Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials

Abstract

1. Introduction

2. Materials and Methods

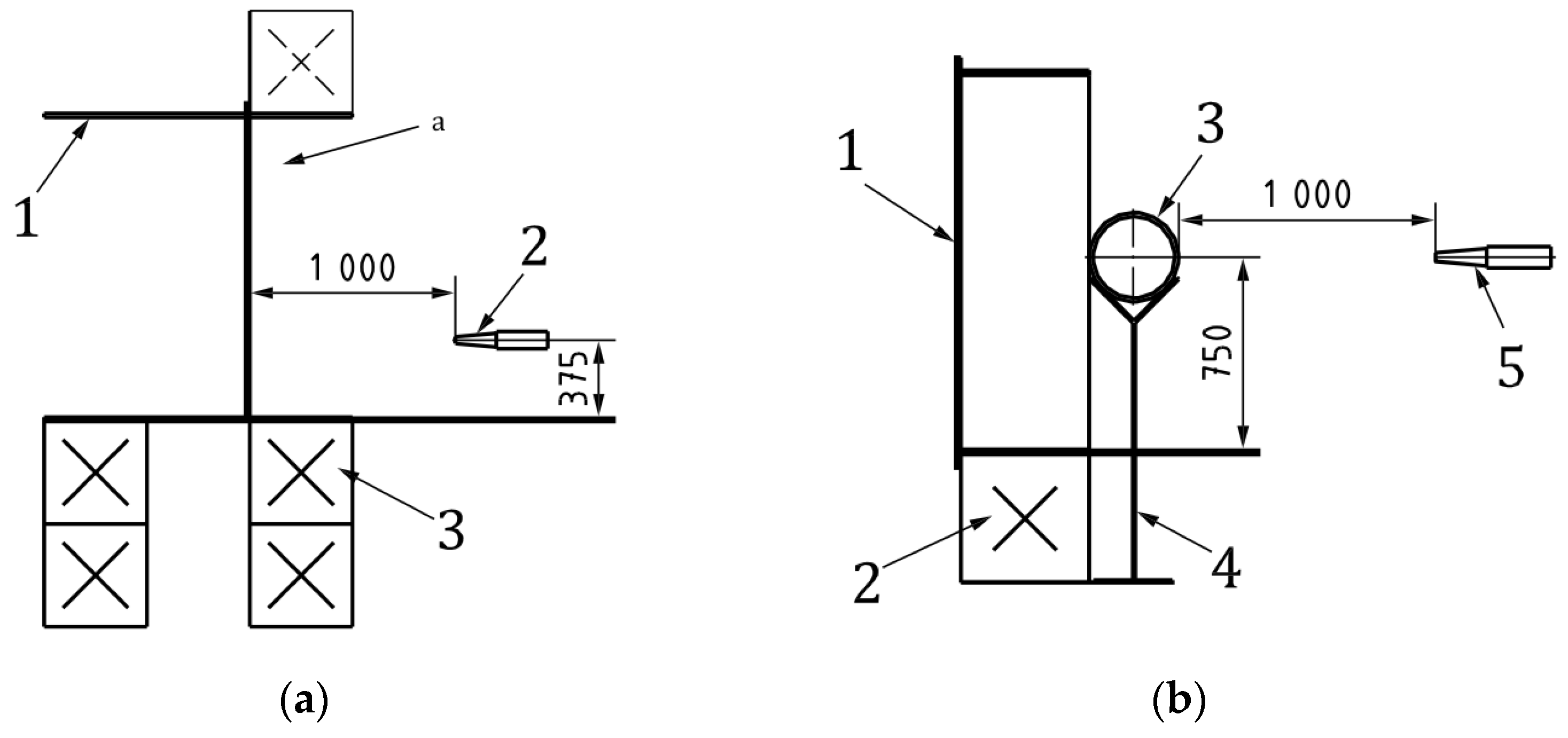

2.1. Methods

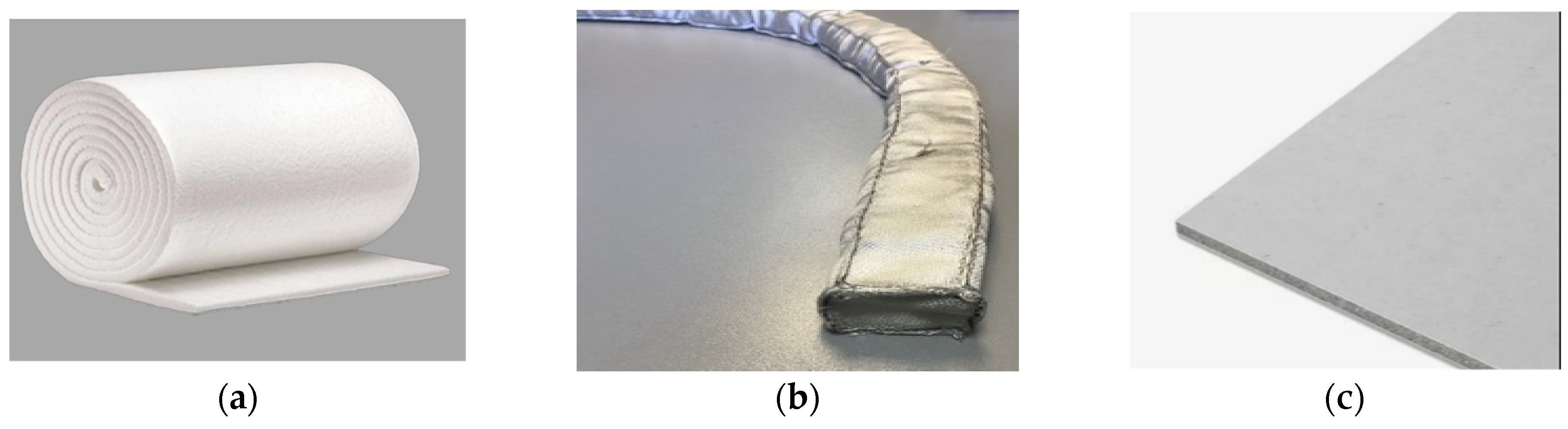

2.2. Materials

2.2.1. Structural Fire Protection

2.2.2. Fire Protection Coatings (FPC)

2.2.3. Fireproof Plaster

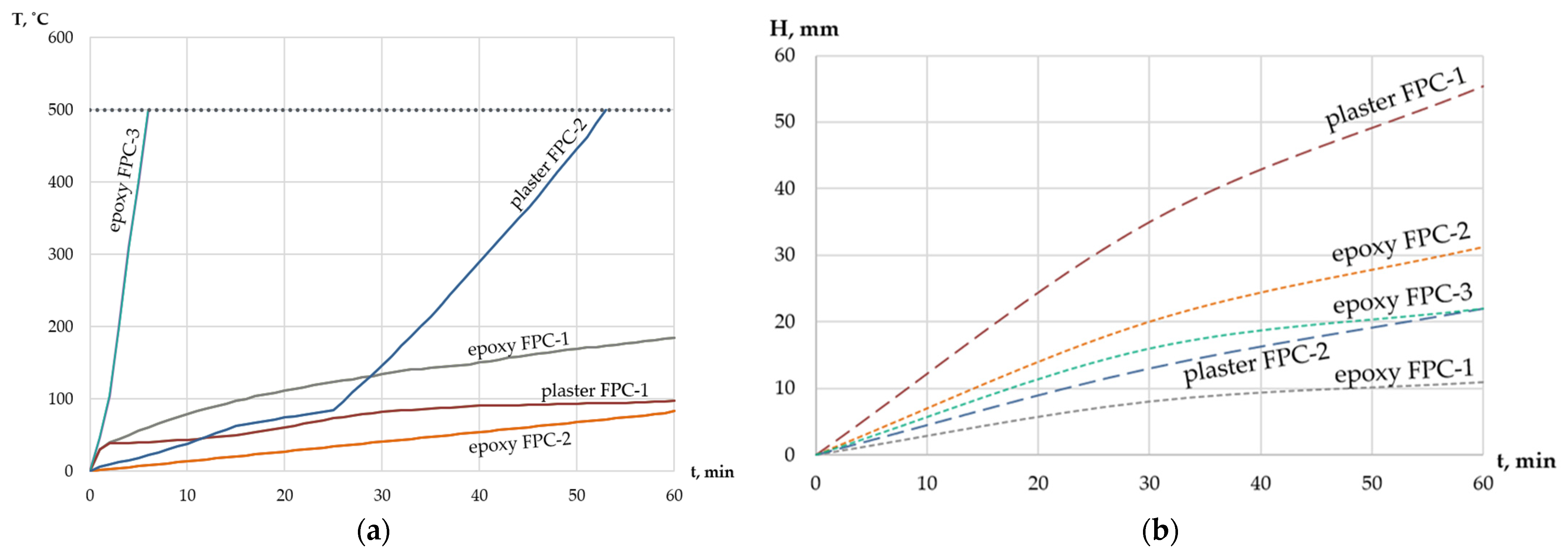

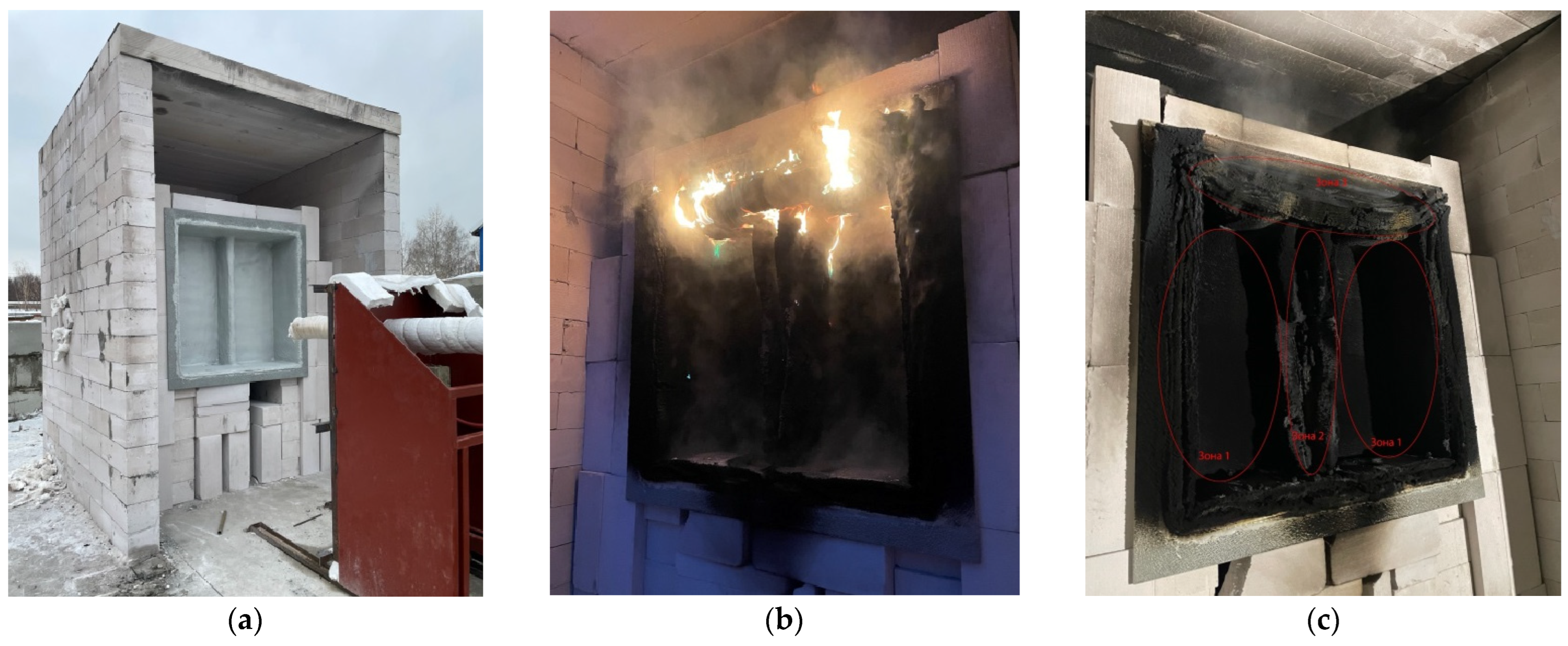

3. Results

- -

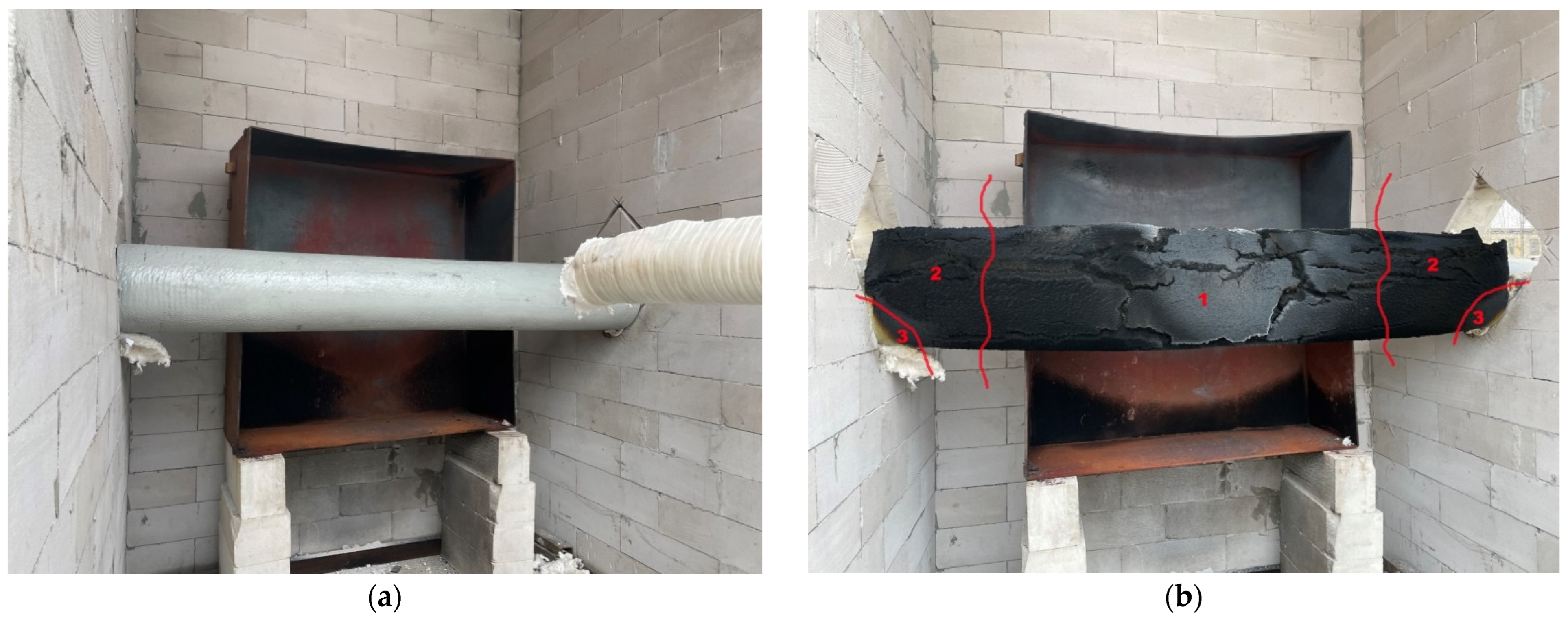

- Zone 1—reacted up to the second (outer) mesh, the flame-retardant coating is firmly in place, and the entire mesh is intact and attached;

- -

- Zone 2—has reacted up to the second (outer) mesh, the fireproofing is firmly in place, there is localized FPC failure, and the entire mesh is intact and anchored;

- -

- Zone 3—bare metal insulation, poor condition of reinforcement, and the reacted FPC is easily separated.

- -

- Zone 1—the flame retardant that reacted on the second (outer) mesh is firmly retained, a localized FPC failure is observed, and the entire mesh is intact and anchored;

- -

- Zone 2—the flame retardant that reacted on the surface is firmly retained, and the entire mesh is intact and secured;

- -

- Zone 3—the unreacted/partially-reacted material is present, the unreacted-material and reinforcement are firmly retained.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Zhou, K.; Zhang, L.; Nie, X.; Wu, Y.; Jiang, J.; Dederichsc, A.S.; He, L. Flame extension area and temperature profile of horizontal jet fire impinging on a vertical plate. Process Saf. Environ. Protect. 2021, 147, 547–558. [Google Scholar] [CrossRef]

- Li, M.; Wang, Z.; Jiang, J.; Lin, W.; Ni, L.; Pan, Y.; Wang, G. Numerical Simulation and Consequence Analysis of Full-Scale Jet Fires for Pipelines Transporting Pure Hydrogen or Hydrogen Blended with Natural Gas. Fire 2024, 7, 180. [Google Scholar] [CrossRef]

- Karimi Dehkordi, M.; Behnam, B.; Ghasemi Pirbalouti, R. Probabilistic fire risk analysis of process pipelines. J. Loss Prev. Process Ind. 2022, 80, 104907. [Google Scholar] [CrossRef]

- Kashi, E.; Bahoosh, M. Jet fire assessment in complex environments using computational fluid dynamics. Braz. J. Chem. Eng. 2020, 37, 203–212. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, K.; Huang, M.; Zhou, M. Flame behavior of jet fire confined by the tank wall. Huagong Xuebao/CIESC J. 2021, 72, 2896–2904. [Google Scholar] [CrossRef]

- Xie, W.; Li, J.; Shi, J.; Zhang, X.; Usmani, A.S.; Chen, G. Probabilistic real-time natural gas jet fire consequence modeling of offshore platforms by hybrid deep learning approach. Mar. Pollut. Bull. 2023, 192, 115098. [Google Scholar] [CrossRef] [PubMed]

- Panaitescu, M.; Panaitescu, F.-V.; Voicu Iscupi, A.-A. FTA on ship firefighting plant. J. Mar. Technol. Environ. 2023, 42–49. [Google Scholar] [CrossRef]

- Zhou, N.; Wu, L.; Li, X.; Li, X.; Shi, J.; Cao, L. Experimental study on failure features of petrochemical pipelines under jet fire. China Saf. Sci. J. 2022, 32, 135–141. [Google Scholar] [CrossRef]

- NORSOK M-501:2022; Surface Protection and Protective Coating. NORSOK. 2022. Available online: https://www.scribd.com/document/664856568/Norsok-M-501-2022 (accessed on 7 August 2024).

- UL 1709–2022; Standard for Safety Rapid Rise Fire Tests of Protection Materials for Structural Steel. Underwriters Laboratories (UL): Northbook, IL, USA, 2022. Available online: https://www.normadoc.com/english/ul-1709-2022.html (accessed on 7 August 2024).

- API RP 2218; Fireproofing Practices in Petroleum and Petrochemical Processing Plants. API Publishing Services: Washington, DC, USA, 2013; p. 68. Available online: https://www.apiwebstore.org/standards/2218 (accessed on 7 May 2024).

- GS EP SAF 337; Total, S.A. «General Specification Safety. Passive Fire Protection: Basis of Design». TOTAL S.A. Available online: https://www.collegesidekick.com/study-docs/1530436 (accessed on 7 August 2024).

- EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1–2: General Actions—Actions on Structures Exposed to Fire. CEN (European Committee for Standardization): Brussels, Belgium, 2002. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1991.1.2.2002.pdf (accessed on 25 May 2024).

- Gravit, M.; Dmitriev, I.; Shcheglov, N.; Radaev, A. Oil and Gas Structures: Forecasting the Fire Resistance of Steel Structures with Fire Protection under Hydrocarbon Fire Conditions. Fire 2024, 7, 173. [Google Scholar] [CrossRef]

- Bjørge, J.S.; Metallinou, M.-M.; Kraaijeveld, A.; Log, T. Small Scale Hydrocarbon Fire Test Concept. Technologies 2017, 5, 72. [Google Scholar] [CrossRef]

- Put, F.; Lucherini, A.; Merci, B.; van Coile, R. Model uncertainty in a parametric fire curve approach: A stochastic correction factor for the compartment fire load density. Fire Saf. J. 2024, 144, 104113. [Google Scholar] [CrossRef]

- Bradley, I.; Willoughby, D.; Royle, M. A review of the applicability of the jet fire resistance test of passive fire protection materials to a range of release scenarios. Process Saf. Environ. Prot. 2019, 122, 185–191. [Google Scholar] [CrossRef]

- ASTM E 1529-14A; Standard Test Methods for Determining Effects of Large Hydrocarbon Pool Fires on Structural Members and Assemblies. ASTM International: West Conshohocken, PA, USA, 2014.

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire Hazards, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010.

- Mikalsen, R.F.; Glansberg, K.; Wormdahl, E.; Stølen, R. Jet fires and cryogenic spills: How to document extreme industrial incidents. In Proceedings of the Sixth Magdeburg Fire and Explosion Days Conference Proceedings, Magdeburg, Germany, 25–26 March 2019; pp. 1–6. [Google Scholar]

- Bogdanova, V.V.; Kobets, O.I.; Buraya, O.N.; Ustinov, A.A.; Zybina, O.A. Intumescent compounds for fireproofing of polymer pipelines. Mag. Civ. Eng. 2022, 116, 11607. [Google Scholar]

- Lucherini, A.; de Silva, D. Modelling intumescent coatings for the fire protection of structural systems: A review. J. Struct. Fire Eng. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Yew, M.C.; Yew, M.K.; Yuen, R.K.K. Experimental Analysis of Lightweight Fire-Rated Board on Fire Resistance, Mechanical, and Acoustic Properties. Fire 2023, 6, 221. [Google Scholar] [CrossRef]

- Garg, K.; Singh, S.; Rokade, M.; Singh, S. The Behavior of Passive Fire Protection Materials Used for Fire Protection of Steel Structures in Standard, Hydrocarbon, and Jet Fire Exposure. Fire Technol. 2023, 59, 2517–2541. [Google Scholar] [CrossRef]

- Tamás-Bényei, P.; Sántha, P. Potential applications of basalt fibre composites in thermal shielding. J. Therm. Anal. Calorim. 2023, 148, 271–279. [Google Scholar] [CrossRef]

- ISO 22899-1:2021; Determination of the Resistance to Jet Fires of Passive Fire Protection Materials Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO/TR 22899-2-2013; Determination of the Resistance to Jet Fires of Passive Fire Protection Part 2: Guidance on Classification and Implementation Methods. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO/DIS 22899-3; Determination of the Resistance to Jet Fires of Passive Fire Protection Materials—Part 3: Extended Test Requirements. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:22899:-3:dis:ed-1:v1:en (accessed on 7 August 2024).

- Rules for the Classification and Construction of Fixed Offshore Platforms nd no. 2-020201-027-e Rule Change. Notice Enters into force: 01.07.2024. © Russian Maritime Register of Shipping. 2024. Available online: https://lk.rs-class.org/regbook/getDocument2?type=rc_eng&d=24-80396 (accessed on 7 August 2024).

- GB 14907-2018; Fire resistive coating for steel structure. State Administration of Markets and China National Standardization Administration: Beijing, China, 2018.

- National Standard of Russian Federation GOST 53295-2009 Fire Retardant Compositions for Steel Constructions. General Requirement. Method for Determining Fire Retardant Efficiency. Available online: https://meganorm.ru/Data2/1/4293830/4293830765.htm (accessed on 7 May 2024).

- Charcoat. Jet Fire Coating. Available online: https://www.charcoat.com/jet-fire-coating (accessed on 14 March 2024).

- Pat. PCTEP2013065775 European. High Heat Resistant Composition DEOGON/ M.S. DEOGON, M. Singh. International Publication. Number WO 2014/019947 Al. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2014019947&_cid=P11-LZL4HZ-03296-1/ (accessed on 7 August 2024).

- Industrial Coatings Ltd. Jotun Jotachar JF750. Available online: https://industrialcoatingsltd.com/products/jotun-jotachar-jf750 (accessed on 14 March 2024).

- International Chartek 1709. Passive Fire Protection-Epoxy Intumescent. Available online: https://www.international-pc.com/en/products/chartek-1709?page=1#tds/ (accessed on 14 March 2024).

- GOST 8239-89; Hot-Rolled Steel Flange Beams; Rolling products. Publishing House of Standards: Moscow, Russia, 1989.

- Technical Specification of «Ignis-Mat». Available online: https://prozask.ru/f/ignis-mat_sv-opisanie.pdf (accessed on 7 August 2024).

- Technical Specification of Fire Barrier «Promizol-DSh Proplate». Available online: http://tdpromizol.com/ (accessed on 7 August 2024).

- Technical Specification of the «Faire-Panel». Available online: https://prozask.ru/prozask-fayerpanel (accessed on 7 August 2024).

- Gravit, M.; Shabunina, D.; Shcheglov, N. Thermal Characteristics of Epoxy Fire-Retardant Coatings under Different Fire Regimes. Fire 2023, 6, 420. [Google Scholar] [CrossRef]

- ASTM D 3359-22; Standard Test Methods for Rating Adhesion by Tape Test. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- GOST 19007-23; Paintwork materials; Method for determination of drying tine and degree. Institute of Standardization: Moscow, Russia, 2023.

| № | Name of Indicator | Value |

|---|---|---|

| 1 | Appearance of the plate: (a) front side; (b) back side | (a) smooth, colored; (b) polished |

| 2 | Thermal conductivity, W/m·K | 0.35 (±10%) |

| 3 | Resistance to vapor permeability, % | 60 |

| 4 | Tensile strength at bending, not less, MPa | 5.4 |

| 5 | Board density, kg/m3 | 1100–1200 |

| 6 | Fire resistance, REI (depends on the number of boards), min | 240 |

| № | Name of Indicator | Value |

|---|---|---|

| 1 | Apparent density, kg/m3 | 128 |

| 2 | Chemical composition, %: CAO, SiO2 and others, not more | 68 |

| 3 | Relative weight change during calcination, %, not more than | 1.0 |

| 4 | Tensile strength, MPa, not less than | 0.050 |

| 5 | Mass fraction of moisture, not more, % | 1.0 |

| 6 | Mass fraction of inclusions larger than 0.5 mm, %, not more than | 3.0 |

| № | Technical Specifications | Value |

|---|---|---|

| 1 | Color and appearance of the coating | Gray |

| 2 | Adhesion [41], rating, not less than | 4A |

| 3 | Composition density, kg/m3 | 1.22–1.27 |

| 4 | Stability after mixing at T = (20 ± 2) °C, h, at least | 1 |

| 5 | Theoretical consumption for one layer coating thickness of 1000 microns, kg/m2 | 1.2 |

| 6 | Drying time to degree 3 [42] (T = (20 ± 2) °C and relative humidity (65 ± 5)%, not more than | 12 ч |

| № | Types of Samples | Internal Configuration Tests | External Configuration Tests |

|---|---|---|---|

| 1 | Boards and mats system | - | Sample 1 |

| 2 | FPC-1 | Sample 2 | - |

| 3, 4 | FPC-2 | Sample 3 | Sample 4 |

| 5 | Plaster | Sample 5 | - |

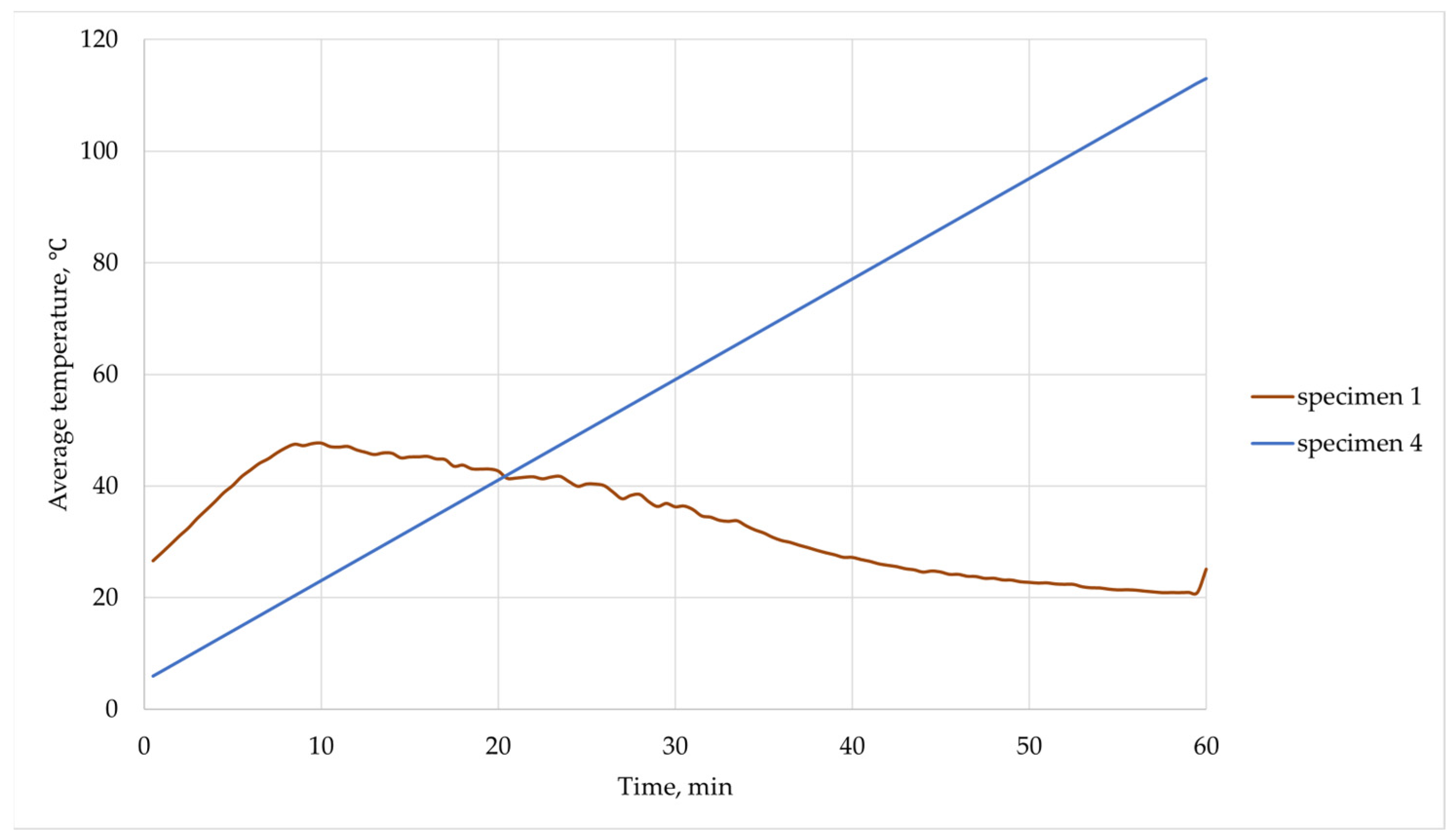

| № | Types of Samples | Configuration Tests | H, mm | T (Unheated Surface), °C | |

|---|---|---|---|---|---|

| Internal | External | ||||

| 1 | Boards and mats system | - | Sample 1 | 25 + 50 | 47.73 |

| 2 | FPC-1 | Sample 2 | - | 10.9 | 184.84 |

| 3 | FPC-2 | Sample 3 | - | 31.2 | 82.00 |

| 4 | FPC-2 | - | Sample 4 | 31.8 | 113.00 |

| 5 | Plaster FPC-1 | Sample 5 | - | 55.4 | 97.00 |

| 6 [24] | organic material (FPC-3) | Sample 6 | 22.0 | 7.50 | |

| 7 [24] | inorganic material (Plaster FPC-2) | Sample 7 | 22.0 | 55.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gravit, M.; Korolchenko, D.; Nedviga, E.; Portnov, F.; Diachenko, S. Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials. Fire 2024, 7, 281. https://doi.org/10.3390/fire7080281

Gravit M, Korolchenko D, Nedviga E, Portnov F, Diachenko S. Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials. Fire. 2024; 7(8):281. https://doi.org/10.3390/fire7080281

Chicago/Turabian StyleGravit, Marina, Dmitry Korolchenko, Ekaterina Nedviga, Fedor Portnov, and Semen Diachenko. 2024. "Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials" Fire 7, no. 8: 281. https://doi.org/10.3390/fire7080281

APA StyleGravit, M., Korolchenko, D., Nedviga, E., Portnov, F., & Diachenko, S. (2024). Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials. Fire, 7(8), 281. https://doi.org/10.3390/fire7080281