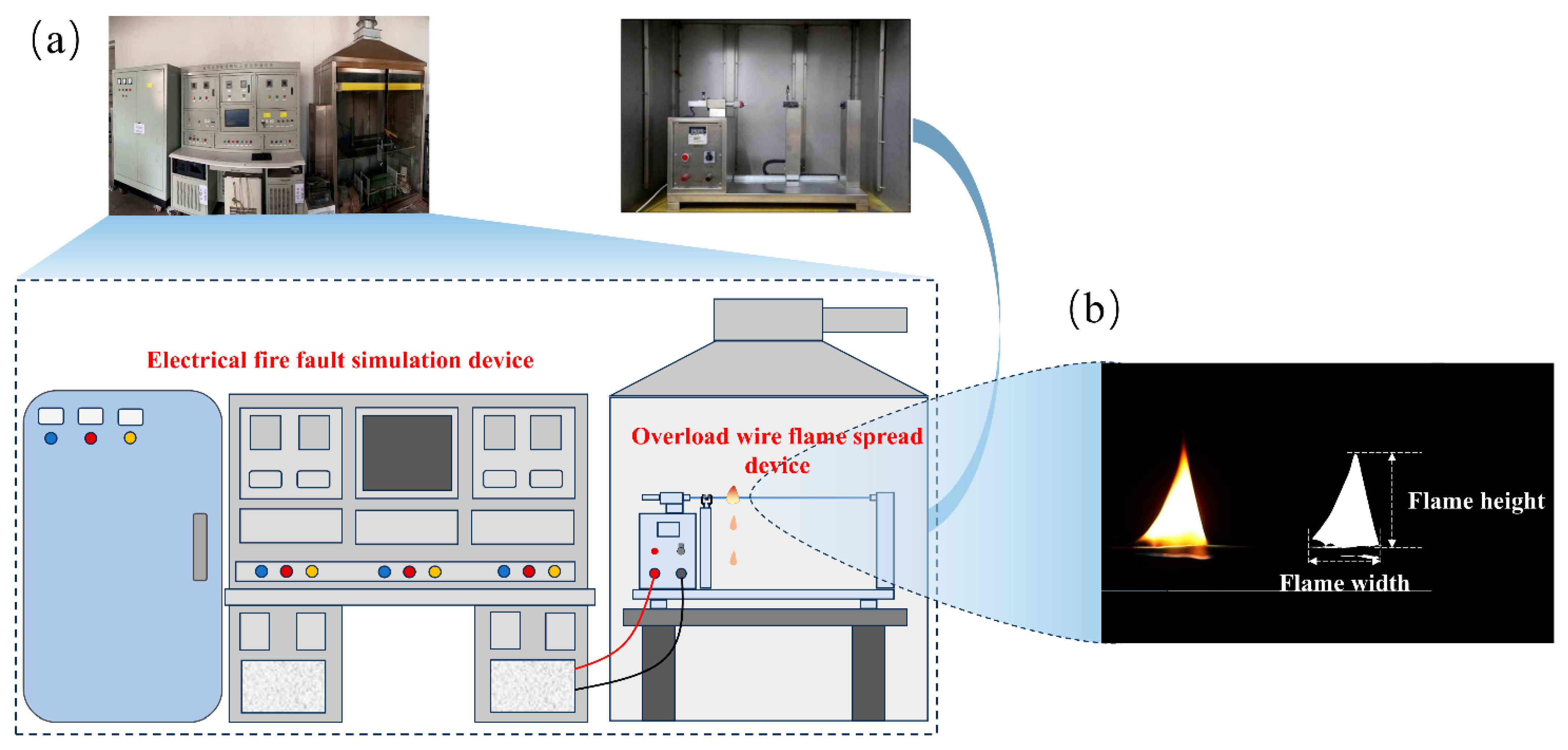

In light of the above research gaps, this study focused on the molten dripping behavior of thermoplastic polyethylene cable insulation under electrical overload, conducting a comprehensive investigation through both experimental and theoretical analyses. A series of constant-current tests were designed to observe and record the accumulation, initial dripping, and subsequent periodic evolution of the molten insulation. The influence of current intensity on key parameters—including initial dripping time, dripping frequency, and dripping period—was systematically examined. Additionally, high-resolution video imaging was employed to analyze the disturbance effects of molten dripping on flame morphology and propagation stability. A thermodynamic model based on heat balance and fluid detachment principles was developed to uncover the intrinsic coupling between electrical current and dripping characteristics. Overall, this study aimed to deepen the understanding of melting behavior in thermoplastic insulation, clarify the independent role of molten dripping in cable fire propagation, and provide both theoretical insights and experimental evidence to support fire risk prediction and insulation material optimization in electrical systems.

3. Results and Discussions

3.1. Accumulation and Dripping Process of Molten Material

Figure 2 illustrates the accumulation and dripping process of molten XLPE insulation under non-electrified (0 A) and overloaded current conditions (60 A and 80 A). Experimental observations revealed that under the combined effect of external thermal radiation and internal Joule heating, the insulation layer undergoes a series of phase transitions including softening, melting, and viscous flow, eventually leading to dripping driven by gravity [

38]. This dripping behavior is governed by a thermo-mechanical coupling mechanism, wherein the key determinant is whether the gravitational force acting on the molten mass is sufficient to overcome the surface adhesion and interfacial shear resistance [

37]. Based on the force balance analysis, droplet detachment occurs when the gravitational force satisfies the following condition:

where

is the gravitational force of the molten droplet;

is the adhesive force due to surface tension acting along the contact boundary (proportional to the peripheral contact length

); and

is the shear force arising from interfacial adhesion (proportional to the contact area

). Therefore, the criterion for droplet detachment can be expressed as:

where

is the density of molten XLPE,

is the volume of the droplet,

is the surface tension coefficient between XLPE and the copper conductor, and

is the interfacial shear strength.

From the image sequences, it can be observed that under the 0 A condition, the absence of additional Joule heating within the wire resulted in a slower melting rate and longer droplet formation cycles, exhibiting characteristics of “slow accumulation and delayed dripping”. In contrast, under 60 A and 80 A conditions, the overload current significantly enhanced the rate of heat input, leading to the rapid accumulation of molten material and shorter dripping cycles. This indicates that as the temperature increases, the material viscosity decreases, making the critical dripping condition (Equation (2)) more easily satisfied. Moreover, the dripping process exerts a notable disturbance on the flame morphology. Each droplet detachment not only removes part of the heat and combustible components—causing a momentary attenuation of the local flame—but may also form a secondary combustion zone at the dripping site. This behavior enhances vertical flame spread and increases both the uncertainty and complexity of fire propagation paths.

Previous studies, such as those by Guibaud et al. [

39,

40], have explored the role of soot in radiative heat transfer during flame spread in microgravity conditions. The spatial distribution of radiative heat flux from sooting flames is influenced by the axisymmetric configuration of the wire, which significantly impacts the pyrolysis rate and flame spread. While our experiments focused on normal gravity conditions, the findings from these studies underline the importance of incorporating soot quantification and radiative modeling in future work to better understand flame dynamics in terrestrial environments.

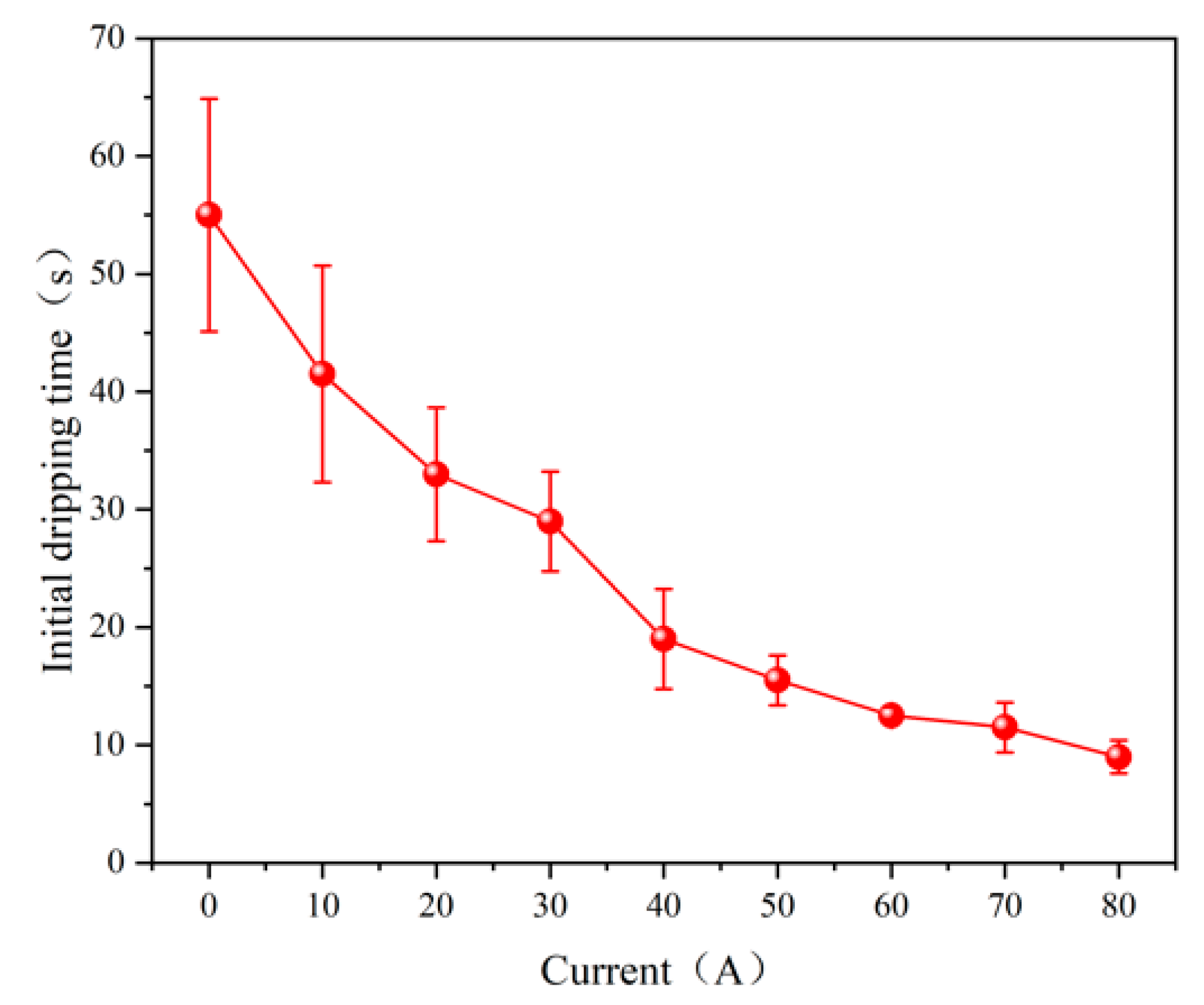

3.2. Effect of Overload Current on Initial Dripping Time

Figure 3 illustrates the relationship between the initial molten dripping time and overload current for XLPE wires. The

initial dripping time is defined as the duration from the moment the wire is ignited by the external radiant heat source to the point when the insulation material first forms a molten droplet and naturally detaches. The results demonstrated a clear decreasing trend in the initial dripping time with increasing current. Under low current conditions (10–20 A), the initial dripping time was relatively long—approximately 45–65 s—indicating a slower accumulation rate of molten material. As the current increased (40–60 A), the initial dripping time decreased rapidly. When the current reached 80 A, the initial dripping occurred in approximately 10 s, suggesting that molten material can rapidly accumulate and detach in a very short period under high current conditions.

The fundamental cause of this phenomenon lies in the significant enhancement of Joule heating within the conductor due to increased current. According to Joule’s law, the heat power generated by the conductor is expressed as , where I is the current, Rc is the conductor resistance, and t is time. On a comparable timescale, a squared increase in current results in a rapid temperature rise in the wire core, thereby accelerating the thermal decomposition and melting rate of the insulation material. Consequently, the molten droplet reaches the critical threshold for gravity-driven detachment more quickly. As a result, pyrolysis products accumulate in a short time, facilitating the early formation and detachment of molten droplets. This behavior indicates that overload current is not only a key triggering factor for molten dripping, but also significantly intensifies the instability and sudden onset of dripping events, thereby accelerating fire spread and increasing the overall risk level of electrical fires.

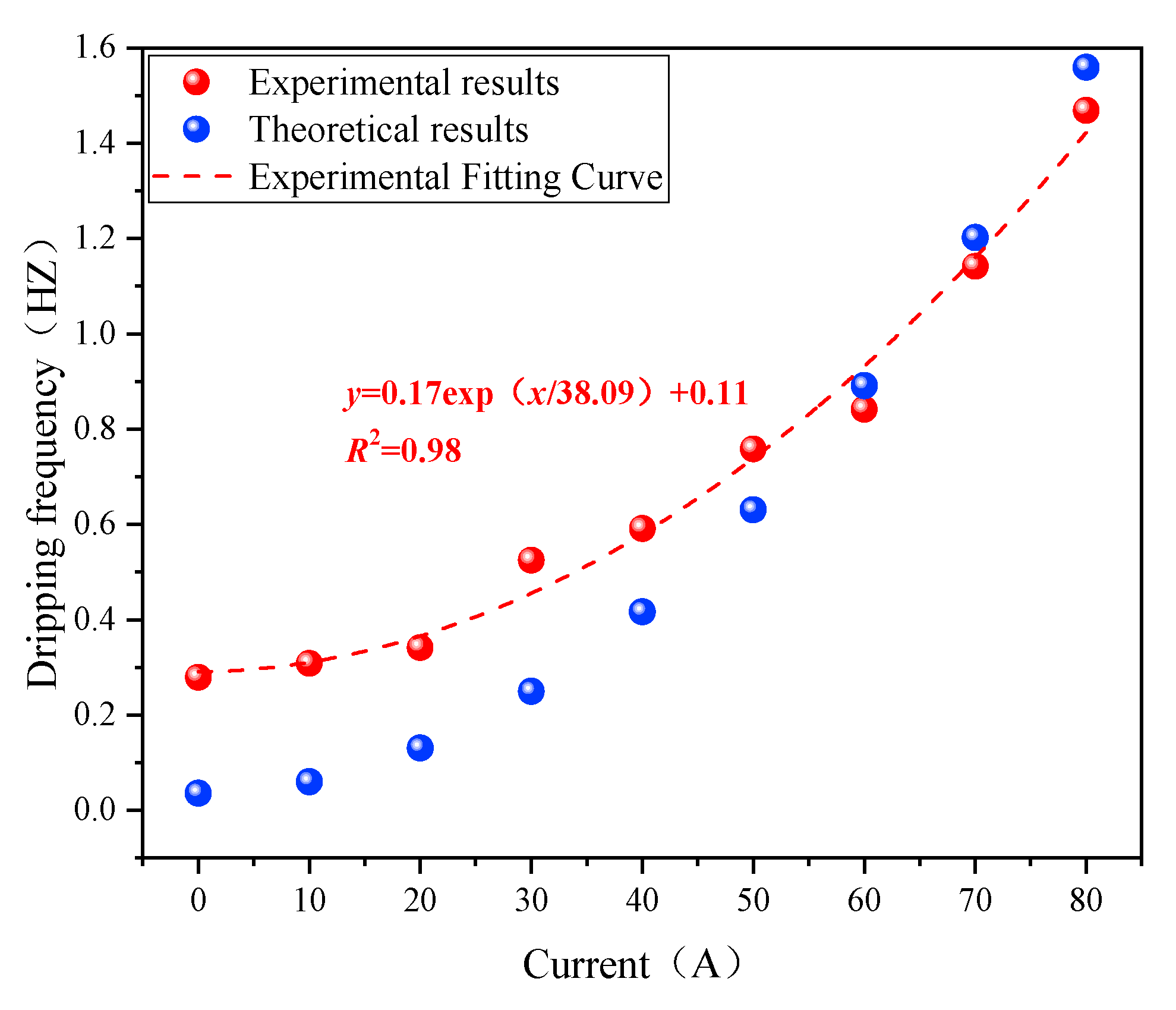

3.3. Effect of Overload Current on Dripping Frequency

During the steady-state melting phase, the XLPE insulation layer continuously softens under the combined effect of Joule heating caused by overload current and external thermal radiation. The molten material gradually accumulates on the underside of the wire. When the accumulated mass reaches a critical value

, gravity overcomes the surface tension and adhesive forces, triggering droplet detachment and forming a dripping behavior with a certain periodicity. Let the dripping period be

, the dripping frequency be

, and the melting rate be

; the following relationship can be obtained:

The melting rate

depends on the effective heat absorbed by the material per unit time. This heat input consists of two main components: (1) the Joule heat

generated by the current passing through the conductor, and (2) the external radiative heat flux

. Considering the material’s latent heat of melting

and the effective heat absorption efficiency

, the melting rate can be expressed as:

Substituting Equation (5) into Equation (4), the theoretical relationship between dripping frequency and current can be expressed as:

Accordingly, the expression for the dripping period is:

The above derivation indicates that the dripping frequency exhibits a nonlinear positive correlation with the square of the overload current , while the dripping period decreases significantly with increasing . This theoretically reveals the physical mechanism by which a higher current accelerates the formation and detachment of molten droplets: as the current increases, the enhanced Joule heating within the conductor rapidly raises the temperature of the insulation layer, increases the melting rate, and allows molten droplets to reach the critical mass more quickly—thereby increasing the dripping frequency and reducing the period.

Figure 4 presents the comparison between the theoretical predictions and experimental measurements of the molten dripping frequency of XLPE insulation under different current conditions.

As shown in

Figure 4, the dripping frequency exhibited a pronounced nonlinear increase with rising current. The theoretical predictions, calculated based on Equation (6), closely aligned with the overall trend of the experimental results, confirming the model’s rationality and applicability in describing the relationship between molten dripping behavior and electrical load.

However, in the low current range (0–30 A), the predicted frequency was significantly lower than the measured values, showing noticeable deviations. This discrepancy mainly arose because the model assumes that the thermal input for melting primarily comes from the combined effects of Joule heating in the metal core and external thermal radiation. Under low current conditions, the Joule heat contribution is minimal, and the thermal input relies mainly on a constant external radiation source . In this case, the model’s assumed thermal absorption efficiency parameter differs from the actual heat absorption characteristics of the material. It fails to account for local overheating, thermal accumulation, and early softening behavior of the XLPE insulation under low heat flux, thus underestimating the melting rate , leading to lower predicted frequencies.

As the current increases—particularly beyond 60 A—the internal Joule heating increases rapidly and becomes the dominant heat source in the melting process. At this stage, thermal input is mainly governed by current, making the model’s key driving terms more consistent with the actual physical process. Consequently, the accuracy of the model improves significantly, and the gap between prediction and measurement narrows considerably. This also demonstrates that under high-current conditions, the thermal control mechanism of molten dripping becomes more singular, thereby enhancing the applicability of the theoretical model.

The oscillatory behavior of molten dripping observed in this study, influenced by the electrical overload current, can be likened to the cyclic pattern reported by Li et al. under partial gravity conditions [

35]. While the forces driving the dripping in our experiments (i.e., Joule heating and electrical current) differ from the gravitational forces in their study, the underlying oscillatory regime—characterized by periodic dripping and flame disturbances—appears to share similarities, suggesting that the basic principles of molten material detachment and flame interaction may be generalized across different conditions.

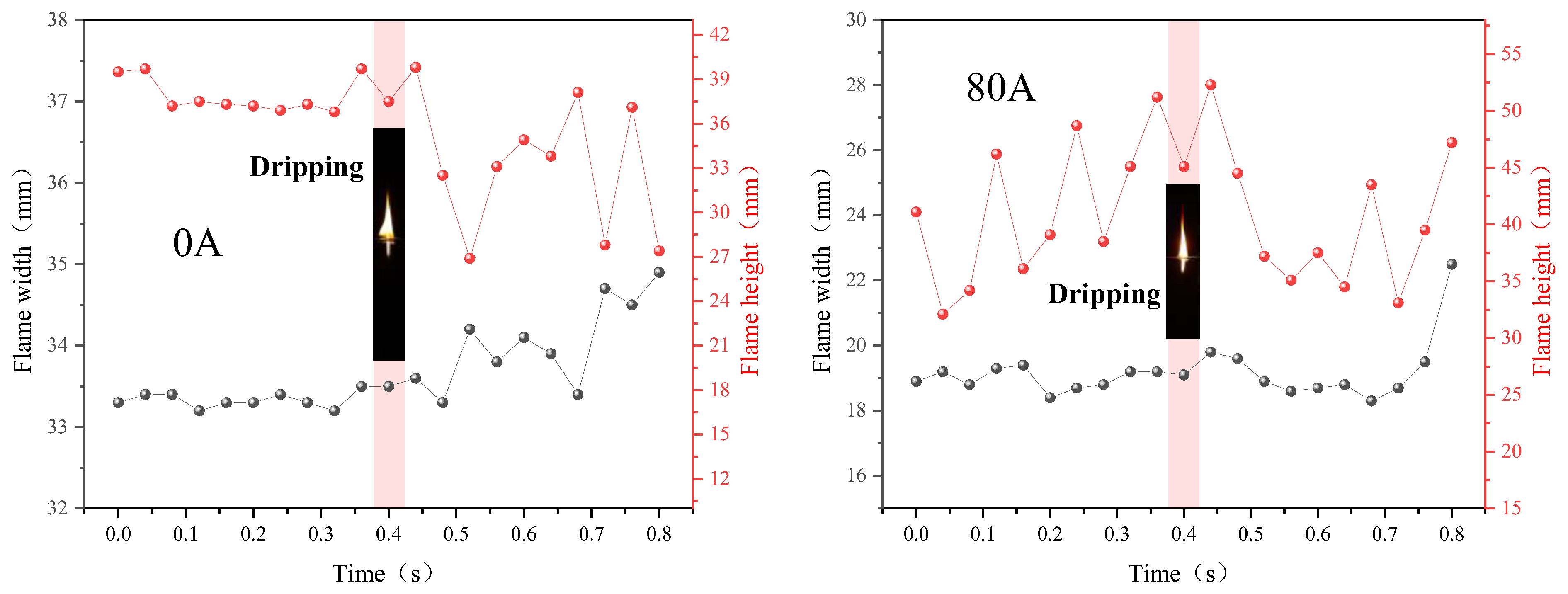

3.4. Influence of Dripping Behavior on Flame Morphology

As shown in

Figure 5, the flame morphology exhibited significant disturbances during the molten dripping process under different overload current conditions, with both the amplitude and frequency of the disturbance increasing as the current rose. Particularly under the 60 A and 80 A conditions, the flame contour underwent intense fluctuations after the onset of dripping, characterized by irregular oscillations at the flame tip and a sudden increase in brightness. This reflects the strong thermal disturbances and the release of incompletely combusted materials accompanying the dripping process, which significantly disrupt the flame structure.

Figure 6 further quantitatively analyzes the temporal evolution of flame geometry (height and width) before and after molten dripping. The results show that under the 0 A condition, the flame remained relatively stable, with the flame height fluctuating slightly between 36 and 38 mm and the width remaining steady at 34–36 mm within 0–0.4 s before dripping, indicating minimal variation. After dripping occurred, the flame geometry showed minor fluctuations but maintained overall stability. In contrast, under the 80 A condition, significant disturbance was already observed in the flame height before dripping, fluctuating between 15 and 55 mm, indicating that even before dripping, the flame was heavily influenced by thermal disturbances in high current environments. After the onset of dripping, the fluctuation in flame height intensified, displaying a periodic surge pattern, reflecting the thermal pulse effects induced by high-frequency dripping behavior. Meanwhile, the flame width remained relatively stable throughout, fluctuating within the range of 18–26 mm.

The above results indicate that the influence of molten dripping on flame structure is mainly reflected in vertical flame height disturbances, whose intensity is highly correlated with dripping frequency and current magnitude. In contrast, changes in lateral flame width were relatively limited. This characteristic reveals that under high current conditions, molten dripping significantly promotes vertical flame expansion but contributes less to horizontal flame spread. It suggests that in actual fire scenarios, overloaded wires are more likely to form rapidly developing vertical flame channels, increasing the risk of vertical fire spread. Moreover, high-frequency dripping may lead to continuous or multiple ignition points, greatly enhancing the uncontrollability and propagation speed of fires.

4. Conclusions

This study systematically investigated the thermally-induced molten dripping behavior of PE wire insulation under electrical overload conditions. Through experimental observations and theoretical modeling, in-depth analyses were conducted on the formation mechanism, periodic characteristics, and flame interaction effects of the dripping process. The main conclusions are as follows:

(1) Experimental results demonstrated that with increasing overload current, the initial dripping time of the insulation material significantly decreases, the dripping frequency increases, and the dripping period shortens, all exhibiting strong nonlinear responses. This indicates that current intensifies the melting process by enhancing Joule heating.

(2) A thermodynamic model based on heat balance and mechanical criteria successfully revealed the functional relationships between current and both dripping frequency and period. The model predictions showed strong agreement with the experimental data in the high-current range (≥60 A), verifying its accuracy and applicability in describing molten dripping behavior.

(3) Before and after dripping events, flame height exhibited periodic and intense fluctuations, with the disturbance increasing alongside current intensity. In contrast, the flame width remained relatively stable, indicating that molten dripping primarily affects vertical flame expansion.

In future research, it is recommended that soot quantification and couple radiative heat transfer models are incorporated to further enhance the understanding of molten dripping behavior and improve the accuracy of electrical fire risk assessments, especially under varying gravity conditions. The experimental methods developed in this study—including the custom-designed test platform and dynamic simulation techniques—have provided new insights into the molten dripping behavior and flame dynamics of cables under overload conditions, laying a solid foundation for the future modeling and risk prediction of cable fire behavior. Further research could extend this experimental framework to other insulation materials, such as polypropylene, to compare their pyrolysis behavior and flame propagation characteristics under similar overload conditions. Such comparative analysis would help identify material-specific fire hazards and promote the optimization and performance enhancement of fire-resistant cable design.